Device for controlling mud sample manufacturing precise proportioning through computer and control method

A computer and mud sample technology, applied in the field of accurate batching devices for mud sample production, can solve the problems of inability to prompt insufficient material information, high labor intensity, poor fault tolerance, etc., to simplify the process from weighing to delivery, and avoid material pollution and errors. , The effect of simple and reliable mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with drawings and embodiments.

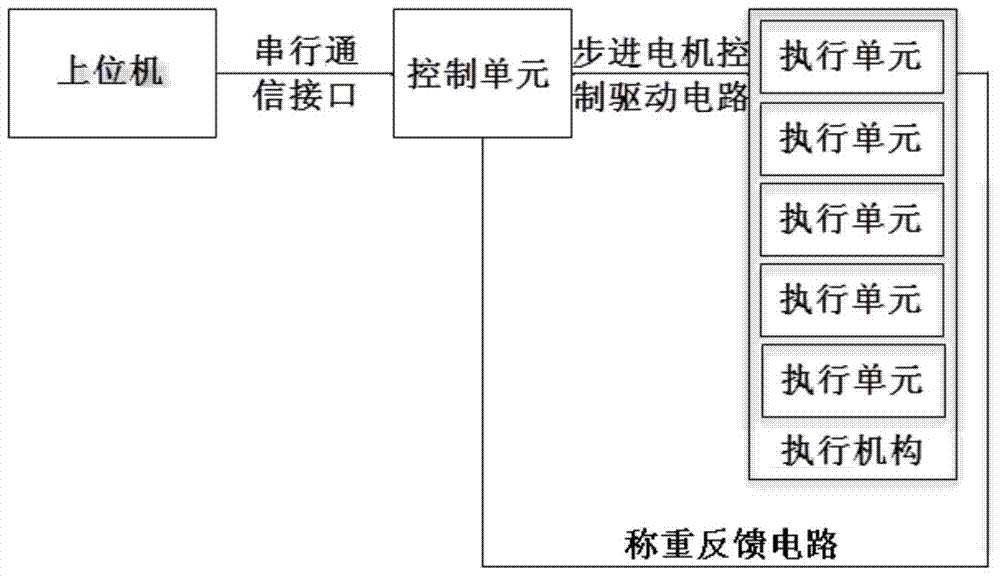

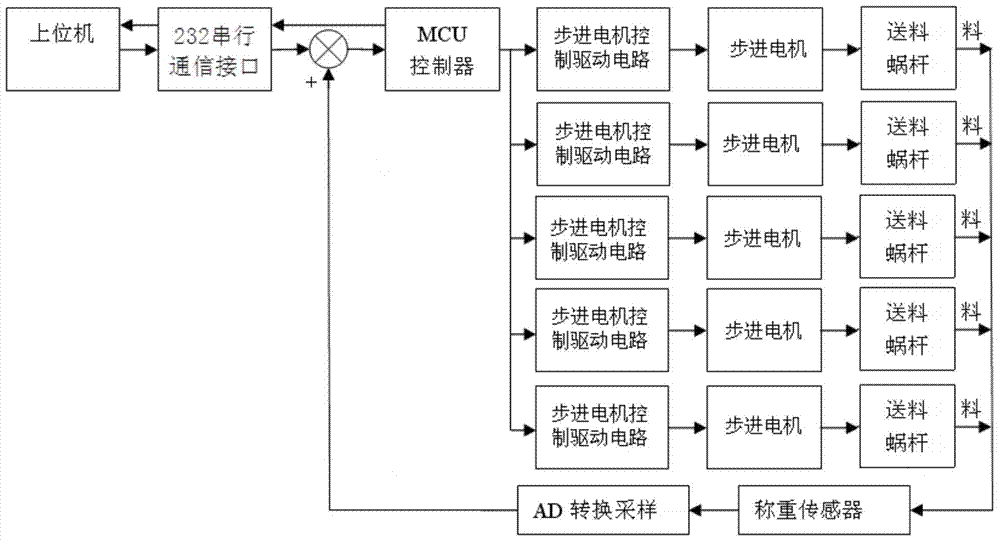

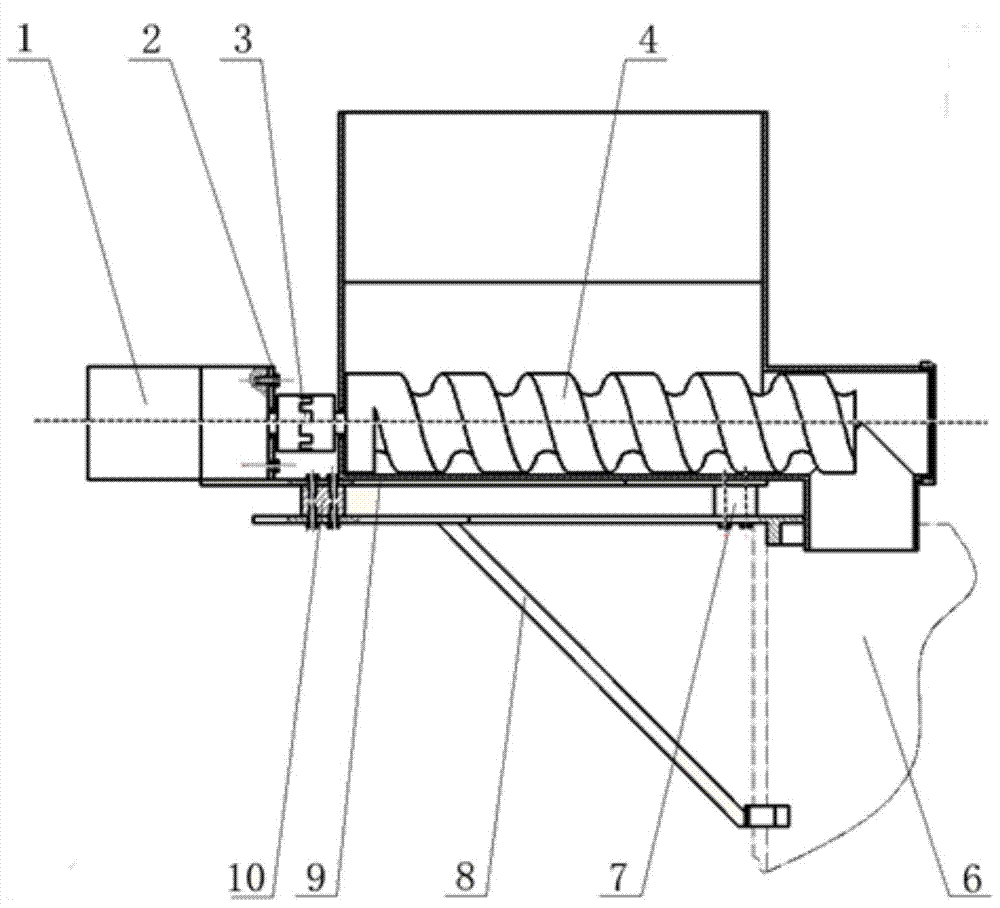

[0032] Refer to as figure 1 As shown, a computer-controlled mud sample preparation and precise batching device provided by the present invention at least includes a control unit and an execution mechanism, and the control unit is connected to the host computer through a serial communication interface; the execution mechanism is composed of at least one group of execution units, each A group of execution units includes a stepper motor, a feeding worm, a filling funnel, a weighing platform, a load cell and a bracket; in each group of execution units, the stepper motor is connected to the control unit through a stepper motor control drive circuit, and the load cell It is connected with the control unit through the weighing feedback circuit. In this embodiment, both the stepper motor control drive circuit and the weighing feedback circuit are conventional circuits.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com