Large changing diameter double-drag-blade hole reaming drill

A technology of reaming bit and two wings, used in drill bits, drilling equipment, earthwork drilling and other directions, can solve the problems of invariable diameter, small reaming range, unreachable diameter changing range, etc., and achieves large diameter changing range and reliable strength. , The effect of simple and reliable mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

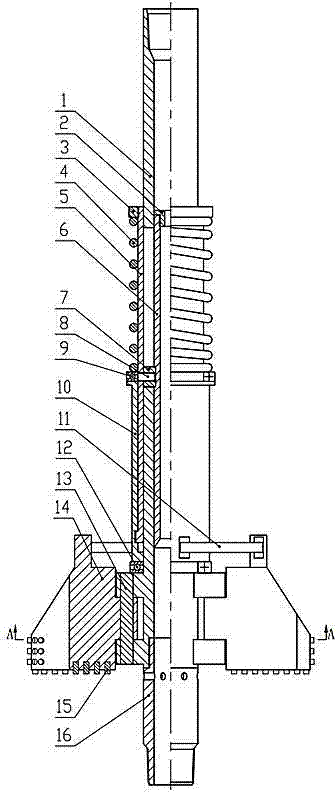

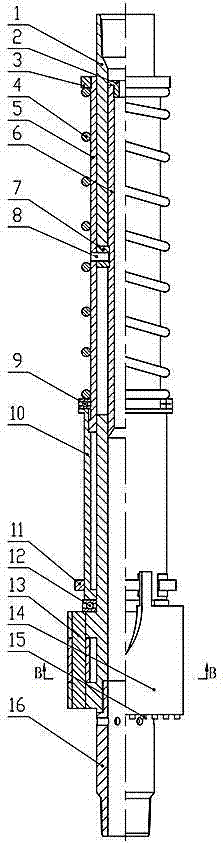

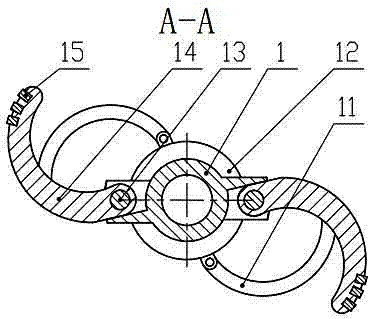

[0013] Such as figure 1 with figure 2 As shown, a large-diameter two-wing reamer bit of the present invention includes a main cylinder 1, a water nozzle 2, a retaining ring 3, a return spring 4, an outer center tube 5, an inner center tube 6, a slider 7, a screw 8, Thrust bearing a9, rotating cylinder body 10, arc connecting rod 11, thrust bearing b12, pin 13, knife wing 14, cutting teeth 15, lower joint 16; its structural feature is: the upper part of the main cylinder body 1 is processed with a standard thread, and The upper part of the drill string is connected, and the lower part is connected with the lower joint 16 with standard threads. The lower joint 16 is radially processed with 3 to 5 nozzle holes. The lower part of the lower joint 16 is machined with standard threads to connect with the pilot drill bit; main cylinder 1 Two sets of hinge supports are processed on the outside of the lower part. The two sets of hinge supports are distributed symmetrically. The two blade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com