A method for adjusting the weight of filling on the arch of a masonry arch bridge by region

A masonry arch bridge, sub-regional technology, used in bridges, bridge construction, bridge maintenance and other directions, can solve the problems of unadjustable, difficult to achieve ideal state, non-continuous distribution of dead loads, etc., to facilitate construction and reduce bridge deck paving. The effect of pretending to be diseased and saving the compaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

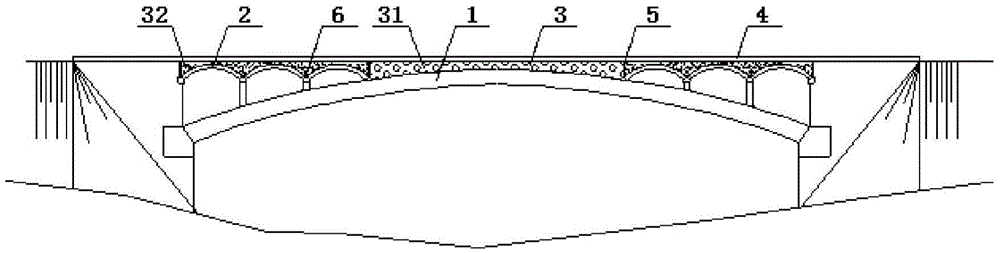

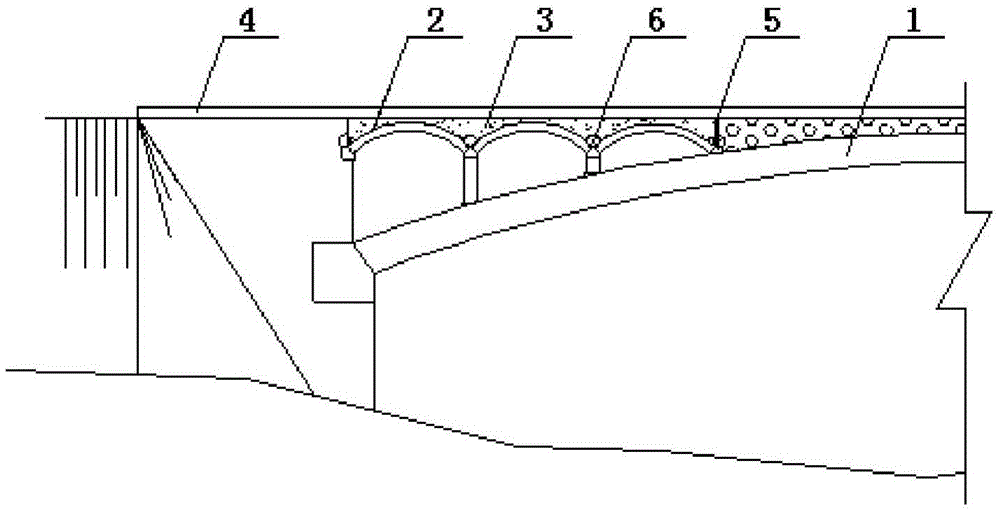

[0036] as attached figure 1 and 2 As shown, a certain bridge is a variable-section catenary vierendeel double-curved arch bridge with a span of 100 meters and a net loss height of 12.24 meters. The width of the bridge is 20.2 meters. , the thickness of the vault is 1.4 meters, and the thickness of the arch foot is 2.26 meters.

[0037] This embodiment is an old bridge reinforcement project, including the main arch ring 1, the belly arch ring 2, the filler layer 3 on the arch and the bridge deck 4. The vault area 31 is between the main arch ring 1 and the bridge deck 4, and the belly arch ring 2 Between the bridge deck 4 is the belly arch area 32; the filling density of the vault area is 800kg / m 3 ~1200kg / m 3 lightweight concrete filler, the apparent density of the belly arch area is 1200kg / m 3 ~1950kg / m 3 Lightweight concrete filler or ordinary soil filler; lightweight concrete filler is concrete made of lightweight aggregate or ordinary sand, with cement and water. Among...

Embodiment 2

[0050] as attached figure 1 and 2 As shown, the span of a new bridge is 57.622 meters, and the net loss is 9.568 meters. Net (7+2×0.43) meters.

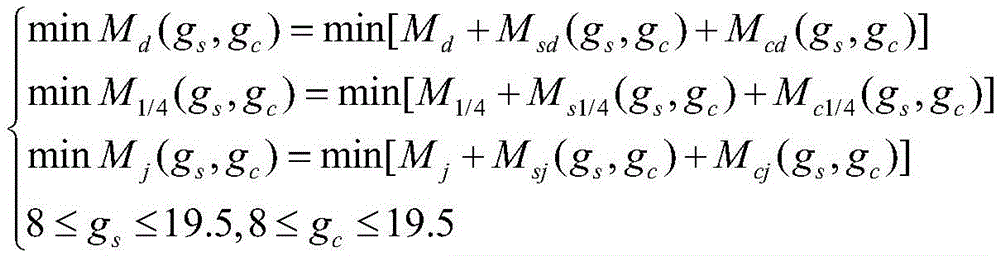

[0051] This embodiment is designed for the filling on the arch of a new bridge, including the main arch ring 1, the belly arch ring 2, the filling layer 3 on the arch and the bridge deck 4. There is a vault area 31 between the main arch ring 1 and the bridge deck 4, and the belly arch Between the circle 2 and the bridge deck 4 is the belly arch area 32; the filling density of the vault area is 800kg / m 3 ~1200kg / m 3 lightweight concrete filler, the apparent density of the belly arch area is 1200kg / m 3 ~1950kg / m 3 lightweight concrete filler or ordinary soil filler; lightweight concrete filler is light coarse aggregate, light fine aggregate or ordinary sand, mixed with cement and water to form concrete, wherein the lightweight aggregate can be fly ash ceramsite, Clay ceramsite, shale ceramsite, pumice or scoria, spontaneous combu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com