Ball screw executing mechanism driven by electric automobile parking P-gear servo motor

A technology of servo motor and ball screw, which is applied in the direction of mechanical equipment, components with teeth, transmission device control, etc., can solve the problems of unsuitable handbrake structure, etc., and achieve the effect of simple and reliable mechanical structure, fast response and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

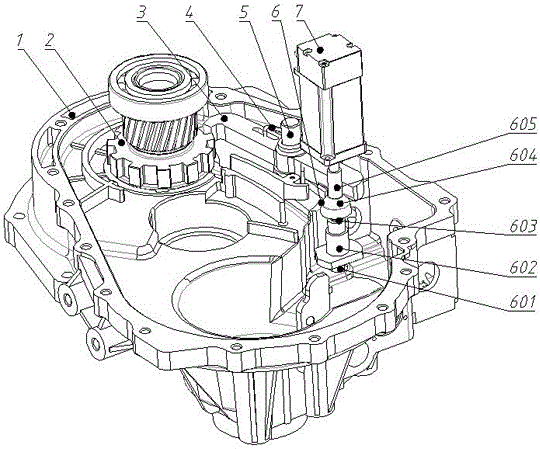

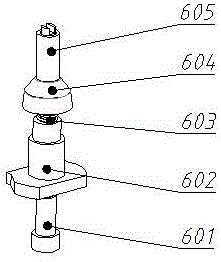

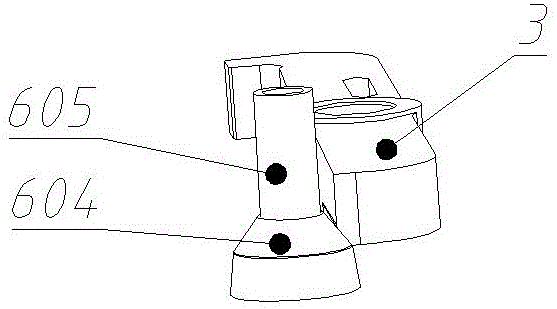

[0012] Such as figure 1 , figure 2 and image 3 As shown in the figure, a ball screw actuator driven by a P-range servo motor for parking an electric vehicle, a ball screw actuator driven by a P-range servo motor for an electric vehicle parking, including a cylinder head 1, a ratchet 2, and a pawl 3 , torsion spring 4, pin shaft 5, transmission assembly 6, P gear servo motor 7, ratchet 2 is installed in the cylinder head 1, ratchet 2 can be connected with the output shaft of the reducer, and pawl 3 passes through torsion spring 4 and pin shaft 5 Installed in the cylinder head 1, the source of the restoring force of the pawl 3 is a torsion spring, the transmission assembly 6 is installed in the cylinder head, the transmission assembly is connected with the P gear servo motor 7, the front end of the pawl 3 and the ratchet 2 are meshed and connected through the transmission assembly 6 Separation; the transmission assembly 6 includes a ball screw 601, the tail end of the ball s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com