Method and device for forecasting concrete anti-leaking U-shaped groove by using permeability formwork gasket

A prefabricated concrete and U-shaped trough technology, which is applied in the direction of manufacturing tools, ceramic molding machines, ceramic molding workshops, etc., can solve the problems of low profit, low product quality, and difficult promotion of concrete anti-seepage U-shaped troughs, and achieve improved concrete Effects of compactness, improvement of concrete strength and impermeability, and cost reduction

Active Publication Date: 2010-11-24

NANJING HYDRAULIC RES INST THE MINISTRY OF WATER RESOURCES THE MINIST +1

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the concrete anti-seepage U-shaped grooves used in domestic farmland irrigation canals are affected by many factors such as design, production technology, and material costs. Most of the finished product section lengths can only be 50cm.

The shorter the joint length of the concrete anti-seepage U-shaped groove, the more joints will be assembled on site, and the more leakage will occur during water delivery. This is an obvious shortcoming of the current concrete anti-seepage U-shaped groove.

At the same time, due to the large amount of basic construction of farmland water conservancy and the relatively small investment, the profit of concrete anti-seepage U-shaped grooves is low, resulting in low quality products and difficult to promote

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

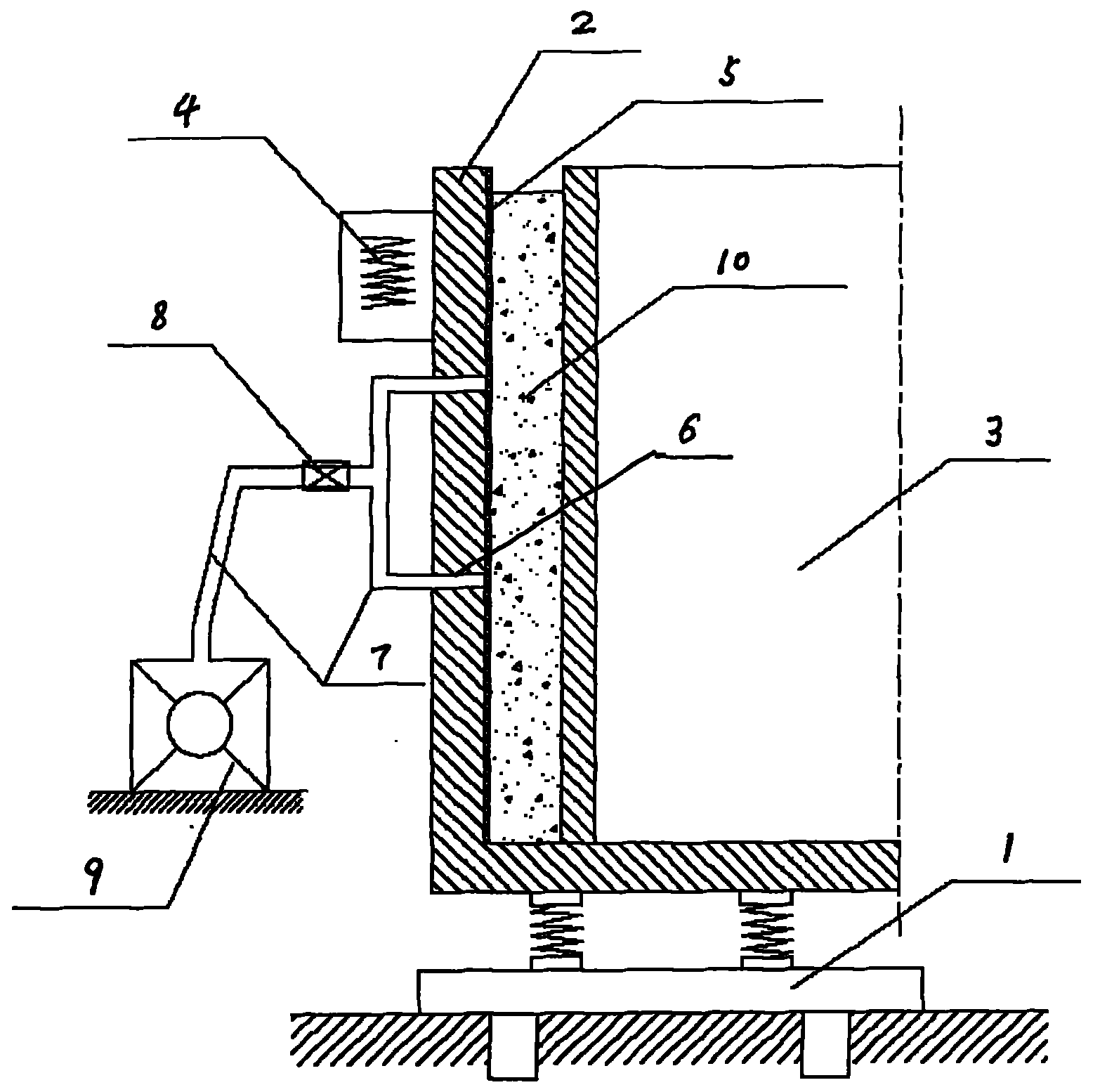

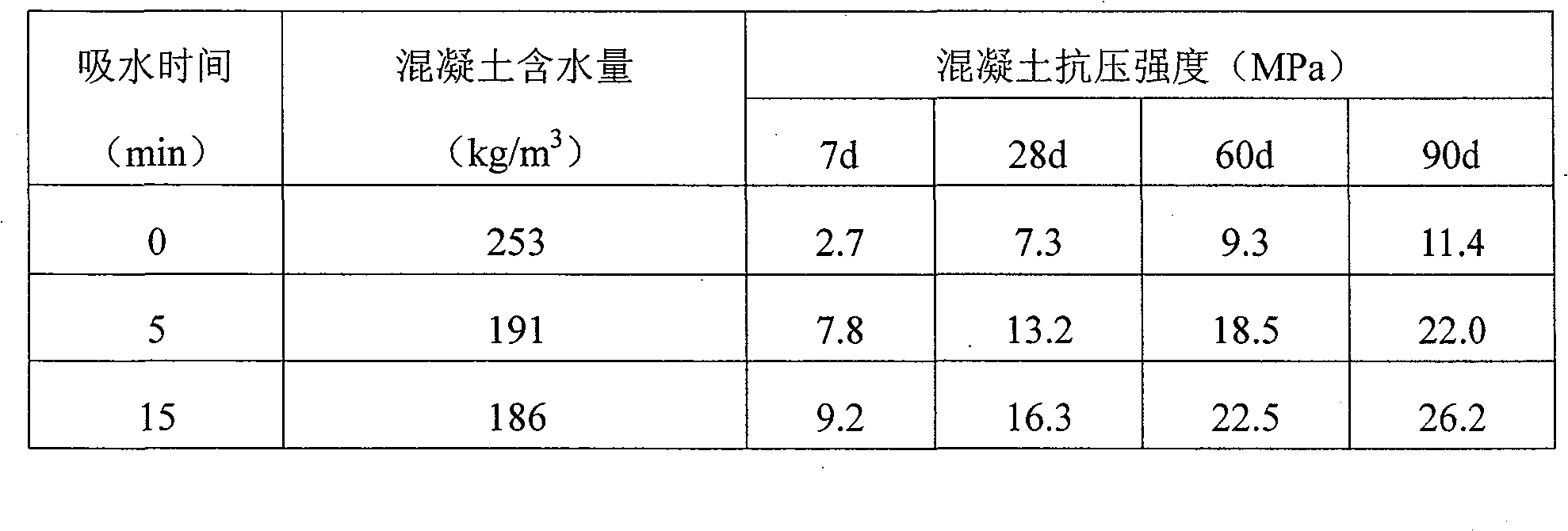

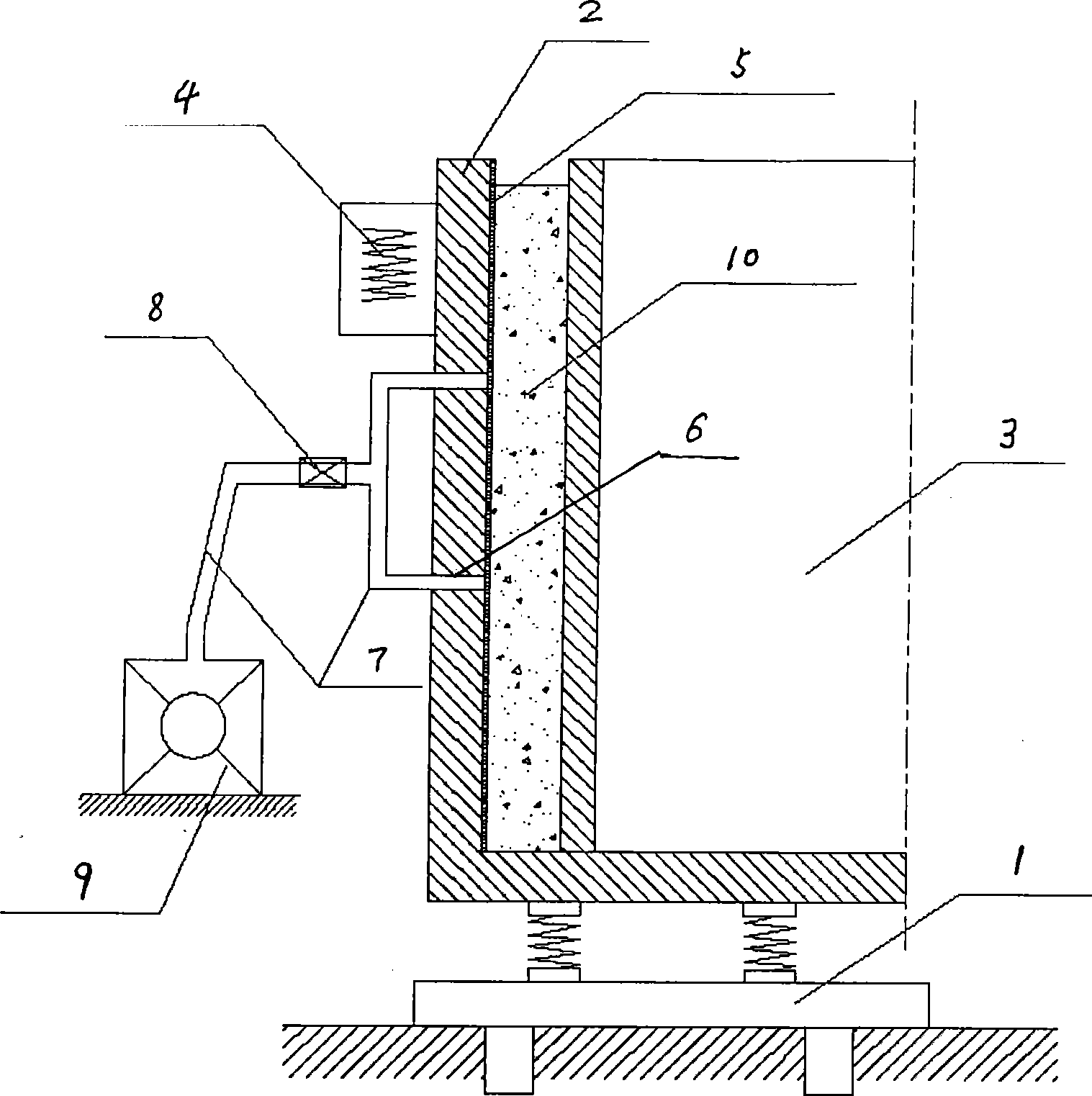

A method of prefabricating concrete antiseepage U-shaped groove by the permeable moldboard pad, the steps are that: placing the permeable moldboard pad in the steel die; placing the concrete mixture; vibrating the dense concrete; vacuum dewatering by actuating the hydro-exhauster water machine, at the same time vibration forming the concrete; hoisting to remove steel external mold of the U-shapedgroove; taking off the permeable moldboard pad; curing the concrete; removing the steel internal model of the U-shaped groove to obtain a U-shaped permeable groove product. The using devices of the method are that: an external mold is provided on the spring support, a vibrator is provided on the external mold, an internal model is placed in the external mold; the characteristics are that: a permeable moldboard pad and a suction hole are all provided on the external mold, the suction hole connects to the suction engine by the suction pipe. The invention can improve density, intensity and antiseepage of the concrete antiseepage U-shaped groove, and improve the end product quality; also can reduce cost; can remove the steel external mold of the U-shaped groove, the permeable moldboard pad after placing, the repeat utilizing rate and the prefabricating production efficiency of the steel external mold and the permeable moldboard pad are improved.

Description

Method and equipment for prefabricating concrete anti-seepage U-shaped groove by using permeable template liner technical field The invention relates to a method for prefabricating a concrete anti-seepage U-shaped groove by using a permeable template liner, and equipment used in the production method. Background technique At present, the concrete anti-seepage U-shaped grooves used in domestic farmland irrigation canals are affected by many factors such as design, production technology, and material costs. Most of the finished product section lengths can only be 50cm. The shorter the joint length of the concrete anti-seepage U-shaped groove, the more joints will be assembled on site, and the more leakage will occur during water delivery. This is an obvious shortcoming of the current concrete anti-seepage U-shaped groove. At the same time, due to the large amount of farmland water conservancy infrastructure construction and the relatively small investment, the profit of the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B28B1/08B28B1/26B28B15/00B28B1/087

Inventor 陈迅捷张燕迟鄢俊梁菊明钱文勋欧阳幼玲

Owner NANJING HYDRAULIC RES INST THE MINISTRY OF WATER RESOURCES THE MINIST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com