Novel internal mould trolley walking device for carriageway in prefabrication of immersed tube tunnel tube segment

An immersed tunnel and traveling device technology, which is applied to ceramic forming cores, ceramic forming mandrels and other directions, can solve the problems of increased construction cost, large amount of disassembly and assembly works, increased construction period and cost, etc., and achieves simple sliding mode and driving Simple way and the effect of improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

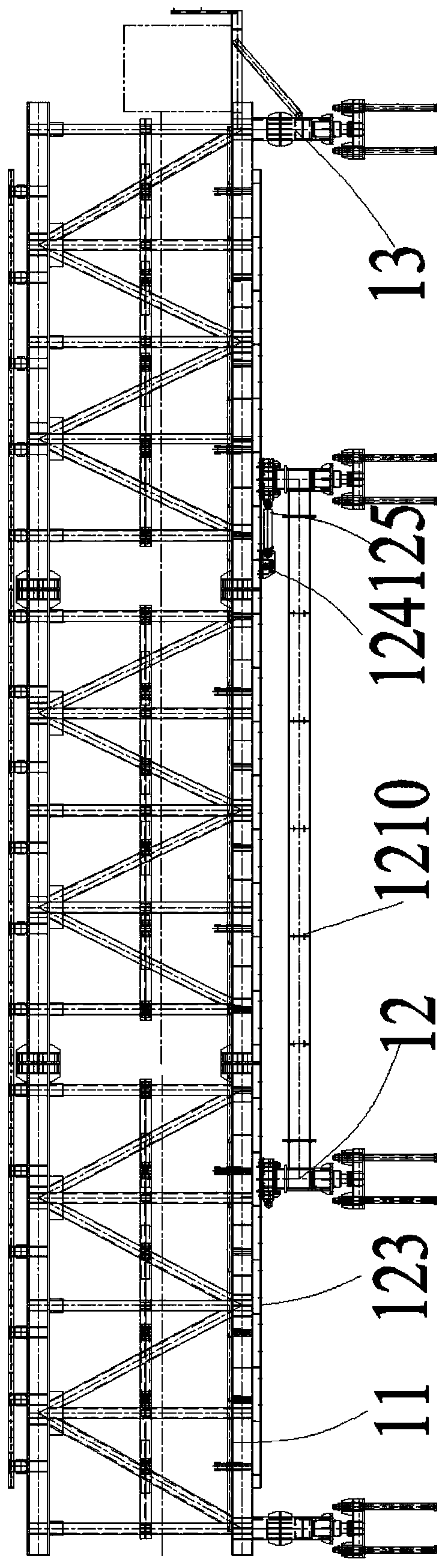

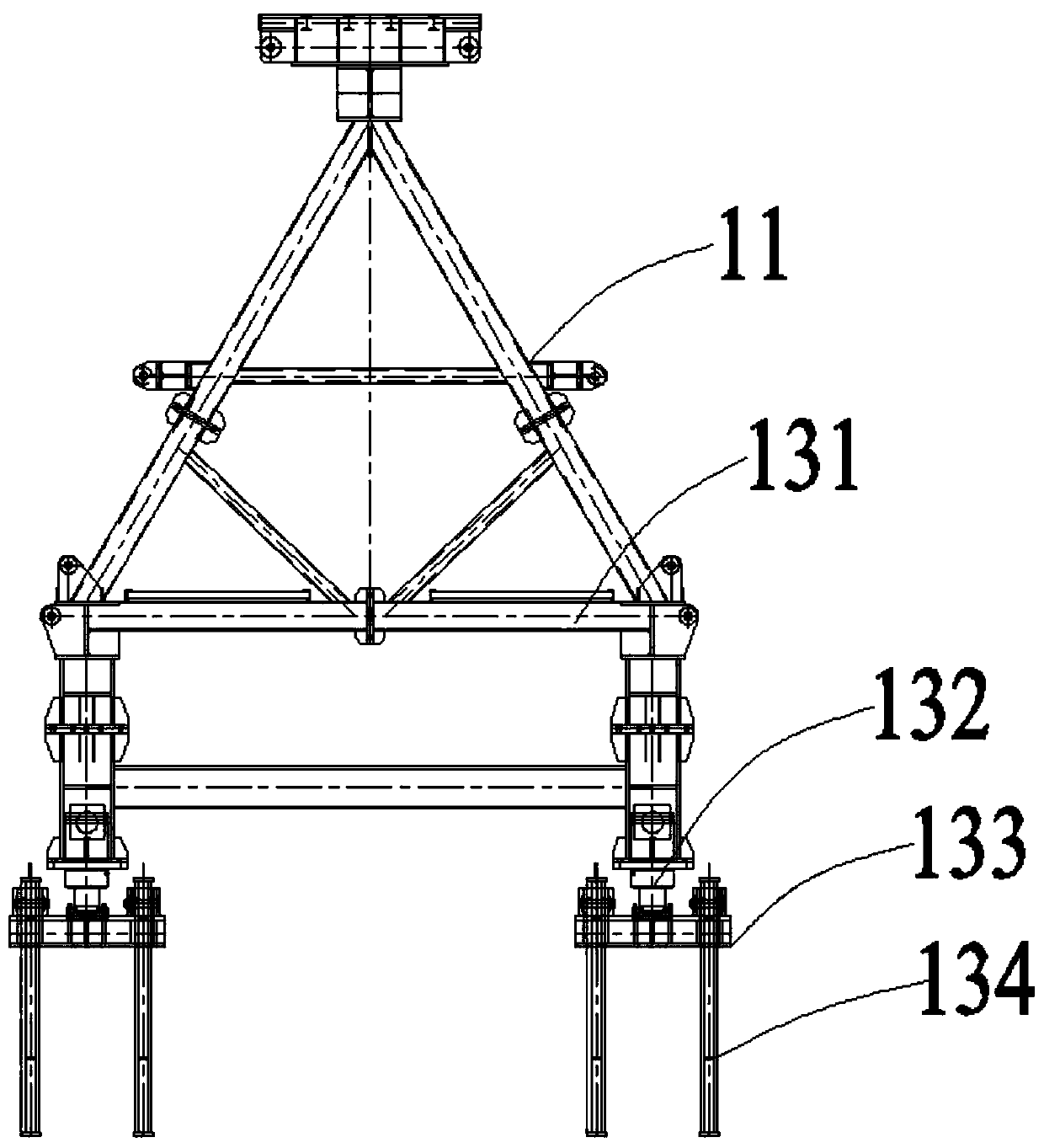

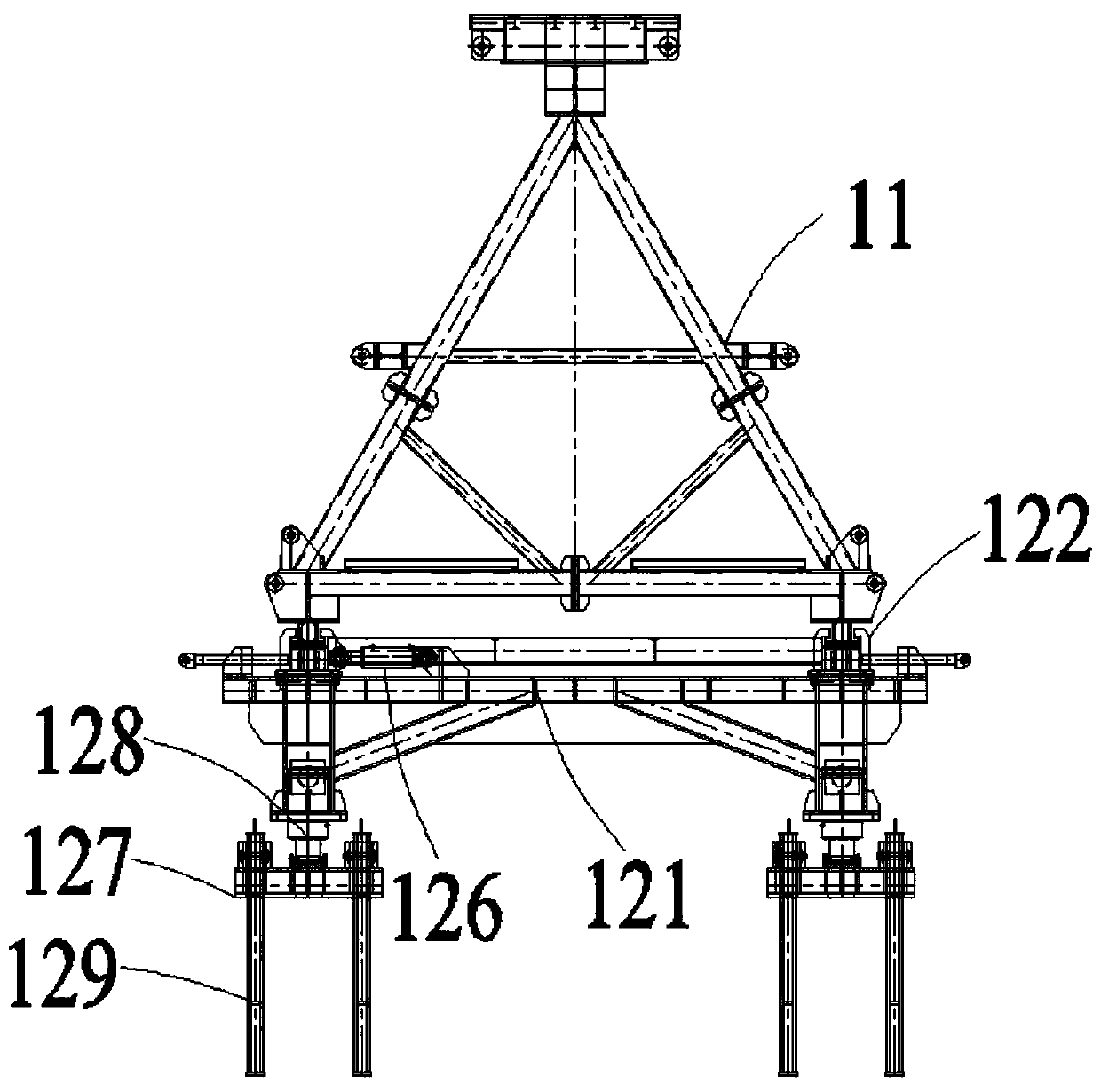

[0025] The walking device of this embodiment is located below the inner mold trolley 11, so that the inner mold trolley 11 has the functions of longitudinal, horizontal and vertical position adjustment. The lower end of the inner mold trolley 11 is provided with at least two inner mold fixing legs 13 and at least two movable legs 12 of the inner mold, such as Figure 1~3 As shown, the present embodiment is two inner mold fixed legs 13 and two inner mold movable legs 12, and the two inner mold fixed legs 13 are respectively located at the longitudinal ends of the inner mold trolley 11, and the two inner molds are movable The legs 12 are located between the two fixed legs 13 of the inner mold, and the inner mold connecting beams 1210 arranged horizontally and longitudinally are arranged between the two groups of movable legs 12 of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com