Central cable surface steel box girder integral type bridge deck crane

A steel box girder, integrated technology, applied in the direction of bridges, walking mechanisms, bridge construction, etc., can solve the problem that the integrated bridge deck crane cannot be used, and achieve the effect of improving assembly efficiency, improving efficiency and ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

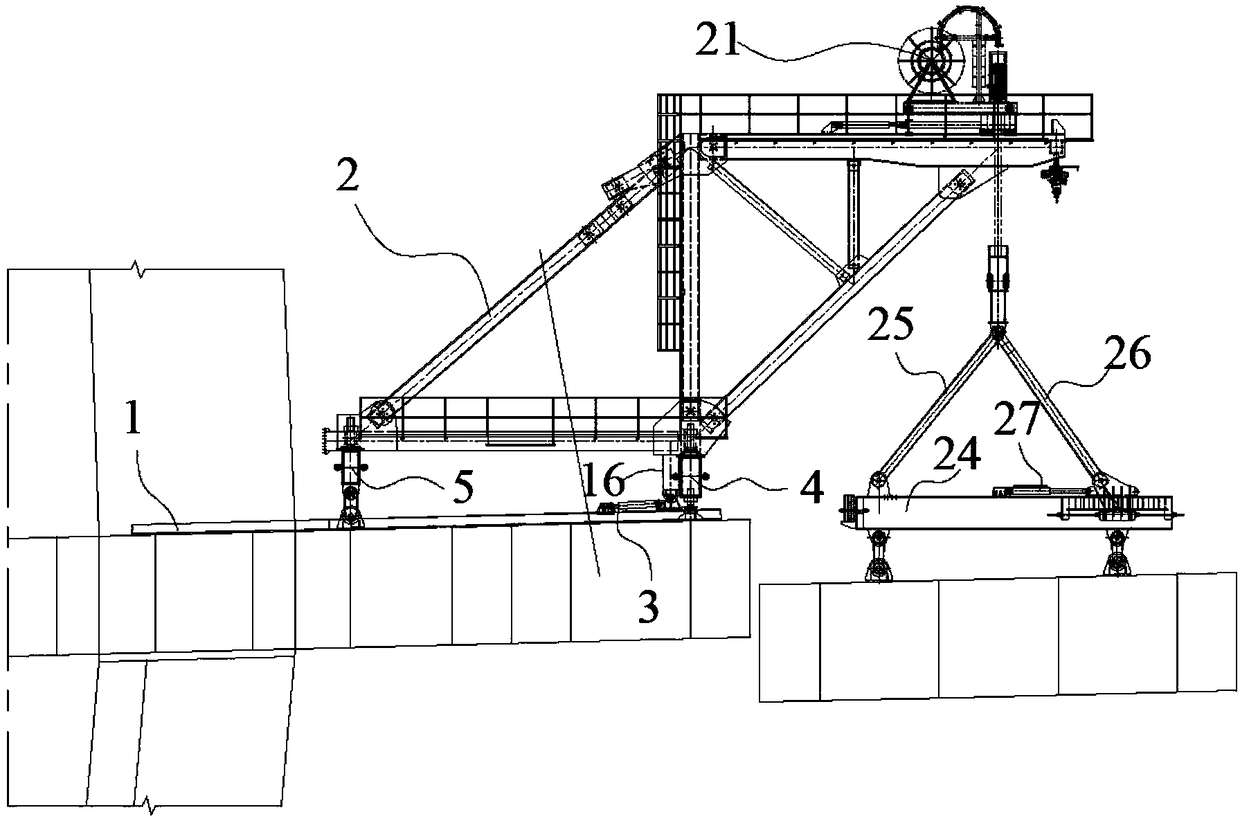

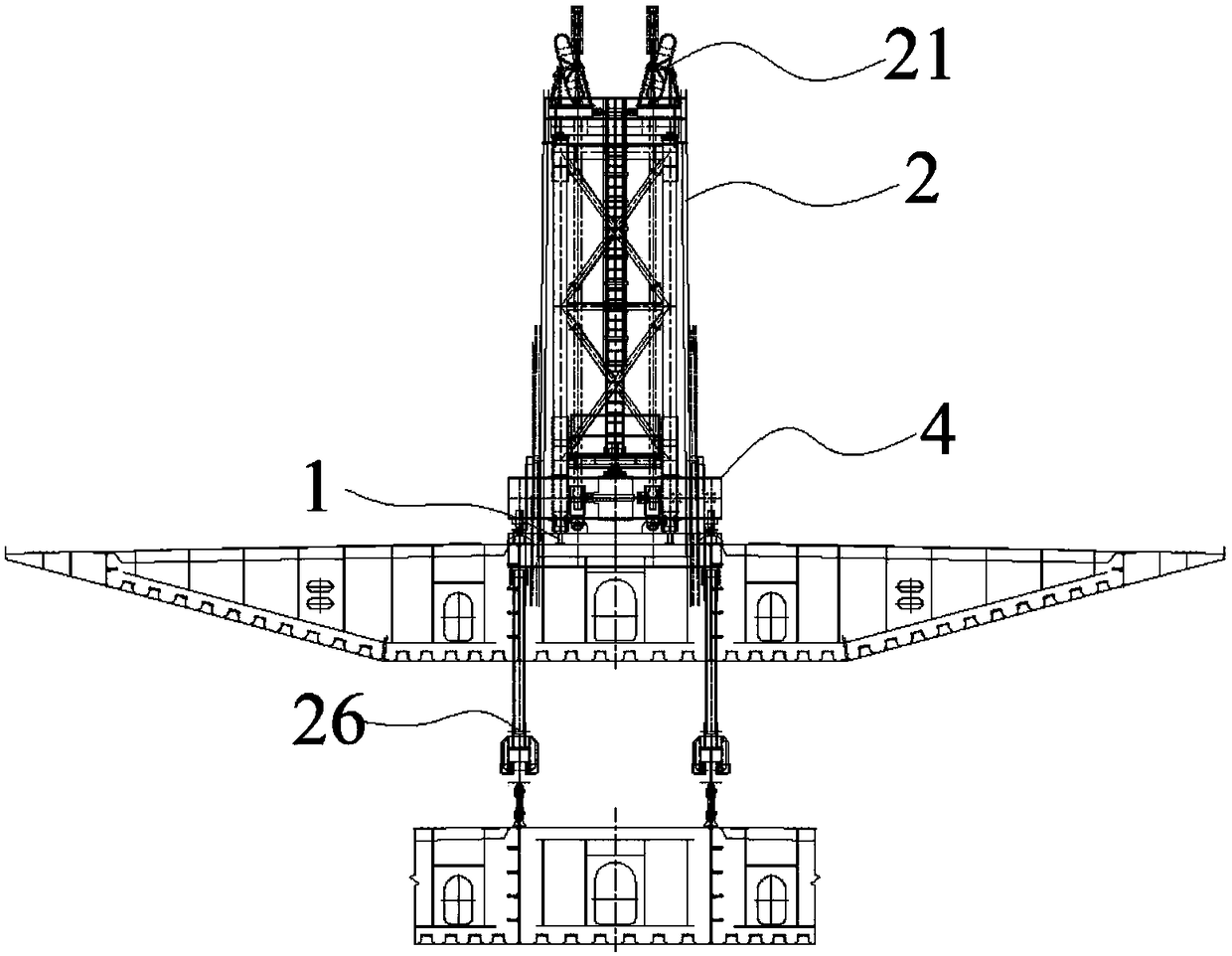

[0033] A cable-stayed bridge with a central cable plane is built in a certain place. The main girder is a steel box girder structure. Two rows of cable-stayed cables are anchored in the middle of the steel box girder. The bridge deck crane is located between the two rows of cable-stayed cables. The steel box girder is hoisted by the bridge deck crane to complete the assembly construction of the main girder.

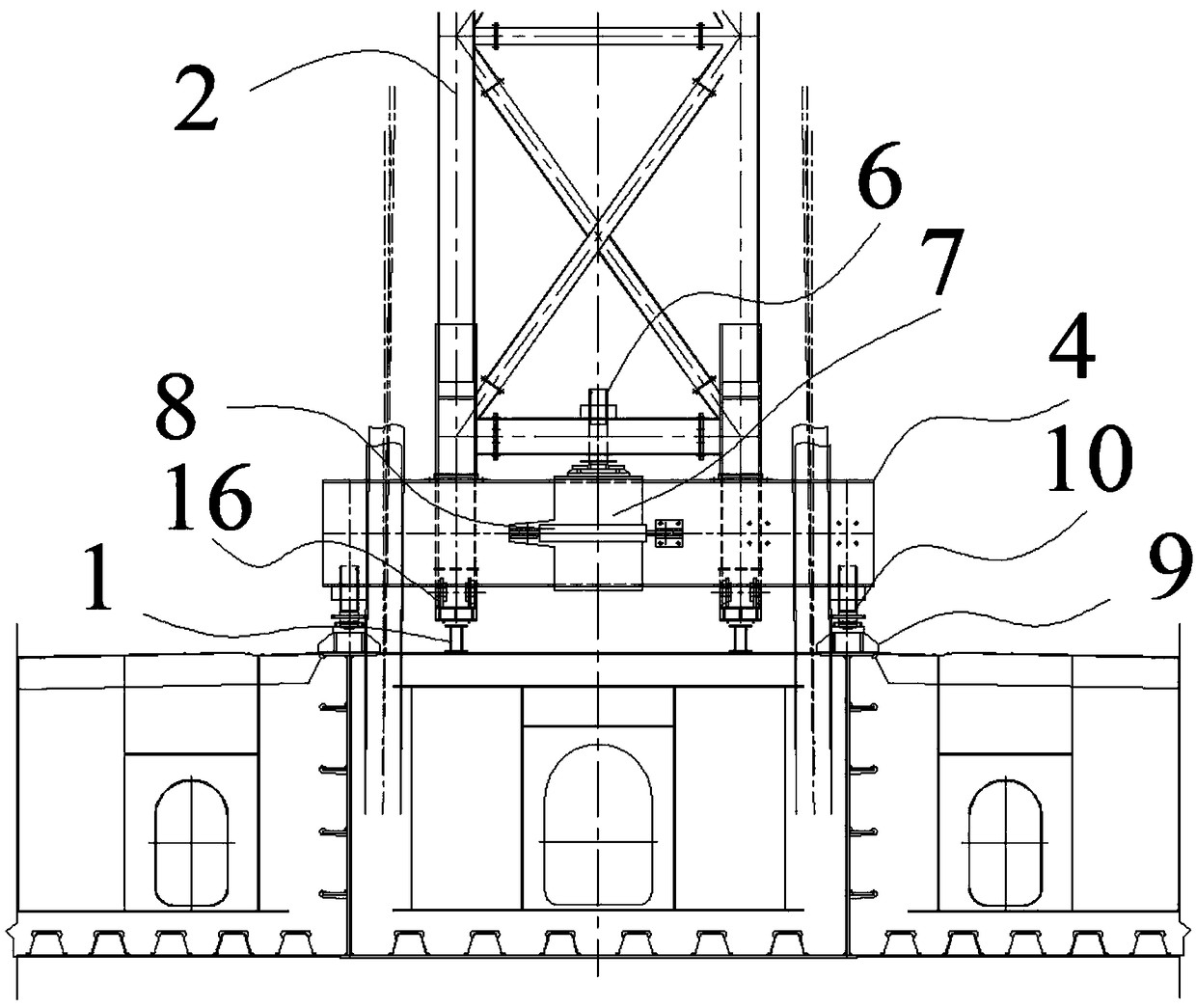

[0034] Such as Figure 1-8 , including a slide rail 1 laid on the assembled steel box girder along the bridge direction, a support truss 2 slidingly connected to the slide rail 1 and a hoisting device fixed on the support truss 2 . The slide rail 1 of this embodiment is an I-shaped steel structure fixed on the assembled steel box girder along the bridge direction, and the two slide rails are located between two rows of stay cabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com