Patents

Literature

51results about How to "Increase bending moment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

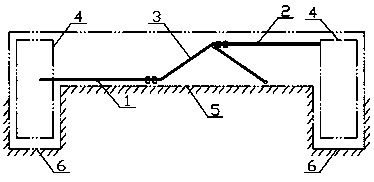

Method for adjusting weight of fillers on masonry arch bridge in partitioning manner

ActiveCN104074139AReduce bending momentUniform moment distributionBridge erection/assemblyBridge strengtheningApparent densityCarrying capacity

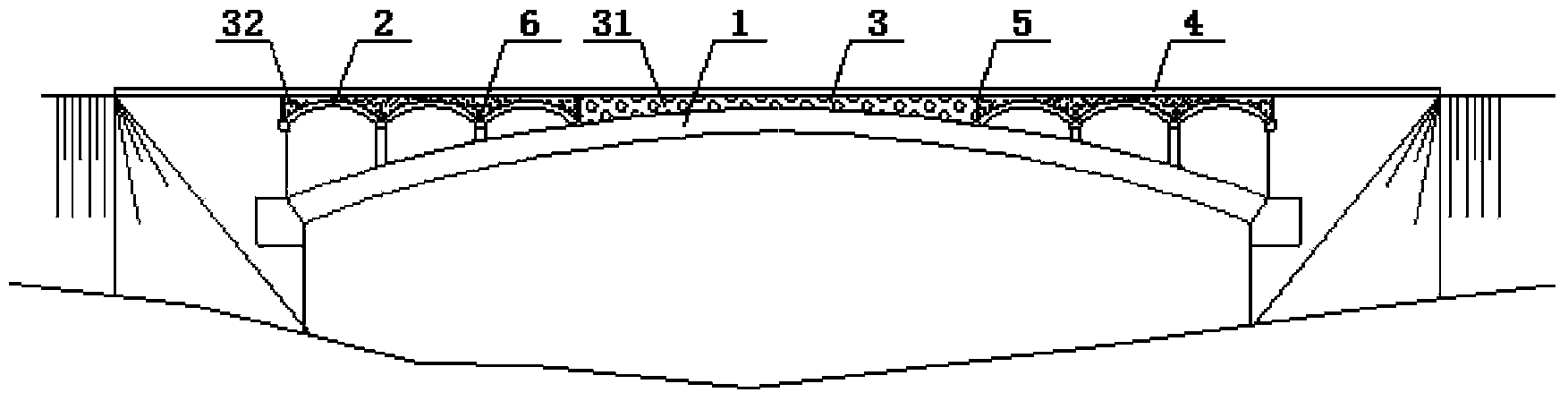

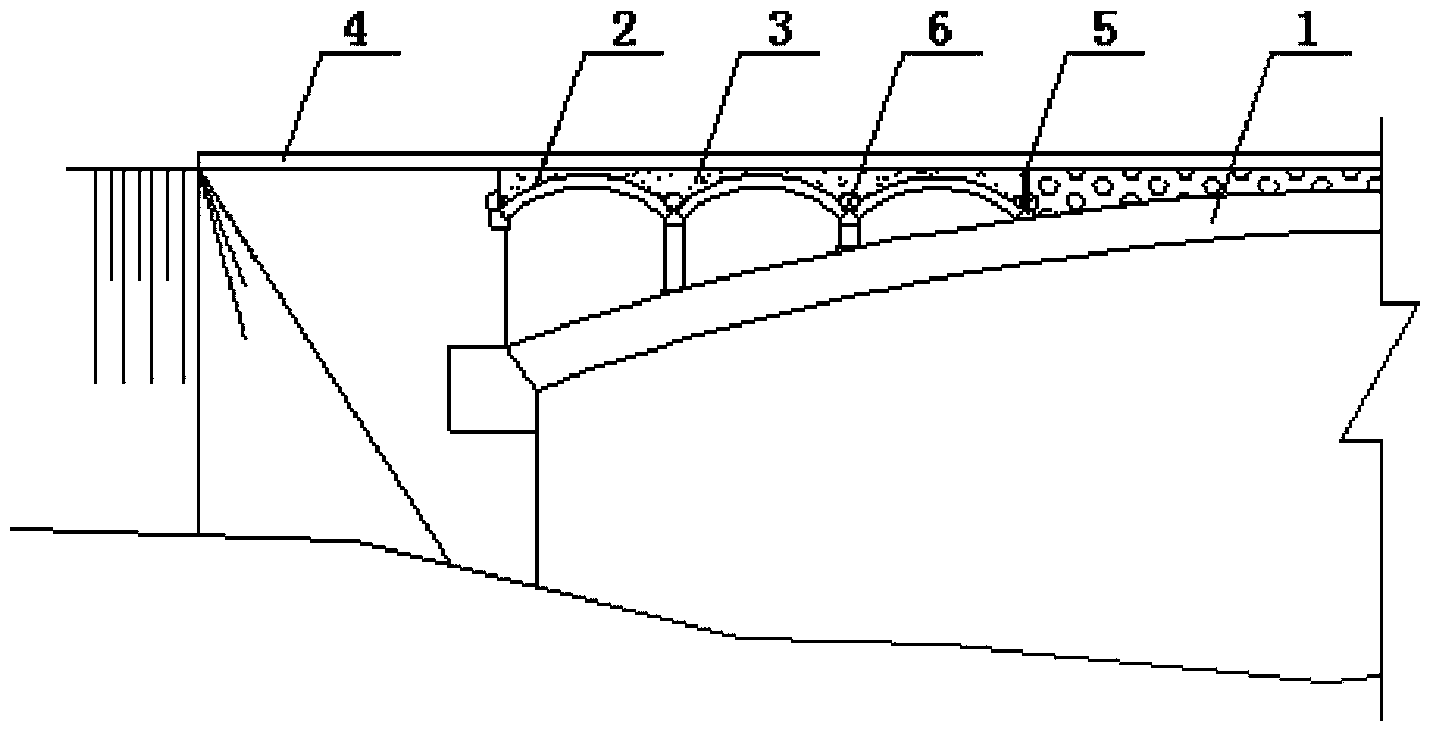

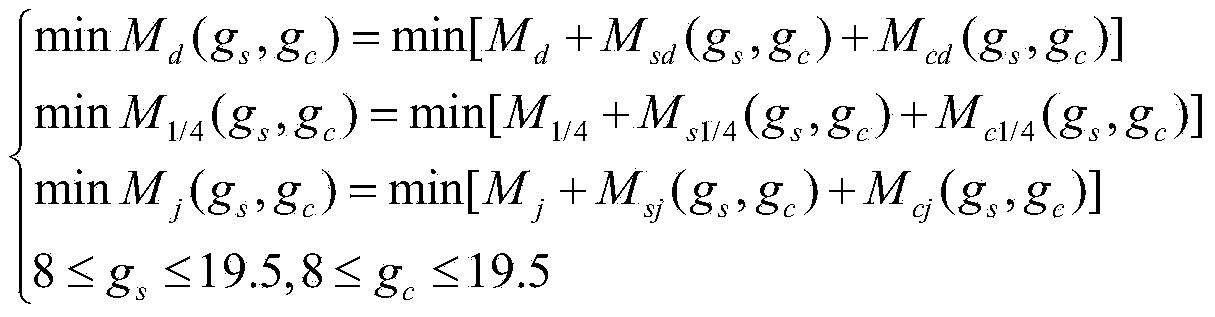

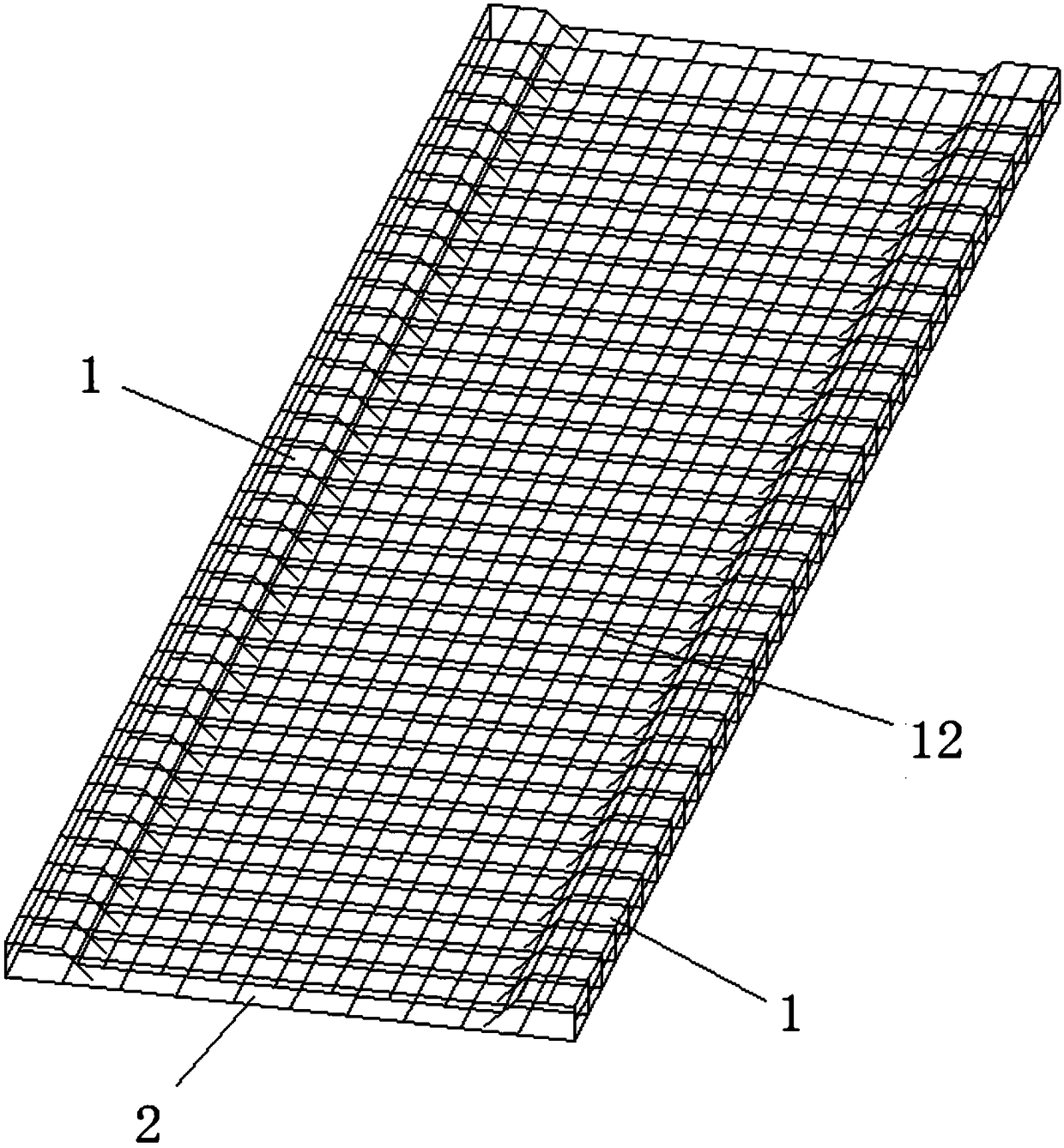

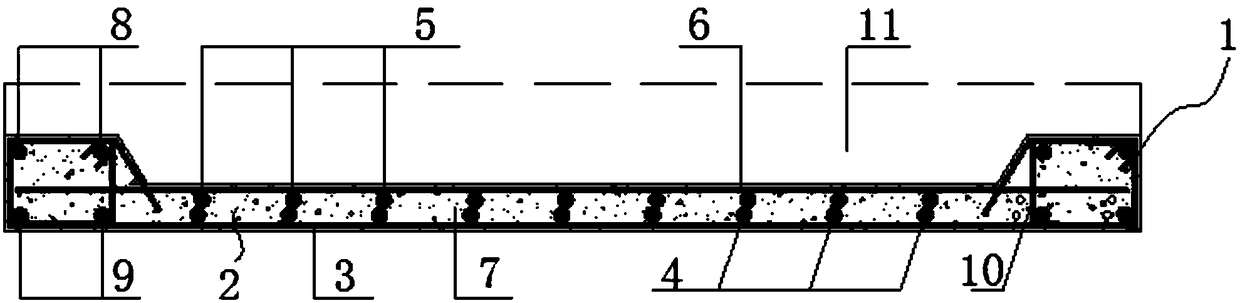

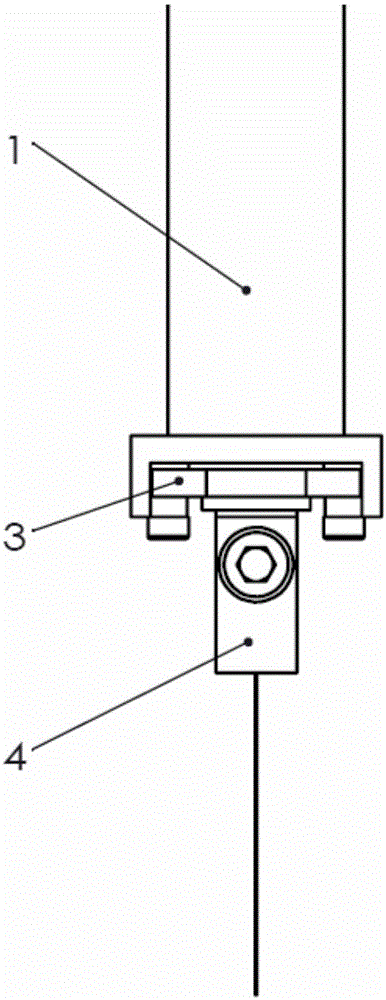

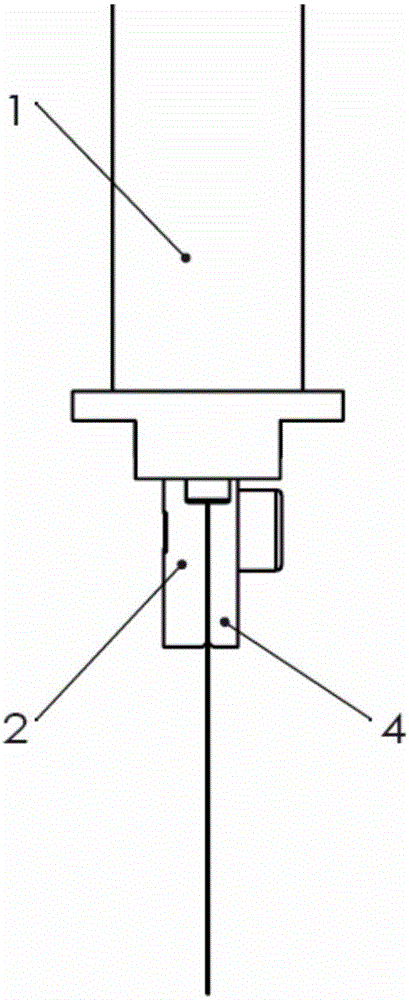

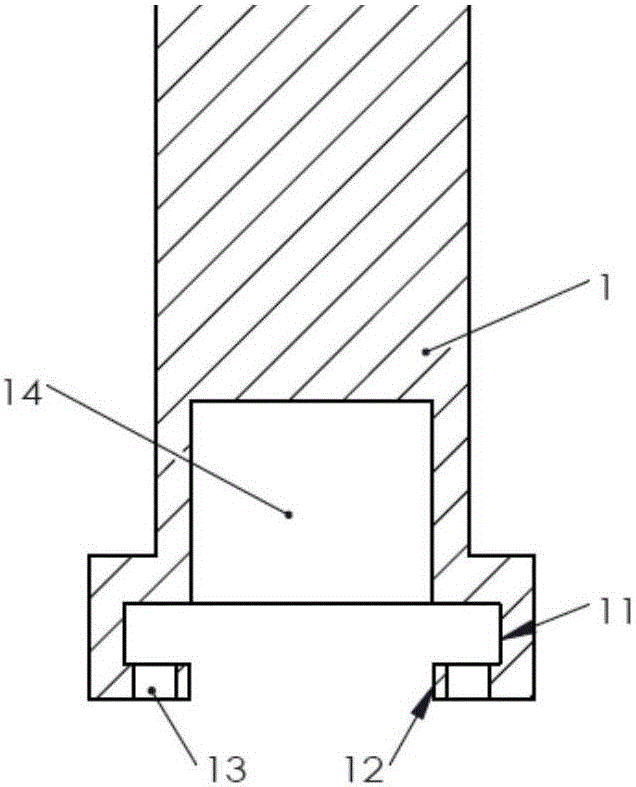

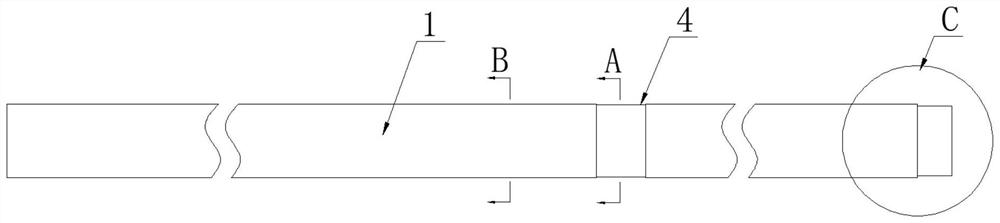

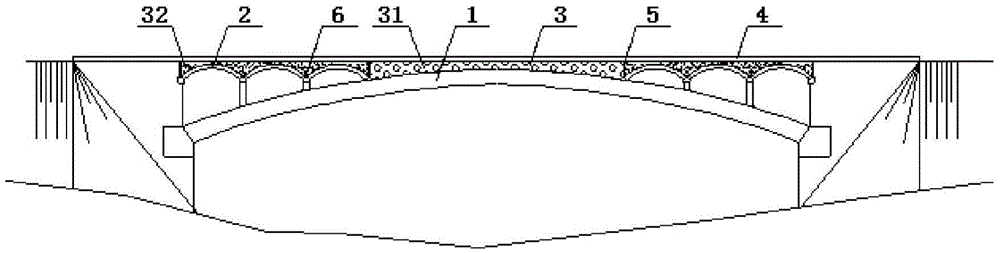

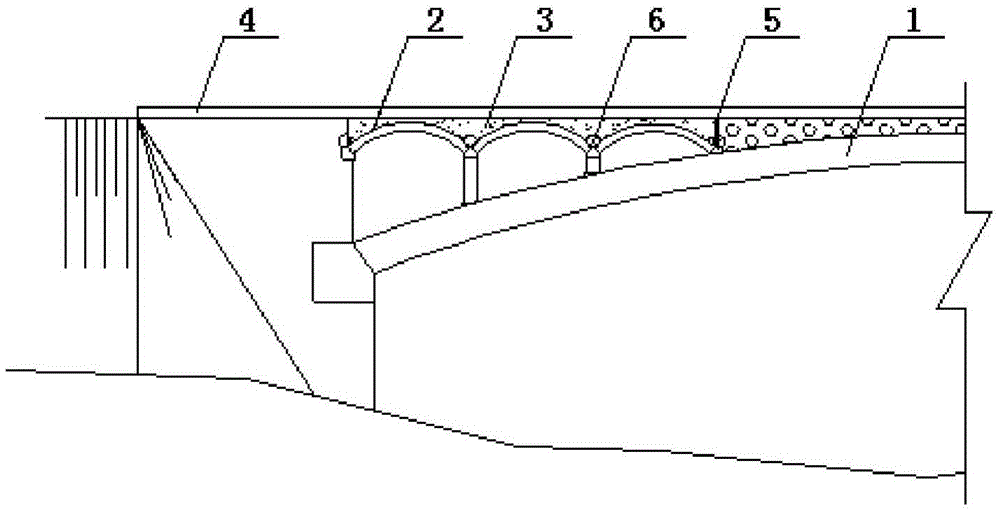

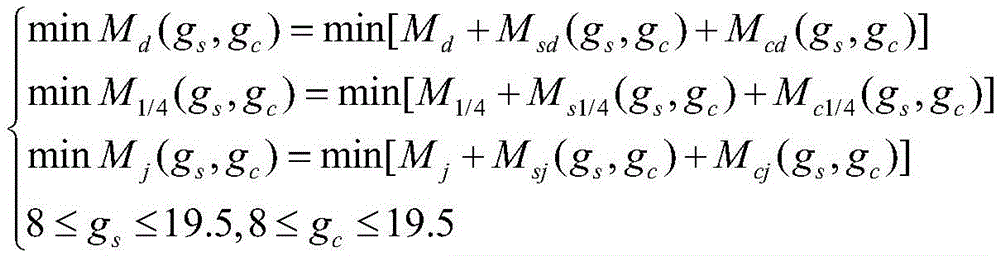

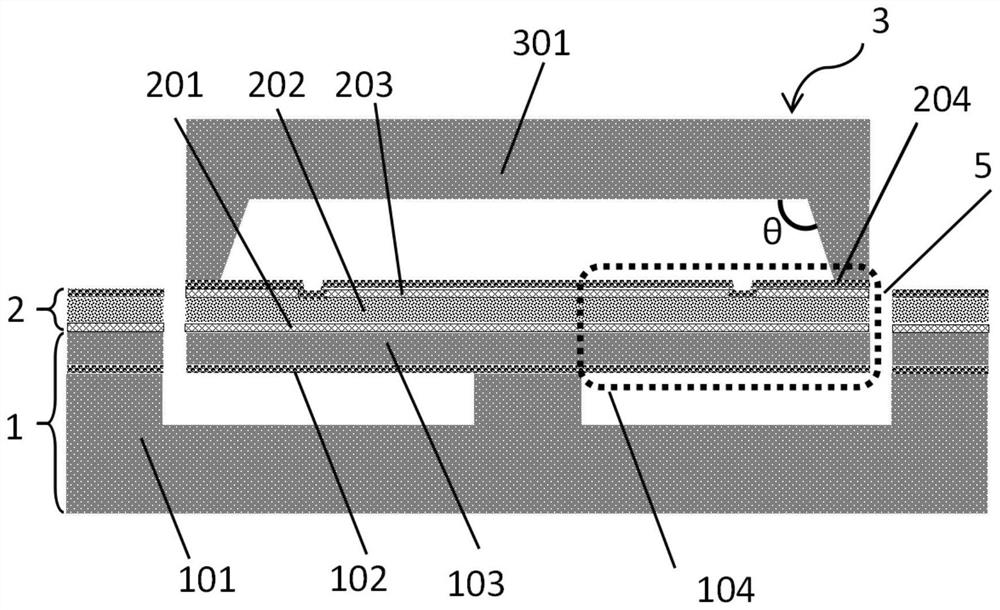

The invention discloses a method for adjusting the weight of fillers on a masonry arch bridge in a partitioning manner. The masonry arch bridge comprises a main arch ring (1), spandrel arch rings (2), a filler layer (3) on arches, and a bridge panel (4). The method comprises the steps: the filler layer (3) on the arches is divided into an arch top area (31) and spandrel arch areas (32), wherein the arch top area (31) is formed between the main arch ring (1) and the bridge panel (4), and the spandrel arch areas (32) are formed between the spandrel arch rings (2) and the bridge panel (4); lightweight concrete fillers with the apparent density from 800kg / m3 to 1200 kg / m3 are filled into the arch top area (31), and lightweight concrete fillers or ordinary soil quality fillers with the apparent density from 1200kg / m3 to 1950 kg / m3 are filled into the spandrel arch areas (32); and the weight of the filler layer (3) on the arches is adjusted by calculating three objective functions, i.e. bending moments Md, M1 / 4 and Mj generated by the main arch ring on the arch top, the one quarter of an arch span, and arch feet, and the like. The method has the advantages that the utilization efficiency of arch ring materials can be improved, the distribution of the internal force of the main arch ring is improved, and the carrying capacity of the arch bridge is improved.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD

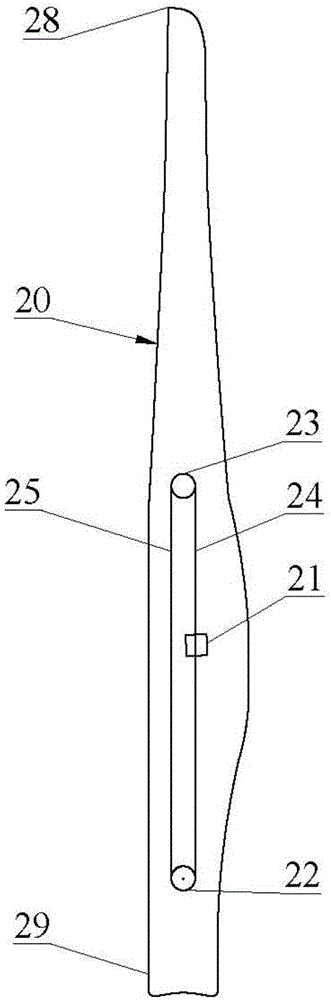

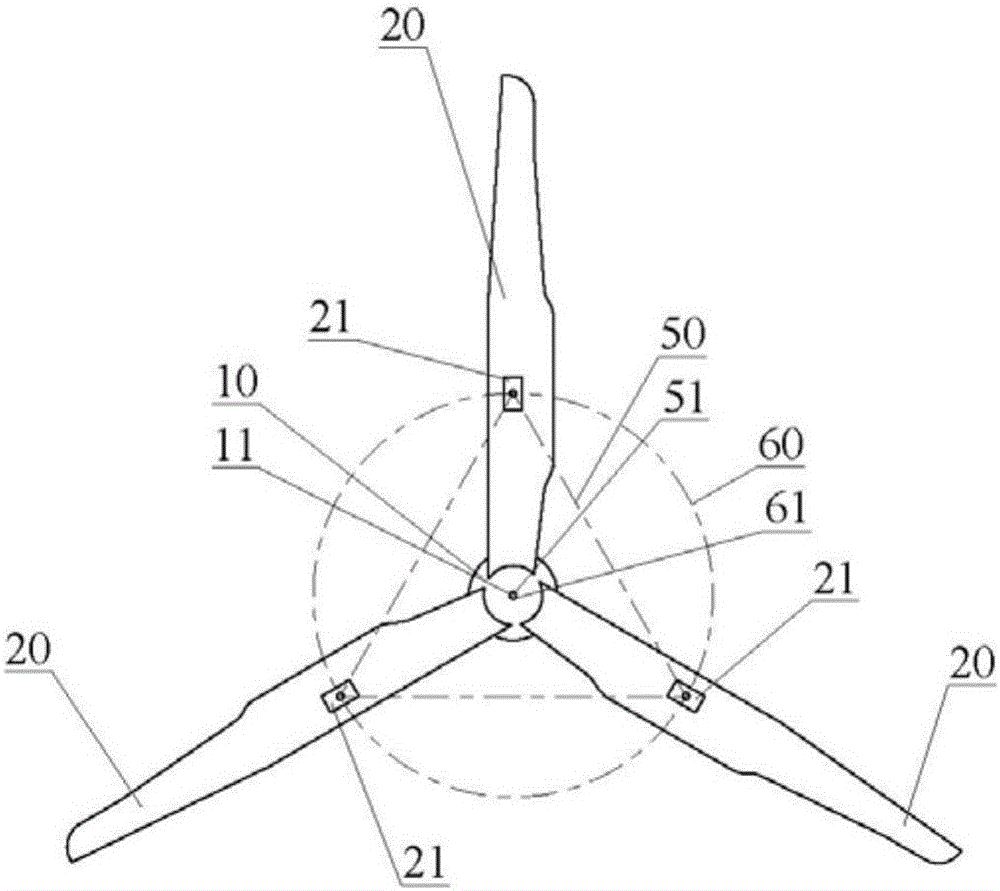

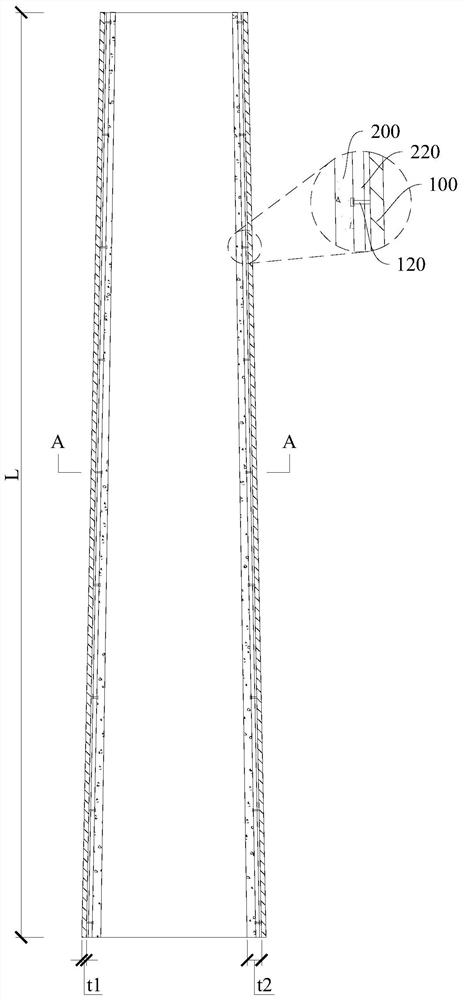

Blade as well as wind-driven power generating set and method

ActiveCN106762465AExtend your lifeReduce pitch frequencyWind motor controlMachines/enginesImpellerWind driven

The invention discloses a blade as well as wind-driven power generating set and method. Pitch regulating frequency in the speed regulating process of the wind-driven power generating set can be reduced. The blade of the wind-driven power generating set comprises a hollow cavity, a mass assembly, a driving assembly and a sensor, wherein the mass assembly, the driving assembly and the sensor are arranged in the hollow cavity; the driving assembly is used for driving the mass assembly to move in the length direction of the blade; and the sensor detects the movement quantity of at least part of elements in the driving assembly or the displacement quantity of the mass assembly. According to the blade provided by the invention, the rotating inertia of an impeller can be changed through the movement of the mass assembly in the blade, so that the speed of the impeller is regulated.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

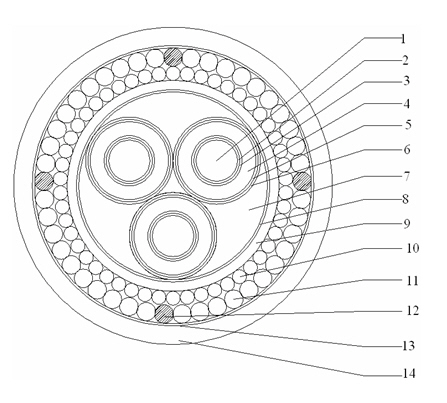

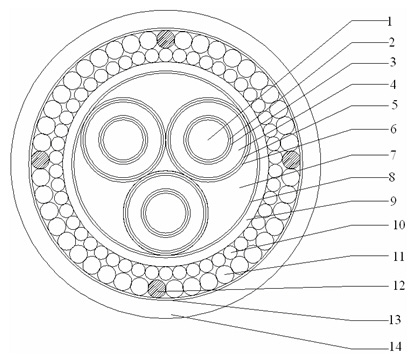

Seismic-resistant electrical cable

InactiveCN102157242AEven by forceLow elastic modulusPower cables with screens/conductive layersCopper conductorElastomer

The invention relates to a seismic-resistant electrical cable comprising a conductor, a semiconductive layer, a conductor shielding layer, an insulating layer, an insulating shielding layer, a copper strip shielding layer, an elastic body packing, a wrapping layer, an isolating sleeve, a thin round steel wire armoring layer, a thick round steel wire armoring layer, a copper conductor, an isolated layer and an outer sheath. The seismic-resistant electrical cable is characterized in that a semiconductive band layer is wrapped outside the conductor; insulating materials, packing materials, isolating sleeve materials and outer sheath materials are all elastic body polymers; and double-layer steel wire armoring is adopted for the armoring layers. The invention has higher shearing rigidity, bending rigidity and damping ratio, obvious effects of shear resistance, bending moment, axial force, torsion, and the like, and excellent seismic-resistant and seismic-proof capacity.

Owner:江苏天地龙电缆有限公司

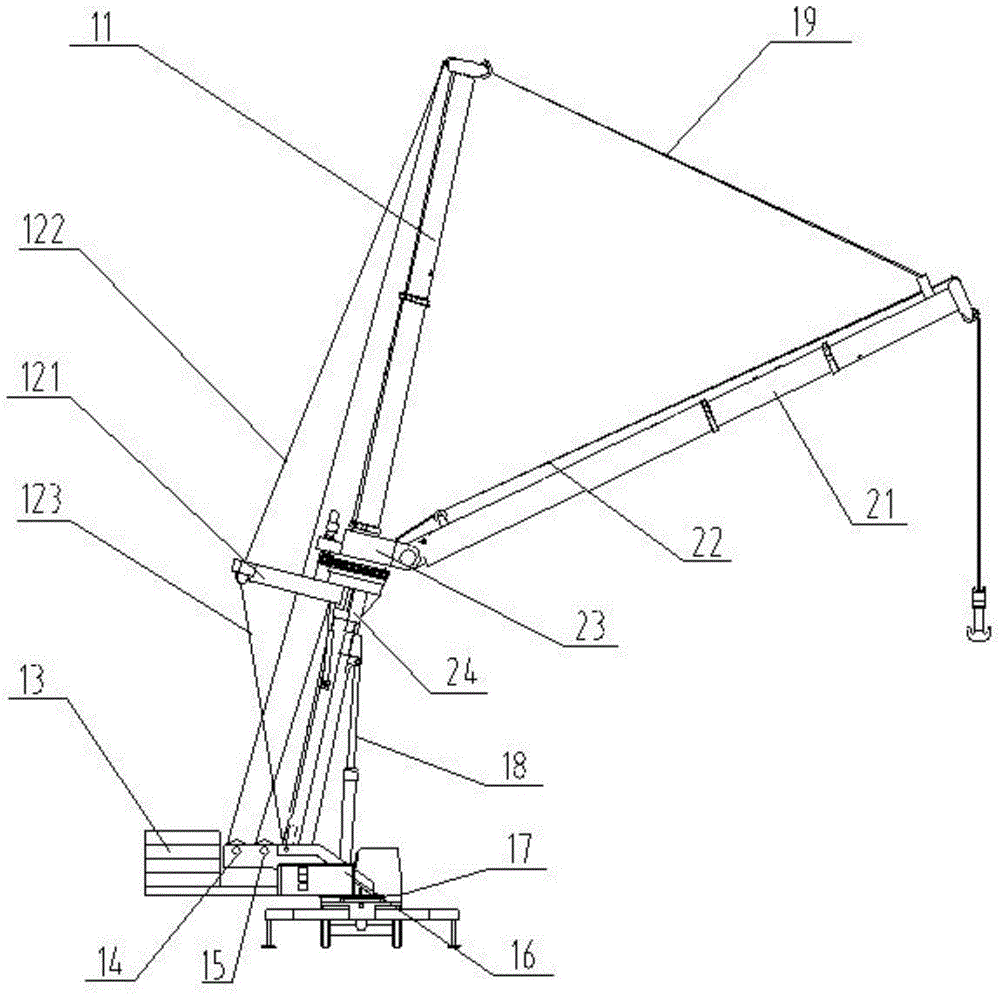

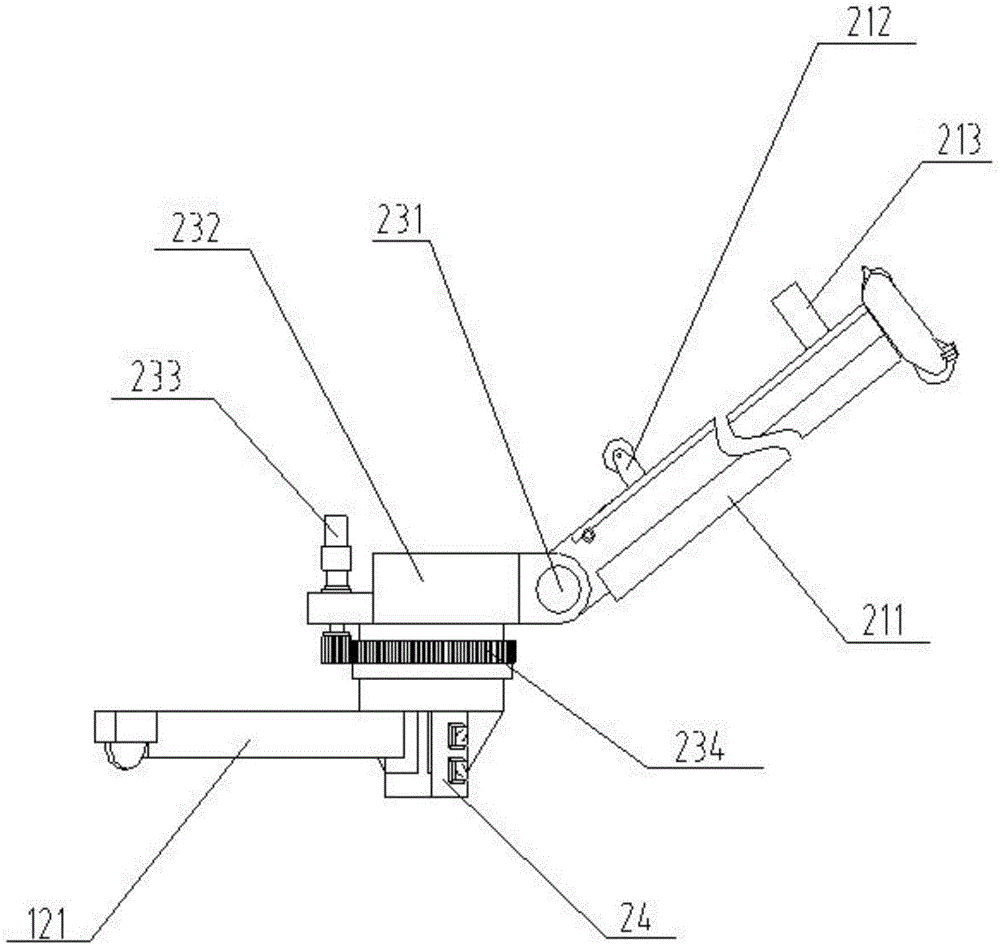

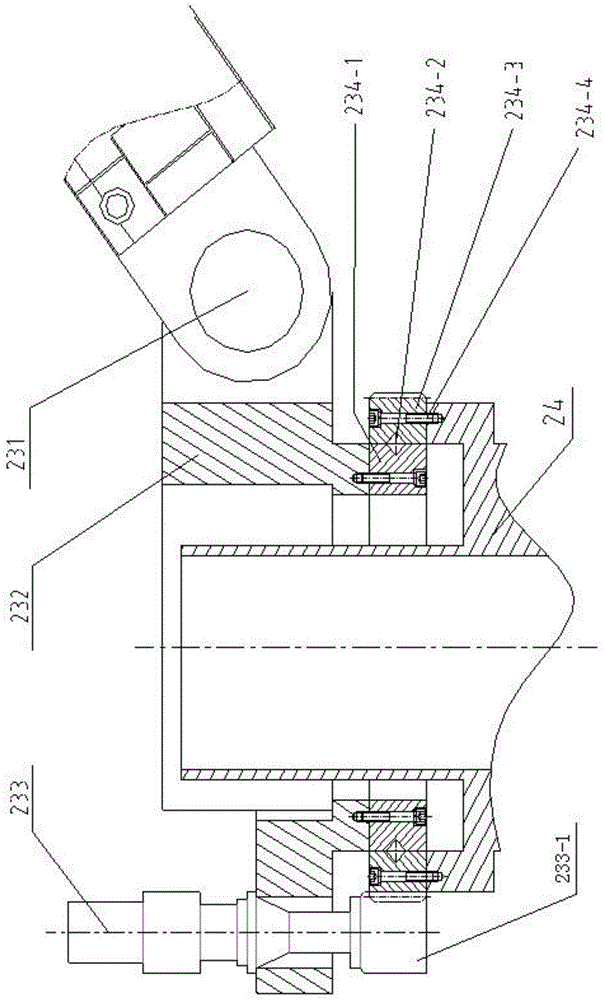

Auxiliary slinging device and method through combination process of a plurality of cranes

The invention discloses an auxiliary slinging device and method through combination process of a plurality of cranes. The auxiliary slinging device comprises an auxiliary winch, an elastic auxiliary suspension arm, an auxiliary suspension rope, a turnable auxiliary rotation support, a connecting base and a connecting device for the cranes, wherein the connecting base is connected with main suspension arms of the cranes; the auxiliary rotation support is connected with the connecting base, and the arm tail of the auxiliary suspension arm is hinged to the auxiliary rotation support; the auxiliary wince is arranged on a rotary table of each crane, the auxiliary suspension rope winds the auxiliary winch , and the auxiliary suspension rope winds around the arm head of the auxiliary suspension arm; the main suspension ropes of the cranes wind around the arm head of the main suspension arm to be connected with the auxiliary suspension arm; the connecting device for the cranes is connected with the connecting base, and the auxiliary hoisting method adopts the auxiliary slinging device to sling heavies. The auxiliary slinging device and method, disclosed by the invention, can realize hoist in a large working space for the cranes under the condition of not enlarging the length of an elevating arm, so that the destabilizing resistance and the hoisting stability of the cranes are improved, and the hoisting efficiency is improved.

Owner:CHINA UNIV OF MINING & TECH

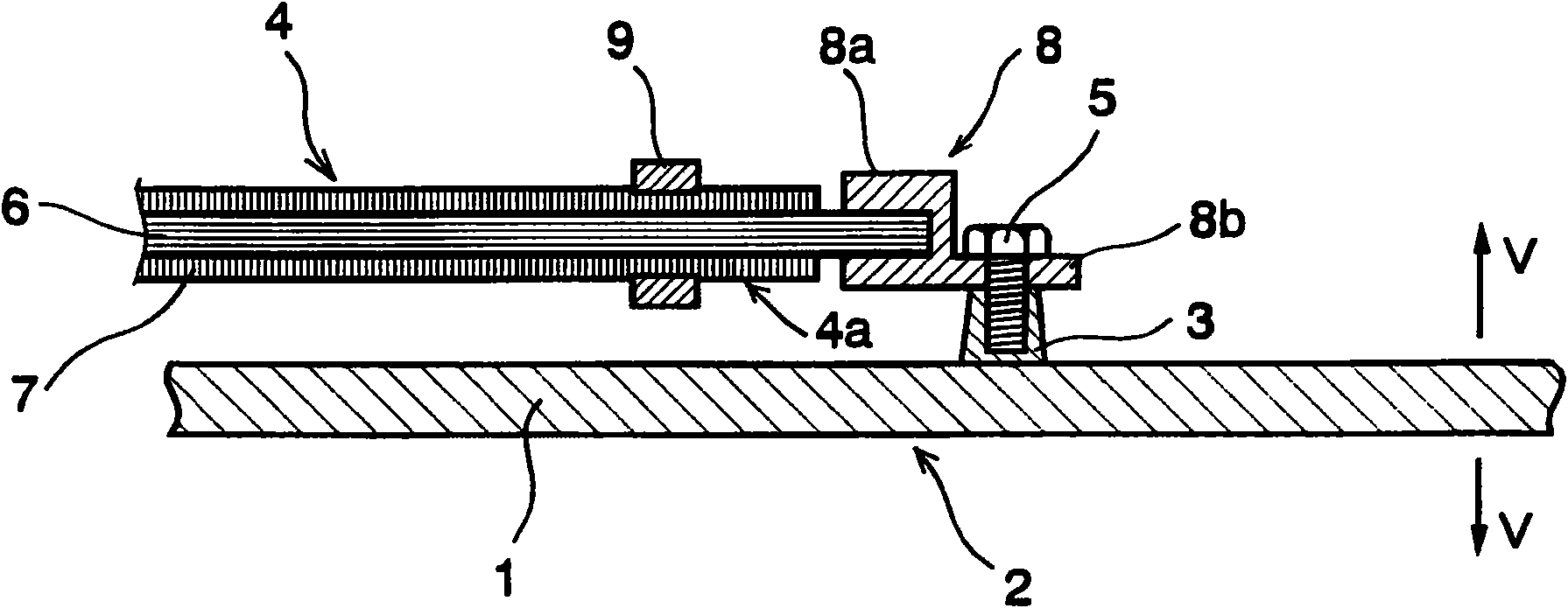

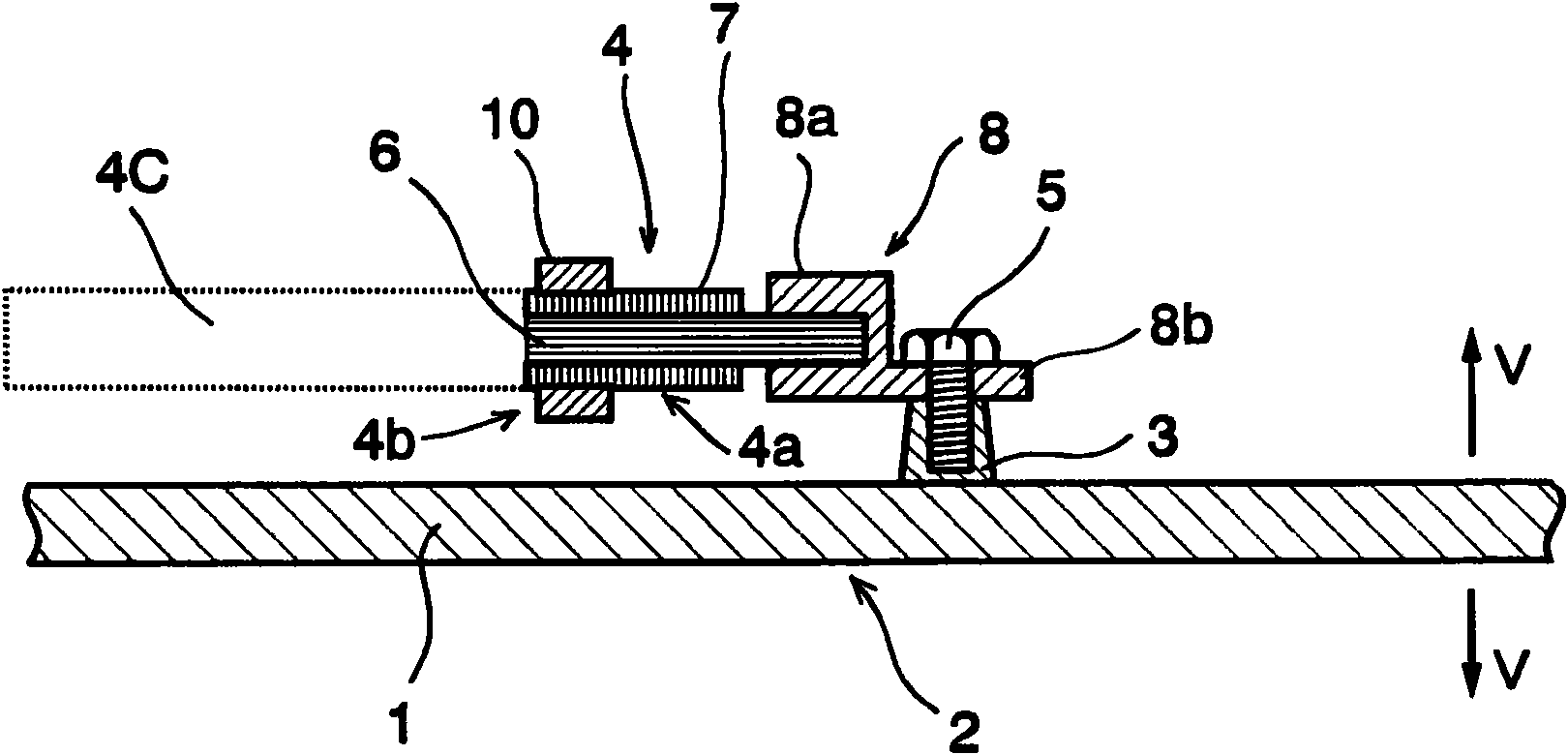

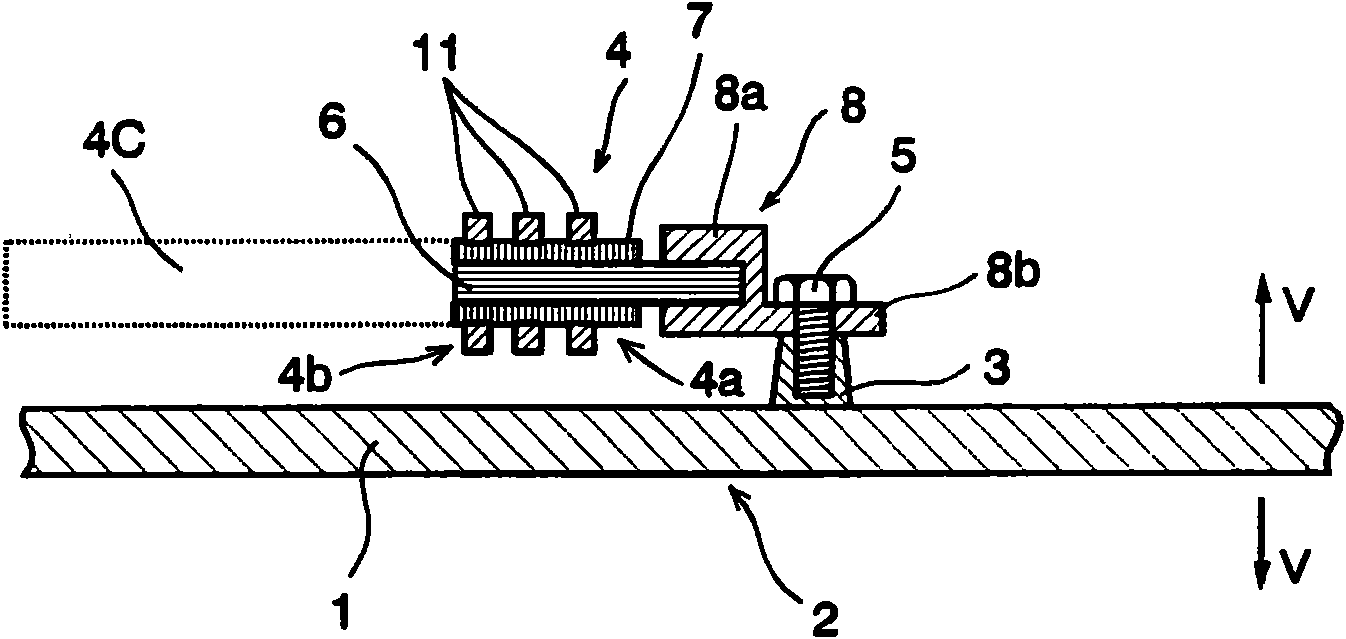

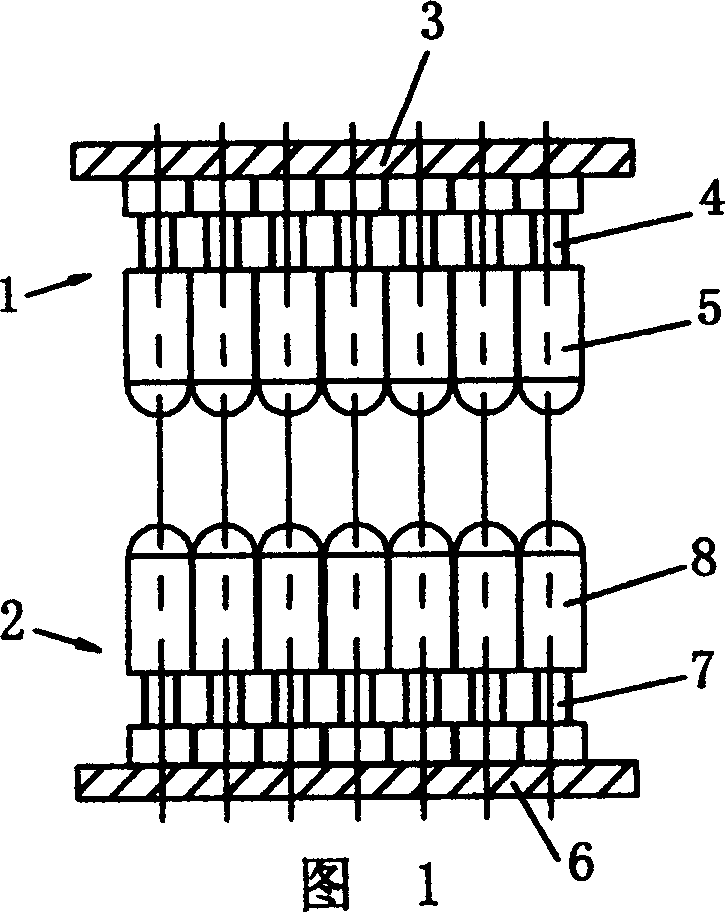

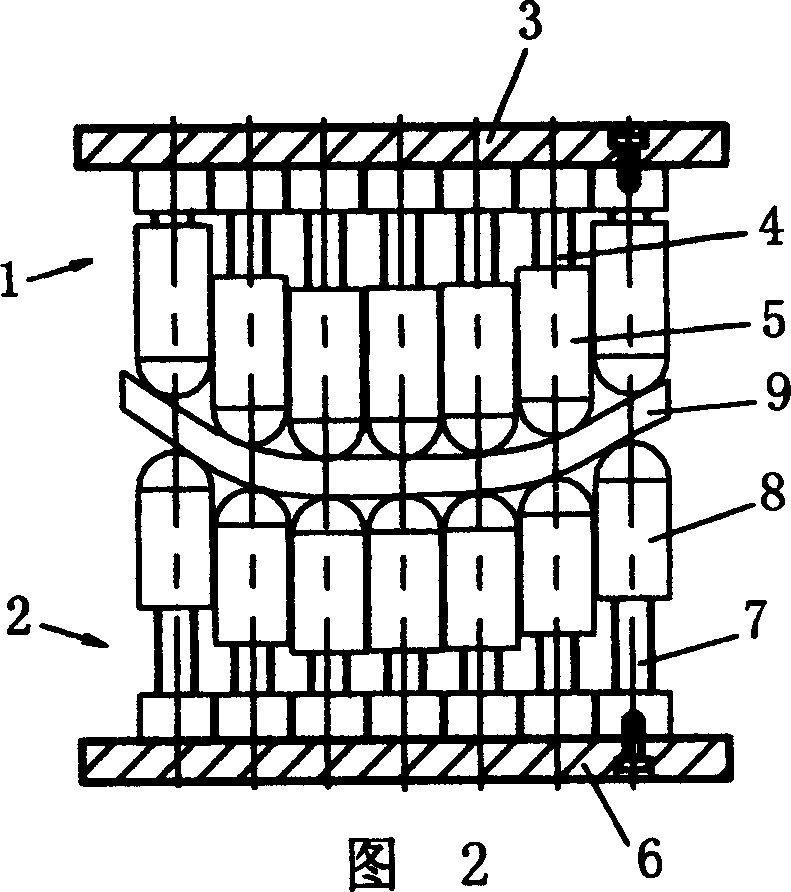

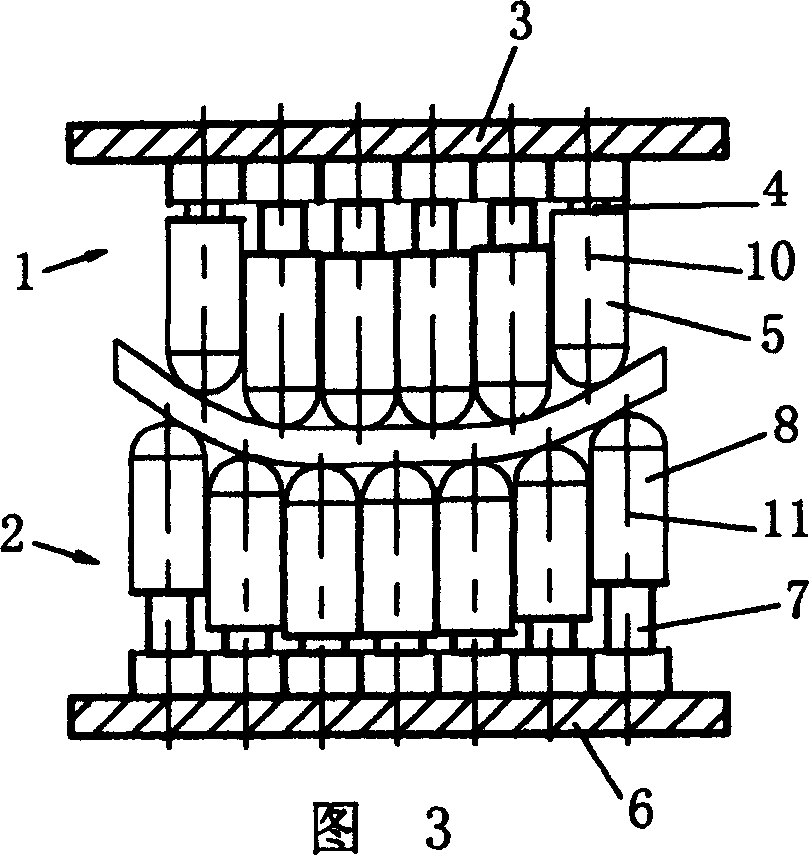

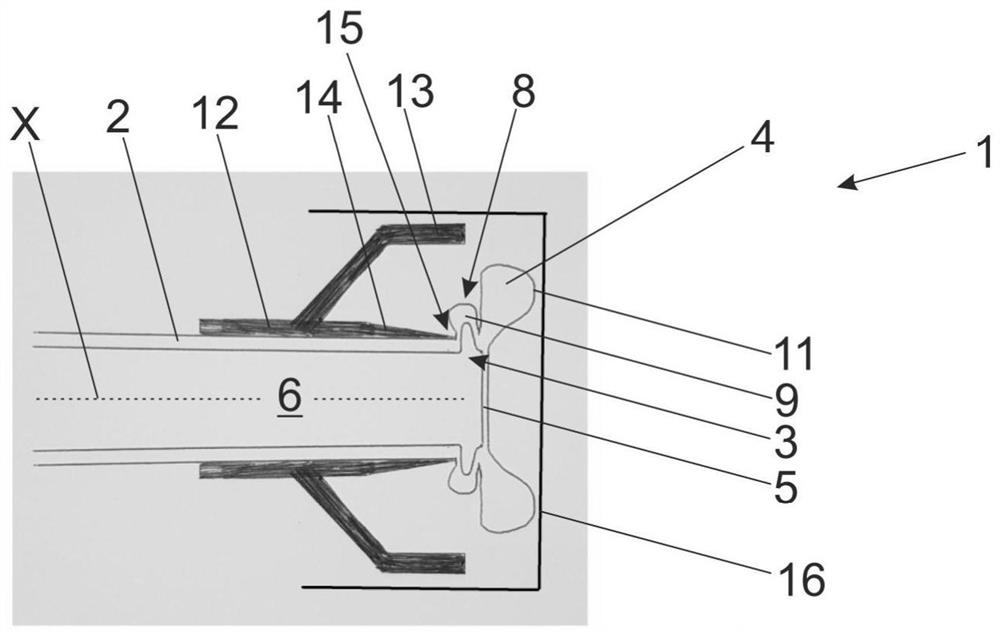

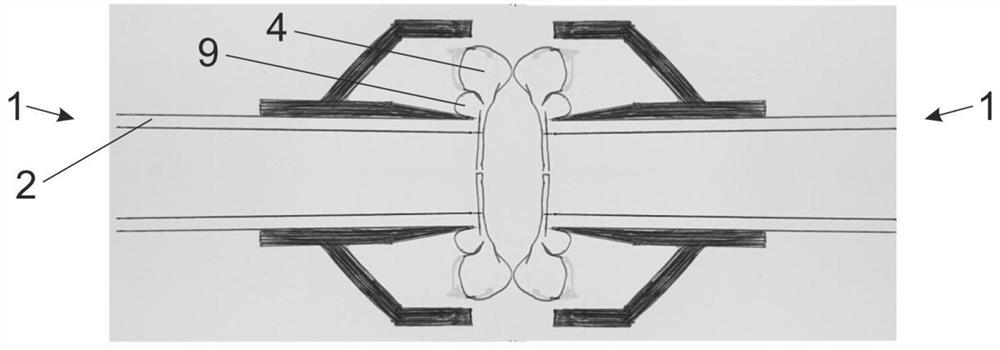

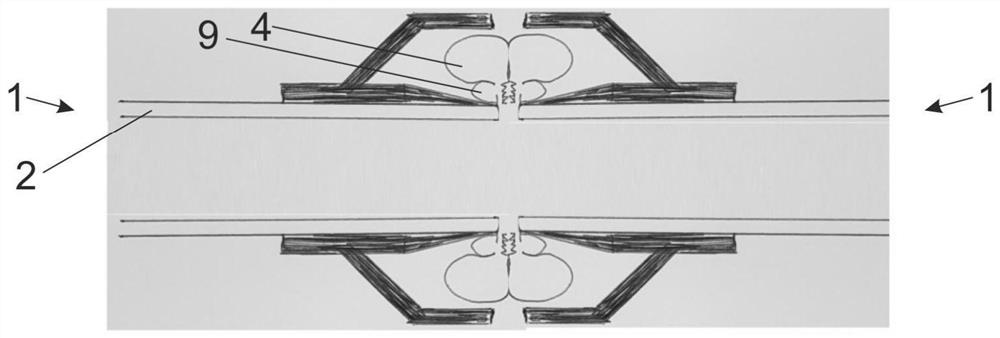

Vibration suppressing structure

InactiveCN101573545AIncrease frictionReduce vibrationNon-rotating vibration suppressionFriction dampersThermal energyEngineering

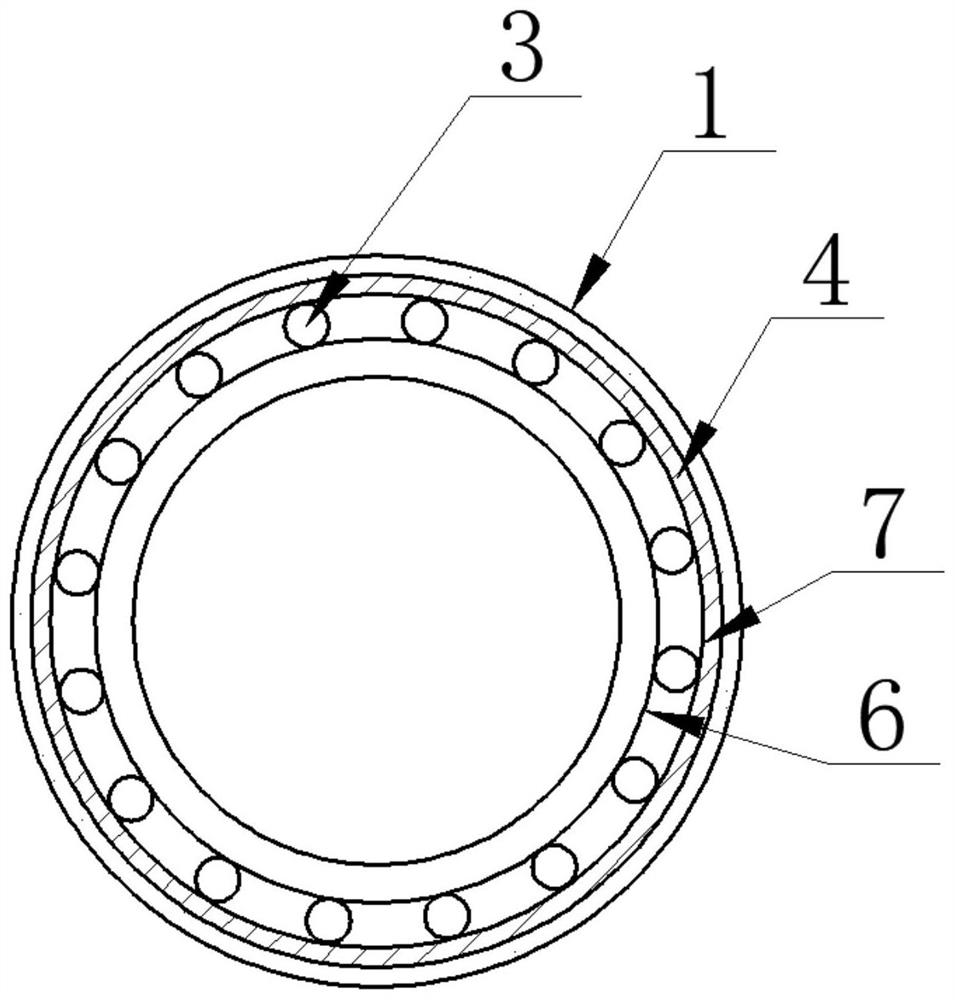

The invention provides a vibration suppressing structure which can obtain a sufficient vibration suppression effect by using a member capable of converting kinetic energy into thermal energy. A plurality of members (6) are held in contact with one another so that they can be relatively displaced. The members (6) a attached to a vibration-to-be-controlled object (1). When the vibration-to-be-controlled object (1) vibrates, the kinetic energy relatively displaces the plurality of members (6) so as to convert the kinetic energy into thermal energy, thereby suppressing vibration of the vibration-to-be-controlled object (1). A pressed contact member (9) is mounted on the members (6) so as to bring the members (6) into a pressed contact with one another and increase a frictional force between the members (6).

Owner:TOYOTA JIDOSHA KK

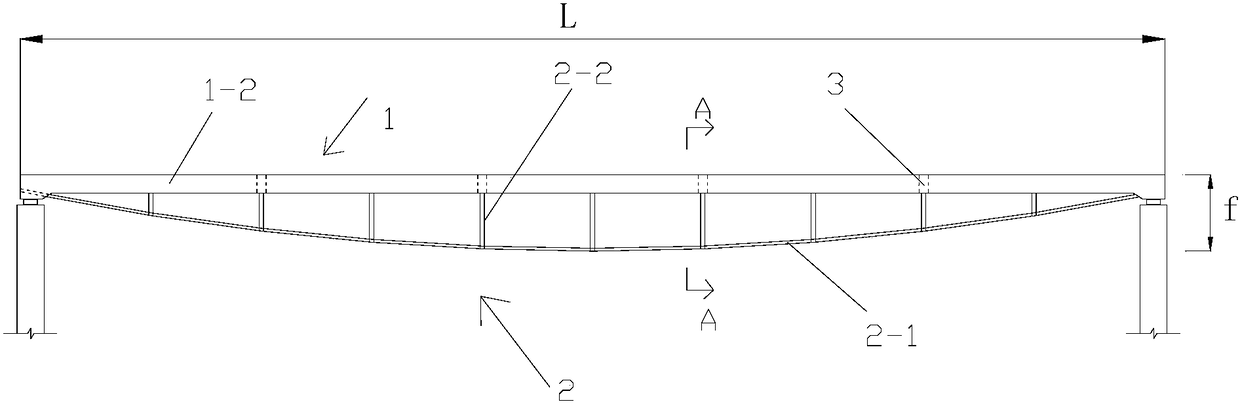

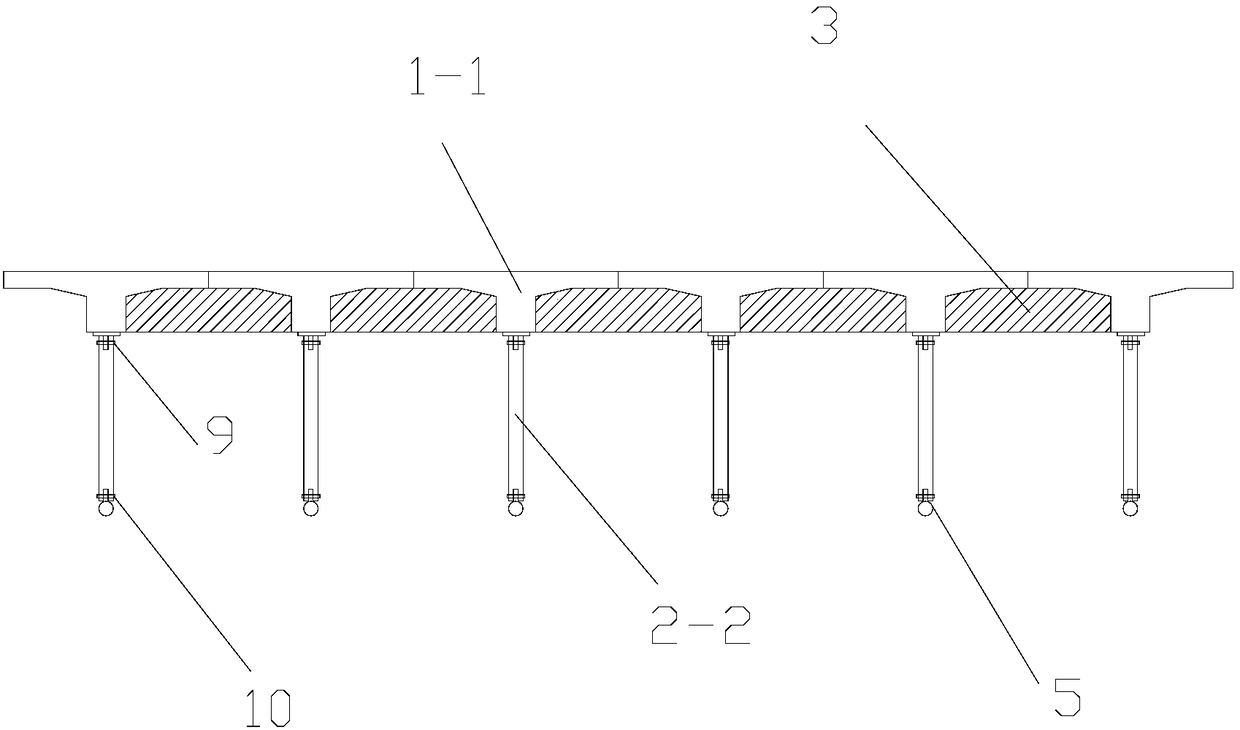

A cable-beam composite bridge and its construction method

ActiveCN106758753BReasonable structural designEasy constructionBridge erection/assemblyBending momentSelf weight

The invention discloses a cable-girder combined type bridge and a construction method thereof. The cable-girder combined type bridge comprises a plurality of bridge sections, each bridge section comprises a girder body structure, a pavement layer and a cable structure, the girder body structure comprises a plurality of columns of longitudinal beams, and the cable structure comprises a cable and stay bars. The construction method is characterized in that the bridge is constructed in bridge sections from front to the back along the longitudinal direction of the bridge, construction methods on the bridge sections are the same, and the construction process of each bridge section includes the steps of 1), construction of the first bridge section includes: 101, construction of the girder body structure, 102, mounting of the cable structure, and 103, pavement of the bridge floor; 2), construction of the next bridge section; 3), multiple repeat of the step 2) till all the construction process of the constructed bridge is completed. All the girder structure is under pressure, the cable is under tension, the cross section and self weight of the girder body structure are reduced, bending moment of the girder body structure is reduced, and spanning capability is increased.

Owner:XIAN UNIV OF SCI & TECH

Discrete face mold device for plate material heat forming

Owner:HUNAN UNIV

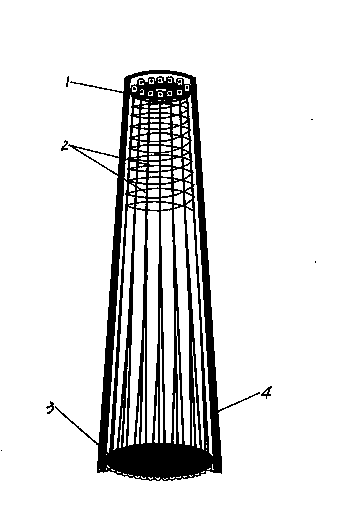

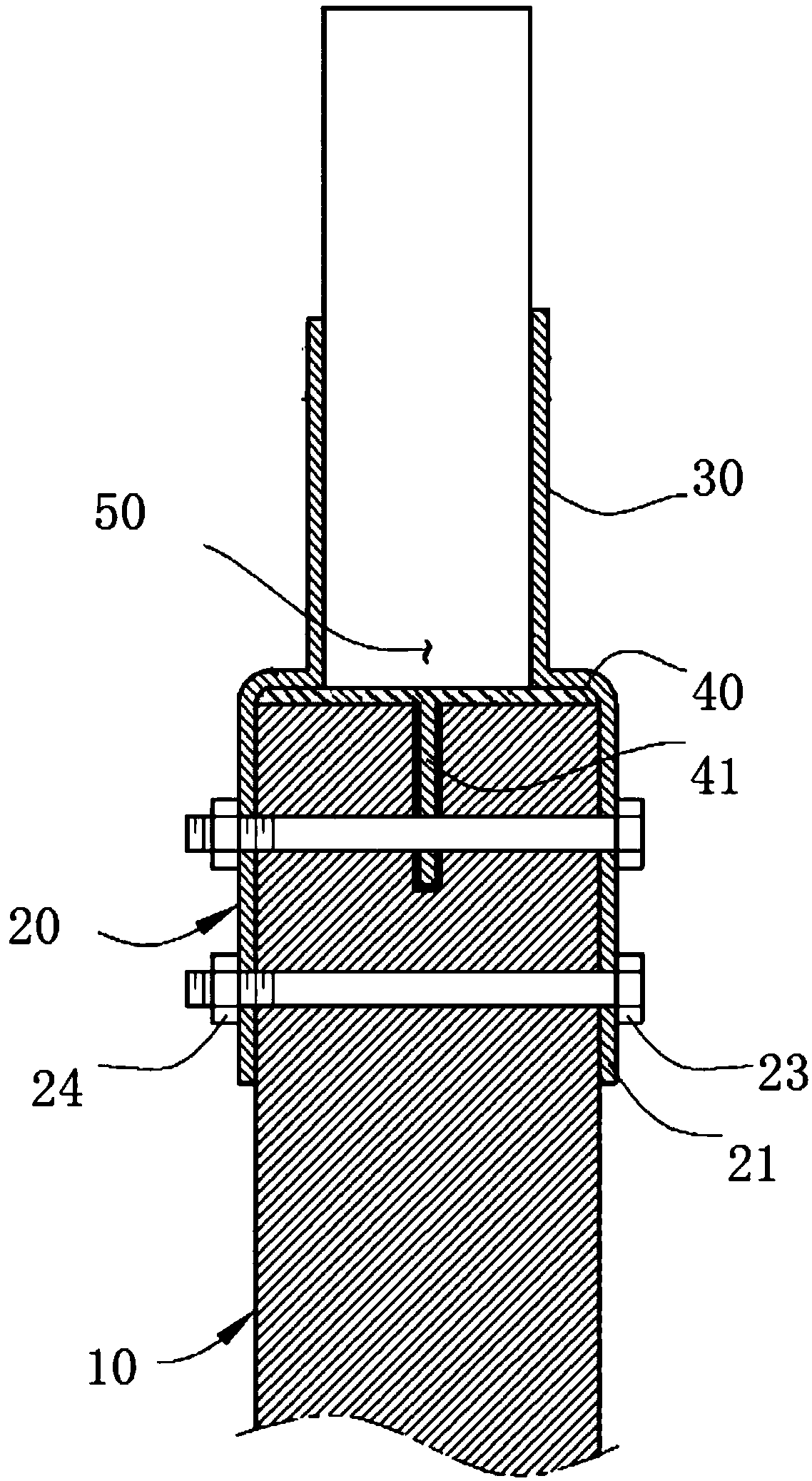

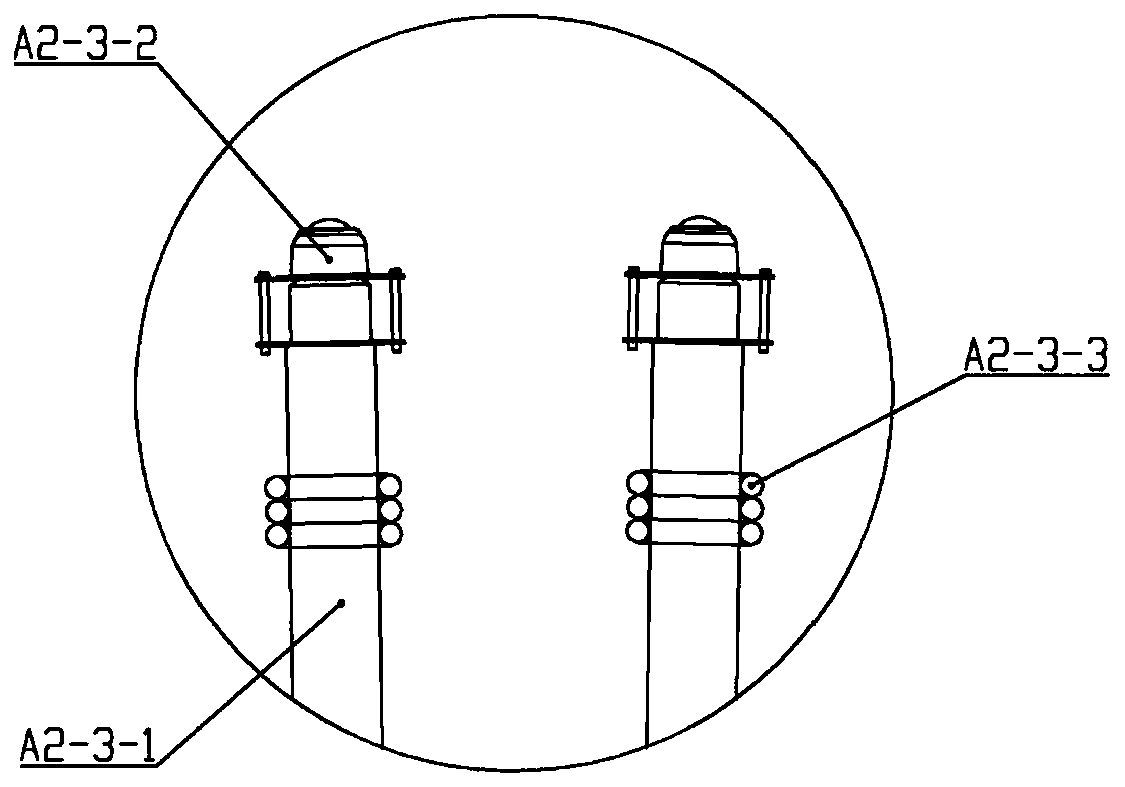

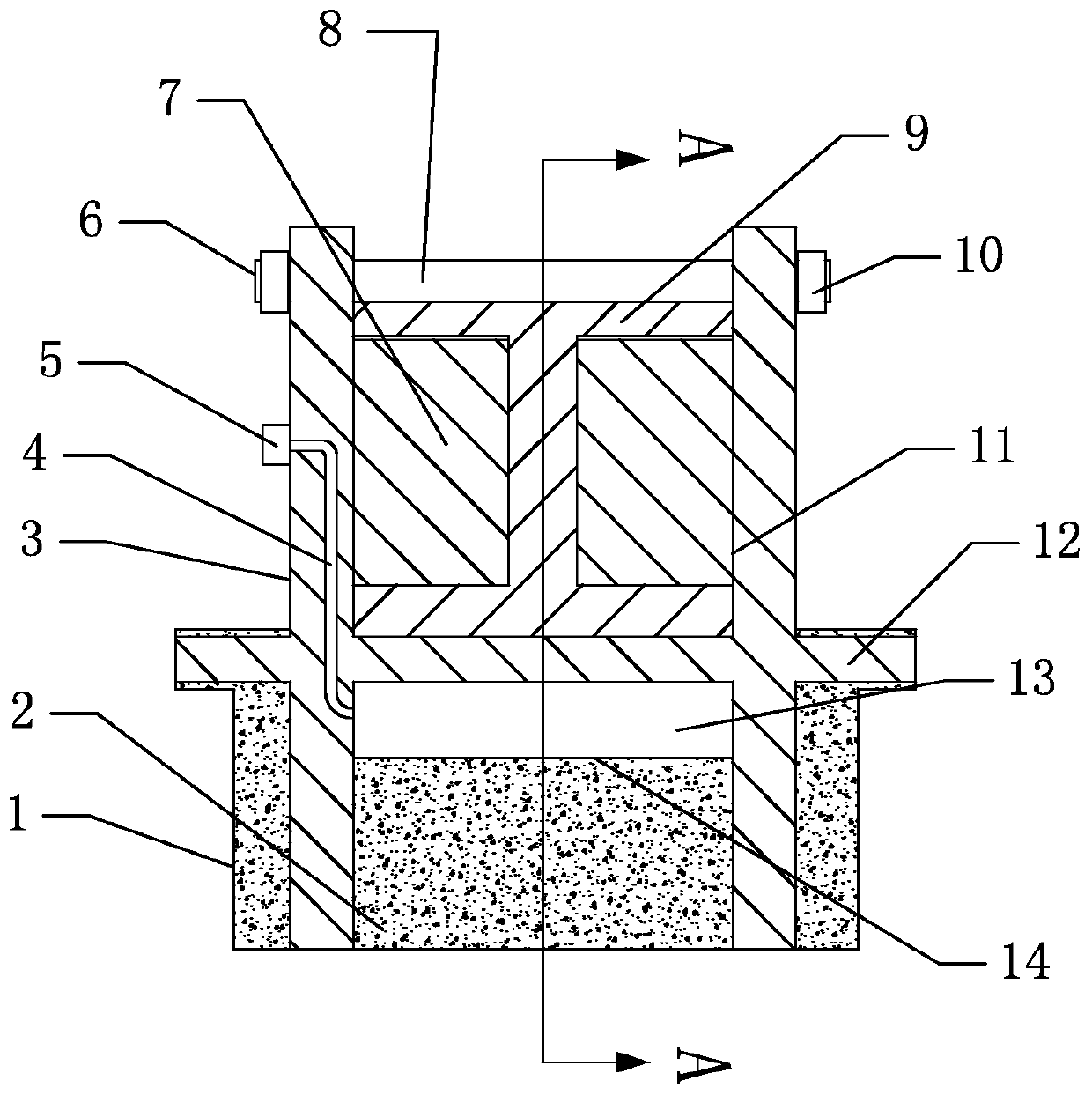

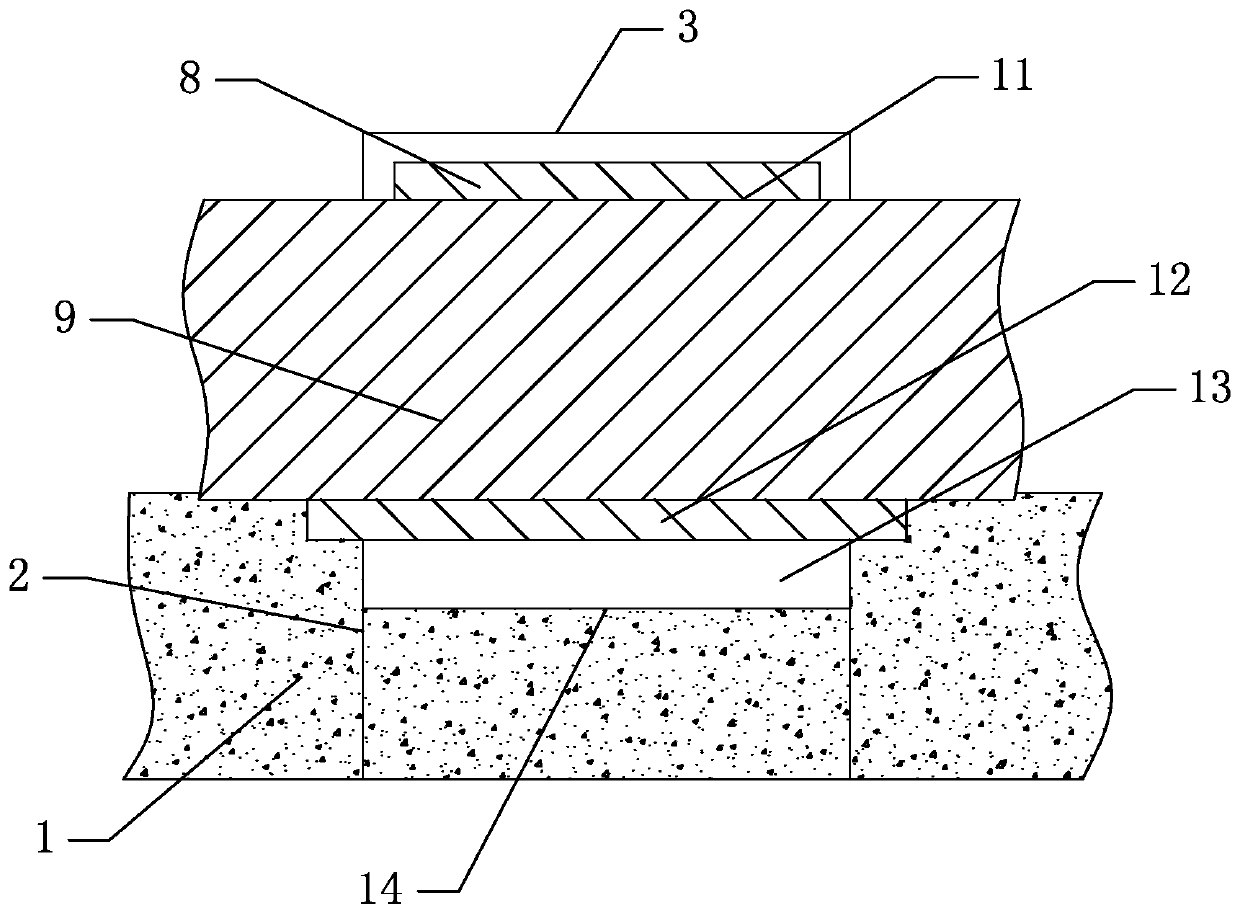

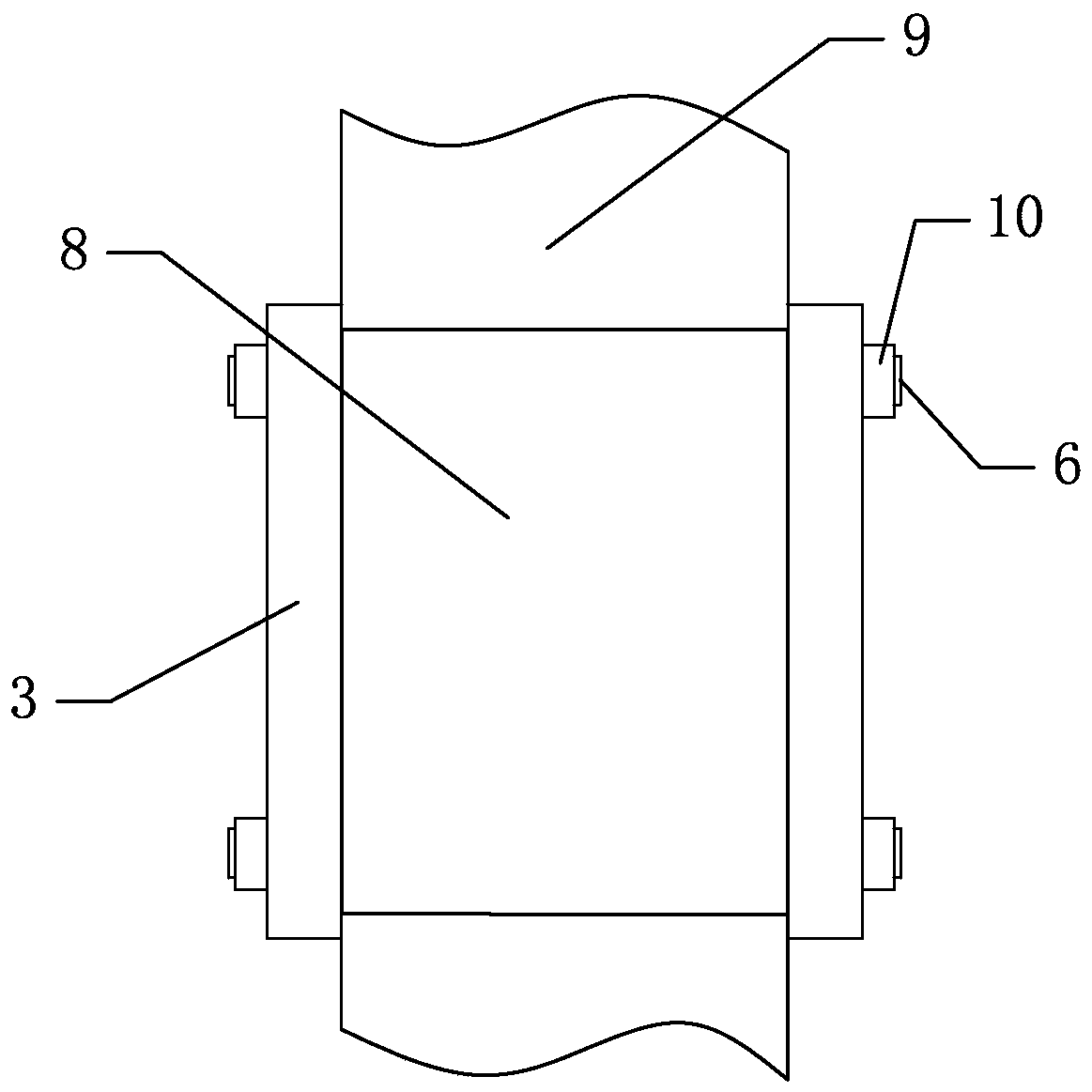

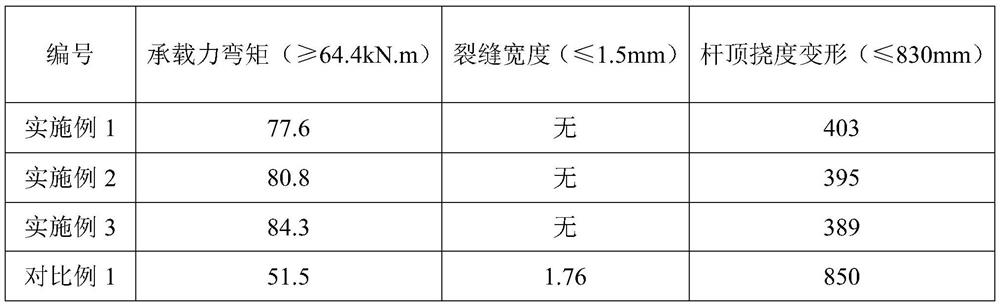

Production technology of large bending moment and high strength post tensioning reinforced concrete electric pole and electric pole

ActiveCN103909574AIncrease bending momentHigh strengthShaping reinforcementsTowersReinforced concretePre stress

The invention relates to a production technology of a large bending moment and high strength post tensioning reinforced concrete electric pole and an electric pole, and mainly aims at providing the production technology of the large bending moment and high strength post tensioning reinforced concrete electric pole and the electric pole produced by using the post tensioning production technology. The production technology of the large bending moment and high strength post tensioning reinforced concrete electric pole includes the steps of 1, weaving a reinforcement cage, and confirming that taper degrees of all seamless steel tubes in the reinforcement cage relative to the axis of the reinforcement cage are equal; 2, hoisting the reinforcement cage into a base seat of an electric pole steel mold, pouring concrete sizing agents into the electric pole steel mold, closing the mold, lifting the mold off the base seat and placing the mold on a balance position after centrifugal shaping, performing mold releasing after three days of natural curing, and performing the natural curing for 21 days; 3, disposing a pre-stressed steel strand in the seamless steel tubes in penetration mode, anchoring one end of the pre-stressed steel strand, tensioning the other end of the pre-stressed steel strand, and locking up the tensioned end of the pre-stressed steel strand after design value is achieved. The production technology of the large bending moment and high strength post tensioning reinforced concrete electric pole is used on the electric pole in an electric line.

Owner:STATE GRID CORP OF CHINA +3

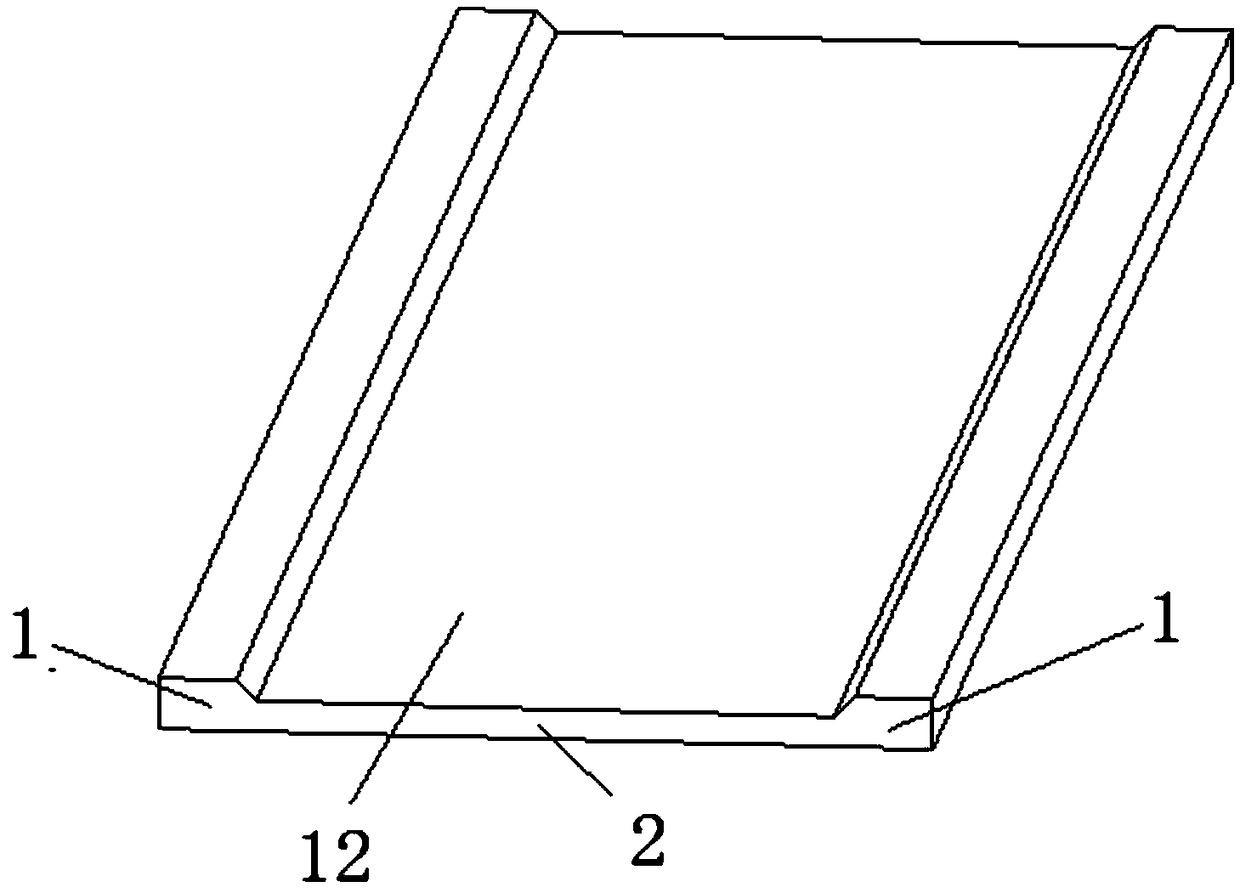

Reverse rib laminated floor slab and construction method thereof

PendingCN109113248AIncreasing the thicknessIncrease bending momentFloorsFloor slabBuilding construction

The invention relates to the field of assembling an integrated building structure, in particular to a reserve rib laminated floor slab and a construction method thereof. The reserve rib laminated floor slab comprises a plurality of prefabricated reserve rib plates assembled together; a sunken groove is formed in the upper surface of each prefabricated reserve rib plate; and a later pouring concrete layer is arranged above the plurality of spliced prefabricated reserve rib plates. The construction method of the reserve rib laminated floor slab comprises the following steps of S1, making the prefabricated reserve rib plates; S2, mounting supports on a main beam and a sub beam; S3, hoisting the plurality of prefabricated reserve rib plates with the groove surfaces upwards, horizontally layingthe plurality of prefabricated reserve rib plates on the main beam or the sub beam in sequence, and splicing the plurality of prefabricated reserve rib plates to form a floor slab; and S4, pouring aconcrete layer to form the laminated floor slab. According to the reserve rib laminated floor slab and the construction method thereof, through adoption of the structure, the reserve rib laminated floor slab can be used as a cast-in-place concrete template so that the template usage and the support usage can be reduced, the construction efficiency can be effectively enhanced, and the cost can be saved. The reserve rib laminated floor slab has the advantages of smoother lower surface of the floor slab and more beautiful building effect.

Owner:SOUTH CHINA UNIV OF TECH

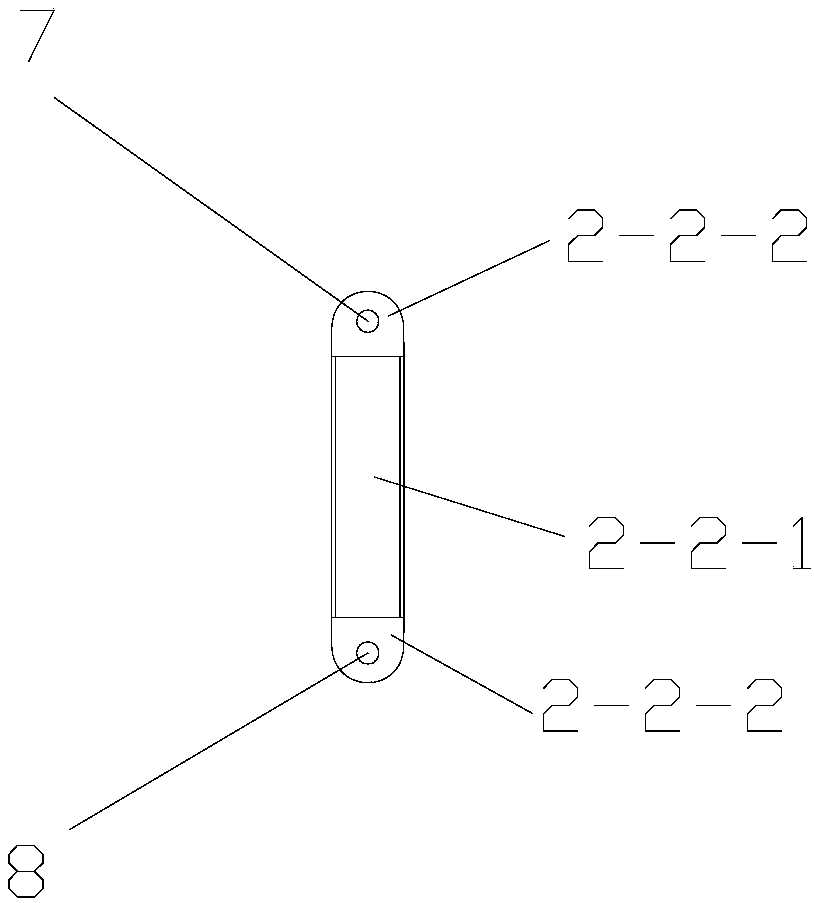

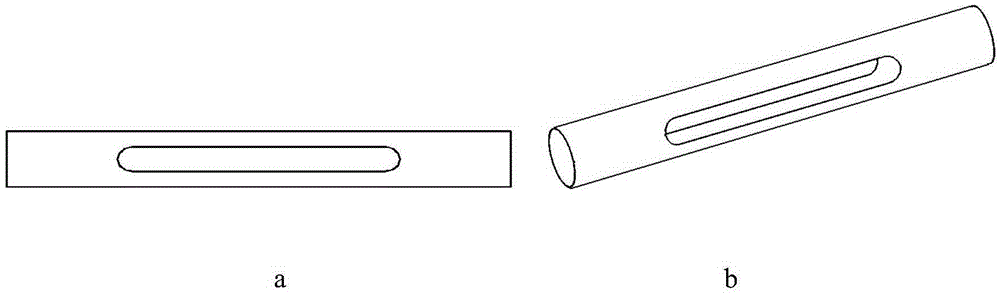

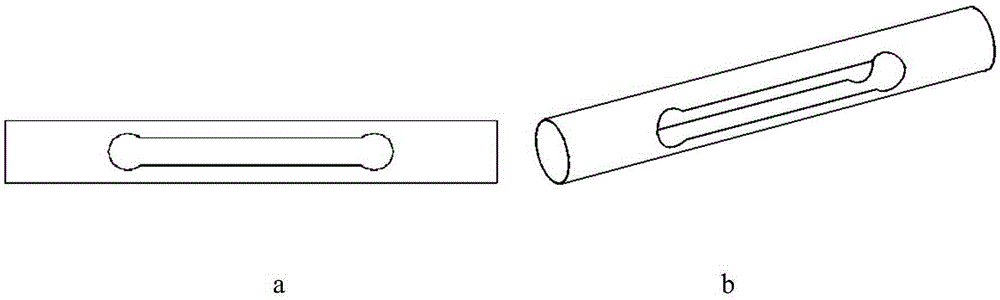

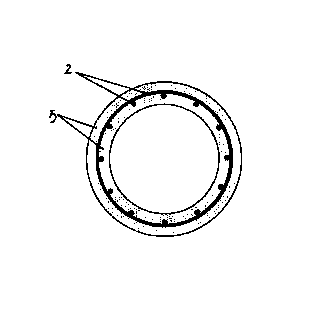

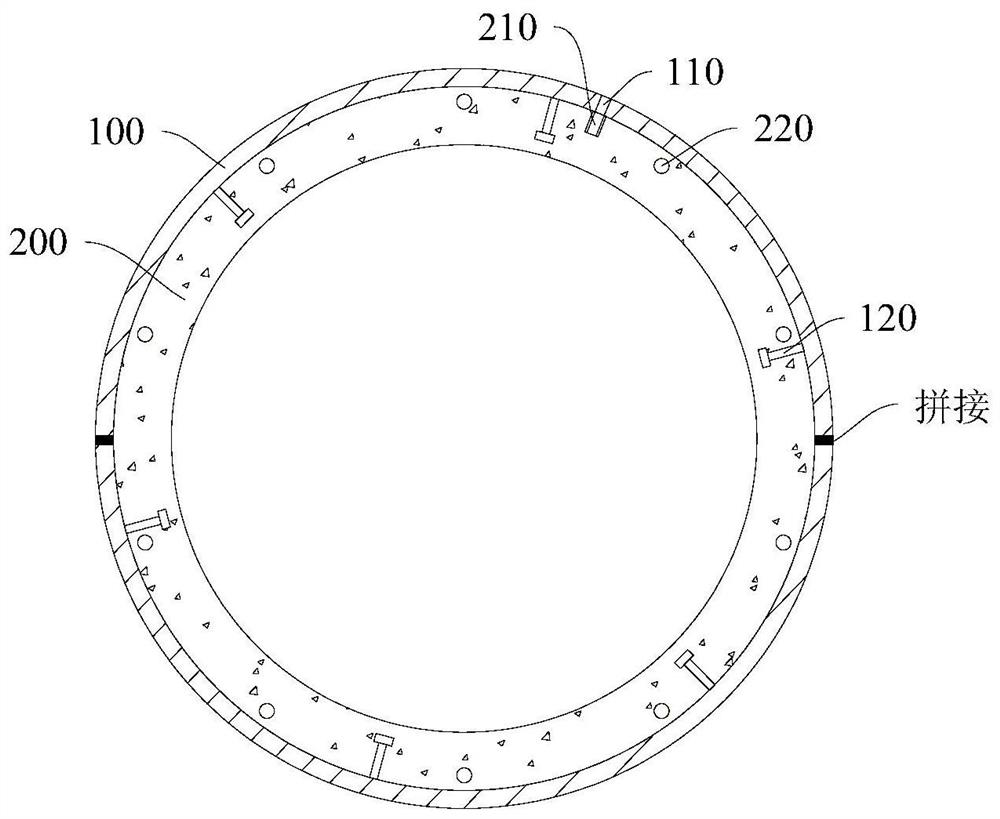

Preparation method of foldable self-resilience composite material pipe type hinge

InactiveCN105313346AIncrease stiffnessIncrease bending momentDomestic articlesDegrees of freedomResin-Based Composite

The invention belongs to the technical field of hinges, and relates to a preparation method of a foldable self-resilience composite material pipe type hinge. The composite material pipe type hinge is prepared by an ultrathin resin base composite material prepreg, and adopts a structural form of a thin-wall composite material round pipe symmetrically perforated in middle. The thickness of the ultrathin prepreg is generally 15-30% of the thickness of a conventional prepreg; and the ultrathin prepreg is suitable for preparing a thin-wall composite material part, and is high in mechanical design degree of freedom. The ultrathin prepreg can realize high performance of a light composite material structure; and on the basis of satisfying a folding function of the composite material hinge, such mechanical performances as rigidity and bending moment of the structure are improved. The foldable self-resilience composite material pipe type hinge, prepared by the method, can be applied to the aerospace field having higher requirements on weight reduction, specific strength and specific rigidity.

Owner:AVIC COMPOSITES

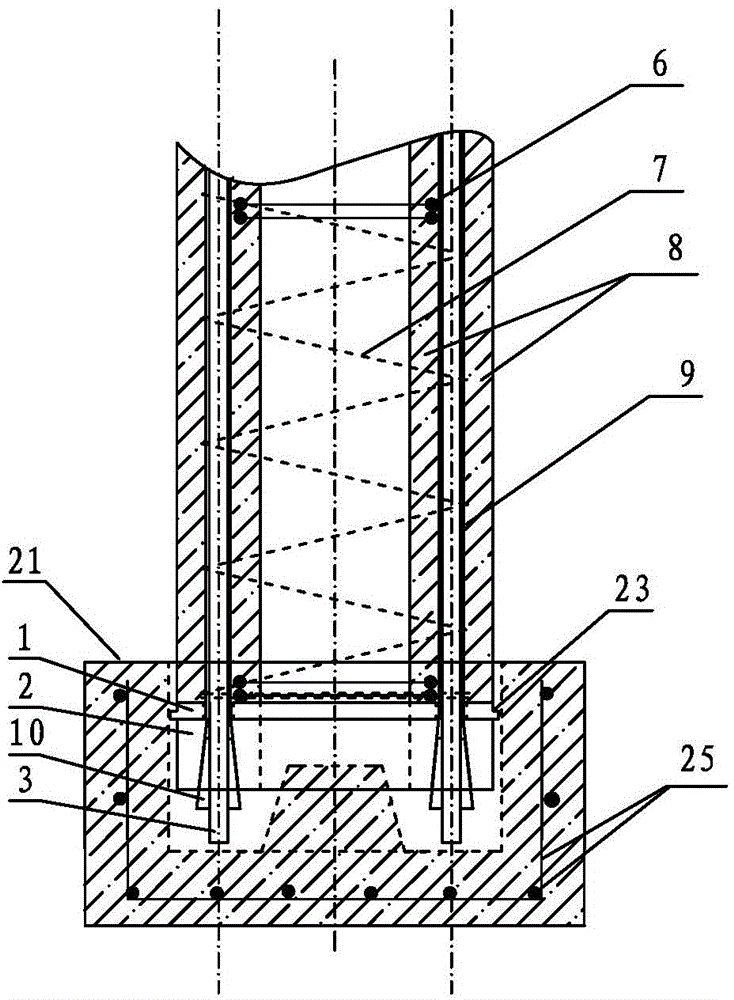

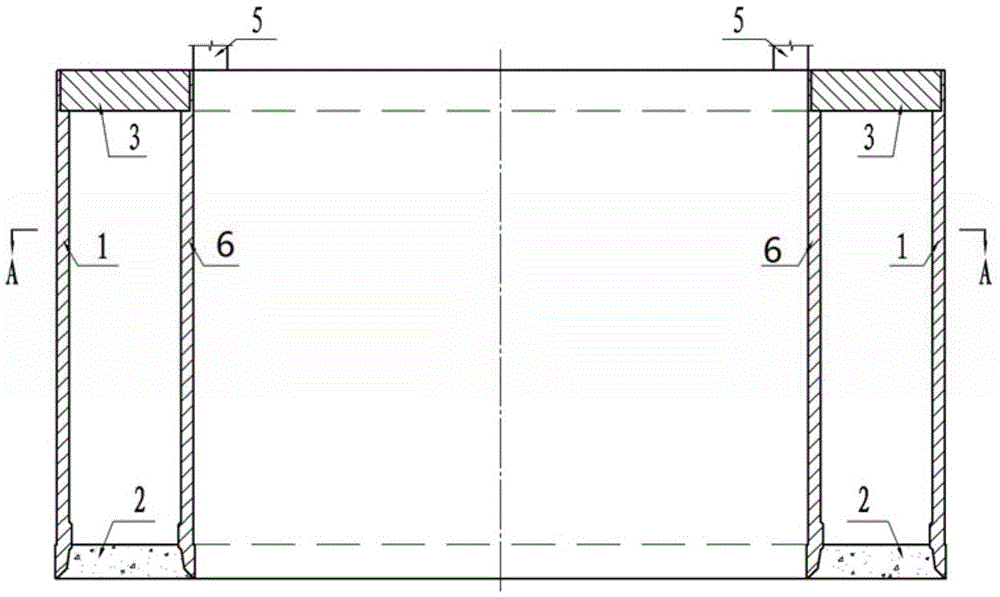

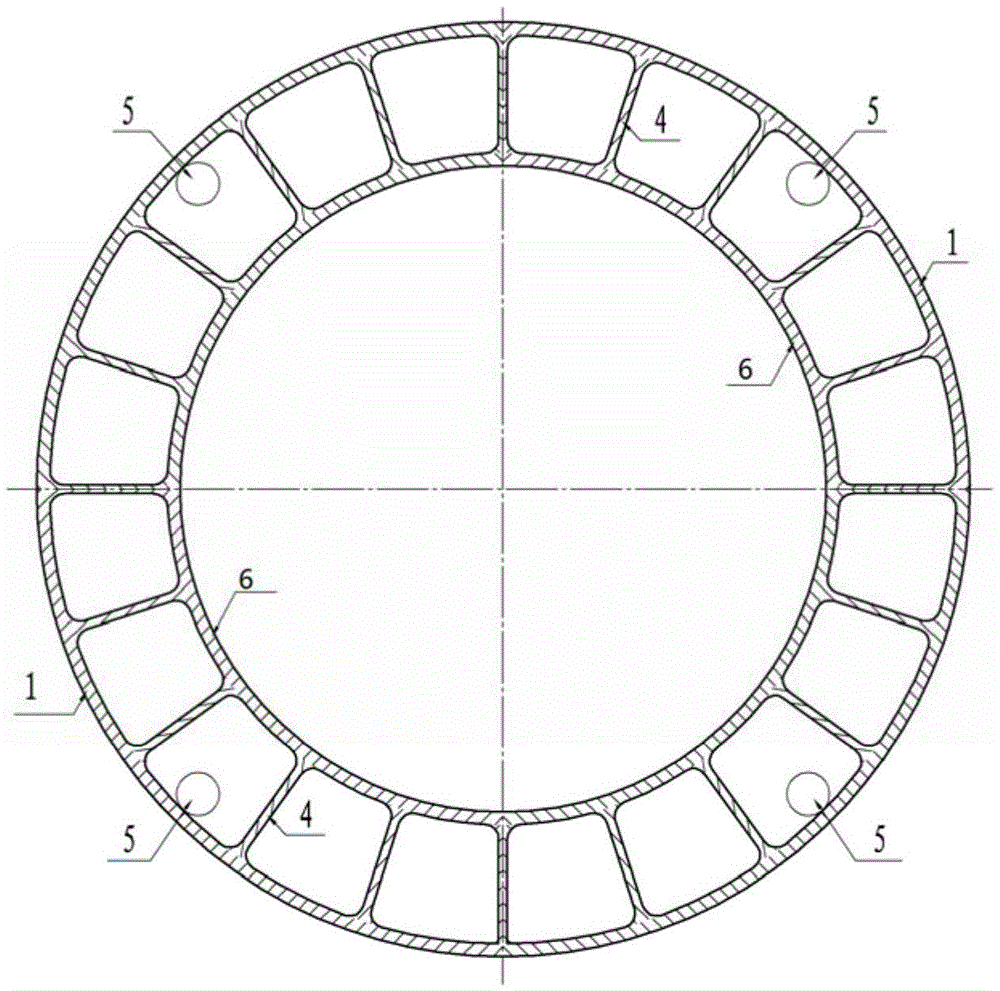

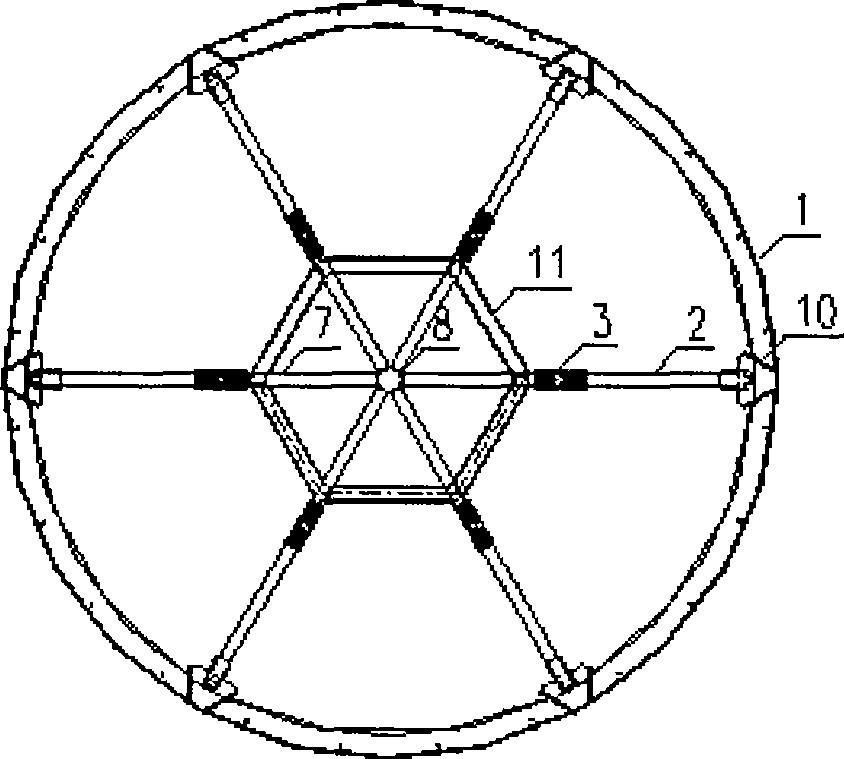

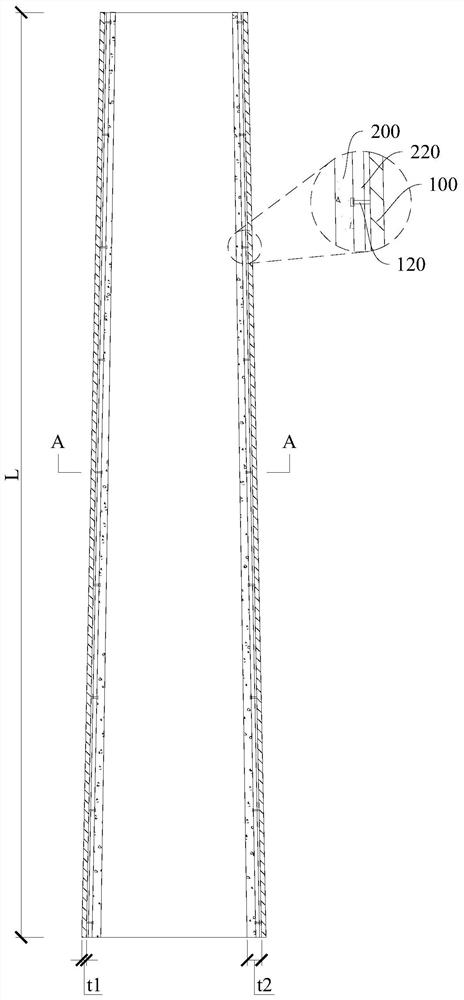

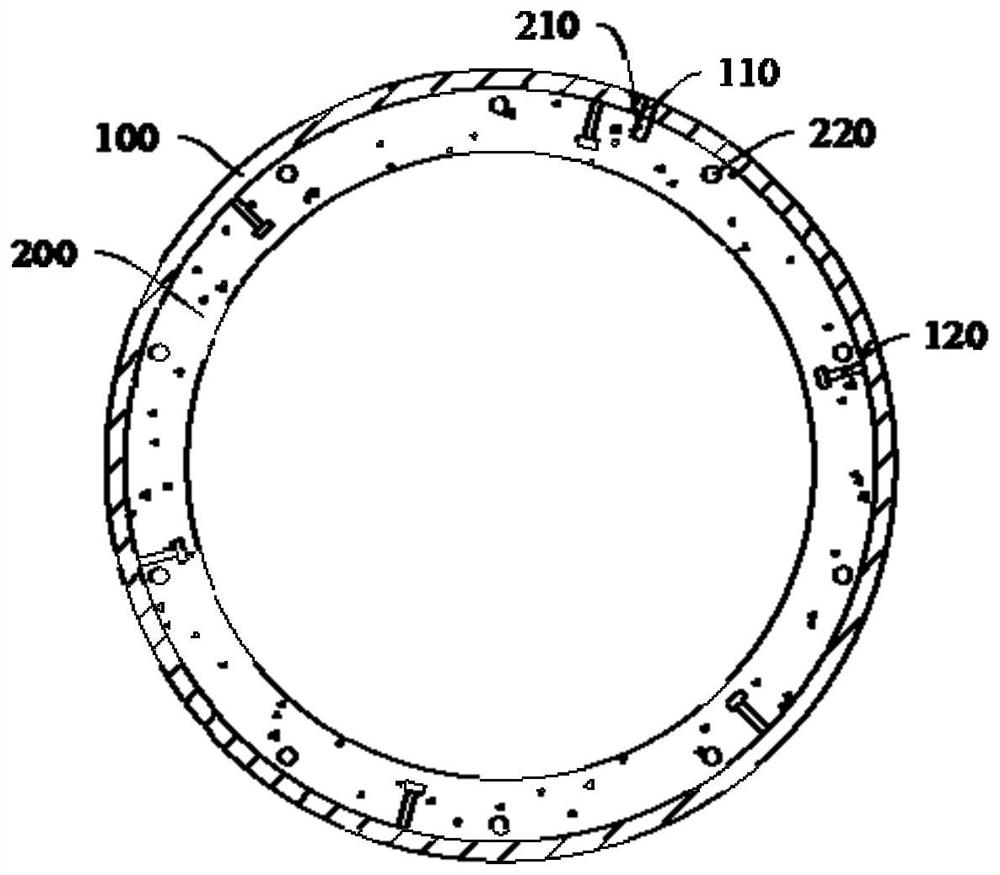

Large-scale wading ring-shaped rigid foundation and construction method thereof

InactiveCN105421479AIncrease bending momentSave materialFoundation engineeringForce structureHorizontal force

The invention relates to a large-scale wading ring-shaped rigid foundation and a construction method thereof. An inner well wall is arranged in the position, 20-25 m away from an outer well wall, of the interior of the outer well wall. A sealed ring-shaped body is formed by placing a ring-shaped cover plate on the upper portion of the inner well wall and the upper portion of the outer well wall and pouring ring-shaped bottoming concrete to the lower portion of the inner well wall and the lower portion of the outer well wall. Partition walls are arranged between the inner well wall and the outer well wall. The construction method comprises the steps that 1, after being manufactured in the land or a dock, foundation base section steel shells of steel shell concrete enter the water and are floatingly transported to a scene to be positioned precisely, watering and sinking are conducted, and after a bed is stable, the steel shell concrete is poured; 2, the well walls and the partition walls are heightened through reinforced concrete and sunken through soil sampling, when soil is sunken to a design elevation, bottom clearing is conducted, and the bottoming concrete is poured; and 3, top cover plate concrete is poured, and an overall ring-shaped forced structure is formed. According to the large-scale wading ring-shaped rigid foundation and the construction method thereof, the foundation is designed to be a ring-shaped deeply-buried-type rigid foundation in accordance with a high-rise structure with the characteristics of being large in electric tower foundation horizontal force, bending moment and foundation top surface construction size, and a part with the small stress in the middle is hollowed out skillfully; compared with an ordinary sunk well foundation, a large number of materials are saved, and the integrity, the loaded property and the economy are good.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

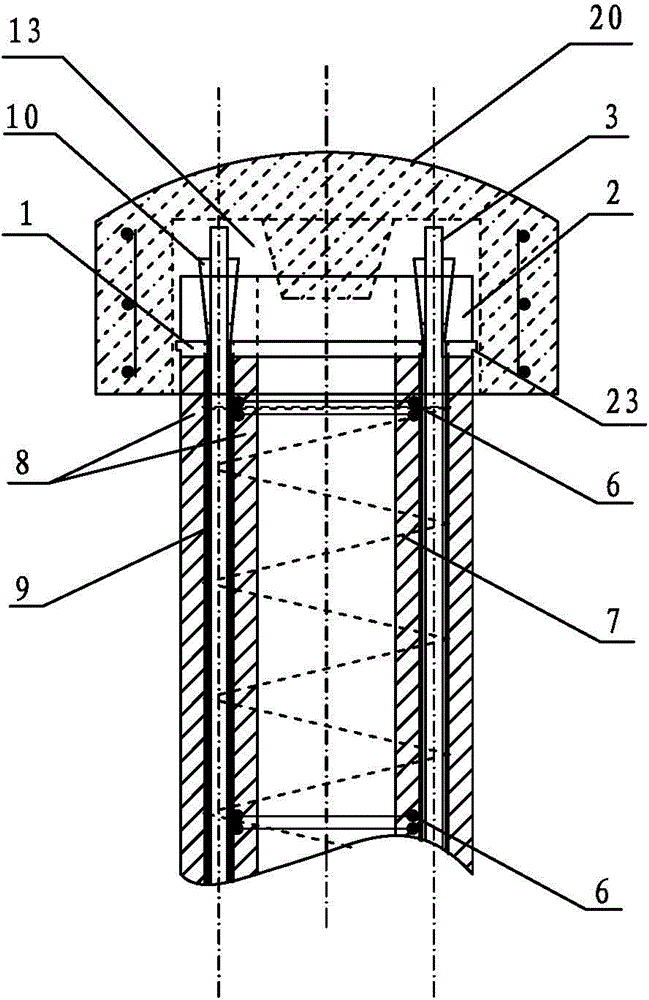

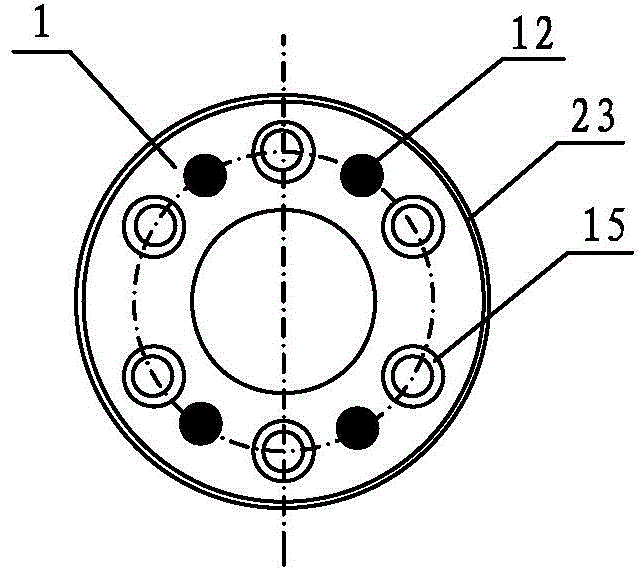

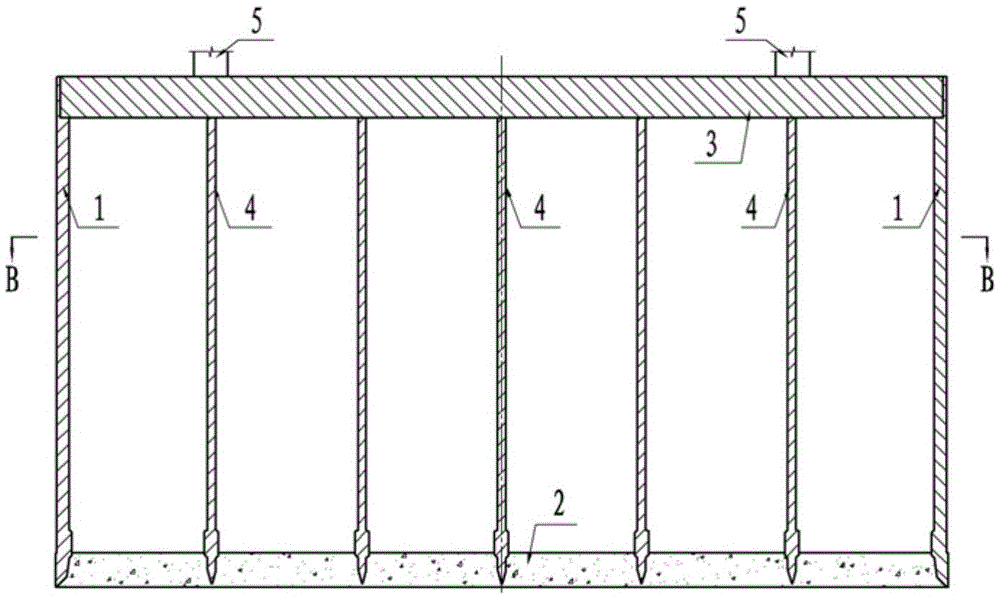

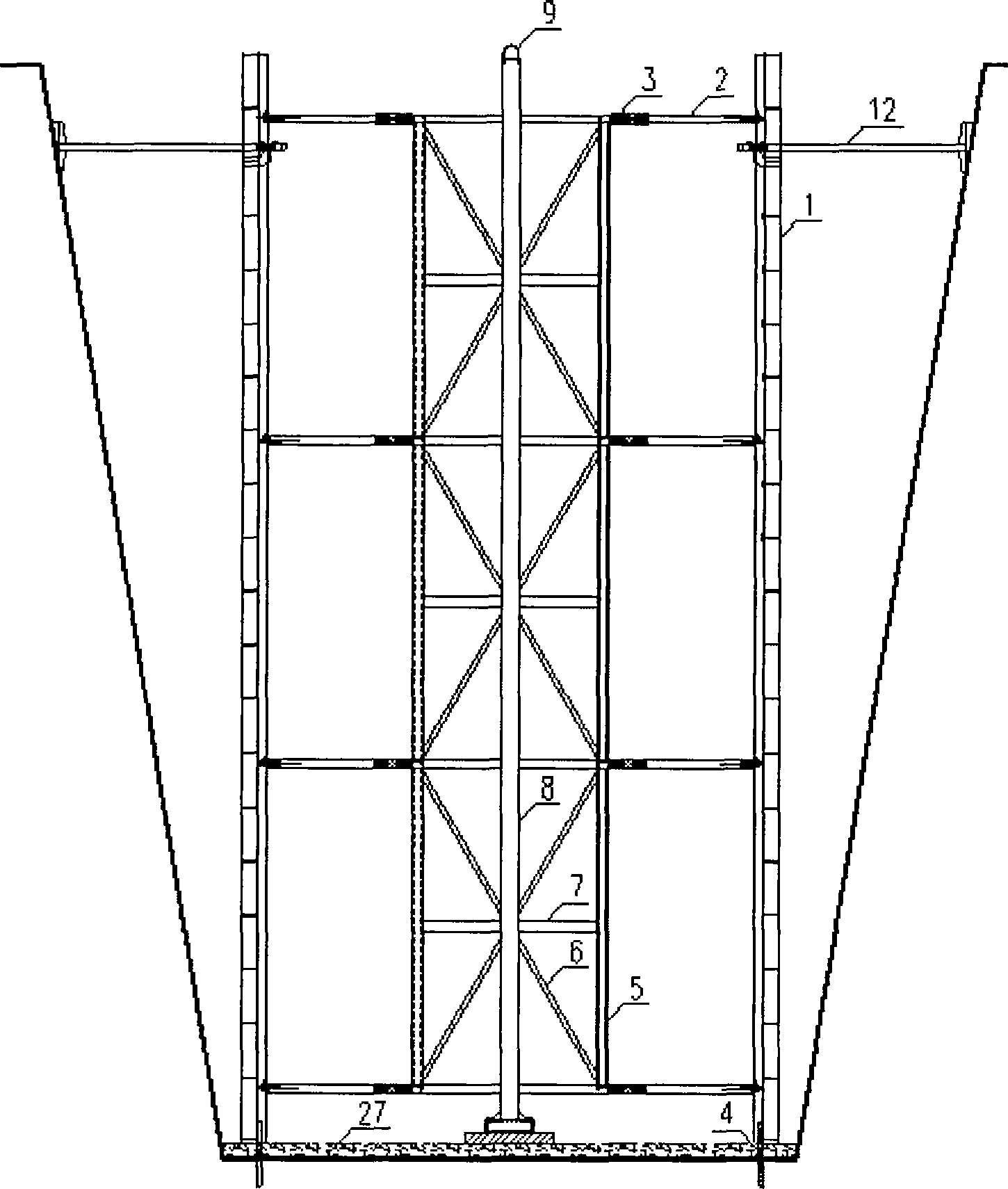

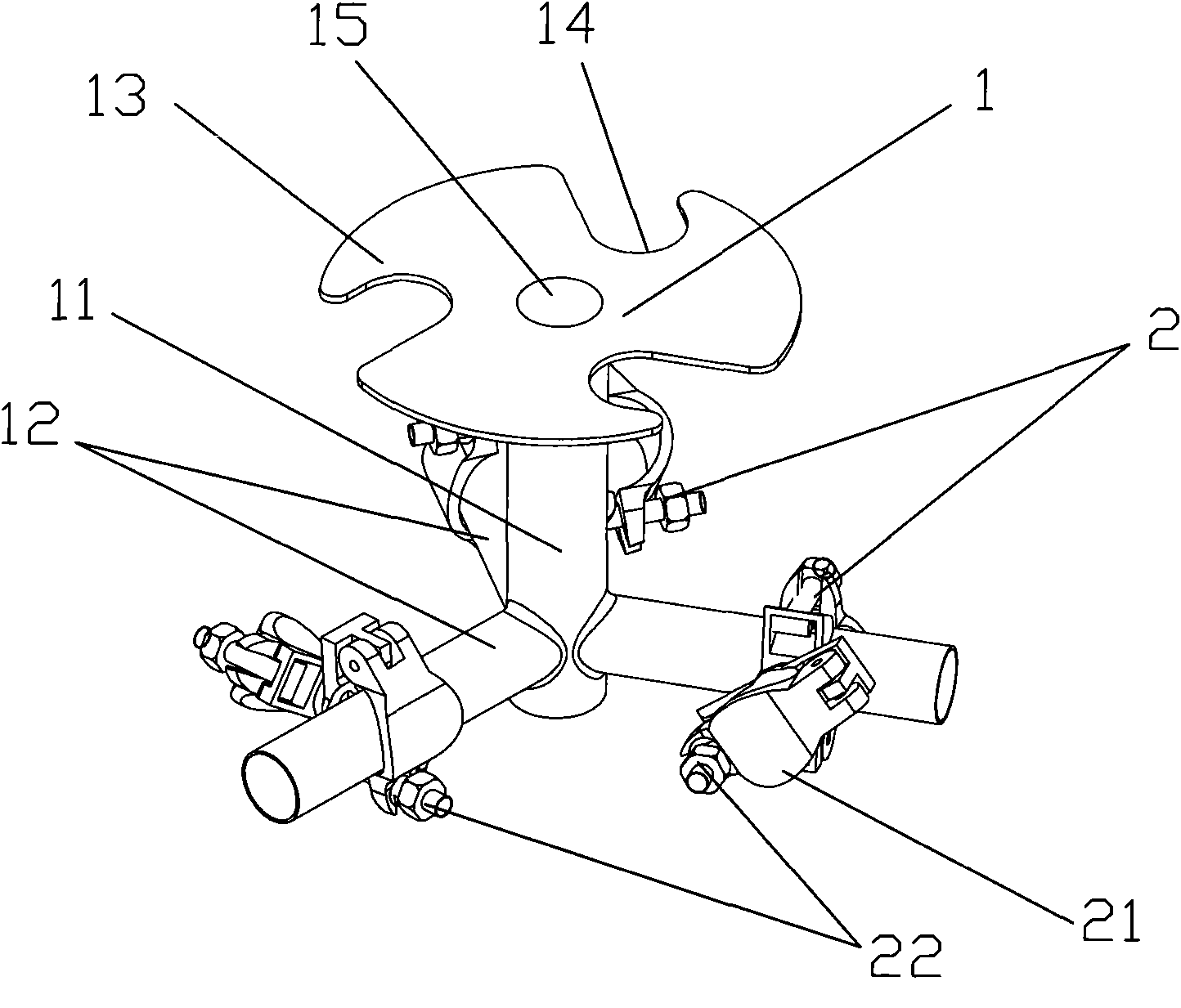

Reversing formwork for manufacturing cast-in-situ prestressed concrete cylindrical fan foundation

ActiveCN104343129AImprove bending abilityLow base pressureFoundation engineeringEngineeringStructural engineering

The invention provides a reversing formwork for manufacturing a cast-in-situ prestressed concrete cylindrical fan foundation. The reversing formwork assembled in whole is placed into a dug foundation pit in a lifting manner. Turn buckles are contracted after plain concrete is poured in a space between the cylinder wall of the reversing formwork and the wall of the foundation pit, connecting bolts between specially-shaped piles of the reversing formwork and the cylinder wall of the reversing formwork move along elliptical holes, so as to enable the reversing formwork to be contracted, the demoulding of plain concrete is realized, and a cylindrical bearing ring inner wall and an inner die cylinder wall are formed after demoulding and used as an outer die and an inner die of a concreting cylinder body. An inner formwork matched with the reversing formwork consists of an inner formwork cylinder wall, inner support rods, inner formwork horizontal support rods, top fixing beams, inner formwork specially-shaped piles, turn buckles, foundation leveling bolts, inner truss uprights, inner truss oblique rods, inner truss cross rods, inner main uprights, lifting hooks, inner formwork specially-shaped pile elliptical holes and inner formwork connecting bolts, the formwork erecting and demoulding technology is identical to that of the reversing formwork, the pit is refilled with soil after the concrete cylinder is cured by filling the pit with steam, and a post-cast concrete slab is poured at the upper part.

Owner:JIANGSU JINHAI NEW ENERGY TECH +1

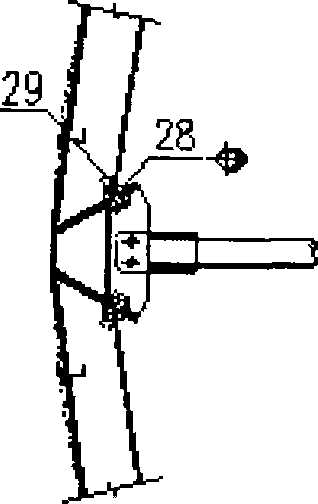

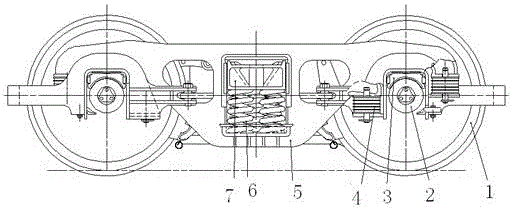

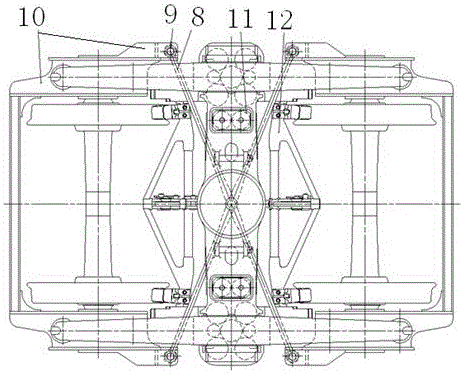

Automatic-directing bogie of railway truck and automatic-directing method

The invention relates to an automatic-directing bogie of a railway truck and an automatic-directing method. The automatic-directing bogie comprises a wheel pair, a rolling bearing device, a load bearing saddle, a shaft tank rubber spring, a side frame, a swing bolster, a spring damping device, a basic braking device and automatic-directing devices. The automatic-directing bogie is characterized in that two secondary frameworks of the automatic-directing device of the bogie are arranged at the outer ends of the bogie, and connecting points of the two secondary frameworks and a corresponding cross rod are located on two sides of the bogie. According to the automatic-directing bogie disclosed by the invention, the two secondary frameworks on the outer side of the side frame are in hinge connection with the cross connecting rods, so that under the situation that the total arrangement of a conventional bogie is not changed, the automatic-directing of the bogie can be realized, so that the structure of the secondary frameworks is simplified, mounting and overhauling are facilitated, and a central distance of the shaft diameter of the bogie is reduced; mounting the basic braking device of the bogie, particularly a unit type braking device is facilitated, so that the purposes that manufacturing cost and maintaining cost are greatly reduced, the manufacturing of the bogie is improved and the technological properties are maintained are achieved.

Owner:株洲市求拙机械制造有限公司

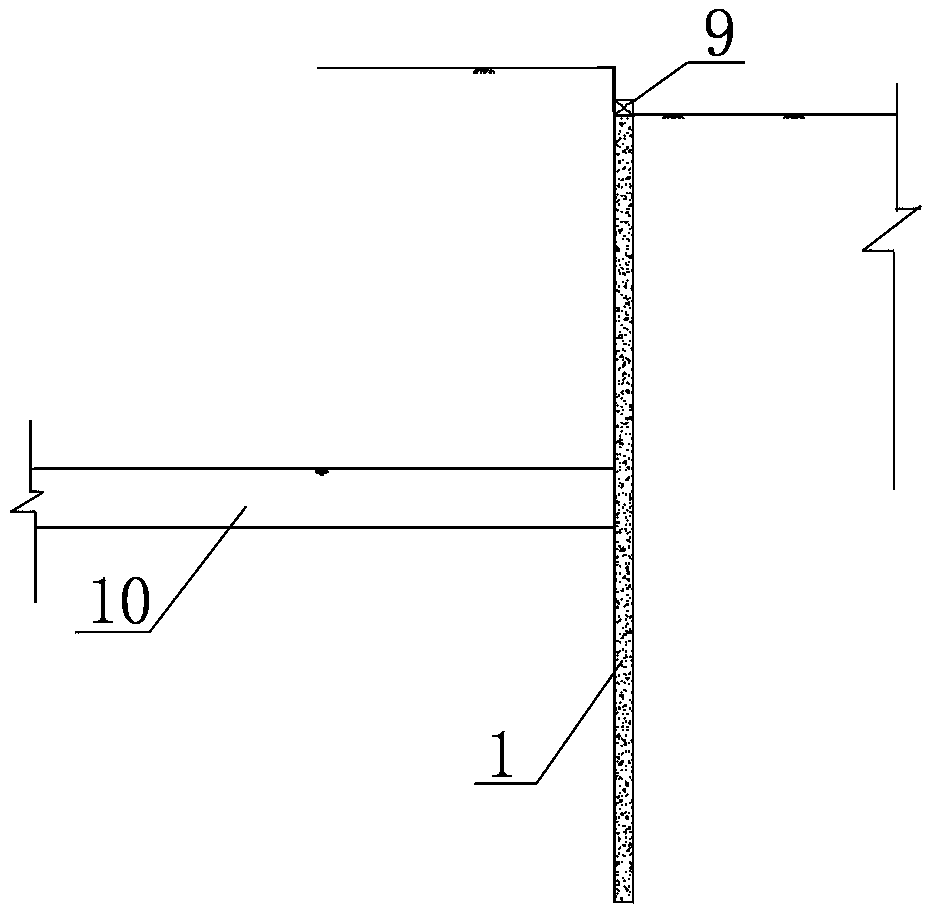

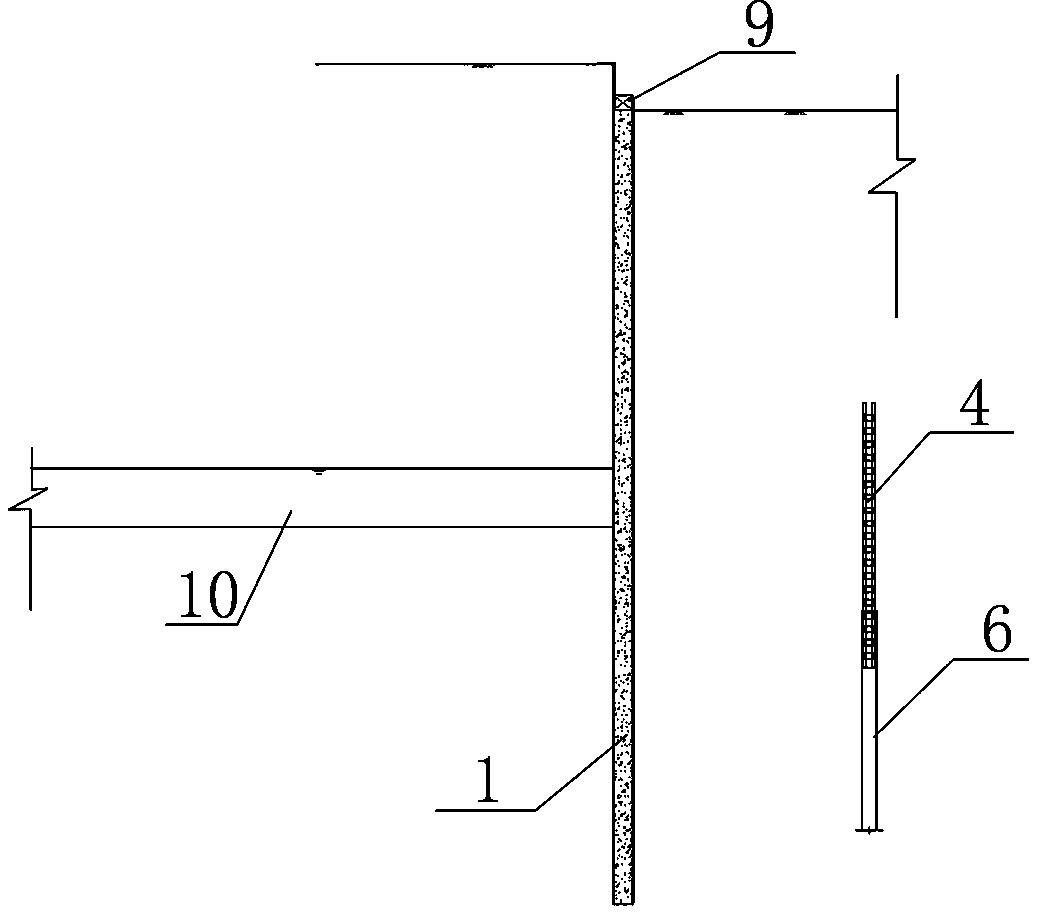

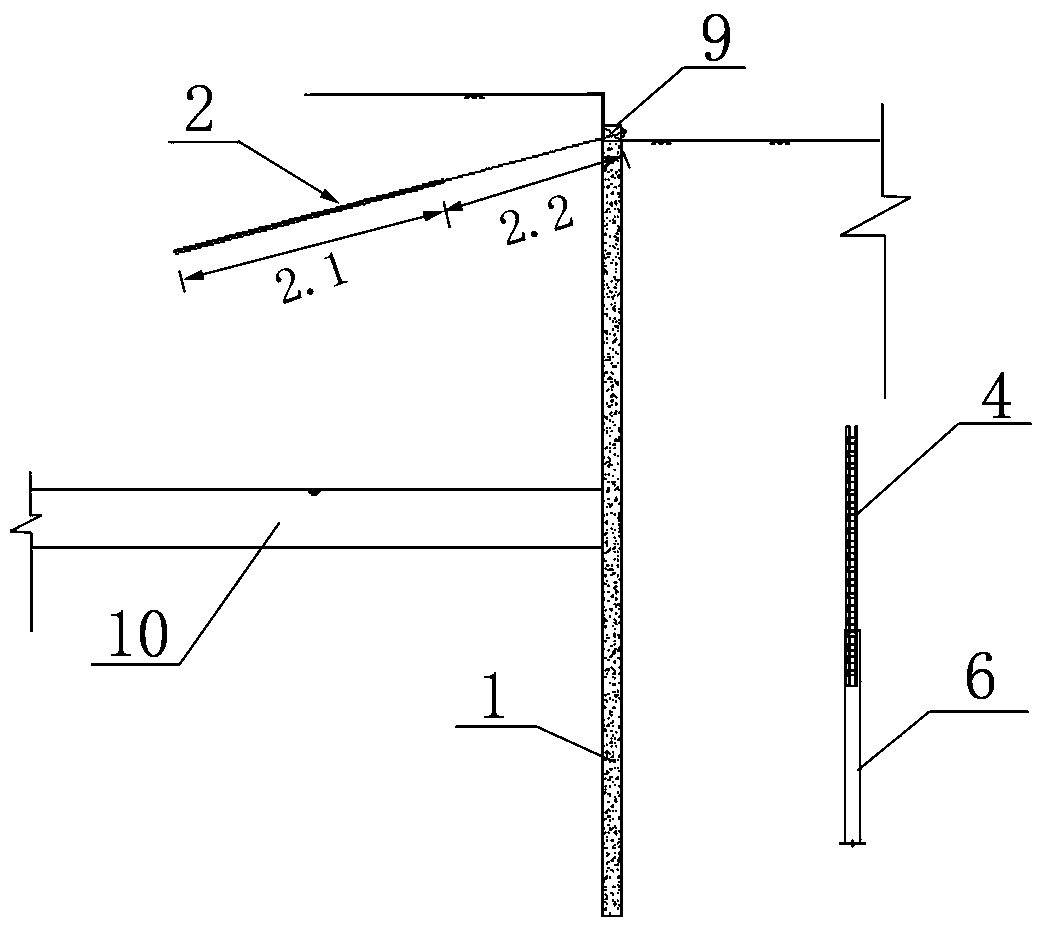

Top-rigid-and-bottom-flexible deep foundation pit supporting system and construction method thereof

PendingCN109403349AEasy constructionShort construction periodExcavationsBulkheads/pilesEngineeringHigh pressure

The invention relates to a top-rigid-and-bottom-flexible deep foundation pit supporting system and a construction method thereof. The top-rigid-and-bottom-flexible deep foundation pit supporting system comprises vertical shoring members, flexible pulling anchor members, rigid supporting members and stand columns; the flexible pulling anchor members are arranged on the upper portions of the vertical shoring members in inclined and pulling manners; the rigid supporting members are horizontally arranged at the lower portions of the vertical shoring members in an erected manner; at least two rowsof flexible pulling anchor members are arranged; each row of rigid supporting members are arranged vertically and horizontally in the same horizontal plane in a crossed manner; and the distance between the rigid supporting members on the bottommost row and the bottom of a foundation pit is not less than 3 m, and the distance between the rigid supporting members on the topmost row are arranged in azone matched with a water surface of a pressure bearing water layer, and the distance between the flexible pulling anchor members on the bottommost row and the rigid supporting members on the topmostrow is 2 m to 4 m. The top-rigid-and-bottom-flexible deep foundation pit supporting system and the construction method solve the technical problems that flexible pulling anchor structures are adoptedin a high pressure bearing water zone, construction is influenced, stability of the supporting system is not facilitated, and sedimentation of buildings or roads around the foundation pit is caused,and solve the technical problems that when rigid supporting anchor structures are adopted, earth excavation is inconvenient, the construction progress is slow, materials are wasted, and the cost is high.

Owner:CHINA CONSTR FIRST DIV GROUP CONSTR & DEV

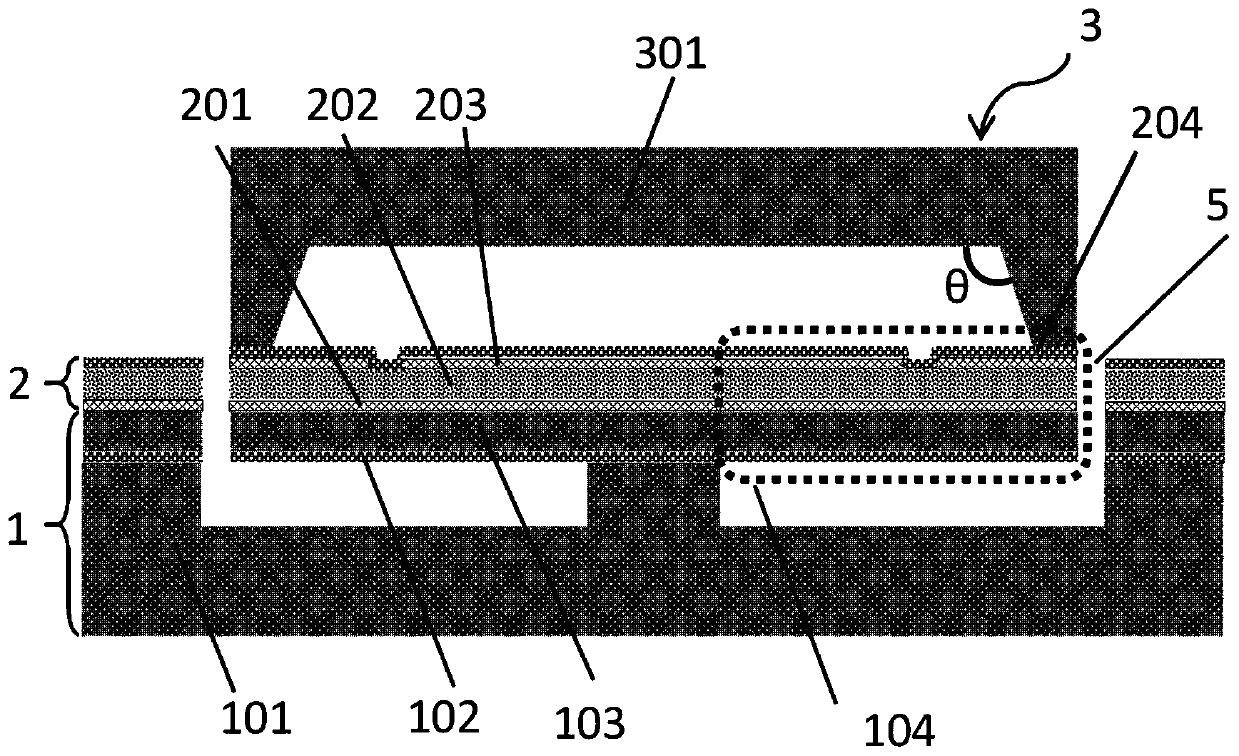

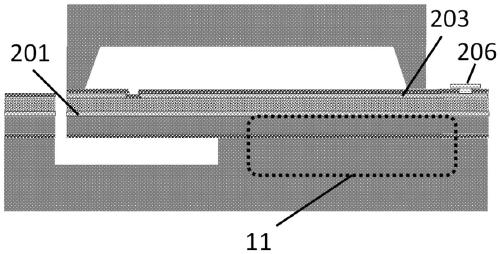

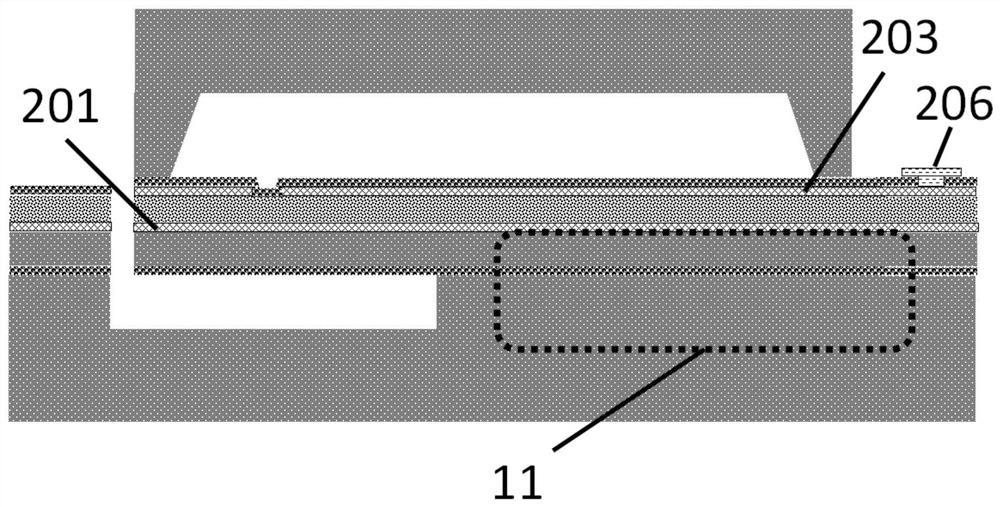

High-sensitivity vibration sensor

ActiveCN111337119AIncrease bending momentLarge degree of deflectionSubsonic/sonic/ultrasonic wave measurementUsing electrical meansCantilevered beamPiezoelectric cantilever

The invention discloses a high-sensitivity vibration sensor, and the sensor comprises a substrate with a cavity and a plurality of piezoelectric cantilever beams; a fixed column is arranged in the center of the bottom surface of the cavity, and a signal receiving area is defined by the plurality of cantilever beams and is fixed above the substrate through the fixed column; each piezoelectric cantilever beam comprises a fixed end and a free end, wherein the width of the free end is greater than that of the fixed end, the fixed end is fixed to the fixed column, the free end is suspended above the cavity, and a gap is formed between every two adjacent piezoelectric cantilever beams. The sensor further comprises a sealing cap with a groove, and the groove edge of the sealing cap is connected with the free end of each piezoelectric cantilever beam. The section of the groove can be in any shape, and a trapezoid with the included angle between the bottom face and the side wall greater than 90degrees is preferably selected. According to the invention, a load generated by a vibration signal is concentrated at the free ends of the piezoelectric cantilever beams through the sealing cap, so the bending moment borne by the piezoelectric cantilever beams is larger, the deflection degree of the piezoelectric cantilever beams is larger, a larger transverse load can be generated when the included angle is greater than 90 degrees, and the sensitivity of the vibration sensor is effectively improved.

Owner:武汉敏声新技术有限公司

High-bending-moment carbon-fiber reinforced concrete pole and manufacturing method thereof

InactiveCN103669973ALow priceHigh strengthCeramic shaping apparatusTowersCarbon fibersCentrifugation

Disclosed are a high-bending-moment carbon-fiber reinforced concrete pole and a manufacturing method thereof. Carbon-fiber ropes or carbon-fiber rope and concrete together constitute a pole framework, and high-grade concrete is poured to the framework, so that the high-bending-moment carbon-fiber reinforced concrete pole is made. The manufacturing method includes fixing and tightening the carbon-fiber ropes to an upper pier head and a lower pier head of a steel mold through wedge-hinged C-shaped clamps, pouring the high-grade concrete by a conventional reinforced concrete pole centrifugation process, performing steam curing, and finally forming the full-carbon-fiber concrete pole or carbon-fiber reinforced concrete pole. The pole manufactured by the method has all advantages of the conventional prefabricated reinforced concrete pole, and further, steel can be saved greatly while cost can be lowered, and the pole body has high intensity and high bending moment. On the premise of not increasing manufacturing cost or increasing pole diameter, limitation to height and diameter of the conventional prefabricated concrete pole is broken through, the defect of the design depending on selecting high-intensity steel and increasing steel usage is overcome, and concrete poles with larger diameter and height can be produced by the manufacturing method.

Owner:SHANGQIU POWER SUPPLY CO OF STATE GRID HANAN ELECTRIC POWER CO

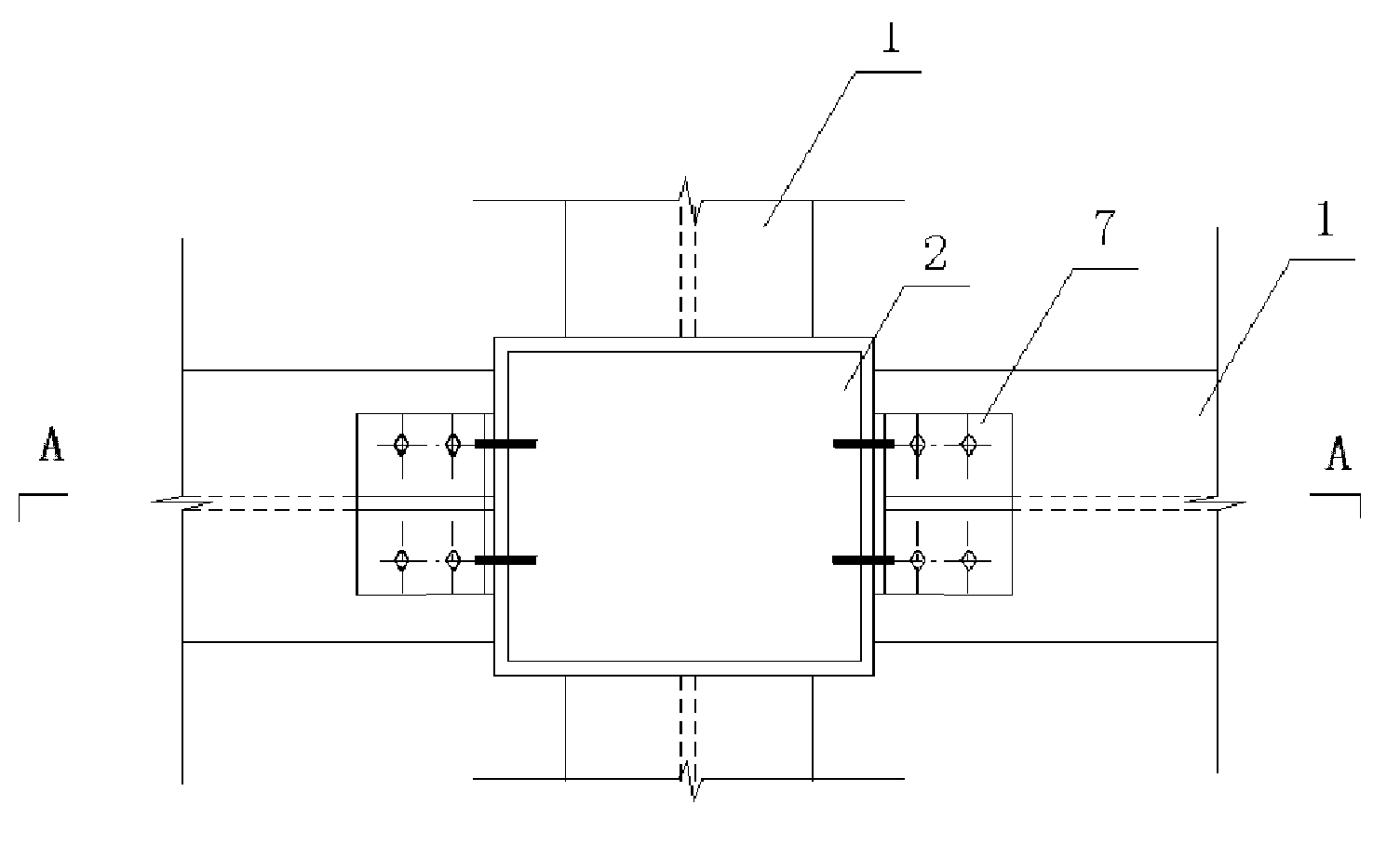

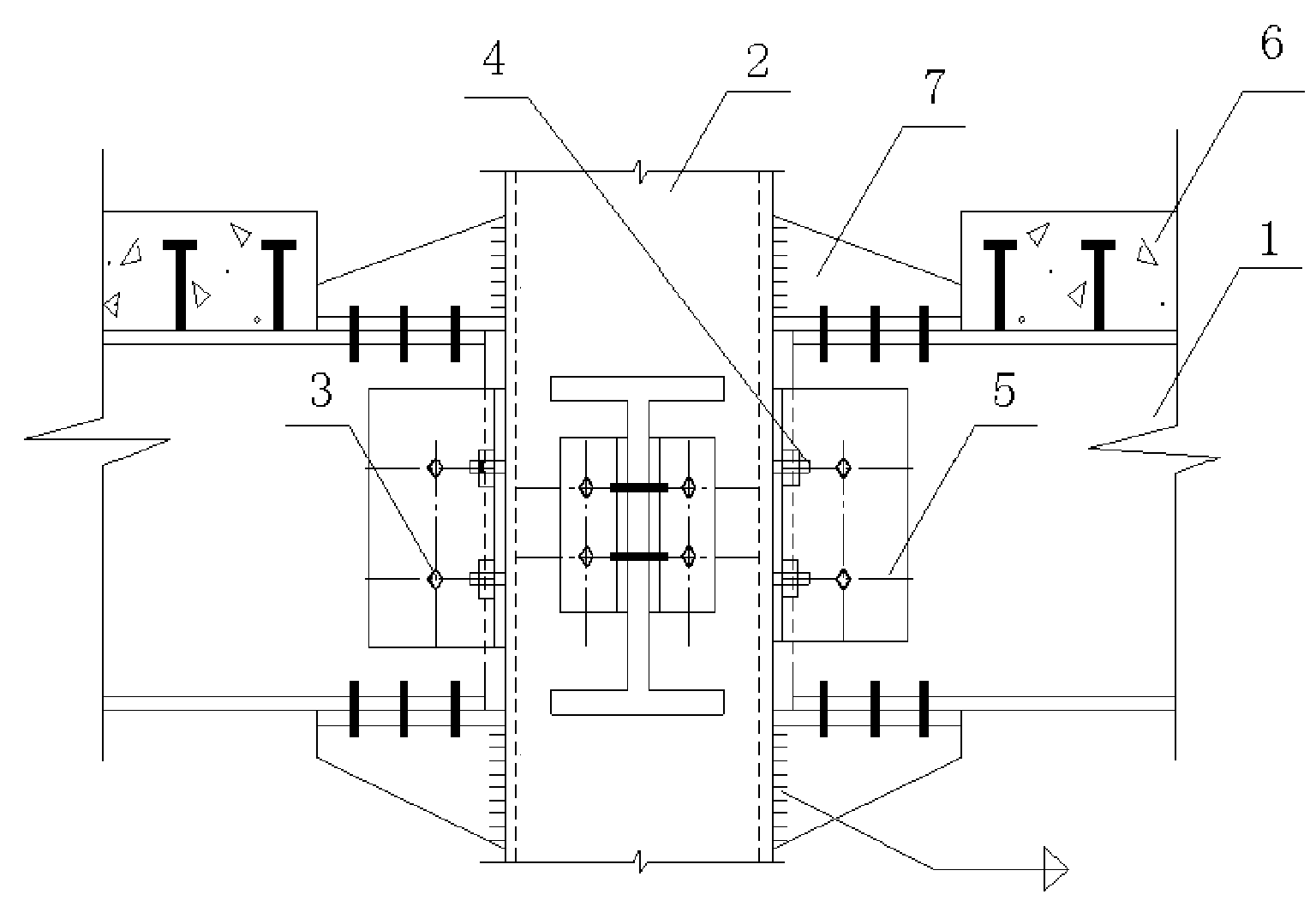

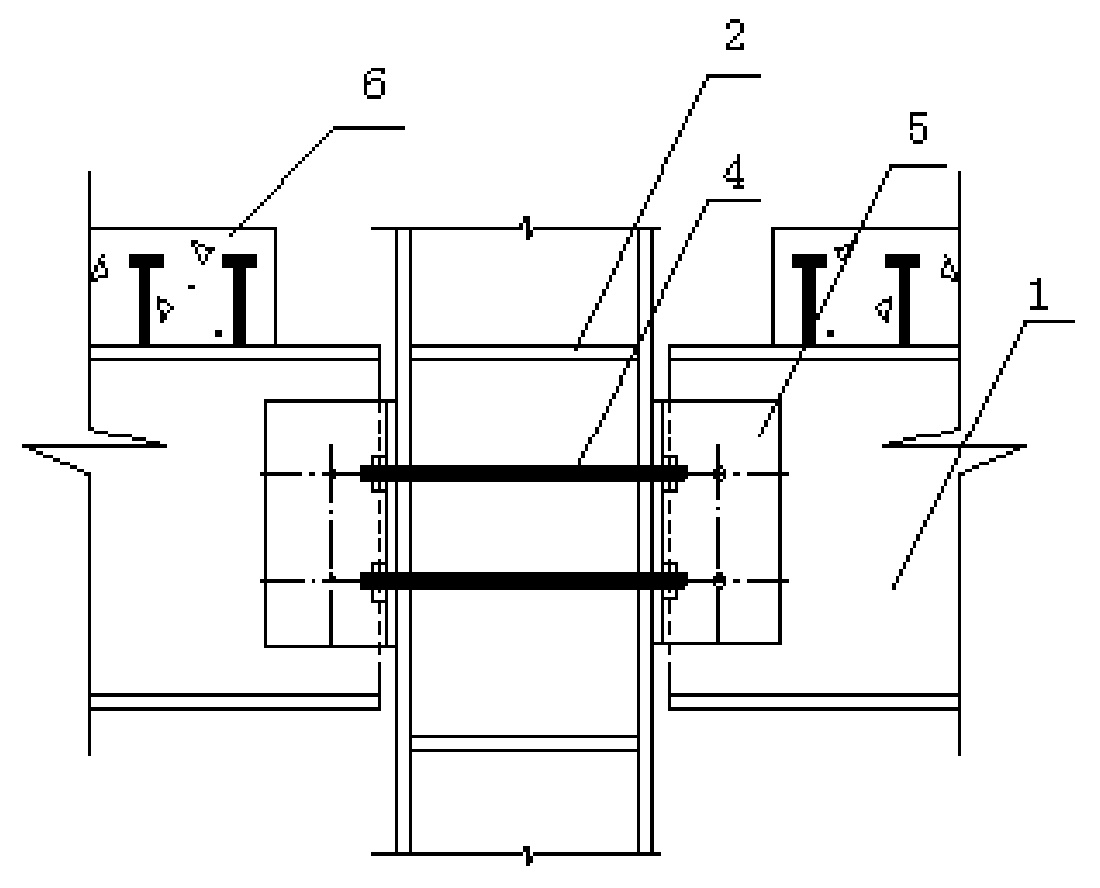

Connecting structure of beam column nodes and construction method thereof

A connecting structure of beam column nodes and a construction method thereof, wherein the connecting structure comprises a square steel tube concrete column, an I-shaped steel beam, T-type splitting plates and a long screw bolt, wherein two ends of the long screw bolt are respectively fixedly connected with the I-shaped steel beam and the square steel pipe concrete column, four T-shaped splitting plates are respectively and symmetrically arranged between the square steel tube concrete column and the I-shaped steel beam, and is fixedly connected with the square steel tube concrete column and the I-shaped steel beam. Compared with a traditional node, the integral intensity of the node is high, the construction is convenient, materials are saved, the I-shaped steel beam flanges of the structure are connected through the T-shaped steel, the integral bearing performance of the node is increased, the rigidity of the nodes is bigger, and the aseismic performance is good.

Owner:SHANGHAI JIAOTONG UNIV

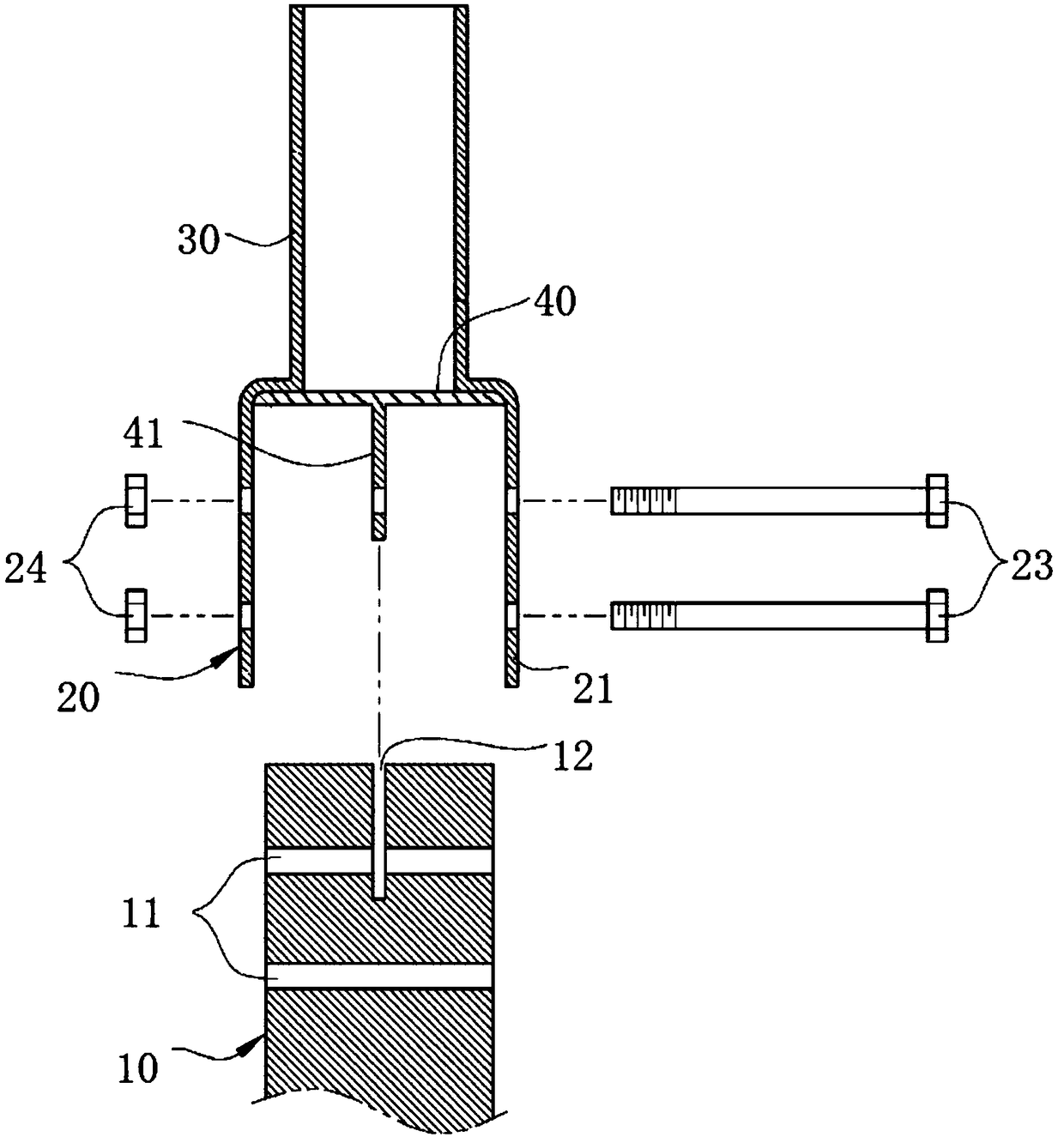

Connecting component for existing construction wood column replacing and application method of connecting component

PendingCN109296215AIncrease bending momentLow costBuilding repairsArchitectural engineeringCommunicating cavity

Owner:SUZHOU CROWNHOMES TIMBER STRUCTURE TECH CO LTD

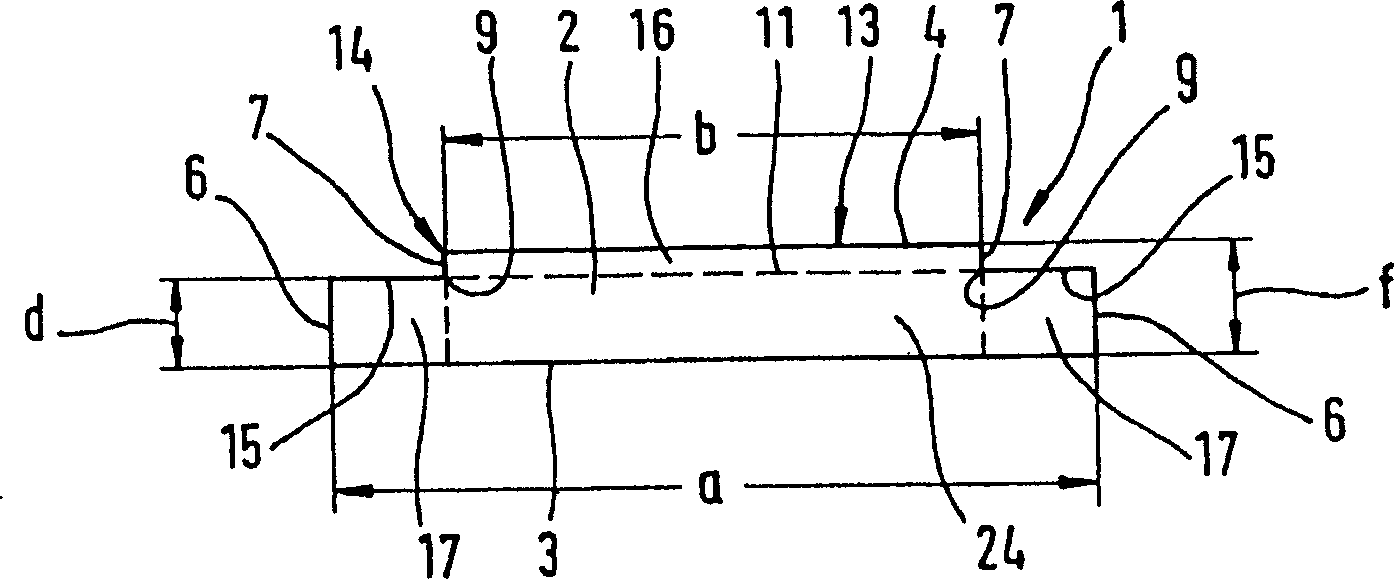

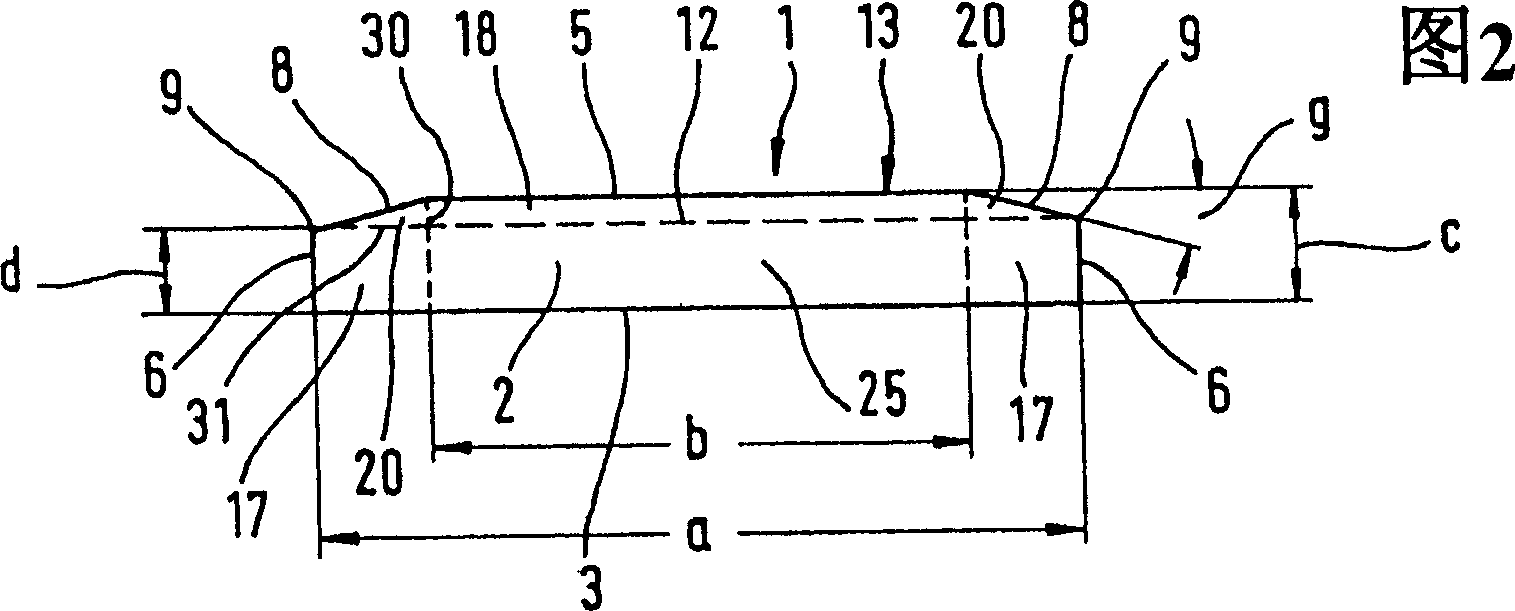

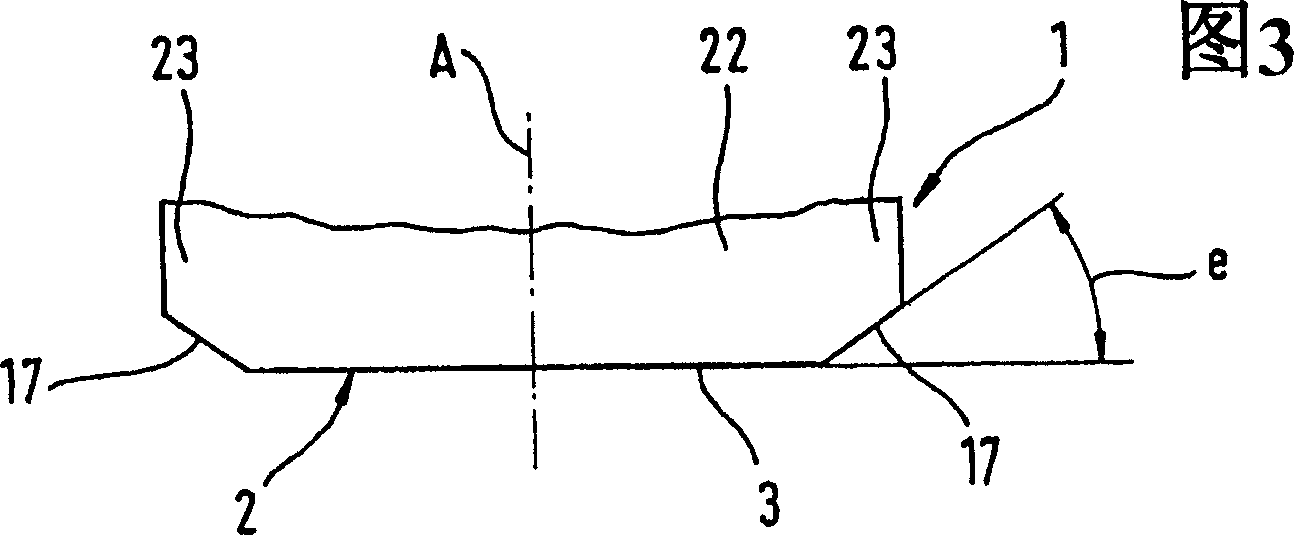

Ram for a plugging device for driving a strip-type retaining element into a bore of a toothbrush head that holds a tuft of bristles

ActiveCN1784158AImprove the immunityIncrease bending momentBrush bodiesBristleMechanical engineering

The invention relates to a plunger (1) of a filling tool according to EP 1 088 495 A1 for inserting a strip-shaped holding element, preferably an anchor, into a bristle hole of a brush head capable of receiving bristle tufts . The push rod (1) has on the end side an embedding surface (2) for engaging the retaining element, its cross-section (3, 4, 15; 3, 5, 8; 3) is defined by the longitudinal face and the end face (6, 7; 6, 8; 6, 10) limited. The push rod (1) has an end region (17, 20, 21) on the end side, which is pierced into the material of the brush head when the retaining element is inserted. According to the invention, the cross-sectional area ( 24 , 25 , 26 ) of the push rod ( 1 ), which enters the bristle opening and lies outside the end area, is wider than the end-side end area ( 17 ).

Owner:BRAUN AG

Clamp used for tension-torsional fatigue performance test of samples of micron-grade sizes

InactiveCN105021454AEasy to installSolve the accuracy problemStrength propertiesEngineeringMechanical engineering

The invention relates to a clamp used for the tension-torsional fatigue performance test of samples of micron-grade sizes. The clamp comprises an actuation shaft. A detachable main clamping block is arranged in the actuation shaft and is coaxially positioned together with the actuation shaft. A pressing plate is used in cooperation with the main clamping block for pressing the samples. A main clamping block locking nut is locked on the main clamping block and fastens the main clamping block and the actuation shaft. The samples are positioned and clamped through the detachable clamping block according to the center mark, the installation coaxiality of the main clamping block is ensured through the coaxial cooperation of the main clamping block and the actuation shaft, and therefore the main clamping block is convenient to position and install, the problems that when tiny samples are clamped through conventional clamps, the positioning accuracy is poor and positioning and clamping are not convenient are solved, and the clamping accuracy and the sample clamping efficiency can be improved. The horizontally-pushing structural form is adopted as the sample clamping mode, clamping is reliable, the structure is simple, and the clamp is suitable for the tension-torsional fatigue performance test of the samples of the micron-grade sizes and has the advantages of being high in clamping accuracy, reliable in clamping, small in clamping installation torque, capable of conveniently conducting the positioning and clamping operation, simple in structure and easy to machine.

Owner:TIANJIN UNIV

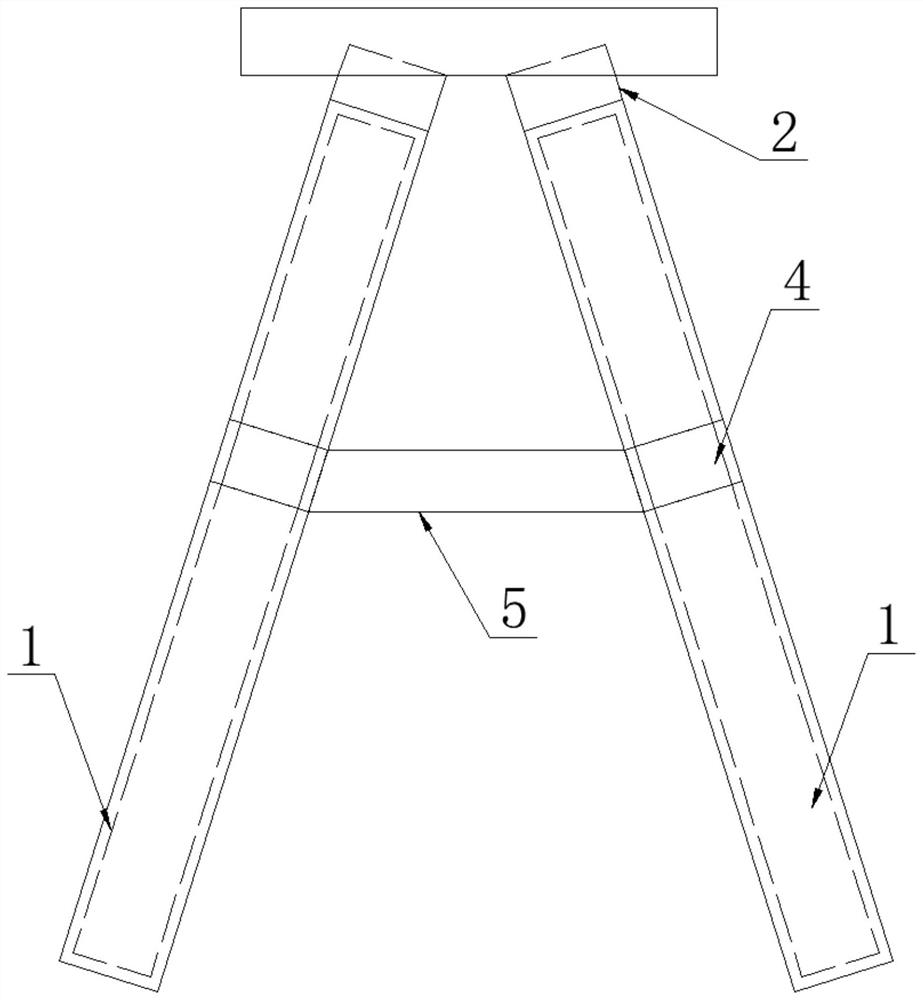

Transformer substation reinforced concrete herringbone electric pole and manufacturing method

InactiveCN112431470AIncrease bending momentImprove mechanical propertiesTransformer housesShaping reinforcementsReinforced concreteTransformer

The invention provides a transformer substation reinforced concrete herringbone electric pole and a manufacturing method. The transformer substation reinforced concrete herringbone electric pole comprises two concrete supporting rods with the same diameter, wherein the top ends of the two concrete supporting rods are each provided with an end steel ring, the tops of the two concrete supporting rods are connected through the end steel rings, a gap is formed between the bottoms of the two concrete supporting rods, and the two concrete supporting rods are of a herringbone structure after being connected. The transformer substation reinforced concrete herringbone electric pole is of the herringbone structure formed by connecting tops of two concrete supporting rods, and compared with the modethat a traditional reinforced concrete electric pole is basically single, the herringbone electric pole is better in stability and high in bending moment, pole section deflection and other mechanicalproperties; the herringbone electric pole is more suitable for special regions with strong wind; and the two concrete supporting rods are produced at a time, the uniformity and integrity of the wholerod section are structurally achieved, the bending moment, the rod section deflection and other mechanical properties of the concrete electric pole are improved, the field assembly procedure is simplified, and the field construction efficiency is improved.

Owner:宁夏平罗凌云建材实业有限公司

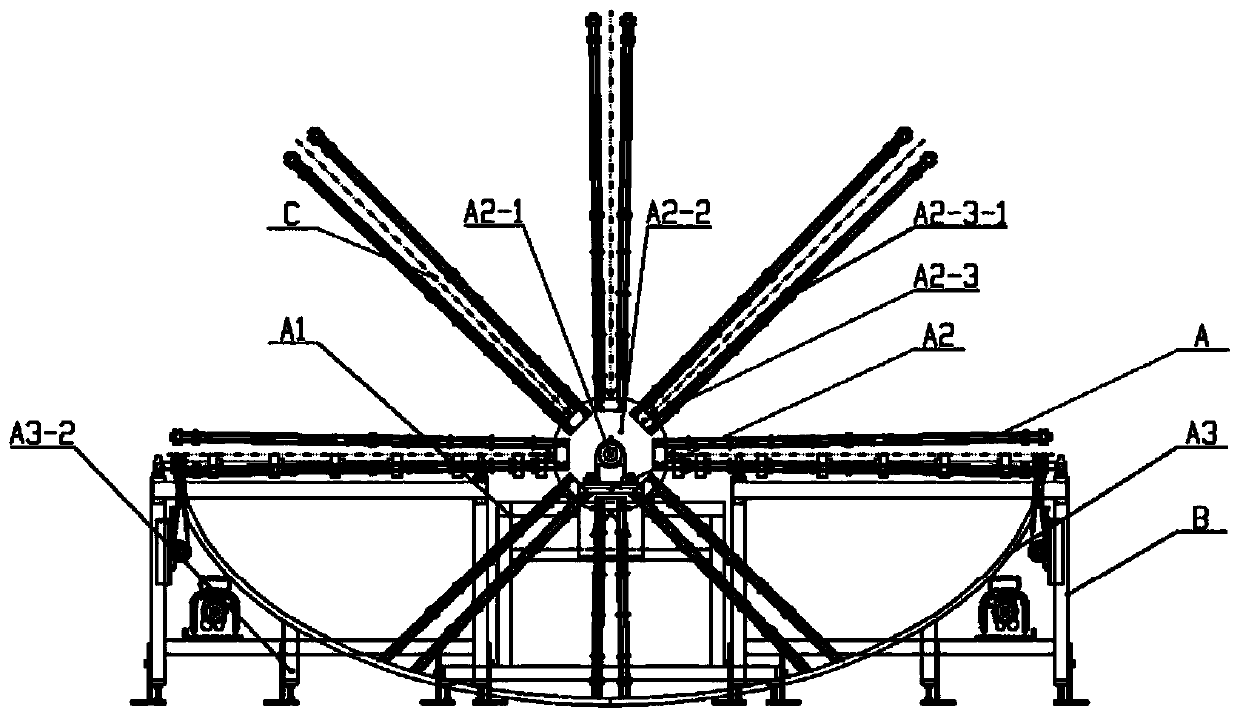

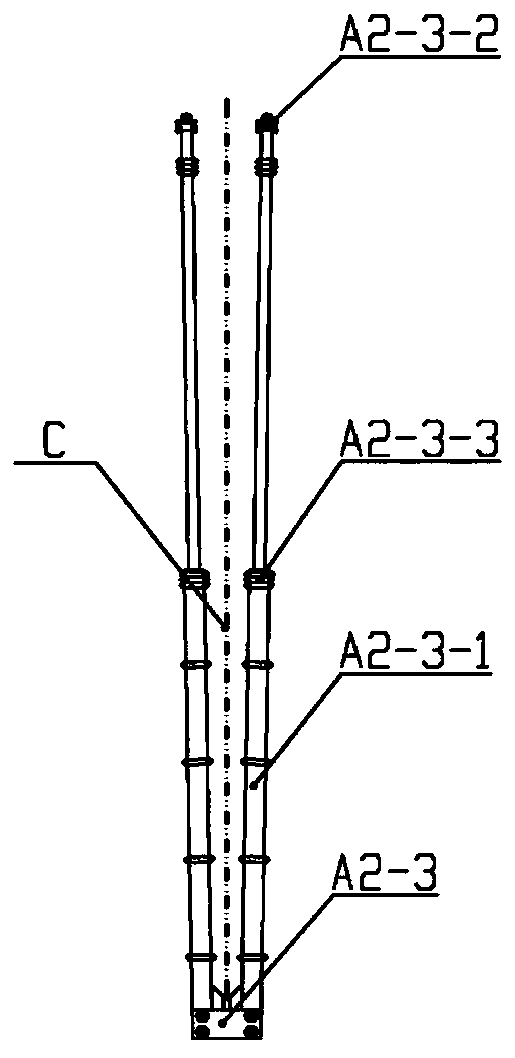

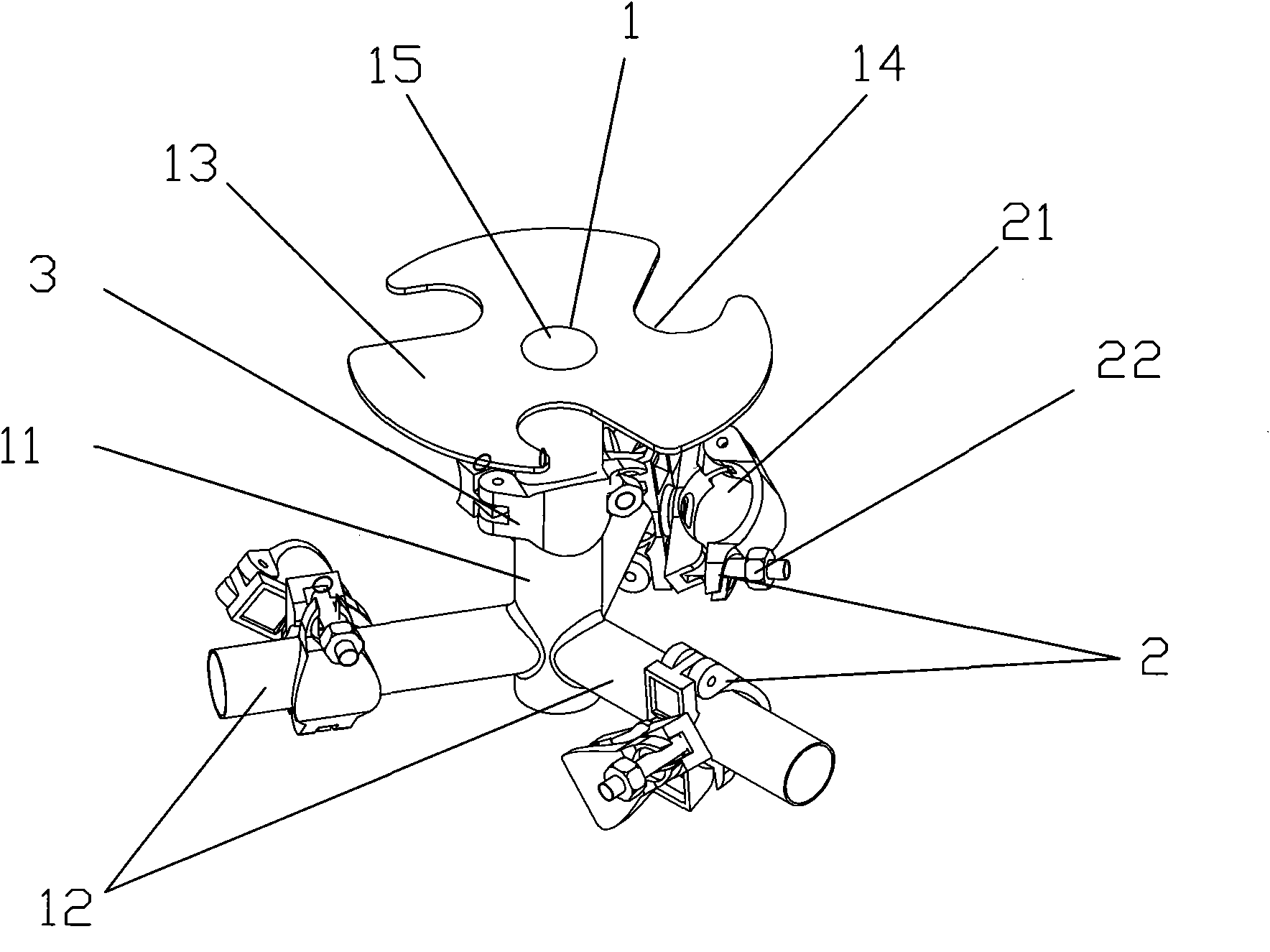

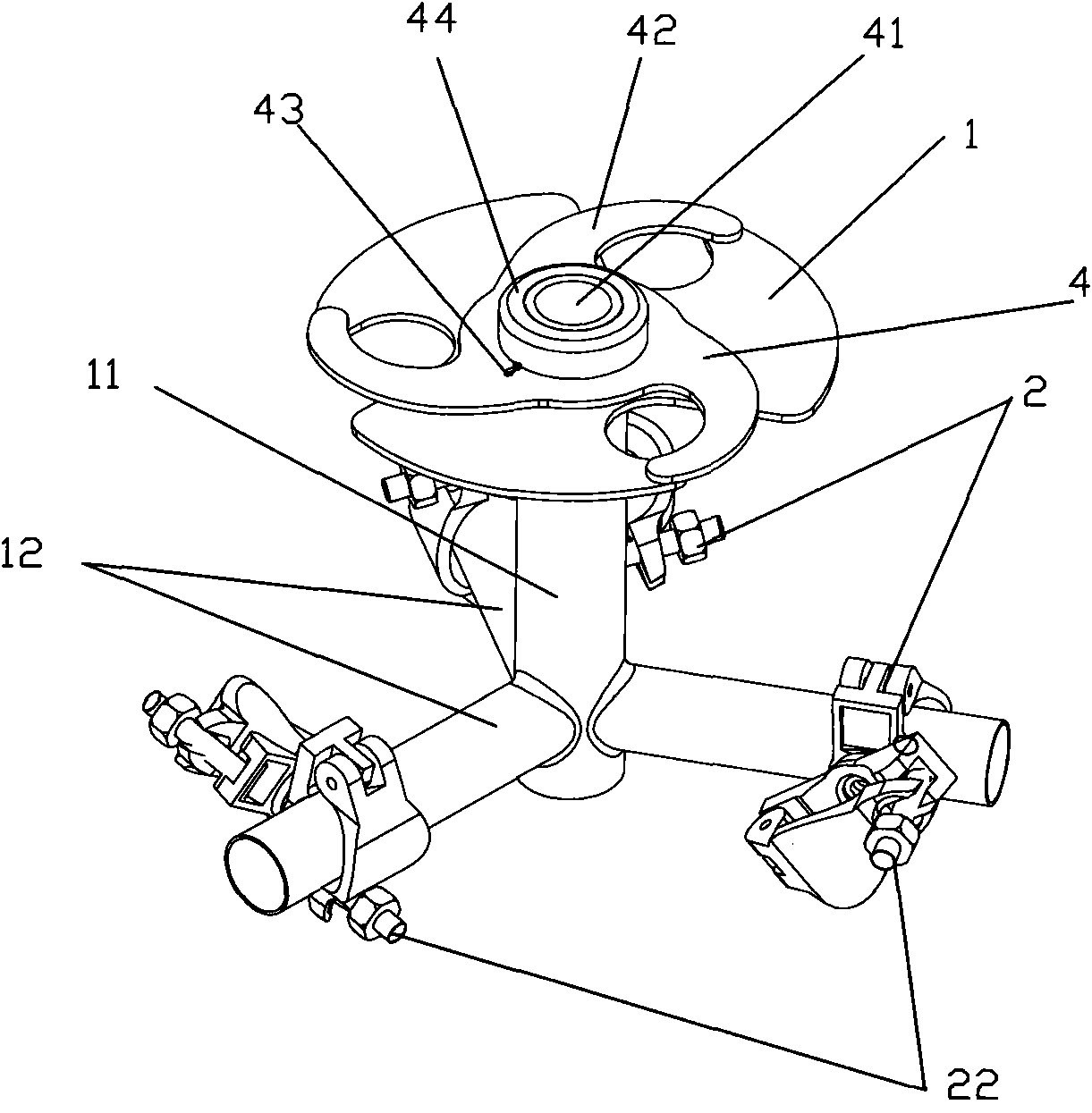

Telescopic cantilever and telescopic cantilever type plate turnover machine comprising same

ActiveCN110525976ASolve the problem that the maximum flap size is limited by the conveying elevationFlip realizationBio-organic fraction processingCharge manipulationEngineeringCantilever

The invention discloses a telescopic cantilever and a telescopic cantilever type plate turnover machine comprising the same, and relates to the technical field of glass deep processing, the turnover machine comprises a rack and a turnover device body arranged on the rack. The turnover machine comprises a mandrel, a plurality of rotary discs are arranged on the mandrel at equal intervals, a plurality of clamping cantilever sets are arranged on the circumferential side wall of each rotary disc, each clamping cantilever assembly comprises two clamping cantilevers which are symmetrically arranged,a working gap used for clamping glass exists in the middle of each clamping cantilever assembly, and each clamping cantilever is of a telescopic structure. An arc-shaped guide rail is further arranged below the clamping cantilever assembly, wherein in the process that the clamping cantilever rotates from the opening in one end to the opening in the other end, the compressed shortest length is smaller than or equal to the conveying elevation. According to the plate turnover machine, the problem that the maximum plate turnover size of the plate turnover machine is limited by the conveying elevation is solved, and under the condition of the same conveying elevation, the plate turnover machine can achieve plate turnover of glass with the larger size.

Owner:中建材智能自动化研究院有限公司

Novel overhanging I-steel pre-embedded anchor device and anchor method

PendingCN111287443AIncrease the attachment areaImprove deformation resistanceScaffold accessoriesBuilding support scaffoldsFloor slabClassical mechanics

The invention relates to a novel overhanging I-steel pre-embedded anchor device and anchor method, and belongs to the field of constructional engineering. The novel overhanging I-steel pre-embedded anchor device comprises two steel plates which are vertically arranged at intervals, an upper steel plate and two stop blocks, wherein the lower ends of the two steel plates extend into pre-embedded pits of a concrete floor; the upper steel plate is arranged between the two steel plates, and is arranged on the upper parts of the two steel plates; the two steel plates, the upper steel plate and the concrete floor are enclosed into an accommodating cavity, I-steel penetrates through the accommodating cavity, and the upper end surface of the I-steel abuts against the lower end surface of the uppersteel plate; the two stop blocks are correspondingly fixed to the two steel plates, the two stop blocks extend to the accommodating cavity between the I-steel and the two steel plates, and the two stop blocks correspondingly abut against webs of the I-steel. Through the two steel plates, the contact area with the I-steel at the left and right ends can be increased, and the torsion of the I-steel in a horizontal plane can be limited; the stop blocks are further arranged between the I-steel and the steel plates, so as to further increase the attachment area of the I-steel at the left and right sides, the bending moment of the required torsion of the I-steel in the horizontal plane is increased, and the anti-torsion ability is improved.

Owner:ZIBO TECHNICIAN COLLEGE

Sterile connector

PendingCN114073814AEasily brokenIncrease bending momentEngine sealsPipe couplingsMechanical engineeringClosed tube

Sterile connector for tubing comprising a section of tubing (2) with an end portion (3) to be connected to a further end portion of a further section of tubing and / or another counterpart in order to establish fluid communication,- at least one axial protrusion (4) extending away from the end portion (3) of the section of tubing in an axial direction of the section of tubing, and- a separation layer (5) which closes off an inside (6) of the section of tubing (2),wherein the separation layer (5) comprises a predetermined breaking site (7) and that the at least one axial protrusion (4)- is connected pivotally to the end portion (3) of the section of tubing (2) to pivot from a first position to a second position when engaged with a further axial protrusion on the further end portion of the further section of tubing and / or with the other counterpart and- is coupled to the separation layer (5) so as to exert a breaking force on the separation layer (5) in the second position which breaking force is big enough to break the separation layer (5) at the predetermined breaking site (7).

Owner:SINGLE USE SUPPORT GMBH

Portable overlapping fixing bracket for jack bracket

InactiveCN101979305AConvenient to implicate and fixIncrease bending momentBase supporting structuresBraking devices for hoisting equipmentsEmergency rescueEngineering

The invention discloses a portable overlapping fixing bracket for a jack bracket. The fixing bracket is characterized by comprising a bracket body consisting of a central vertical pipe, at least three Y-type pipes symmetrically fixed at the bottom end of the central vertical pipe and a limiting plate at the top end of the central vertical pipe, wherein scaffold rotating buckles are arranged on the Y-type pipes of the bracket body respectively and used for inserting and fixing support rods conveniently; and the limiting plate is provided with support rod limiting notches of which the number corresponds to that of the Y-type pipes. The scaffold rotating buckles on each Y-type pipe can conveniently adjust the extension length of each support rod according to the topographical condition and can rapidly fix the support rod with the fixing bracket in a drawing mode, so that the central vertical pipe of the fixing bracket is kept in a vertical state, the stable hoisting and safe operation ofa jack hung on the bracket can be ensured. The fixing bracket can be stably erected on the ground within 3 minutes. The portable overlapping fixing bracket for the jack bracket has a simple structureand small size, is convenient to carry and very suitable for performing emergency rescue on an external field with complex topographical condition and enhances the timeliness of emergency rescue.

Owner:SHENZHEN UNIV

A method for adjusting the weight of filling on the arch of a masonry arch bridge by region

ActiveCN104074139BReduce bending momentUniform moment distributionBridge erection/assemblyBridge strengtheningApparent densityCarrying capacity

The invention discloses a method for adjusting the weight of fillers on a masonry arch bridge in a partitioning manner. The masonry arch bridge comprises a main arch ring (1), spandrel arch rings (2), a filler layer (3) on arches, and a bridge panel (4). The method comprises the steps: the filler layer (3) on the arches is divided into an arch top area (31) and spandrel arch areas (32), wherein the arch top area (31) is formed between the main arch ring (1) and the bridge panel (4), and the spandrel arch areas (32) are formed between the spandrel arch rings (2) and the bridge panel (4); lightweight concrete fillers with the apparent density from 800kg / m3 to 1200 kg / m3 are filled into the arch top area (31), and lightweight concrete fillers or ordinary soil quality fillers with the apparent density from 1200kg / m3 to 1950 kg / m3 are filled into the spandrel arch areas (32); and the weight of the filler layer (3) on the arches is adjusted by calculating three objective functions, i.e. bending moments Md, M1 / 4 and Mj generated by the main arch ring on the arch top, the one quarter of an arch span, and arch feet, and the like. The method has the advantages that the utilization efficiency of arch ring materials can be improved, the distribution of the internal force of the main arch ring is improved, and the carrying capacity of the arch bridge is improved.

Owner:GUANGXI TRANSPORTATION SCI & TECH GRP CO LTD

Non-prestressed stainless steel tube-concrete composite electric pole and preparation method thereof

InactiveCN112282482AImprove mechanical propertiesImprove corrosion resistanceShaping reinforcementsTowersPre stressSS - Stainless steel

The invention relates to the technical field of electric poles, and discloses a non-prestressed stainless steel tube concrete composite electric pole and a preparation method thereof.The non-prestressed stainless steel tube concrete composite electric pole comprises a stainless steel tube and a concrete layer poured on the inner wall of the stainless steel tube, the stainless steel tube is composed of two half tubes split along the axis, and a steel reinforcement framework is planted in the concrete layer. The composite hollow structure is mainly formed by centrifugally forming the stainless steel pipe and the concrete, the characteristics of good mechanical properties and good corrosion resistance of the stainless steel pipe and the concrete are fully played, the overall performance of the structure is improved, and compared with a traditional composite pole structure, the composite pole structure is easy to form, high in bearing capacity, high in rigidity, good in impact resistance and capable of preventing collision and collapse. Moreover, the corrosion resistance is relatively strong, and the corrosion resistance to atmosphere, water, acid, alkali, salt and various solvents with general concentrations is relatively good. The problems that an existing traditional concrete electric pole is insufficient in bending moment, poor in frost resistance, poor in steel pipe pole corrosion resistance and high in manufacturing cost are solved.

Owner:惠州富盈新材料科技有限公司

A Highly Sensitive Vibration Sensor

ActiveCN111337119BIncrease bending momentLarge degree of deflectionSubsonic/sonic/ultrasonic wave measurementUsing electrical meansCantilevered beamPiezoelectric cantilever

The invention discloses a high-sensitivity vibration sensor, and the sensor comprises a substrate with a cavity and a plurality of piezoelectric cantilever beams; a fixed column is arranged in the center of the bottom surface of the cavity, and a signal receiving area is defined by the plurality of cantilever beams and is fixed above the substrate through the fixed column; each piezoelectric cantilever beam comprises a fixed end and a free end, wherein the width of the free end is greater than that of the fixed end, the fixed end is fixed to the fixed column, the free end is suspended above the cavity, and a gap is formed between every two adjacent piezoelectric cantilever beams. The sensor further comprises a sealing cap with a groove, and the groove edge of the sealing cap is connected with the free end of each piezoelectric cantilever beam. The section of the groove can be in any shape, and a trapezoid with the included angle between the bottom face and the side wall greater than 90degrees is preferably selected. According to the invention, a load generated by a vibration signal is concentrated at the free ends of the piezoelectric cantilever beams through the sealing cap, so the bending moment borne by the piezoelectric cantilever beams is larger, the deflection degree of the piezoelectric cantilever beams is larger, a larger transverse load can be generated when the included angle is greater than 90 degrees, and the sensitivity of the vibration sensor is effectively improved.

Owner:武汉敏声新技术有限公司

Prestressed stainless steel tube-concrete composite electric pole and preparation method thereof

InactiveCN112267746AImprove mechanical propertiesImprove corrosion resistanceTowersPre stressSS - Stainless steel

The invention relates to the technical field of electric poles, and discloses a prestressed stainless steel tube-concrete composite electric pole and preparation method thereof. The prestressed stainless steel tube-concrete composite electric pole comprises a stainless steel tube and a concrete layer poured on the inner wall of the stainless steel tube, and a prestressed reinforcement framework isplanted in the concrete layer. According to the prestressed stainless steel tube-concrete composite electric pole and preparation method thereof, the composite hollow structure is mainly formed by centrifugally forming the stainless steel tube and concrete, the characteristics of good mechanical properties and good corrosion resistance of the stainless steel tube and the concrete are fully played, the overall performance of the structure is improved, and compared with a traditional composite pole structure, the composite pole structure is easy to form, high in bearing capacity, high in rigidity, good in impact resistance and capable of preventing collision and collapse; and moreover, the corrosion resistance is relatively strong, and the corrosion resistance to atmosphere, water, acid, alkali, salt and various solvents with general concentrations is relatively good. According to the prestressed stainless steel tube-concrete composite electric pole and preparation method thereof, the problems that the prior traditional concrete electric pole is insufficient in bending moment and poor in frost resistance, and the steel tube pole is poor in corrosion resistance and high in manufacturing cost are solved.

Owner:惠州富盈新材料科技有限公司

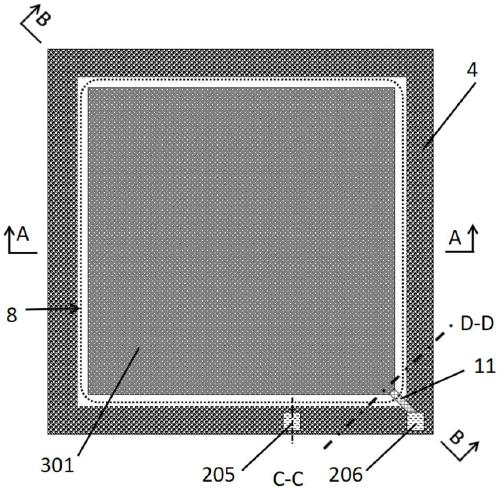

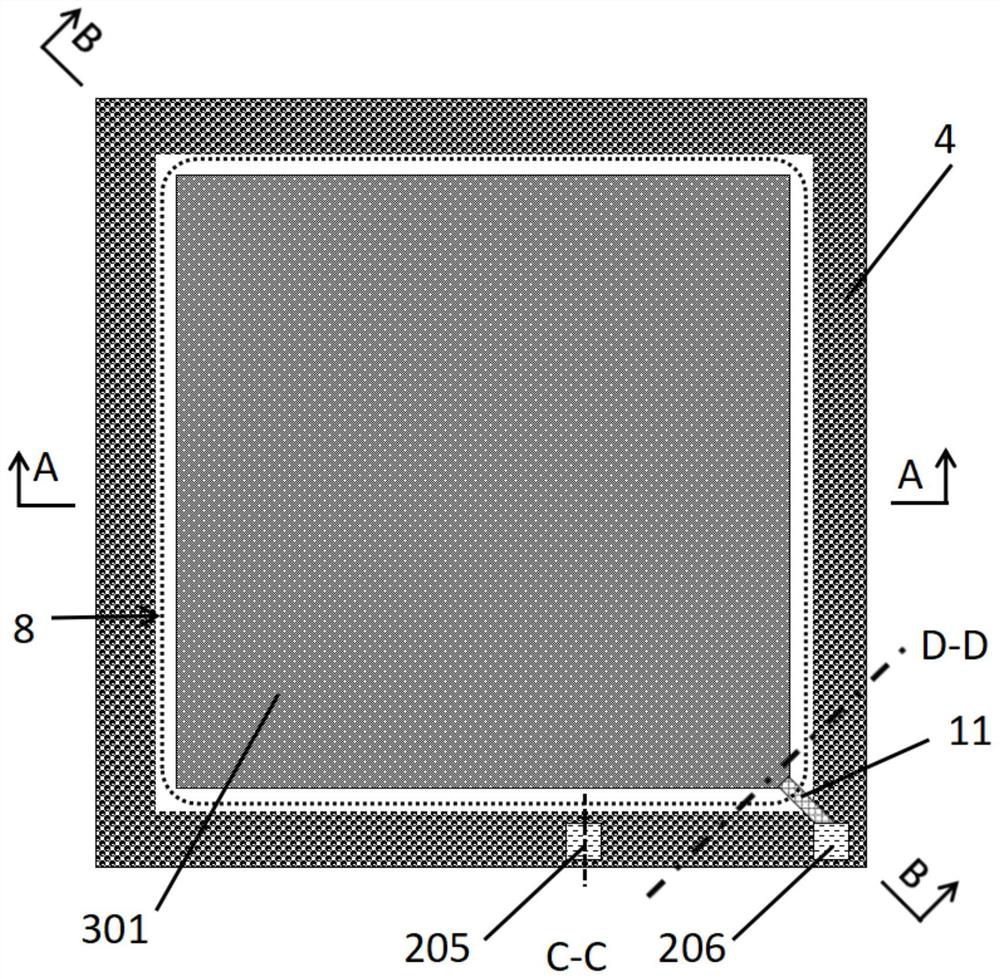

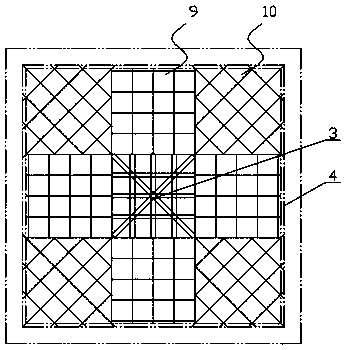

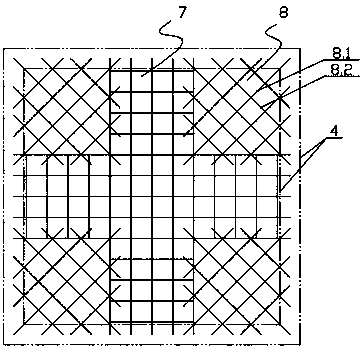

A rice-shaped reinforced structure of a floor slab

ActiveCN106351403BImprove performanceImprove bearing capacityBuilding reinforcementsChinese charactersFloor slab

The invention provides a reinforcing steel bar distribution structure shaped like a Chinese character mi for a floorslab. The reinforcing steel bar distribution structure shaped like a Chinese character mi mainly is mainly used on a rectangular floor slab with girders at the periphery, and mainly comprises a lower-layer reinforcing mesh, an upper-layer reinforcing mesh and a top and bottom opposite angle connecting bracket. The periphery of the lower-layer reinforcing mesh penetrates through a reinforcing steel bar body of the girder, and the lower-layer reinforcing mesh comprises a cross-shaped reinforcing mesh and a slab corner reinforcing mesh. The upper-layer reinforcing mesh is distributed above the lower-layer reinforcing mesh, and the periphery of the upper-layer reinforcing mesh is connected with the upper side part of the reinforcing steel bar body. The upper-layer reinforcing mesh comprises a middle reinforcing mesh and a girder corner reinforcing mesh. Through the mode of distributing the reinforcing steel bars in a shape like a Chinese character mi at the upper and lower layers, the performance of the various reinforcing meshes are given full play, and the materials are also saved. The reinforcing steel bar distribution structure can be prefabricated in a factory and is then constructed on the site, the site operation is convenient, and the construction efficiency and the construction quality are improved. The top and bottom opposite angle connecting bracket leads to integral connection of the upper-layer reinforcing mesh and the lower-layer reinforcing mesh, so that cracks on four corners of the floorslab are eliminated, and the bearing capacity of the floorslab and the rigidity of a floor system structure are also improved.

Owner:福州鼓楼纹英建筑工程有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com