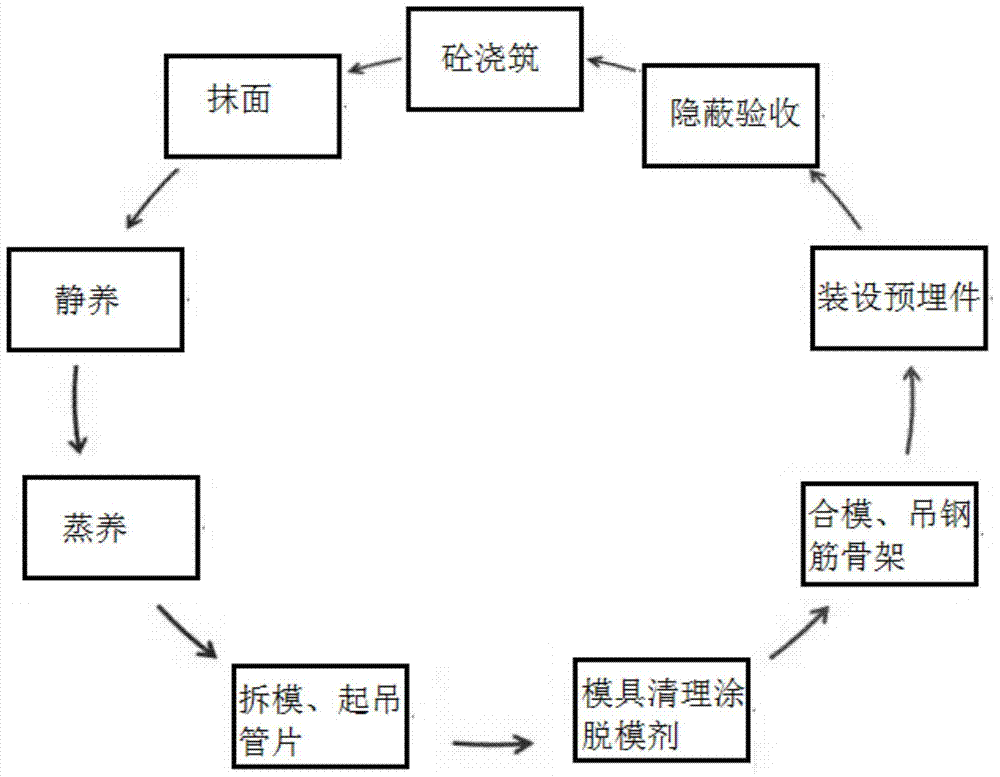

Shield tunnel segment prefabrication method

A shield segment and pre-steaming technology, applied in manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve the problems of low degree of automation and low production efficiency, and achieve the effect of promoting development and improving turnover utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0020] Rail transit has the characteristics of large capacity, fast speed, safety, punctuality, environmental protection, energy saving and land use. Rail transit has been developed into a backbone urban public transportation system.

[0021] During the construction of rail transit, a large number of shield segments are required. For example, Xiamen Rail Transit Line 1, as the most important central radial backbone line in the planning network of Xiamen City, radiates from the island to the north to form a cross-sea tunnel. The fast connection channel has a line length of 32.865km, 15.7km on the main island and 17.165km outside the island. Among them, the length of the shield construction section is about 25km, and the shield segment is about 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com