Automatic clamping and automatic clamping loosening threading machine and work method thereof

An automatic clamping and threading machine technology, which is applied to the accessories of toolholders, thread cutting machines, manufacturing tools, etc., can solve the problems of restricting threading machines, large energy loss, and limited automation, so as to expand the processing application range and reduce Production cost, effect of long-lasting clamping function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

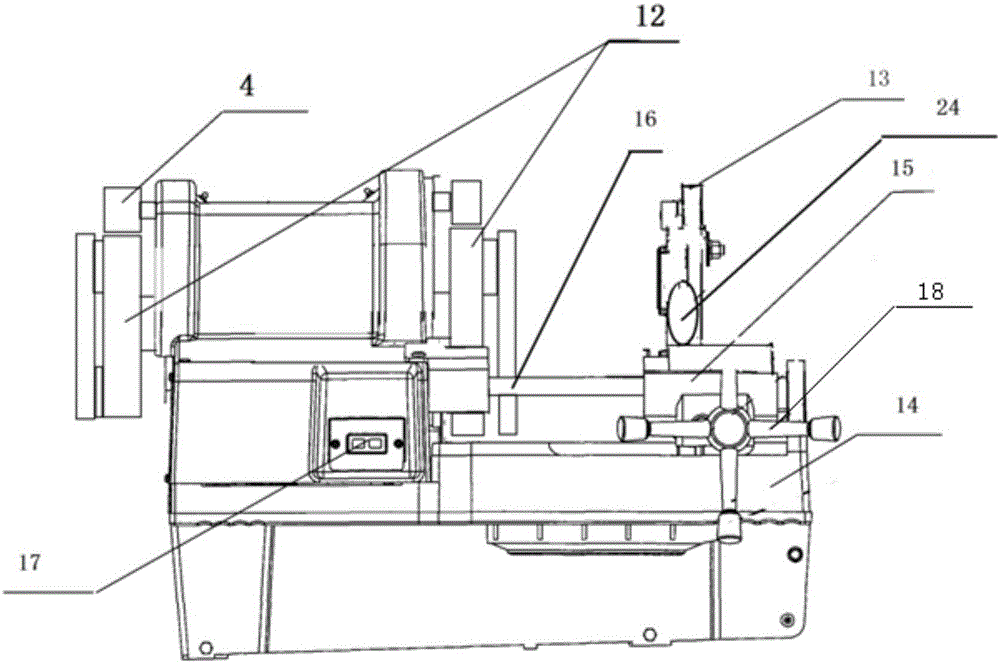

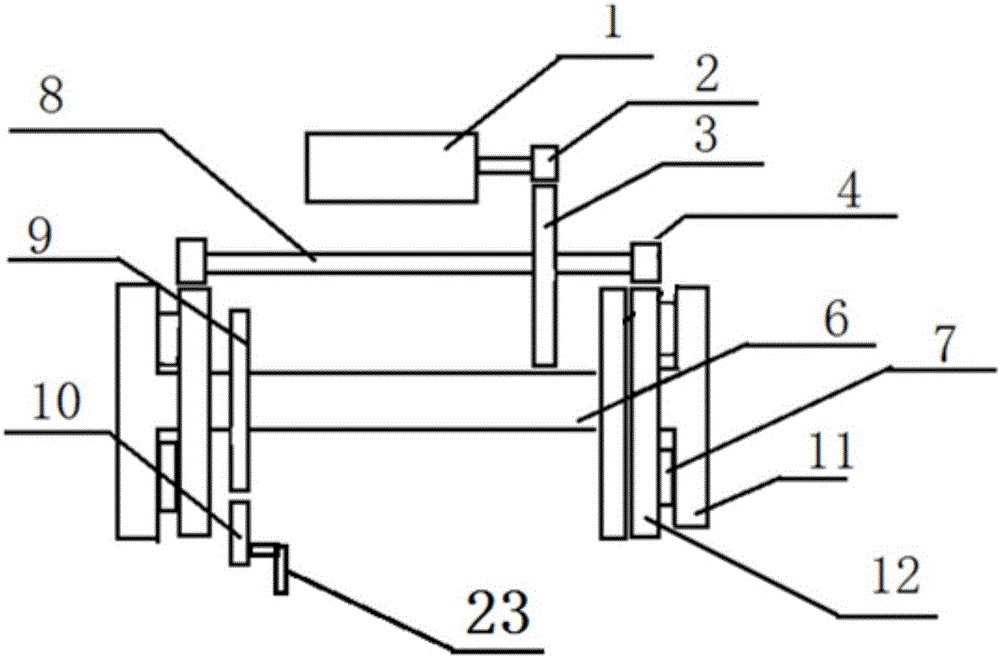

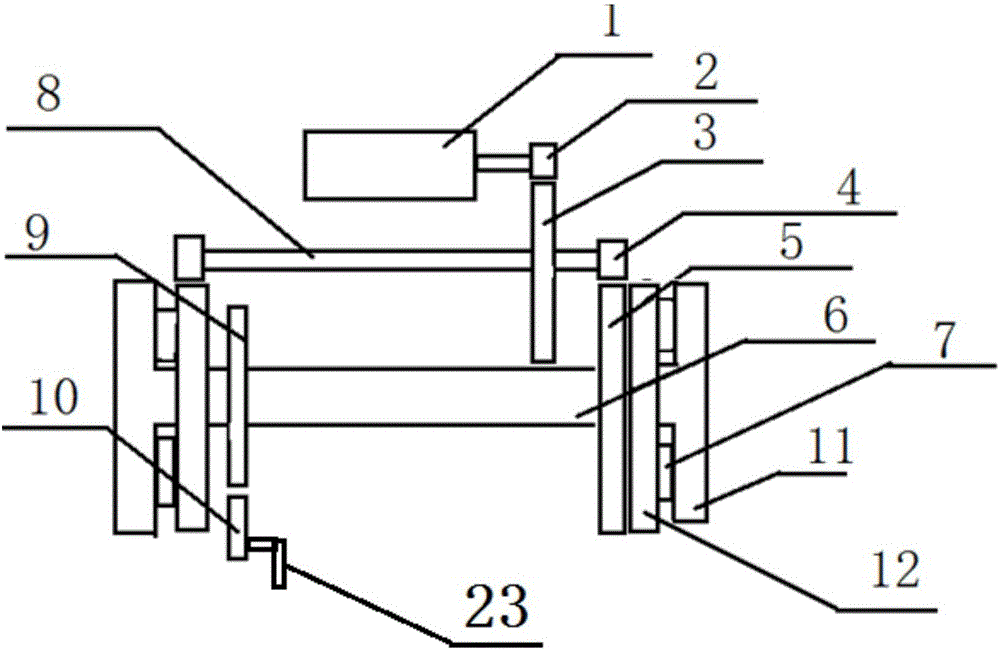

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] Such as Figure 1-3 As shown, the present invention comprises a frame 14 and a control device installed on the frame 14, a motor 1, a power deceleration transmission system, a chuck, a chuck shaft braking system, a carriage guide rail 16; the motor 1 and the chuck The shaft brake system is connected with the control device, and the control device is used to control the operation of the chuck shaft brake system and the motor 1; the power deceleration transmission system is connected with the motor 1; the chuck is fixedly installed on the chuck On the chuck shaft of the shaft brake system, the chuck is connected to the drive wheel 4 of the power reduction transmission system in transmission, and the carriage guide rail 16 is provided with a carriage 15, and the carriage 15 is provided with a die head 13 and a slide Frame advance and retreat handle 18. In the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com