Offset type reducing device for telescopic section of wind power tower drum lifting construction platform

A technology for wind power towers and construction platforms, which is applied in the installation/support of wind turbine configuration, wind energy power generation, wind turbines, etc., can solve the problem of limited diameter change range of the telescopic operation section, affecting the hoisting construction of the tube section, and short length of the telescopic mechanism, etc. problems, to achieve the effect of shortening working time at height, easy operation and debugging, easy installation accuracy and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

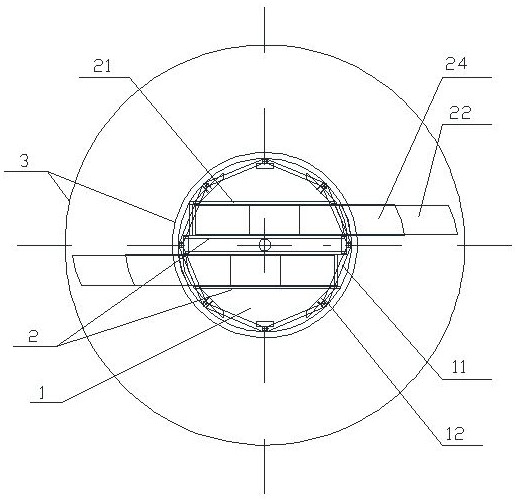

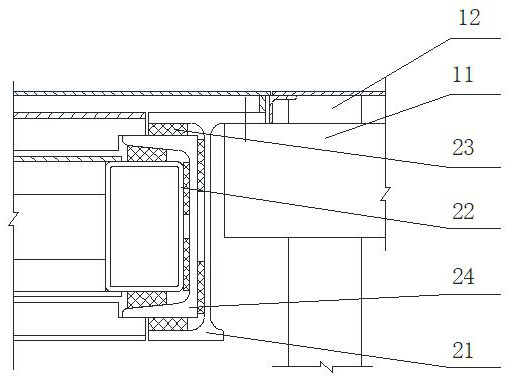

[0042] Please see attached Figures 1 to 3 , the maximum diameter of the bottom of the wind power tower 3 is 6.7m, the minimum diameter of the top is 3.1m, the diameter of the telescopic operation section 1 is 2.9m and coaxially arranged in the wind power tower 3 . The telescoping operation section 1 is equipped with a layer of telescopic section diameter-reducing structure via a guide rail bracket 11 , and the layer of telescopic section diameter-reducing structure includes two three-stage diameter-reducing mechanisms 2 arranged symmetrically with respect to the center of the telescopic operation section 1 . The telescopic movable plate 22 of the three-stage diameter reducing mechanism 2 can meet the diameter reduction requirement of 3.1-6.7m, and the diameter reduction ratio is 1:2.2 or greater, thereby meeting the hoisting requirements of the entire wind power tower 3 .

Embodiment 2

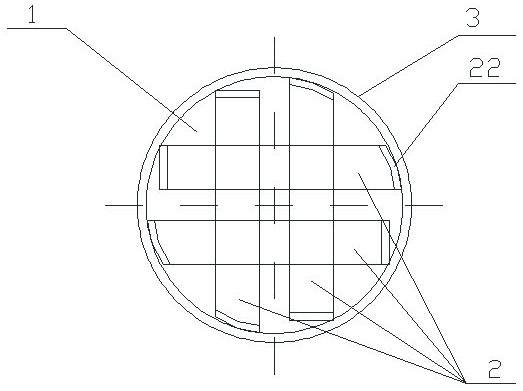

[0044] Please see attached Figures 3 to 5 , the maximum diameter of the bottom of the wind power tower 3 is 6.7m, the minimum diameter of the top is 3.9m, and the diameter of the telescopic operation section 1 is 2.9m and is set in the wind power tower 3 . The telescopic operation section 1 is equipped with a two-layer telescopic section variable diameter structure through the guide rail bracket 11, and each layer of telescopic section variable diameter structure includes two three-stage variable diameter mechanisms 2 arranged symmetrically about the center of the telescopic operation section 1, and The variable diameter mechanisms 2 of the two-layer telescopic section variable diameter structure are perpendicular to each other and form a well shape.

[0045] A ladder 31 is provided on the inner wall of the wind power tower 3 , and the width of the ladder 31 along the radial direction of the wind power tower 3 is 0.75m. During the construction of the lower part of the wind p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com