Silicon nitride ceramic piece and processing method thereof

A technology of silicon nitride ceramics and ceramic materials, which is applied in the processing field of silicon nitride ceramic grading wheels, can solve the problems of high porosity, difficult processing of finished products, and large wear, and achieve uniform density and eliminate micro pores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

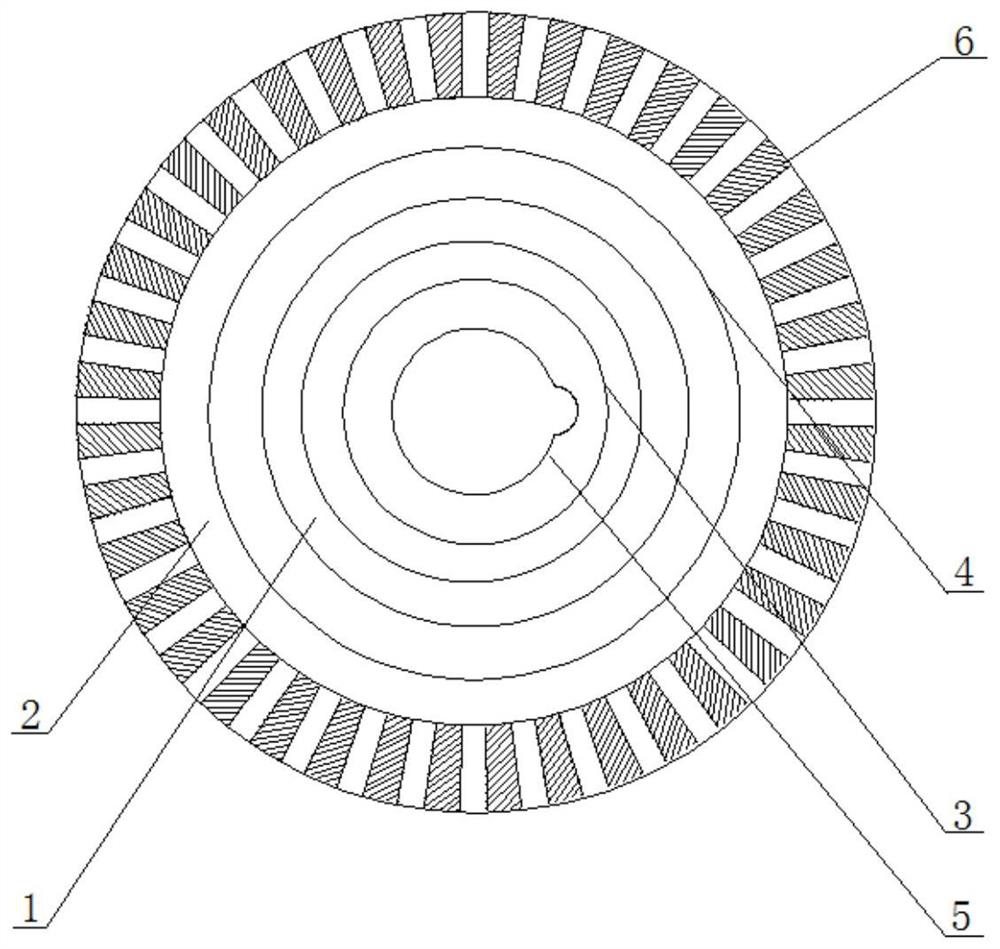

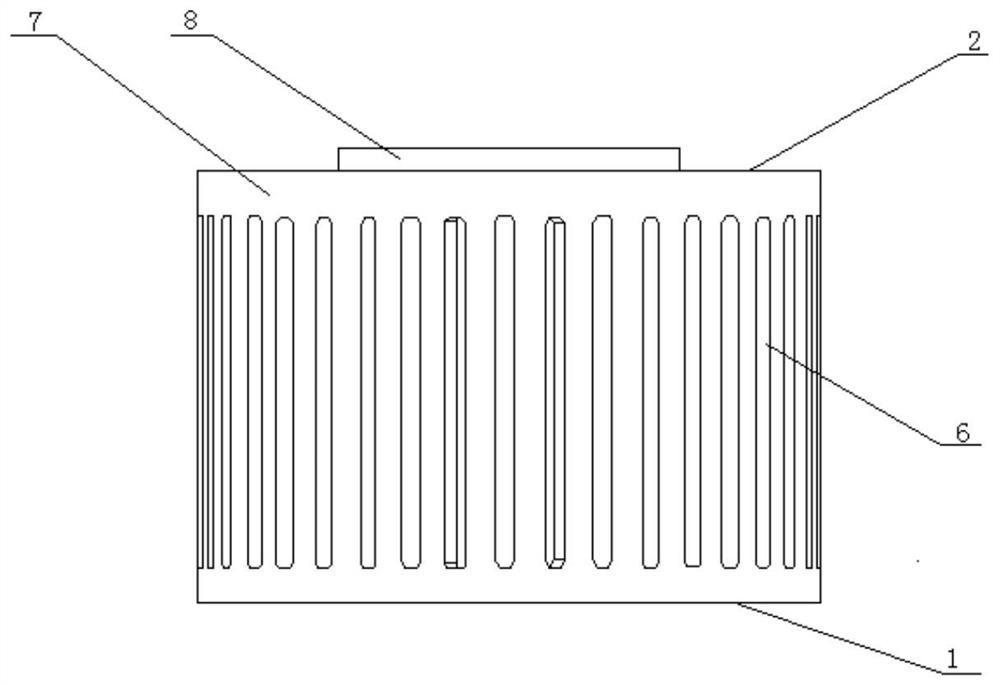

[0076] One aspect of this embodiment provides a silicon nitride ceramic part, which includes a first cylinder 7, and the two ends of the first cylinder 7 are respectively provided with a first end face 1 and a second end face 2; 7 is provided with a first fixing seat, and the first fixing seat is connected through the first end surface 1; the surface of the first end surface 1 is provided with a fixing groove 5;

[0077] The upper surface of the second end surface 2 is provided with a second fixing seat 8, and the second fixing seat 8 is connected through the second end surface 2;

[0078] The first fixed seat is a truncated cone structure; the second fixed seat 8 is a cylindrical structure; the inner diameter of the first cylinder 7 is 200mm; the through hole through which the second fixed seat 8 connects with the second end face 2 is The second through hole 4, the diameter of the second through hole 4 is 130mm; the ratio of the inner diameter of the first cylinder 7 to the d...

Embodiment 2

[0095] Where this embodiment is the same as Embodiment 1, details are not repeated here;

[0096] One aspect of this embodiment provides a silicon nitride ceramic part, the first fixing seat is a cylindrical structure; the inner diameter of the first cylinder 7 is 180mm; the diameter of the second through hole 4 is 130mm; the first cylinder The ratio of the inner diameter of the body 7 to the diameter of the second through hole 4 is 1.38;

[0097] The number of the first through holes 6 is 35, and the width of the through holes is 5 mm;

[0098] The finished silicon nitride ceramic part has a bending strength of 795Mpa and a fracture toughness of 7.4MPa.m 1 / 2 ,HV 10 The hardness is 1520; the density is 3.245g / cm3; the density change is 0.04%.

[0099] Another aspect of this embodiment provides a method for preparing a silicon nitride ceramic part, the first duration is 48 hours; the second duration is 48 hours;

[0100] The mass ratio of the silicon nitride powder to the s...

Embodiment 3

[0109] Where this embodiment is the same as Embodiment 1, details are not repeated here;

[0110] One aspect of this embodiment provides a silicon nitride ceramic part, the first fixing seat is a cylindrical structure; the inner diameter of the first cylinder 7 is 190mm; the diameter of the second through hole 4 is 120mm; the first cylinder The ratio of the inner diameter of the body 7 to the diameter of the second through hole 4 is 1.58;

[0111] The number of the first through holes 6 is 30, and the width of the through holes is 6 mm;

[0112] The finished silicon nitride ceramic part has a bending strength of 795Mpa and a fracture toughness of 7.4MPa.m 1 / 2 ,HV 10 The hardness is 1520; the density is 3.24g / cm 3 ; The density change is 0.05%.

[0113] Another aspect of this embodiment provides a method for preparing a silicon nitride ceramic part, the first duration is 48 hours; the second duration is 48 hours;

[0114] The mass ratio of the silicon nitride powder to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com