Patents

Literature

55results about How to "Avoid the risk of deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

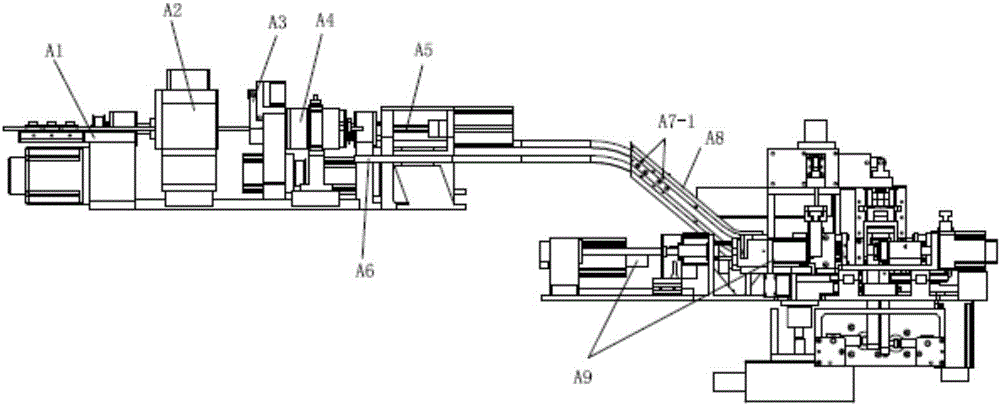

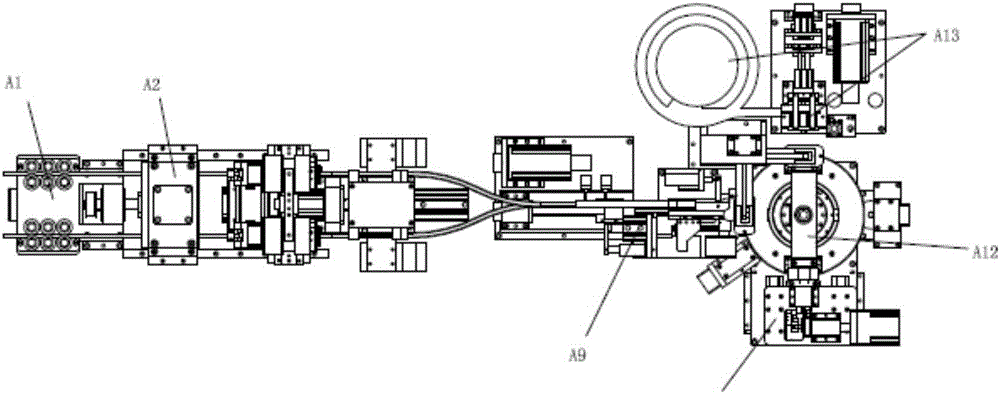

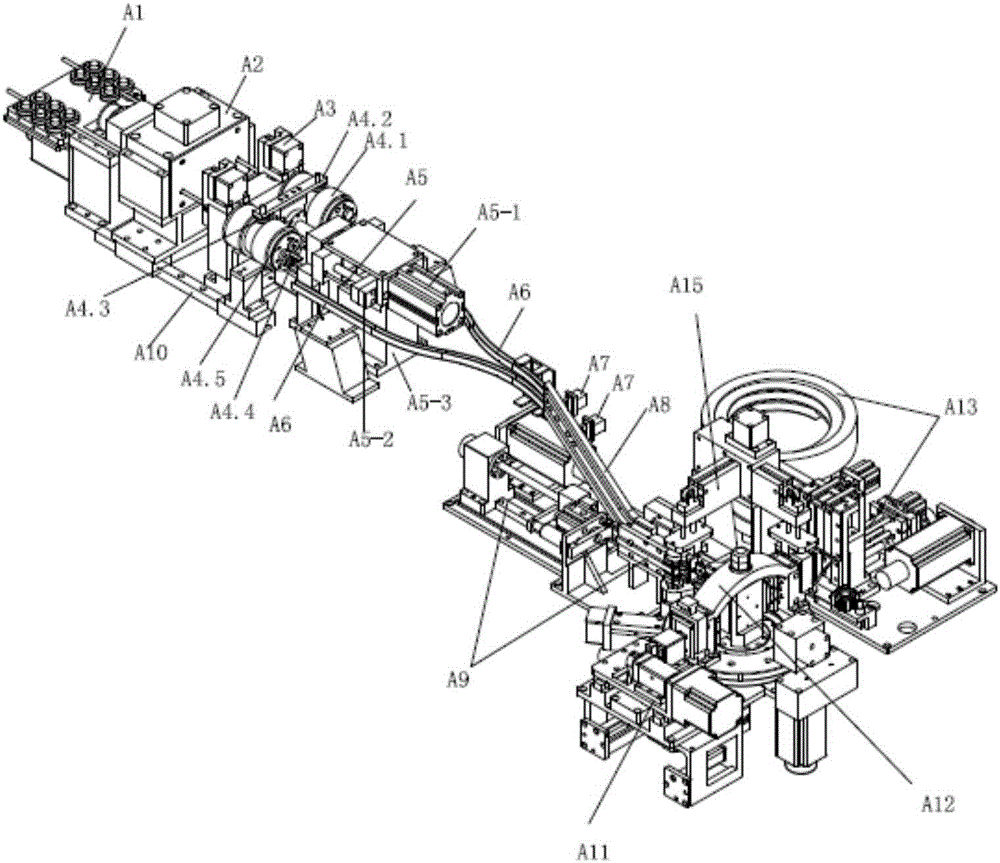

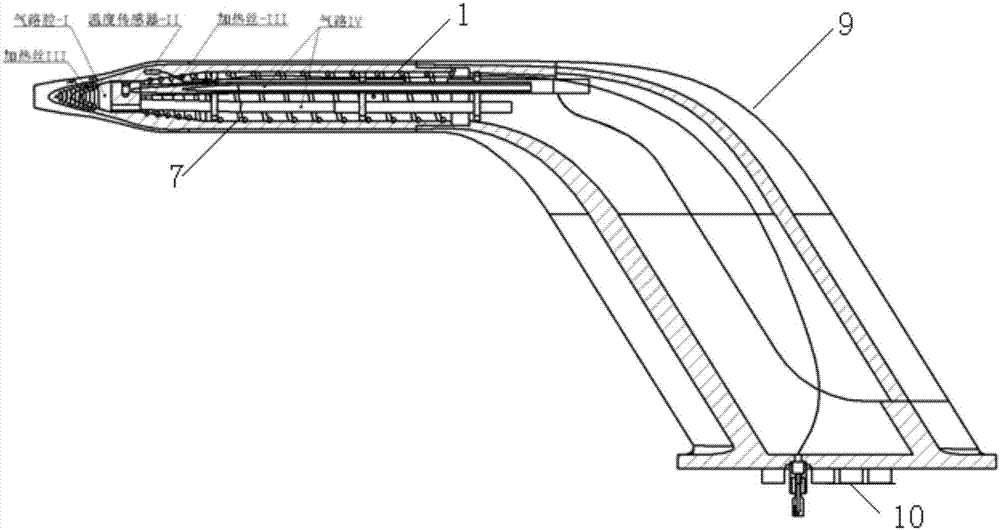

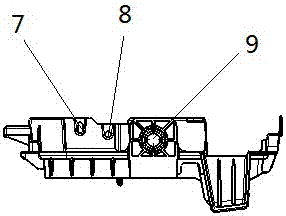

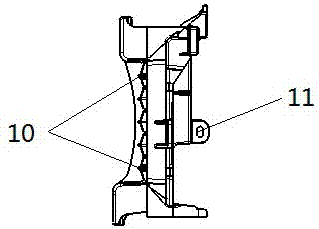

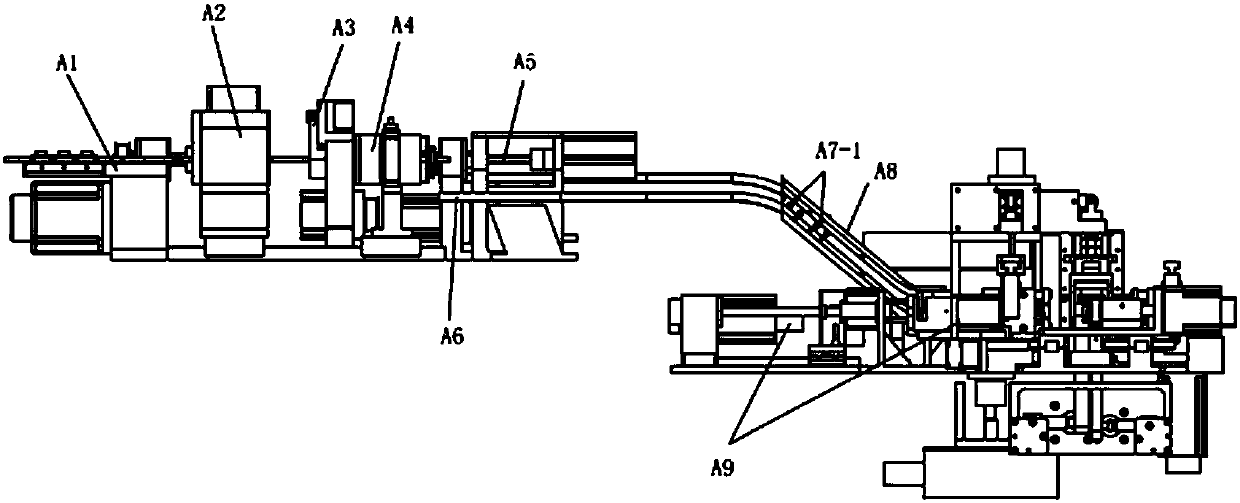

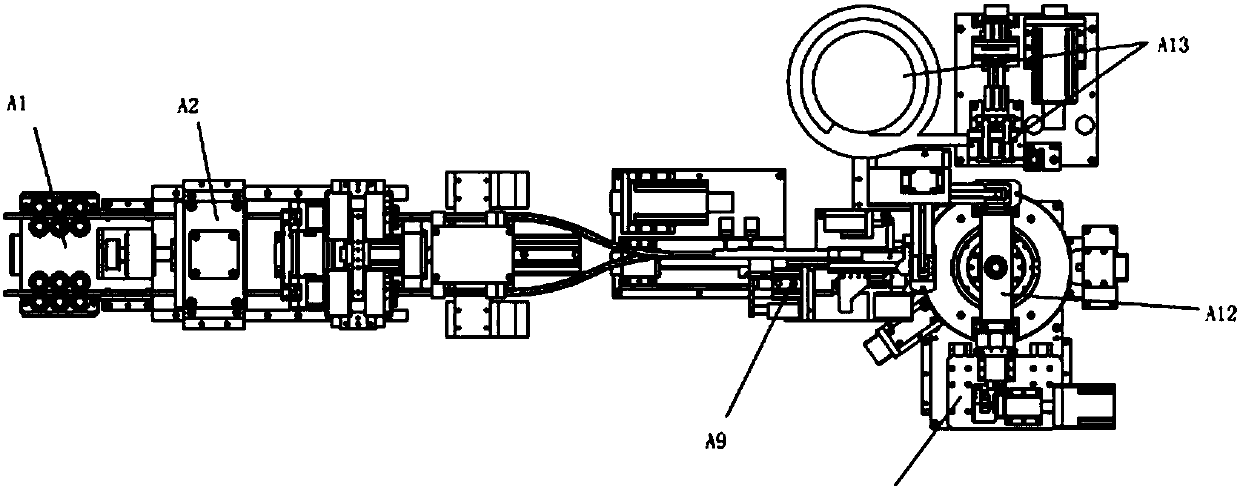

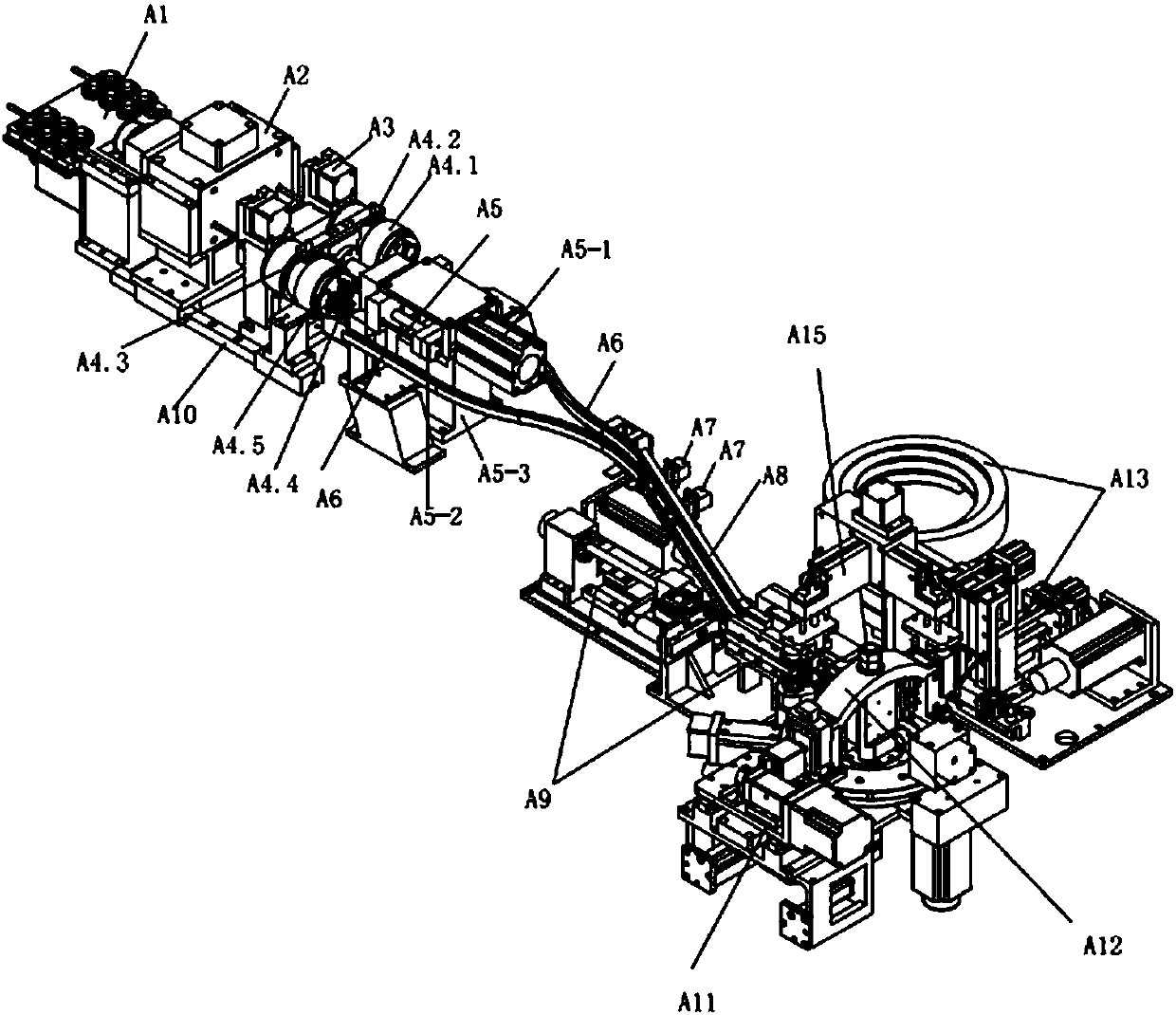

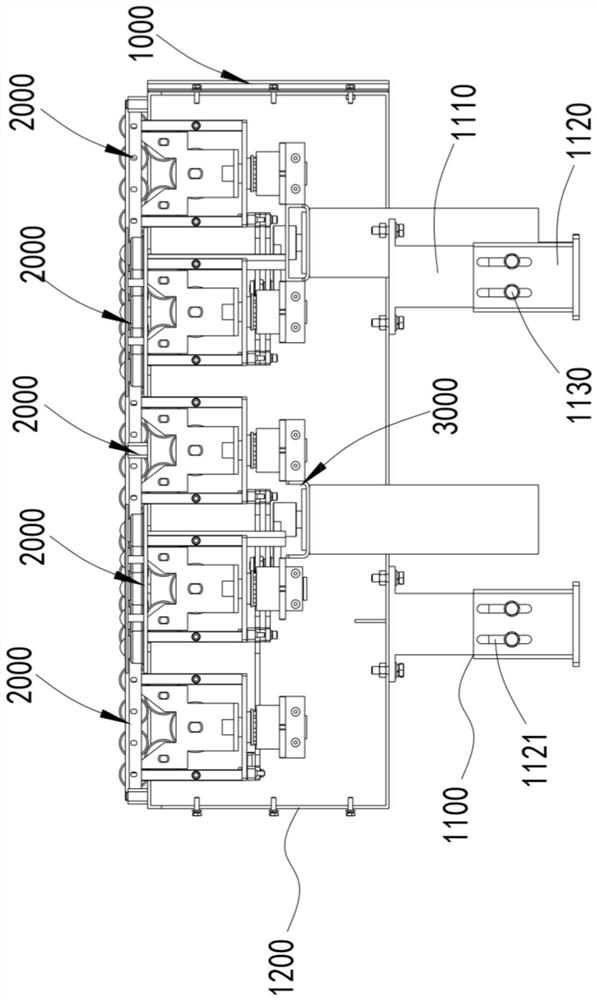

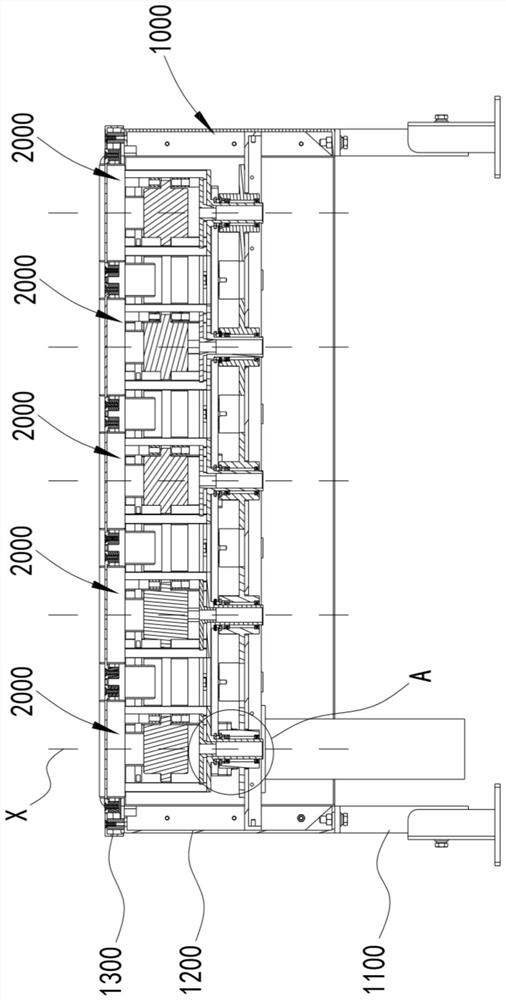

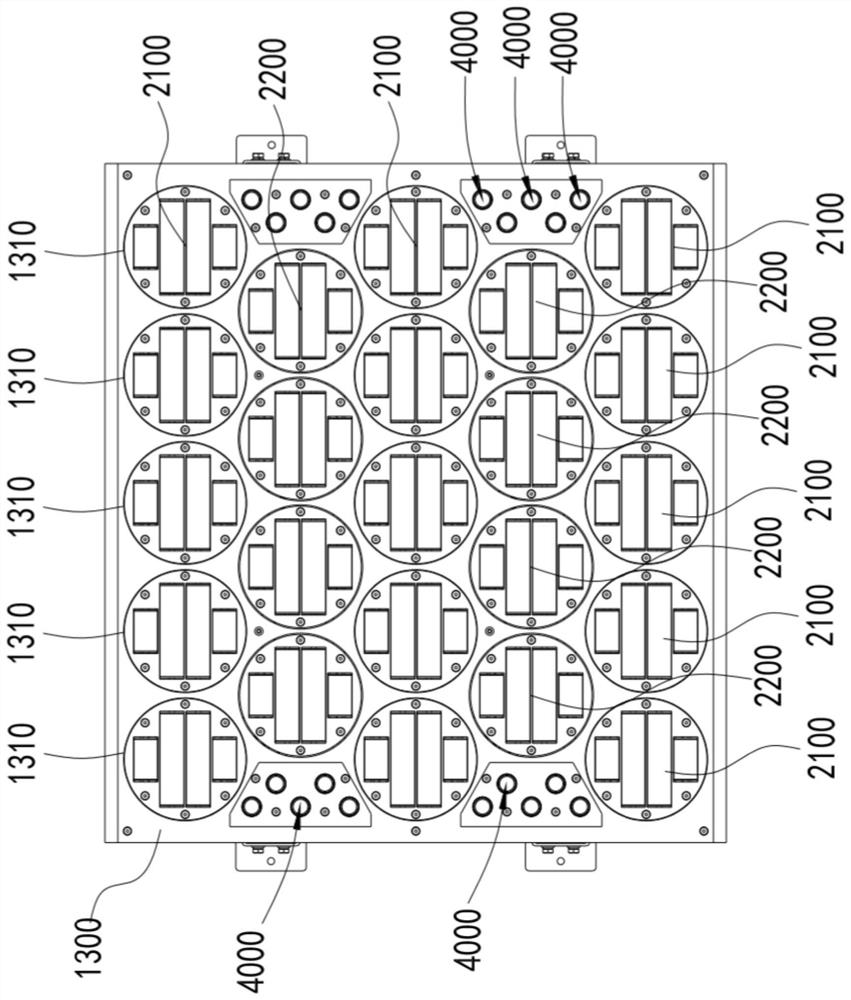

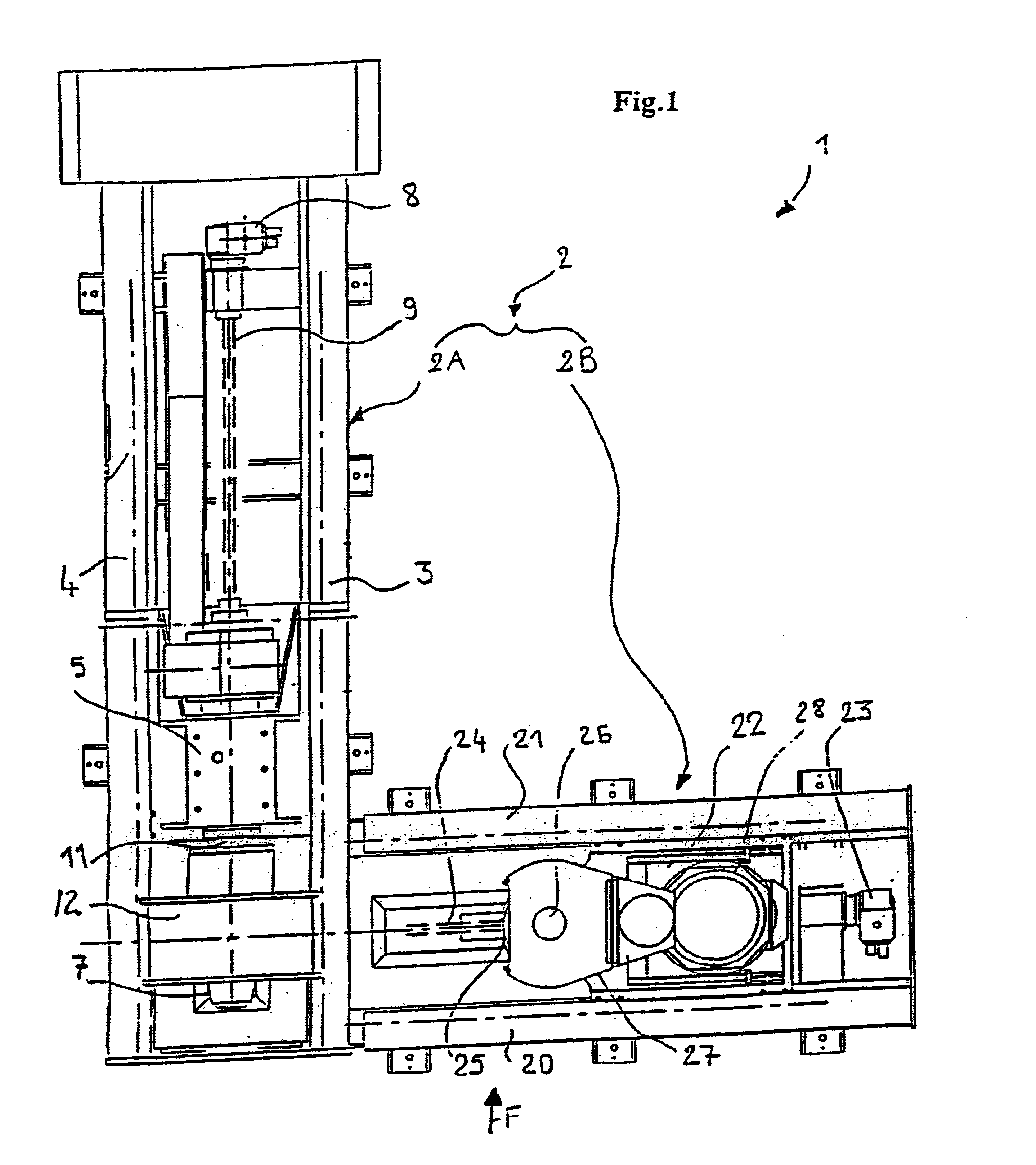

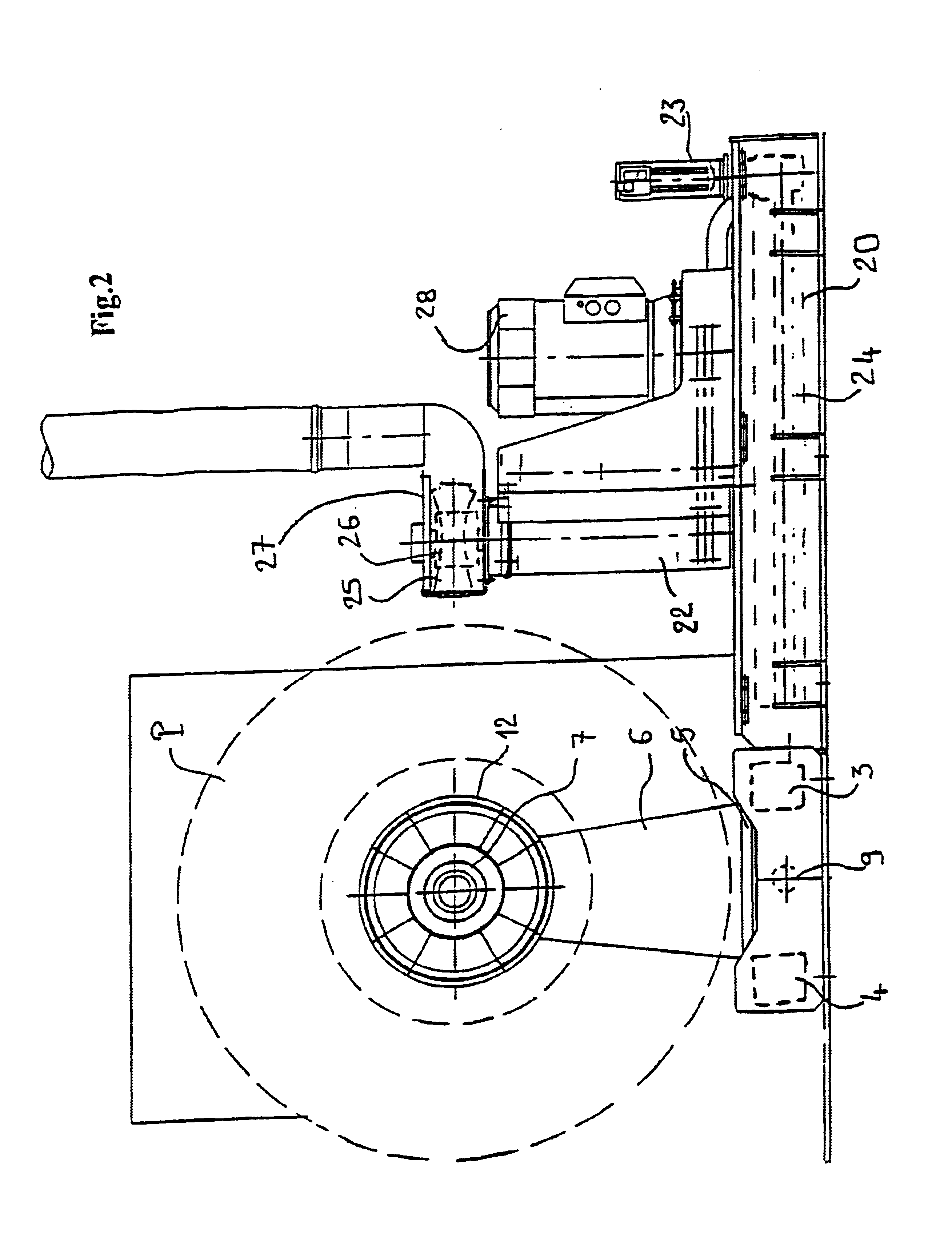

Automatic forming machine of thin-walled short U bent pipe with welding ring

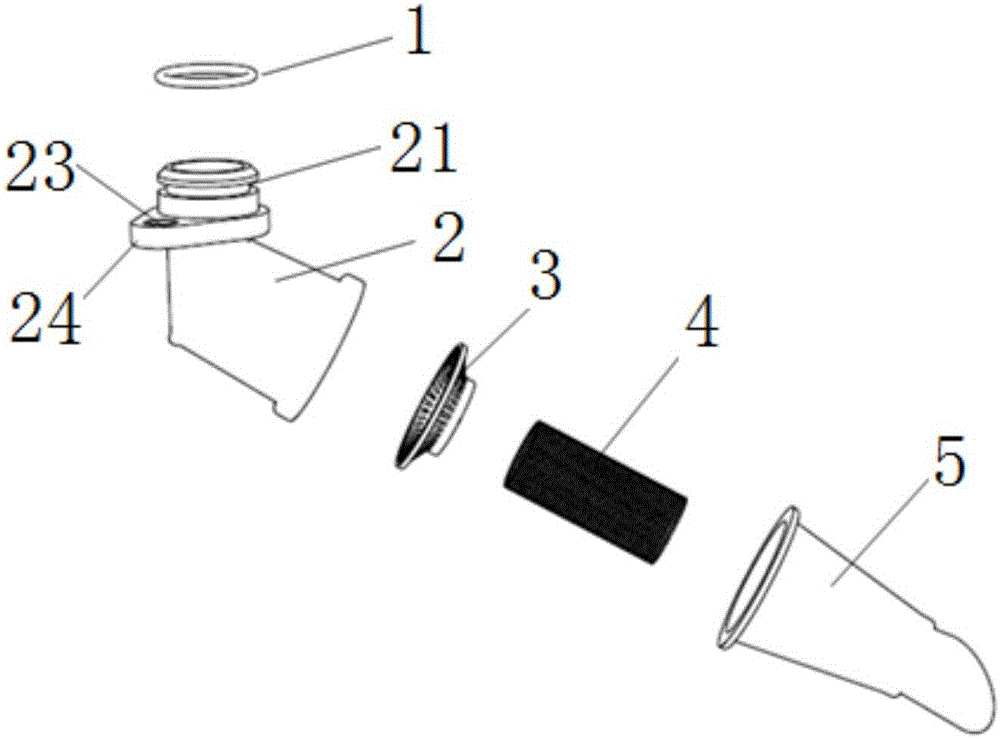

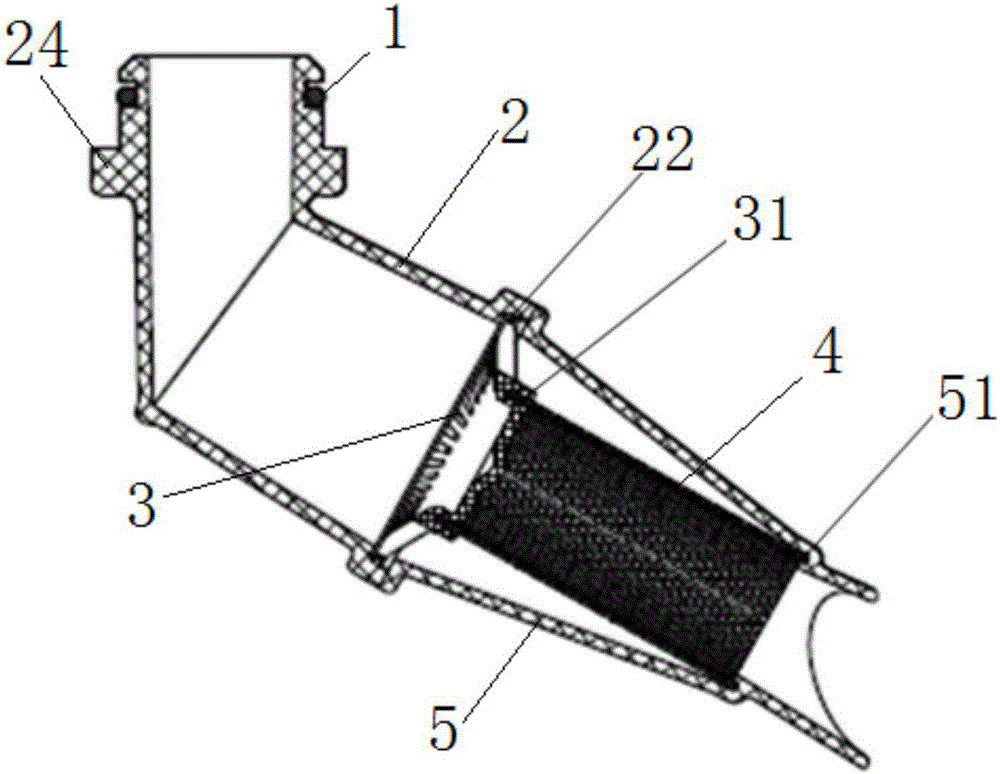

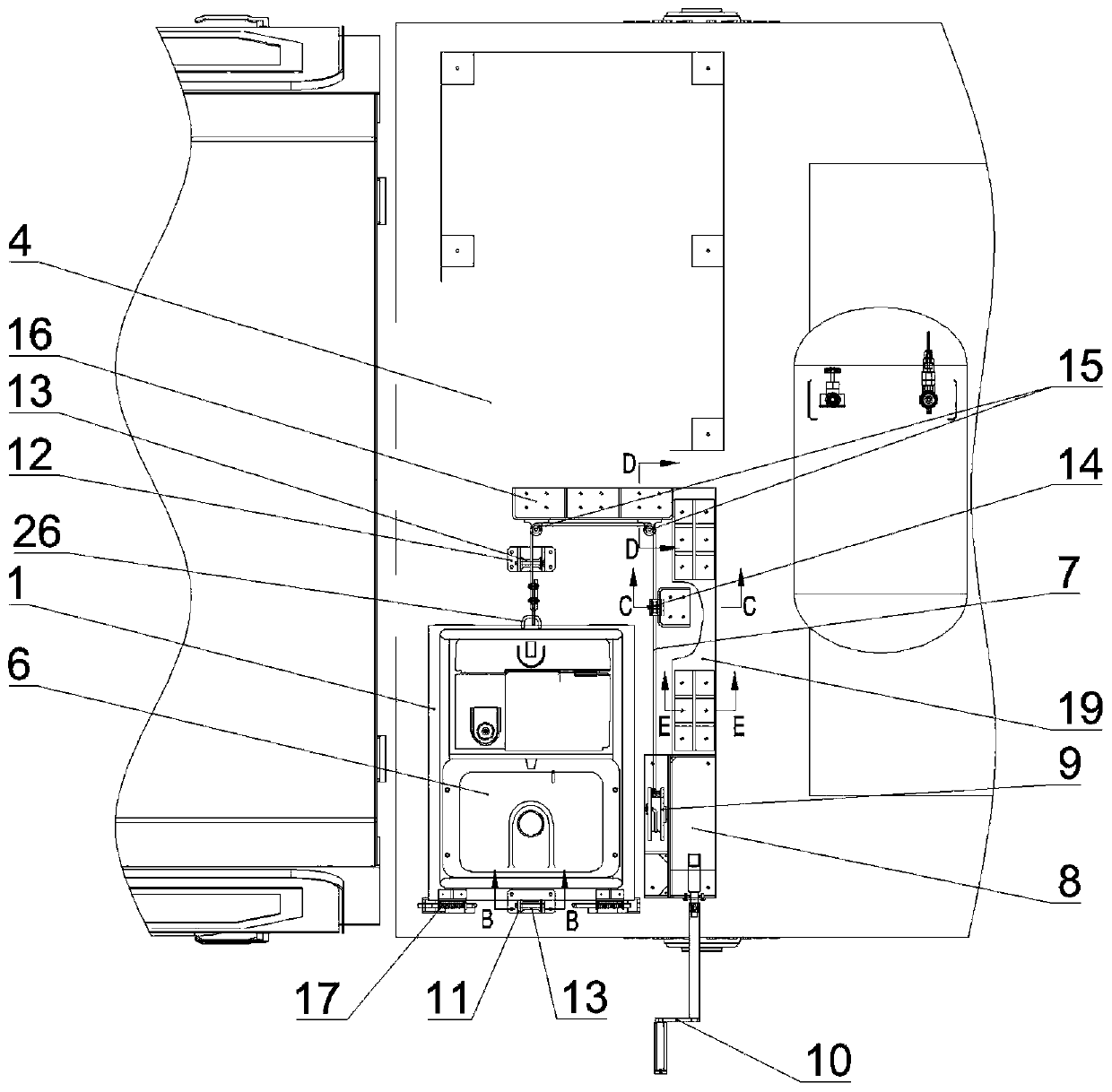

ActiveCN106270239AEliminate wasteGuaranteed not to deformMetal-working feeding devicesOther manufacturing equipments/toolsEngineeringFixed length

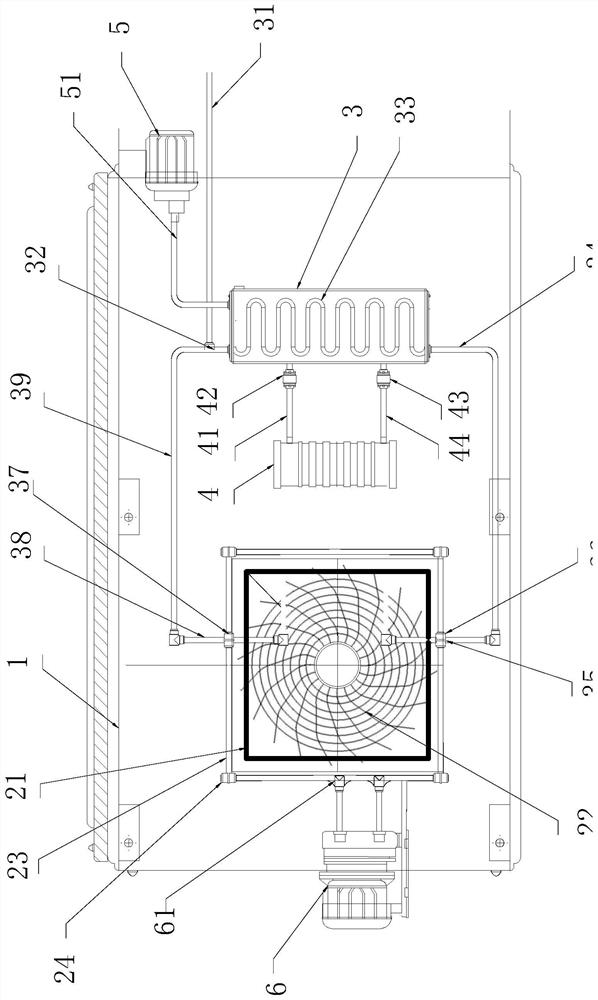

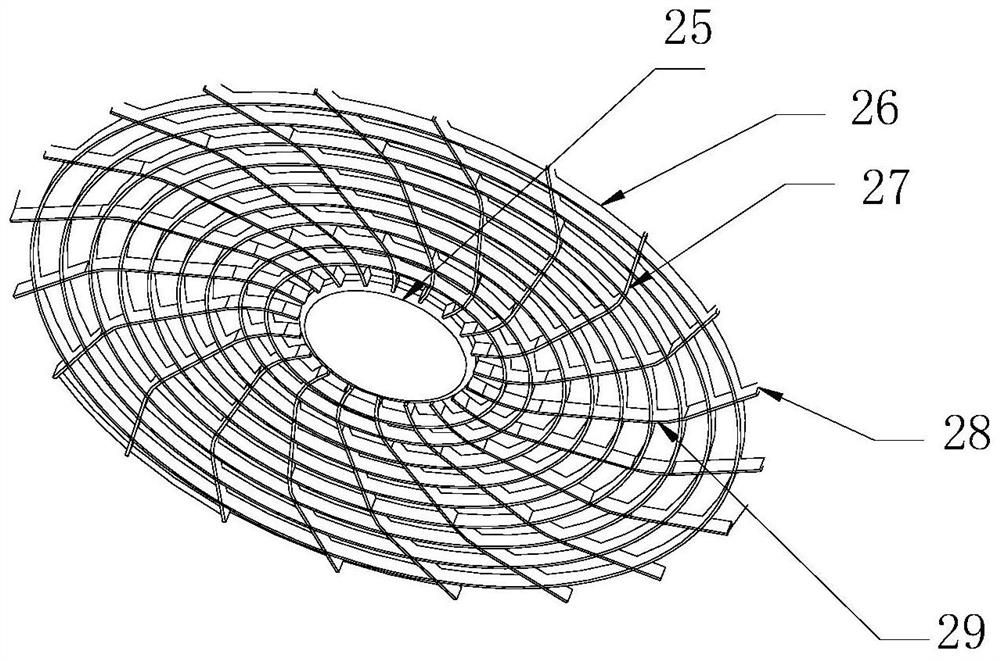

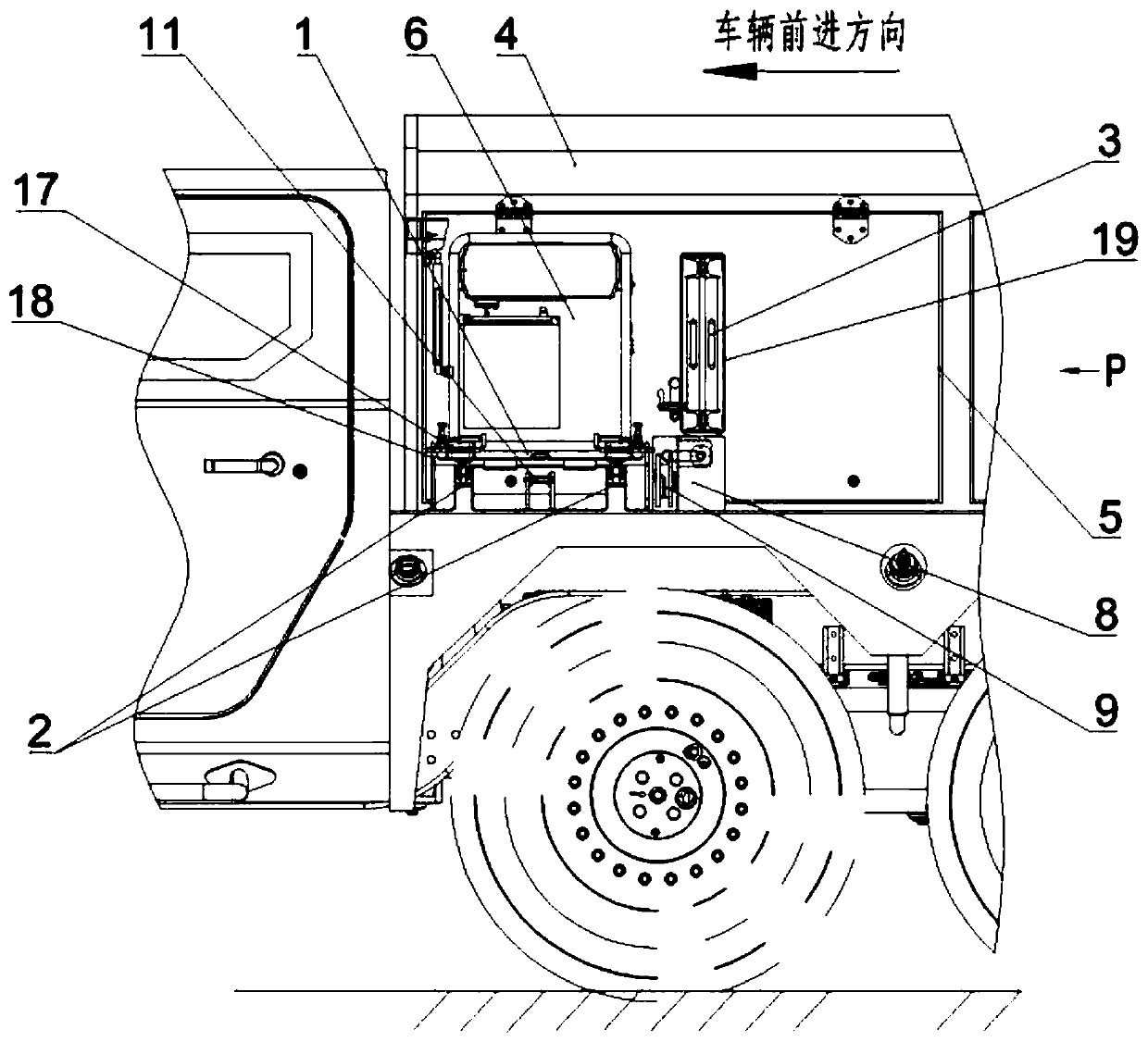

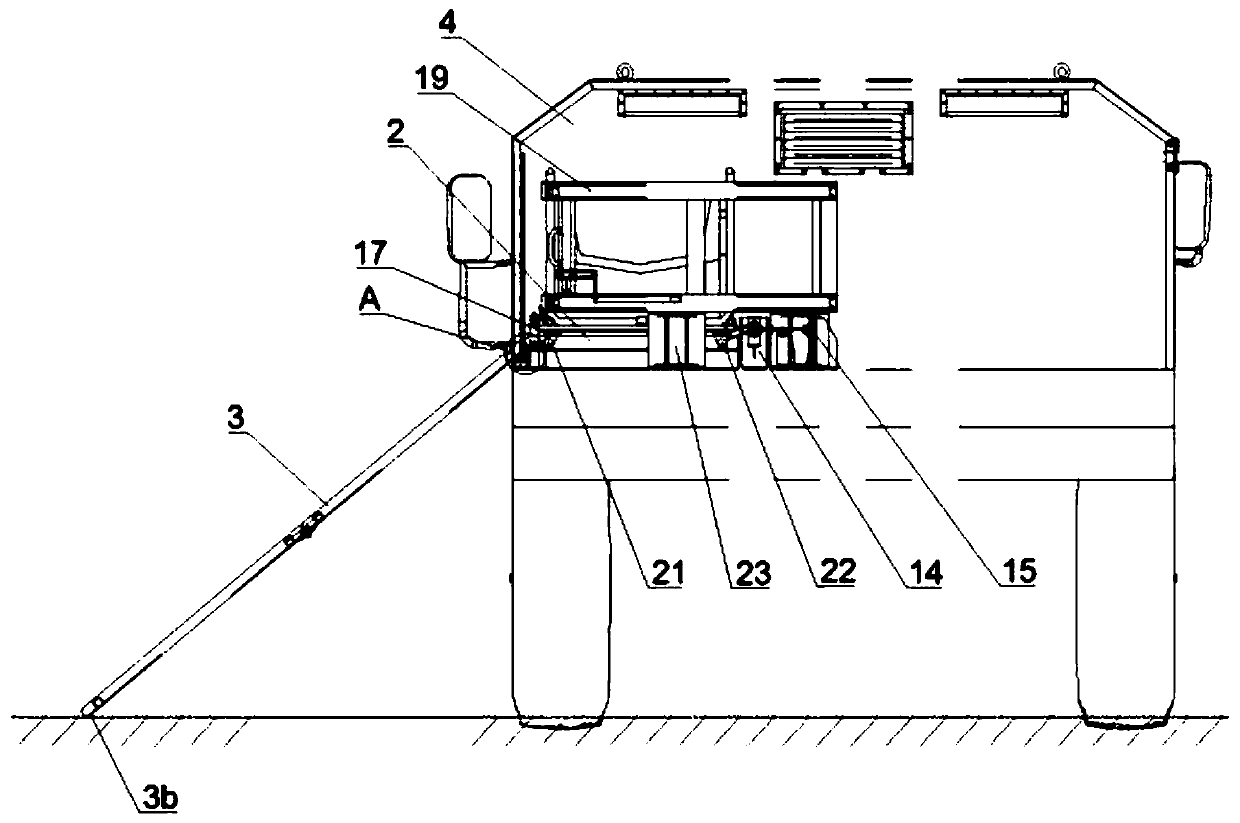

The invention discloses an automatic forming machine of a thin-walled short U bent pipe with a welding ring, relates to the technical field of automation equipment, and can continuously accomplish the forming of the thin-walled short U bent pipe and socket welding ring operation, so as to prevent a pipe wall from folds. The automatic forming machine comprises a feeding assembly, a pipe cutting assembly, a pipe bending assembly, a circumference position rotating assembly and a socket welding ring assembly, wherein the feeding assembly at least comprises a clamping mechanism and a No.1 driving mechanism; the No.1 driving mechanism drives the clamping mechanism to perform forward feeding; the pipe cutting assembly at least comprises a cutting tool mechanism and a No.2 driving mechanism; the No.2 driving mechanism drives a cutting tool to act; the pipe bending assembly at least comprises a fixed part, a semicircle die, a movable part and a No.3 driving mechanism; one end of a fixed length pipe is clamped at the fixed part; the other end of the fixed length pipe gets over the semicircle die and then is movably matched with the movable part; the circumference position rotating assembly at least comprises a rotating frame, a pipe clamping mechanism, a No.4 driving mechanism and a discharging cylinder; the socket welding ring assembly at least comprises a welding ring feeding unit, a welding ring guide unit and a socket welding ring unit; the socket welding ring unit pushes the welding ring to a straight pipe section of the thin-walled short U bent pipe.

Owner:TONGLU QIANDING TECH

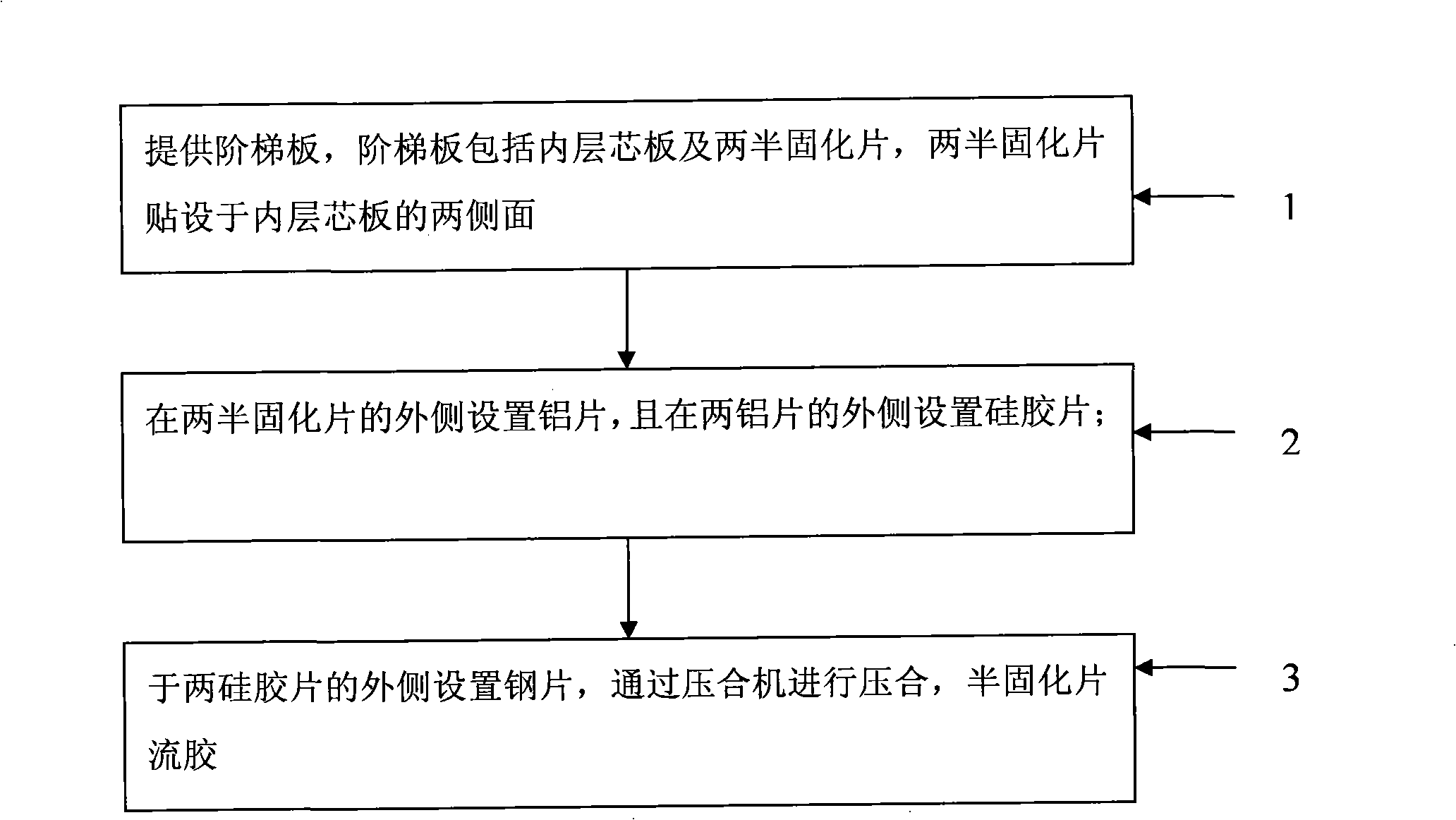

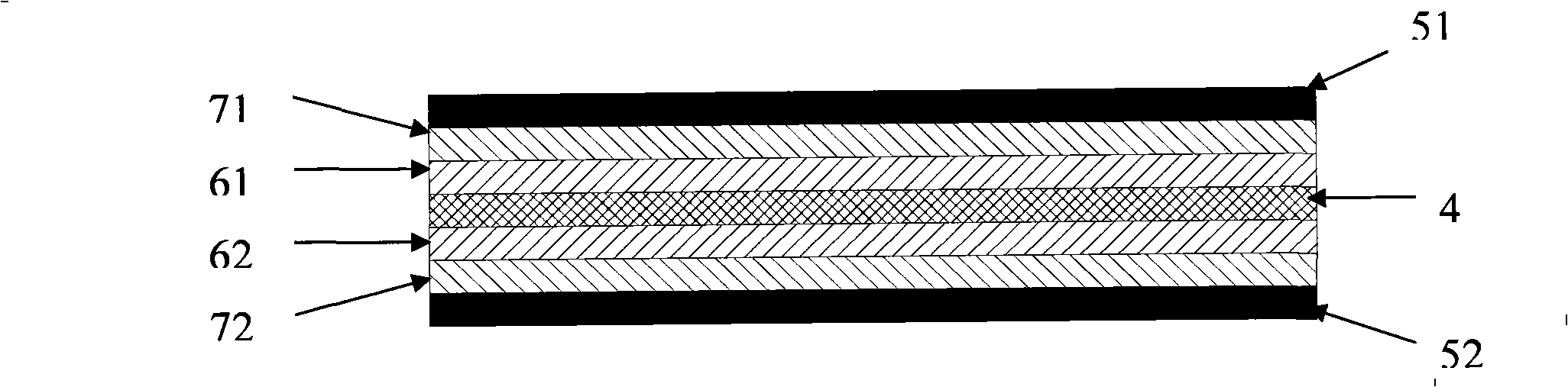

Method for processing step ladder PCB plate

InactiveCN101351079AAvoid local voidsDecrease the horizontal stretchLaminationLamination apparatusEngineeringSilicon rubber

The invention relates to a method for processing a ladder PCB plate, which includes the following steps: a ladder plate is provided and comprises an inner layer core plate and two prepregs which are attached to the two sides of the inner layer core plate; silicon rubber slices are arranged at the external sides of two aluminum sheets which are arranged at the external sides of the two prepregs; steel sheets which are arranged at the external sides of the two silicon rubber slices are pressed by a pressing machine and the gummosis is carried out for the prepregs. By arranging the aluminum sheets and silicon rubber slices in the laminating process, the method for processing the ladder PCB plate leads the gummosis of the ladder plate to be distributed evenly to avoid the local cavity of the ladder plate with the help of the cushioning property of the silicon rubber slices; at the same time, the combination mode of the aluminum sheets and the silicon rubber slices is adopted to reduce the level tensile force imposed to a ladder groove by the silicon rubber slices so as to avoid the risk of deformation in the laminating process, caused by the middle suspension of the ladder groove and the ladder PCB plate manufactured is caused to have good qualified rate and excellent performance.

Owner:DONGGUAN SHENGYI ELECTRONICS

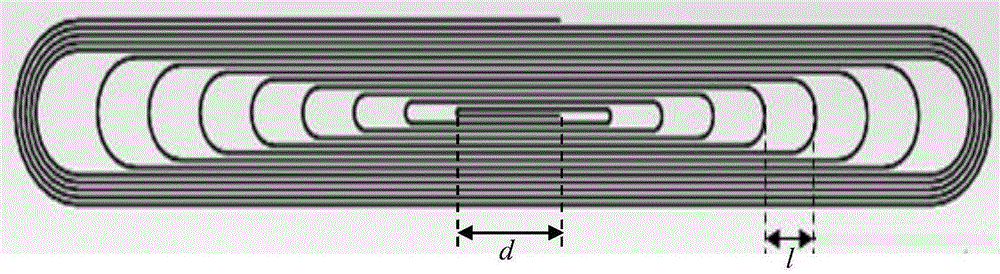

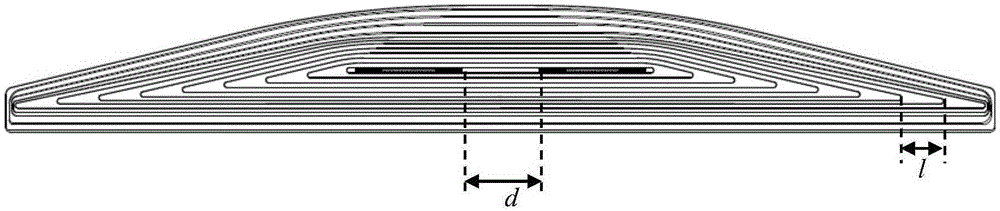

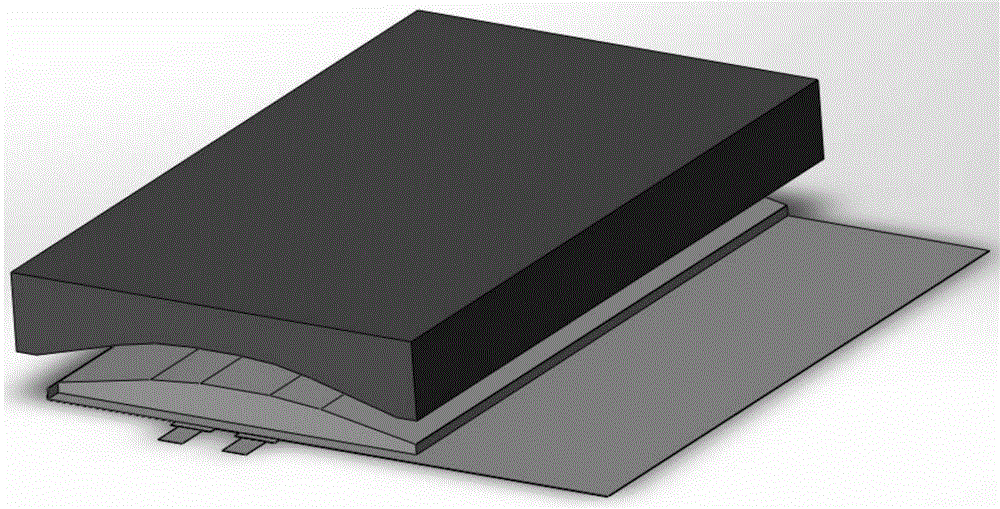

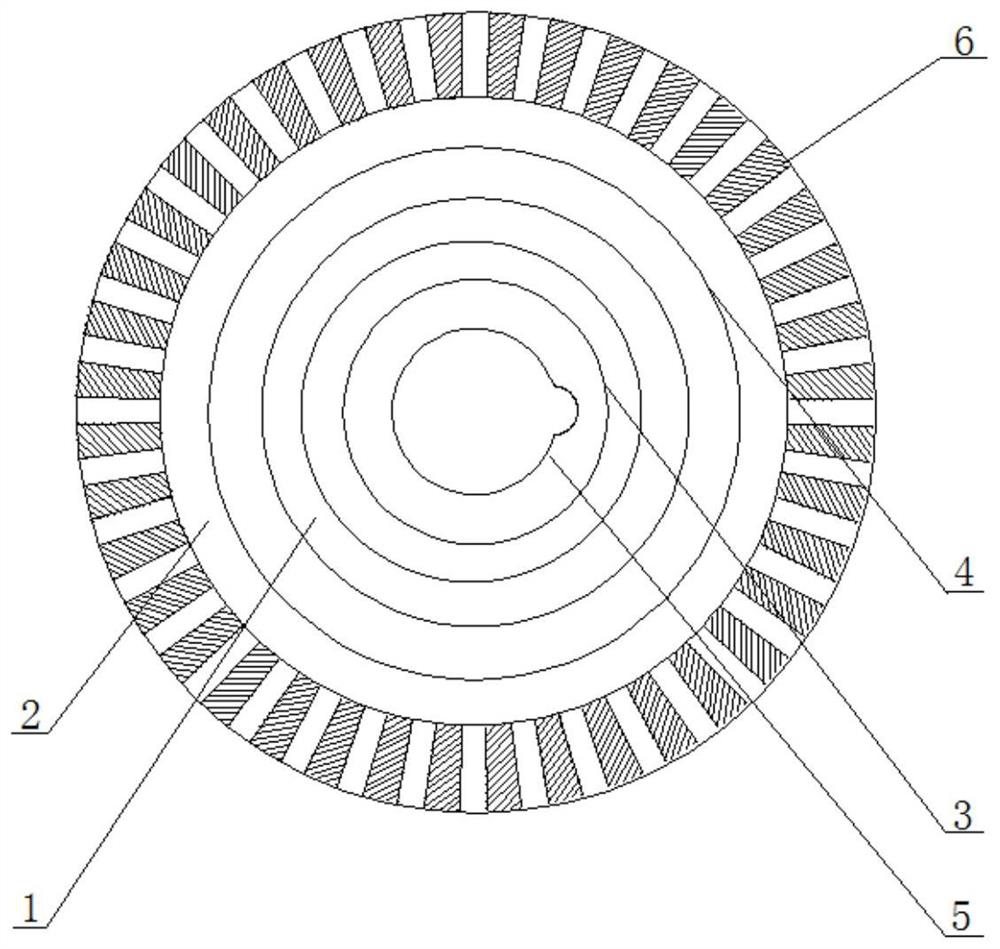

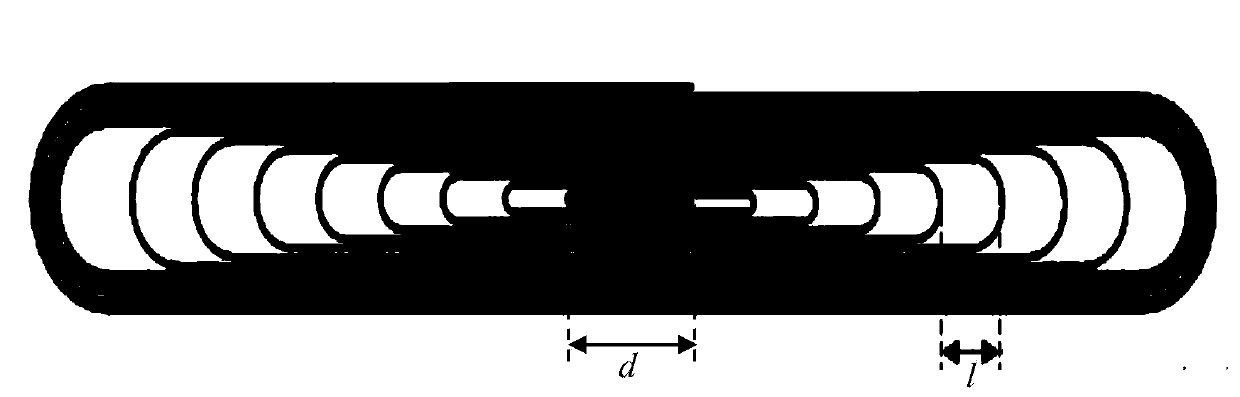

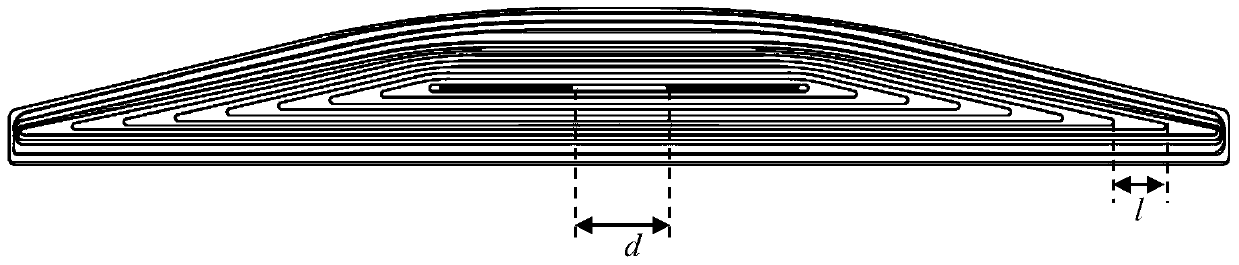

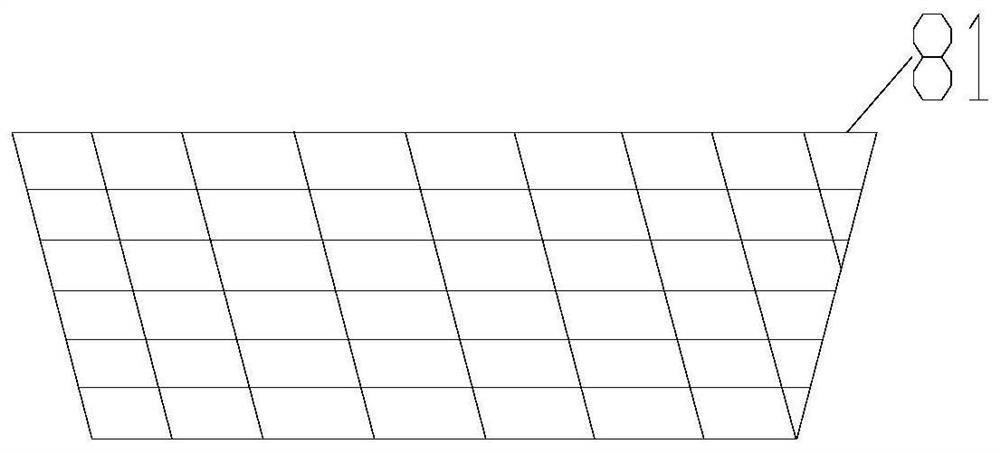

Manufacturing method for coiled trapezoidal battery cell and trapezoidal battery cell

ActiveCN105428725AAppearance continuous smooth declineUniform stress distributionFinal product manufactureSecondary cellsEngineeringBattery cell

The invention discloses a manufacturing method for a coiled trapezoidal battery cell and the trapezoidal battery cell. Intervals are formed between turning points of first to Nth circles of adjacent coiled materials of the trapezoidal battery cell; no intervals are formed between turning points of Nth to Mth circles of adjacent coiled materials; and the hotly pressed cross section of the battery cell is trapezoidal. The method comprises: during battery cell coiling, inserting a coiling needle when each of first to Nth circles is coiled, and increasing the coiling diameter of each circle by one expansion width relative to that of a previous circle, so that an interval is formed between the turning point of the nth circle of the coiled material and the turning point of the (n+1)th circle of the coiled material; completely coiling the residual coiled material by the fixed coiling diameter from the Nth circle to the Mth circle; and hotly pressing and shaping a coiled cell by adopting a clamp with a trapezoidal groove to obtain the battery cell with the trapezoidal cross section. The trapezoidal battery cell manufactured with the method can maximally use a reserved space of a device, so that the design capacity of the battery cell is increased; and the stress can be averagely distributed to the transitional oblique surface of the battery cell, so that the problem of deformation of the battery cell after long-term cycle can be avoided.

Owner:ZHUHAI COSMX BATTERY CO LTD

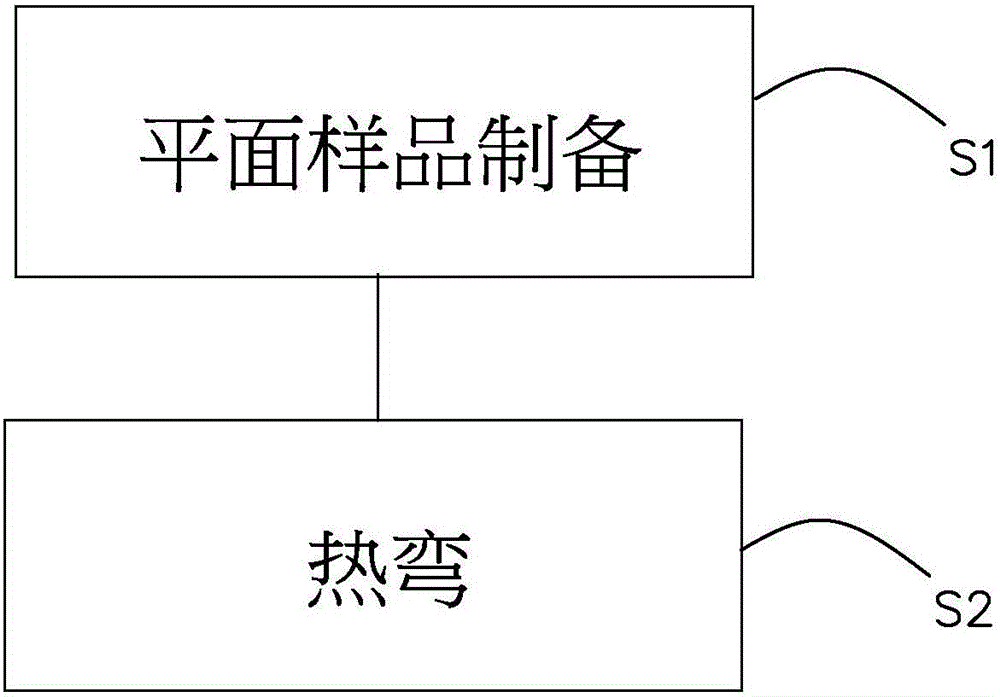

Preparation method for mobile communication equipment outer shell

InactiveCN107433670AAvoid the risk of deformationImprove yieldCeramic extrusion diesEngineeringCommunication device

The invention provides a preparation method for a mobile communication equipment outer shell. The mode that a flat sample is prepared first and then hot bending is conducted is adopted, the risk of deformation caused by the fact that a formed product is sintered is avoided, the yield rate of the product is greatly increased, and therefore the production cost is reduced; and meanwhile a certain pressure is applied in the sintering process, so that finally, the prepared product is good in density, fracture toughness, bending resistance and the like.

Owner:AAC TECH PTE LTD

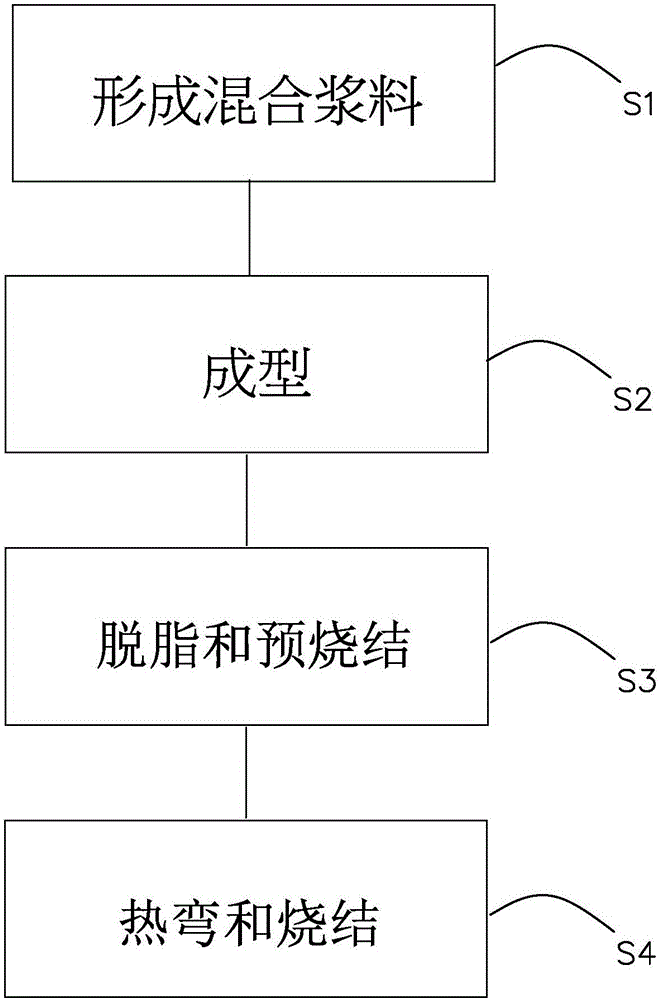

Preparation method for mobile communication equipment outer shell

InactiveCN107433672AReduce processAvoid the risk of deformationShaping conveyorsTelephone set constructionsVolumetric Mass DensityCommunication device

The invention provides a preparation method for a mobile communication equipment outer shell. The mode that sintering and hot bending are integrated is adopted, the working procedure is reduced, thus the risk of deformation caused by independent sintering is avoided correspondingly, the yield rate of a product is greatly increased, and therefore the production cost is reduced; and meanwhile a certain pressure is applied in the sintering process, so that finally, the prepared product is good in density, fracture toughness, bending resistance and the like.

Owner:AAC TECH PTE LTD

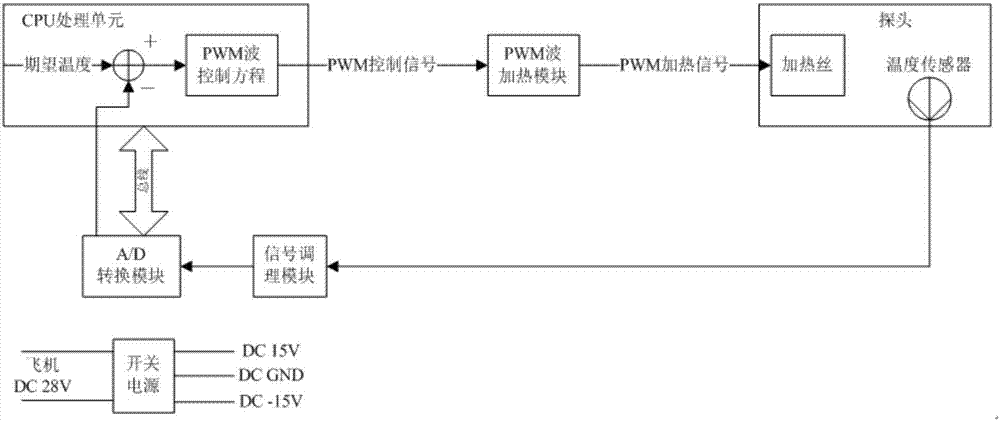

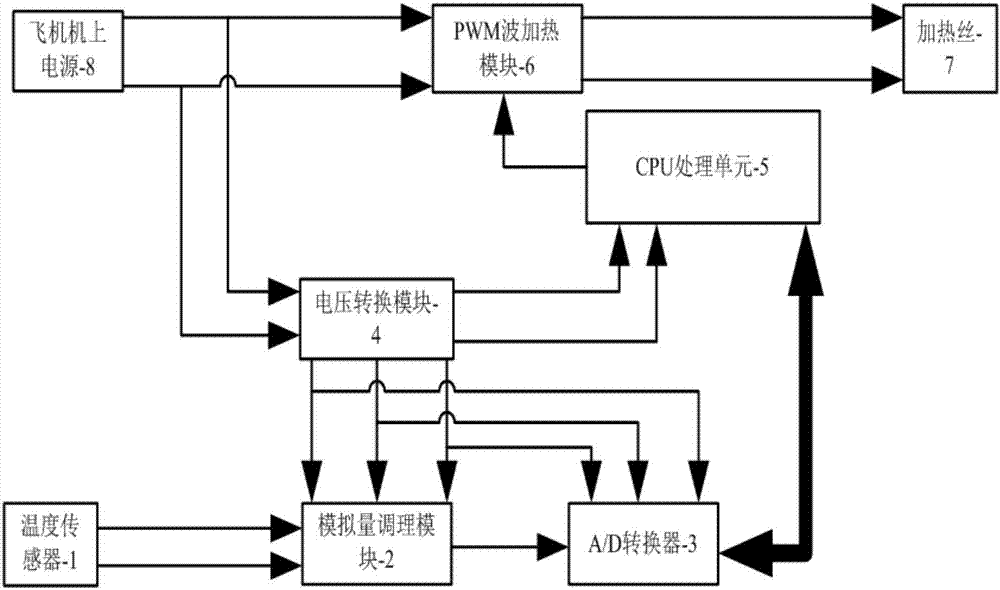

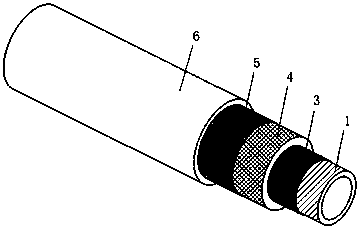

Closed-loop probe heating control system

PendingCN107065969AReduce power consumptionReduce heating power consumptionTemperatue controlControl signalClosed loop

The present invention provides a closed-loop probe heating control system to provide a heating control system with accurate temperature control, low power dissipation and high reliability. The closed-loop probe heating control system is realized through the following technical schemes: a probe temperature sensor (1) feeds resistance signals into an analog quantity conditioning module (2) for conditioning and converts the resistance signals to voltage signals, an A / D converter (3) converts the voltage signals to digital signals and then the digital signals are processed through a central processing unit (CPU) (5), the central processing unit (CPU) (5) emits control signals to a regulation PWM wave heating module (6) according to the collected temperature signals, the control signals are compared to the preset threshold of probe heating, the duty ratio of the PWM wave heating module is regulated according to a comparison result, pulse width modulation (PWM) waves are output to a probe heating wire (7), the heating power of the probe heating wire is regulated, the temperature of the probe is controlled on a preset threshold, and the duty ratio of a heating power supply is regulated to realize the regulation of the probe heating wire heating power.

Owner:CHENGDU KAITIAN ELECTRONICS

Epoxy resin composition for semiconductor encapsulation and semiconductor device

ActiveCN1802415AIncrease productivityAvoid leakage or short circuitSemiconductor/solid-state device detailsSolid-state devicesFilling materialsPhenols

Outstanding YAG laser marking characteristics can be obtained without electric defects such as a short circuit and leak current and without deforming gold wires by using an epoxy resin composition for semiconductor sealing comprising an epoxy resin, a phenol resin, an inorganic filler, a curing accelerator, and a carbon precursor having a specific electric resistivity in a semiconductor region of 1x10<2>.cm or more but less than 1x10<7>.cm as essential components, wherein the amounts of the inorganic filler and the carbon precursor in the epoxy resin composition are respectively 65-92 wt % and 0.1-5.0 wt %.

Owner:SUMITOMO BAKELITE CO LTD

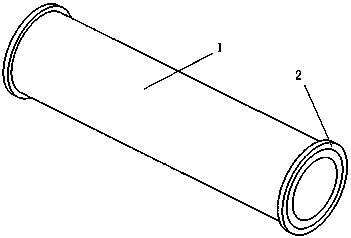

Co-curing preparation method of composite material/metal laminated-structure composite tube

InactiveCN108099223ASolve the problem of difficult demouldingAvoid the risk of deformationShaftsPressure differencePressure balance

The invention discloses a co-curing preparation method of a composite material / metal laminated-structure composite tube, and belongs to the technical field of composite material moulding. The method comprises the following steps: 1) according to the metal inner wall size and the blank lay-up design, preparing a steel tube as a blank laying mould; 2) according to the lay-up design, laying prepreg on the tool surfaces in turn; 3) demoulding the prepreg blank coated with a coating from the laying tool by using the lubricating effect between two layers of polytetrafluoroethylene cloth; 4) roughening the inner wall of the metal tube to enhance the bonding force between the composite material and the metal; 5) heating the prepreg blank coated with the coating on the outer surface in a heating device below the given safe temperature of resin and the coating. According to the method disclosed by the invention, the tool and the product are encapsulated in an integral mode so as to realize pressure balance inside and outside, and the risk of metal tube deformation caused by pressure difference is effectively avoided while the preparation of the laminated-structure composite tube is finishedin once curing period.

Owner:沈阳浦利尔科技有限公司

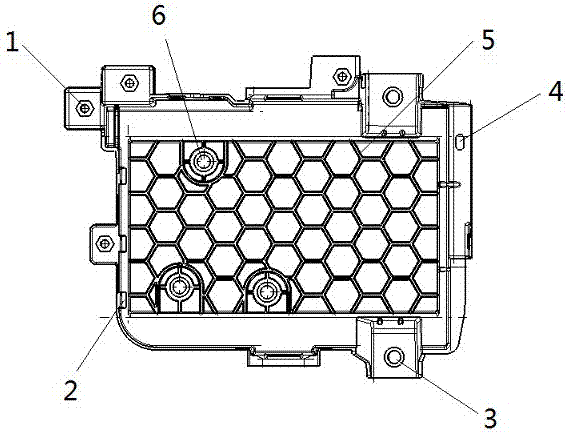

Automobile storage battery tray

InactiveCN107302068AStrong heat aging resistanceIncreased durabilityBattery isolationElectric propulsion mountingElectrical and Electronics engineeringEngineering

Owner:CHERY AUTOMOBILE CO LTD

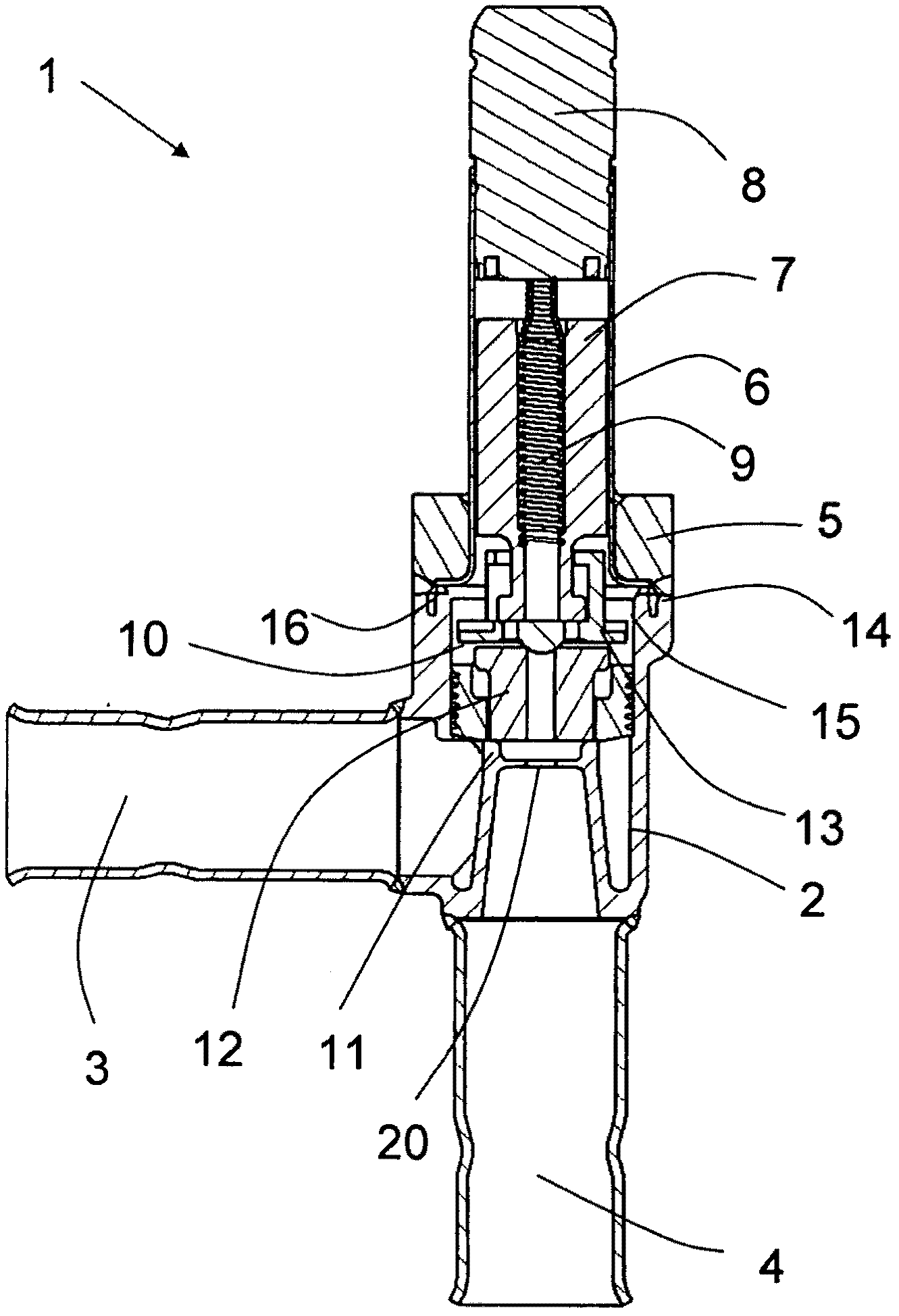

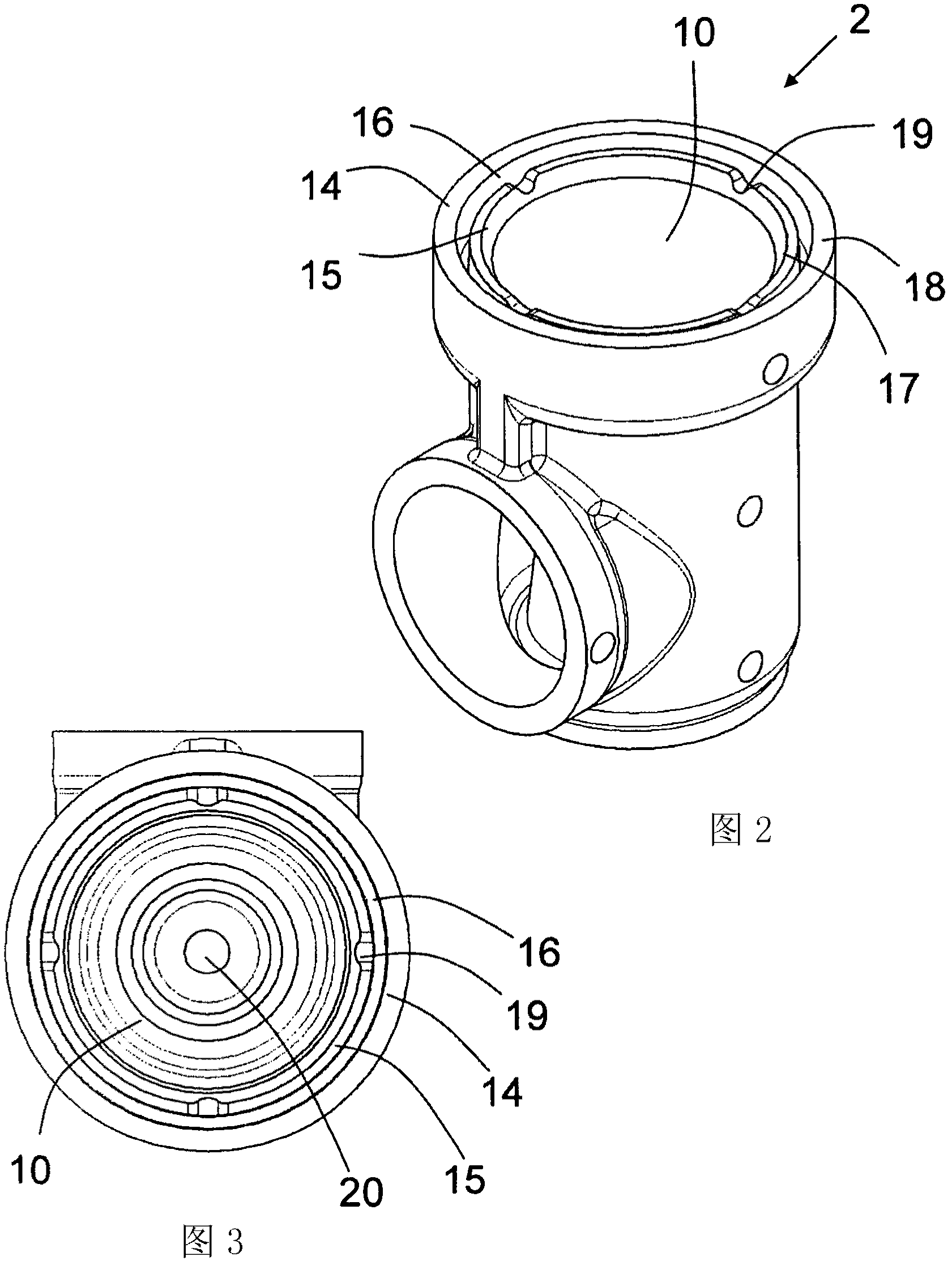

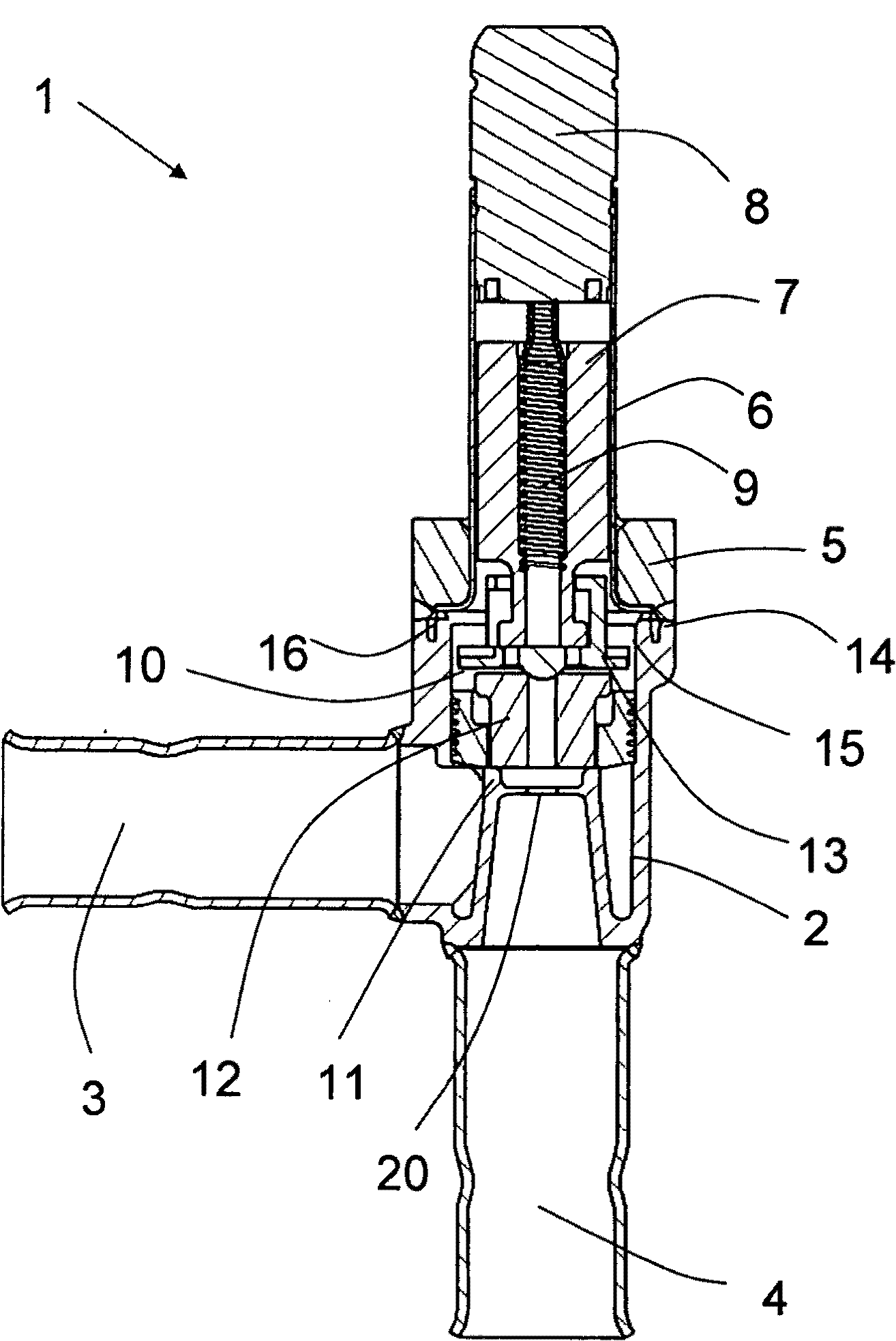

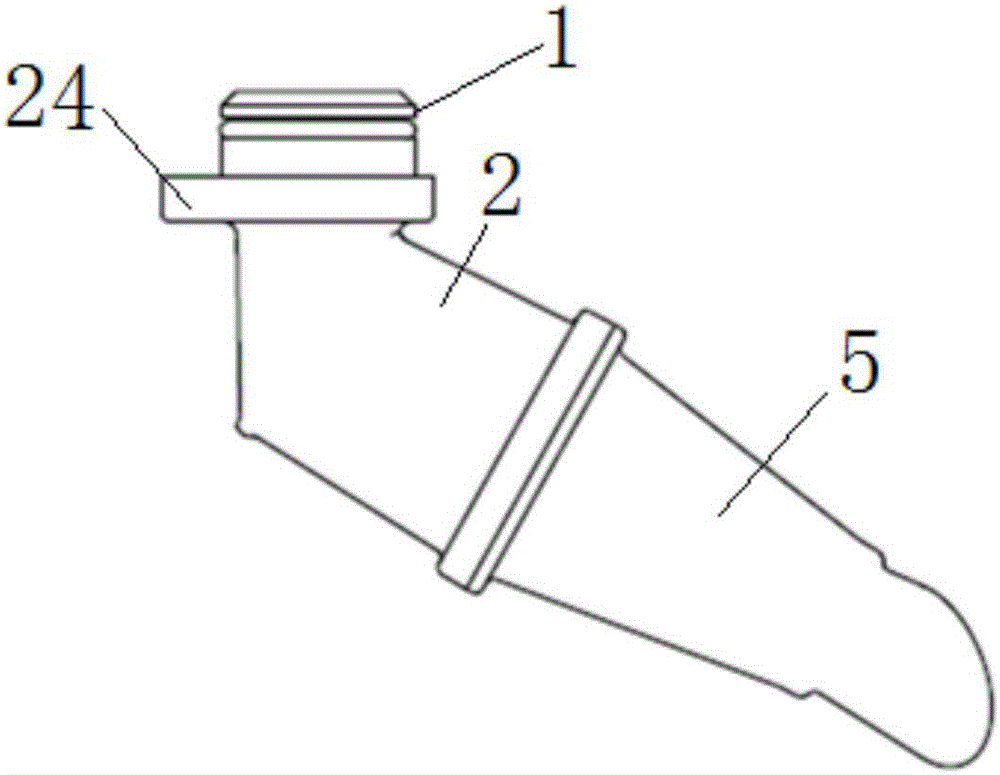

Manufacturing method of a valve

A method to manufacture a valve using metal injection moulding is disclosed. The valve housing (2) comprises a welding cap (14) for welding the upper part (5) of the valve to the valve housing (2). The welding cap (14) is placed so the upper part (5) can be welded to the housing (2) without damaging the inner cavity (10) of the housing. There is a gap between the welding cap (14) and the inner liner (15) so the heat from the welding do not damage the inner liner (15) allowing the inner parts of the valve to move freely.

Owner:DANFOSS AS

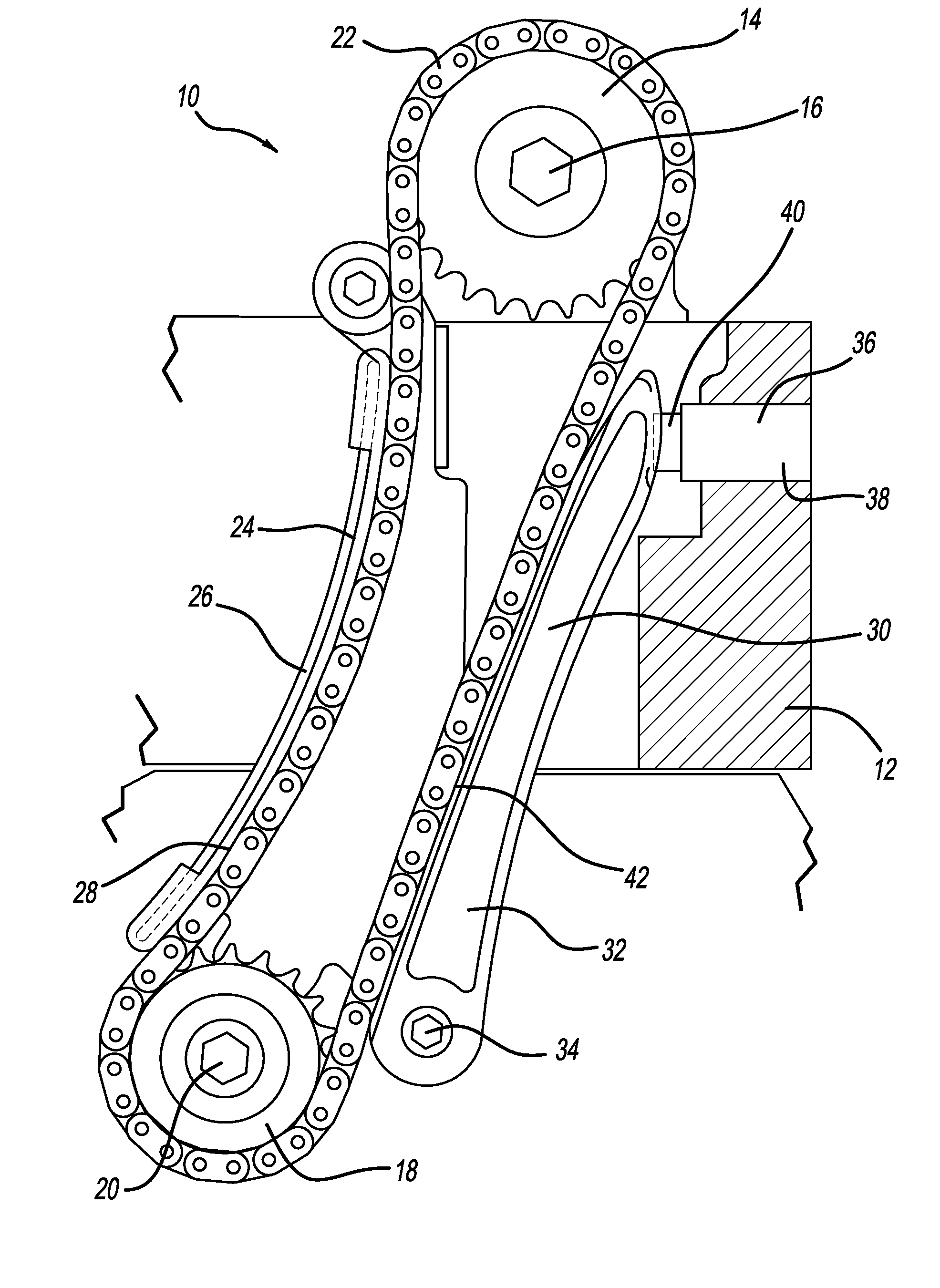

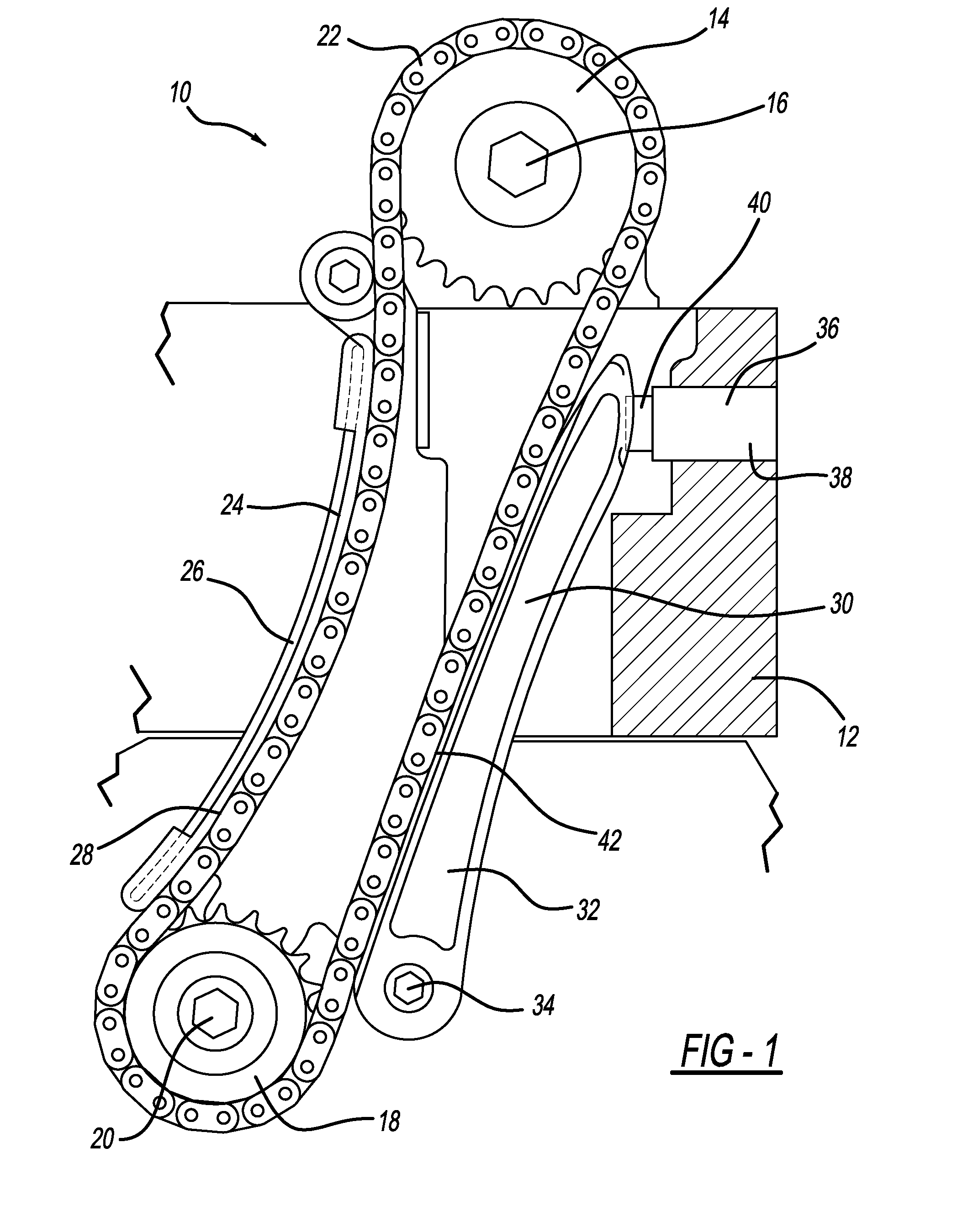

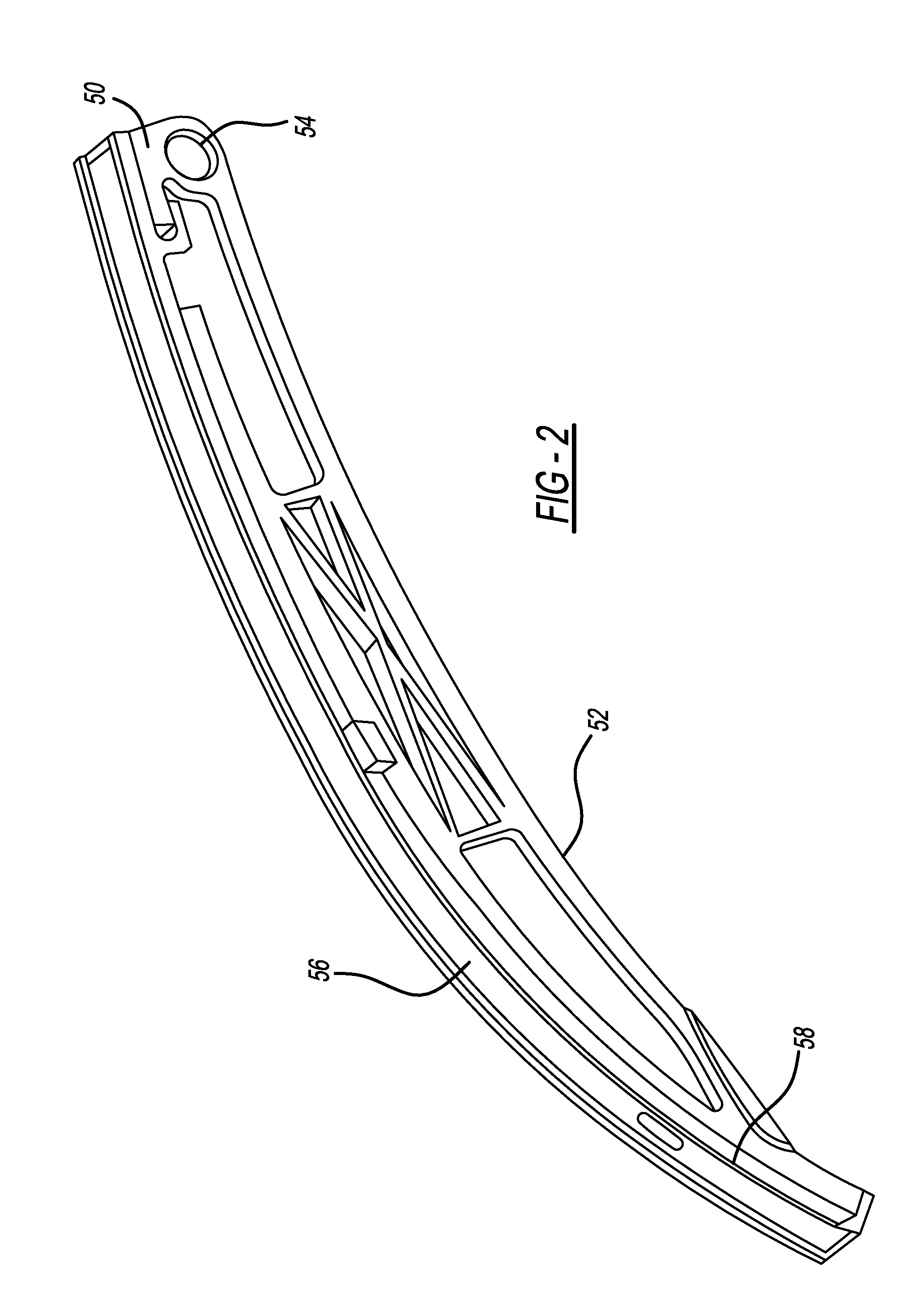

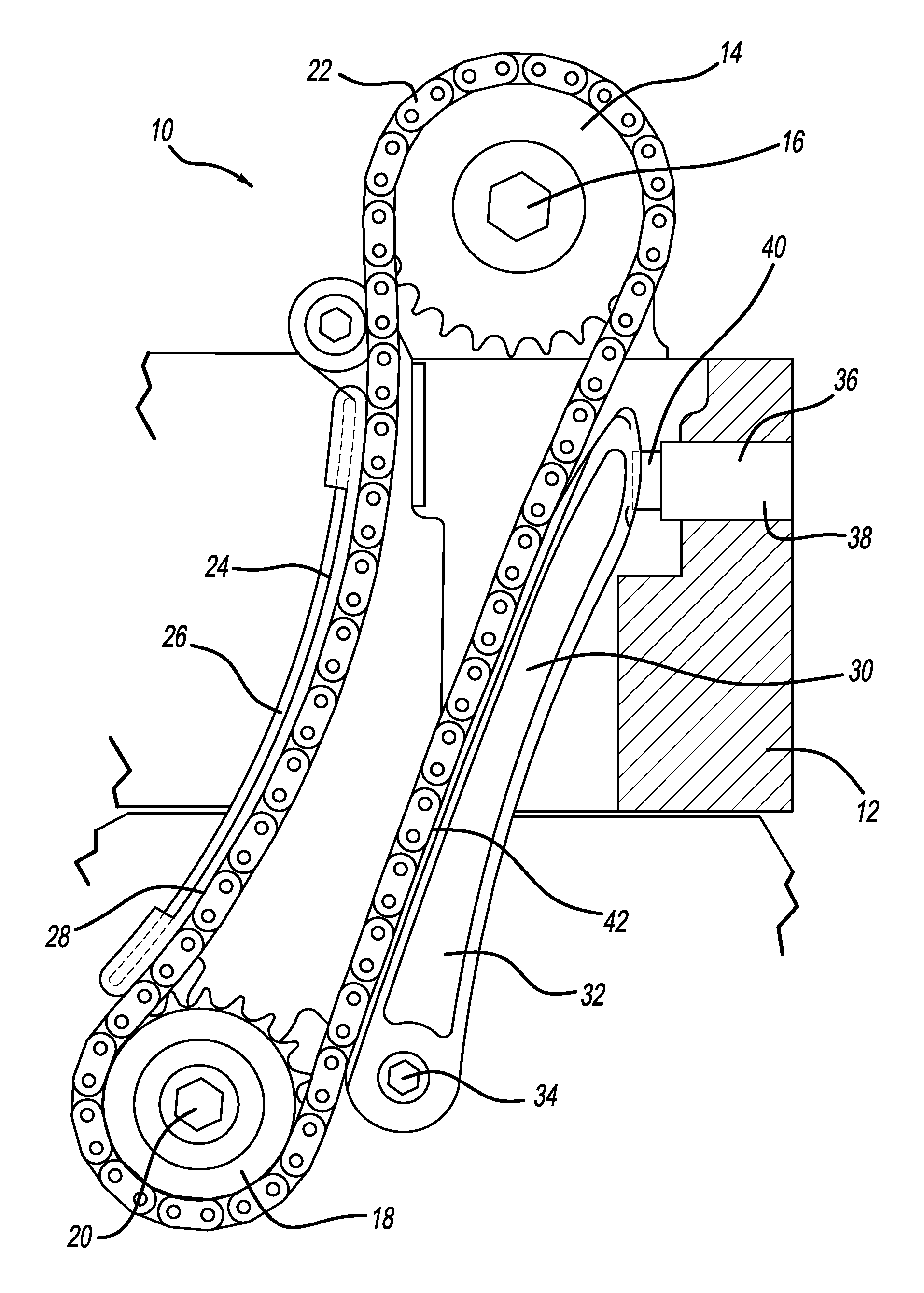

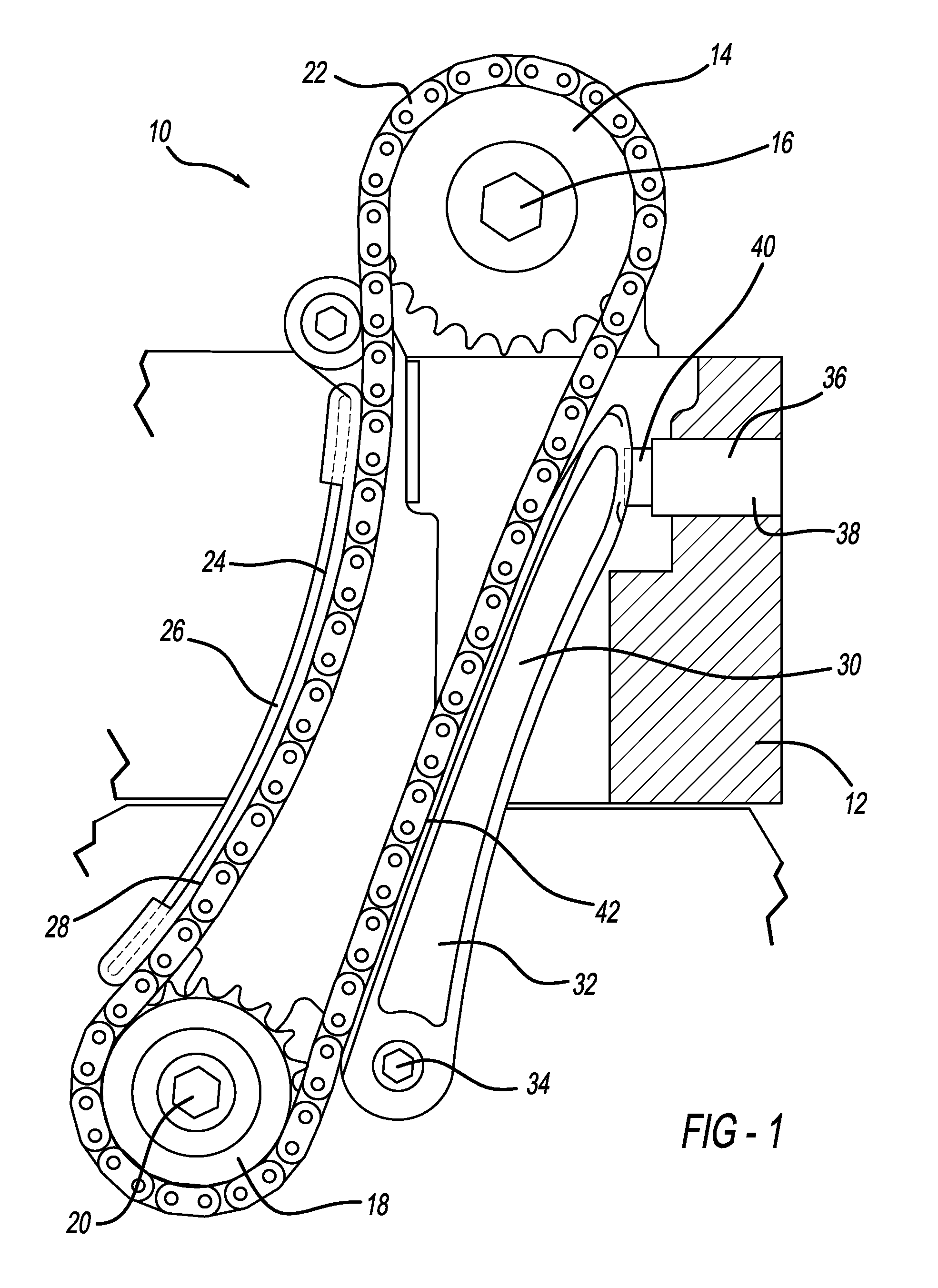

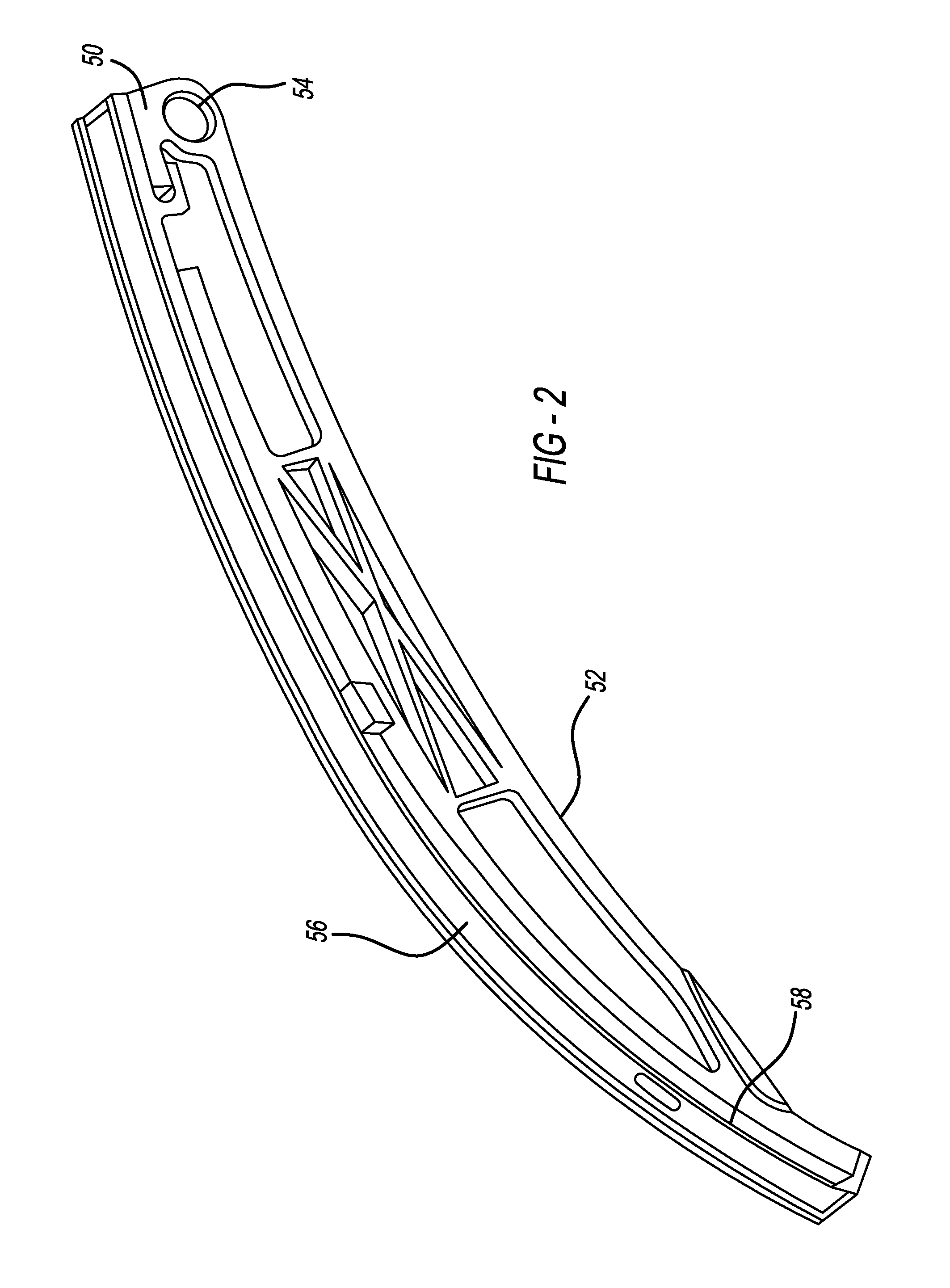

Diamond-like carbon coating on chain guides and tensioning arms for internal combustion engines

InactiveUS20150260263A1Highly desirable surface propertyReduce frictionGearingVacuum evaporation coatingFiberCarbon fibers

A nylon chain tensioning arm and nylon chain guide having diamond-like carbon coatings are provided. The diamond-like carbon coating is formed on the substrate by methods including physical vapor deposition, for example, by sputtering or chemical vapor deposition of coating systems composed of various combinations of amorphous carbon. A preferred method for applying the diamond-like carbon coating to the nylon substrate is a hybrid process of plasma-based ion implantation and deposition. The chain tensioning arm or guide may be formed from any number of plastics appropriate to the purpose, although a synthetic polymer, such as the aliphatic polyamide nylon, is the preferred material. The substrate may be a conventional nylon or may be a composite reinforced with glass or carbon fibers. The diamond-like carbon coating may be applied to the nylon substrate by vapor deposition, either directly to the chain-contacting surface or upon a primed surface formed on the substrate prior to deposition.

Owner:FORD GLOBAL TECH LLC

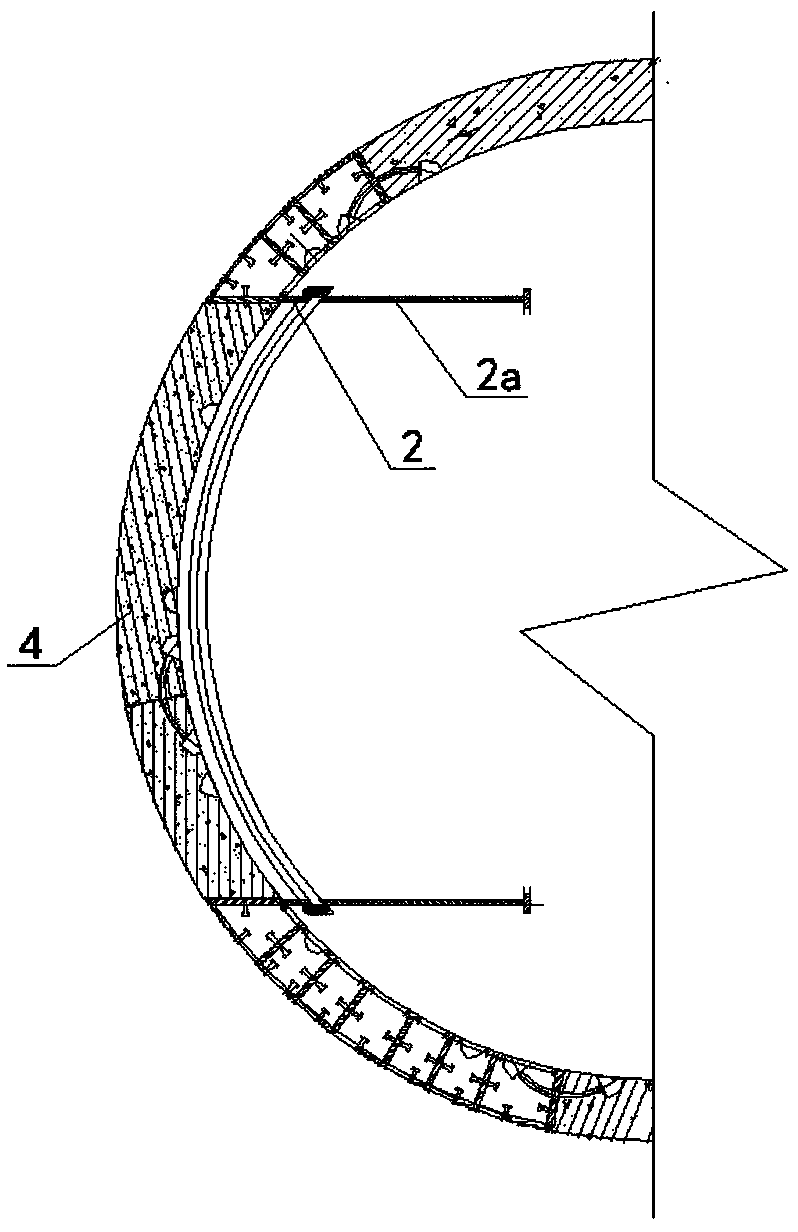

Shield method contact channel starting tunnel portal steel sleeve adapting structure and mounting method thereof

PendingCN109653774AReduce volumeEasy to operateUnderground chambersTunnel liningStructure of the EarthThermal deformation

The invention discloses a shield method contact channel starting tunnel portal steel sleeve adapting structure and a mounting method thereof. The structure is characterized in that a steel sleeve applied to shield method contact channel starting tunnel portal construction is split into a sleeve body and an adapting cylinder positioned at the front end of the sleeve body, a front end opening of theadapting cylinder is mounted at a tunnel opening in a welded manner, a flange structure is arranged between a tail end opening of the adapting cylinder and a front end opening of the sleeve body, andbolts are used for connection in the flange structure. The mounting success rate of the tunnel opening of a steel sleeve contact channel starting tunnel portal can be effectively increased, thermal deformation of the steel sleeve is avoided, project quality is ensured, and project schedule is improved.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD

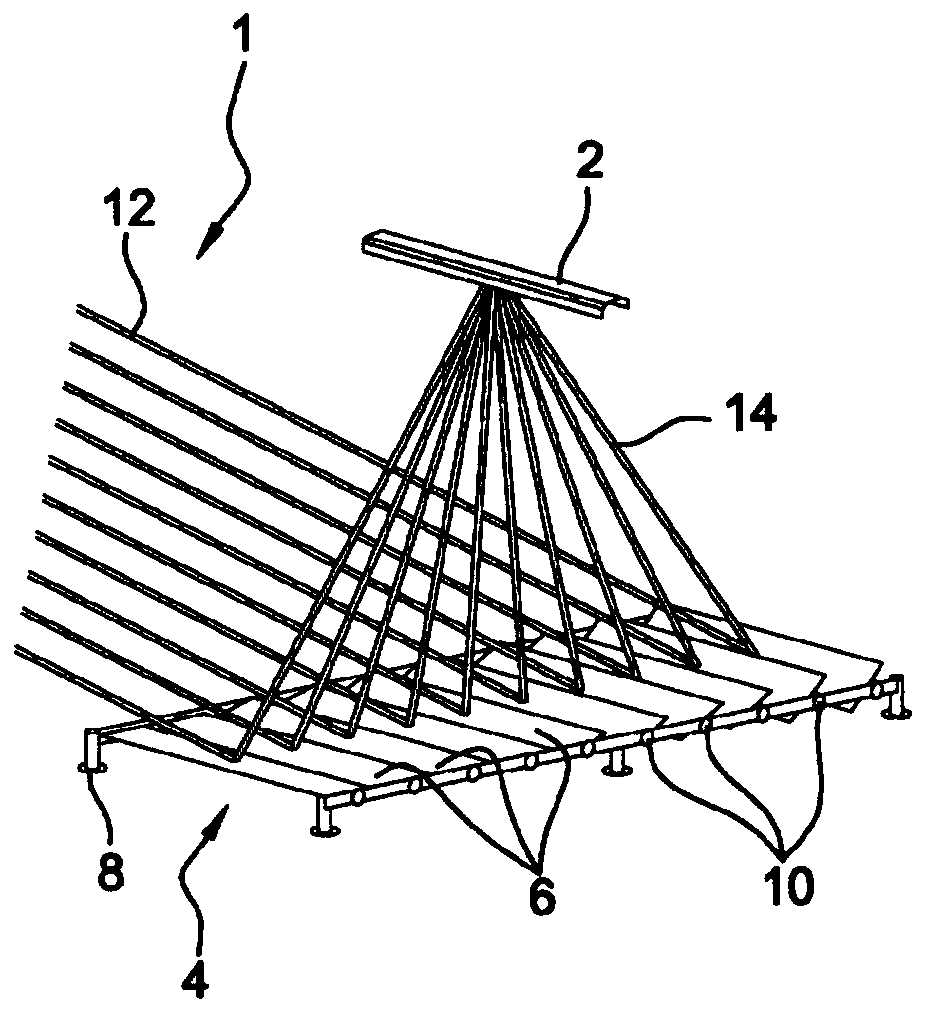

Reflector of improved design and its manufacturing process, for the field of solar energy

The invention relates to a reflector (6) comprising a supporting structure (18) and a mirror (16) that is preferably of non-planar form, the structure (18) being equipped with pivoting members (19) that allow the reflector to be rotated. According to the invention, the mirror (16) includes a plurality of adjacent mirror elements (16a), the reflector includes, associated with each mirror element (16a), a chassis (20) that is interposed between the structure (18) and the mirror element and that includes crosspieces (22) to which are fastened rails (24), the non-reflective surface of the mirror element (16a) being fastened to the rails (24) preferably using adhesive, the structure (18) comprises members (40) for positioning each chassis, forming points of contact (42) that define a reference bearing surface (46) for the frame (20), and each chassis (20) is mounted on the structure (18) using mechanical fastening means (36, 38) that are preferably demountable.

Owner:阿尔索伦特工业设计公司

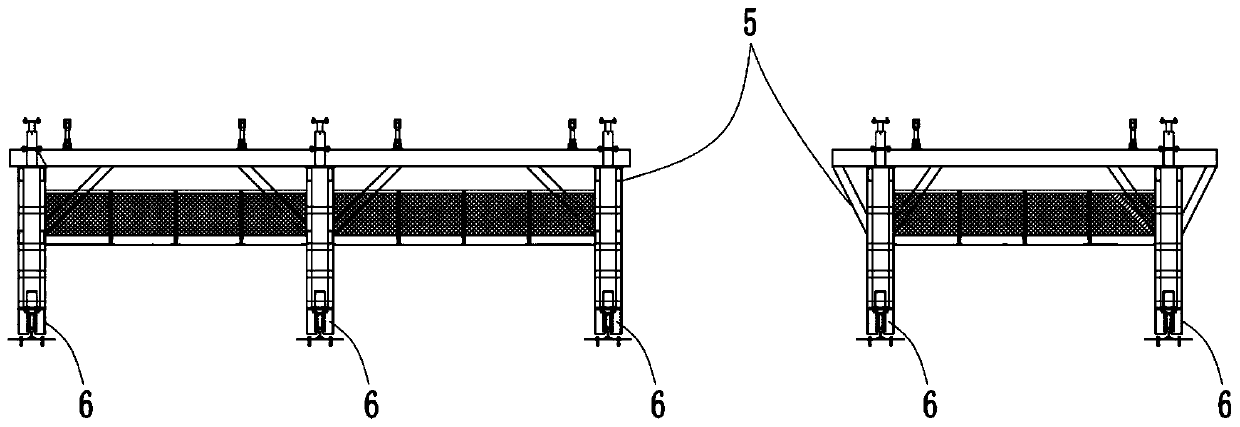

Mold suitable for producing fabricated undercrossing channel frame through long-line matching method and prefabrication method

ActiveCN110497511AAvoid the risk of deformationReduced strength requirementsMouldsEngineeringLine matching

The invention relates to the technical field of building engineering, in particular to a mold suitable for producing a fabricated undercrossing channel frame through a long-line matching method and aconstruction method. The mold comprises bottom mold assemblies matched with the bottom of a frame segment, inner mold assemblies matched with the inner wall of the frame segment, side mold assembliesmatched with the outer walls of the two sides of the mold segment and end mold assemblies matched with the two ends of the mold frame. The mold further comprises an inner mold support used for supporting the inner mold assemblies. A drive device used for driving the inner mold assemblies to be switched between a pouring position and a separation position is arranged on the inner mold support. First walking assemblies are further arranged on the inner mold support and are used for proving movement in the length direction of the frame for the inner mold support.

Owner:成都城投城建科技有限公司

Silicon nitride ceramic piece and processing method thereof

ActiveCN114230349AReduce porosityAvoid the problem of uneven pore distributionComposite materialSilicon nitride

The invention discloses a silicon nitride ceramic part and a processing method thereof. The silicon nitride ceramic part comprises a first cylinder, and two ends of the first cylinder are respectively provided with a first end face and a second end face; a first fixing seat is arranged in the first cylinder body, and the first fixing seat is connected with the first end face in a penetrating manner; a second fixing base is arranged on the upper surface of the second end face and connected with the second end face in a penetrating mode. The preparation method of the silicon nitride ceramic part comprises the following steps: granulating, carrying out cold isostatic pressing molding to obtain a primary green body, carrying out finish machining to obtain a second green body, pre-sintering to obtain a third green body, and finally sintering to obtain the silicon nitride ceramic part. The silicon nitride ceramic piece is uniform in internal density distribution, high in strength, low in density, large in size, easy to process and high in finished product percent of pass.

Owner:BEIJING SINOMA SYNTHETIC CRYSTALS CO LTD +1

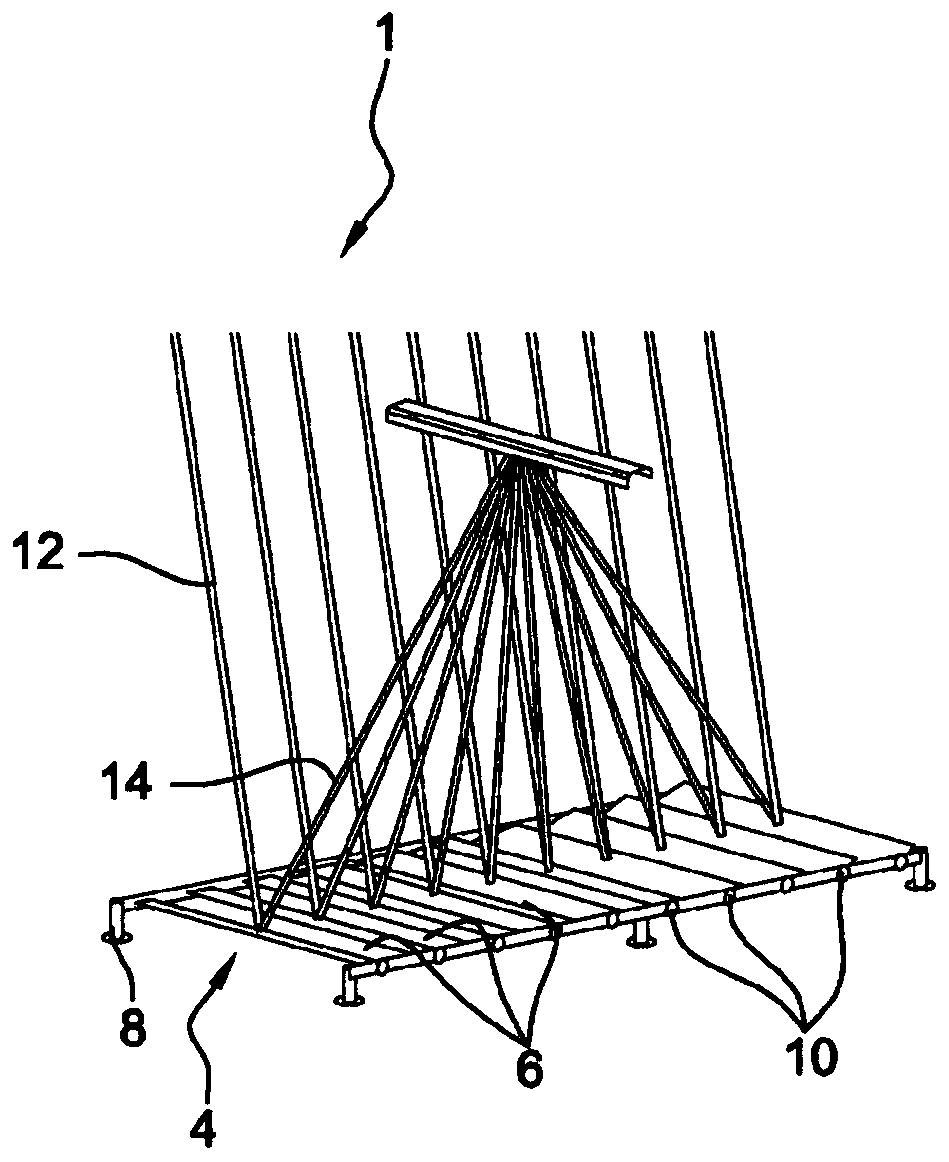

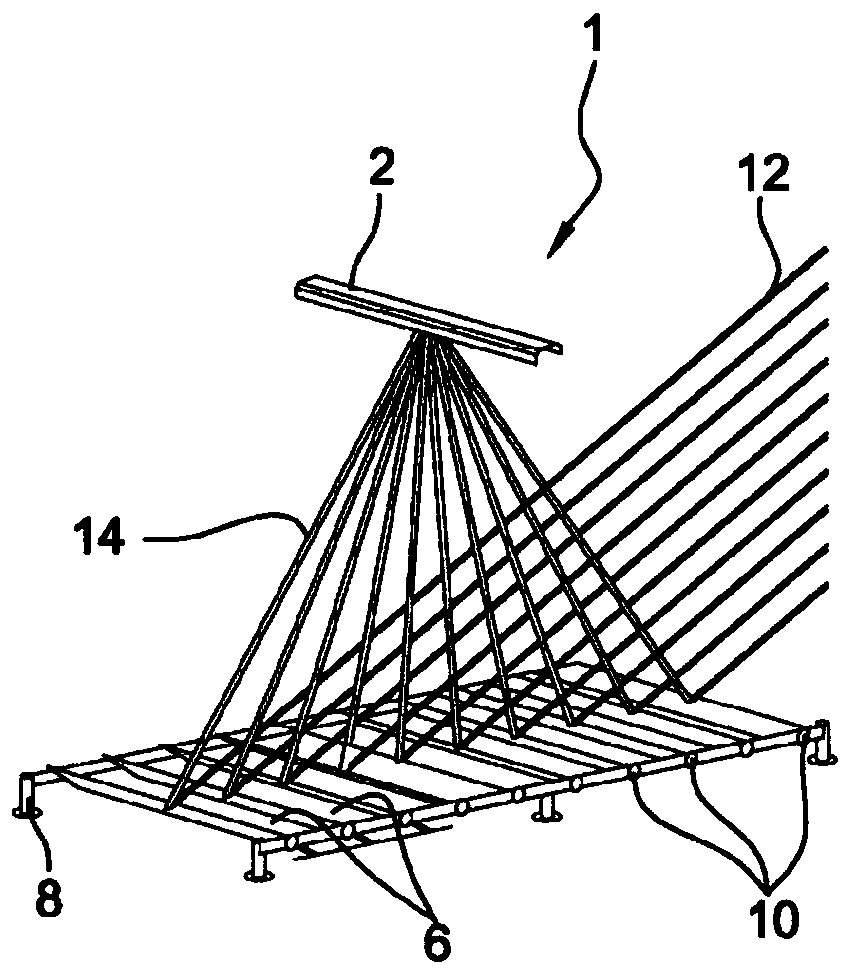

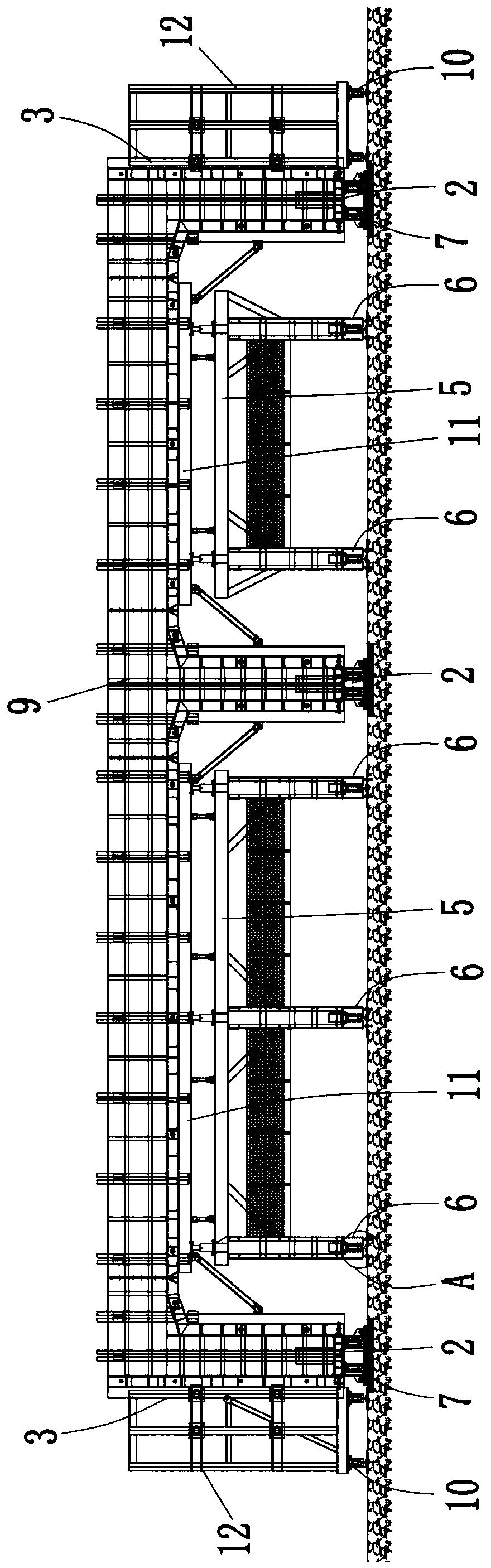

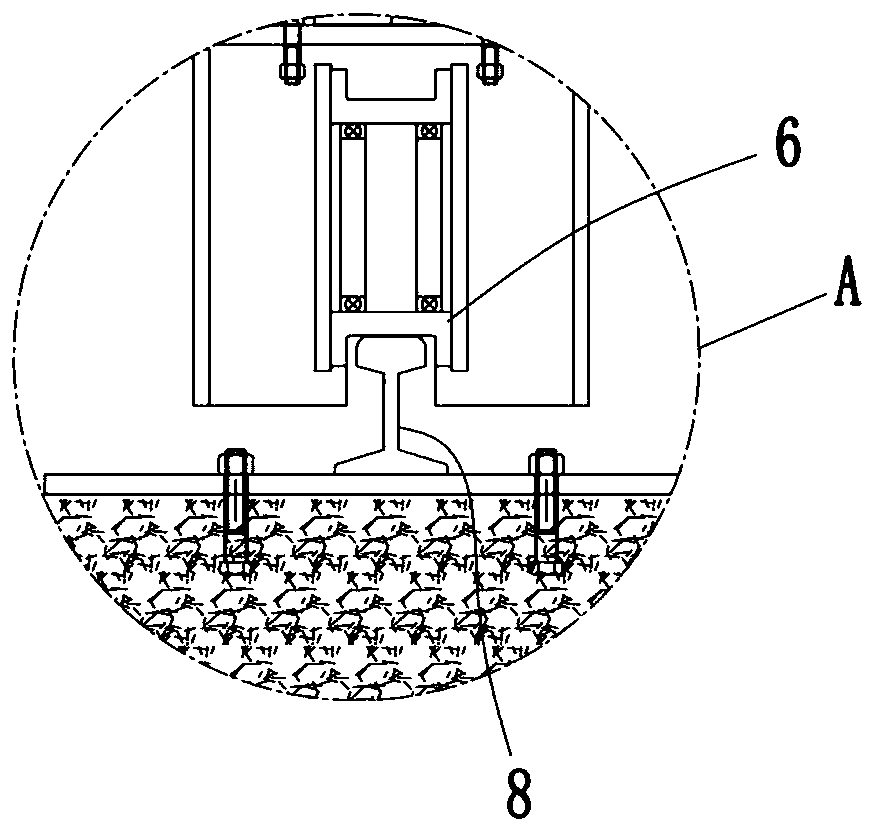

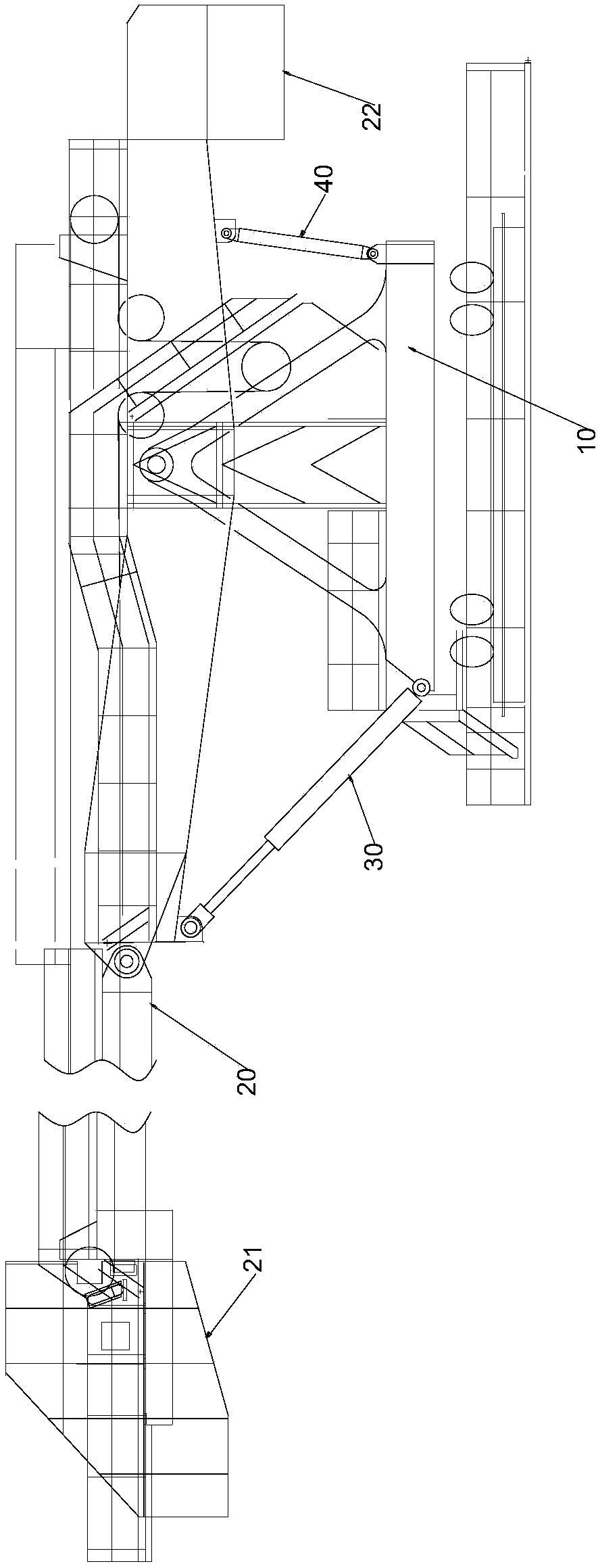

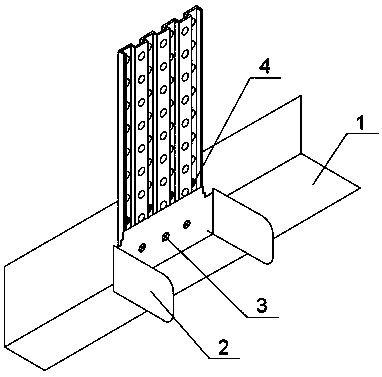

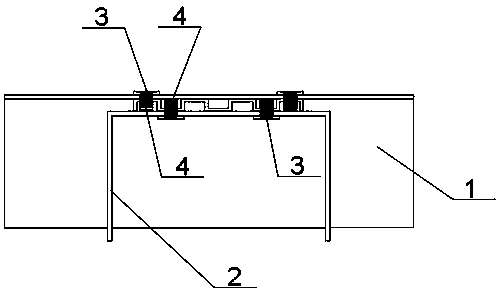

Replacing method for hydraulic oil cylinder of stacker-reclaimer

InactiveCN110181242AReduce riskAvoid the risk of deformationMetal working apparatusHydraulic cylinderPulp and paper industry

The invention relates to a replacing method for a hydraulic oil cylinder of a stacker-reclaimer. The stacker-reclaimer comprises an installing base (10), an arm frame (20) and the hydraulic oil cylinder (30). The arm frame (20) is hinged to the installing base (10). The two ends of the hydraulic oil cylinder (30) are hinged to the installing base (10) and the arm frame (20) correspondingly. The replacing method for the hydraulic oil cylinder comprises the following steps that S1, a stabilizing component (40) for supporting or pulling the arm frame (20) is installed so as to fix the arm frame (20); S2, the hydraulic oil cylinder (30) needing to be replaced is detached; S3, a new hydraulic oil cylinder is installed; and S4, the stabilizing component (40) is detached. Through the technical scheme, maintenance risk of replacement of the hydraulic oil cylinder of the stacker-reclaimer is lowered greatly, the arm frame is fixed in advance through the ready-made stabilizing component, and deformation risk caused by uneven stress on the arm frame is avoided.

Owner:CHINA SHENHUA ENERGY CO LTD +1

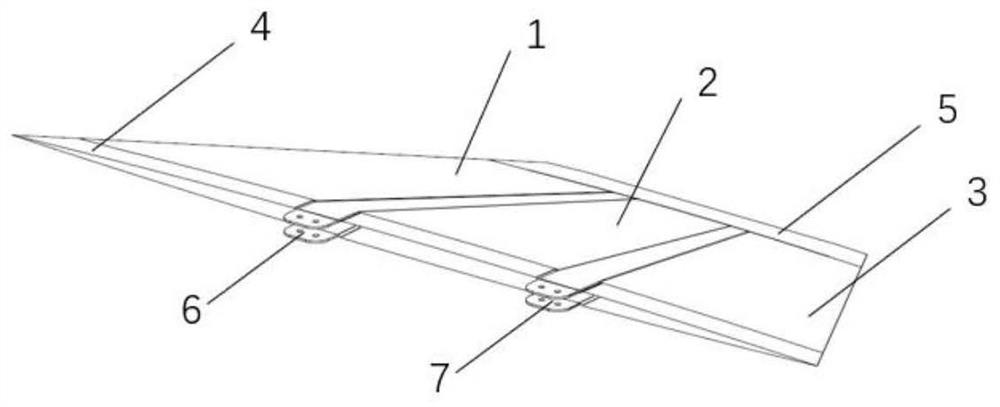

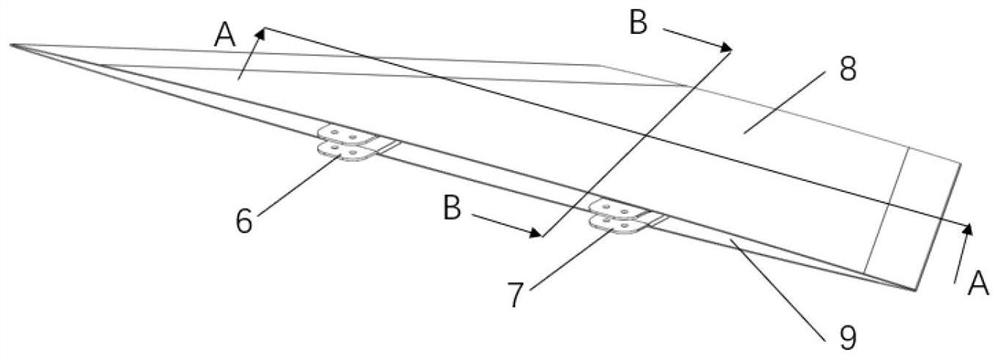

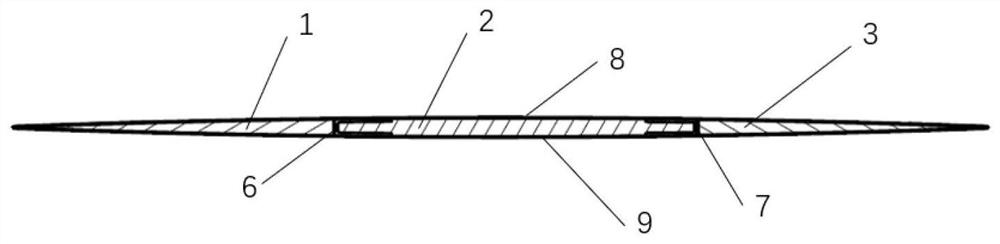

Joint-variable RTM integrally-formed composite material missile wing and manufacturing method thereof

The invention discloses a joint-variable RTM integrally-formed composite material missile wing and a manufacturing method thereof, a root rib and an end rib are respectively arranged at two ends along the wingspan direction, a front beam and a rear beam are arranged between the root rib and the end rib, and the front beam and the rear beam are respectively vertical to the root rib and the end rib; the end parts of the front beam and the rear beam on the root rib side extend outwards and cross over the root rib, and the extending parts of the front beam and the rear beam are used as connecting joints of the front beam and the rear beam; and three areas divided by the front beam and the rear beam between the root rib and the end rib are filled with foam, the exterior of the overall structure filled with the foam is covered with the upper skin and the lower skin to obtain the missile wing, the missile wing is made of full-carbon-fiber composite materials, the bearing capacity of the missile wing is improved, and the problems of complexity, deformation and complex connection mode of metal parts in a mixed structure are solved. In addition, a missile wing structure is prepared through the RTM integral forming process, and a low-cost solution is provided for product joint form change.

Owner:长三角先进材料研究院

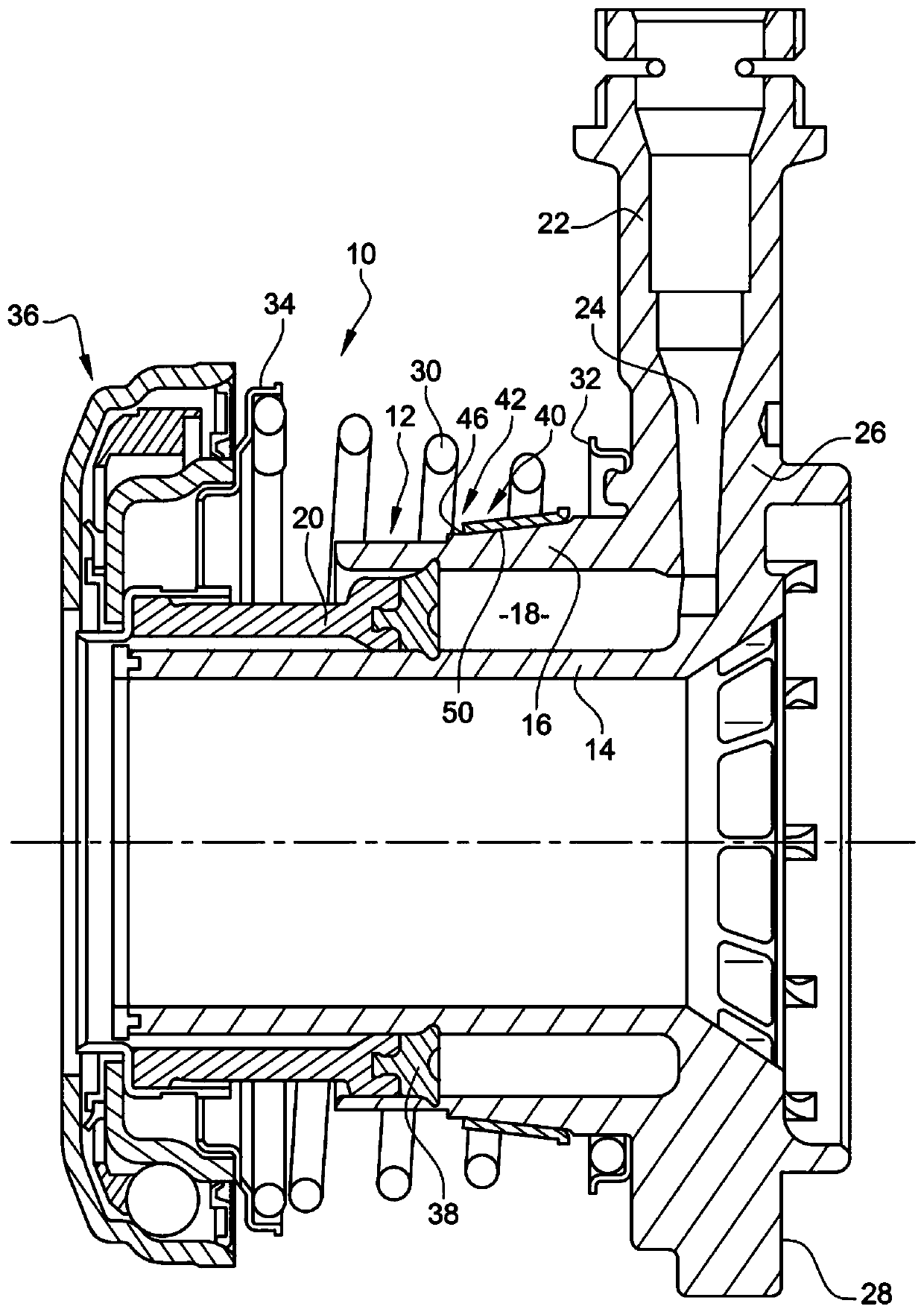

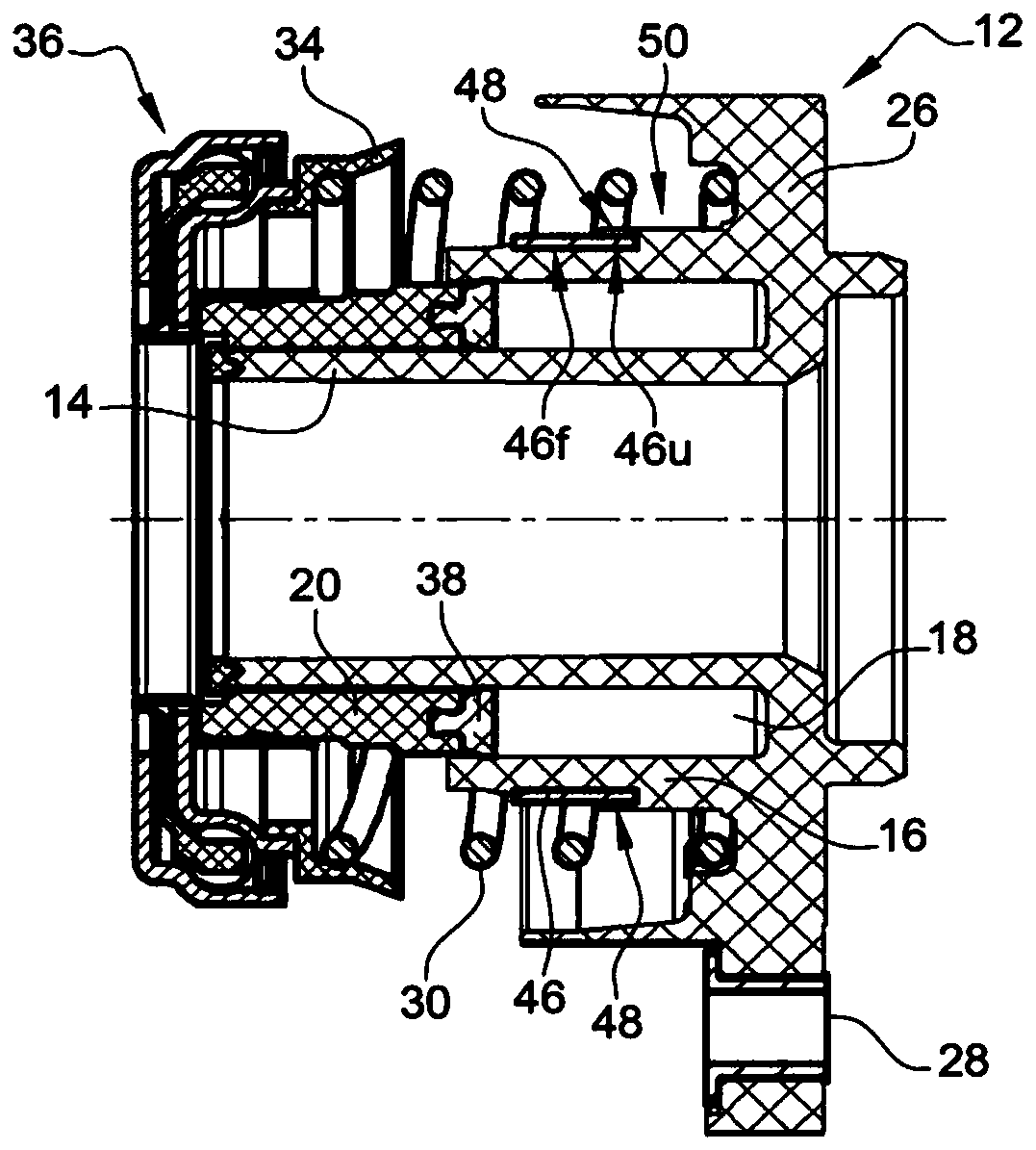

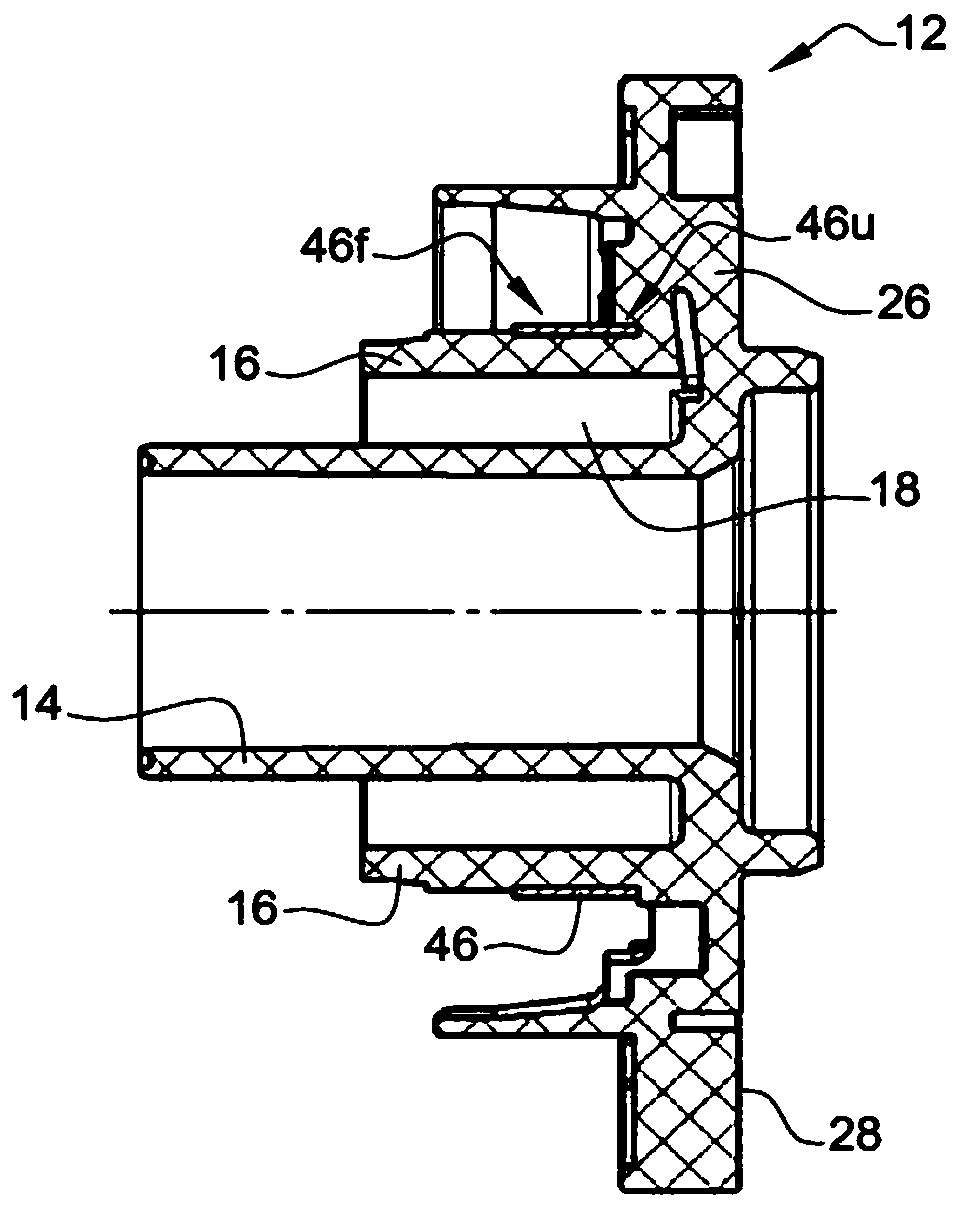

Central actuator for a hydraulic or pneumatic clutch actuation

PendingCN110657169ASmall dependence on dimensional tolerancesReinforcement and dimensional stabilityFluid actuated clutchesCouplingsPhysicsPiston

The invention relates to a central actuator (10) for a hydraulic or pneumatic clutch actuation, having a cylinder housing (12) which has at least one cylinder wall (14, 16) made of a plastic which delimits a ring-shaped pressure chamber (18) in a radial direction, in which a ring piston (20) that can be operatively connected to the clutch is displaceably received, wherein the cylinder wall (14, 16) is provided with at least one reinforcement ring (44, 46) on its peripheral side facing away from the compression chamber (18), wherein the reinforcement ring (46) is attached to the outside of theouter cylinder wall (16) and is divided in its axial extent into two abutting partial regions (46u, 46f), the first partial region (46u) whereof is surrounded on the outside by plastic from the cylinder housing (12) and the second partial region (46f) is free from plastic from the cylinder housing (12) on the outside.The invention further relates to a method of producing the cylinder housing (12)for a central actuator (10) of this kind.

Owner:FTE汽车有限责任公司

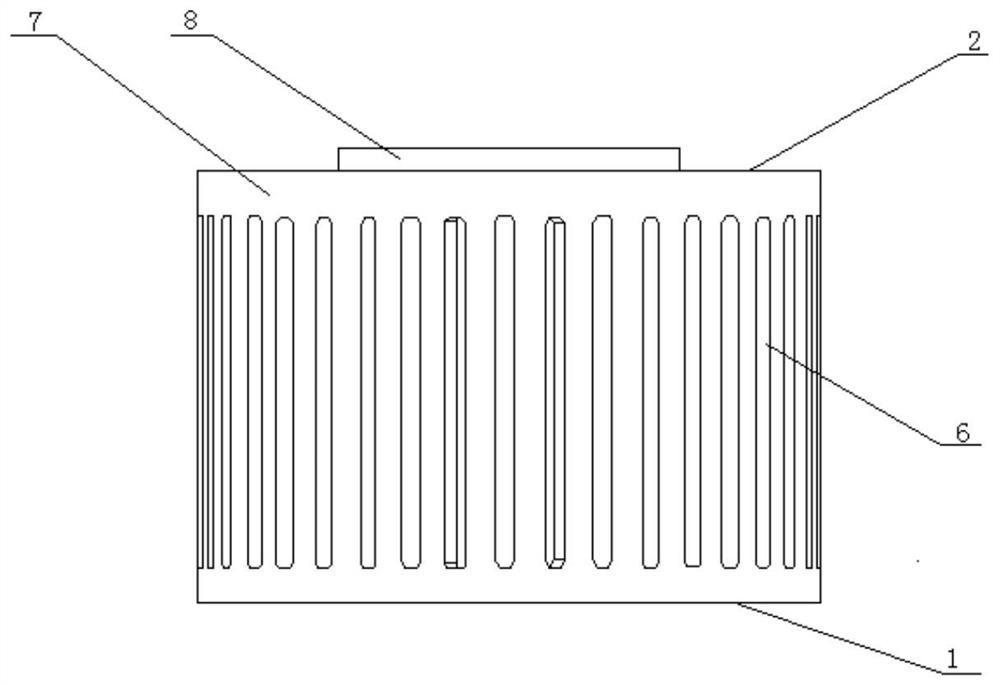

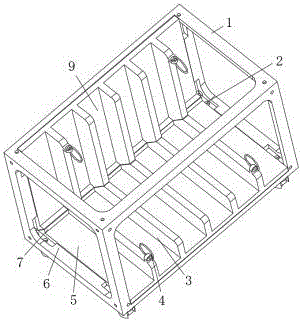

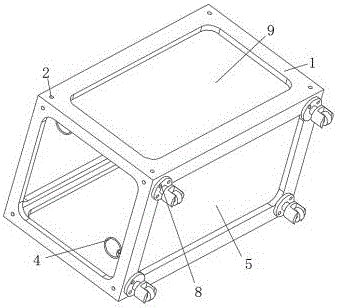

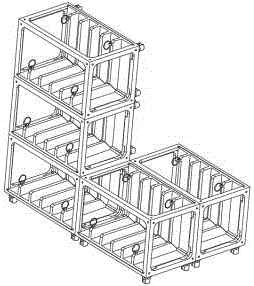

Combination type metal die protecting frame

InactiveCN106142037AAvoid the risk of deformationHigh utility valueWork tools storageEngineeringMetal mold

The invention discloses a combination type metal die protecting frame. The combination type metal die protecting frame comprises a support frame, wherein screw joint holes matched with each other are formed in all connecting parts in the support frame, and the support frame is provided with clamping grooves used for clamping nuts at all parts corresponding to the screw joint holes; and universal wheels are mounted at the lower end of the support frame. According to the device, by designing a die protecting frame capable of being freely spliced and combined, placing plates can be changed according to the sizes of dies, or bigger die frames can be spliced according to the placing requirements of the dies and the sizes of rooms; in particular, for dies with large mass, a plurality of die frames can be directly placed on the ground after being disassembled, so that the deformation risk of the die frames, caused by the placing of the too many large-mass dies on the same die frame for a too-large height is avoided; and therefore, the device is strong in universality and high in practical value.

Owner:天津三兆金属制品有限公司

Diamond-like carbon coating on chain guides and tensioning arms for internal combustion engines

InactiveUS9476485B2Highly desirable surface propertyReduce frictionGearingVacuum evaporation coatingFiberDiamond-like carbon

A nylon chain tensioning arm and nylon chain guide having diamond-like carbon coatings are provided. The diamond-like carbon coating is formed on the substrate by methods including physical vapor deposition, for example, by sputtering or chemical vapor deposition of coating systems composed of various combinations of amorphous carbon. A preferred method for applying the diamond-like carbon coating to the nylon substrate is a hybrid process of plasma-based ion implantation and deposition. The chain tensioning arm or guide may be formed from any number of plastics appropriate to the purpose, although a synthetic polymer, such as the aliphatic polyamide nylon, is the preferred material. The substrate may be a conventional nylon or may be a composite reinforced with glass or carbon fibers. The diamond-like carbon coating may be applied to the nylon substrate by vapor deposition, either directly to the chain-contacting surface or upon a primed surface formed on the substrate prior to deposition.

Owner:FORD GLOBAL TECH LLC

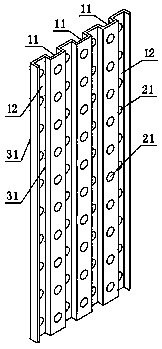

Vertical light steel keel

InactiveCN110029765AImprove construction efficiencyReduce labor intensityCeilingsKeelStress strength

The invention discloses a vertical light steel keel which is applied to the field of building decoration and paving. Strip steel serves as a raw material to be continuously cold-rolled and formed through a machine to form a plurality of continuous staggered forward U-shaped grooves and inverted U-shaped grooves; the bottom faces of the multiple forward U-shaped grooves and the bottom faces of themultiple inverted U-shaped grooves constitute connecting fixing faces with the two opposite sides correspondingly for connecting and fixing other keels or connecting pieces on the double sides; the space of the forward U-shaped grooves and the space of the inverted U-shaped grooves are used for placing the tails of fasteners which are connected and fixed to be used; and when the other keels and connecting pieces are connected on the double sides in the same local position, double-side graded connection and fixing can be achieved, and the flatness of the double-side connecting fixing faces is not destroyed. Through the structural characteristics of the U-shaped grooves, the keel is also naturally provided with a plurality of reinforcing ribs, and thus the stress strength of the keel is improved; and compared with using of a C-shaped cladding keel in the prior art, the advantages of higher efficiency, lower labor intensity and higher stress strength are achieved; and compared with usingof a square pipe in the prior art, the advantages of less consumable use, lower production cost, higher stress strength, more convenient and quicker use and the like are achieved.

Owner:山东集顶装饰科技有限公司

Engine oil collector

ActiveCN106246284AGuaranteed structural reliabilityImprove structural strengthLubricant mounting/connectionPressure lubricationEngineeringMechanical engineering

The invention discloses an engine oil collector. The engine oil collector comprises an upper plastic shell and a lower plastic shell connected with the upper plastic shell; the end, connected with the lower plastic shell, of the upper plastic shell is provided with a plastic supporting frame extending into the lower plastic shell; and a metal filtering net is arranged in the lower plastic shell, wherein one end of the metal filtering net is connected with the plastic supporting frame, and the other end of the metal filtering net is connected with the lower plastic shell. The engine oil collector is reliable in structure, light, compact in structure and easy to distribute.

Owner:CHERY AUTOMOBILE CO LTD

Preparation method of wound trapezoidal cell and trapezoidal cell

ActiveCN105428725BExtend standby timeIncrease intervalFinal product manufactureSecondary cellsConductor CoilLongest cycle

A preparation method of a wound trapezoidal battery core and the trapezoidal battery core, in the trapezoidal battery core, intervals are formed between the inflection points of the 1-Nth circles of adjacent coils, and the inflection points of the N-M circles of adjacent coils are There is no space between them, and the cross-sectional shape of the cell after hot pressing is trapezoidal. When the battery core of the present invention is wound, from the first turn to the Nth turn, a piece of winding needle is inserted for each turn, so that the winding diameter of each turn is increased by an expansion width relative to the winding diameter of the previous turn, so that There is an interval between the inflection point of the nth coil and the n+1 coil; from the Nth coil to the Mth coil, the remaining coil is wound with a fixed winding diameter; the trapezoidal groove is used The jig heat-presses and shapes the winding core, and after hot-pressing and shaping, a battery core with a trapezoidal cross-sectional shape is obtained. The trapezoidal battery cell obtained by the present invention can maximize the reserved space for the use of equipment, increase the design capacity of the battery cell, and can evenly distribute the stress on the transition slope of the battery cell, and can avoid the problem of deformation of the battery cell after long-term cycling.

Owner:ZHUHAI COSMX BATTERY CO LTD

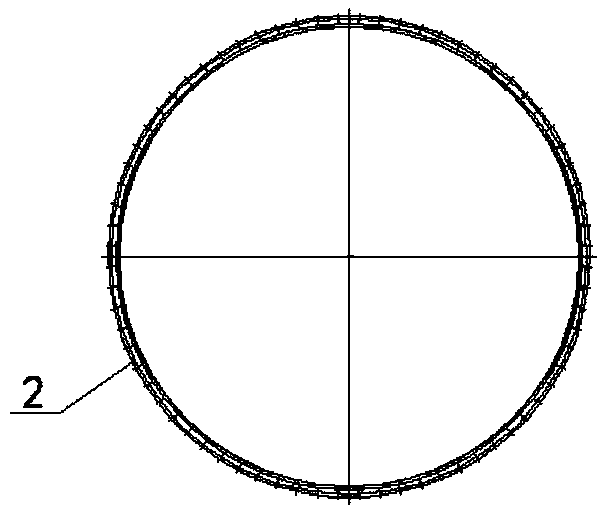

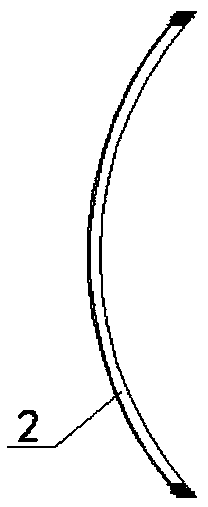

An automatic forming machine for thin-walled short u-bend pipe with welding ring

ActiveCN106270239BEliminate wasteGuaranteed not to deformMetal-working feeding devicesOther manufacturing equipments/toolsMolding machineStraight tube

The invention discloses an automatic forming machine of a thin-walled short U bent pipe with a welding ring, relates to the technical field of automation equipment, and can continuously accomplish the forming of the thin-walled short U bent pipe and socket welding ring operation, so as to prevent a pipe wall from folds. The automatic forming machine comprises a feeding assembly, a pipe cutting assembly, a pipe bending assembly, a circumference position rotating assembly and a socket welding ring assembly, wherein the feeding assembly at least comprises a clamping mechanism and a No.1 driving mechanism; the No.1 driving mechanism drives the clamping mechanism to perform forward feeding; the pipe cutting assembly at least comprises a cutting tool mechanism and a No.2 driving mechanism; the No.2 driving mechanism drives a cutting tool to act; the pipe bending assembly at least comprises a fixed part, a semicircle die, a movable part and a No.3 driving mechanism; one end of a fixed length pipe is clamped at the fixed part; the other end of the fixed length pipe gets over the semicircle die and then is movably matched with the movable part; the circumference position rotating assembly at least comprises a rotating frame, a pipe clamping mechanism, a No.4 driving mechanism and a discharging cylinder; the socket welding ring assembly at least comprises a welding ring feeding unit, a welding ring guide unit and a socket welding ring unit; the socket welding ring unit pushes the welding ring to a straight pipe section of the thin-walled short U bent pipe.

Owner:TONGLU QIANDING TECH

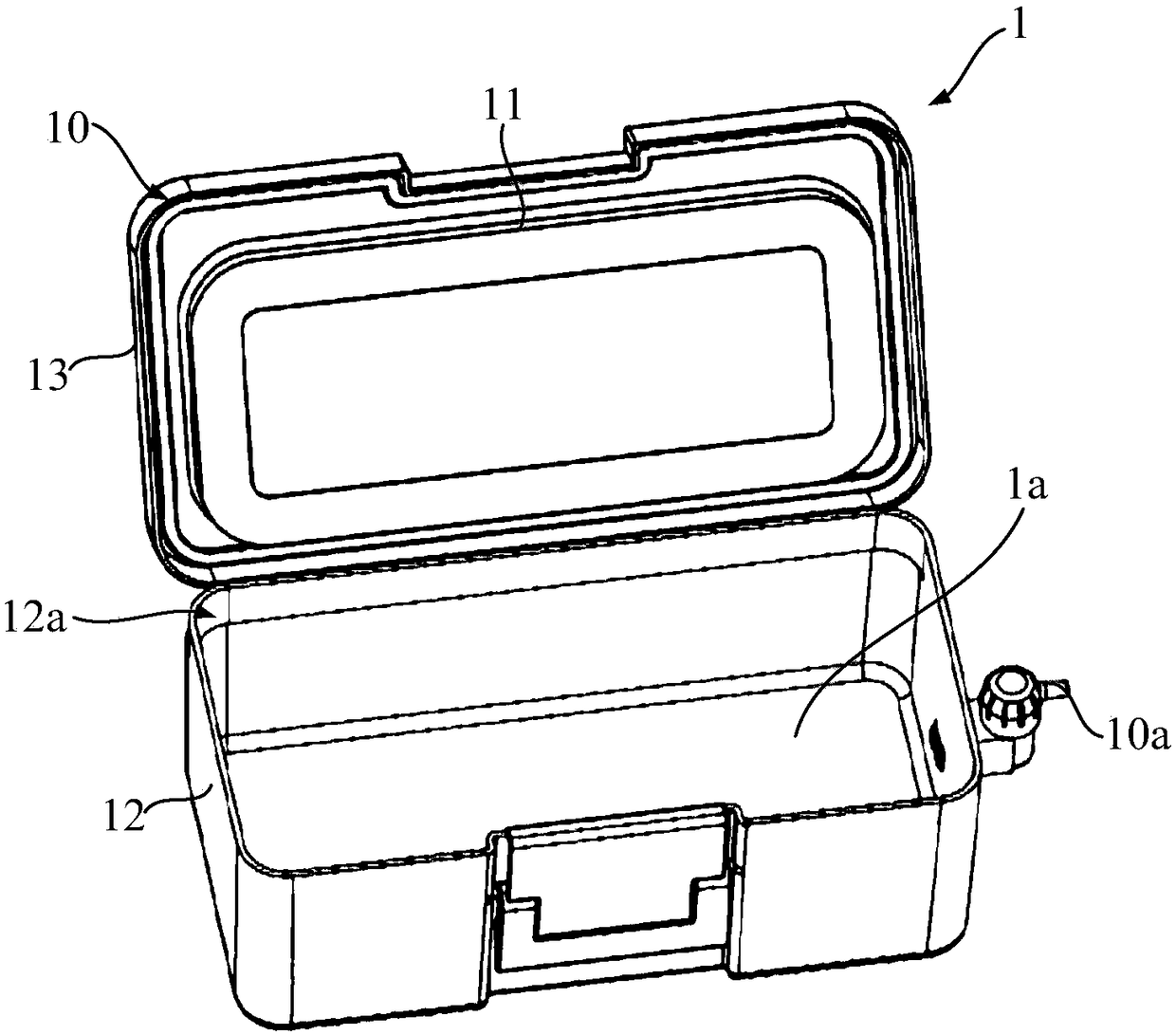

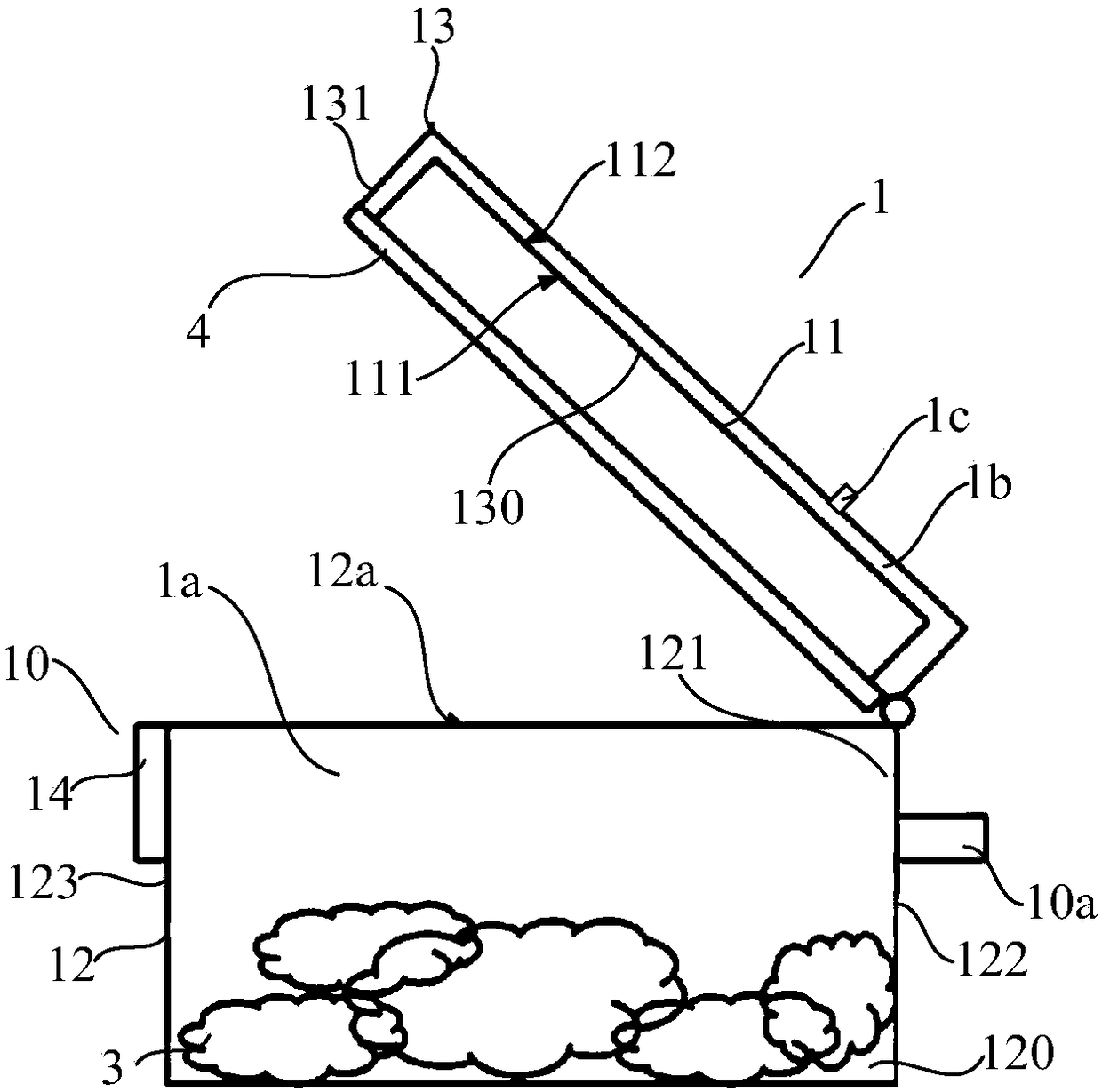

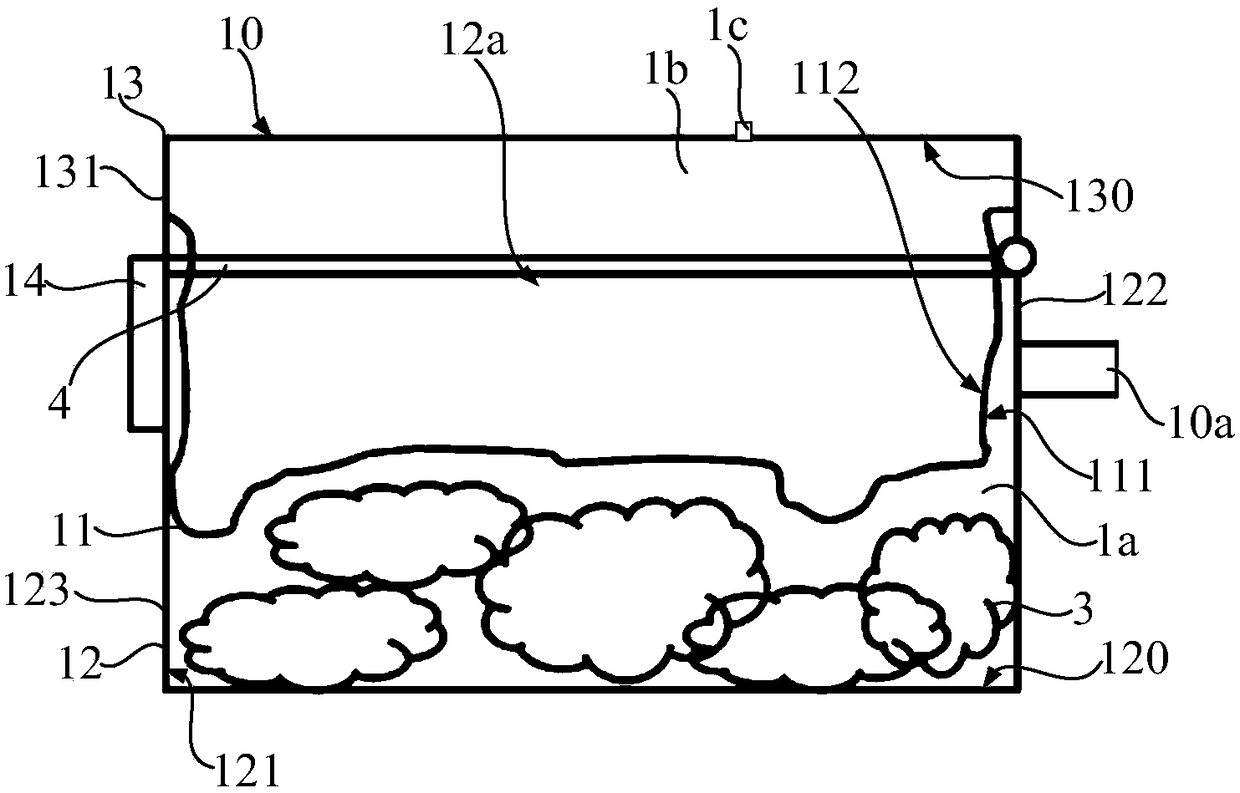

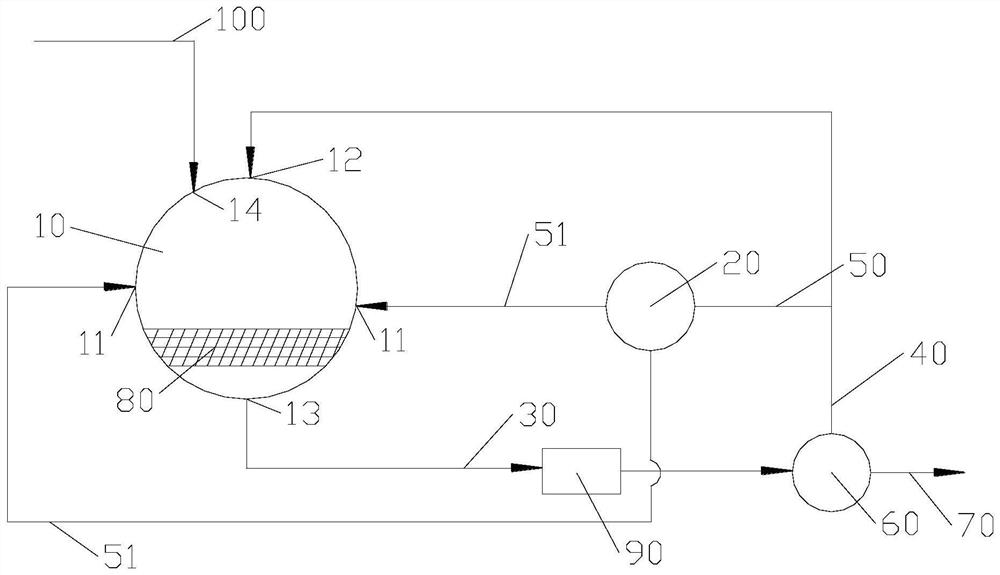

Domestic appliance, storage system and storage unit

InactiveCN108238371AAvoid the risk of deformationLow costPackaging under vacuum/special atmosphereExternal fittingsEngineeringThermodynamics

The invention relates to a domestic appliance, a storage system and a storage unit (1). The storage unit (1) comprises a storage container (10) with exhaust ports (10a, 10b), and membranes (11, 5) located in the storage container (10) so as to form compressible sealed storage spaces (1a, 100a) in the storage container (10), wherein at least partial borders of the storage spaces (1a, 100a) are defined by the membranes (11, 5); and the membranes (11, 5) are suitable for deforming when gases in the storage spaces (1a, 100a) are exhausted through the exhaust ports (10a, 10b) from the storage spaces (1a, 100a) so as to compress the storage spaces (1a, 100a). The storage container (10) and the storage unit (1) provided by the technical scheme have the advantages of small weight and lower cost.

Owner:BSH ELECTRICAL APPLIANCES JIANGSU +1

Air energy heat pump outdoor unit facilitating rapid heat dissipation and method

The invention relates to the technical field of air energy heat pump outdoor units, in particular to an air energy heat pump outdoor unit facilitating rapid heat dissipation and a method. The air energy heat pump outdoor unit comprises a case, and a heat pump mounting area and a cooling area are arranged in the case; a thermal contact plate is arranged in the heat pump mounting area, an annular heat conduction frame is arranged on the thermal contact plate, and an annular guide pipe is arranged on the edge of the thermal contact plate; a low-pressure cavity and a high-pressure cavity are formed in the cooling area, the cooling area is externally connected with a cooling water pipeline, the water conveying end of the cooling water pipeline is provided with a three-way change-over valve, a heat energy medium pipe is arranged in the low-pressure cavity, the heat energy medium pipe extends outwards to be connected with a water conveying pipeline, the water conveying pipeline is provided with a cooling water inlet pipe which is connected with the annular guide pipe through an input pump, and an output pump is arranged on the other side of the annular guide pipe and is externally connected with a backflow pipeline. Two relative space environments of the low-pressure cavity and the high-pressure cavity are designed in the outer case, and medium liquid is converted between the high-pressure environment and the low-pressure environment, so that a solution is vaporized, and heat is absorbed.

Owner:北京诺金伟业机电设备安装工程有限公司

Disengaging device of on-board generator

InactiveCN110576785ARealize detachmentEasy to operateLoading/unloading vehicle arrangmentItem transportation vehiclesOn boardAutomotive engineering

Owner:SUZHOU JIANGNAN AEROSPACE MECHANICAL& ELECTRICAL IND CO LTD

Washing device, door body washing mechanism with spray washing function and control method

PendingCN113235259AImprove general performanceHighly integratedOther washing machinesControl devices for washing apparatusSpray nozzleStructural engineering

The invention provides a washing device, a door body washing mechanism with a spray washing function and a control method. The door body washing mechanism with the spraying washing function comprises a door body structure provided with a door body washing cavity, one or more spraying nozzles, and a water path structure, wherein the spraying nozzles at least include one lateral spraying nozzle, and the lateral spraying nozzle is arranged on the side portion of the door body washing cavity, so that washing water sprayed out of the lateral spraying nozzle enables washings to be stirred in the door body washing cavity; and at least part of the water path structure is arranged in the door body structure and communicates with the spraying nozzles. The problem that a washing device is poor in use effect in the prior art is solved.

Owner:GREE ELECTRIC APPLIANCES INC

Rotary roller deflection type sorting device and logistics sorting system

PendingCN111908057AReduce in quantitySimple structureSupporting framesRoller-waysLogistics managementAgricultural engineering

The invention discloses a rotary roller deflection type sorting device and a logistics sorting system. The rotary roller deflection type sorting device comprises a rack, wherein a group of sorting units are arranged on the rack, each sorting unit comprises a deflection seat, a group of rotary rollers with parallel axes and equal heights are horizontally arranged on each deflection seat, the heightof a conveying surface formed by the rotary rollers is larger than the height of the deflection seat, and the rotary rollers are directly or indirectly driven by a driving roller which is parallel tothe axes of the rotary rollers and is driven by a power source; and each sorting unit can rotate around a longitudinal axis of a corresponding mounting seat and is connected with a deflection drivingdevice for driving the corresponding sorting unit to self-rotate. According to the scheme, one group of rotary rollers are arranged on one deflection seat, so that the number of the deflection seatscan be effectively reduced, the overall structure is simplified, and the dead weight of equipment is reduced; and meanwhile, the multiple rotary rollers are driven by adopting a friction driving mode,so that the driving mode is simple and easy to achieve, no interference exists between the driving mode and the deflection of the rotary rollers, and the stability is good.

Owner:SUZHOU GP LOGISTICS SYST

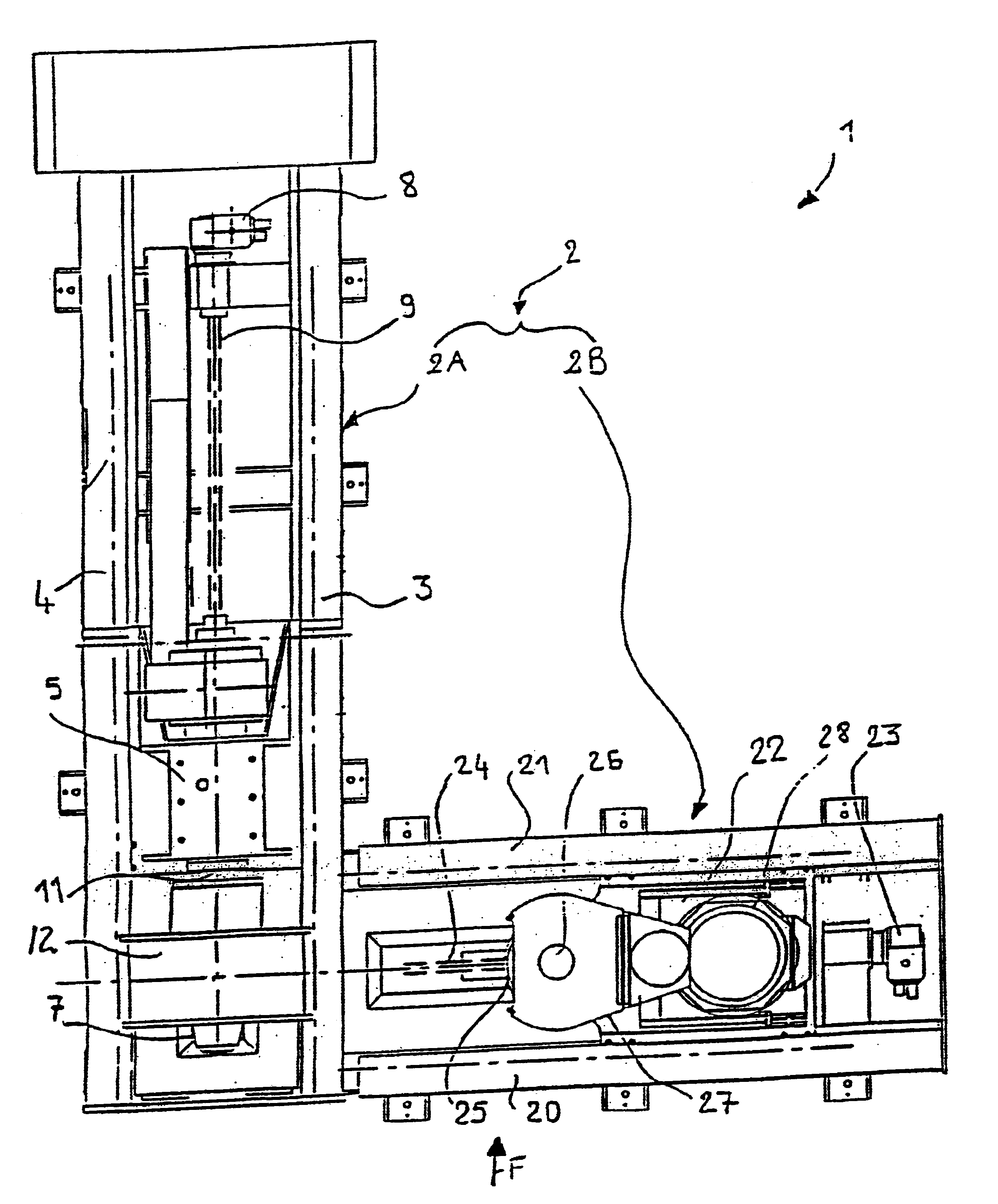

Apparatus for recapping tires

InactiveUS6911113B2Prevents risk of deformationGood stabilityRevolution surface grinding machinesTyresEngineeringMechanical engineering

Owner:RECAMIC SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com