Transverse and longitudinal profiling device for planting mechanism and control method

A profiling device and longitudinal technology, applied in planting methods, transplanting machinery, applications, etc., can solve the problems of large impact, large bending moment of planting mechanism, poor applicability, etc., and achieve obvious and effective horizontal profiling, flexible rotation, and high strength powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

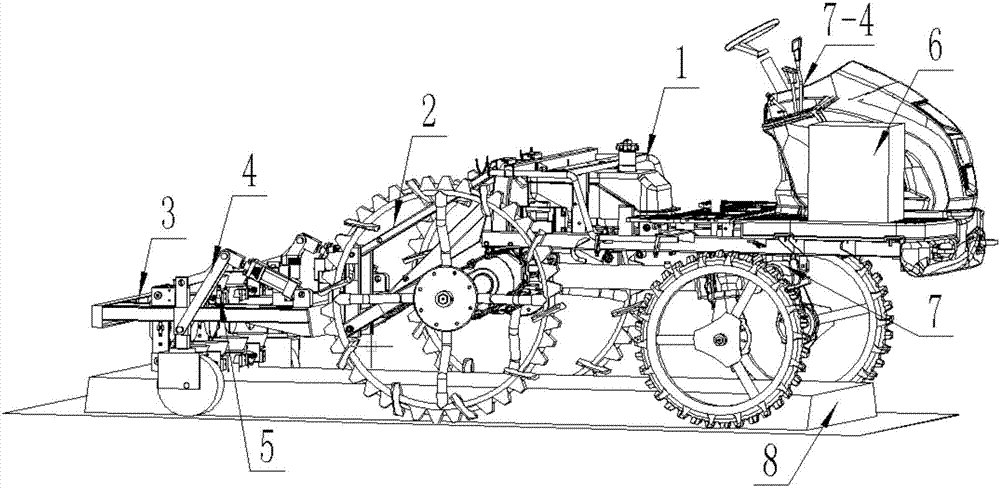

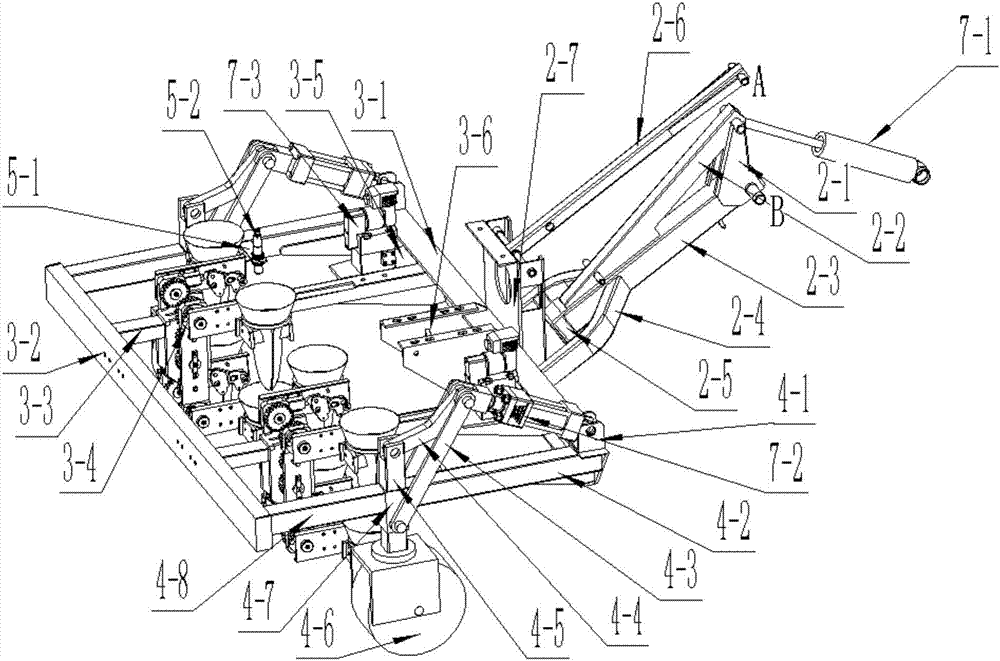

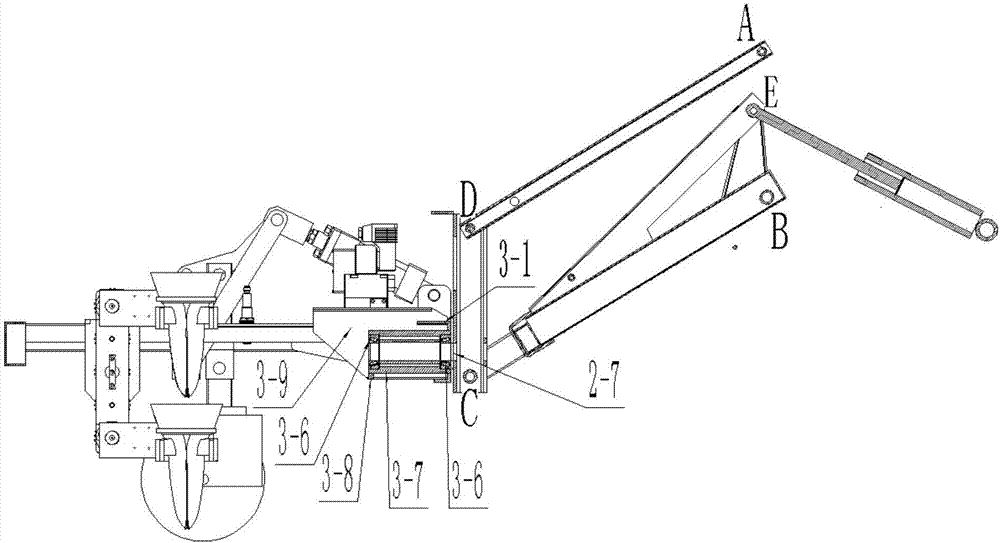

[0036] Such as figure 1 Shown is the horizontal and vertical profiling device of the planting mechanism of the present invention, including a vehicle frame 1, a planting frame lifting mechanism 2, a planting frame 3, a hydraulic profiling mechanism 4, a signal acquisition unit 5, an information feedback control system 6, a hydraulic actuator System 7; the rear part of the vehicle frame 1 and the planting frame lifting mechanism 2 form an up and down rotatable connection at points A and B, the rear end of the planting frame lifting mechanism 2 forms a left and right symmetrical rotational connection with the planting frame 3, and the hydraulic profiling mechanism 4 and The left and right ends of the planting frame 3 are symmetrically fixedly connected, the left a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com