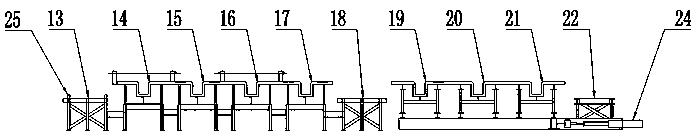

Patents

Literature

66results about How to "Improve prefabrication efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

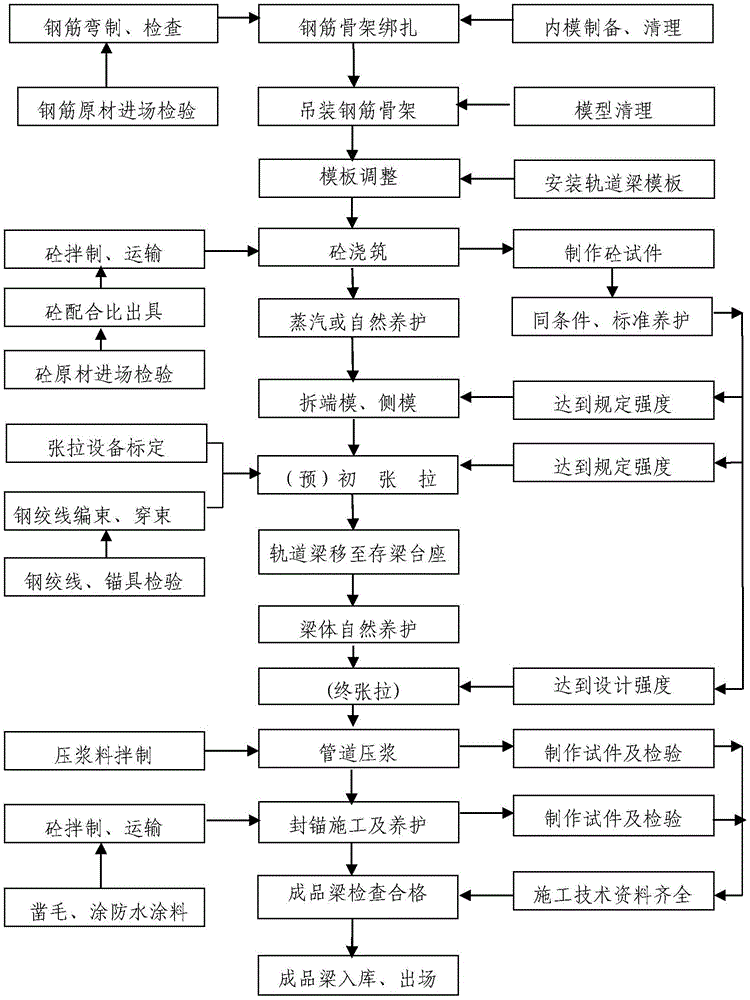

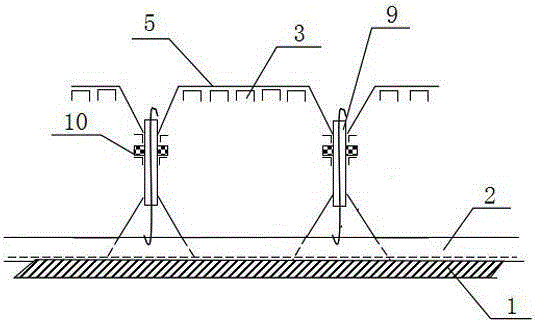

Manufacture method for maglev track beam

ActiveCN105014786AImprove prefabrication efficiencyHigh adjustment accuracyMouldsRailway tracksEngineeringVertical displacement

The invention discloses a manufacture method for a maglev track beam. The manufacture method comprises the following steps: tying a framework of steel reinforcement, manufacturing an internal mold, putting the internal mold in the framework of steel reinforcement, mounting a formwork of track beam, and regulating the formwork of track beam so as to meet the required linearity. The lateral displacement relative to the track beam and the perpendicularity relative to a bottom mold of the side mold of the formwork of track beam can be regulated through a regulating component, and a translating component arranged outside end molds is used for regulating the longitudinal movement relative to the side mold of each end mold. The manufacture method has the advantages of being easy to operate, high in regulating precision and simple to assemble and disassemble the molds. A control component can respectively regulate the transverse displacement, the longitudinal displacement and the vertical displacement of the track beam, the linearity precision can achieve the range of + / -5, and the precast quality of a curved track beam is ensured. The intelligent control can realize high regulating precision, high efficiency and good reliability of a formwork system, and the manufacture method is particularly applicable to precasting of medium-low-speed maglev linear or curved track beams.

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD

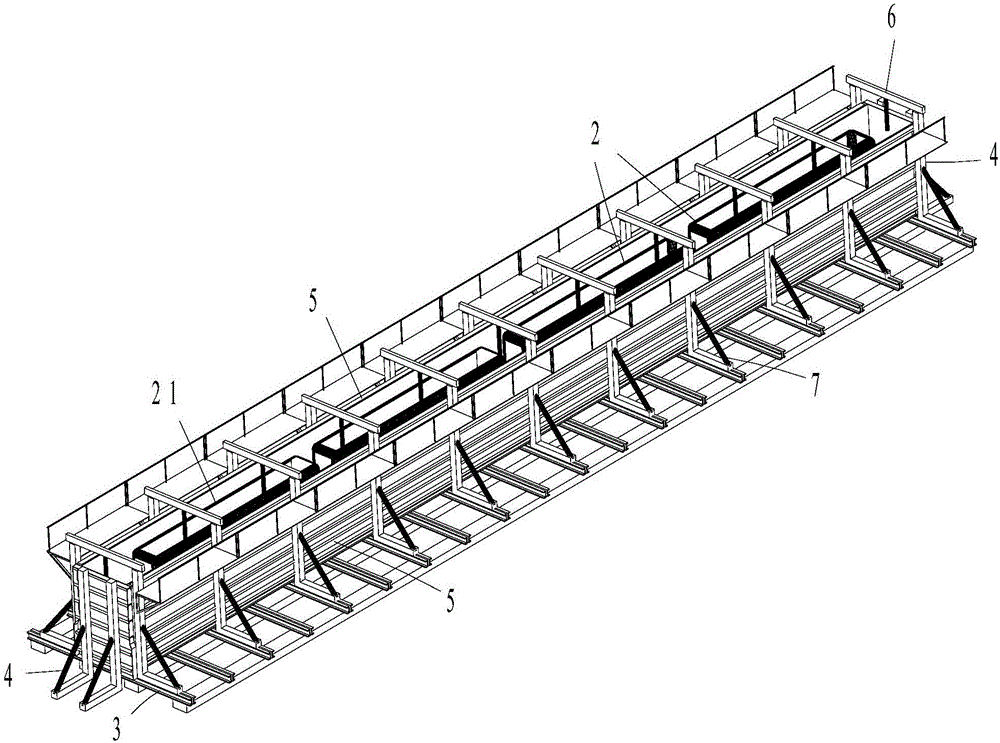

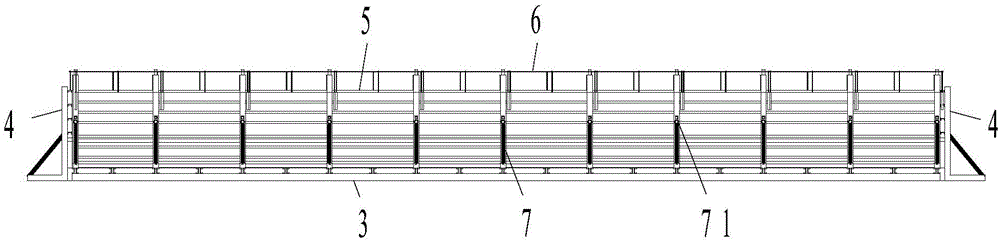

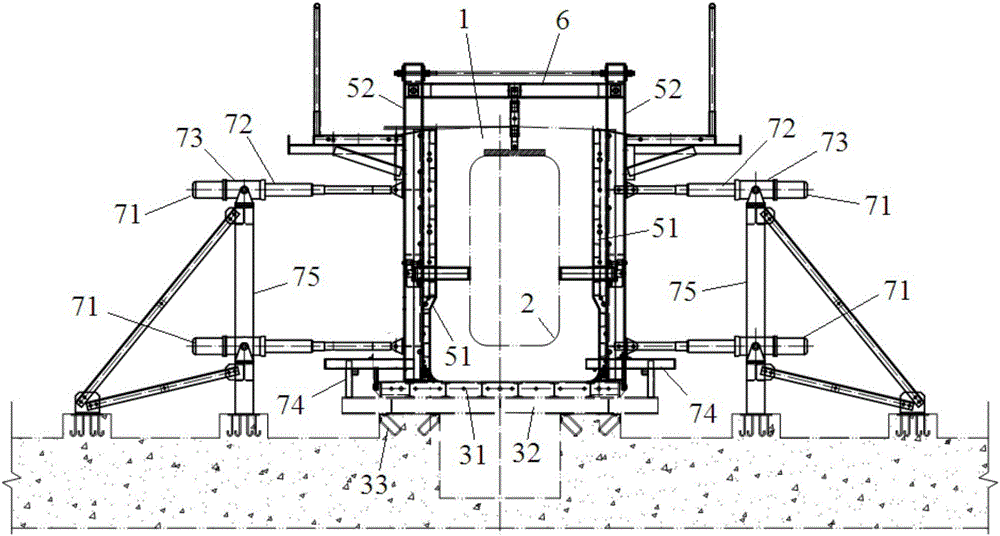

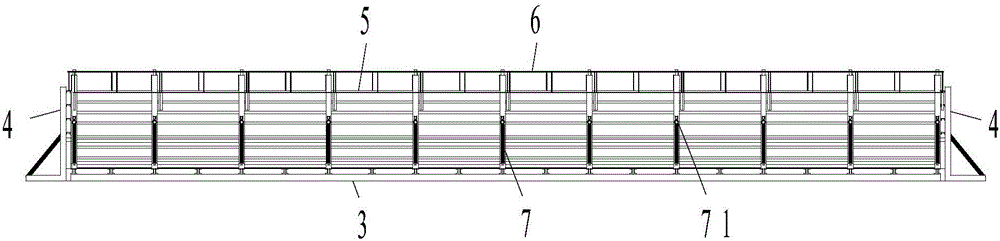

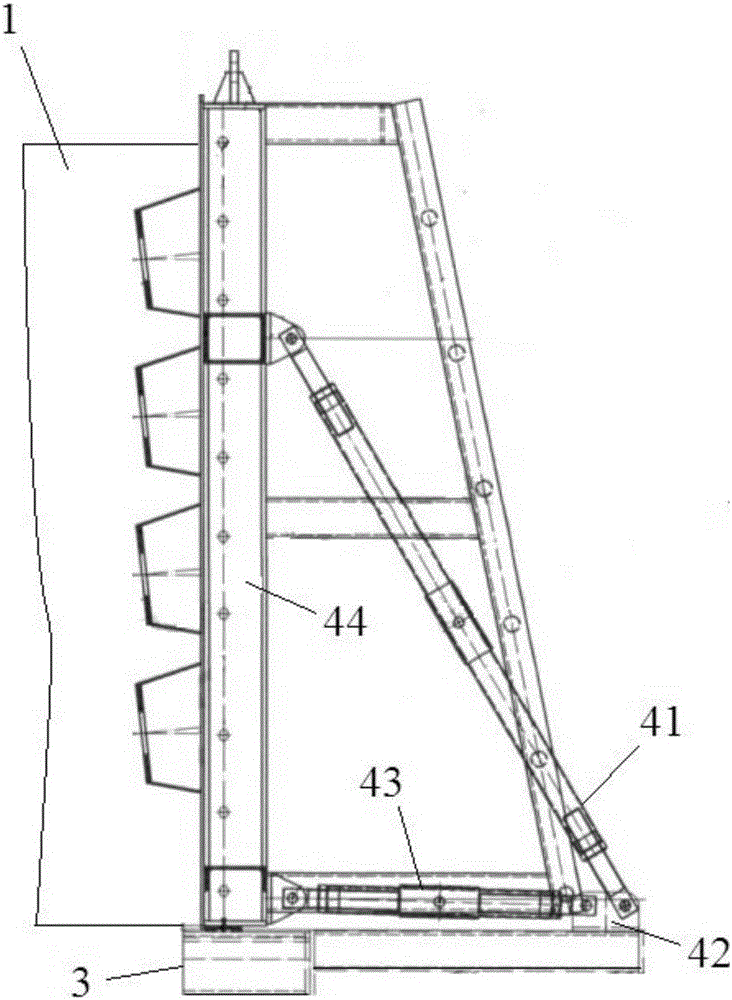

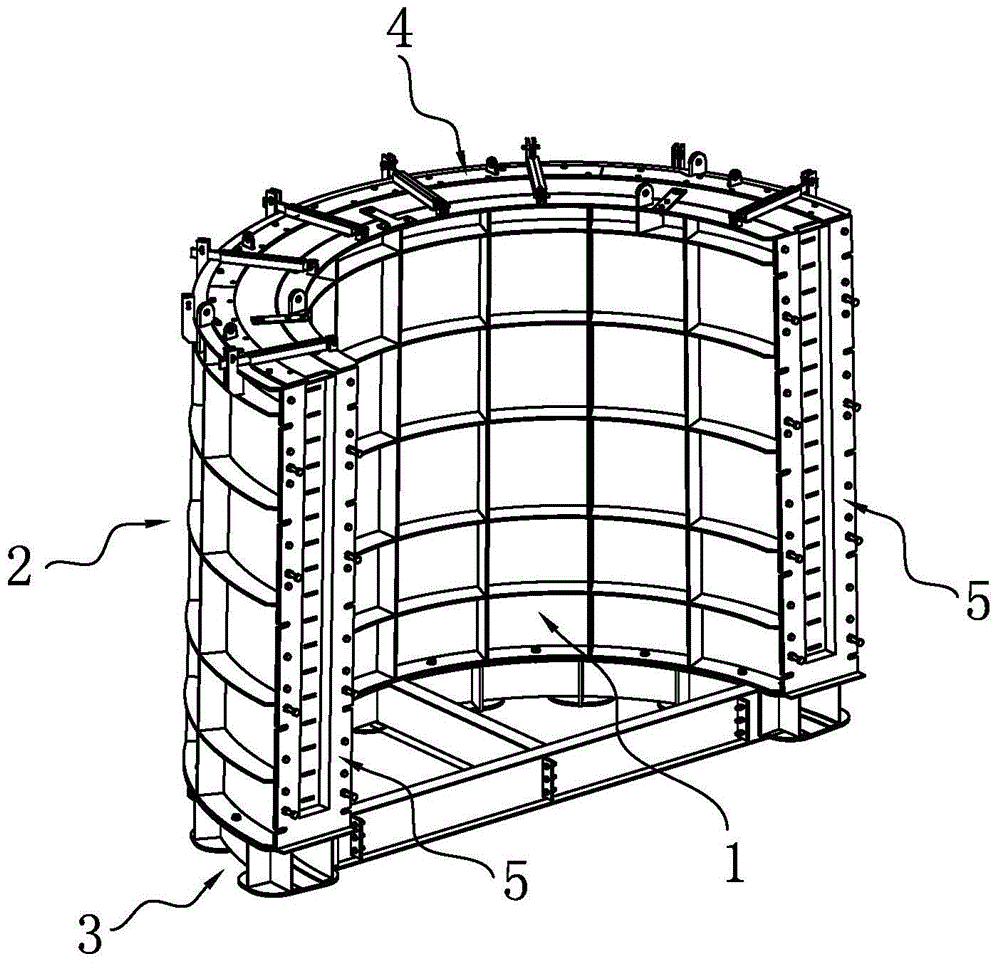

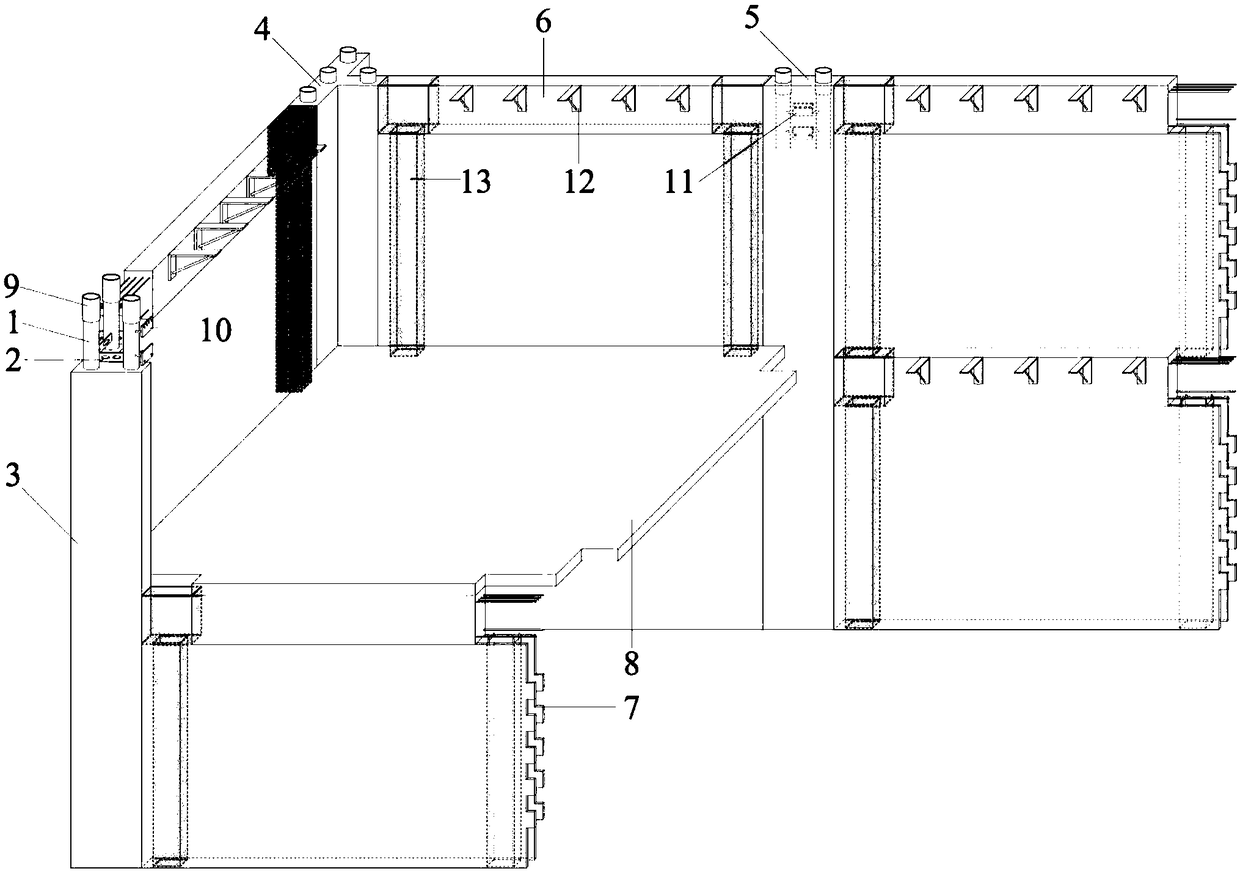

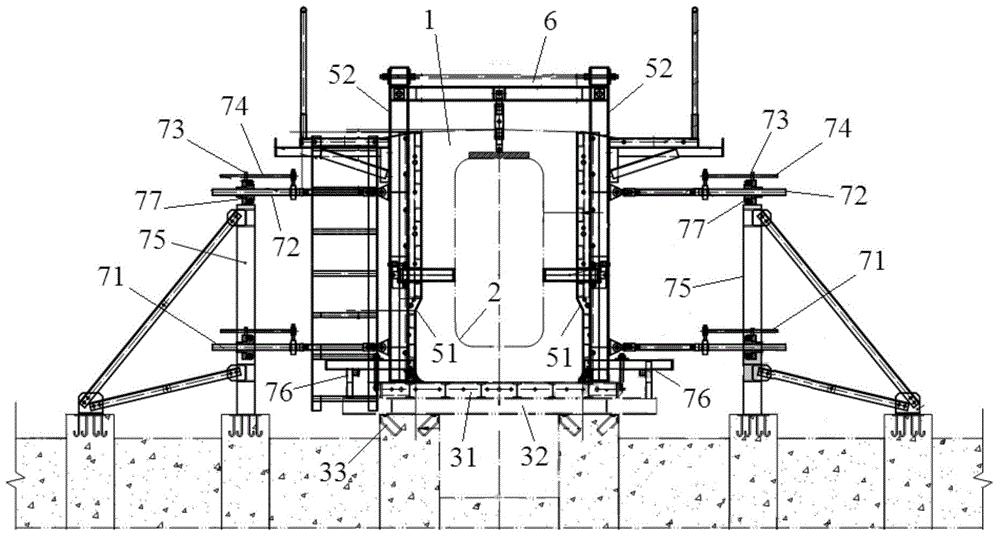

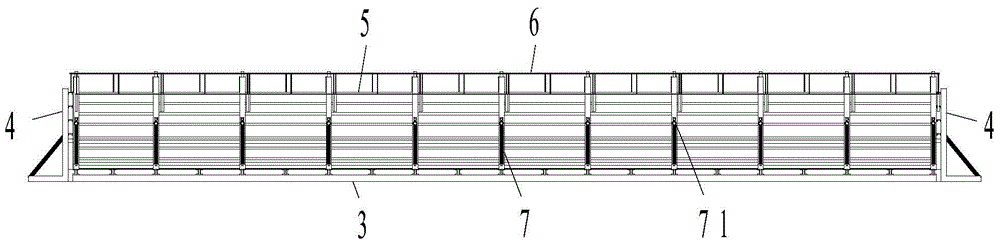

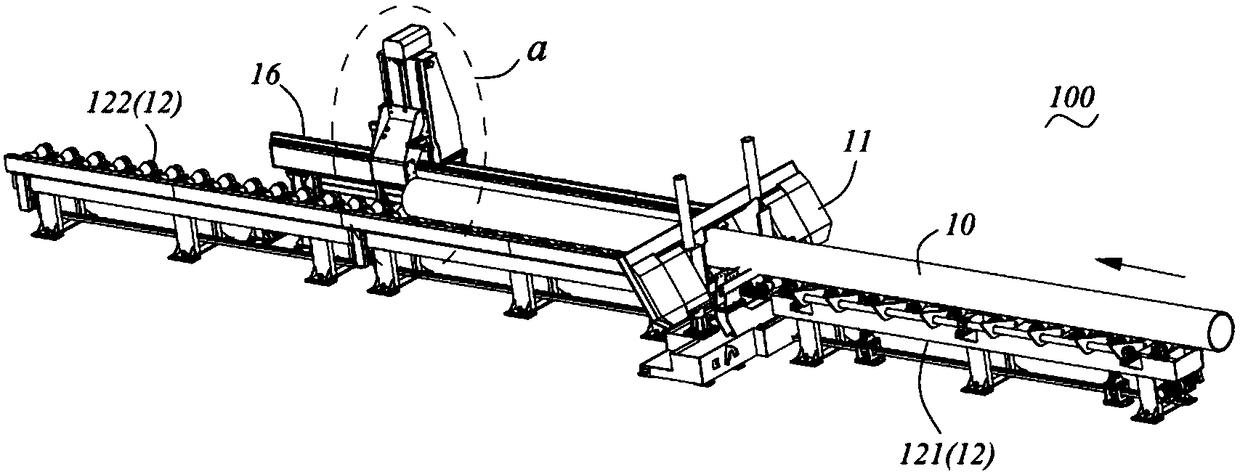

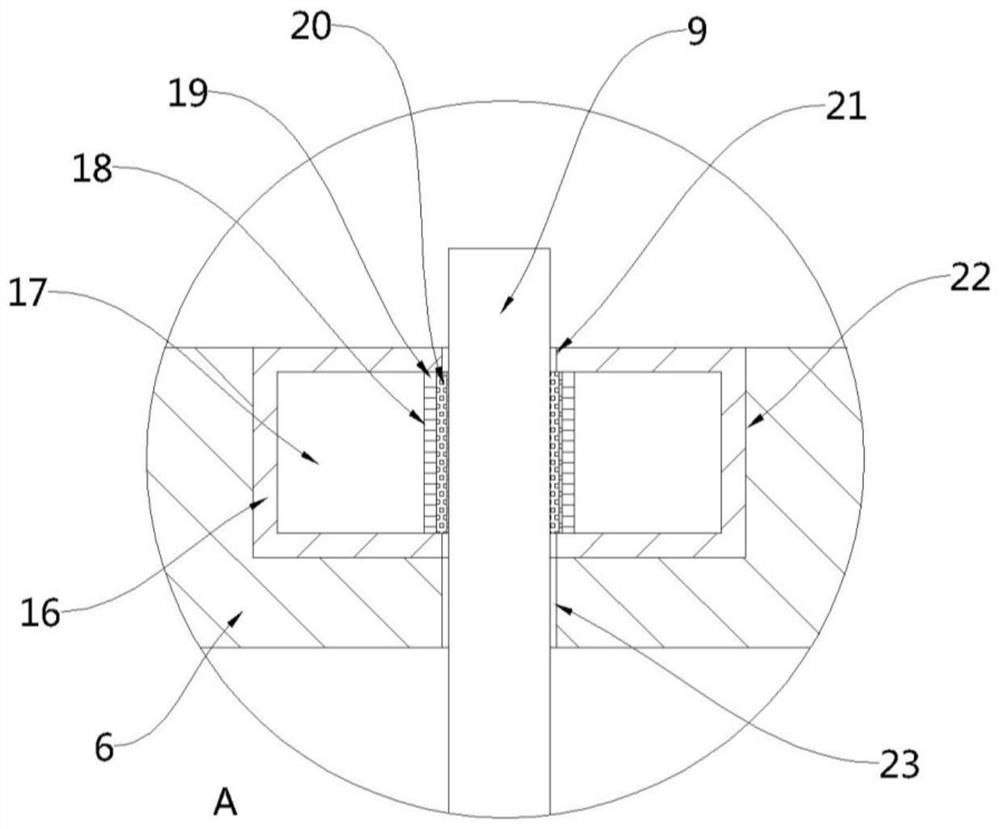

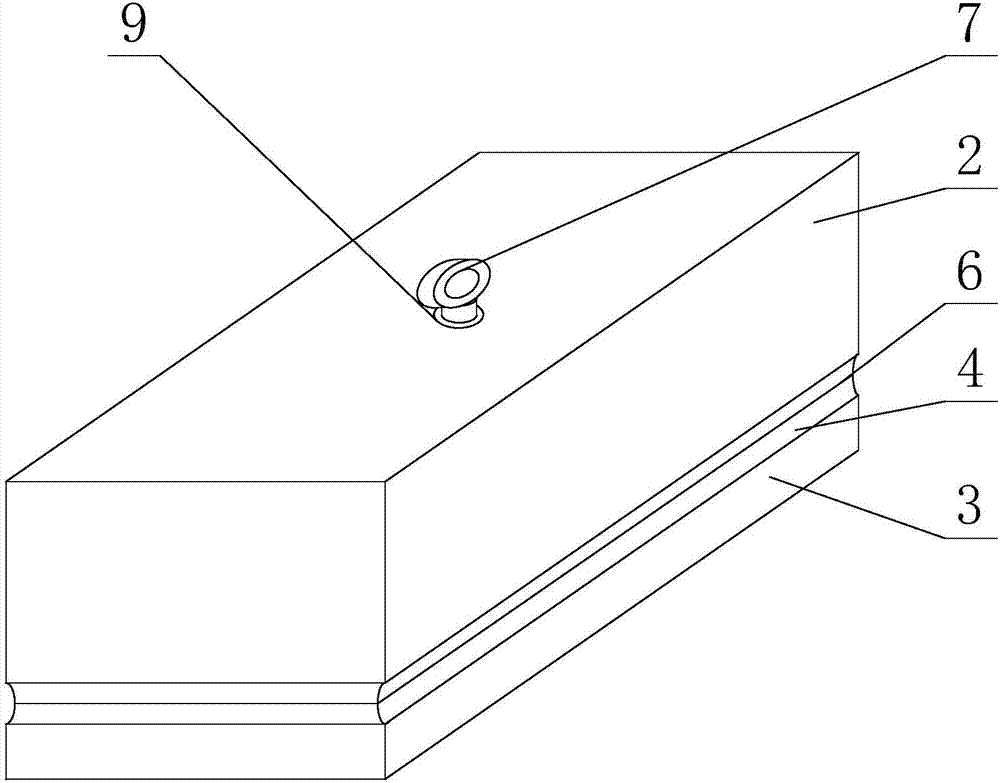

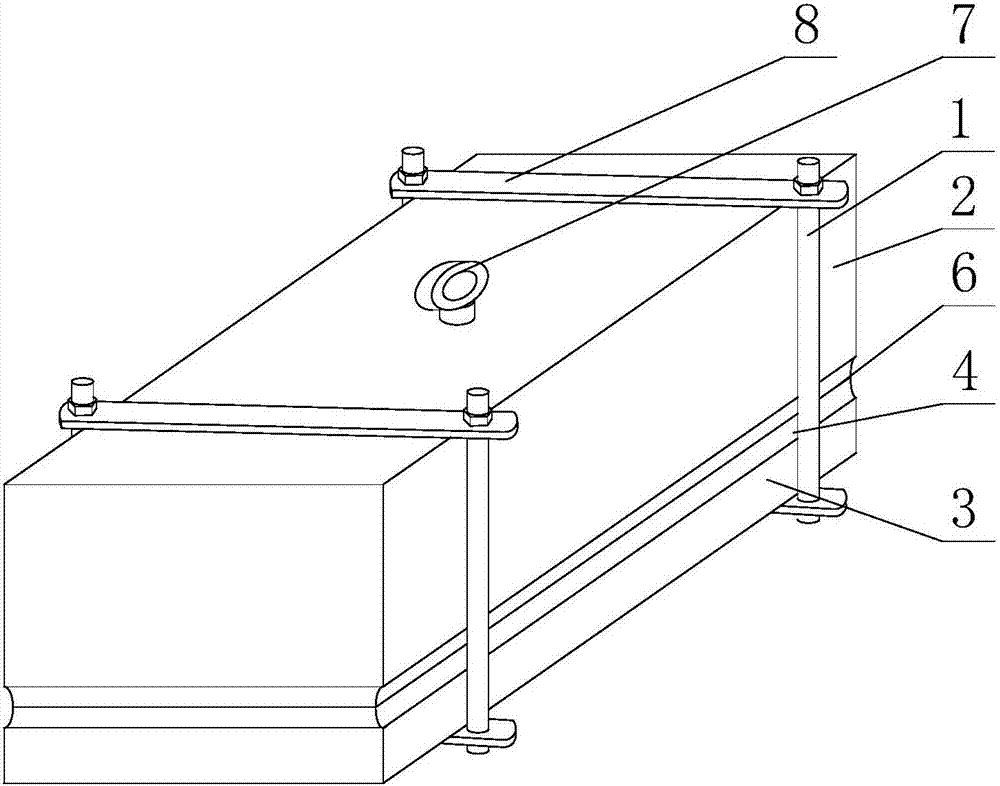

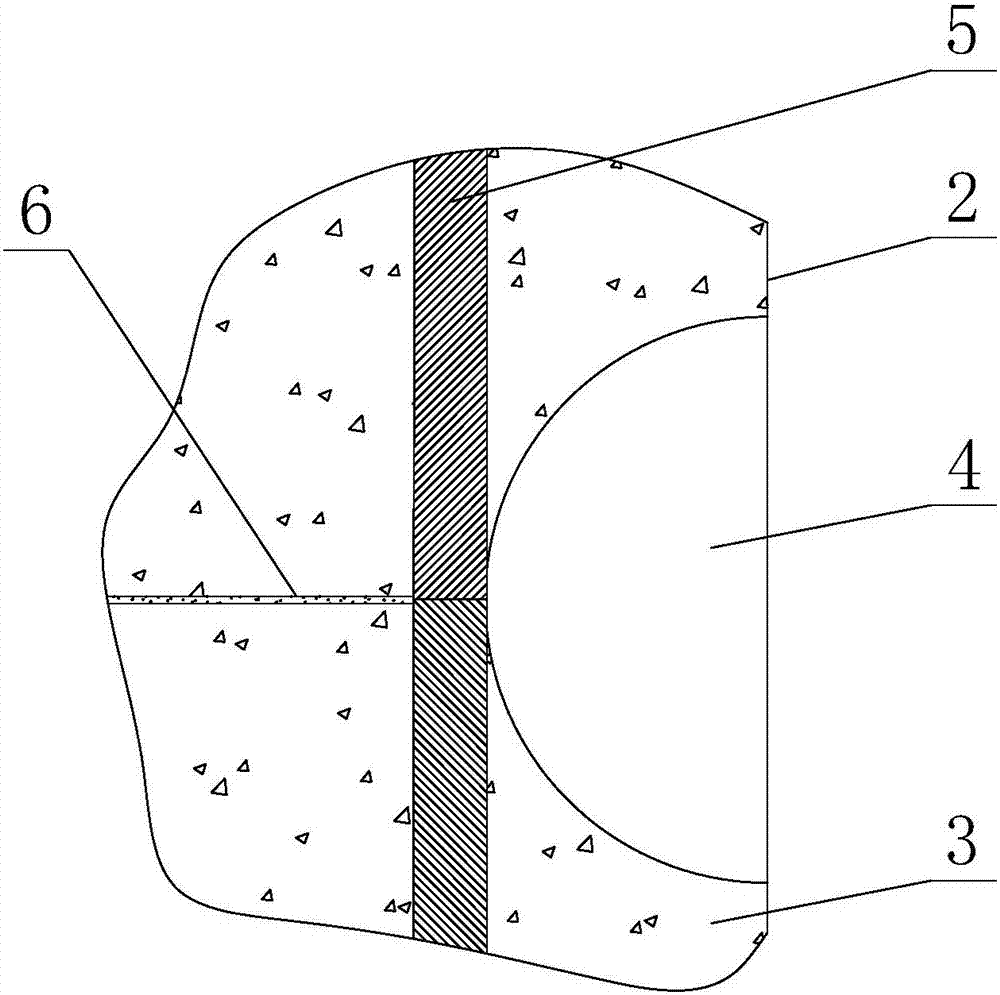

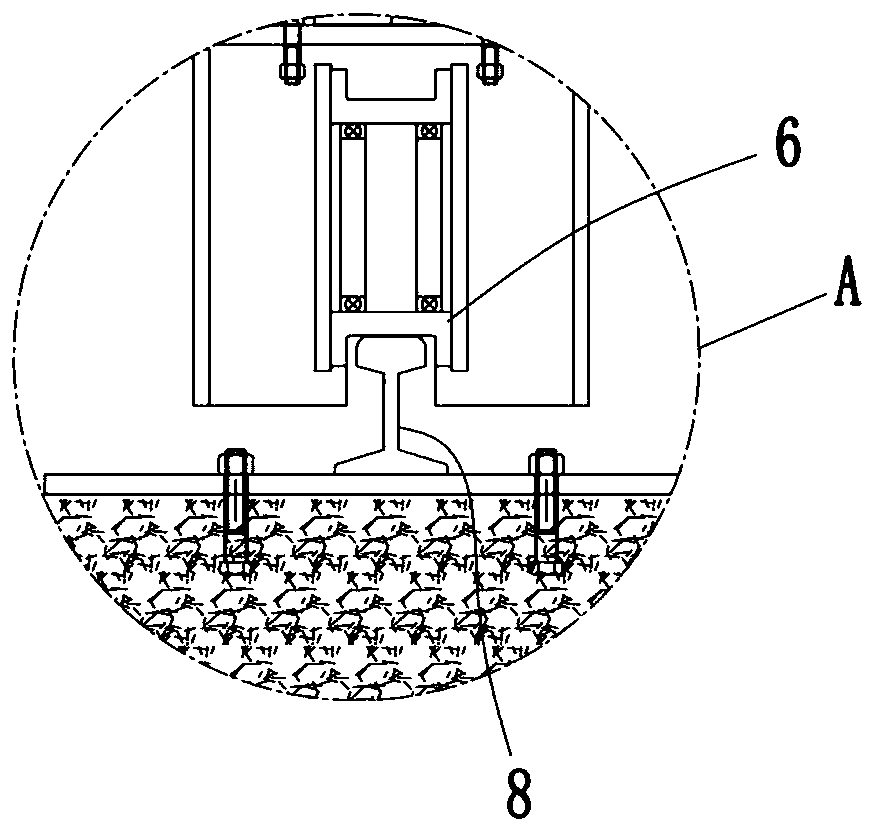

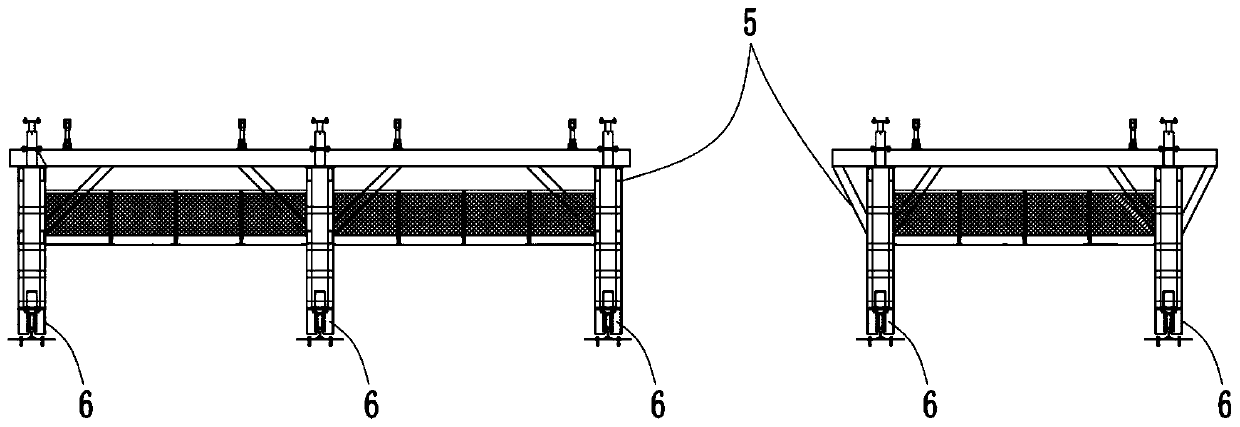

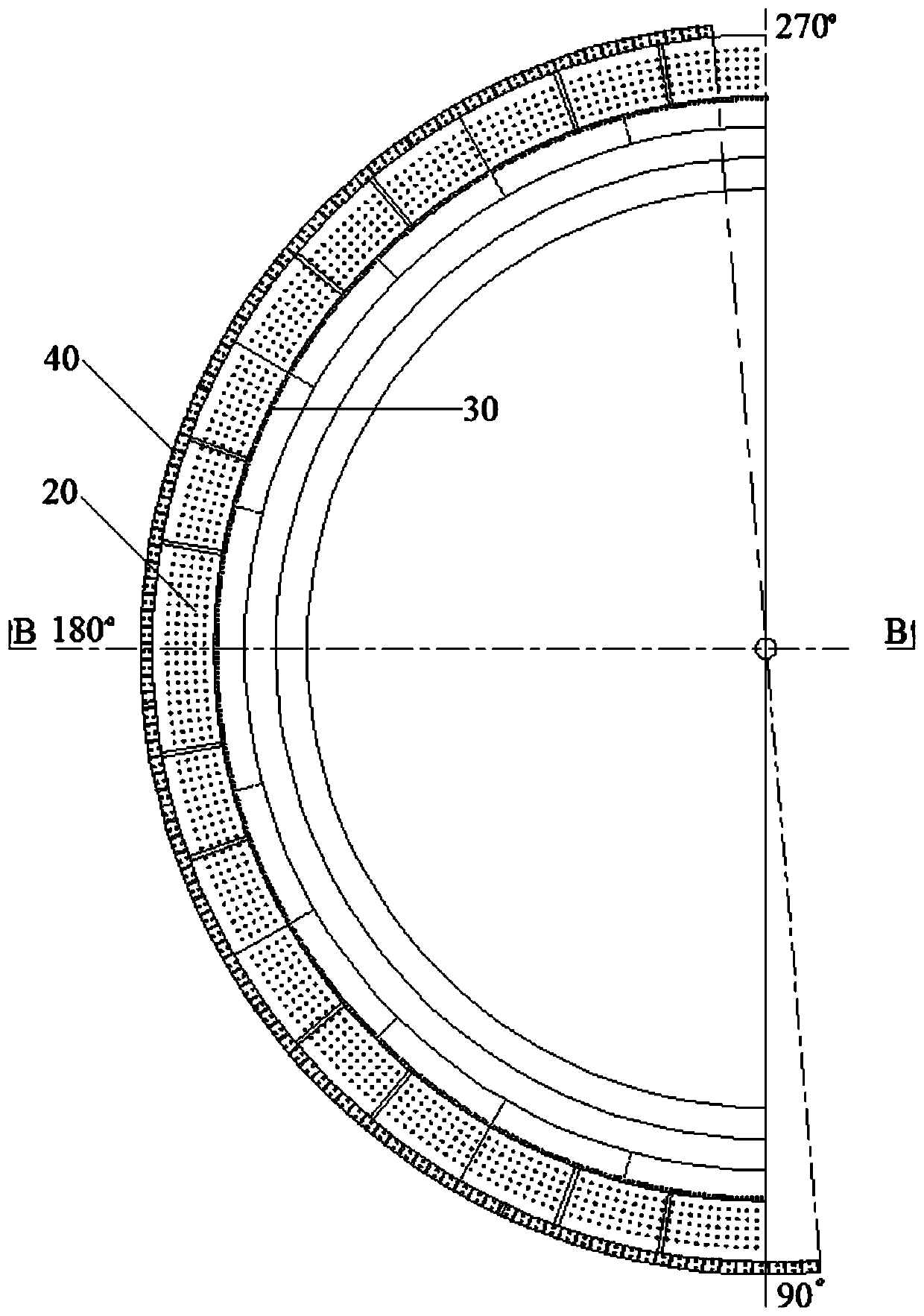

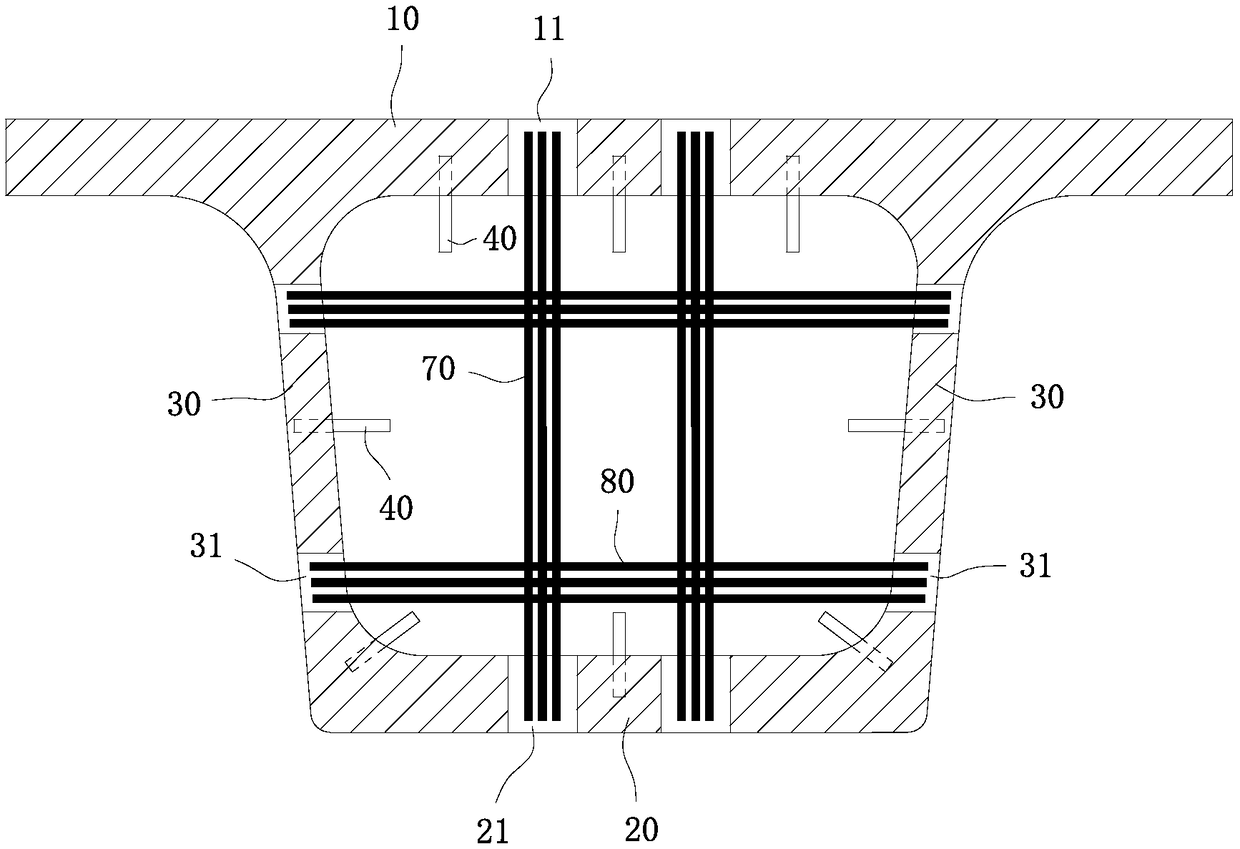

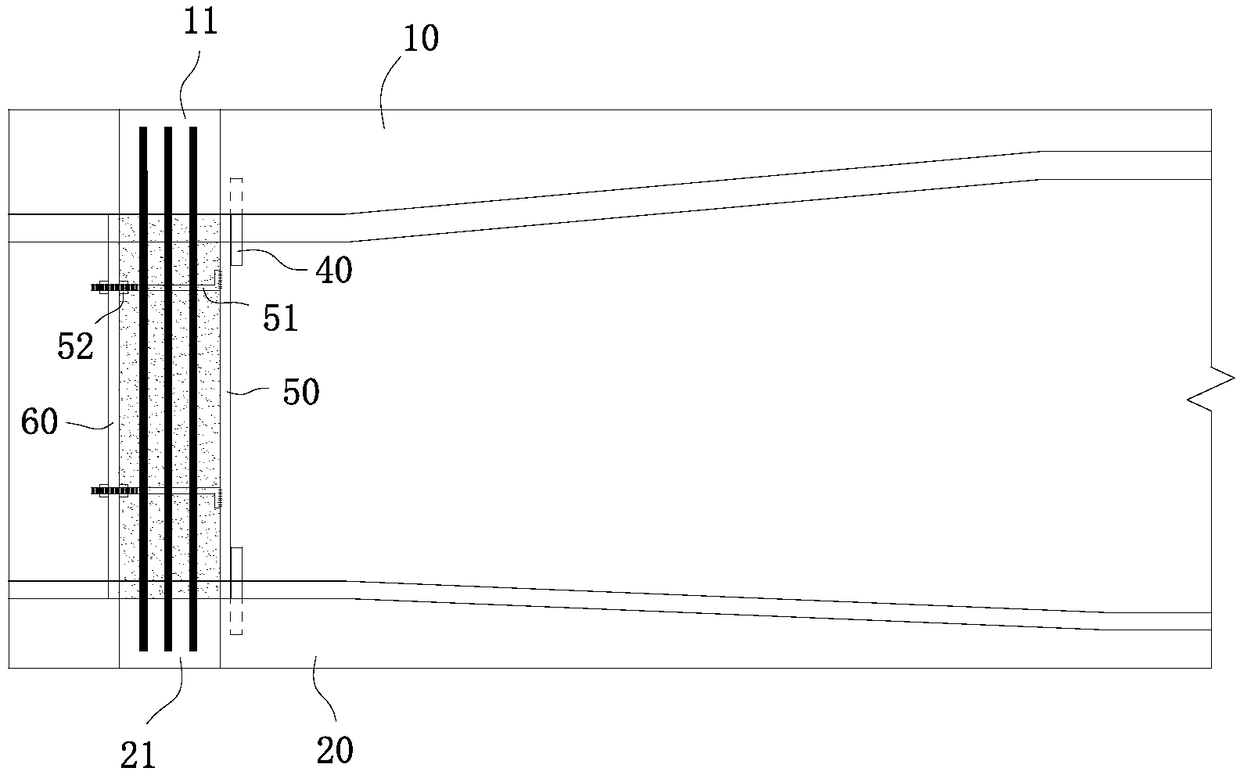

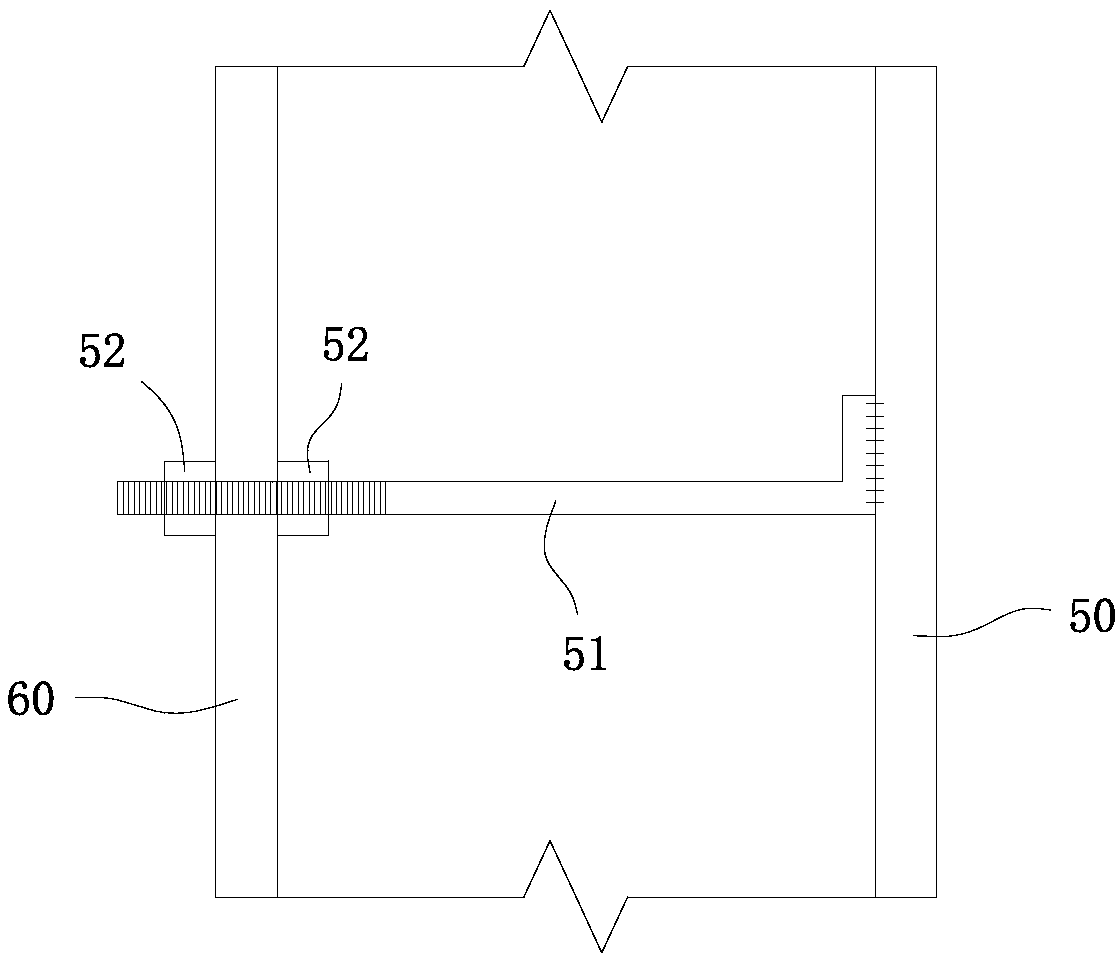

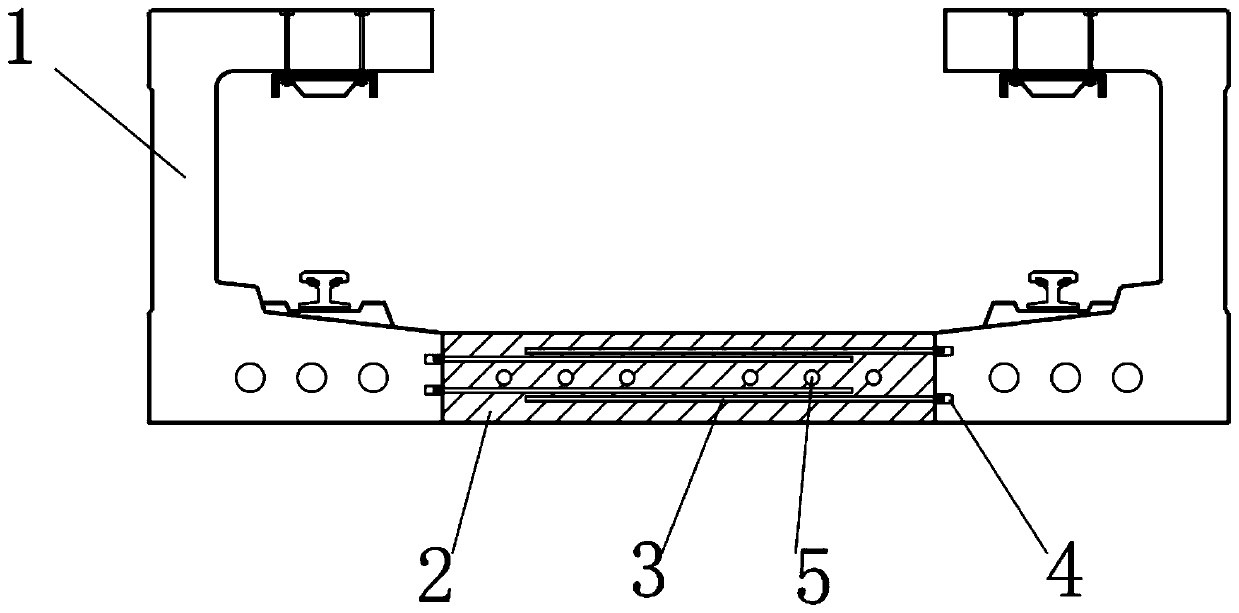

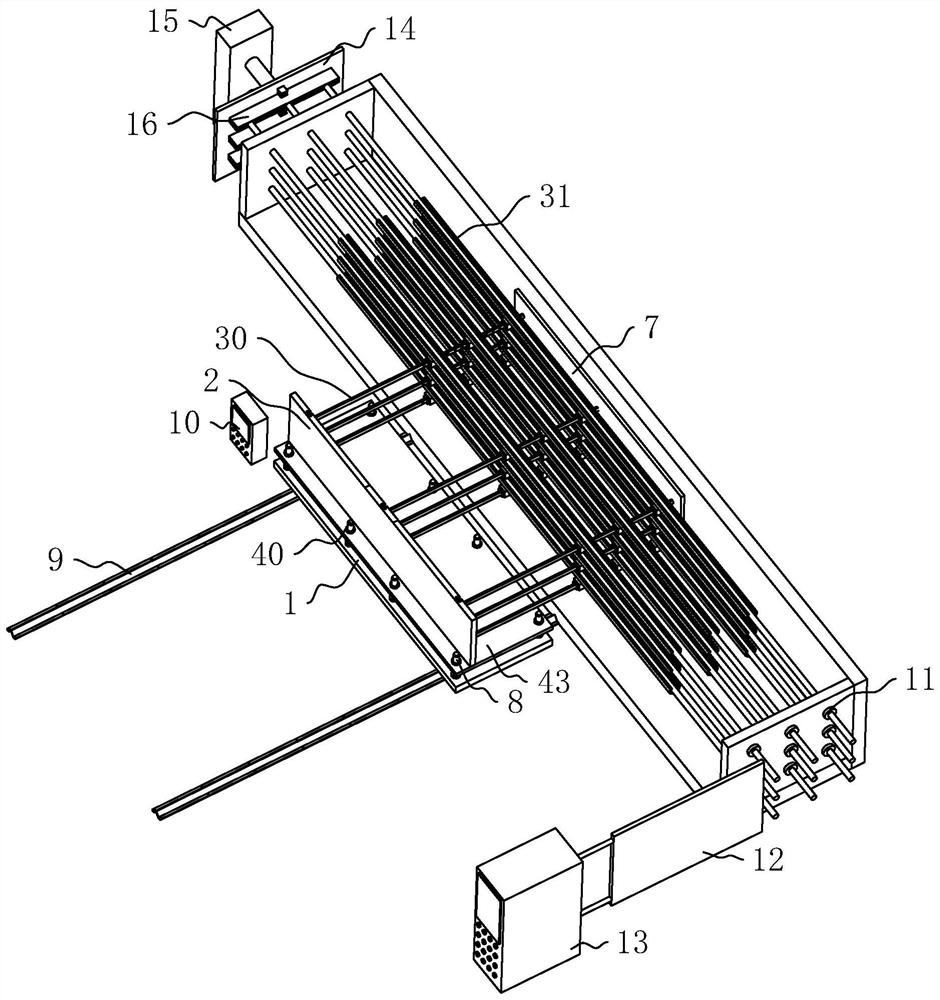

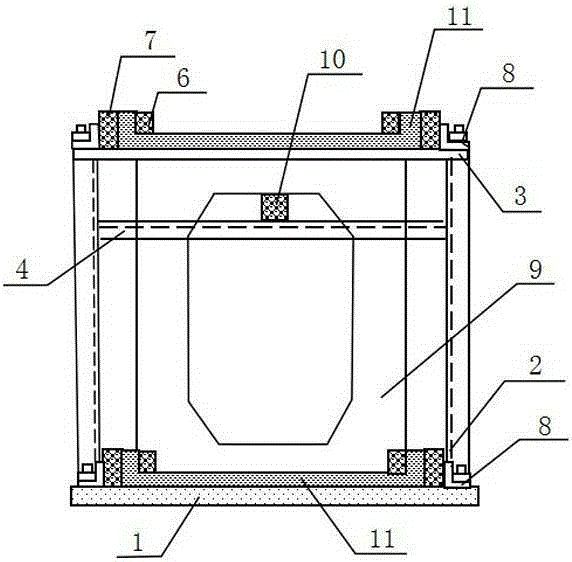

Automatic template system for maglev curve track beam and use method of automatic template system

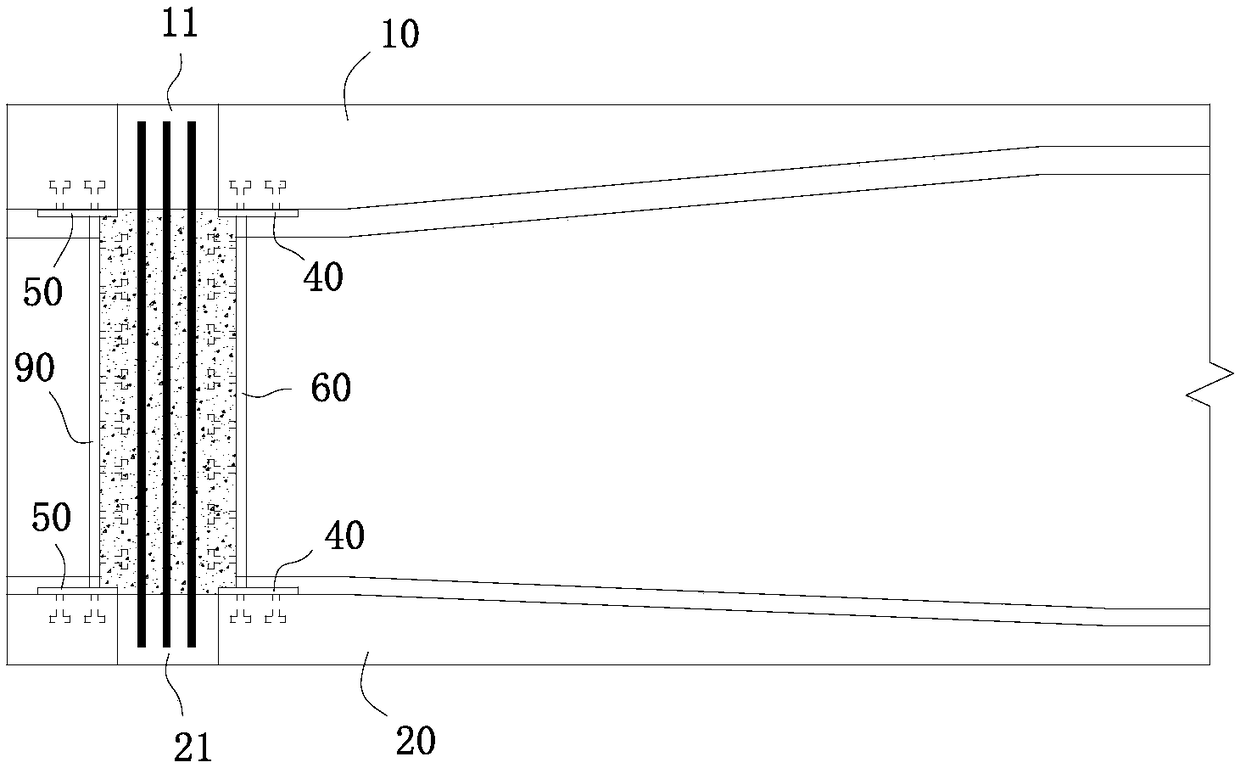

InactiveCN104999547AImprove prefabrication efficiencyImprove efficiencyMould separation apparatusMouldsLow speedLateral displacement

The invention discloses an automatic template system for a maglev curve track beam and an use method of the automatic template system. The template system comprises a bottom die, a side die, end dies, a regulating component and a control component, wherein the bottom die is used for bearing the track beam; the side die comprises flexible side die panels arranged along the two longitudinal sides of the track beam, and a plurality of frameworks are arranged on the outer side of each side die panel; the end dies are arranged at the two end parts of the track beam, and each end die is provided with a translational assembly which can enable the end die to translate in the longitudinal direction of the track beam; the regulating component comprises at least two electric push rod assemblies on the outer side of each framework, each electric push rod assembly is used for regulating the lateral displacement relative to the track beam and the perpendicularity relative to the bottom die of the corresponding framework position; the control component is used for controlling and regulating each electric push rod assembly and each translational assembly. The side die curvature of each electric push rod assembly is automatically regulated through the control component, and the template system is high in regulation precision, high in efficiency and good in reliability due to the intelligent control, can be recycled, is energy-saved and environmental-friendly, and is particularly appropriate for prefabrication of medium and low speed curve track beams.

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD

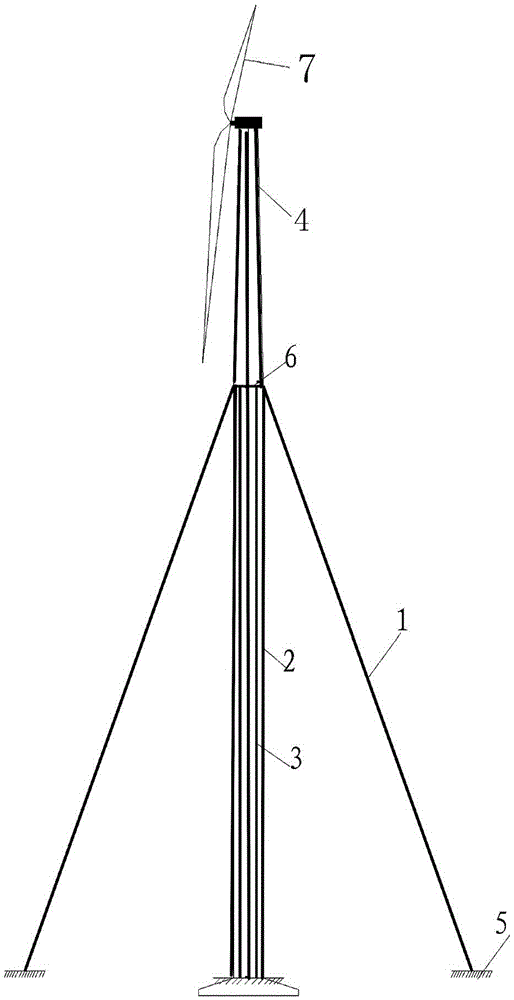

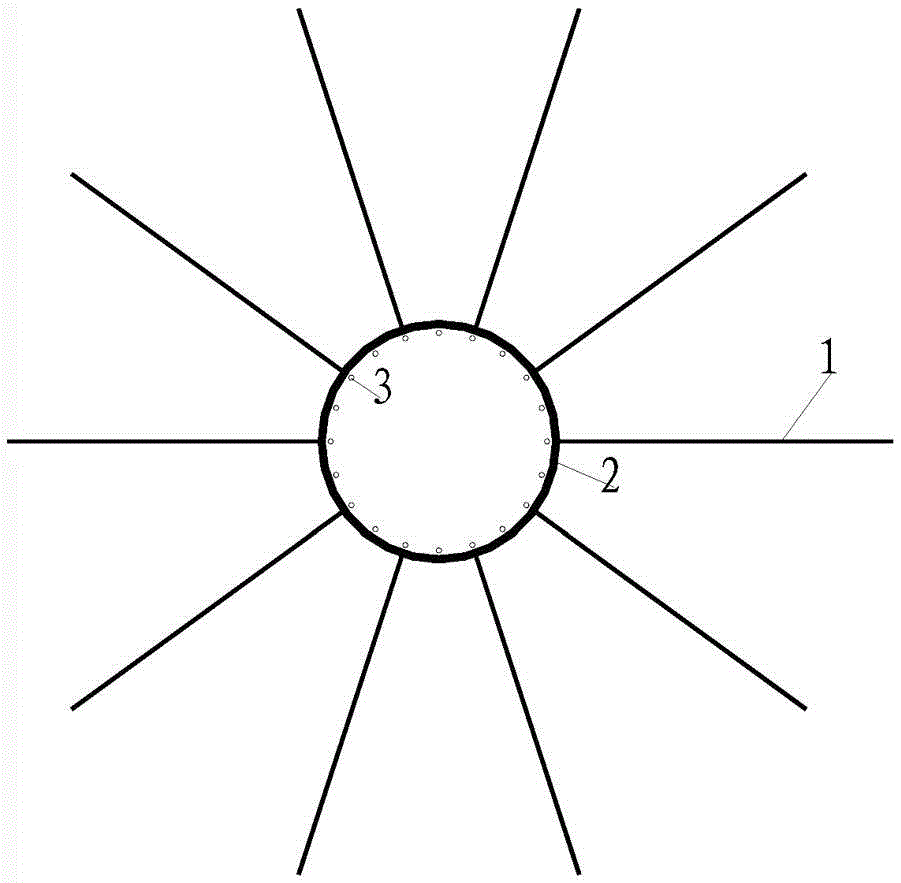

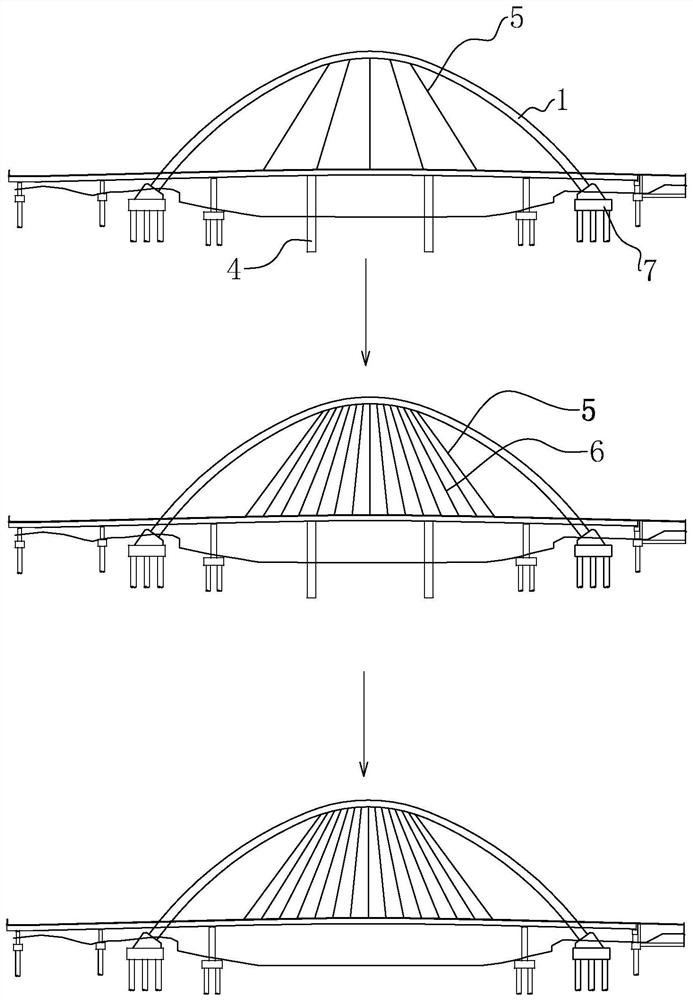

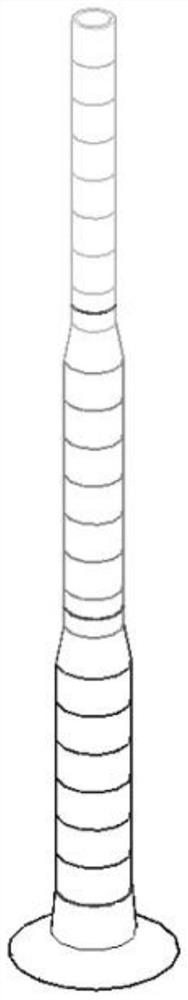

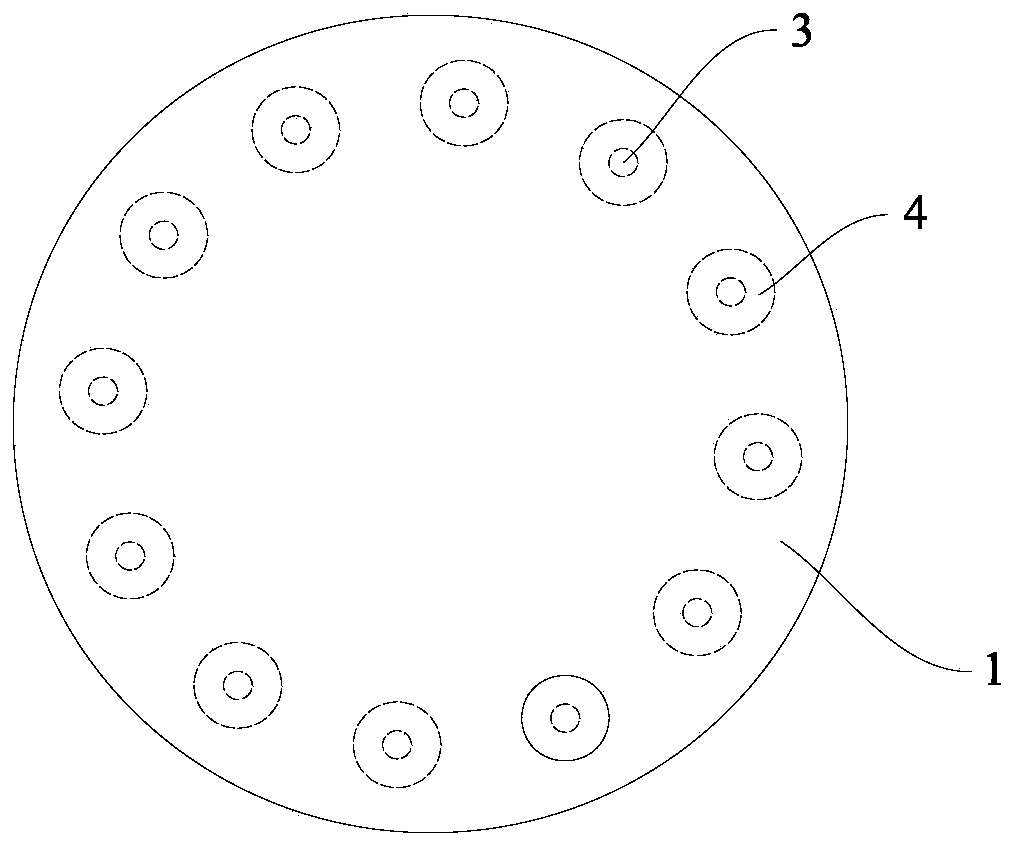

Prestressed concrete wind power tower system and construction method thereof

InactiveCN105179183ASave money on templatesImprove prefabrication efficiencyWind motor componentsWind drivenPre stress

The invention discloses a prestressed concrete wind power tower system and a construction method thereof. The prestressed concrete wind power tower system is characterized in that the upper end of a tower main body is connected to a wind driven generator; the tower main body is formed by sleeve connection of a concrete tower drum located at the lower part and a steel tower section located at the lower part; the tower main body is tied by prestressed cables for fixation; the prestressed cables comprise vertical prestressed tendons arranged inside the concrete tower drum at the lower part and slant prestressed cables arranged outside the concrete tower drum at the lower part; the upper ends of both the vertical prestressed tendons and the slant prestressed cables are anchored on a flange at the bottom of the steel tower section at the upper part; and the lower ends of the slant prestressed cables are fixedly connected to an anti-pulling foundation, and the lower ends of the vertical prestressed tendons are in anchor connection with a pedestal of the concrete tower drum. The wind power tower system has the beneficial effects that template engineering can be simplified to the maximum extent, the template cost of the tower structure is reduced, the prefabrication work in a factory prefabrication stage can be substantially simplified, and the efficiency of factory prefabrication is improved.

Owner:CHINA AVIATION PLANNING & DESIGN INST GRP

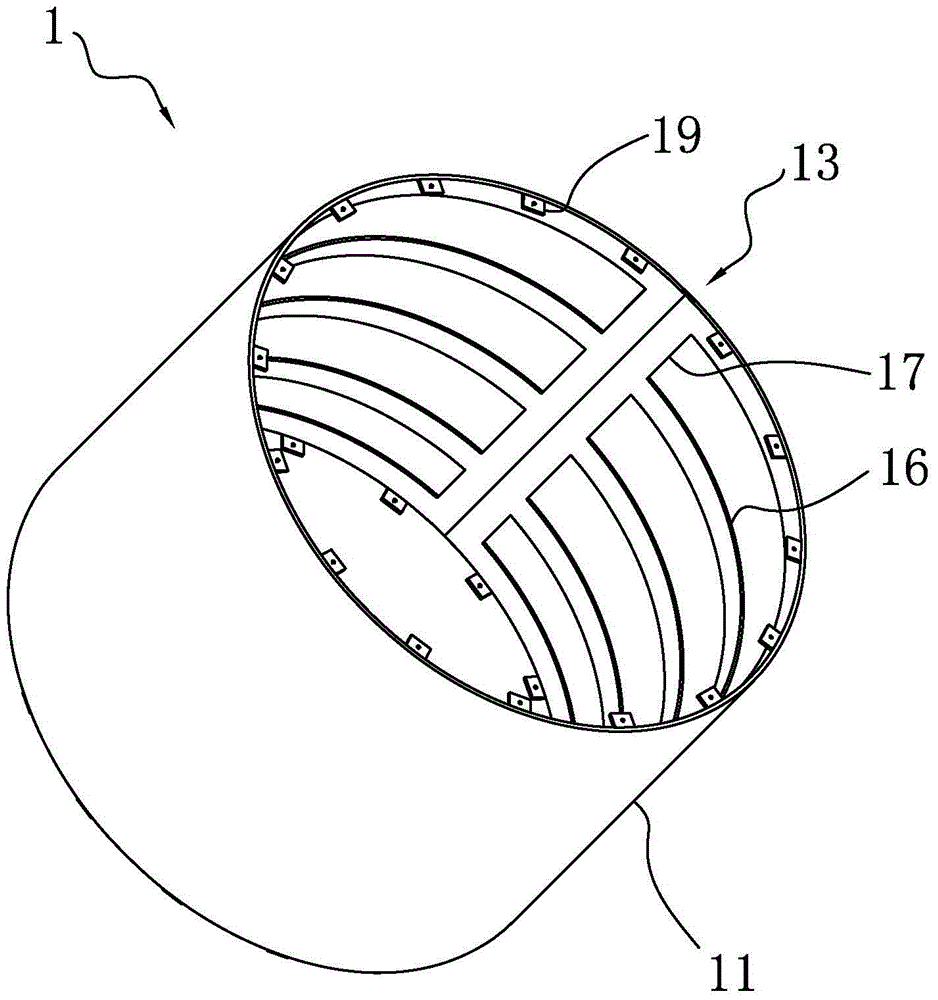

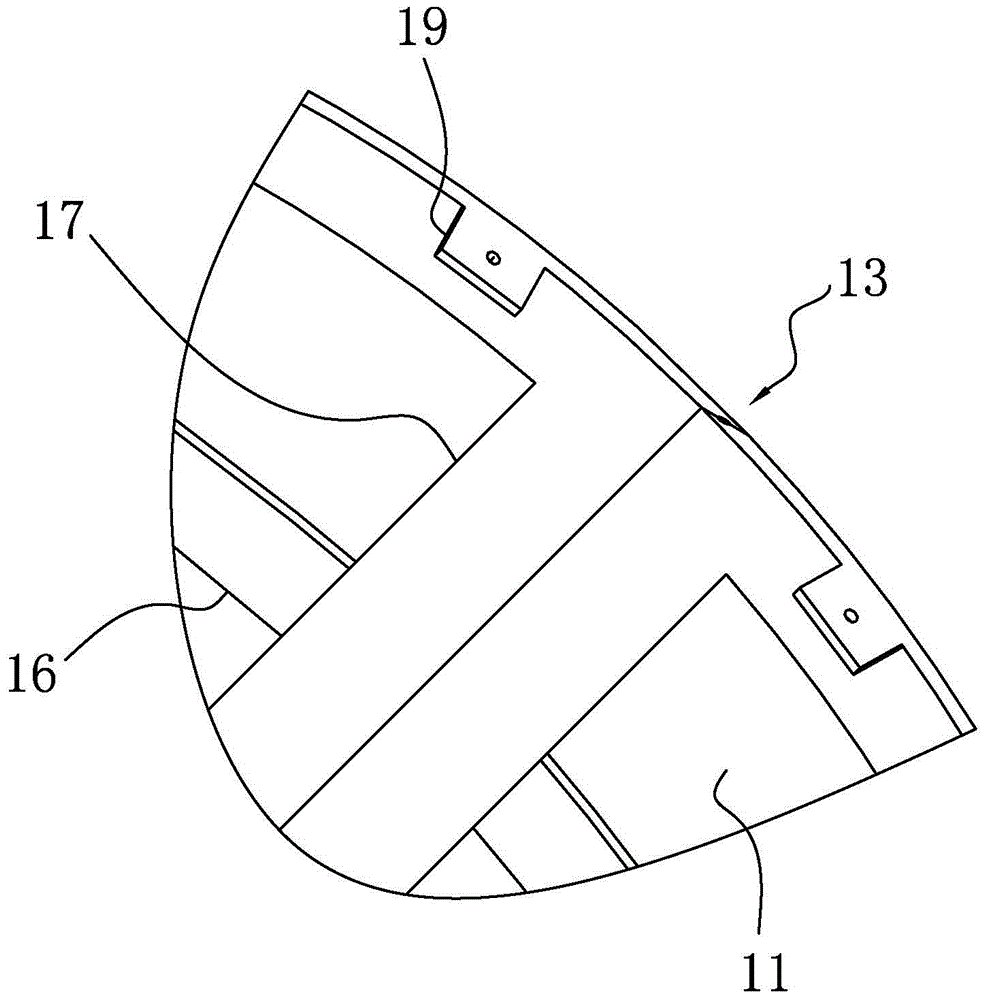

Internal mould, demoulding method thereof, mould for prefabricated concrete tower sections and production method

The invention provides an internal mould, a demoulding method thereof, a mould for prefabricated concrete tower sections and a production method. The internal mould provided by the invention comprises an internal formwork, both ends of the internal formwork are connected, so that the internal formwork is curved into the shape of a barrel, both ends of the internal formwork are provided with slopes, and the slopes of both ends of the internal formwork are matched with each other and form a demoulding opening. The demoulding method of the internal mould provided by the invention includes the following step: one end, which is located inside the demoulding opening, of the internal formwork is moved simultaneously along the radial direction and tangent direction of the internal mould to get close to the center of the internal mould and extend into the space in the internal formwork. The internal mould provided by the invention can be used for casting a whole ring, the overall elastic deformation of the internal formwork can be conveniently utilized to implement the demoulding and restoration of the internal mould, and a great deal of welding work can be reduced.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Hoisting technology for turning over of tower

ActiveCN109502480ASolve the problem of not being able to carry all hoistsImprove prefabrication efficiencyLoad-engaging elementsEngineeringTower

The invention provides a hoisting technology of turning over of a tower. The hoisting technology comprises the steps that the tower is prefabricated on a cup support; the tower is transported to a spraying workshop to be sprayed; 3, an auxiliary scaffold and a straight ladder are arranged on a deck of the top of the tower; 4, on a gantry crane, hoisting ropes are connected to a hoisting point anda supporting rod of the tower correspondingly; 5, an upper trolley hoisting hook and a lower trolley hoisting hook of the gantry crane are lifted up at the same time until the tower is at a vertical state; 6, the position of the tower is adjusted to be consistent with the direction and position after installation; 7, a head of the lower trolley hoisting hook is installed in place, and the tower isinstalled to the corresponding position of a module and fixed; and 8, after safety ropes are connected, buckles are disassembled. According to the hoisting technology, the problems of erection, angleadjustment and in-place installation of the tower are solved, and the overall prefabrication efficiency of the tower is improved greatly; moreover, the problems that the tower is divided and prefabricated, and tower accessories cannot be carried and hoisted completely are solved; and the structure completeness of the tower in the whole construction process is ensured, and the safety in the towerprefabrication process is improved.

Owner:OFFSHORE OIL ENG QINGDAO +1

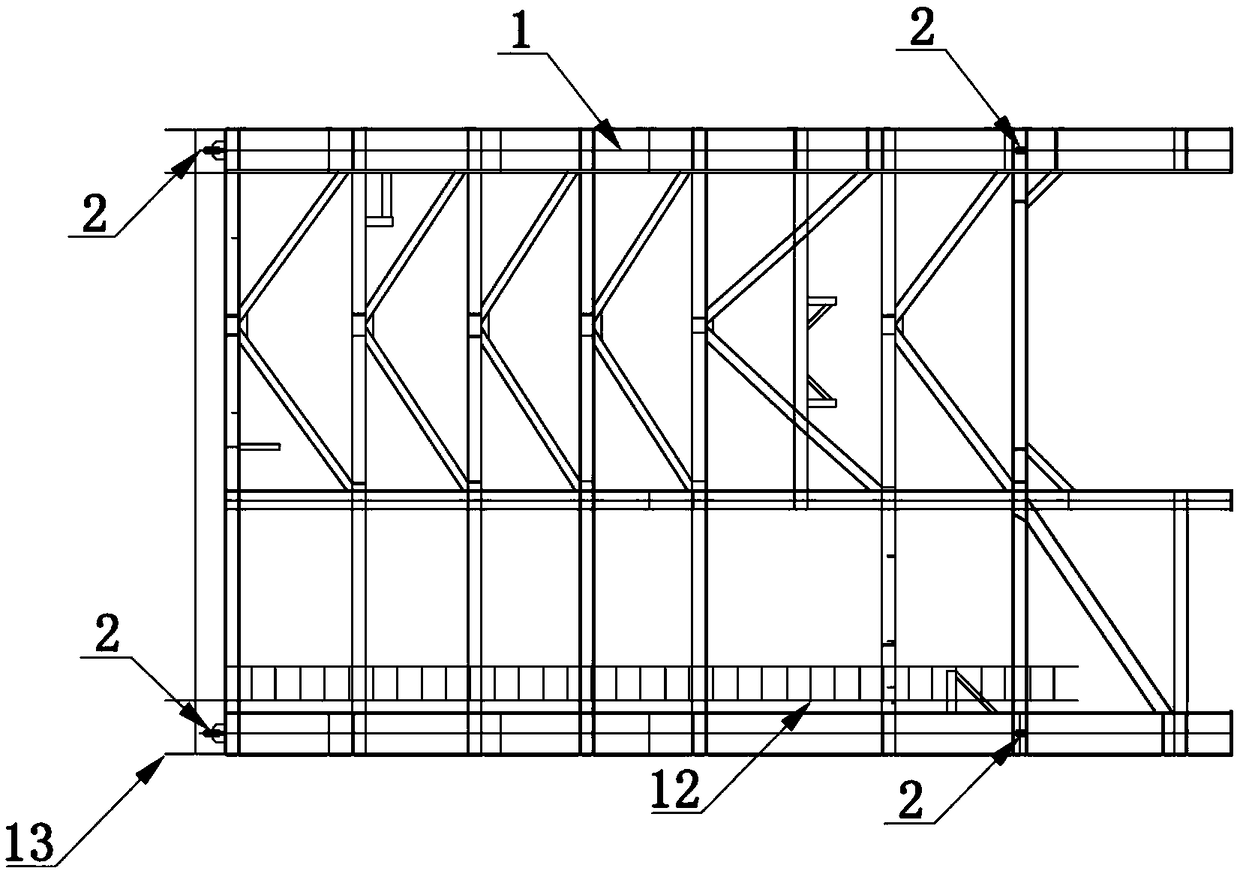

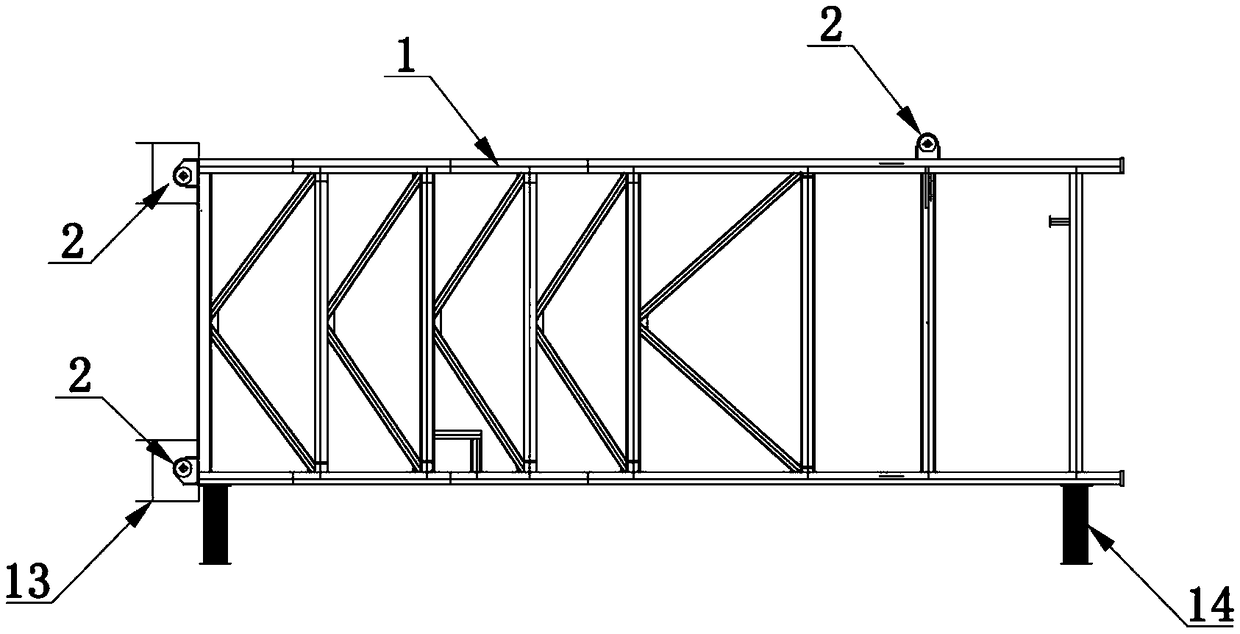

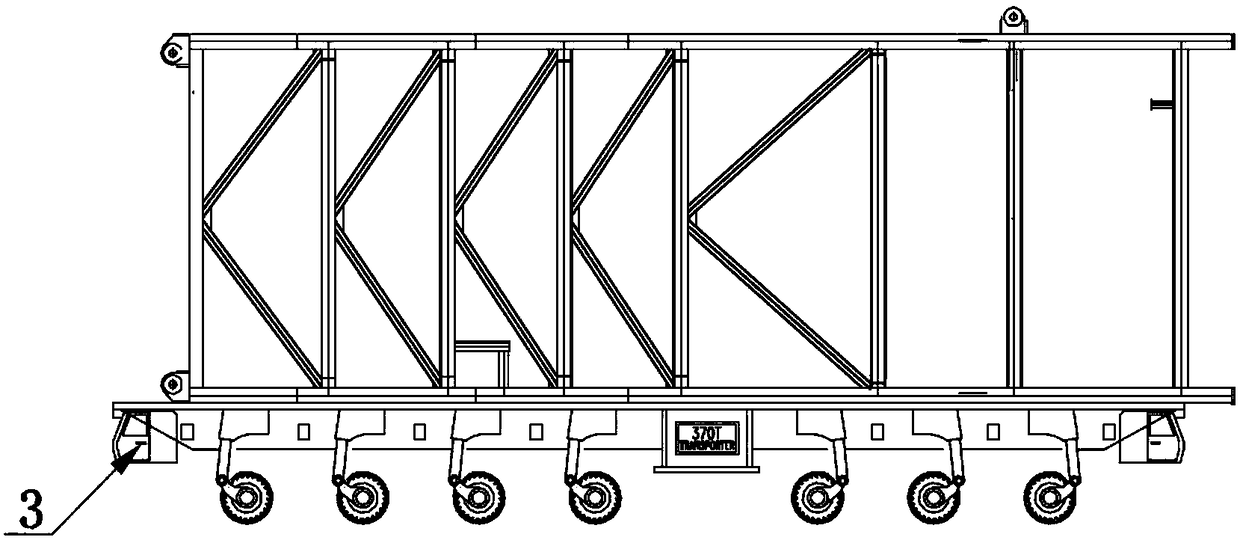

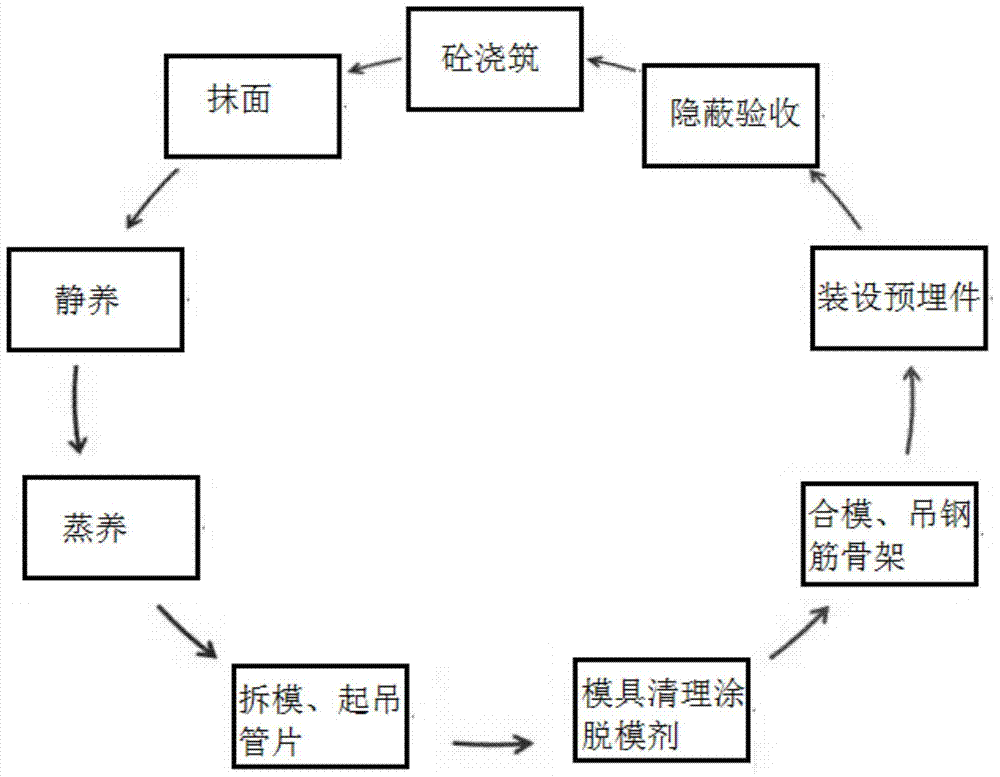

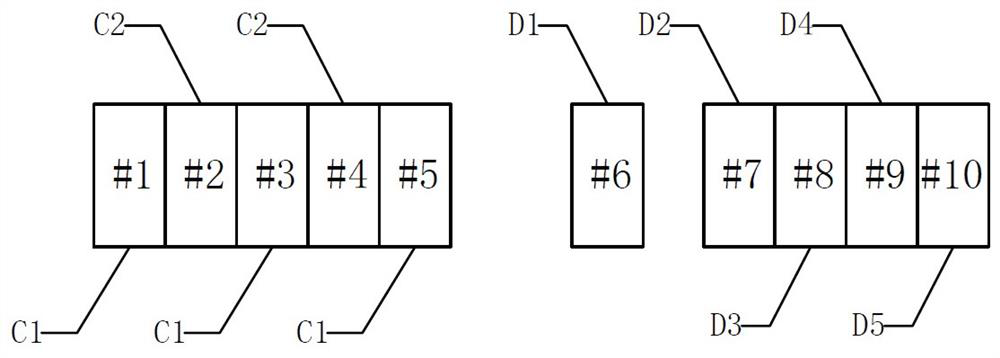

Shield tunnel segment prefabrication method

InactiveCN104708708AImprove precast production efficiencyHigh turnover utilizationCeramic shaping plantsEngineeringPrefabrication

The invention discloses a shield tunnel segment prefabrication method. The prefabrication method is implemented on the basis of at least one pouring line and at least one maintenance line. According to the prefabrication method, ferry vehicles are used for pushing molds completing pouring on the pouring line into the maintenance line for steam maintenance, meanwhile, molds completing steam maintenance on the maintenance line are pushed into the pouring line for demolding and repouring, and therefore cyclic circulating prefabrication of shield tunnel segments is achieved. By means of the shield tunnel segment prefabrication method, streamlined and automated production of the shield tunnel segments can be achieved, so the production efficiency of the shield tunnel segments is effectively improved, and the production cost of the shield tunnel segments is effectively lowered.

Owner:CCCC THIRD HARBOR ENG +1

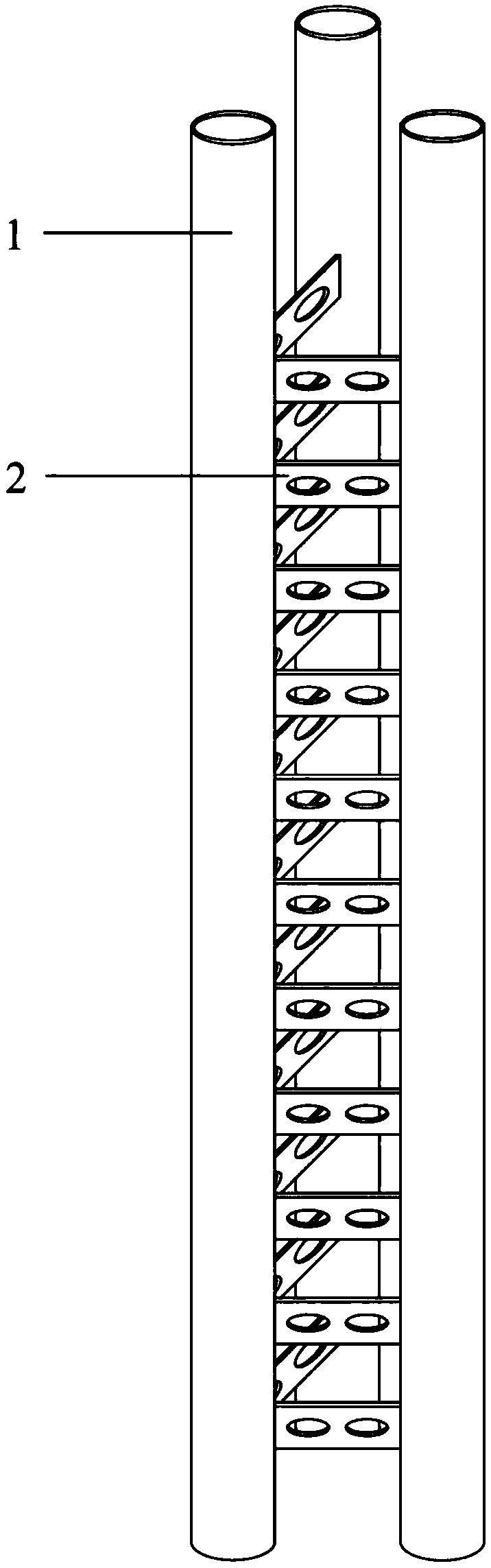

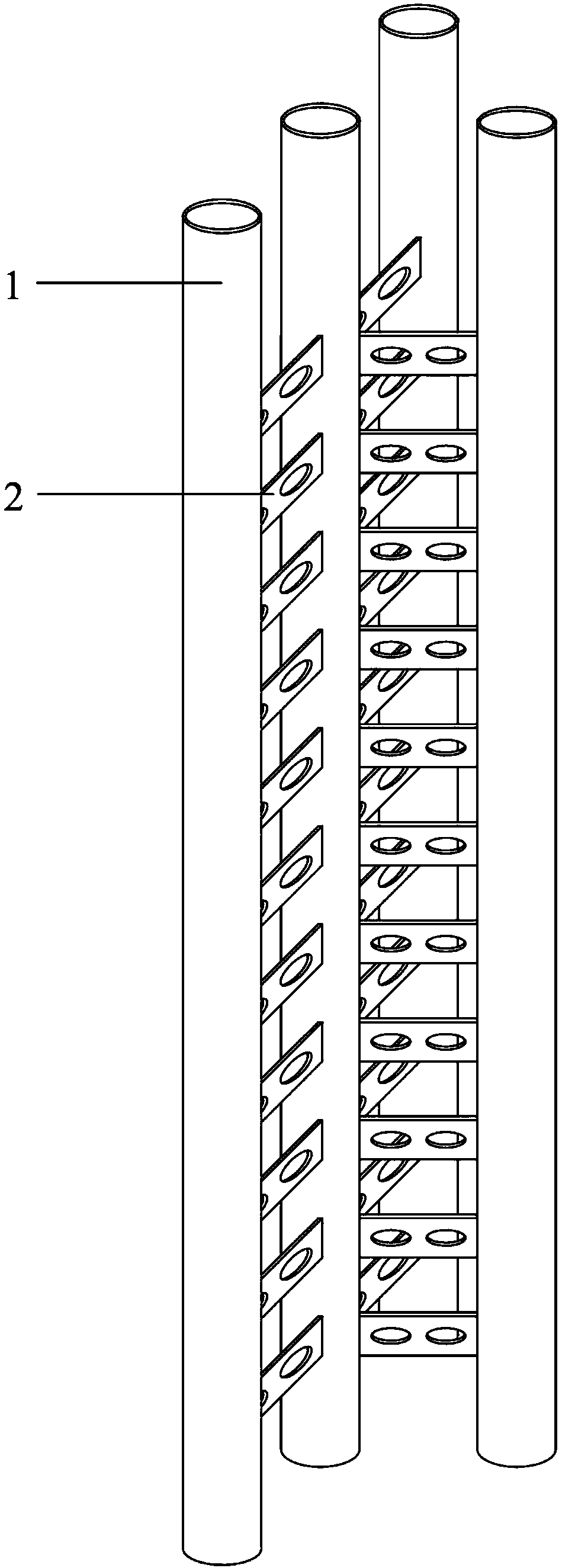

Assembled frame system with concrete filled steel tube branch limb combined special-shaped column and shock absorption wall

ActiveCN109372186AImprove seismic performanceFlexible layoutStrutsWallsEarthquake resistanceReinforced concrete

The invention discloses an assembled frame system with a concrete filled steel tube branch limb combined special-shaped column and a shock absorption wall and belongs to the field of building structure techniques and earthquake resistance and shock absorption of structures. The system primarily comprises a round concrete filled steel tube long column welded steel batten plate, and a prefabricatedcorner column, a prefabricated side column, a prefabricated middle column, a reinforced concrete beam, a steel plate wall, a prefabricated steel floorslab, a column-column connecting sleeve, a column-beam anchoring part, a middle column-beam anchoring part, a beam-plate connecting part, ECC post-cast strips and the like prepared by pouring concrete outside. Upper and lower concrete filled steel tubes are connected through the column-column connecting sleeve, and the column-beam anchoring part, the middle column-beam anchoring part and the round concrete filled steel tube long column are connected and prefabricated through dowels, so that the beam-column node connecting performance is enhanced. The ECC post-cast strips are arranged at two ends of the beam and the wall and are poured up anddown in a penetrating manner, so that the energy consumption ability and the anti-earthquake performance of the structural system are improved. The assembled frame system achieves the functions of hiding column edges and being attractive in building, a project is simple and rapid to construct, the construction efficiency is high, the nodes are connected stably and reliably, and the structural system is good in anti-earthquake performance.

Owner:BEIJING UNIV OF TECH

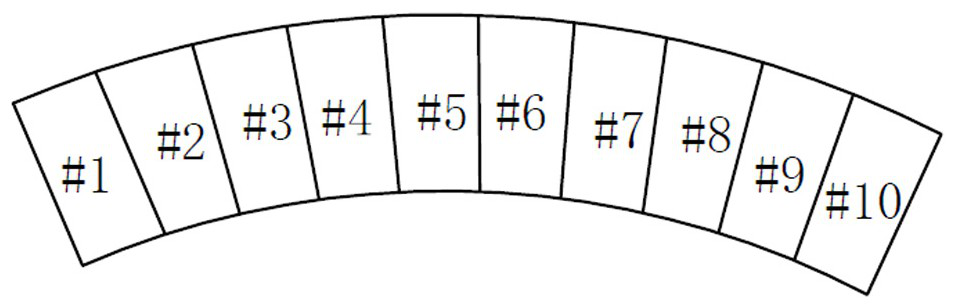

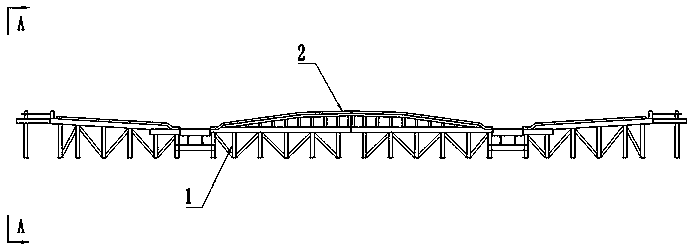

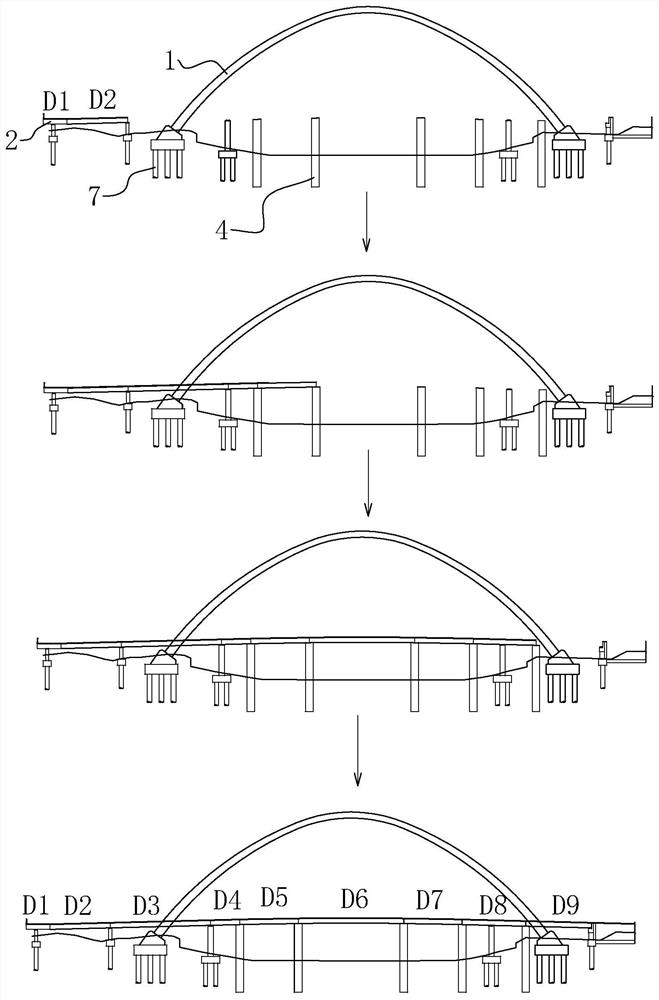

Method of segment prefabricated bridge long and short line method combined bidirectional matching prefabrication

ActiveCN112195781AImprove prefabrication efficiencyOvercome limitationsBridge erection/assemblyLinear controlBridge type

The invention discloses a method of segment prefabricated bridge long and short line method combined bidirectional matching prefabrication, which comprises the following steps of: firstly, distributing box girder segments required to be prefabricated by a long line method and a short line method in the same prefabrication sequence according to a bridge type, and reserving a matching box girder segment for long and short line combined matching pouring in the middle of the prefabrication sequence; wherein prefabricating is conducted from two ends of the prefabrication sequence to the middle direction according to the long line method and the short line method; comparing the line shape of the segment prefabricated by the long line method and the line shape of the segment prefabricated by theshort line method with the designed line shape in all directions of a space coordinate axis to obtain the deviation rectifying amount after the prefabrication of the long line method and the short line method; and placing the measuring point coordinates of two matched sections under the same coordinate system through a professional linear control technology to pour the matched box girder sections.The method is short in construction time, small in occupied construction space and suitable for long line and short line combined matching section prefabrication construction of various kinds of bridge line shape.

Owner:瀚阳国际工程咨询有限公司

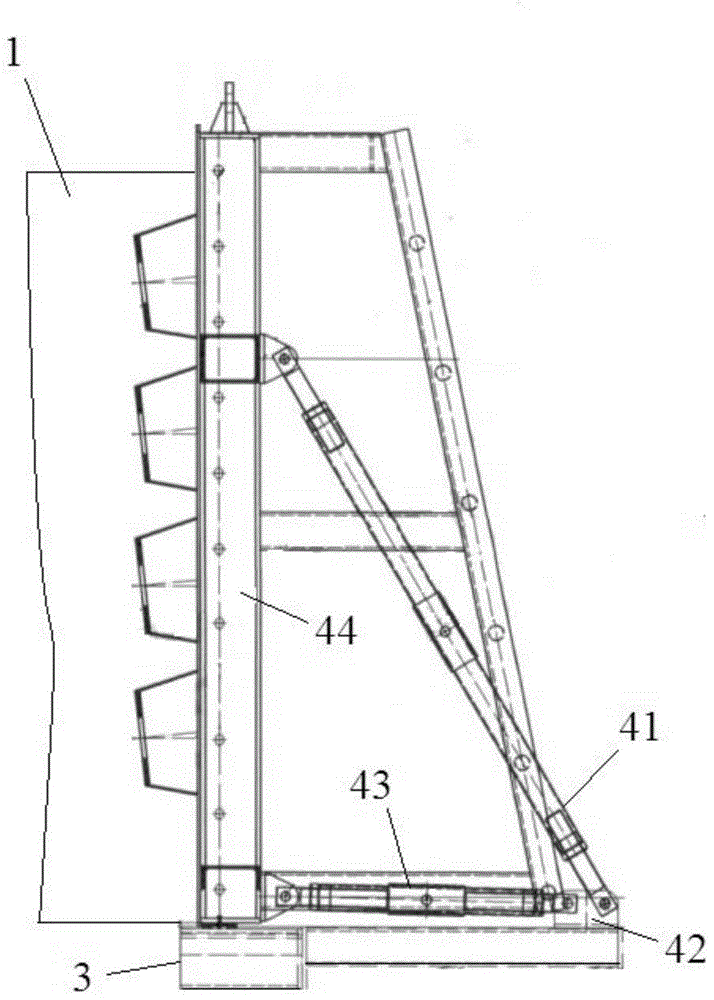

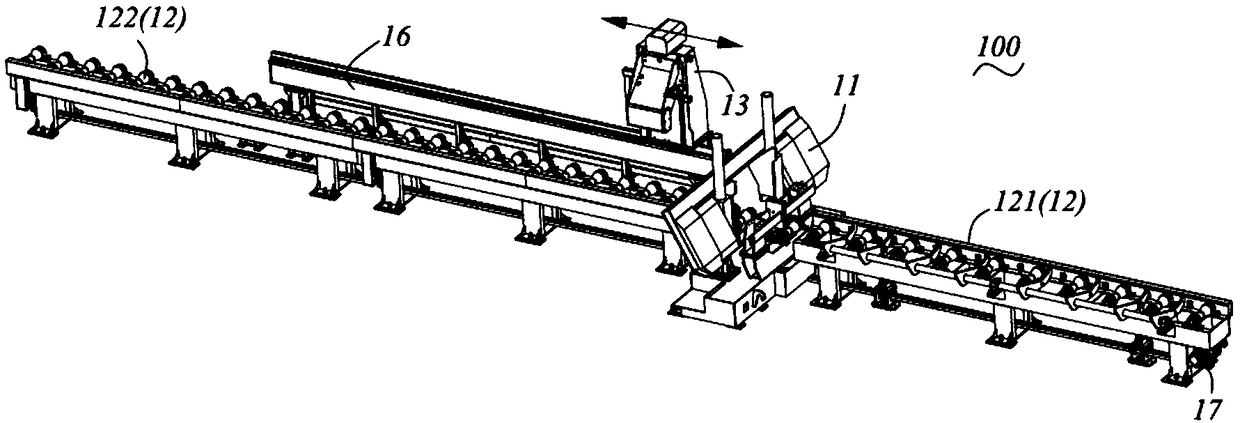

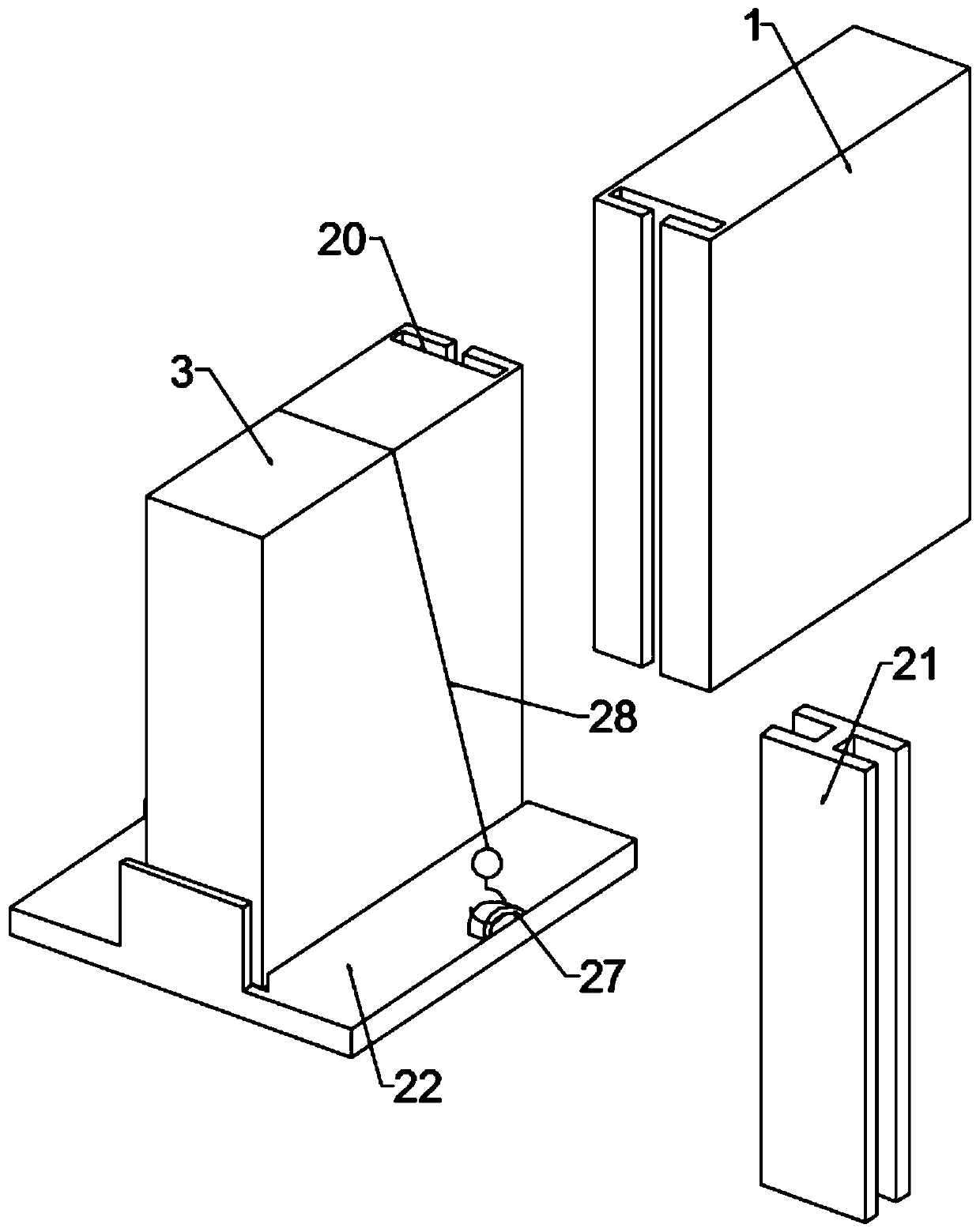

Mechanical template system of curved magnetic levitation track beam and application method of mechanical template system

ActiveCN104999548AImprove prefabrication efficiencyEasy to assemble and disassembleMouldsMould auxillary partsEngineeringLateral displacement

The invention discloses a mechanical template system of a curved magnetic levitation track beam and an application method of the mechanical template system. The mechanical template system comprises a bottom template, a lateral template, end templates and a plurality of regulating components, wherein the bottom template is used for bearing the track beam; the lateral template comprises bendable lateral template panels, the bendable lateral template panels are arranged along two longitudinal sides of the track beam, and a plurality of frameworks are arranged on the outer side of each lateral template panel; the end templates are arranged along the end part of the track beam, and each of the end templates is provided with a translation assembly which can translate the end templates along the track beam in the longitudinal direction; each regulating component comprises at least two mechanical push rod assemblies arranged on the outer side of each framework, and each mechanical push rod assembly is used for regulating the lateral displacement of the corresponding framework relative to the track beam and the perpendicularity of the corresponding framework relative to the bottom template. The template system comprises the bottom template, the lateral template, the end templates, a plurality of the regulating components and the translation assemblies, and is simple in structure, high in regulating efficiency and convenient to mount and dismount; after a template curve is regulated and formed, concrete is directly poured so as to form the track beam, so that the prefabricated efficiency of the track beam is improved; the application method is simple, high in accuracy and good in reliability, so that the prefabricated quality of the track beam is ensured.

Owner:CHINA RAILWAY 23RD CONSTR BUREAU LTD

Fabricated bridge deck slab construction method through combination matching of long and short lines and precast segments

PendingCN110029580AEliminate measurement errorsEliminate construction errorsBridge structural detailsBridge erection/assemblySocial benefitsBridge deck

The invention discloses a fabricated bridge deck slab construction method through combination matching of long and short lines and precast segments. The method has the characteristics that single internode bridge deck slabs are matched and prefabricated through a long line method, and different internode bridge deck slabs are matched and prefabricated through a short line method. The method includes the three steps of framework configuration, standard internode bridge deck slab prefabrication and special-shaped internode bridge deck slab prefabrication. The method has the advantages of high prefabrication efficiency, easy control of precision, adaptability to horizontal curves and vertical curves, framework recycling, and good economic and social benefits.

Owner:THE 5TH ENG MBEC

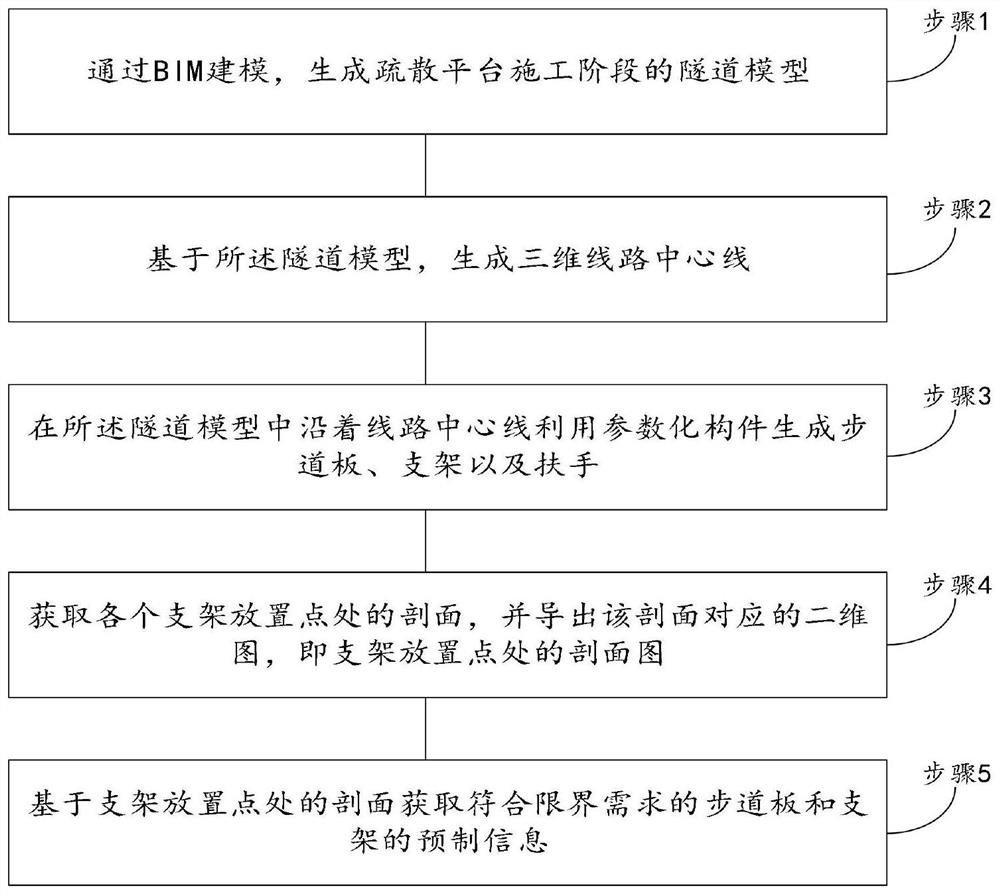

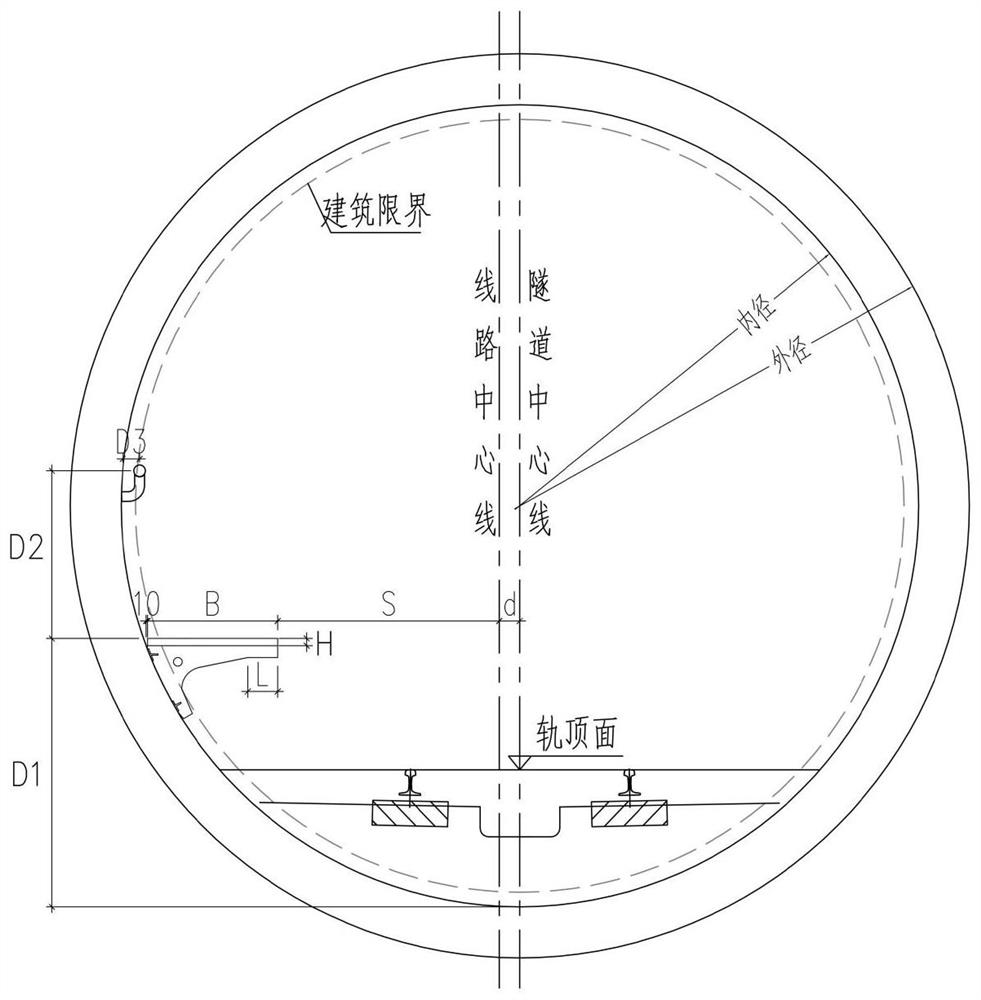

Shield interval evacuation platform pre-assembly method based on BIM technology

InactiveCN112324454ASimplify the installation processEasy accessGeometric CADTunnelsIndustrial engineeringHandrail

The invention discloses a shield interval evacuation platform pre-assembly method based on a BIM technology. The shield interval evacuation platform pre-assembly method comprises the steps of generating a tunnel model in the evacuation platform construction stage through BIM modeling, generating a three-dimensional line center line based on the tunnel model, generating footpath plates, supports and handrails in the tunnel model along the center line, obtaining a profile at every support placement points, exporting a two-dimensional graph corresponding to the profile, namely a profile graph atthe support placement point, acquiring prefabricated information of the footpath plates and the supports meeting limit requirements based on the profile of the support placement points, and performingcollision inspection on support anchor bolts, handrail anchor bolts, hand holes and other duct piece structures. According to the method, the prefabricated information, meeting the limit requirements, of the footpath plates and the supports can be rapidly obtained, collision inspection of the supports and the handrails versus the hand holes, circular seams and longitudinal seams can be conductedin advance, and the problems that in traditional evacuation platform installation engineering, positioning information is inaccurate, the prefabricated information collection efficiency is low, and collision situation cannot be pre-judged are solved.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

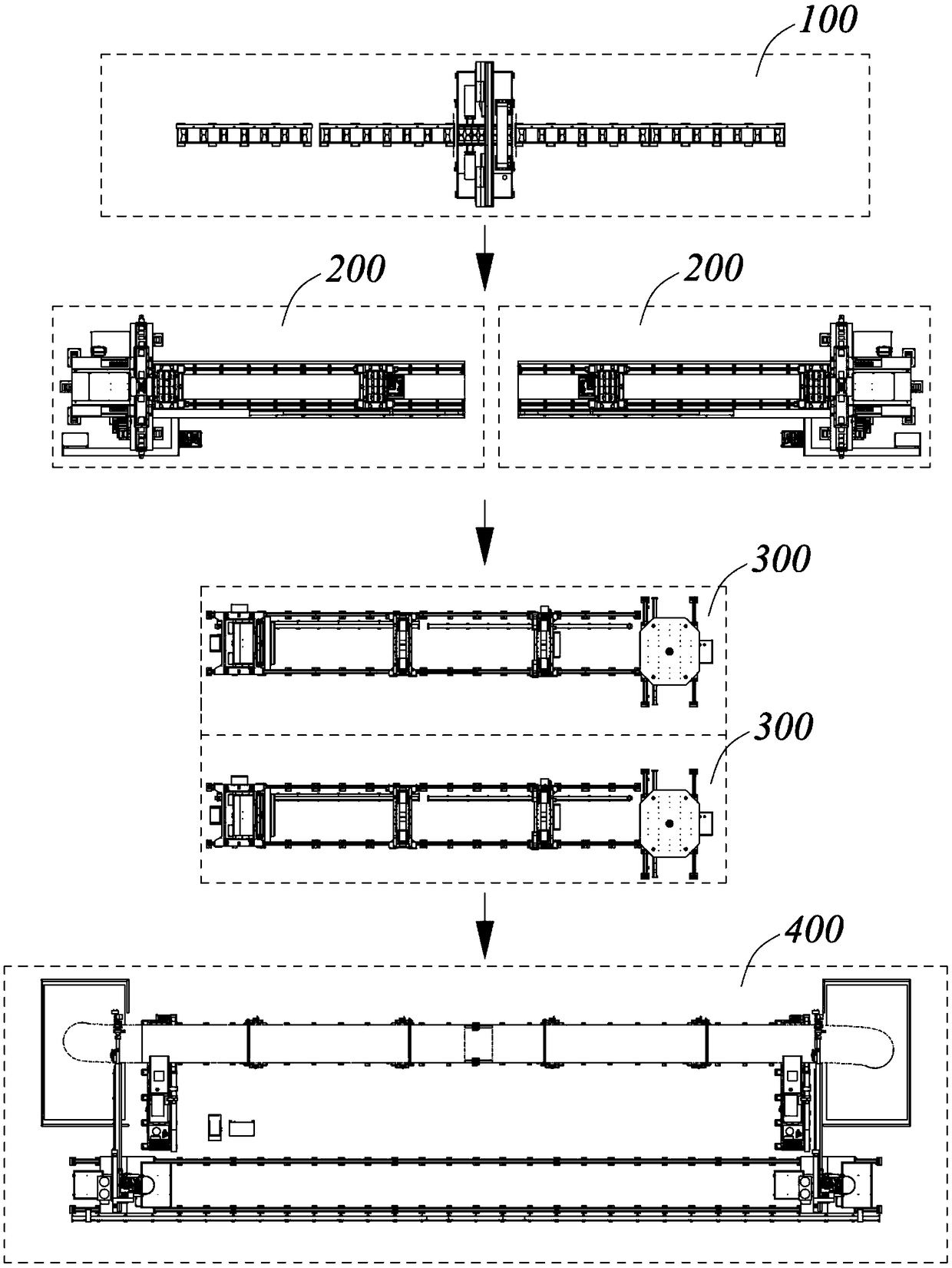

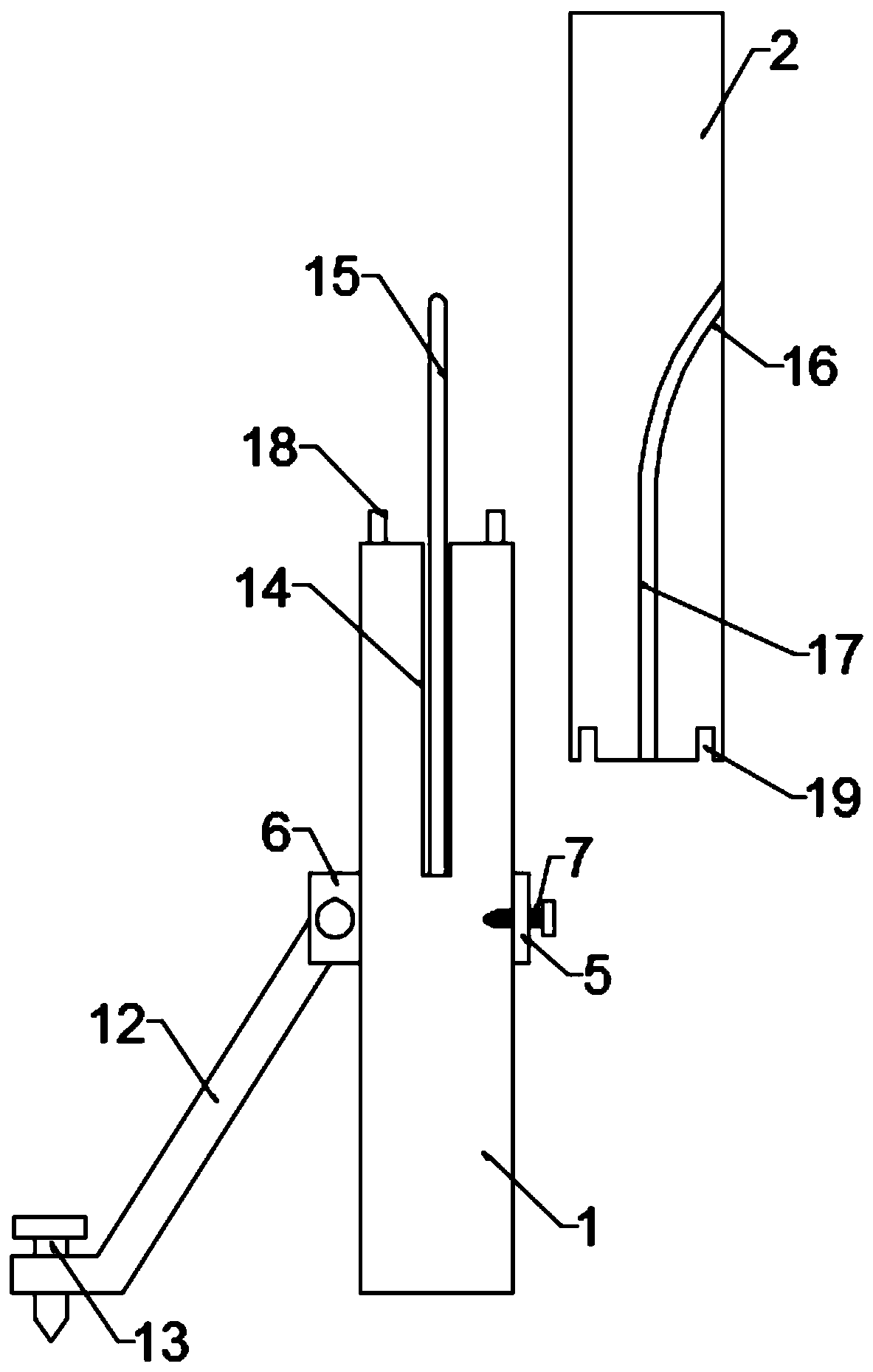

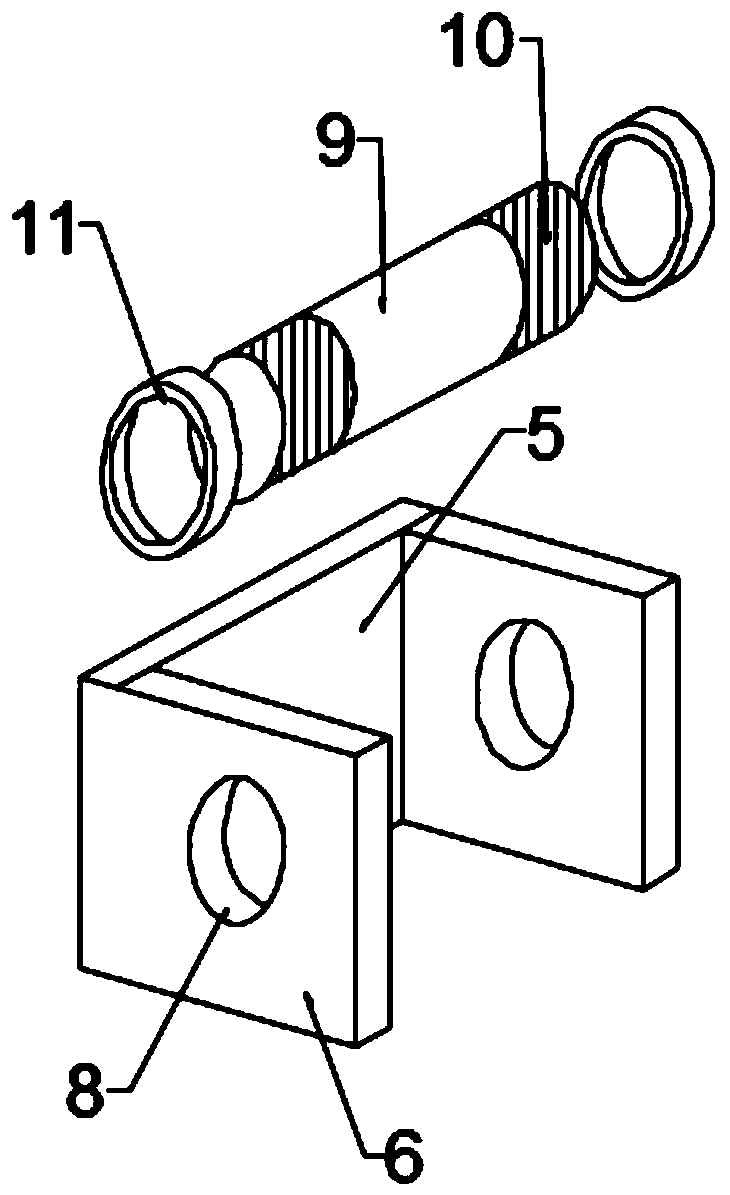

Pipe modular prefabrication production line and pipe module prefabrication method

PendingCN109290808AHigh degree of automationImprove prefabrication efficiencyOther manufacturing equipments/toolsAutomationIndustrial engineering

The invention discloses a pipe modular prefabrication production line and a pipe module prefabrication method. The pipe modular prefabrication production line comprises straight pipe fixed-length cutting equipment, automatic groove processing equipment, pipe component assembling equipment, automatic welding equipment and transferring equipment, wherein the straight pipe fixed-length cutting equipment is used for cutting an original straight pipe according to the preset strength, so that a fixed-length straight pipe can be formed; the automatic groove processing equipment is used for processingthe fixed-length straight pipe, so that a groove can be formed in the end part of the fixed-length straight pipe; the pipe component assembling equipment is used for positioning pipe components to the end part, provided with the groove, of the straight pipe as well as performing the assembling and connecting operation; the automatic welding equipment is used for welding a junction position formedafter the straight pipe and the pipe components are assembled and connected, so that the pipe module assembling operation can be completed; and the transferring equipment is used for transferring thestraight pipe and the pipe components. The automation degree of the pipe modular prefabrication production line provided by the invention is high; the pipe module prefabrication efficiency can be improved; in the specific application process, the pipe modular prefabrication production line can adapt to the prefabrication of an oversized ultra-large-caliber pipe module; and the traditional oversized ultra-large-caliber pipe module construction status can be changed.

Owner:HUAHENG WELDING +2

Connecting structure for jointly prefabricating assembly type shear wall and heat-preservation partition wall

InactiveCN111021585AGuaranteed stabilityImprove prefabrication efficiencyWallsHeat proofingEngineeringHeat conservation

The invention relates to the technical field of constructional engineering, and particularly discloses a connecting structure for jointly prefabricating an assembly type shear wall and a heat preservation partition wall. The connecting structure involves a shear wall body, the top end of the shear wall body is connected with an upper wall through an upper connecting structure body, the left side and the right side of the shear wall body are connected with side walls through side connecting structure bodies, and the outer side wall of the shear wall body is connected with the heat preservationpartition wall through an outer connecting structure body; a detachable supporting mechanism is arranged on the surface of the shear wall body; and the side walls are arranged on the upper surface ofan auxiliary connecting mechanism. According to the connecting structure, a heat preservation plate is prevented from being arranged on a construction site, the shear wall body can be supported and fixed through the detachable supporting mechanism, and then the fabricated prefabrication is performed through the upper connecting structure body, the side connecting structure bodies and the outer connecting structure body, and the prefabricated shear wall is integrally transported to the construction site for construction, so that the construction efficiency is greatly improved, and meanwhile, the connecting effect is good, and the overall quality of a project is guaranteed.

Owner:JILIN JIANZHU UNIVERSITY

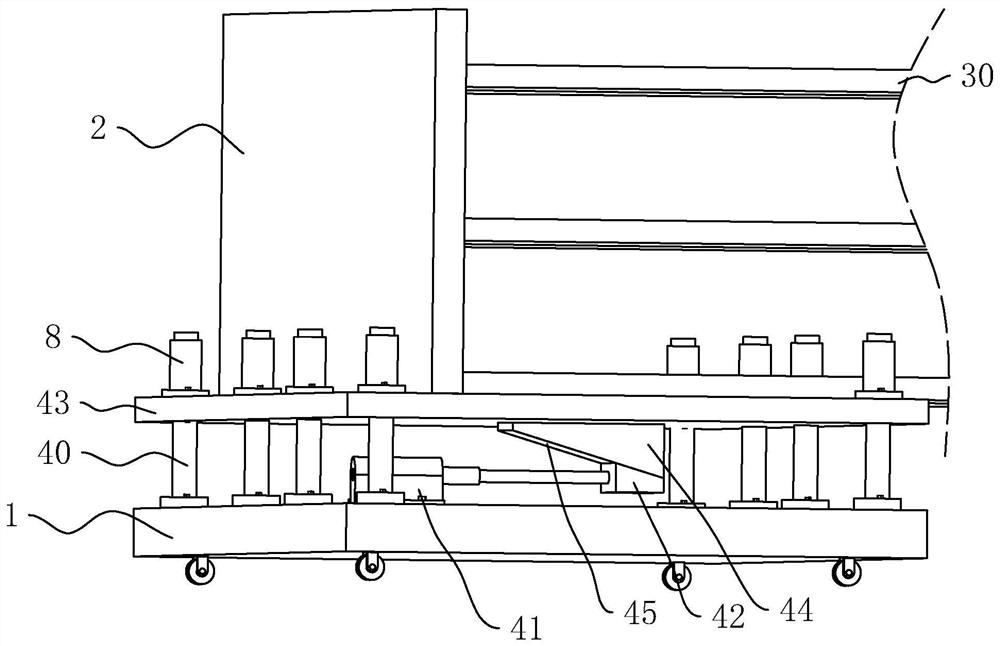

Novel internal mould trolley walking device for carriageway in prefabrication of immersed tube tunnel tube segment

PendingCN110065148ARealize regulationImprove prefabrication efficiencyCeramic shaping mandrelsCeramic shaping coresCarriagewayEngineering

The invention relates to the field of immersed tube prefabrication construction technological structures, in particular to a novel internal mould trolley walking device for a carriageway in the prefabrication of an immersed tube tunnel tube segment. The novel internal mould trolley walking device comprises an internal mould trolley; at least two internal mould fixed supporting legs and at least two internal mould movable supporting legs are arranged at the lower end of the internal mould trolley; the internal mould fixed supporting legs are supporting structures of which the upper ends are fixed to the internal mould trolley and can contract and stretch in the vertical direction; the internal mould movable supporting legs are the supporting structures of which the upper ends can be connected to the internal mould trolley in a manner of sliding in the longitudinal direction and the transverse direction and the lower ends can contract and stretch in the vertical direction; and the internal mould fixed supporting legs and the internal mould movable supporting legs are arranged on the internal mould trolley at intervals in the vertical direction. According to the walking structure disclosed by the invention, the position regulation of the internal mould trolley in the longitudinal direction, the transverse direction and the vertical direction can be realized; the efficiency of immersed tube casting construction is improved; and the novel internal mould trolley walking device has great popularization value.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES +1

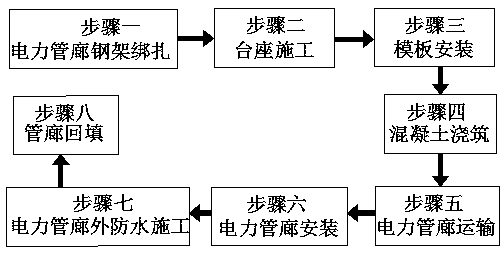

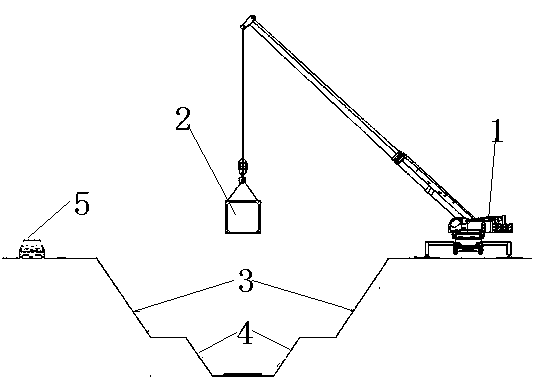

Prefabricated assembled power pipe gallery construction method

ActiveCN110714481AGuaranteed standardEnsure specificationCable installations on groundArtificial islandsArchitectural engineeringSteel frame

The invention relates to the technical field of infrastructure engineering, in particular to a prefabricated assembled power pipe gallery construction method. The method comprises the following steps:step 1, binding a power pipe gallery steel frame; step 2, performing pedestal construction; step 3, installing a template; step 4, pouring concrete; step 5, transporting a power pipe gallery; step 6,installing the power pipe gallery; step 7, performing waterproof construction outside the power pipe gallery; and step 8, backfilling the pipe gallery. The construction method effectively acceleratesthe circulation efficiency of a prefabricated shaping steel mould of a pipe culvert and accelerates the prefabrication efficiency of the pipe culvert. The installation efficiency of the pipe culvertis effectively accelerated, and the installation quality of two adjacent pipe galleries is guaranteed.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

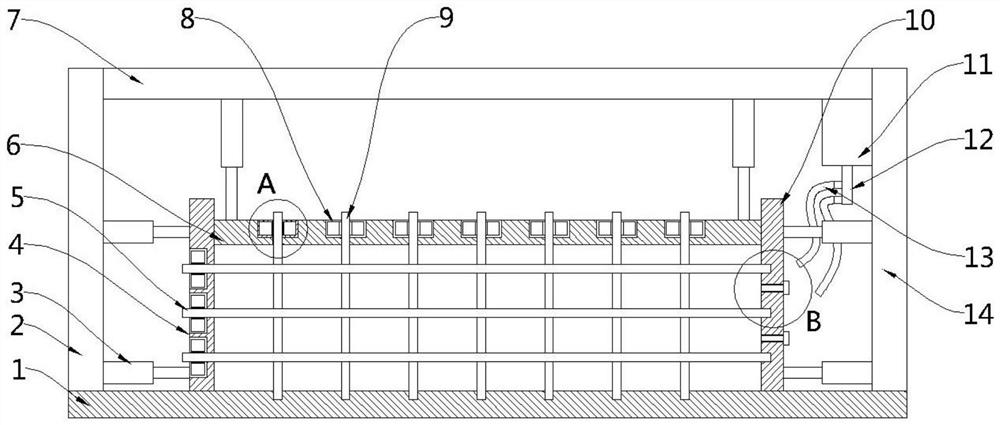

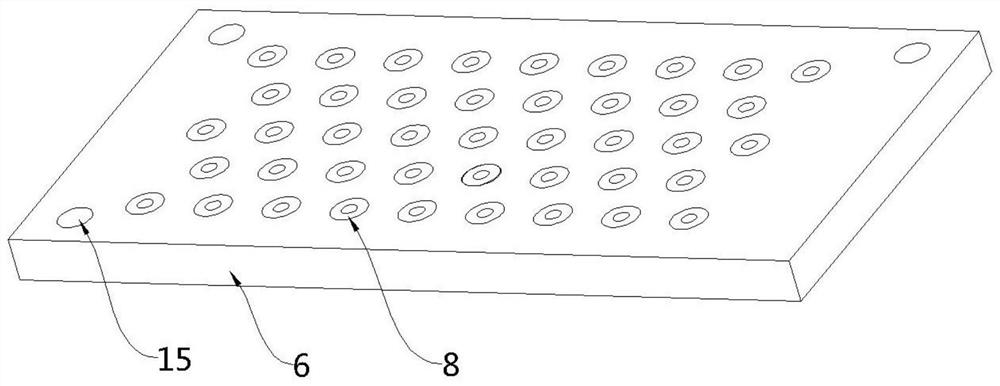

Sea sand recycled mixed concrete member

ActiveCN111923200AImprove prefabrication efficiencyPrevent rustMouldsFeeding arrangmentsStructural engineeringLiquid storage

The invention provides a sea sand recycled mixed concrete member, and belongs to the technical field of concrete members. The member comprises a base and a top plate arranged above the base, the edgeof the upper portion of the base is connected with the top plate through a first side plate and a second side plate, two first baffles and two second baffles are movably arranged at the upper portionof the base, and a rectangular pouring cavity is defined by the two first baffles and the two second baffles. The embodiment has the advantage that the sea sand concrete prefabricating efficiency is high, rust-proof liquid storage parts are arranged on the outer side of the first baffles and the upper portion of a cover plate, and rust-proof liquid can be automatically smeared on the outer surfaces of transverse bars and the outer surfaces of longitudinal bars in the process of inserting the transverse bars and the longitudinal bars into the pouring cavity, so that rust-proof layers are formedoutside the transverse bars and outside the longitudinal bars, chloride ions in the sea sand concrete are prevented from making contact with the transverse bars and the longitudinal bars, the transverse bars and the longitudinal bars are prevented from being rusted, the strength of the sea sand concrete member is improved, and the service life is prolonged.

Owner:SHENZHEN INSTITUTE OF INFORMATION TECHNOLOGY

Honeycombed-core structure

ActiveCN107268855AImprove prefabrication efficiencySimple structureFloorsMechanical engineeringEngineering

Owner:CHINA MCC5 GROUP CORP

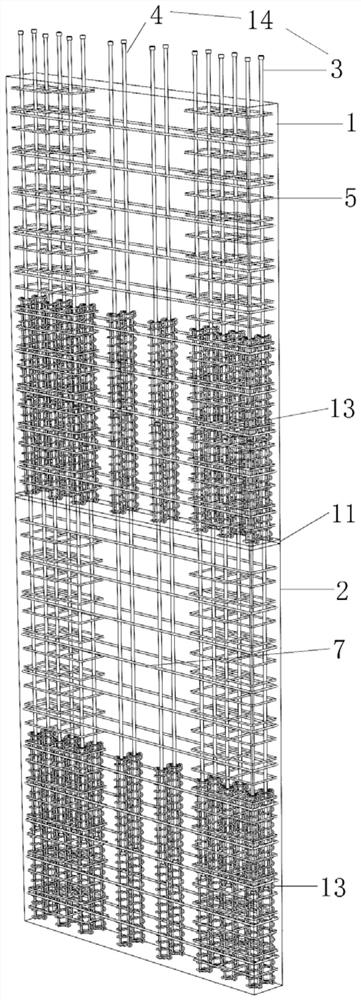

Full-prefabricated concrete shear wall and construction method thereof

PendingCN112780007AGuarantee the quality of prefabricationImprove prefabrication efficiencyConstruction materialWallsButt jointArchitectural engineering

The invention discloses a full-prefabricated concrete shear wall and a construction method thereof. The full-prefabricated concrete shear wall comprises a plurality of layers of full-prefabricated shear wall plates which are fixed in a butt joint mode; each full-prefabricated shear wall plate comprises a prefabricated concrete body and a plurality of vertical butt joint steel bars which are distributed in a mode of penetrating through the prefabricated concrete body, a steel bar butt joint assembly is arranged on the lower portion of the interior of the prefabricated concrete body, the top ends of the vertical butt joint steel bars extend out of the upper surface of the prefabricated concrete body, and the bottom ends of the vertical butt joint steel bars are inserted into the steel bar butt joint assembly; and when the upper layer of full-prefabricated shear wall plate and the lower layer of full-prefabricated shear wall plate are fixed in a butt joint mode, the top ends of the vertical butt joint steel bars on the lower layer are inserted into the steel bar butt joint assembly on the upper layer and are fixed to the bottom ends of the vertical butt joint steel bars on the upper layer in a butt joint mode. According to the full-prefabricated concrete shear wall and the construction method thereof, full prefabrication of shear wall components can be realized, the on-site post-pouring concrete operation is greatly reduced, and the installation quality and efficiency of steel bar butt joint connectors are improved.

Owner:NANTONG CONSTR PROJECT GENERAL CONTRACTING +1

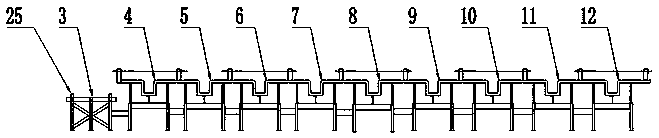

Mold suitable for producing fabricated undercrossing channel frame through long-line matching method and prefabrication method

ActiveCN110497511AAvoid the risk of deformationReduced strength requirementsMouldsEngineeringLine matching

The invention relates to the technical field of building engineering, in particular to a mold suitable for producing a fabricated undercrossing channel frame through a long-line matching method and aconstruction method. The mold comprises bottom mold assemblies matched with the bottom of a frame segment, inner mold assemblies matched with the inner wall of the frame segment, side mold assembliesmatched with the outer walls of the two sides of the mold segment and end mold assemblies matched with the two ends of the mold frame. The mold further comprises an inner mold support used for supporting the inner mold assemblies. A drive device used for driving the inner mold assemblies to be switched between a pouring position and a separation position is arranged on the inner mold support. First walking assemblies are further arranged on the inner mold support and are used for proving movement in the length direction of the frame for the inner mold support.

Owner:成都城投城建科技有限公司

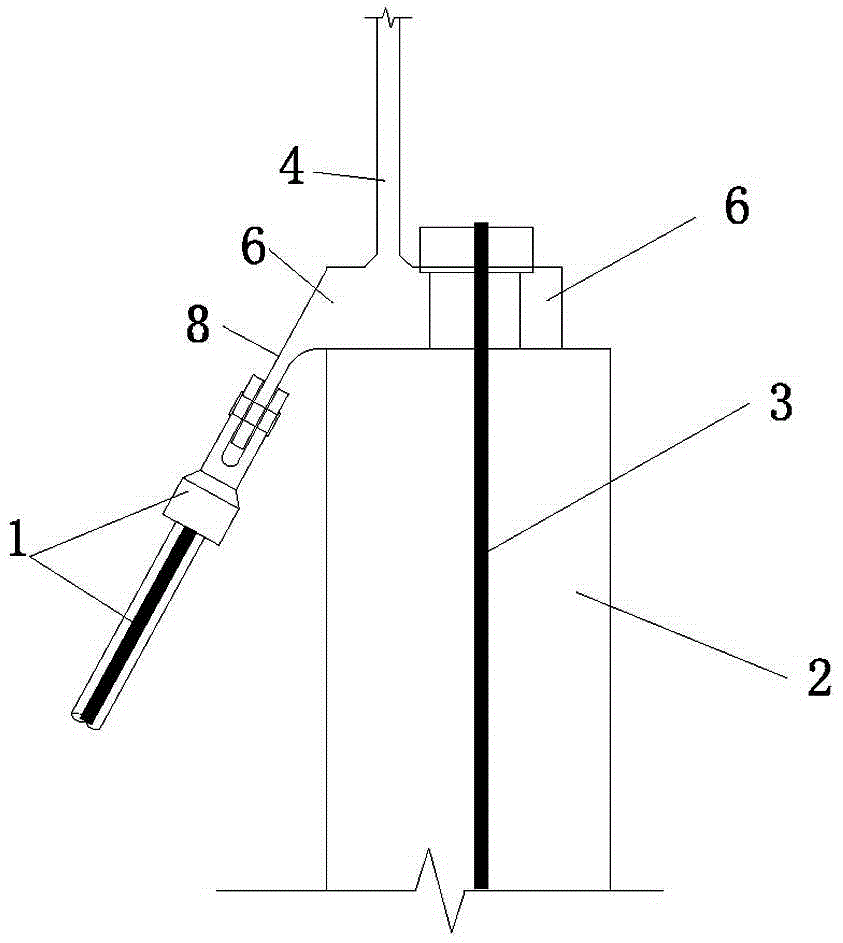

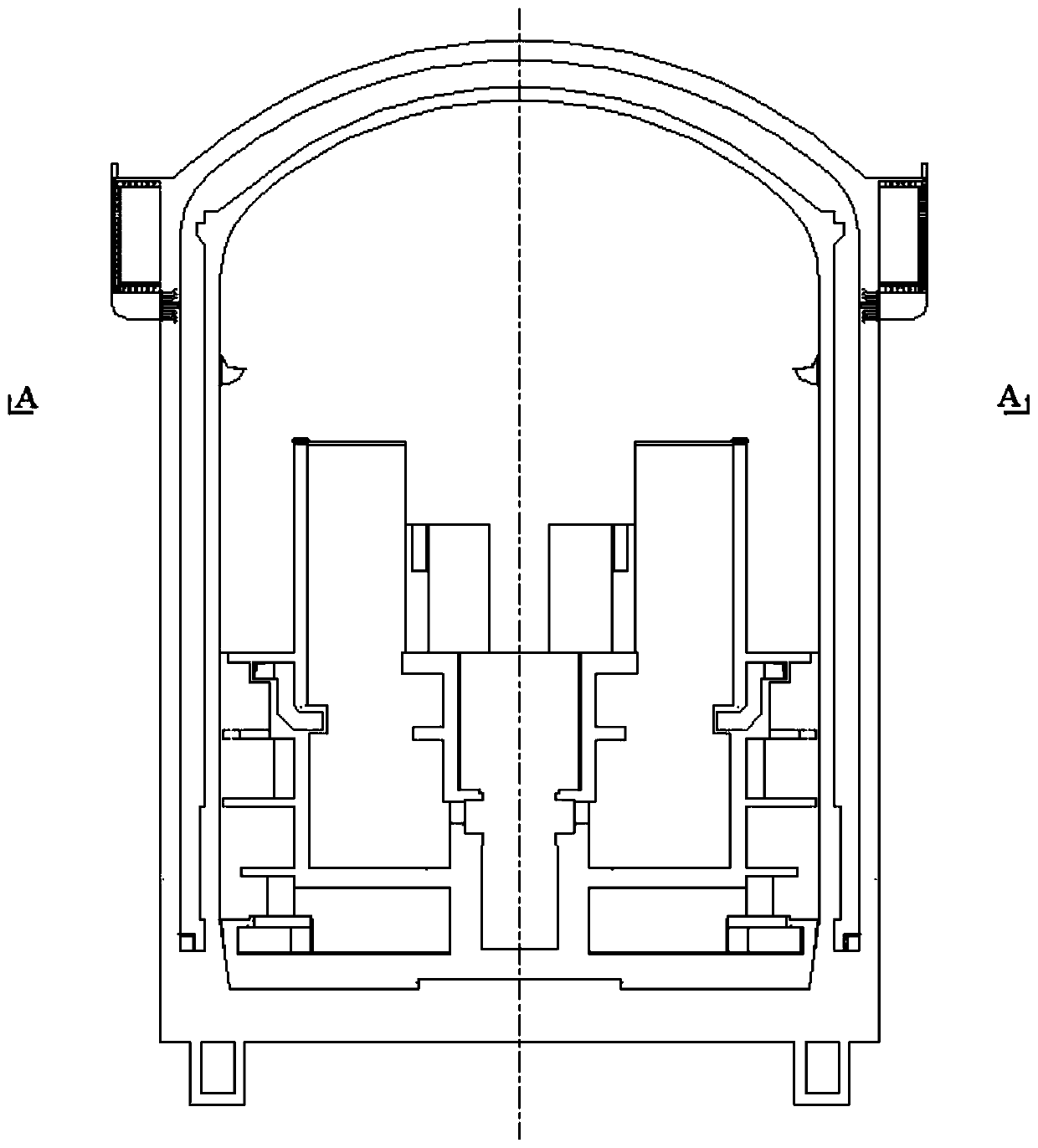

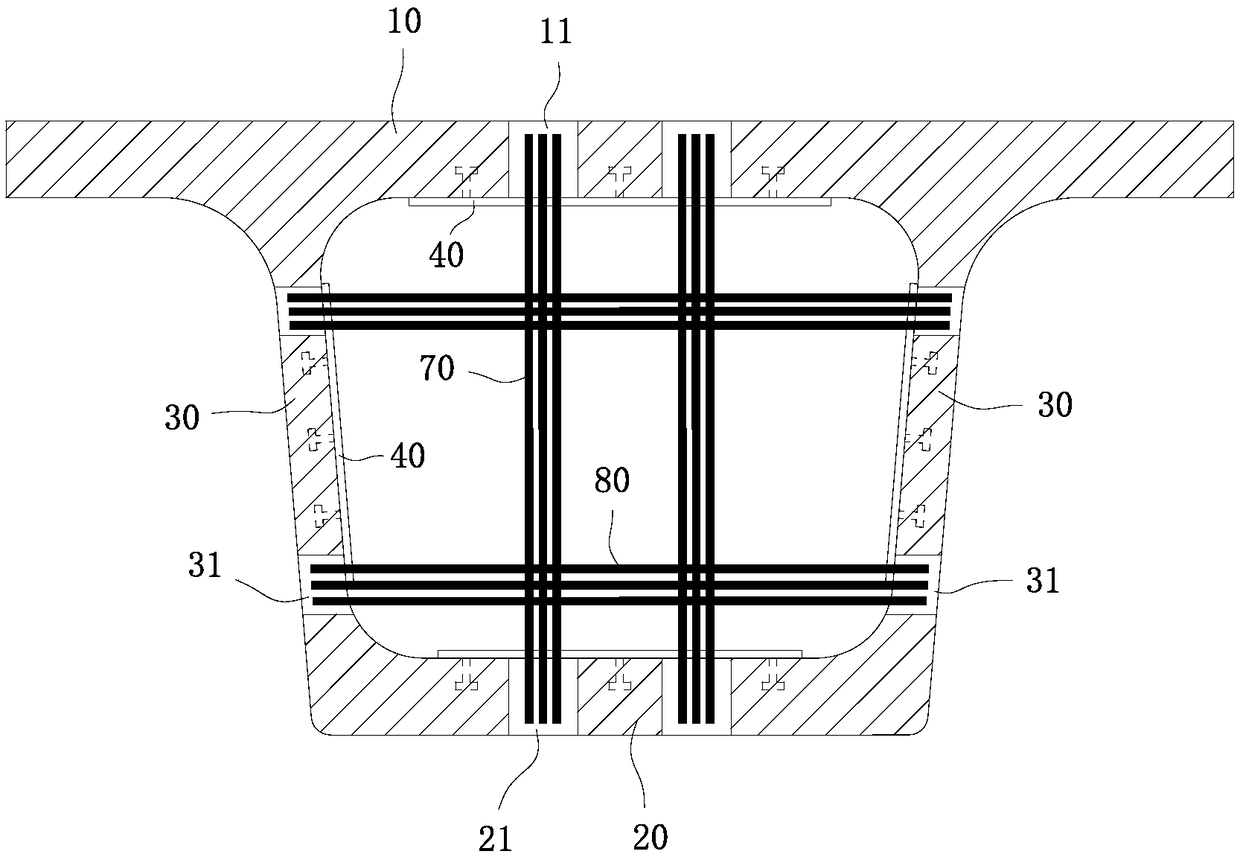

Construction method for passive water tank of nuclear power plant

ActiveCN111075235AFast pouringShorten the construction periodBuilding material handlingBulk storage containerNuclear plantFloor slab

The invention discloses a construction method for a passive water tank of a nuclear power plant. The construction method comprises the following steps that a steel structure supporting module, a bottom floor slab semi-steel plate concrete structure module, a stainless steel plate covered semi-steel plate concrete structure module, a barrel body steel plate concrete structure module and top floor slab semi-steel plate concrete structure modules required by the construction of the passive water tank are precast according to construction requirements and are transported to a containment shell construction site; the steel structure supporting module, the bottom floor slab semi-steel plate concrete structure module, the stainless steel plate covered semi-steel plate concrete structure module and the barrel body steel plate concrete structure module are sequentially hoisted, positioned, but jointed, welded and supported, and concrete is poured in time; after heat exchanger equipment is introduced, the top floor slab semi-steel plate concrete structure modules are hoisted in sequence, and upper concrete is poured to the semi-steel plate concrete structure module; the passive water tank bottom stainless steel covered surface is laid and welded; and the passive water tank and a heat exchanger are transferred.

Owner:中广核工程有限公司 +3

Prefabricating method for UHPC small box beam end diaphragm

InactiveCN108943378AEffective linkEasy to fixMouldsMould auxillary partsAssembly lineStructural engineering

The invention discloses a prefabricating method for a UHPC small box beam end diaphragm. A box beam body is prefabricated by adopting ultra-high-performance concrete, the diaphragm is prefabricated atthe end of the box beam body after the box beam body reaches the preset strength, a cast-in-situ material of the diaphragm adopts ultra-high-performance concrete or common concrete, retard-bonded prestressed tendon tensioning operation is conducted after the diaphragm reaches the preset strength, and finally high-pressure steam curing is conducted on the whole box beam body. The prefabricated boxbeam body is adopted and cooperates with post-poured UHPC or common concrete to form the diaphragm, the cast-in-situ end partition and the prefabricated UHPC box beam body can be effectively connected into a whole, the thickness of the diaphragm can be selectively adjusted according to the pouring concrete material, the prefabricating efficiency of the UHPC small box beam end diaphragm is effectively improved, and the prefabricating method is more suitable for bridge industry assembly line production.

Owner:GUANGZHOU MUNICIPAL ENG DESIGN & RES INST CO LTD

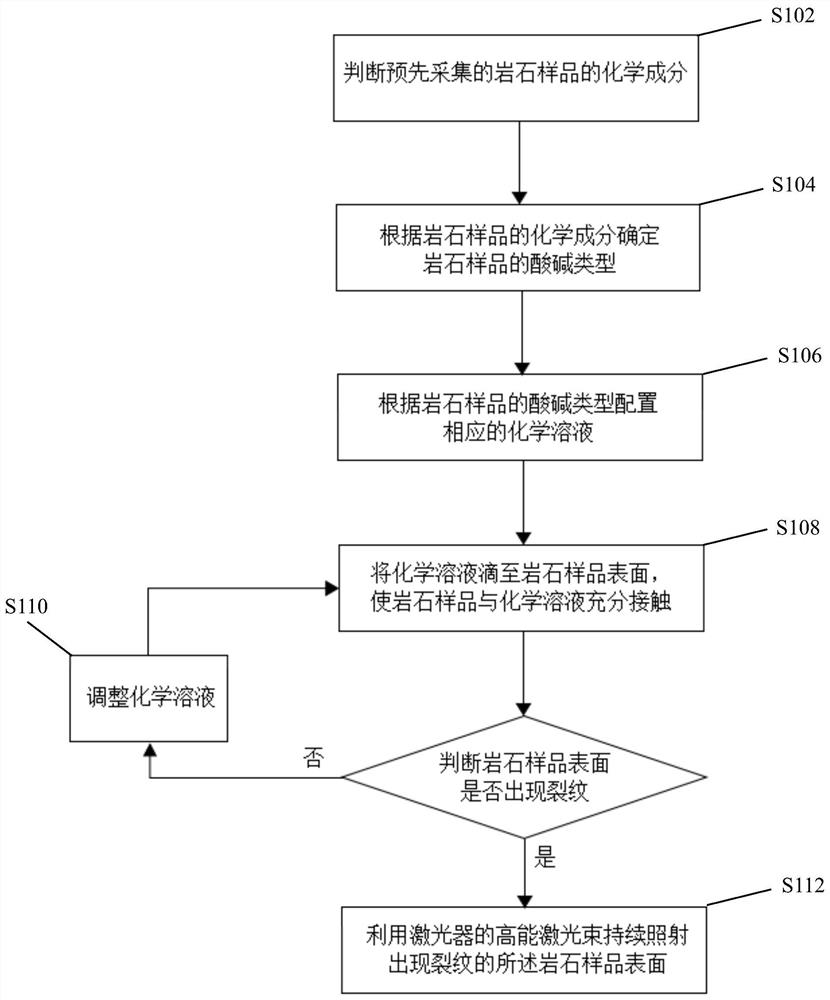

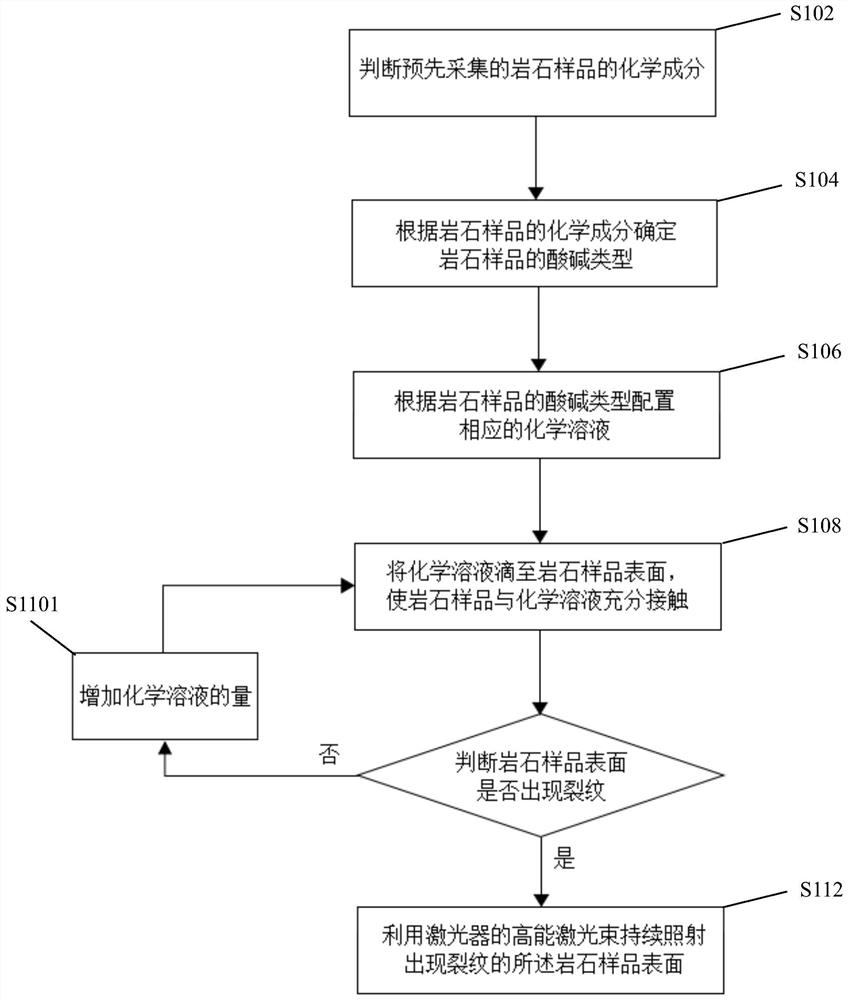

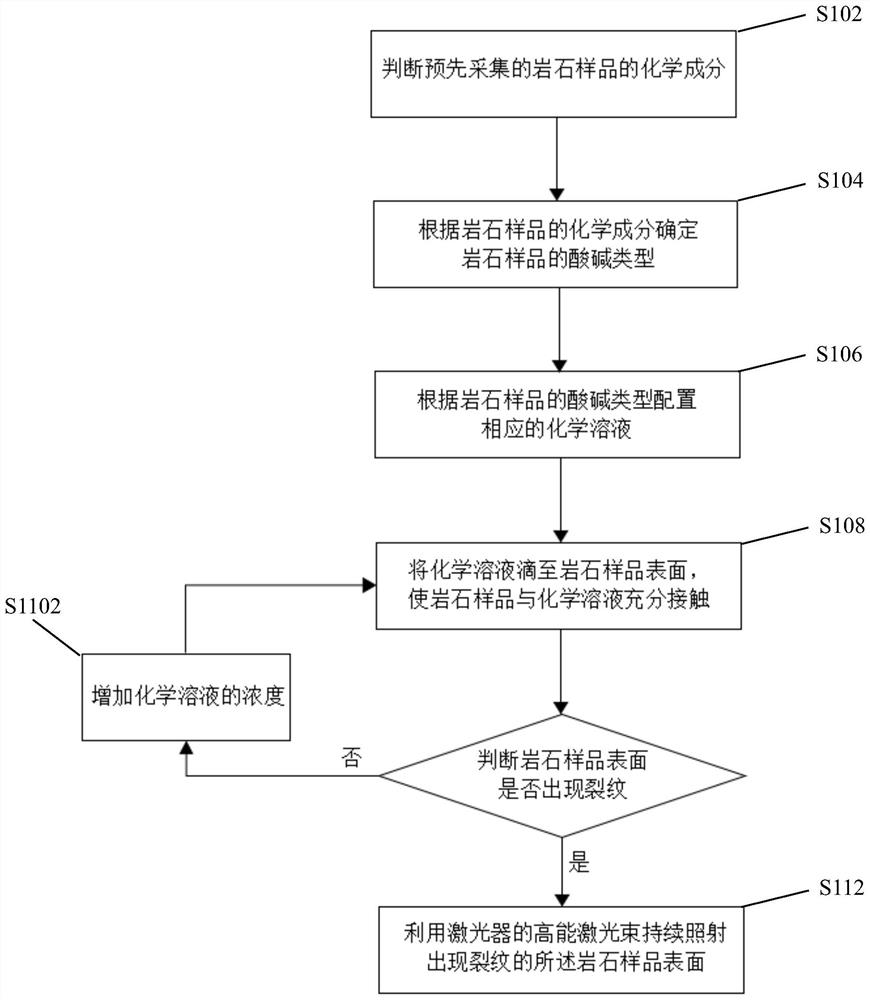

Laser rock breaking method and device

PendingCN113898287AIncreased speed of developmental expansionImprove prefabrication efficiencySurveyThermal drillingErbium lasersGeotechnical engineering

The invention provides a laser rock breaking method and device. The method comprises the following steps that chemical components of a pre-collected rock sample are judged; the acid-base type of the rock sample is determined according to the chemical components of the rock sample; corresponding chemical solution is prepared according to the acid-base type of the rock sample; the chemical solution is dripped onto the surface of the rock sample, and the rock sample is enabled to be in full contact with the chemical solution; if no crack appears on the surface of the rock sample, the amount and / or concentration of the chemical solution is changed to make the crack appear on the surface of the rock sample; and the cracked surface of the rock sample is continuously irradiated by utilizing a high-energy laser beam of a laser. According to the laser rock breaking method and device, the chemical solution is adopted to perform crack prefabrication on the rock sample, the prefabrication operation is simple, the preparation time is short, the economic cost is low, the crack development and propagation speed can be effectively increased, the laser rock breaking efficiency is further improved, and the application of the laser rock breaking technology in actual drilling is promoted.

Owner:PETROCHINA CO LTD +2

Novel production process of prefabricated pier column

PendingCN113618874AIncrease pouring speedImprove prefabrication efficiencyCeramic shaping apparatusBridge structural detailsRebarPier

The invention relates to a novel production process of a prefabricated pier column. The novel production process of the prefabricated pier column comprises the following steps: step 1, a formwork is designed and machined; step 2, the formwork is cleaned; step 3, a bottom formwork is mounted; step 4, a reinforcement cage is hoisted into the formwork; step 5, a side formwork is installed; step 6, concrete is poured; step 7, formwork removal and maintenance are conducted; step 8, the pier column is hoisted away; step 9, storing and inspecting are conducted; and step 10, roughening and leaving the factory are conducted. According to the invention, horizontal pouring is adopted for prefabricated pier column concrete pouring, a series of working procedures such as formwork overturning frame installation, overturning hanging bracket installation, formwork overturning, hoisting the formwork to a pouring table to be fixed, operation platform installation, component overturning and the like are omitted, and limitation of the height / length of a prefabricated pier column, the hoisting height of hoisting equipment and a component overturning mechanism is not needed; and therefore, the pouring speed is increased, time and labor are saved, and the prefabricating efficiency is improved. Horizontal pouring is adopted for prefabricated pier column concrete pouring, and therefore, climbing operation of workers is not needed, operation safety is guaranteed, and production efficiency is improved.

Owner:成都城投城建科技有限公司

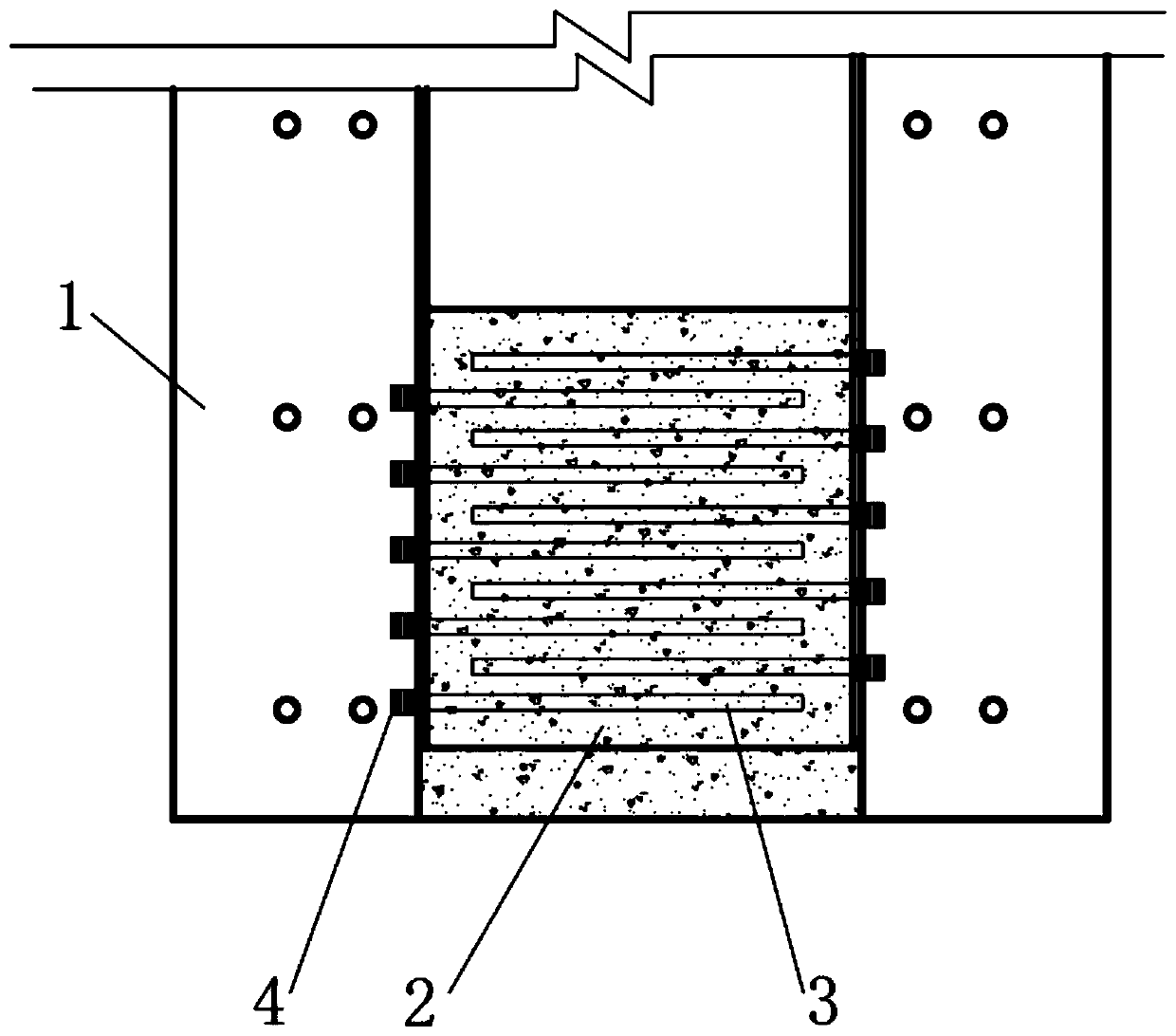

Magnetic levitation track beam post-cast section steel bar and sleeve connecting structure and connecting process

InactiveCN111188231AImprove prefabrication efficiencyShorten the production cycleRailway track constructionClassical mechanicsRebar

The invention discloses a magnetic levitation track beam post-cast section steel bar and sleeve connecting structure and a connecting process. The connecting structure is arranged between two track beams and comprises a plurality of sleeves arranged on the inner side faces of the bottoms of the track beams and steel bars arranged in the sleeves, the length of the steel bars is smaller than the distance between the track beams and larger than one half of the distance between the track beams, and a concrete layer is poured between the bottoms of the track beams. The beneficial effects of the invention are that: according to the scheme, steel bars do not need to be pre-buried at the connecting position of the prefabricated track beams, the track beam prefabricating efficiency can be improved,the production period of the track beams is shortened, the track beams are convenient to transport, the transport cost is reduced, steel bar positioning, straightening and other work do not need to be conducted in the later period, and the surfaces of the track beams cannot be damaged.

Owner:CHINA MCC5 GROUP CORP

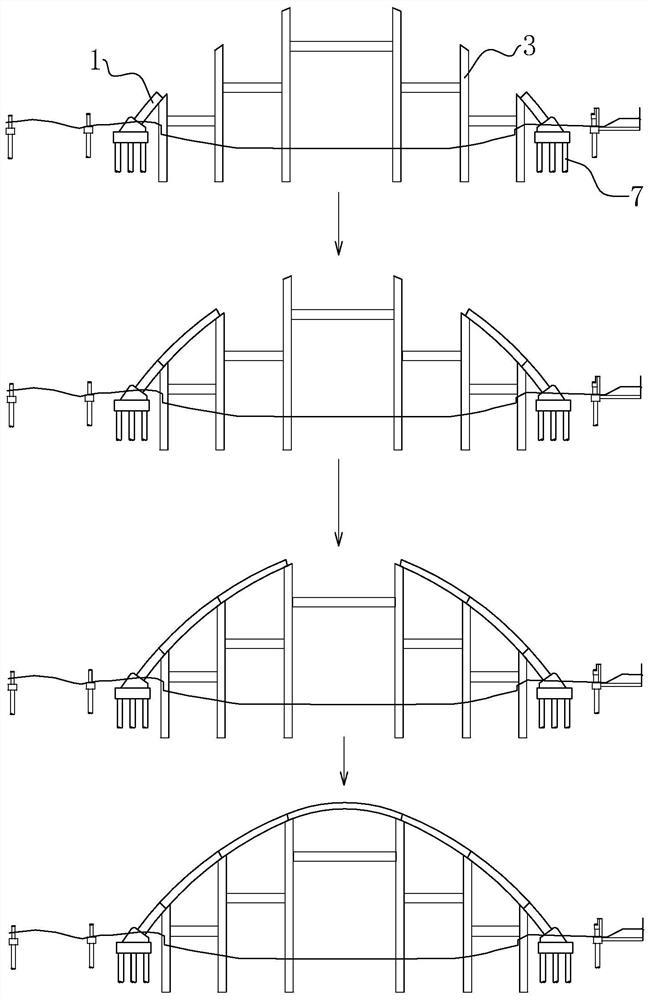

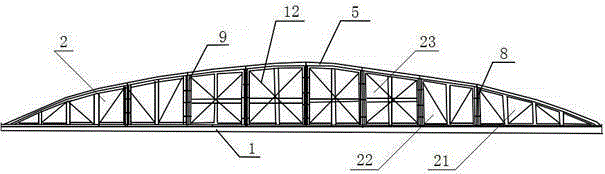

Construction method of prefabricated steel box girder pedestrian landscape bridge

InactiveCN112411342AImprove corrosion resistanceExtended service lifeBridge erection/assemblyRiver routingArchitectural engineering

The invention relates to a construction method of a prefabricated steel box girder pedestrian landscape bridge. The construction method comprises the following steps that S1, cofferdams are built in riverways on the two sides in the width direction of the riverways, and a plurality of pouring piles are poured; S2, a plurality of arch rib sections and box girder sections are prefabricated; S3, thearch rib sections are sequentially hoisted and installed on the pouring piles to form complete arch ribs, and then the box girder sections are installed on the pouring piles to form a steel box girder; S4, a plurality of auxiliary cables are tensioned between the steel box girder and the arch ribs; and S5, a bridge deck is laid on the top surface of the steel box girder. The construction method has the effects of improving the overall construction efficiency of a bridge and reducing the influence of construction on river navigation.

Owner:昆山同济市政工程有限公司

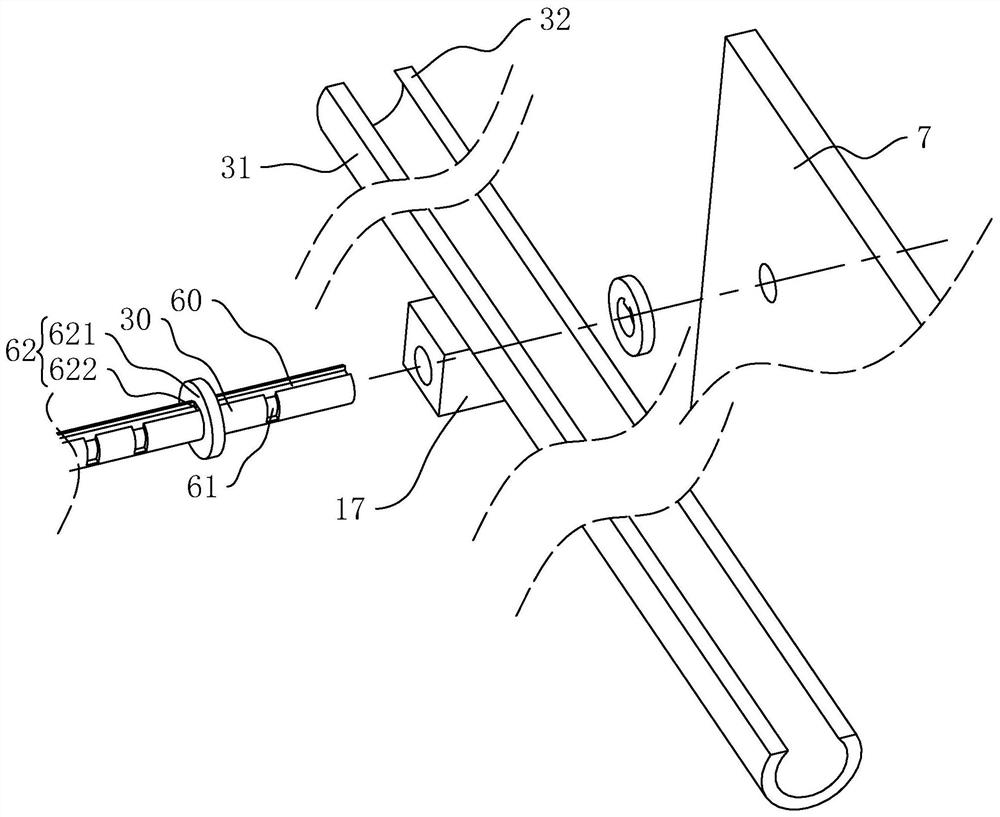

Steel bar prefabricating device for mold frame of aerated concrete plate

ActiveCN112847773AReduce the likelihood of saggingAchieve prefabricationCeramic shaping apparatusClassical mechanicsRebar

The invention relates to a steel bar prefabricating device for a mold frame of an aerated concrete plate. The steel bar prefabricating device for the mold frame of the aerated concrete plate comprises a moving part, a vertical mounting plate and a lifting mechanism used for driving the mounting plate to vertically ascend and descend are arranged on the moving part, a supporting mechanism is arranged on the side wall of the mounting plate, the supporting mechanism comprises at least two supporting rods which are located in the same horizontal plane and are parallel to each other, supporting pipes are arranged on the supporting rods, and material returning openings are formed in the tops of the supporting pipes. The steel bar prefabricating device has the advantage that a main reinforcement can be conveniently arranged between two inner end plates in a penetrating mode.

Owner:江阴天孚新型墙体材料有限公司

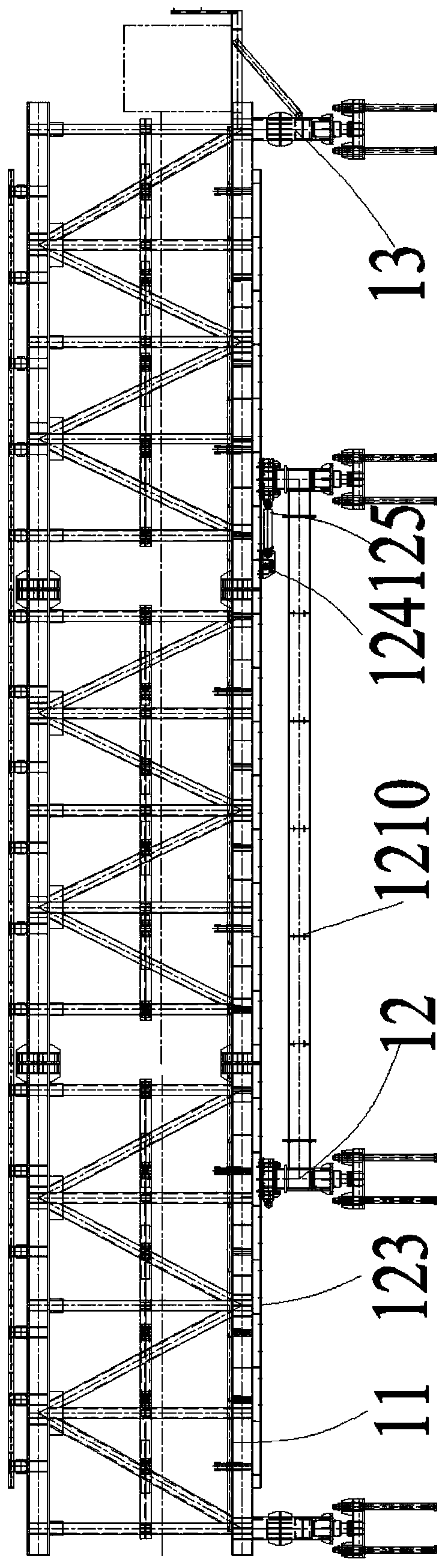

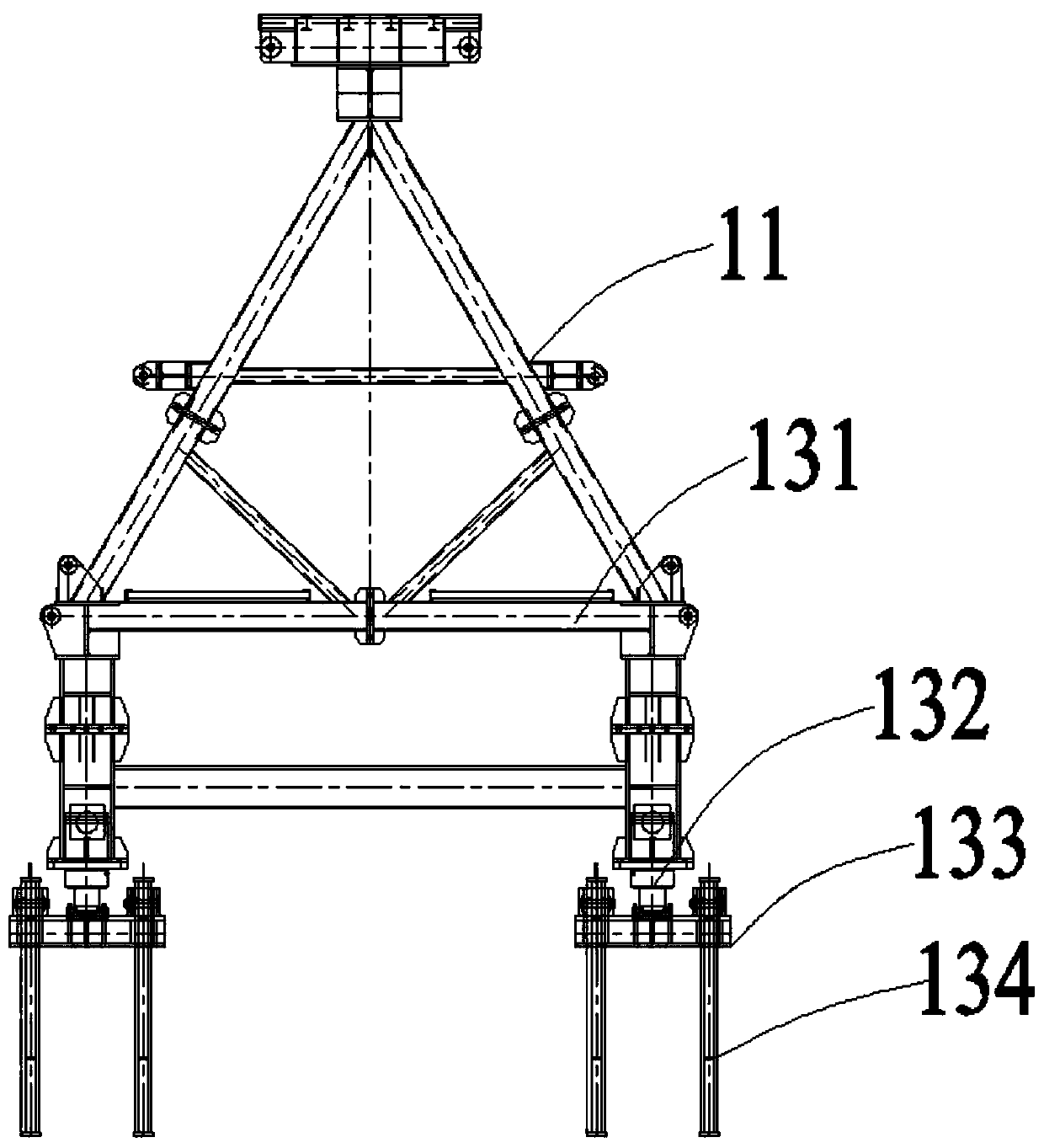

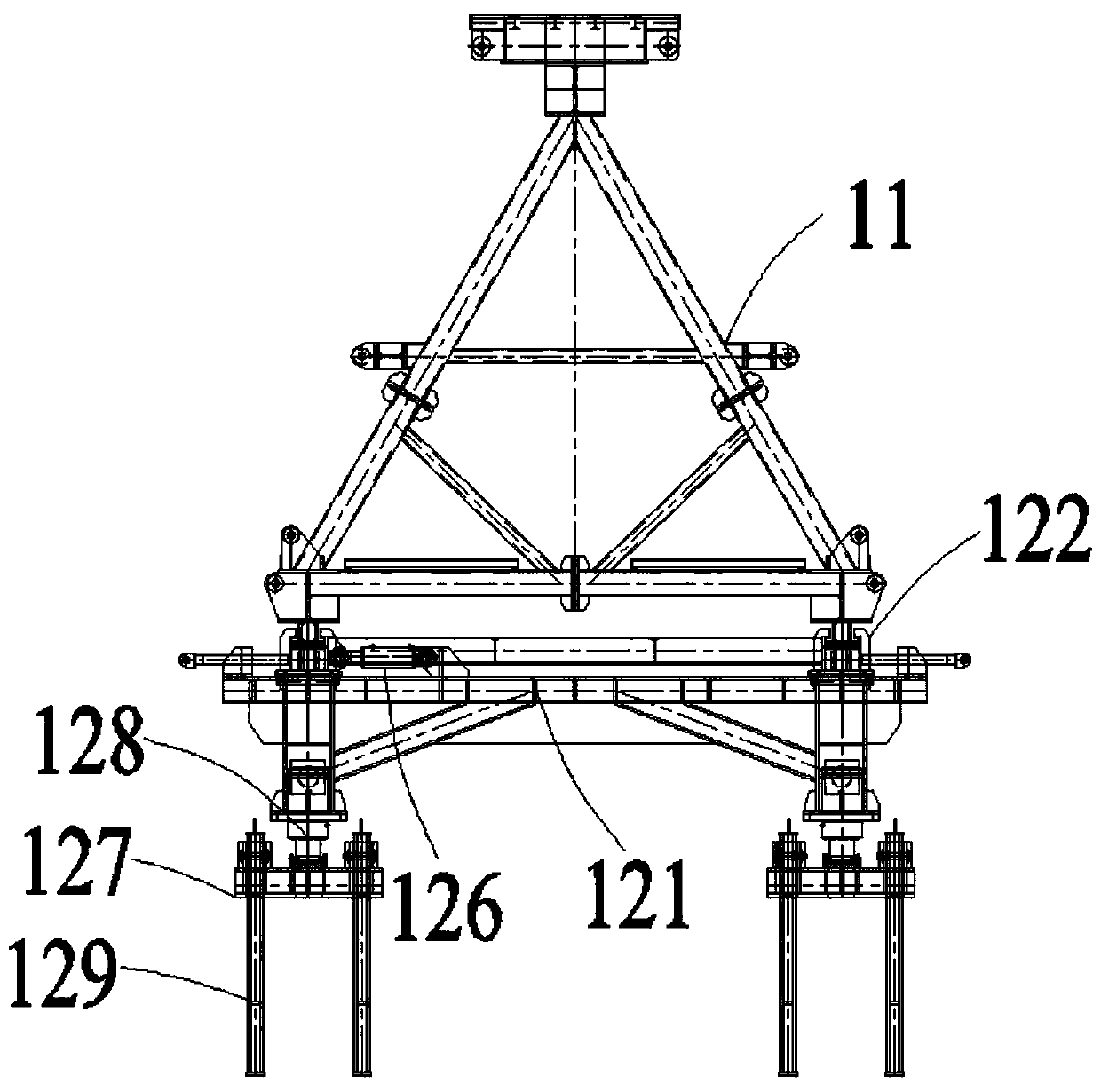

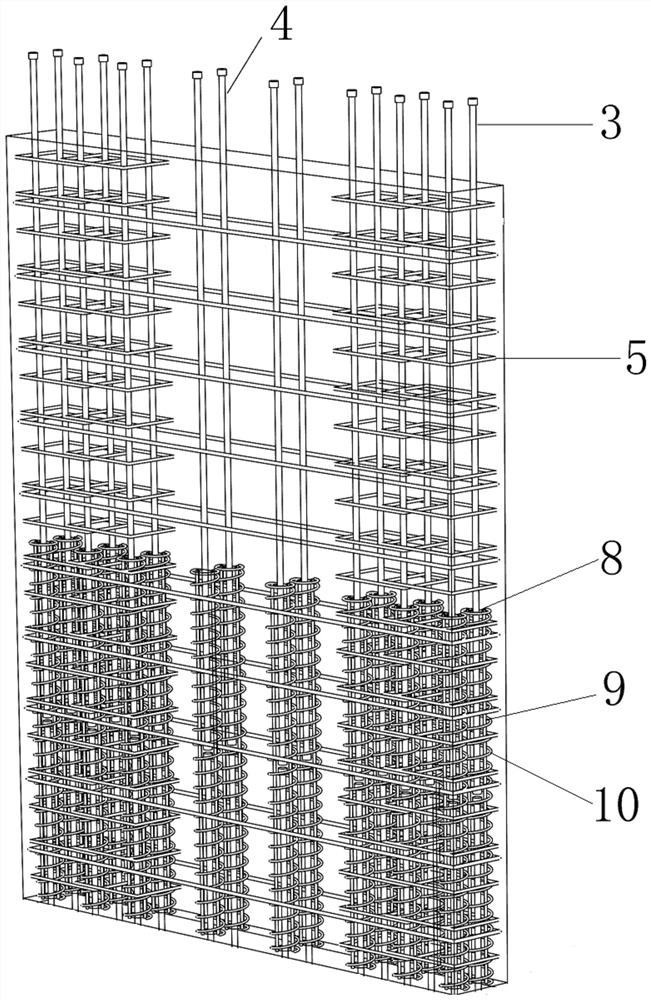

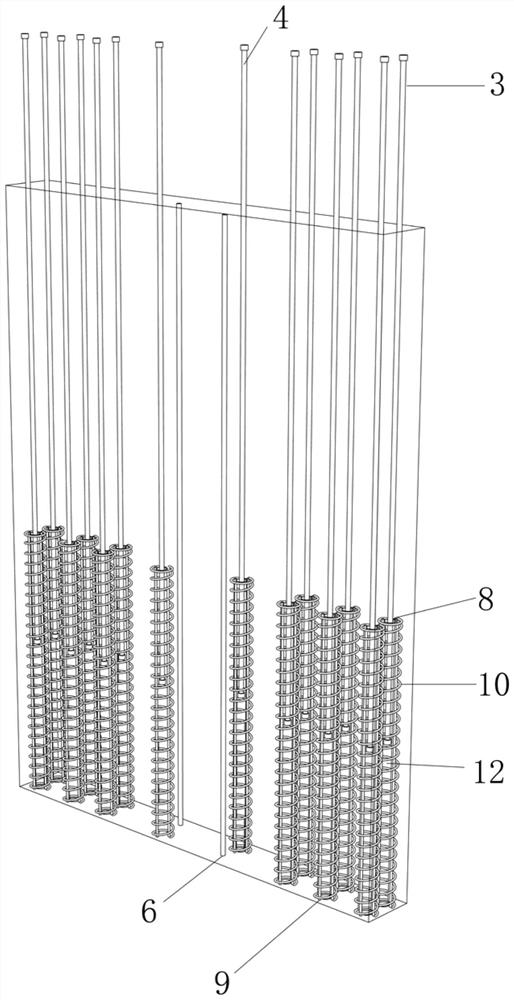

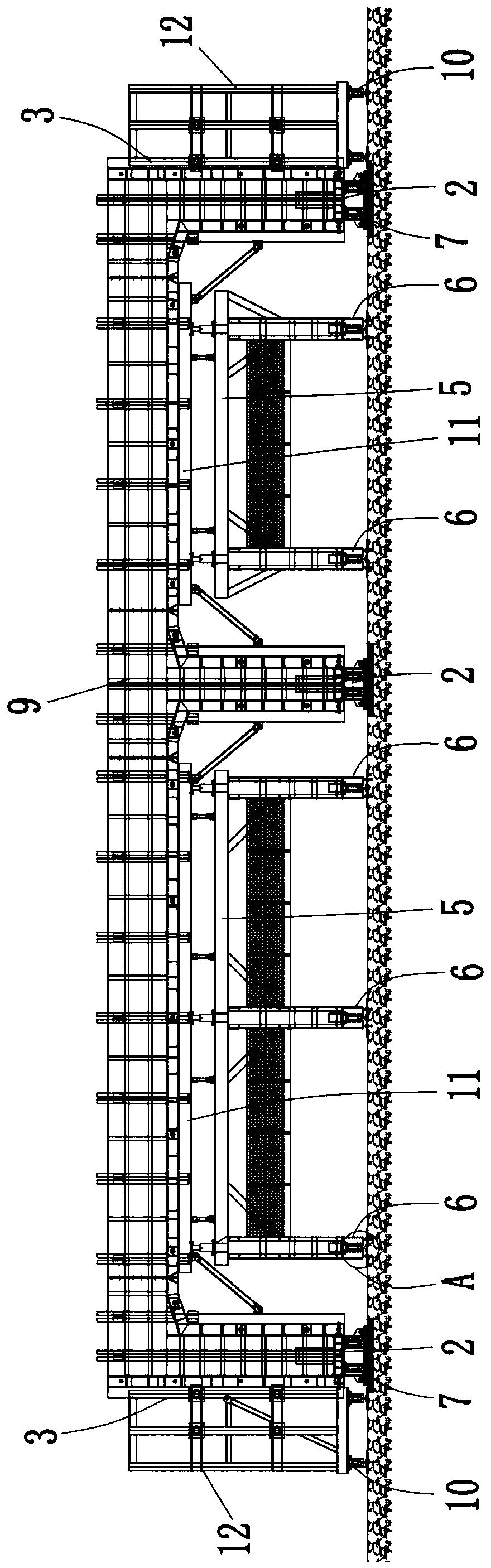

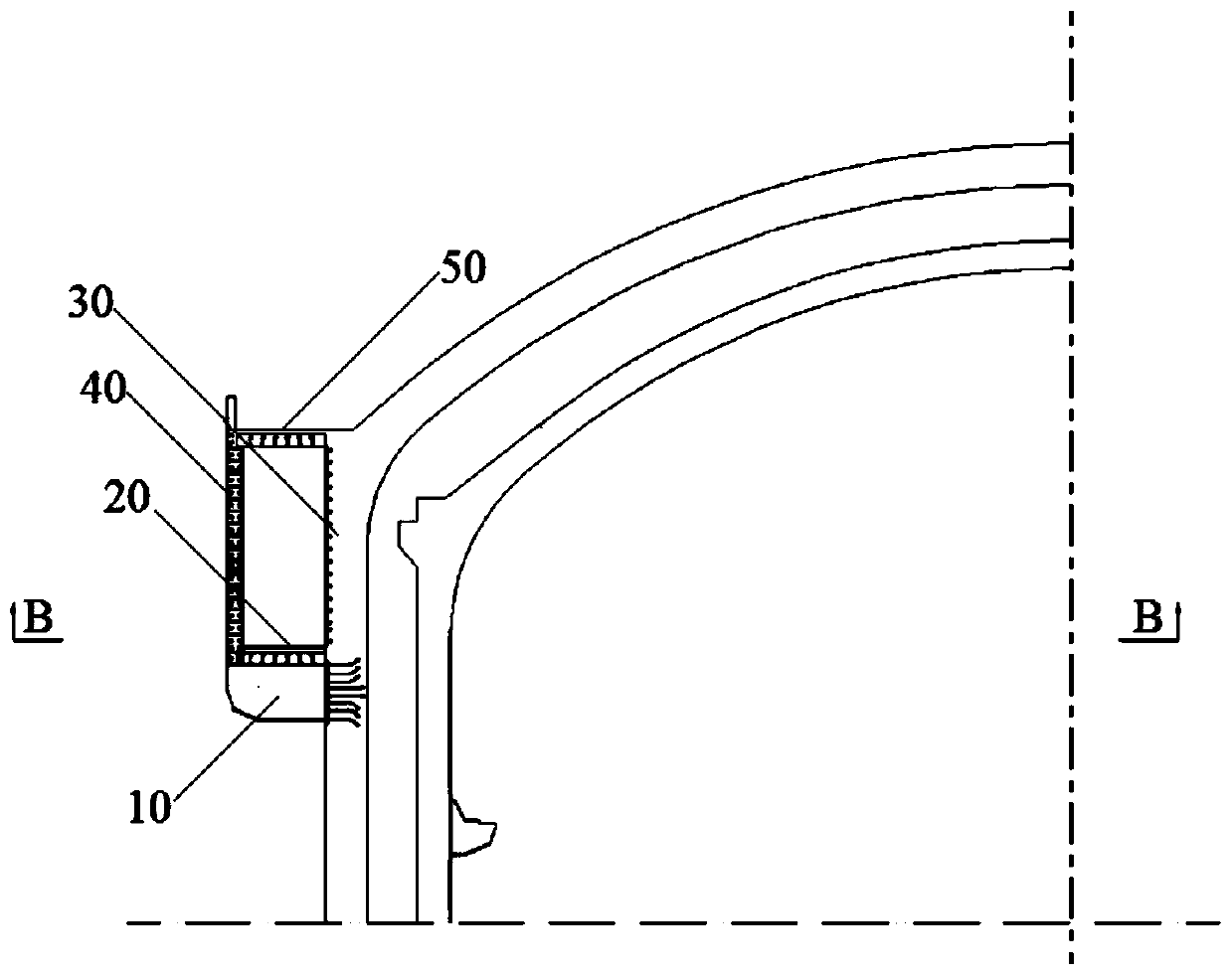

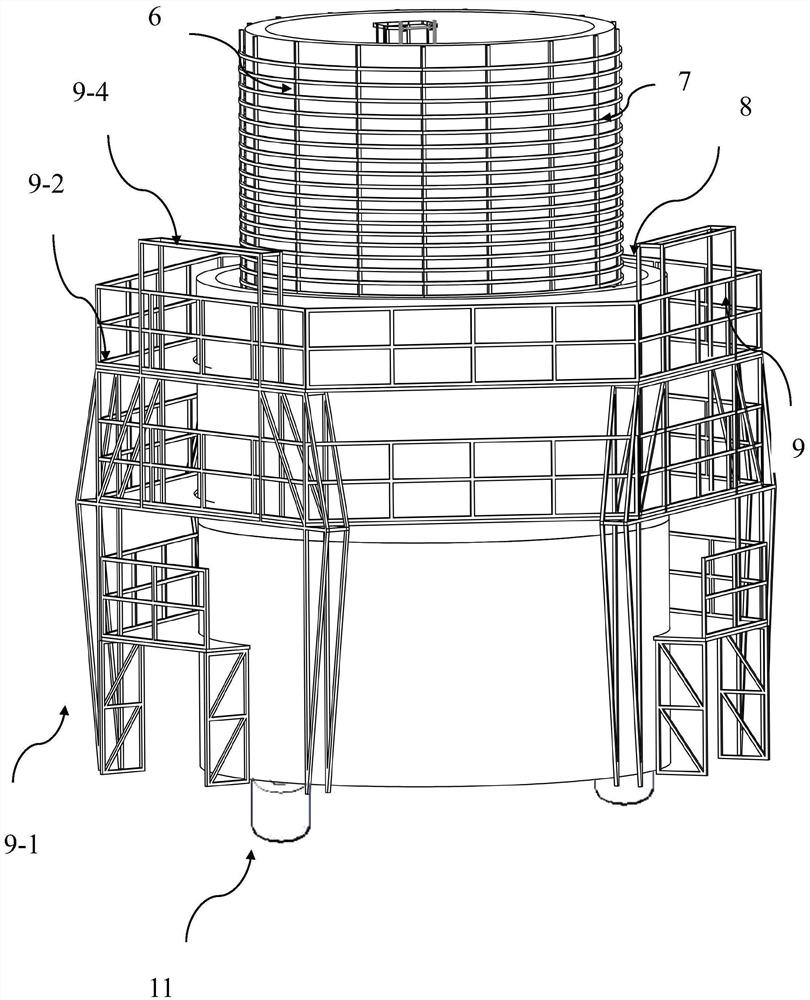

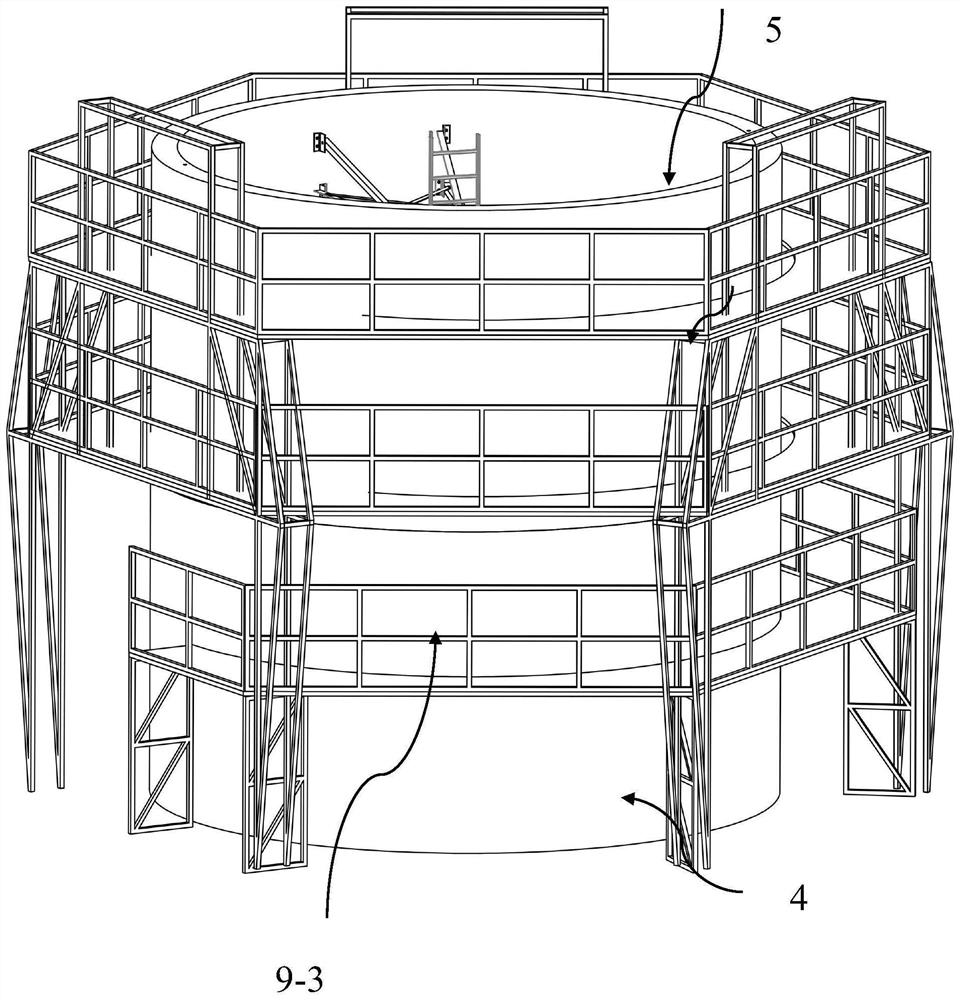

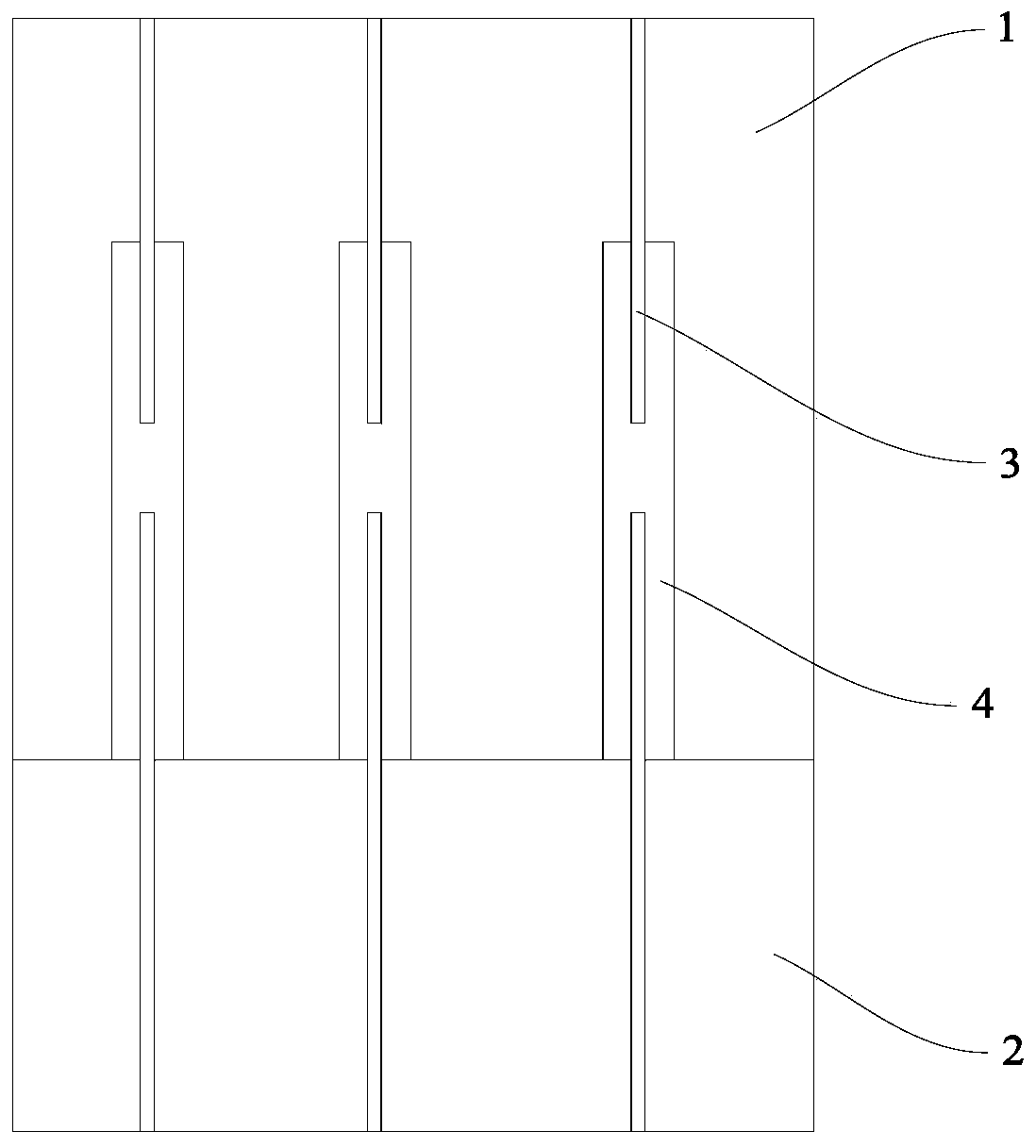

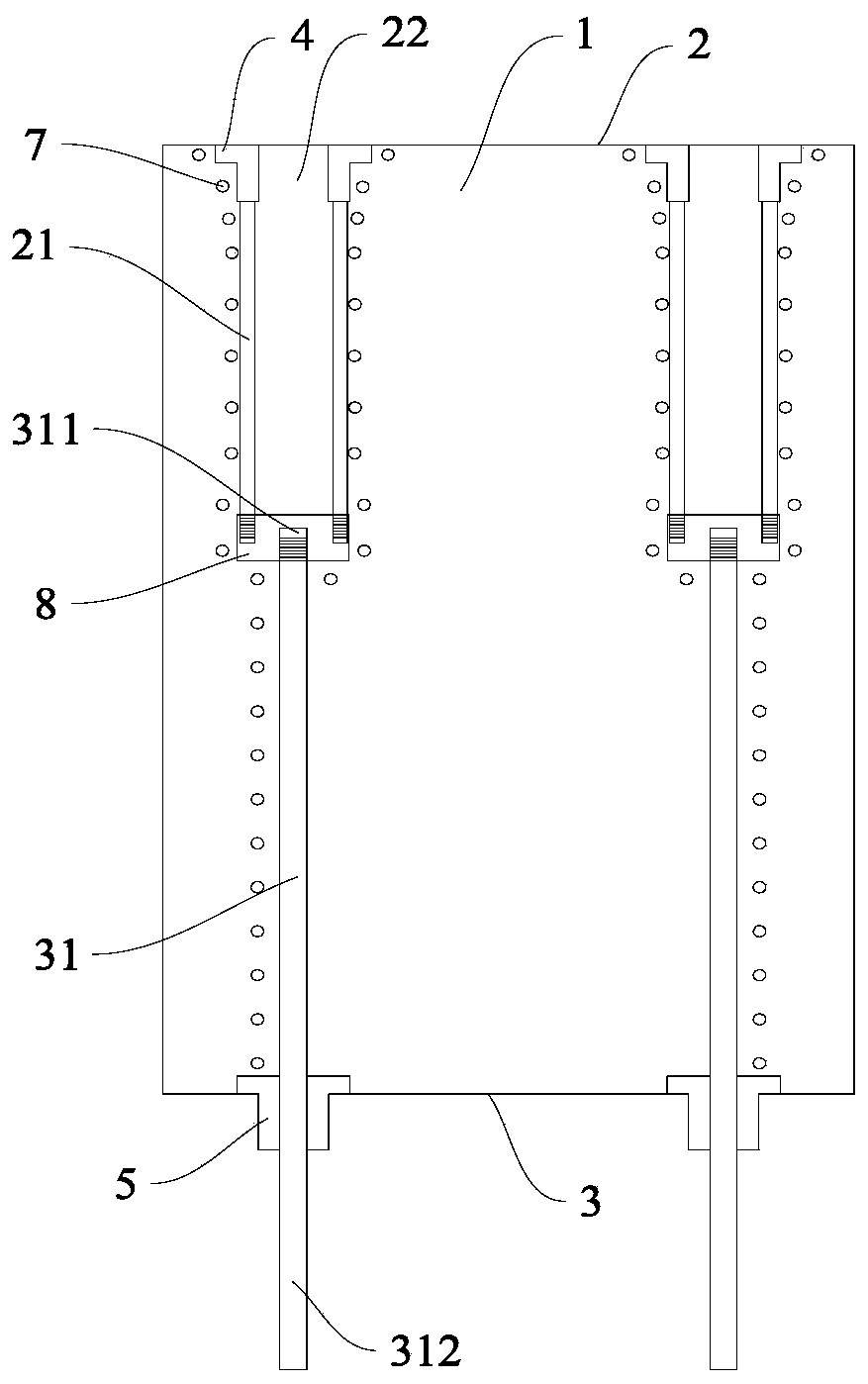

Prefabrication production method of prestressed concrete wind power generation tower drum

InactiveCN113414870AImprove prefabrication efficiencyReasonable process designMouldsSupporting systemArchitectural engineering

The invention discloses a prefabrication production method of a prestressed concrete wind power generation tower drum. The prefabrication production method comprises the specific steps that a supporting system (9) of a corresponding station of a prefabrication production line is installed; the prefabricated Nth section of the tower drum is hoisted into a support (11); an inner mold (6) of the (N+1)th section of the tower drum is supported on the Nth section of the tower drum; a reinforcement cage (7) of the (N+1)th section of the tower drum is hoisted in; an outer mold (8) of the (N+1)th section of the tower drum is supported on the Nth section of the tower drum; the perpendicularity of the inner mold (6) and the outer mold (8) is adjusted; the (N+1)th section of tower drum is poured; the Nth section of tower drum is moved away; the (N+1) th section of the tower drum is transferred into the support (11); and the steps b-g are repeated, and all tower drums are prepared from bottom to top in sequence. The production method is reasonable in process design, low in cost, convenient to implement and efficient; and according to the scheme, the template requirement is low, the initial cost investment is low, and the prefabricating efficiency of the concrete tower drum sections can be greatly improved.

Owner:江苏金海风电塔筒科技有限公司

Prefabrication method of pre-embedded steel plate type UHPC small box girder end diaphragm

InactiveCN108943374AQuick fixEasy to adjust distanceMouldsBridge materialsHigh pressurePre embedding

The invention discloses a prefabrication method of a pre-embedded steel plate type UHPC small box girder end diaphragm. The prefabrication method comprises the steps of prefabricating a box girder body with ultra-high performance concrete; prefabricating the end diaphragm at the end of the box girder body after the box girder body meets the requirement for preset strength, wherein the cast-in-situmaterial of the end diaphragm is the ultra-high performance concrete or common concrete; after the end diaphragm meets the requirement for preset strength, carrying out slow bond prestressed reinforcement tension operation; and carrying out high-pressure steam curing on the whole box girder body finally. According to the prefabrication method of the pre-embedded steel plate type UHPC small box girder end diaphragm, the prefabricated box girder body is adopted to be used in cooperation with post-poured UHPC or common concrete to form the end diaphragm, the cast-in-place end diaphragm and the prefabricated UHPC small box girder body can be effectively connected to form a whole, the thickness of the end diaphragm can be selectively adjusted according to the poured concrete material, the efficiency of fabrication of the UHPC small box girder end diaphragm can be effectively improved, and therefore, the UHPC small box girder end diaphragm can be more applicable to bridge industry flow lineproduction.

Owner:GUANGZHOU MUNICIPAL ENG DESIGN & RES INST CO LTD

Standard segment pier column and splicing and assembling method thereof

PendingCN110258309AImprove shear resistanceImprove construction efficiencyBridge structural detailsBridge erection/assemblyStructural engineeringUltimate tensile strength

The invention discloses a standard segment pier column and a splicing assembling method thereof. The standard segment pier column comprises a bearing platform segment unit and a plurality of standard segment units. One end of the bearing platform segment unit is provided with first grouting sleeves and a plurality of preformed grooves. The first grouting sleeves communicate with the preformed grooves. The cross sectional dimensions of the first grouting sleeves are matched with those of second grouting sleeves of the standard segment units. Second longitudinal bars of the standard segment units are connected with the bearing platform segment unit through the first grouting sleeves and the second grouting sleeves in a grouting manner. The second longitudinal bars of the every two adjacent standard segment units are connected through the first grouting sleeves and the second grouting sleeves in a grouting manner. The splicing and assembling method of the standard segment pier column comprises the steps that the preformed grooves are grouted, vibrating and densifying are conducted, the second longitudinal bars stretch into the preformed grooves of the installed standard segment units, the second grouting sleeves stretch into the first grouting sleeves, and after the grouting materials reach designed strength, splicing and assembling of the next standard segment unit begins.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

A prefabricated combined steel mold for reinforced concrete arch slab and its assembly process

InactiveCN104264983BReduce investmentEasy to operateForms/shuttering/falseworksReinforced concreteJoist

The invention discloses a precasting and shaping combined steel mold of a reinforced concrete arch board. The mold comprises a cement ground mold, two sets of arch board support components mounted on the cement ground mold through foundation bolts and positioned at the two edges of the cement ground mold, a plurality of support beams and connecting rods mounted between the two sets of arch board support components through bolts and used for connecting the two, a plurality of upper arch bottom molds mounted on the support beams, and inner side molds and outer side molds mounted on the cement ground mold and the support beams and fixed by inner clamps and outer clamps, wherein the arch board support components are formed by connecting arch heads, arch bodies and arch tops through bolts; and spacing plates are mounted between the adjacent upper arch bottom molds. The steel mold is quick in production, is low in cost, and is faster by 2-3 times in production compared with a traditional template; the combination is adopted, and the bolts are used for fastening, so that the assembly is quicker by 3-4 times, and the mold release only needs half an hour; the precasting efficiency is high, the efficiency is improved by 2-3 times, and the template investment is reduced when the construction period is shortened; and the worker operation is convenient, the quality of arched boards is good, the template can be used for a long time, and the cost of the arch boards is reduced above 30%.

Owner:姚和祥

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com