Pressure generator for gas pressure fatigue tester

A technology of fatigue testing machine and gas pressure, which is applied in the field of testing, can solve the problems that the technical ability cannot meet the pressure fatigue test, the life is shortened, the reliability and durability of the testing machine cannot meet the long-term fatigue test, etc., and the mechanical structure is simple and reliable. , high durability and reliability, low friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

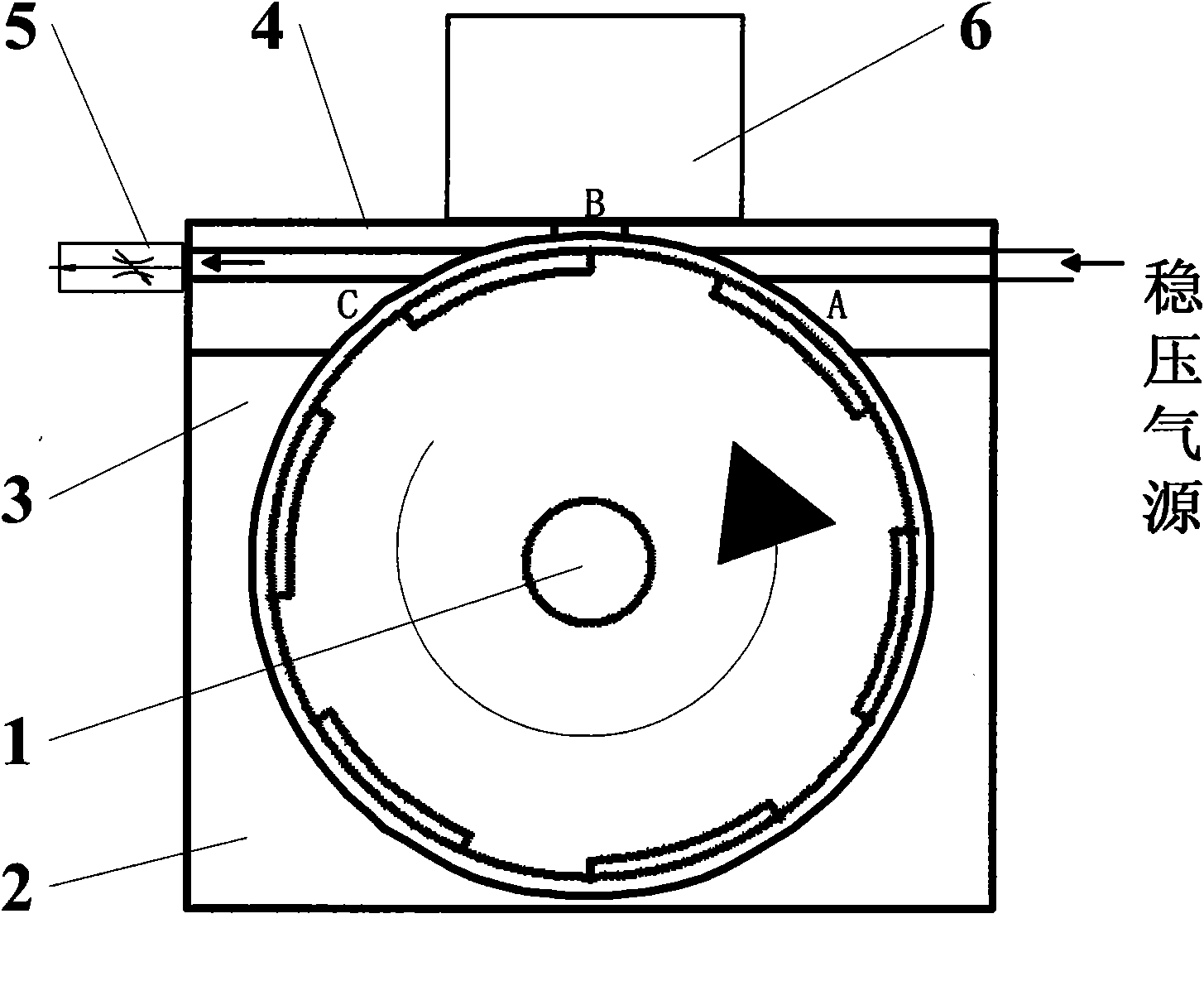

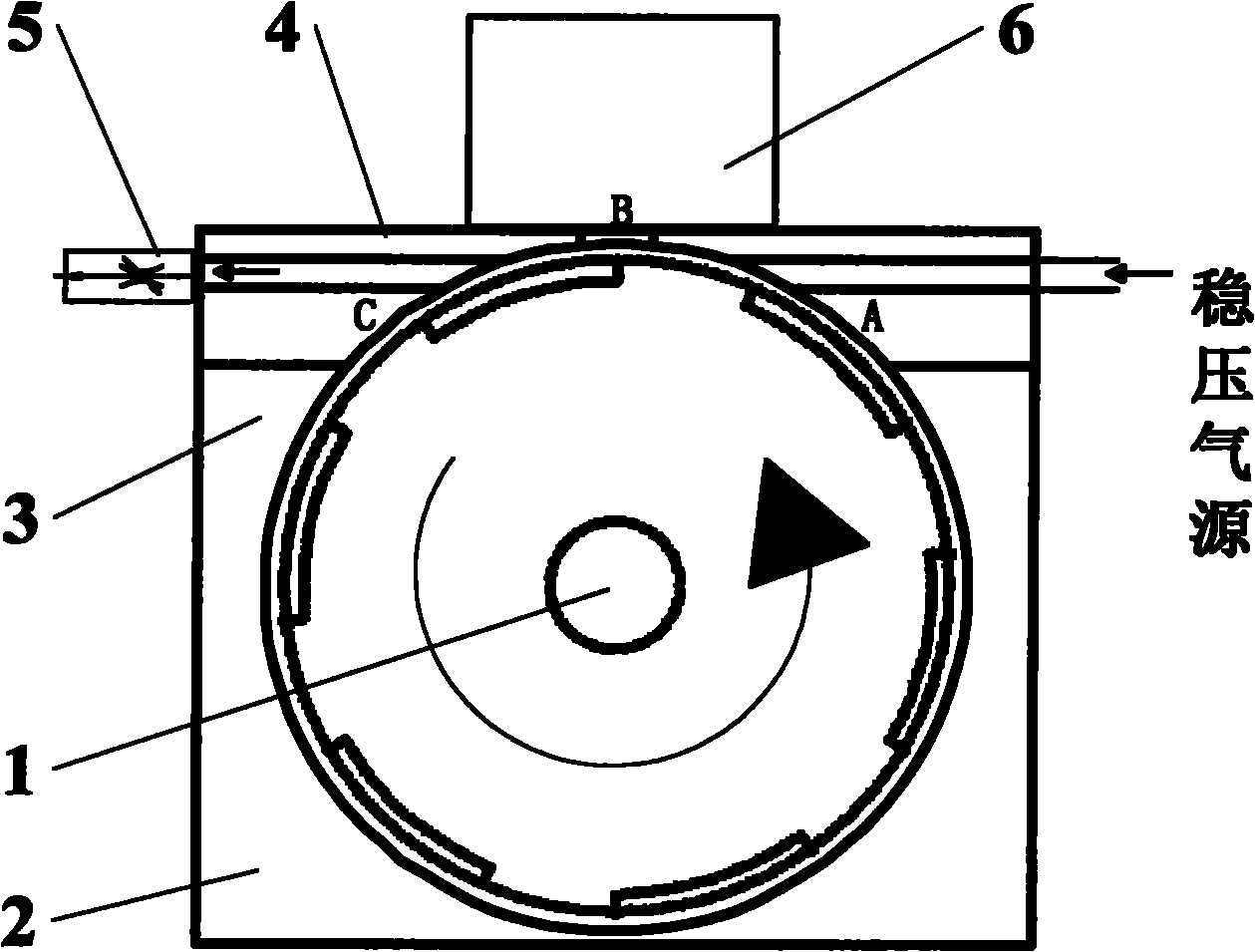

[0008] The principle structure of the pressure generator of the gas pressure fatigue testing machine is as follows: figure 1 , Its main components include rotating motor, coupling 1, bracket 2, rotor 3, connector 4, flow control 5, pressure chamber 6, etc.

[0009] A series of elongated grooves are evenly distributed in the circumferential direction on one end plane or the cylindrical surface of the rotor 3, figure 1 This is the case where grooves are distributed on the curved surface of the column; the vent A, vent B, and vent C are evenly arranged on the same surface of the connector 4 in sequence, and match with the upper curved surface of the rotor 3 where the grooves are located, leaving a very small gap . The vent A port is connected to the gas source, the vent port B is connected to the pressure chamber 6, and the vent C is connected to the atmosphere through the flow control 5 . When the motor drives the rotor 3 to rotate at a constant speed through the coupling 1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com