Fabricated bridge deck slab construction method through combination matching of long and short lines and precast segments

A construction method and bridge deck technology, applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve the problems of long prefabrication period, heavy on-site welding workload, unfavorable control of prefabrication precision, etc., to eliminate measurement and construction errors, Good economic and social benefits, easy control of prefabrication precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

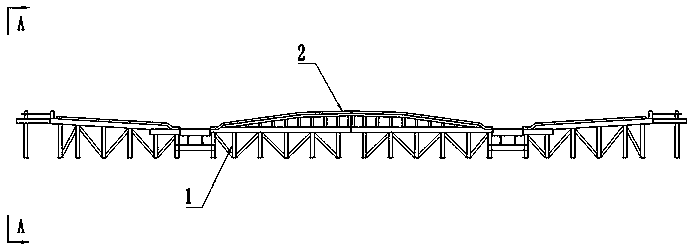

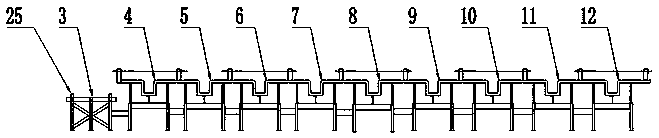

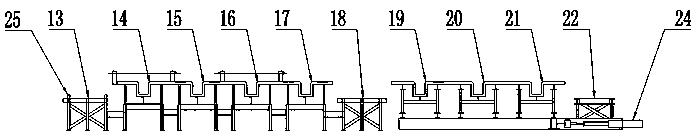

[0034] The invention is suitable for the prefabrication of the steel truss continuous girder prestressed reinforced concrete section assembled bridge deck. The steel truss girder has 6 spans and one connection (named K1~K6), and the steel truss girder and the bridge deck are arranged continuously; the single-span steel girder includes 7 standard internodes and 1 special-shaped internode (named J1~J8), A single internode is composed of 4 pieces of 2m bridge decks and 5 pieces of 2.15m bridge decks (named Q1~Q9); among them, the standard internodes are composed of standard bridge decks (front and rear end faces are parallel), and the special-shaped internodes are composed of standard bridge decks and special-shaped bridge decks. It consists of bridge decks (the front and rear end faces are not parallel); the naming example ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com