Auxiliary slinging device and method through combination process of a plurality of cranes

A lifting device and combined operation technology, applied in cranes, transportation and packaging, etc., can solve the problems of weakened anti-instability, reduced lifting capacity, increased self-weight, etc., so as to improve stability and safety, reduce slewing Inertial force, the effect of enhancing dynamic stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with the accompanying drawings.

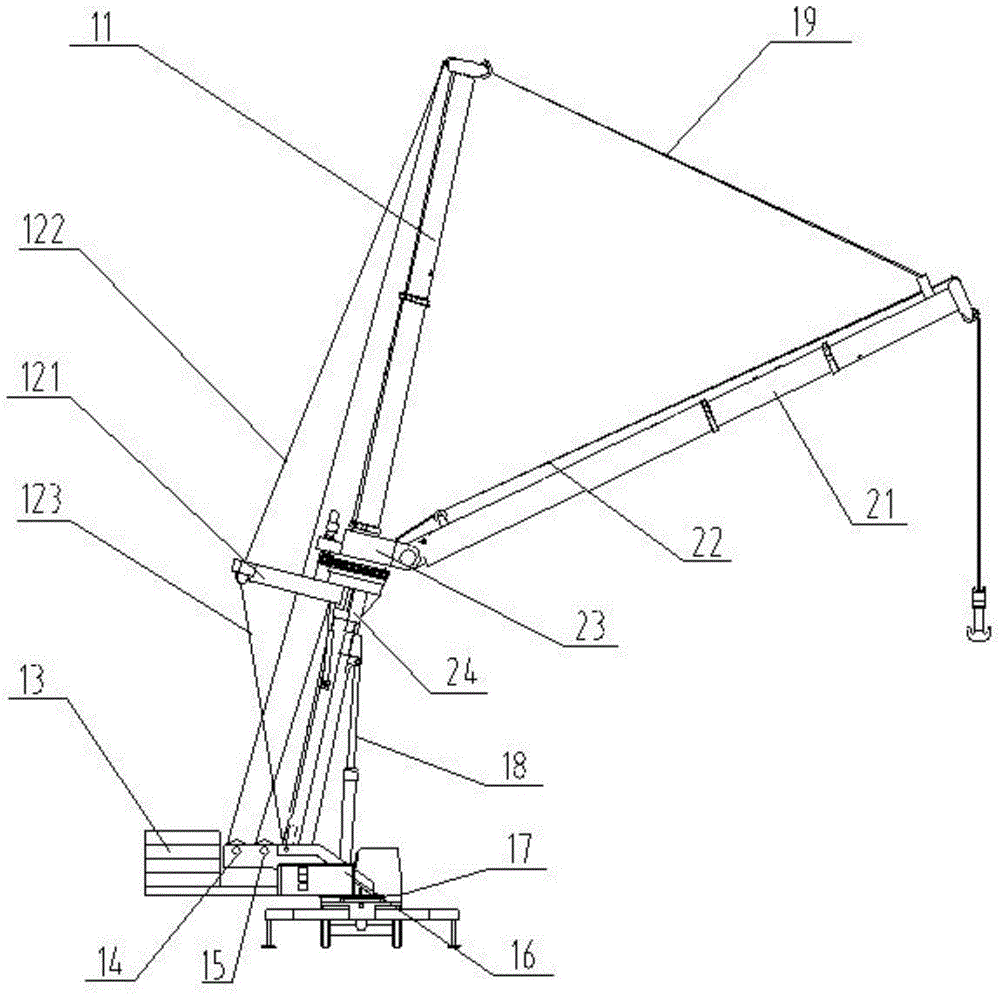

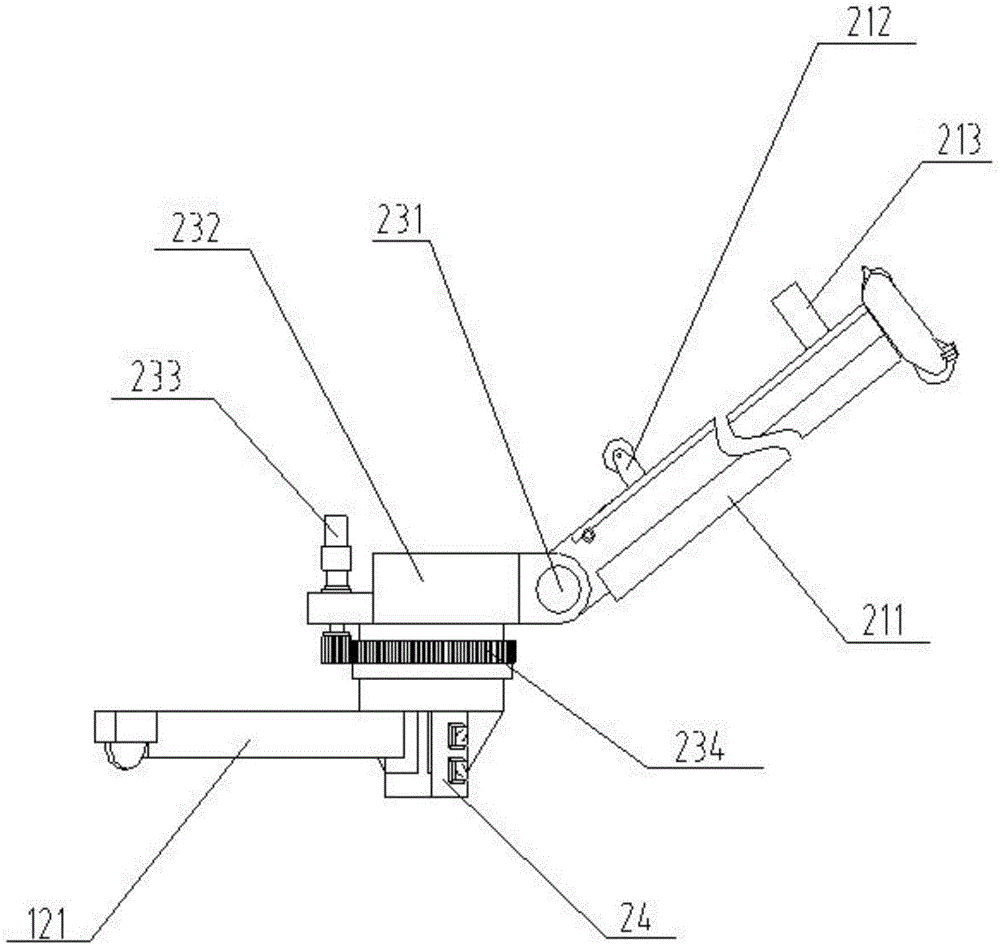

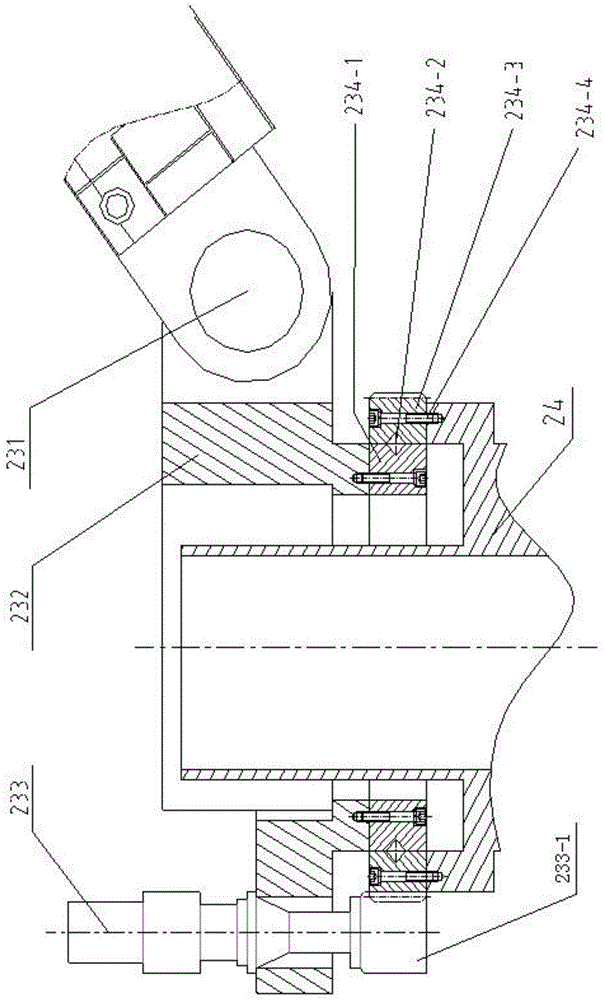

[0020] Such as figure 1 , 2 Shown in and 4, the crane 1 that is equipped with auxiliary hoisting device 2 of the present invention comprises getting off the car 17, is provided with turntable 16 on the car 17, is provided with counterweight 13, main boom 11 and main winch 14 on the turntable 16, main The boom 11 is provided with a super-lifting device 12 and a luffing oil cylinder 18 , and the main hoist 14 is wound with a main suspension rope 19 . The auxiliary lifting device 2 of the present invention includes an auxiliary winch 15 , a telescopic auxiliary boom 21 , an auxiliary lifting rope 22 , a rotatable auxiliary slewing support 23 , a connection base 24 and a crane connection device 4 . The connection base 24 is fixedly connected to the main boom 11 by bolts, and the auxiliary slewing support 23 is rotatably connected to the connection base 24 . The auxiliar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com