Power deceleration transmission system of threading machine

A technology of transmission system and threading machine, which is applied in the direction of thread cutting machine, driving device, automatic in/out workpiece, etc., can solve the problems of large energy loss, complex pipeline, complex structure, etc., and achieve low production cost, high reliability, The effect of simple and reliable mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

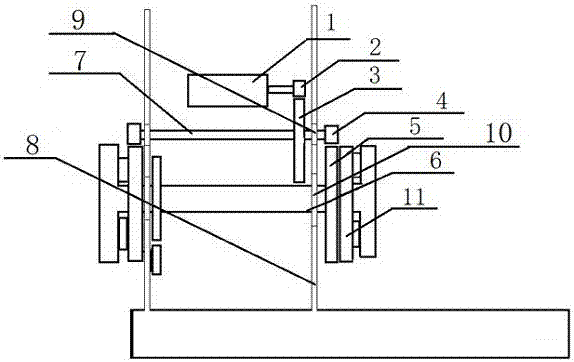

[0014] Embodiment 1: as figure 1 The power deceleration transmission system of a threading machine shown includes a power output wheel 2, a first driven wheel 3, a driving wheel 4, an output shaft 7, a chuck and a chuck shaft 6, and the power output wheel 2 is fixed On the output shaft of the motor 1, the first driven wheel 3 and the driving wheel 4 are fixed on the output shaft 7, the power output wheel 2 is in transmission cooperation with the driven wheel 3, and the output shaft 7 is arranged on the sleeve through a bearing 9. On the frame 8 of the wire machine, the chuck shaft 6 is set on the frame 8 through the rotation of the large bearing 10, and the chuck includes a driven wheel 5 and a flat screw disk 11, and the driven wheel 5 and the flat screw disk 11 are rotated and set On the chuck body of the chuck, the driving wheel 4 is in transmission connection with the plane screw disk 11, and the plane screw disk 11 is connected with the chuck, and the chuck is fixed on th...

Embodiment 2

[0018] Embodiment 2: A power deceleration transmission system of a threading machine, comprising a power output wheel 2, a first driven wheel 3, a driving wheel 4, an output shaft 7, a chuck, and a chuck shaft, and the power output wheel 2 is fixed on On the output shaft of the motor 1, the first driven wheel 3 and the driving wheel 4 are fixed on the output shaft 7, the power output wheel 2 is in transmission cooperation with the driven wheel 3, and the output shaft 7 is arranged on the bushing through a bearing 9 On the frame 8 of the machine, the chuck shaft 6 is set on the frame 8 through the rotation of the large bearing 10, the second driven wheel 5 and the plane screw 11 are set on the chuck shaft 6, and the driven wheel 5 and the plane screw The adjacent end faces of the disk 11 are concavo-convex with large gaps, which are used for transmission connection. The driving wheel 4 is connected to the second driven wheel 5, and the flat screw disk is connected to the chuck, ...

Embodiment 3

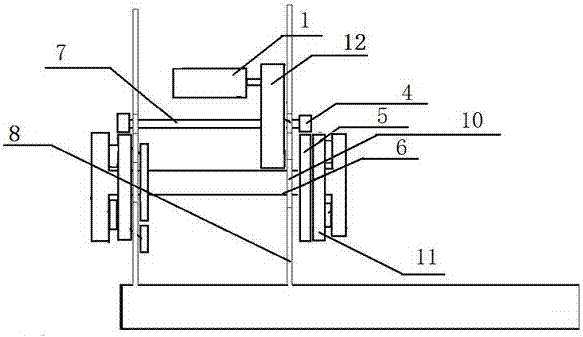

[0019] Embodiment 3 see figure 2 : a power deceleration transmission system of a threading machine, comprising a motor 1, a gear box 12, a gear box output shaft 7, a driving wheel 4, a chuck, and a chuck shaft 6, the motor is connected to the gear box, and the deceleration The box is fixed on the frame, the drive wheel 4 is set and fixed on the output shaft 7 of the reduction box, the chuck shaft 6 is rotated on the frame 8 through the large bearing 10, and the chuck shaft is fixedly installed 6, the second driven wheel 5 and the flat spiral disk 11 are set on it, and the adjacent end faces of the driven wheel 5 and the flat spiral disk 11 are provided with large gaps and convexes, which are used for transmission connection. One is connected with the driving wheel 4, and the flat screw disk 11 cooperates with the brake of the chuck shaft stop system, the chuck is clamped, the chuck shaft brake fails, the chuck shaft rotates, and the power deceleration transmission system comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com