Differential type spherical surface expanding mechanism

A spherical expansion and differential technology, which is applied in the direction of differential transmission, mechanical equipment, transmission, etc., can solve the problems of complex structure of the expansion mechanism, expensive expansion wheel, high use and maintenance costs, and achieve processing and maintenance costs. Low profile, simple shape, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

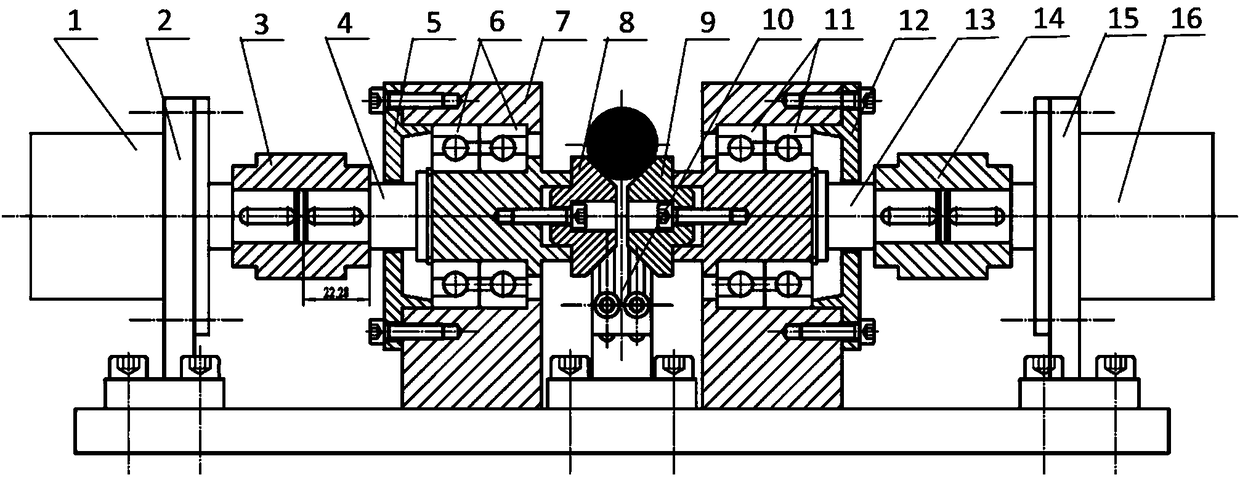

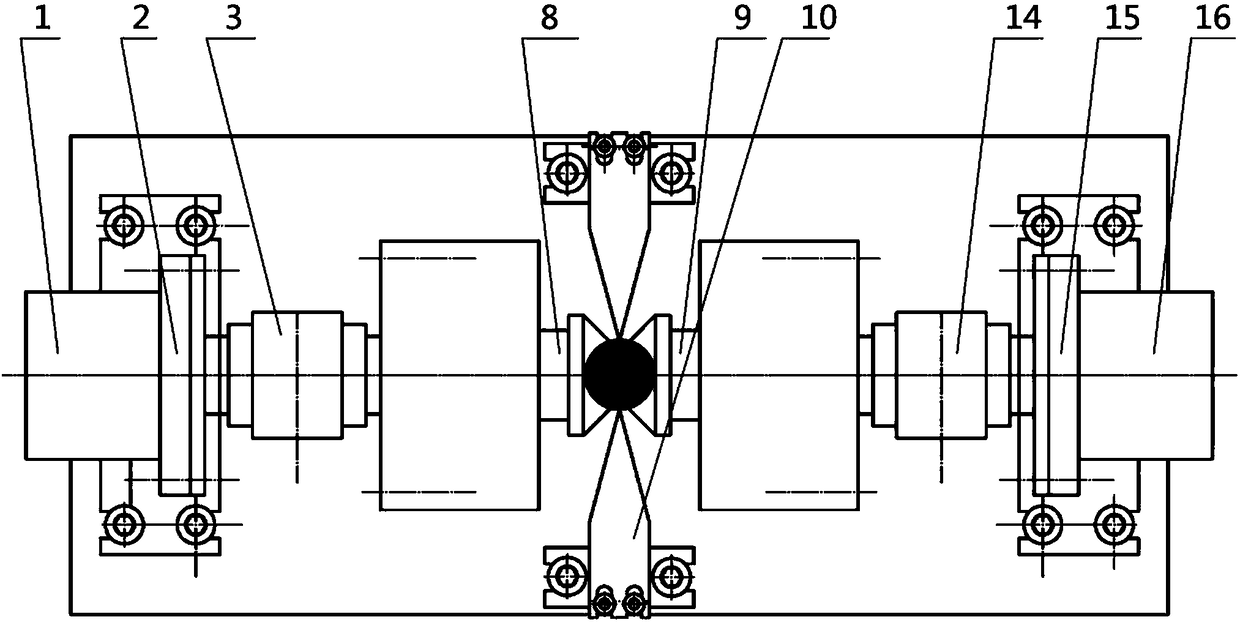

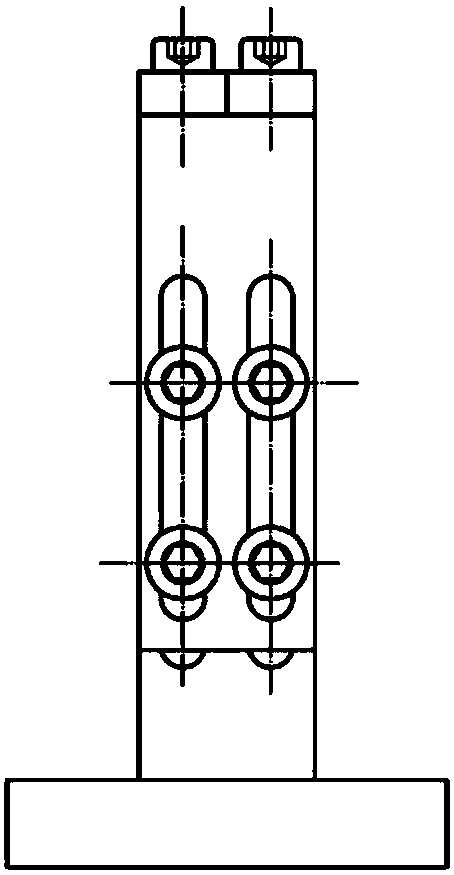

[0030] Use 15.081mm steel balls and ceramic balls for experimental verification, such as figure 1 , figure 2 As shown, according to the diameter of the ball to be detected, the relative position of the baffles 10 on both sides is adjusted, and the structure of the baffles 10 is as follows image 3 , Figure 4 As shown, the detected ball is located just above the driving wheel 8 and the differential wheel 9, so that the detected ball can be in a constant position during the rotation and deflection process; the first bearing end cover 5 is used to fix the first paired angle The contact ball bearing 6, the first pair of angular contact ball bearings 6 supports the driving wheel shaft 4, ensuring the rotation accuracy of the driving wheel 8; the body 7 supports the entire mechanism, ensuring the relative positional relationship between each component; the second bearing end cover 12 To fix the second pair of angular contact ball bearings 11 , the second pair of angular contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com