Patents

Literature

36results about How to "Eliminate microporosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

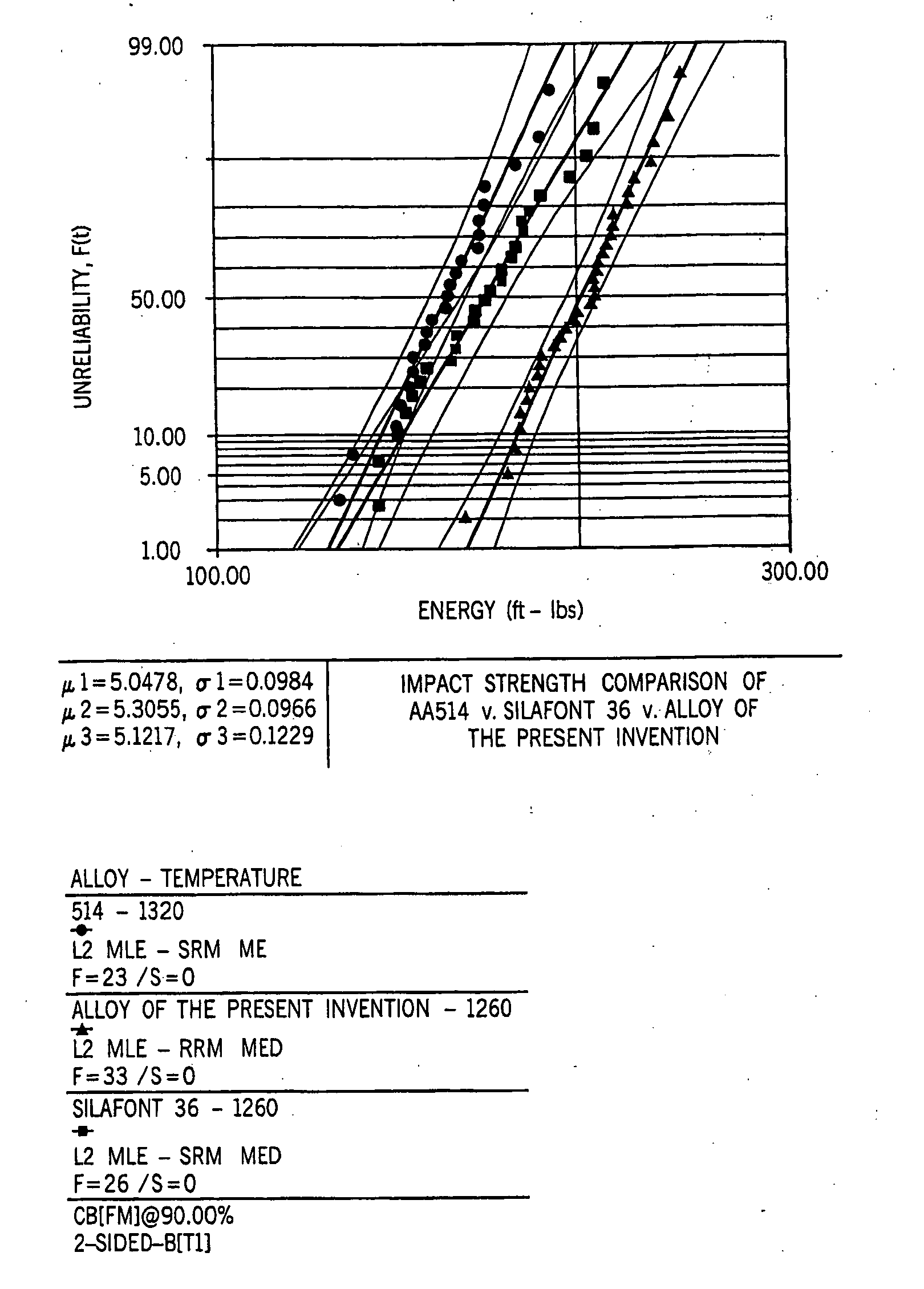

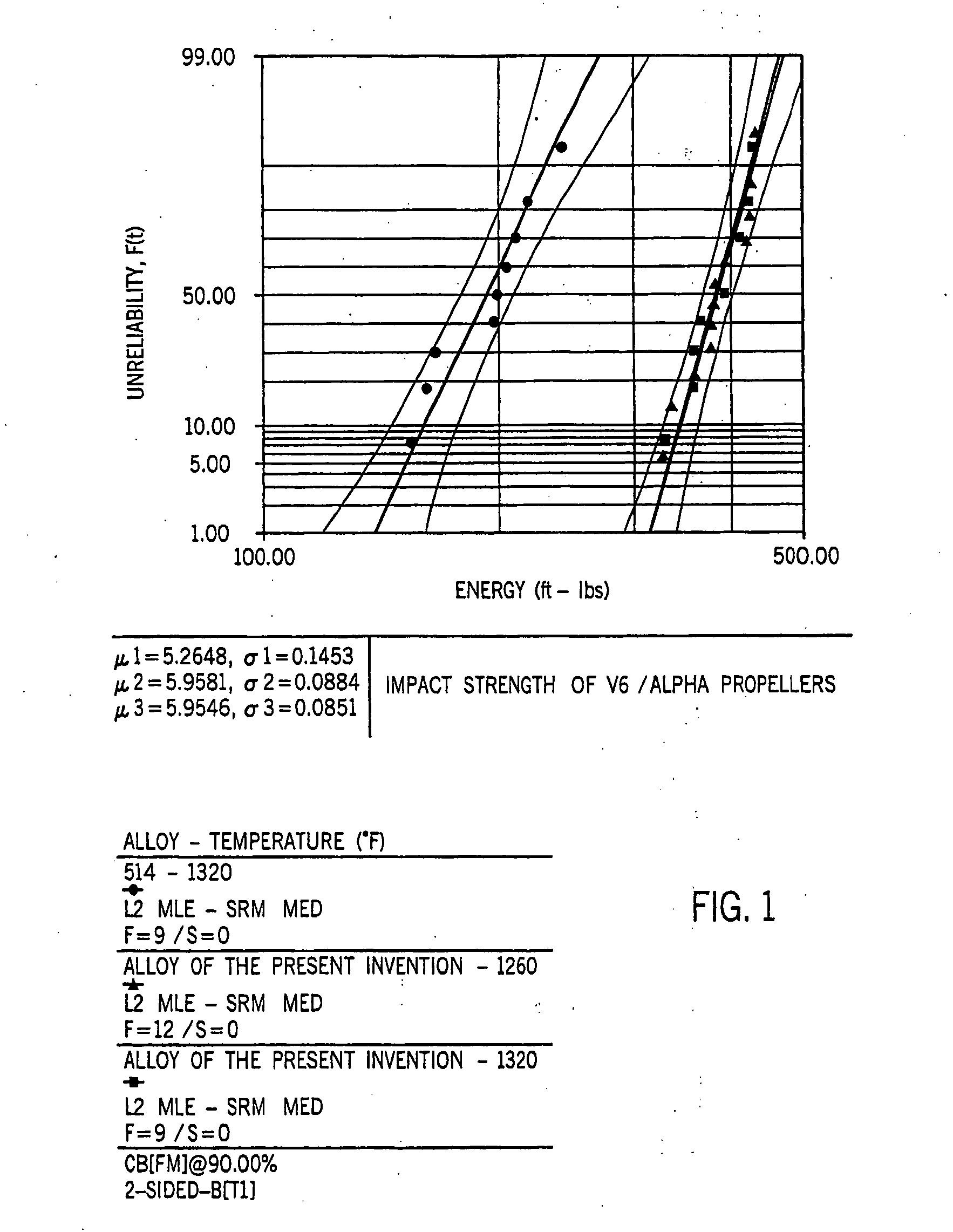

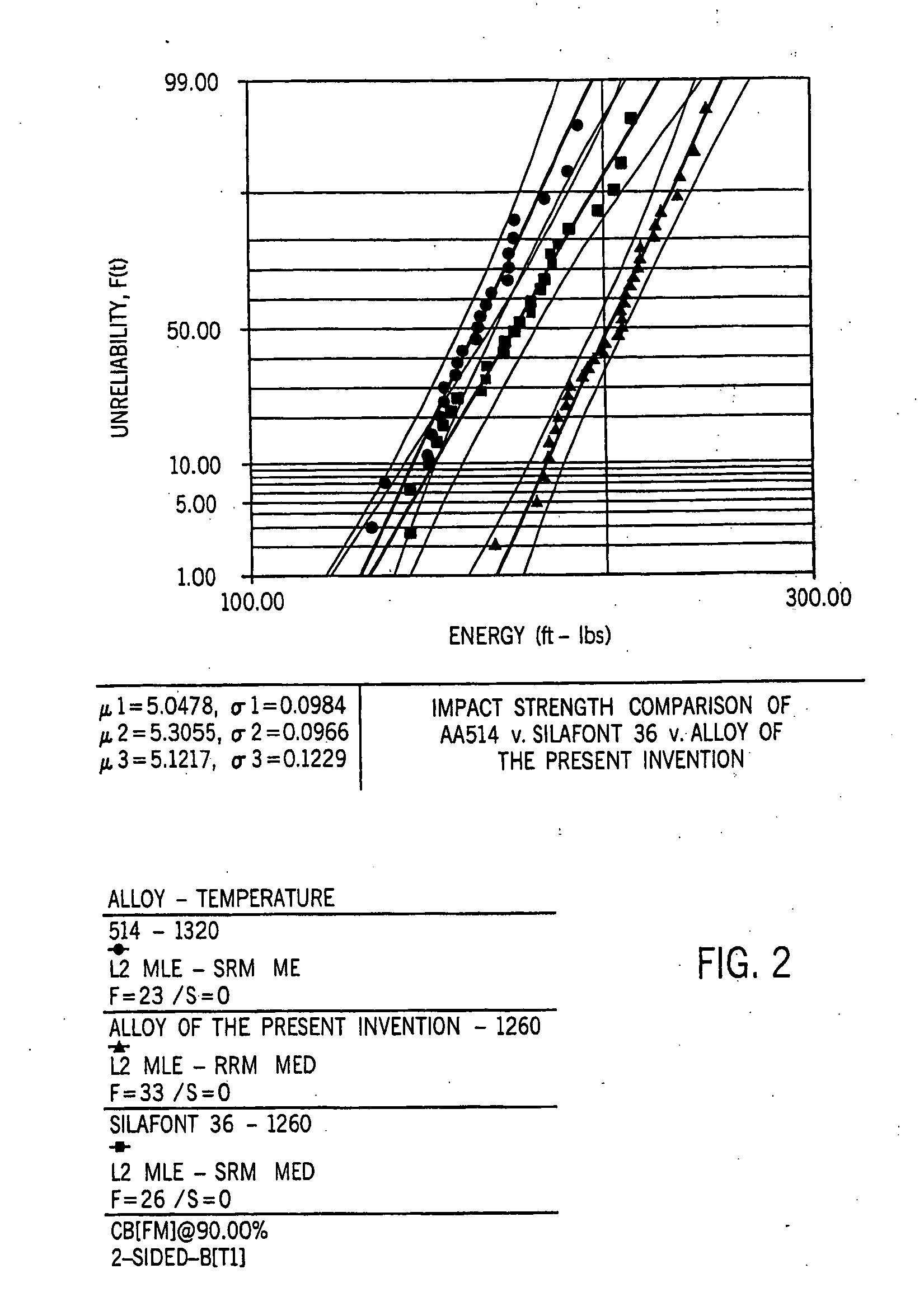

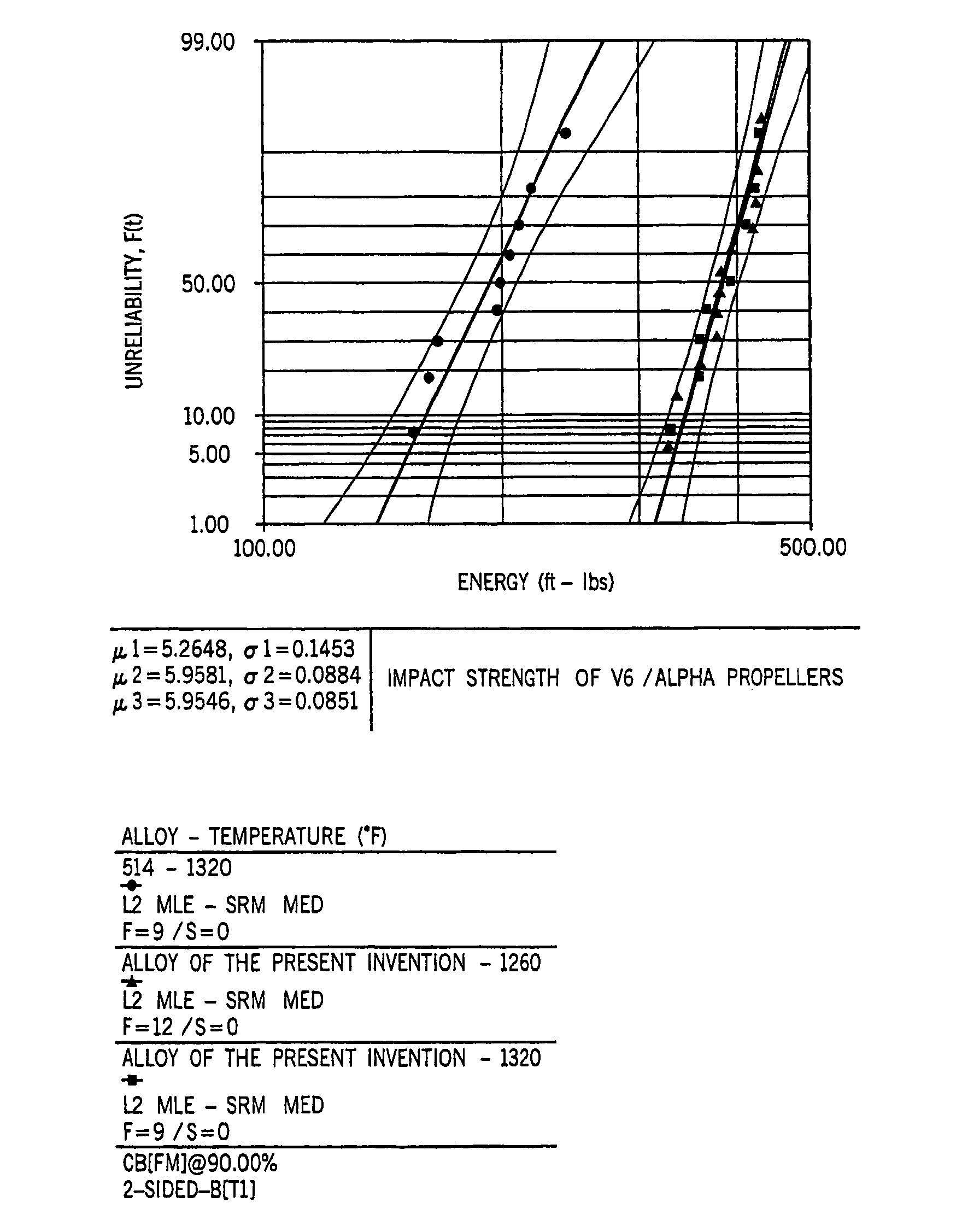

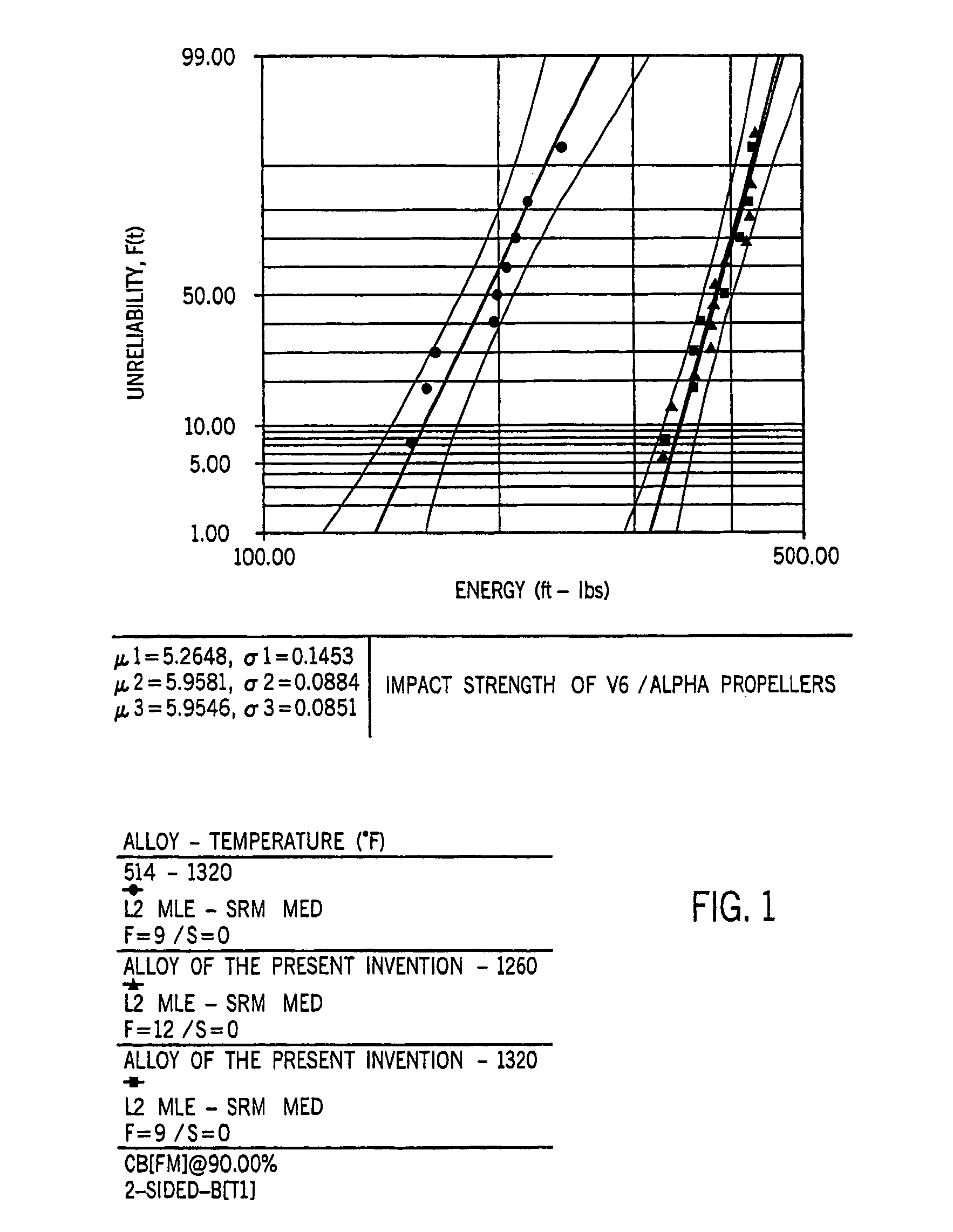

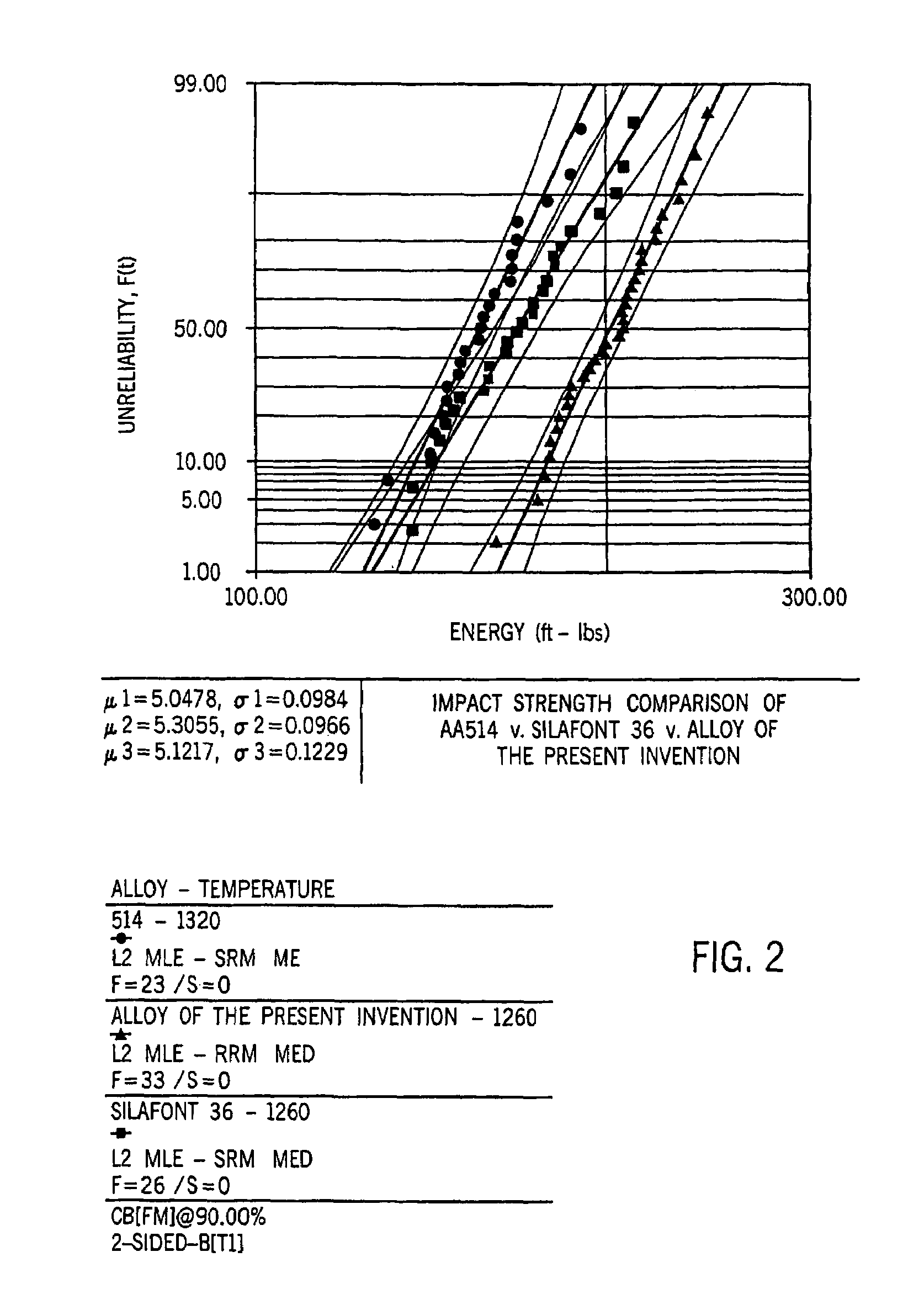

Aluminum-silicon alloy having reduced microporosity

An aluminum silicon die cast alloy having a very low iron content and relatively high strontium content that prevents soldering to dies into die casting process. The alloys of the present invention also have a modified eutectic silicon and modified iron morphology, when iron is present, resulting in low microporosity and high impact properties. The alloy comprises 6-22% by weight silicon, 0.05 to 0.20% by weight strontium and the balance aluminum. Preferably, the alloy of the present invention contains in weight percent: 6-20% silicon, 0.05-0.10% strontium, 0.40% maximum iron and most preferably 0.20% maximum iron, 4.5% maximum copper, 0.50% maximum manganese, 0.60% maximum magnesium, 3.0% maximum zinc, balance aluminum. On cooling from the solution temperature, the strontium serves to modify the eutectic silicon structure as well as create an iron phase morphology change if iron is present, facilitating feeding through the aluminum interdendritic matrix. This, in turn, creates a finished die cast product with extremely low levels of microporosity defects. The strontium content also appears to create a non-wetting monolayer of strontium atoms on the surface of a molten casting, preventing die soldering, even at very low iron contents. The alloy may be used to cast any type of object and is particularly suited for casting outboard marine propellers, driveshaft housings, gear case housings, Gimbel rings and engine blocks.

Owner:BRUNSWICK CORPORATION

Aluminum-silicon alloy having reduced microporosity

An aluminum silicon die cast alloy having a very low iron content and relatively high strontium content that prevents soldering to dies into die casting process. The alloys of the present invention also have a modified eutectic silicon and modified iron morphology, when iron is present, resulting in low microporosity and high impact properties. The alloy comprises 6-22% by weight silicon, 0.05 to 0.20% by weight strontium and the balance aluminum. Preferably, the alloy of the present invention contains in weight percent: 6-20% silicon, 0.05-0.10% strontium, 0.40% maximum iron and most preferably 0.20% maximum iron, 4.5% maximum copper, 0.50% maximum manganese, 0.60% maximum magnesium, 3.0% maximum zinc, balance aluminum. On cooling from the solution temperature, the strontium serves to modify the eutectic silicon structure as well as create an iron phase morphology change if iron is present, facilitating feeding through the aluminum interdendritic matrix. This, in turn, creates a finished die cast product with extremely low levels of microporosity defects. The strontium content also appears to create a non-wetting monolayer of strontium atoms on the surface of a molten casting, preventing die soldering, even at very low iron contents. The alloy may be used to cast any type of object and is particularly suited for casting outboard marine propellers, driveshaft housings, gear case housings, Gimbel rings and engine blocks.

Owner:BRUNSWICK CORPORATION

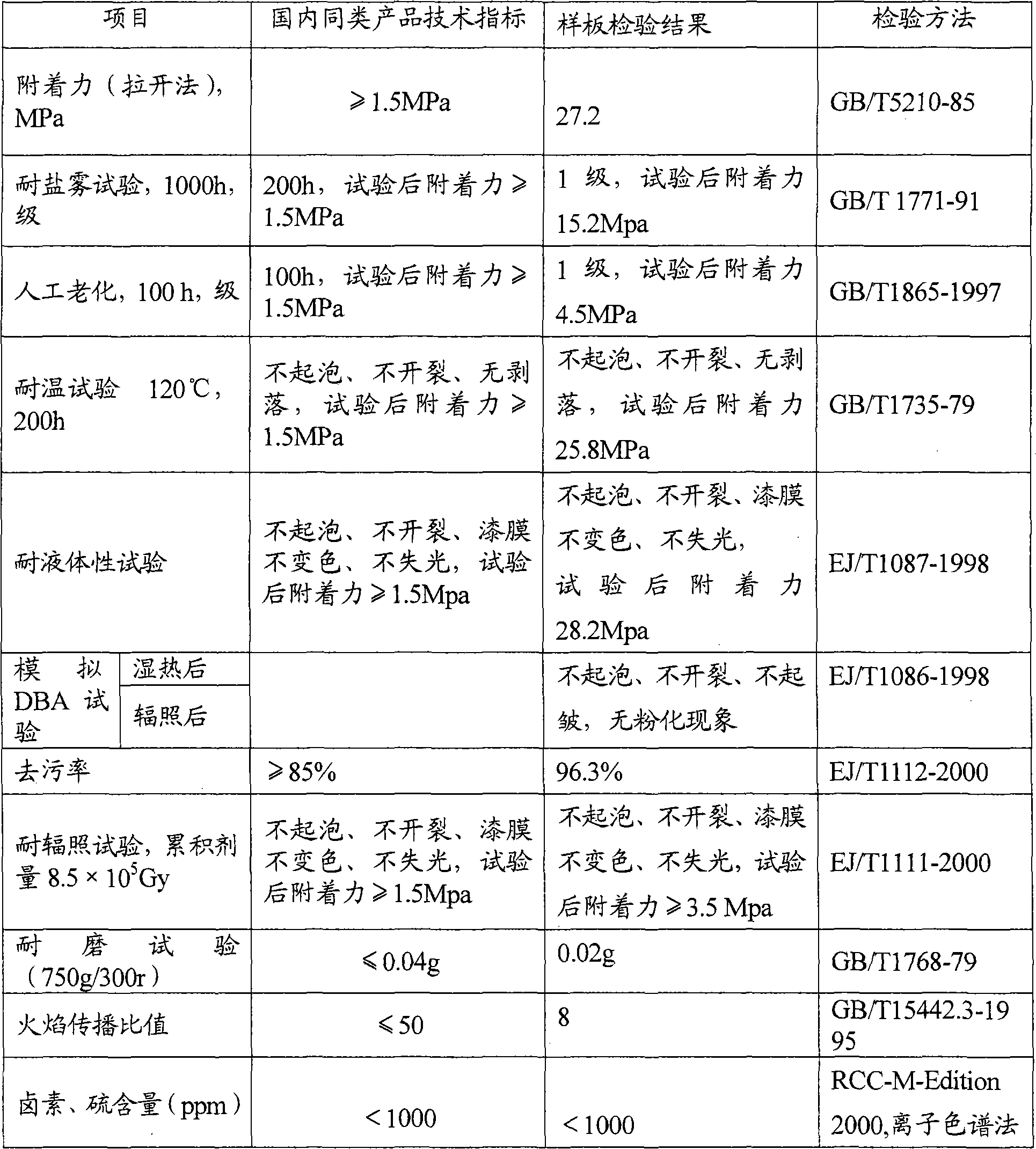

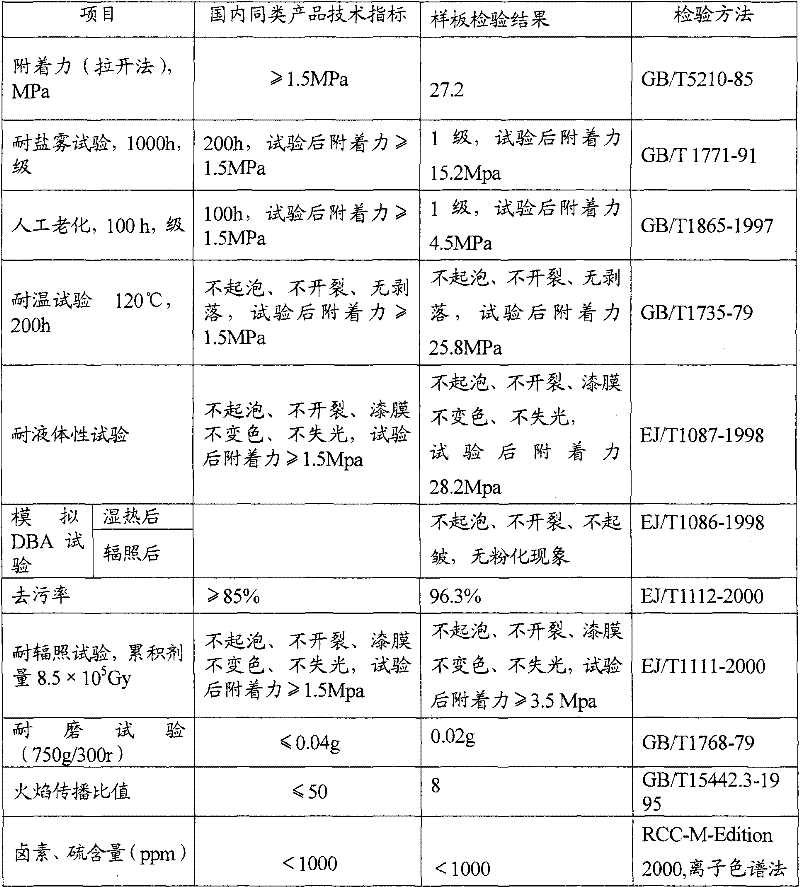

Epoxy protective coating system for high-power nuclear power station

ActiveCN101781508AImprove corrosion resistanceGood radiation protectionAnti-corrosive paintsShieldingNuclear gradeNuclear power

The invention relates to an epoxy protective coating system for a high-power nuclear power station. Priming coat comprises a component A1 and a component B with the weight ratio of 4-6, and finishing coat comprises a component A2 and the component B with the weight ratio of 3-5:1.. The component A1 comprises 20 to 50% of epoxy resin, 10 to 40% of anti-corrosion paint, 10 to 25% of radiation-resistant stuffing, 0.1 to 3% of addition agent and the balance of menstruum by weight percent. The component A2 comprises 20 to 50% of the epoxy resin, 10 to 40% of the anti-corrosion paint, 5 to 20% of the radiation-resistant stuffing, 0.1 to 3% of the addition agent and the balance of the menstruum by weight percent. The component B is a radiation-resistant epoxy-amine adduct curing agent, and is synthesized by 10 to 30% of liquid epoxy resin, 30 to 70% of polyamine with primary amine groups and 20 to 60% of the menstruum. The corrosion resistance and radiation resistance can meet the requirements of nuclear grade paint and can pass simulation DBA tests when the coating system is used for a high-power nuclear power station.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Hypoeutectic aluminum-silicon alloy having reduced microporosity

A hypoeutectic aluminum silicon casting alloy having a refined primary silicon particle size and a modified iron morphology. The alloy includes 10 to 11.5% by weight silicon, 0.10 to 0.70% by weight magnesium and also contains 0.05 to 0.07% by weight strontium. On cooling from the solution temperature, the strontium serves to modify the silicon eutectic structure as well as create an iron phase morphology change. Such changes facilitate feeding through the aluminum interdendritic matrix. This, in turn, creates a finished die cast product with extremely low levels of microporosity defects. The alloy may be used to cast engine blocks for marine outboard and stern drive motors. Furthermore, when the magnesium levels are adjusted to approximately 0.10 to 0.20% by weight magnesium, propellers having a highly advantageous ductility may be obtained.

Owner:BRUNSWICK CORPORATION

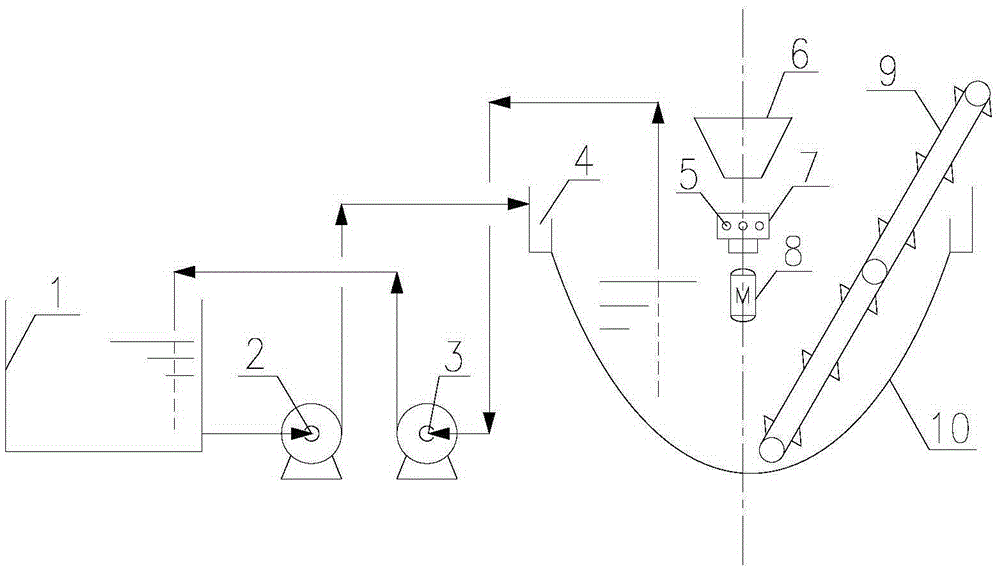

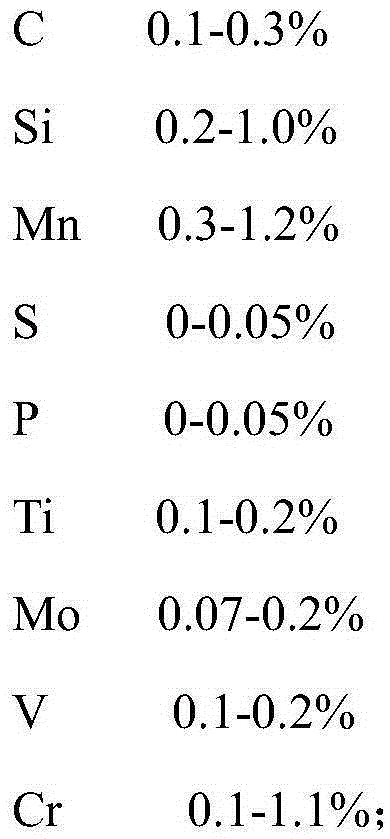

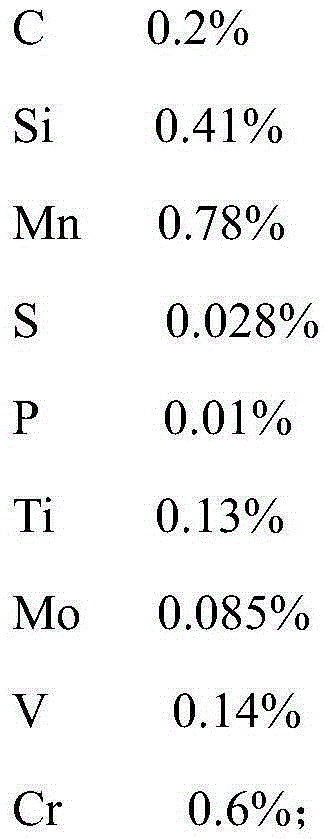

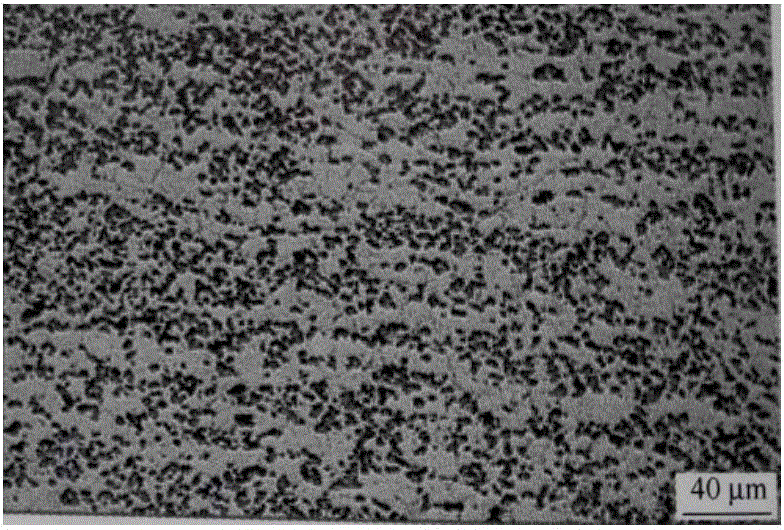

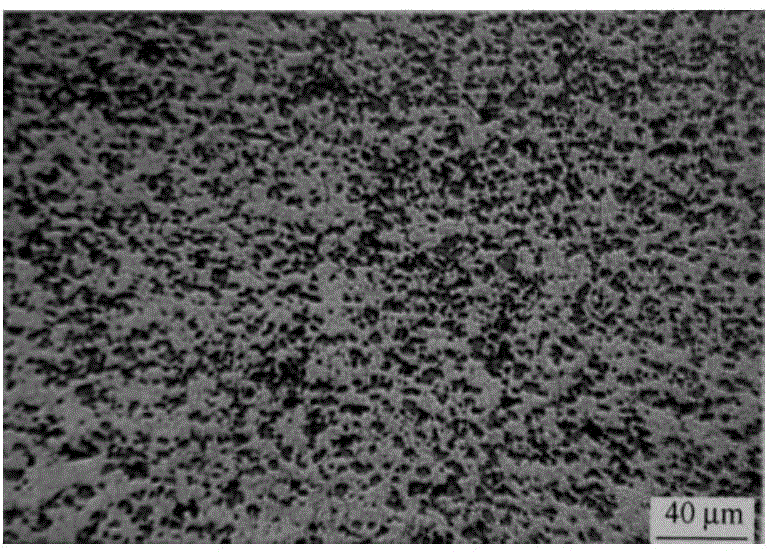

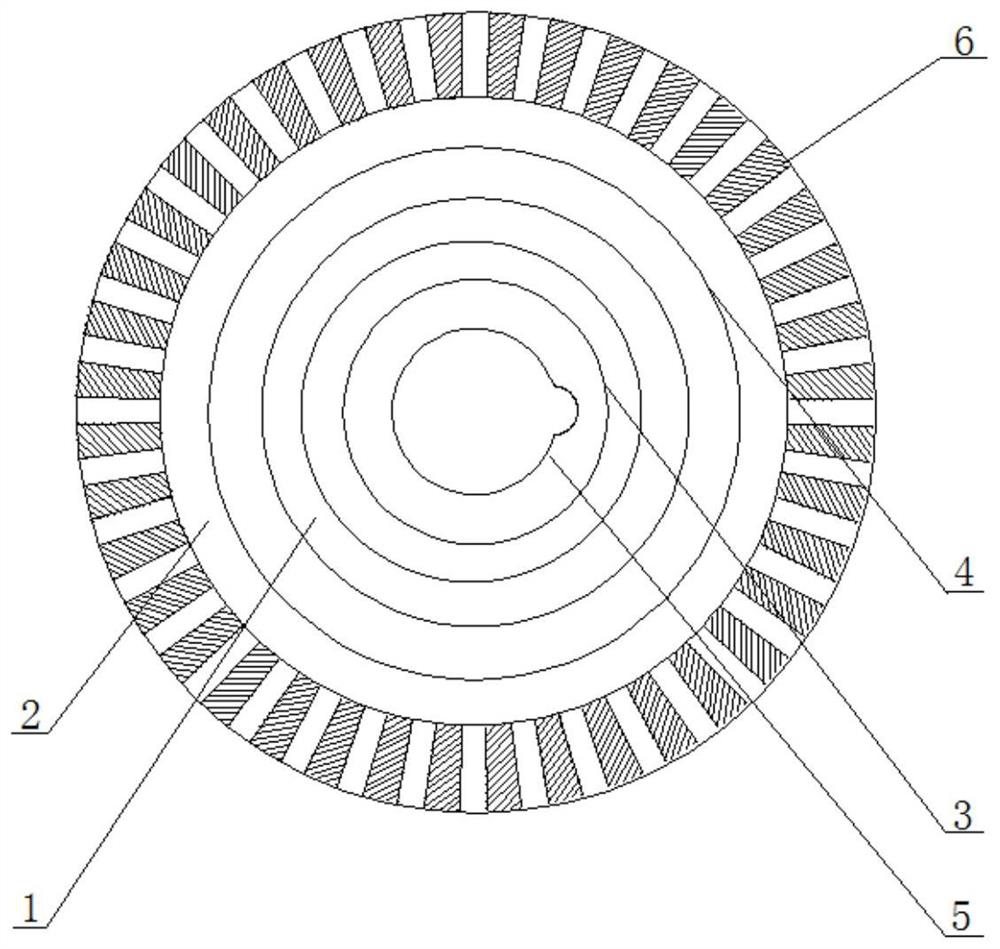

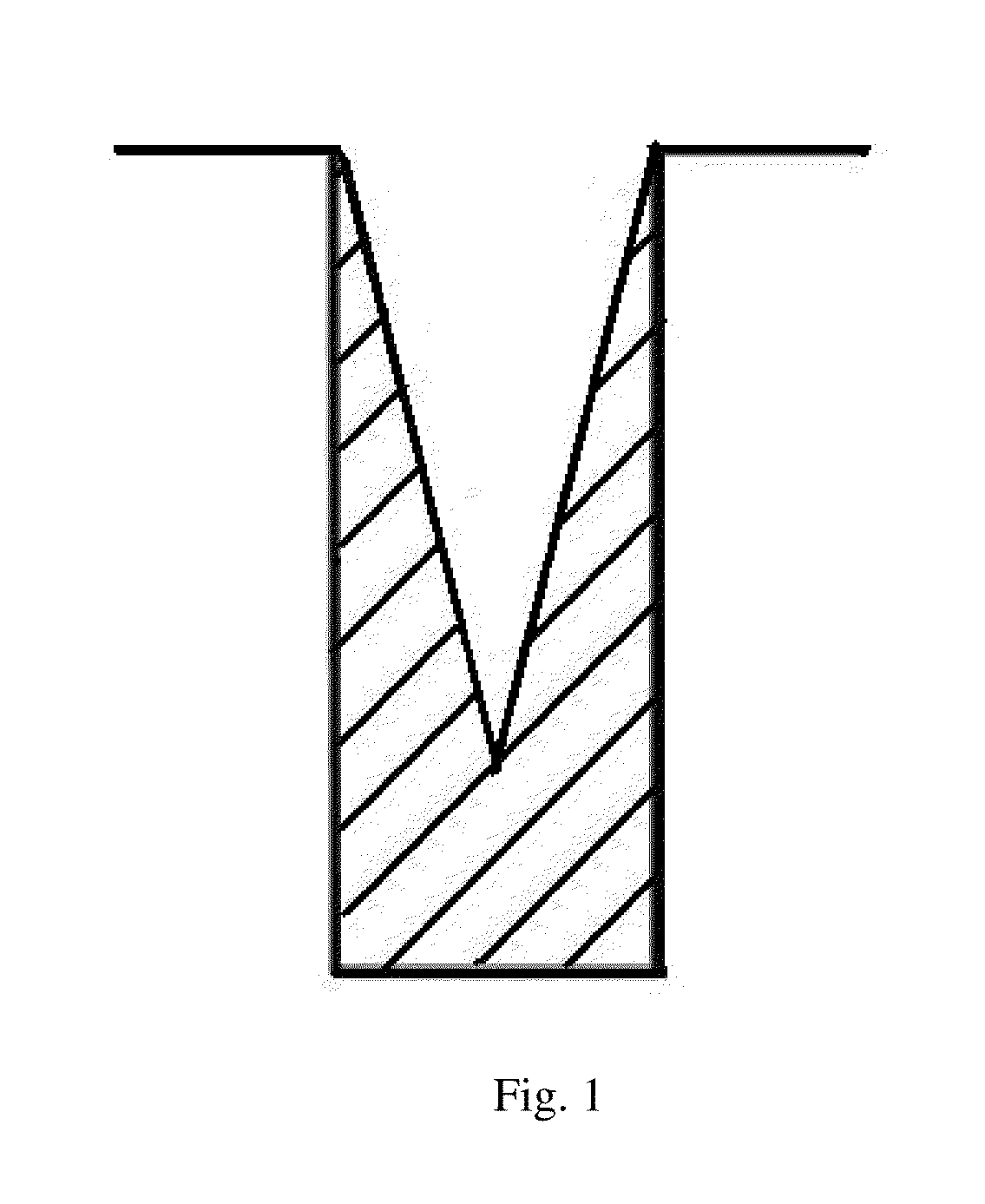

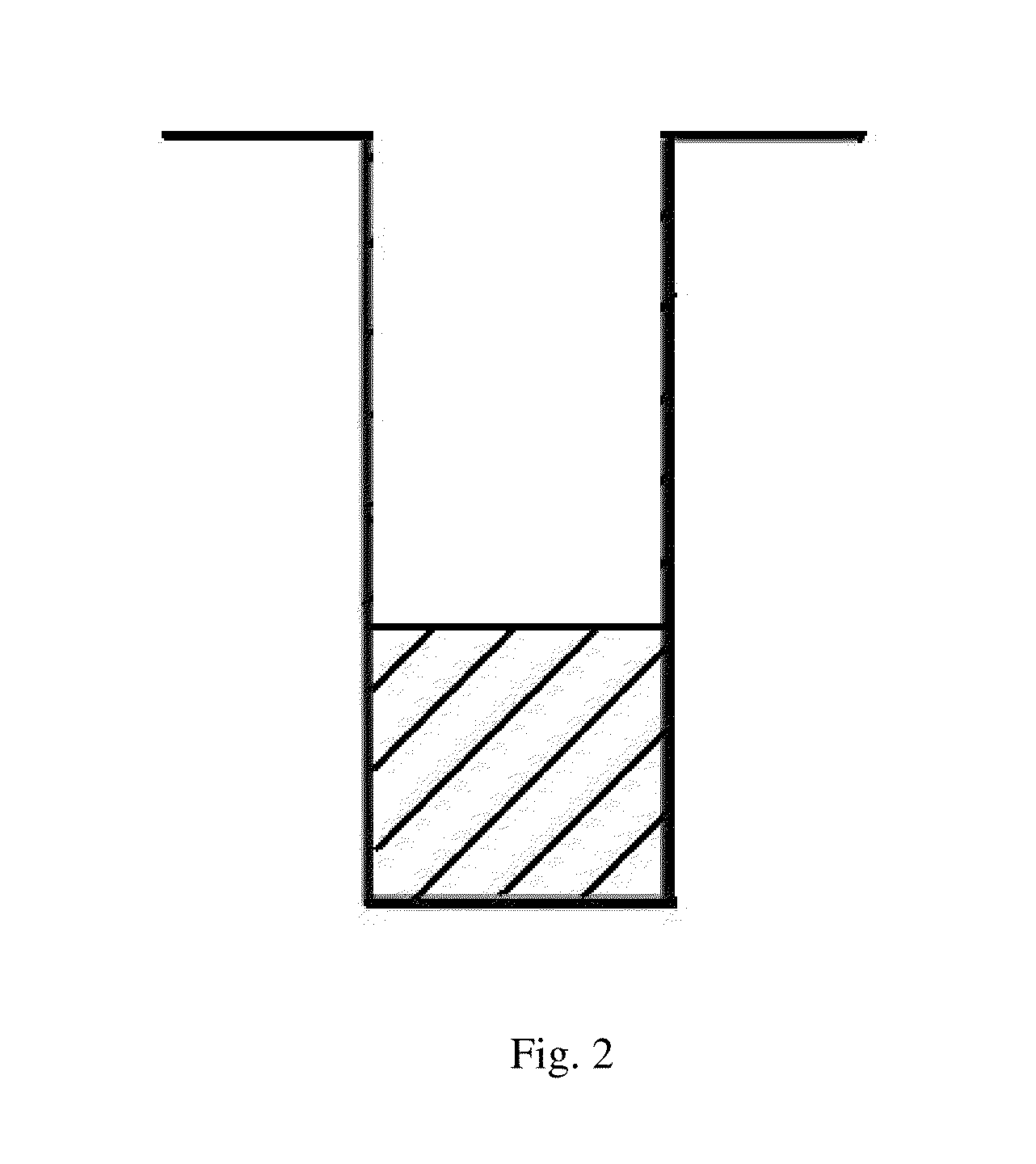

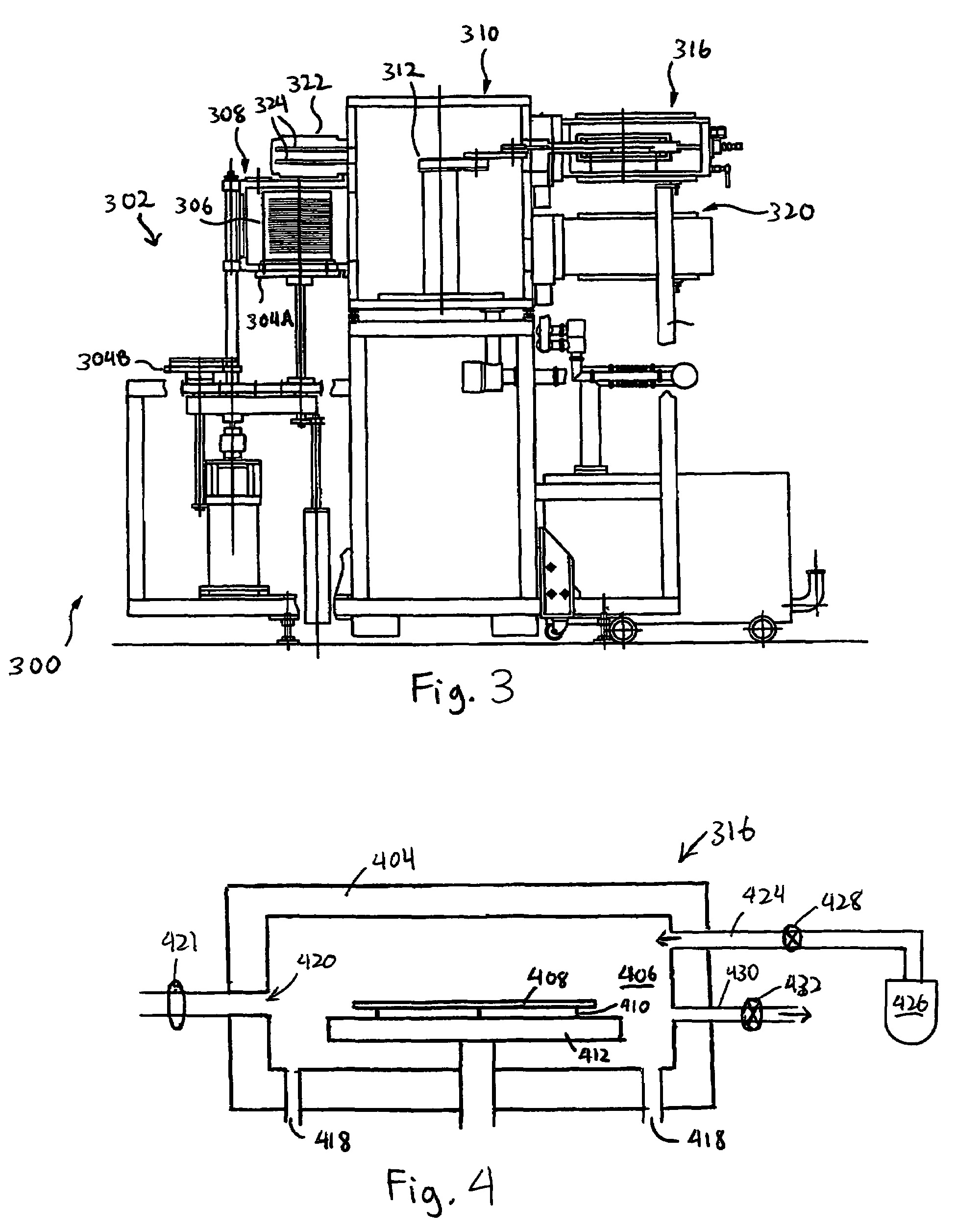

Wear-resisting low-carbon steel shot, preparation method thereof and centrifugal atomizing device

ActiveCN105385961AMeet diverse needsImprove roundnessFurnace typesHeat treatment furnacesWater storage tankThermal treatment

The invention relates to a wear-resisting low-carbon steel shot, a preparation method thereof and a centrifugal atomizing device, and belongs to the technical field of metal abrasives. The wear-resisting low-carbon steel shot consists of the following chemical components in percentage by mass: 0.1-0.3% of C, 0.2-1.0% of Si, 0.3-1.2% of Mn, 0-0.05% of S, 0-0.05% of P, 0.1-0.2% of Ti, 0.07-0.2% of Mo, 0.1-0.2% of V, 0.1-1.1% of Cr and the balance of Fe. The preparation method comprises the following steps: smelting, centrifugal atomizing and forming, drying, coarse screening, quenching and tempering. The centrifugal atomizing device comprises a water storage tank, a centrifugal rotary plate and a centrifugal atomizing tank, wherein the centrifugal atomizing tank sequentially passes through a water outlet pump, the water storage tank and a water inlet pump to form a circulating loop; the upper part of the centrifugal atomizing tank is provided with a centrifugal rotary plate; and the top of the centrifugal atomizing tank is provided with ring-shaped water slots which are distributed along the circumference. The wear-resisting low-carbon steel shot has the characteristics of impact resistance, high cleaning efficiency and fatigue resistance, and has wear-resisting times up to 3500-3600 times; the preparation method is simple and good in thermal treatment effect; and the used centrifugal atomizing device is simple in structure, low in cost and easy to realize.

Owner:ZIBO LUBAO METAL PROD CO LTD

Automobile air conditioner compressor hollow piston and production method thereof

ActiveCN104805339AHigh tensile strengthHigh yield strengthPositive displacement pump componentsPositive-displacement liquid enginesPorosityWeld seam

The invention discloses an automobile air conditioner compressor hollow piston, which comprises aluminum alloy prepared from the following ingredients in percentage by weight: 11 to 13 percent of Si, 3.5 to 4.5 percent of Cu, 0.2 to 0.5 percent of Mg, 0.8 to 1.5 percent of Ni, 0.1 to 0.3 percent of Cr, 0.1 to 0.3 percent of C, 0 to 0.1 percent of Mn, 0 to 0.5 percent of Zn, 0 to 0.15 percent of Ti, 0.1 to 0.3 percent of RE and the balance Al. The invention also provides a production method of the automobile air conditioner compressor hollow piston. Through the selection and the control on elements in the aluminum alloy for the hollow piston, the intensity and the hardness of the piston are improved; through further improvement on the laser welding process, the welding seam fine porosity rate is reduced, the welding tension is enhanced, and the welding quality is improved, so the use performance of the hollow piston is improved, and the service life of the hollow piston is prolonged.

Owner:SHANDONG HUICHUAN AUTO PARTS

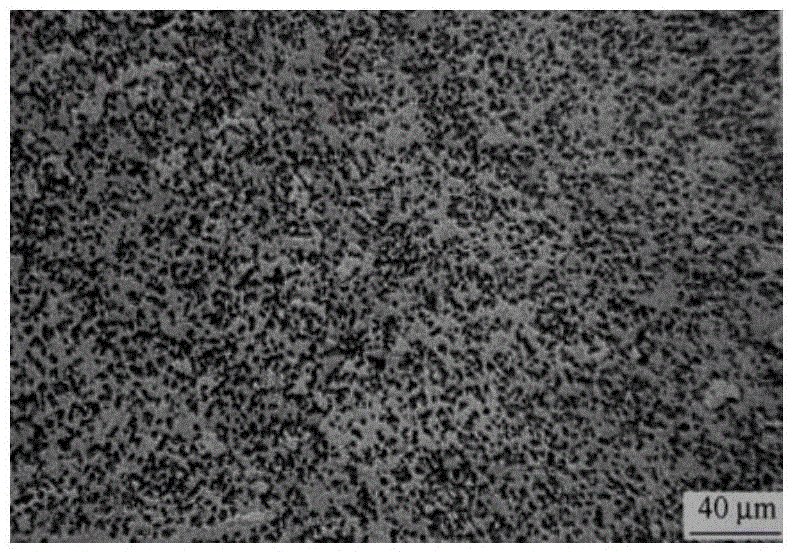

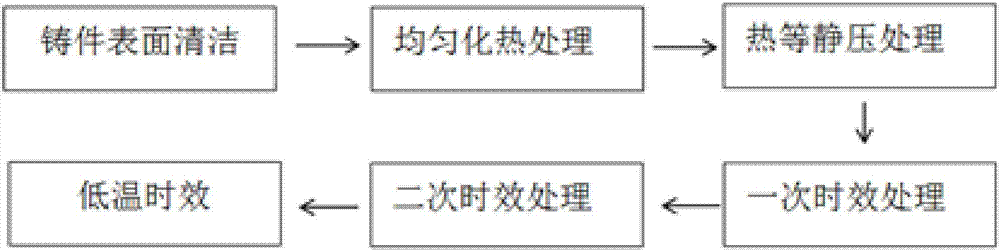

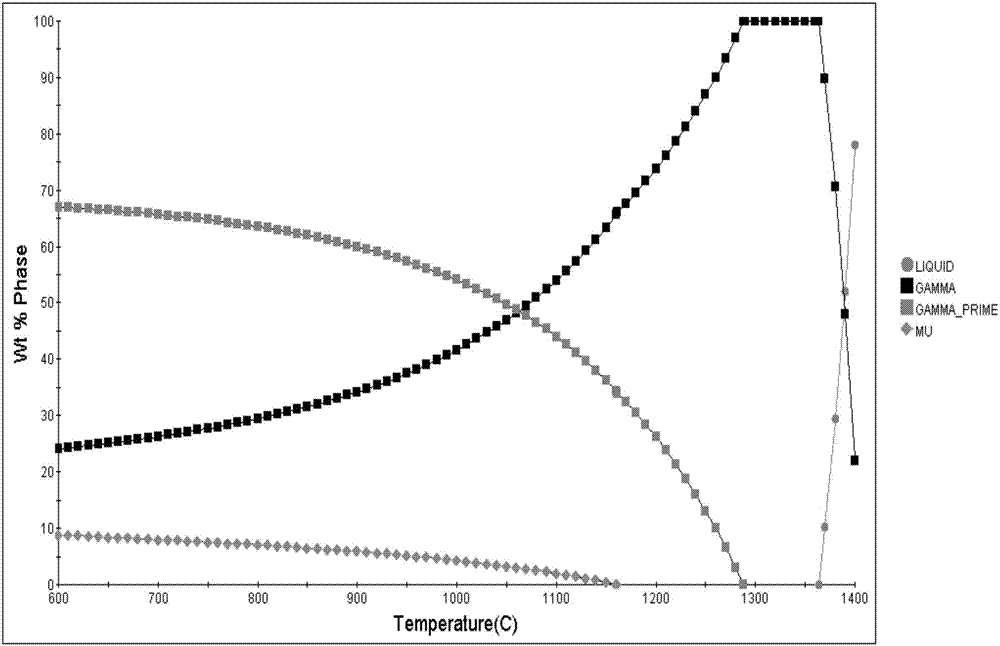

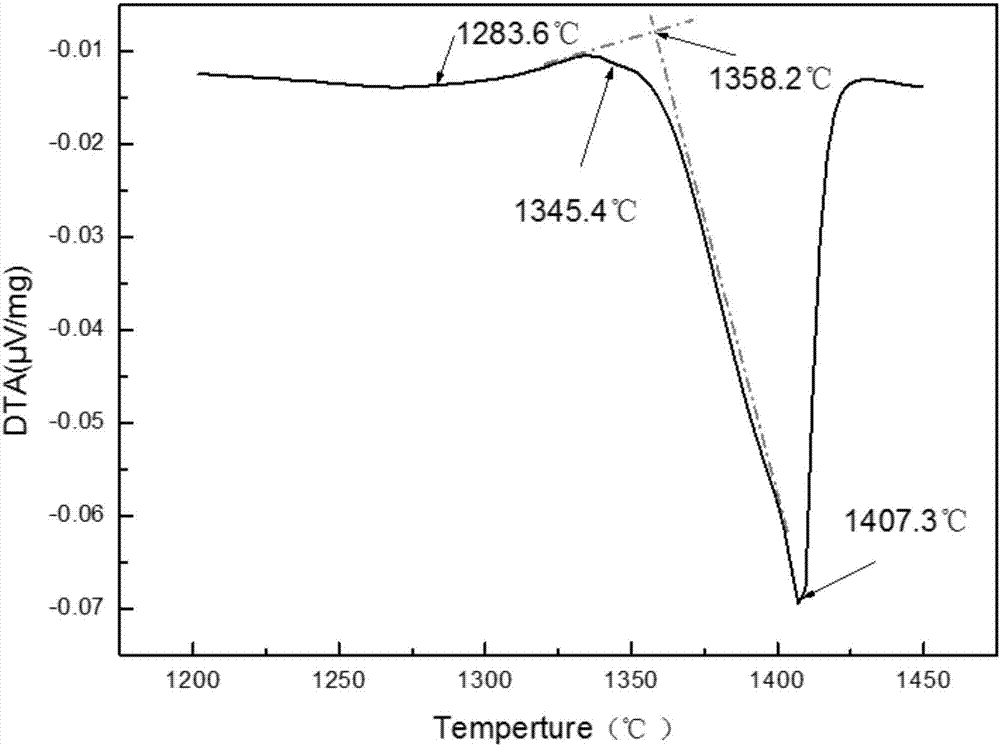

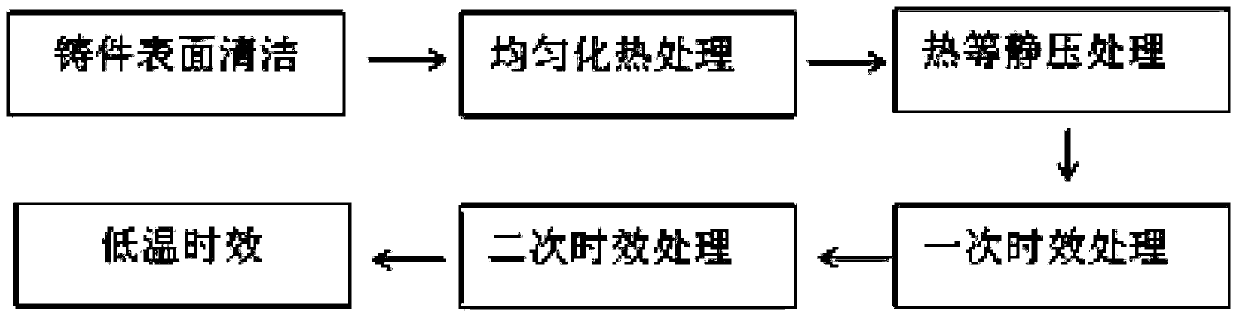

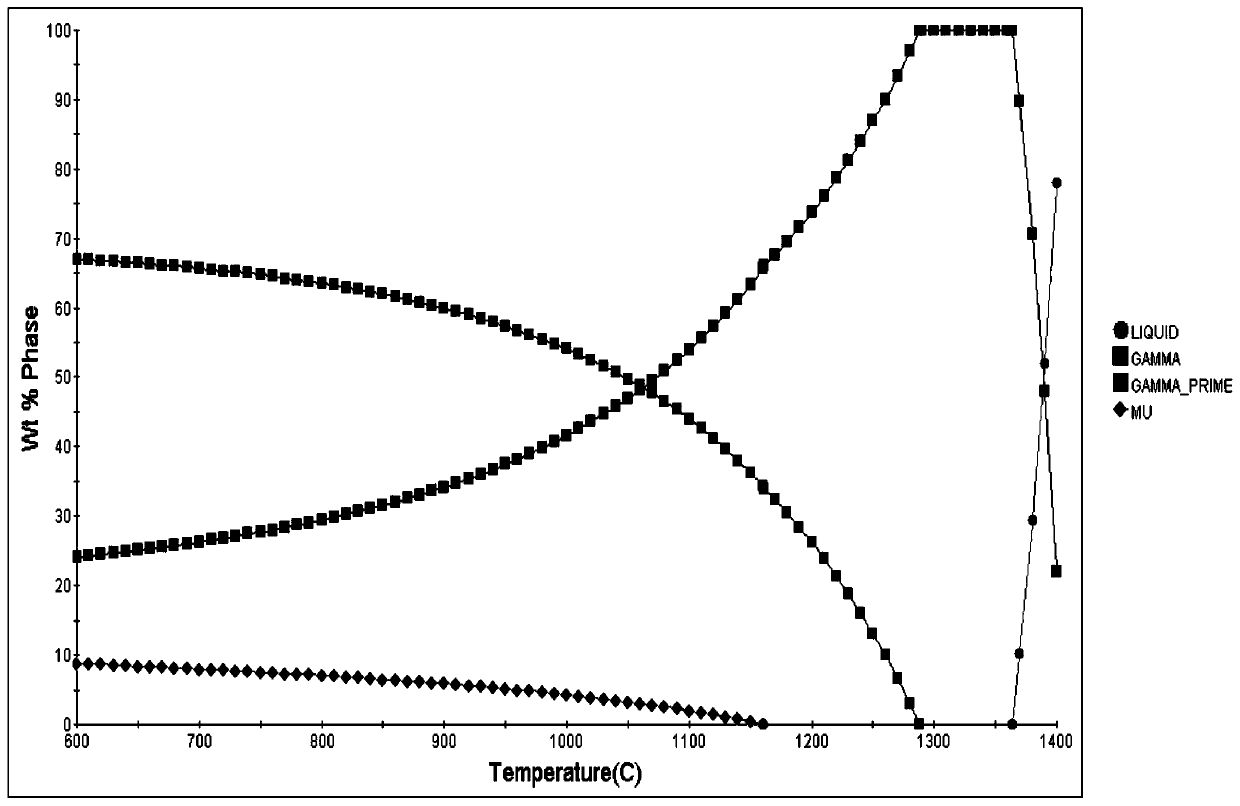

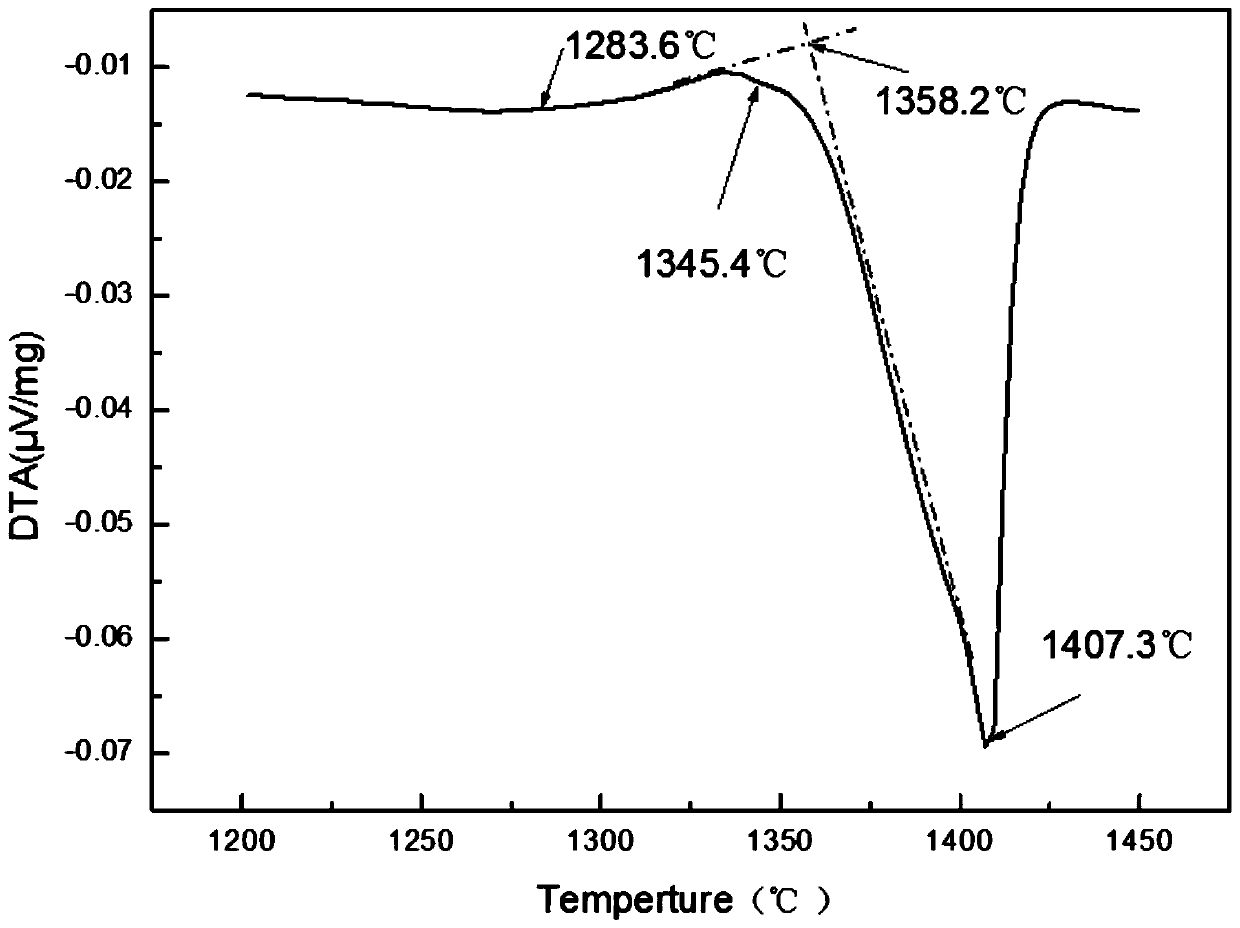

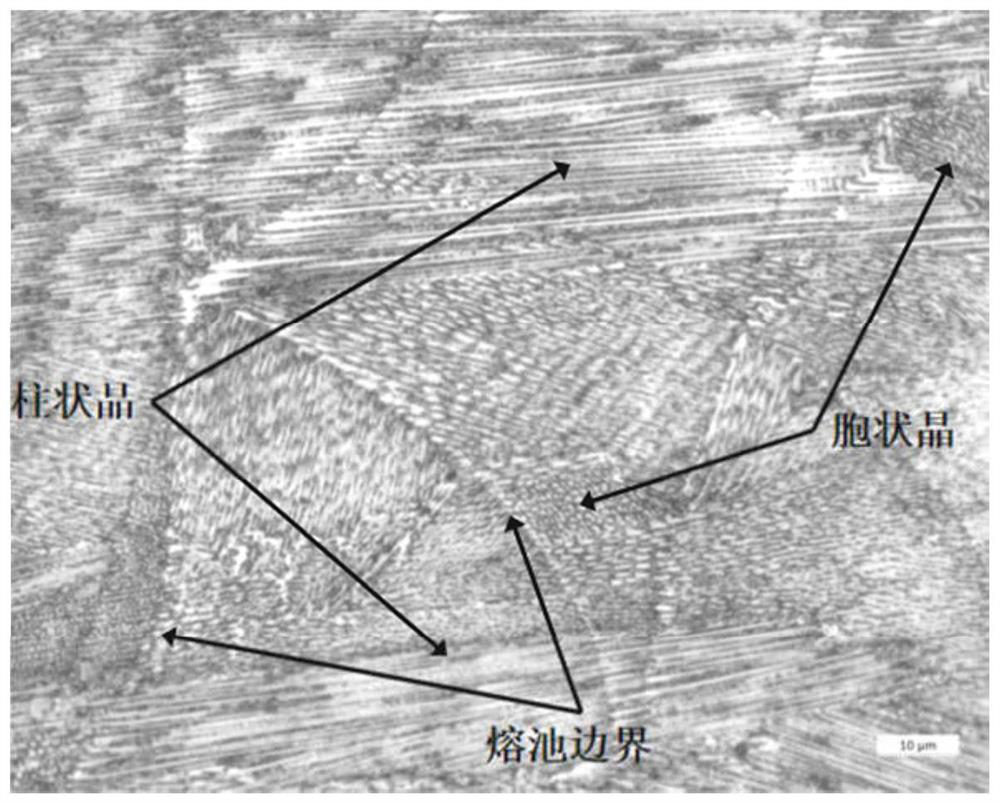

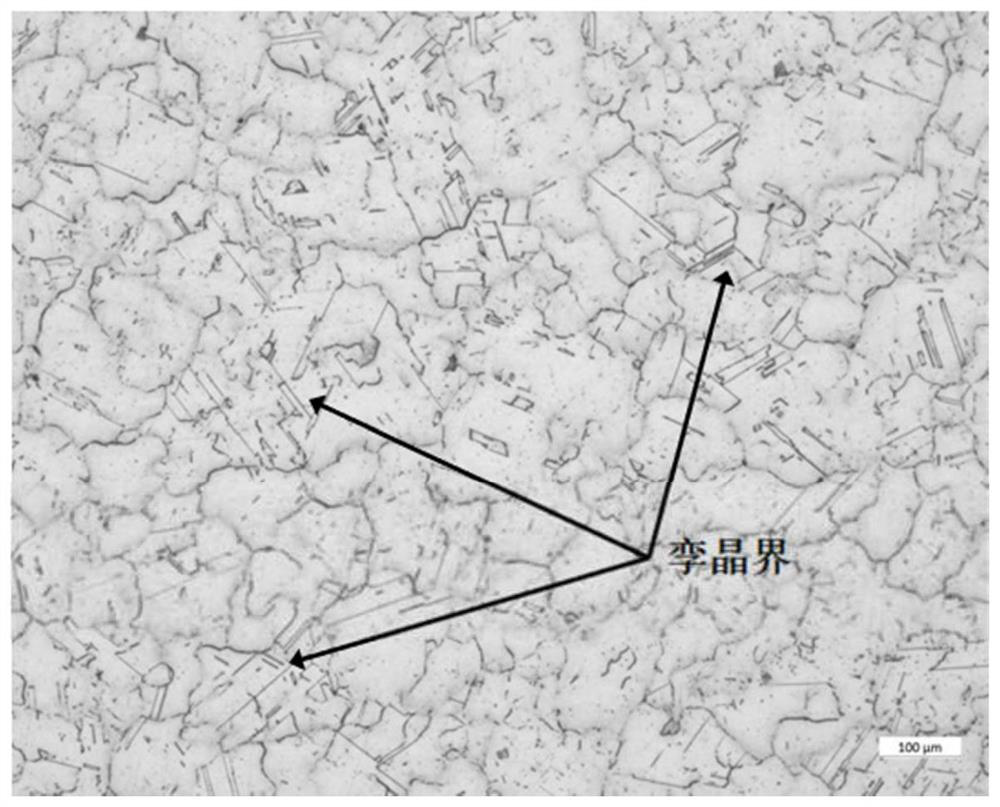

Novel process for optimizing microstructure and performance of low-rhenium single-crystal casting

ActiveCN107460419AEliminate microporosityElimination of casting defects such as shrinkage cavitiesHeat treatment process controlRheniumSingle crystal

The invention belongs to the field of nickel-base high temperature alloy, and particularly relates to a novel process for optimizing the microstructure and performance of a low-rhenium single-crystal casting. The novel process is characterized in that an experimental means of combining a computer simulation software with differential thermal analysis is adopted, so that a heat treatment process system is determined more accurately; meanwhile, the hot isostatic pressing technology and the heat treatment technology are combined, the defects such as microporosity and shrinkage in the single-crystal casting are effectively eliminated, the surface recrystallization problem of the casting in the conventional method is avoided through complementary advantages, and both the strength and the endurance property of the single-crystal casting are improved; moreover, as a stepped temperature rising method is adopted, the phenomenon that the conventional heat treatment process can easily cause incipient melting in the casting is avoided; and besides, three times of aging treatment is adopted, the novel process has the advantage that more gamma' strengthening phases are precipitated compared with the conventional aging treatment, the strengthening phases are uniform in distribution, appropriate in sizes, and regular in shapes, and the anti-fatigue and anti-deformation performances of the alloy are further improved.

Owner:JIANGSU UNIV

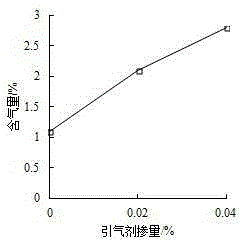

Method for improving anti-penetrability of recycled concrete

The invention provides a method for improving anti-penetrability of recycled concrete. The method comprises 1, partly replacing cement in cementing material by fly ash and slag powder, 2, limiting a recycled coarse aggregate replacement rate use range, 3, adding a proper amount of an entraining-type additive into a recycled concrete mixture, and 4, carrying out complete recycled concrete preparation. The method provides appropriate fly ash, ore powder and tea saponin mixing amounts, a recycled coarse aggregate replacement rate and difference of the recycled concrete from common concrete in preparation. The method is used for improving anti-penetrability and endurance performances of recycled concrete and promotes recycled concrete popularization and application.

Owner:SHANGHAI URBAN CONSTR MATERIAL CO LTD

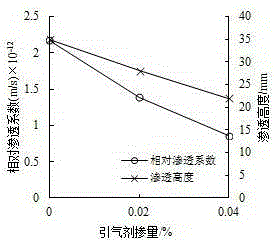

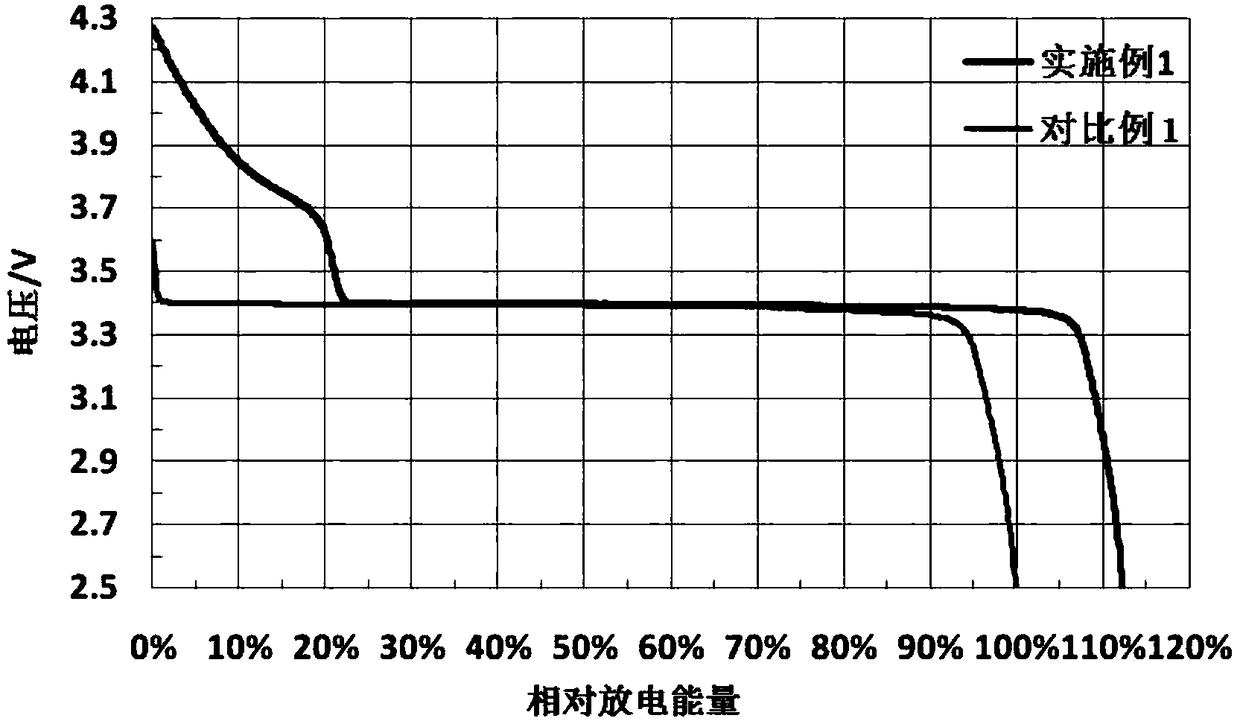

Compound lithium iron phosphate material and preparing method thereof, positive electrode piece and lithium ion battery

InactiveCN108288699AIncrease compaction densityReduce porositySecondary cellsPositive electrodesPorosityLithium iron phosphate

The invention relates to a compound lithium iron phosphate material and a preparing method thereof, a positive electrode piece and a lithium ion battery, and belongs to the technical field of lithiumion batteries. The compound lithium iron phosphate material is prepared from, by mass, 75-85% of lithium iron phosphate, 10-25 parts of nickel cobalt lithium manganate, 1-2% of carbon nano tube and 1-2% of conductive black. The prepared compound lithium iron phosphate material is a high high-energy density compound lithium iron phosphate material, lithium iron phosphate, nickel cobalt lithium manganate, carbon nano tube and conductive black fill one another, the porosity among materials is lowered, and the compaction density of the materials is increased.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG +1

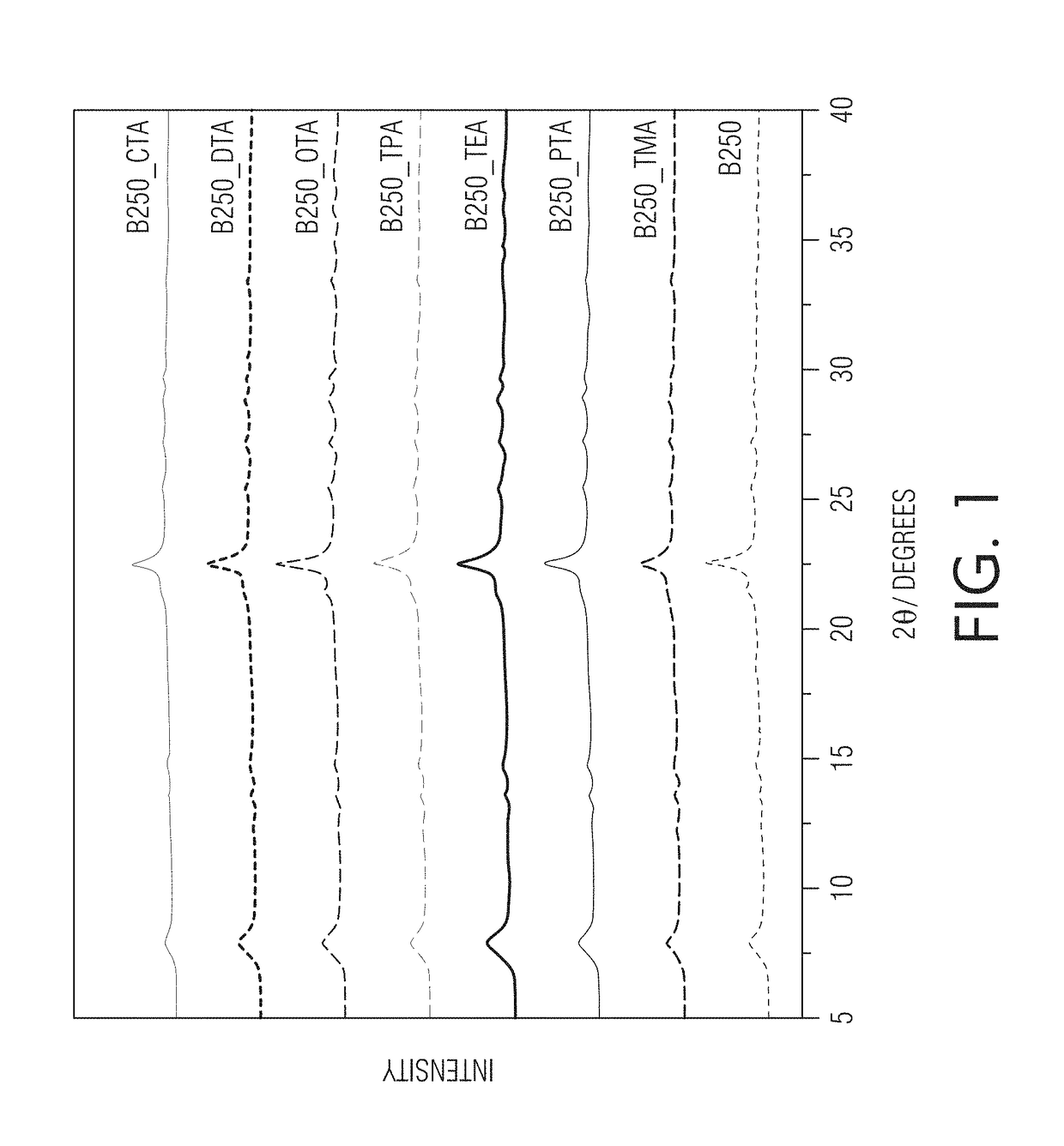

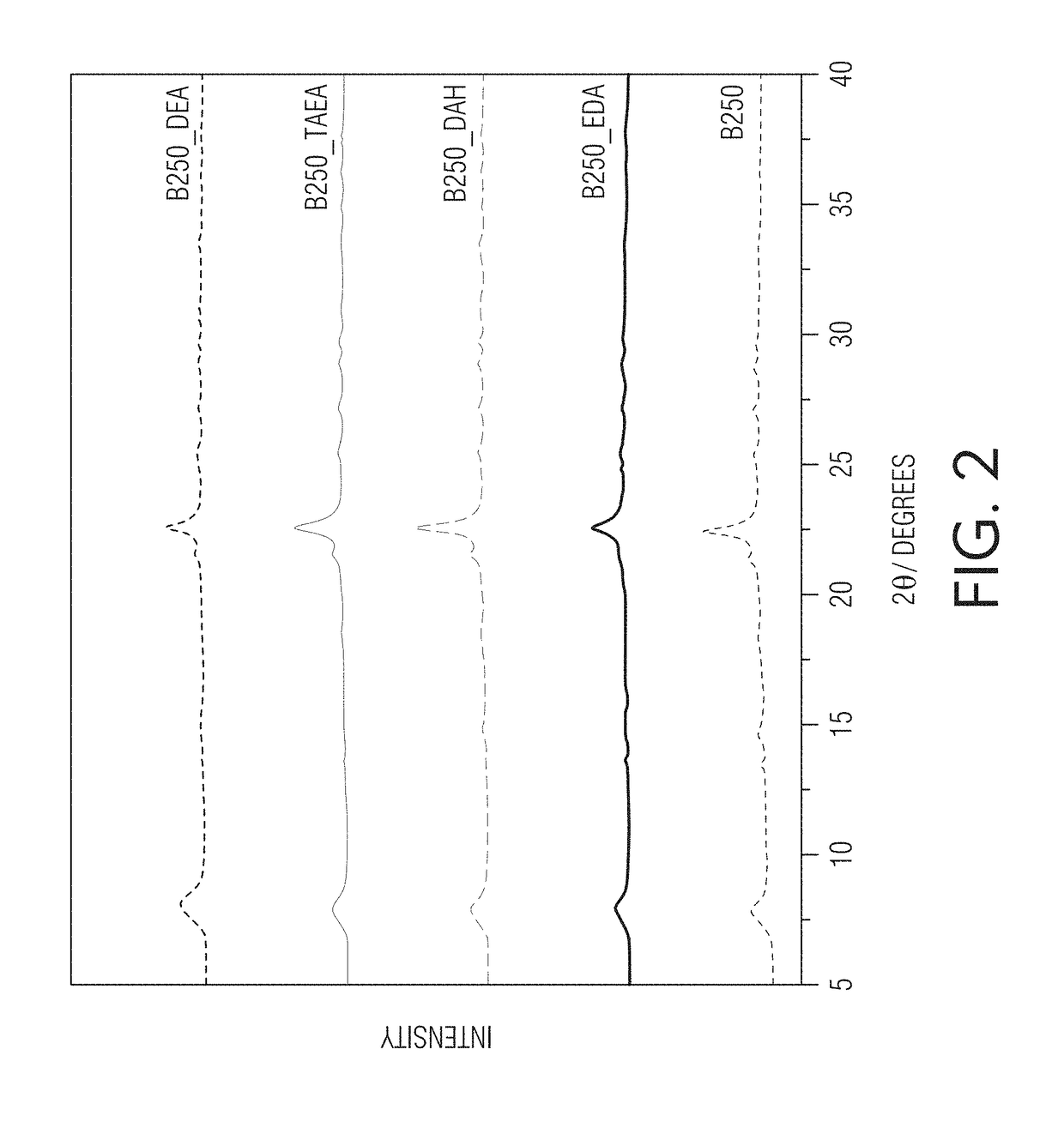

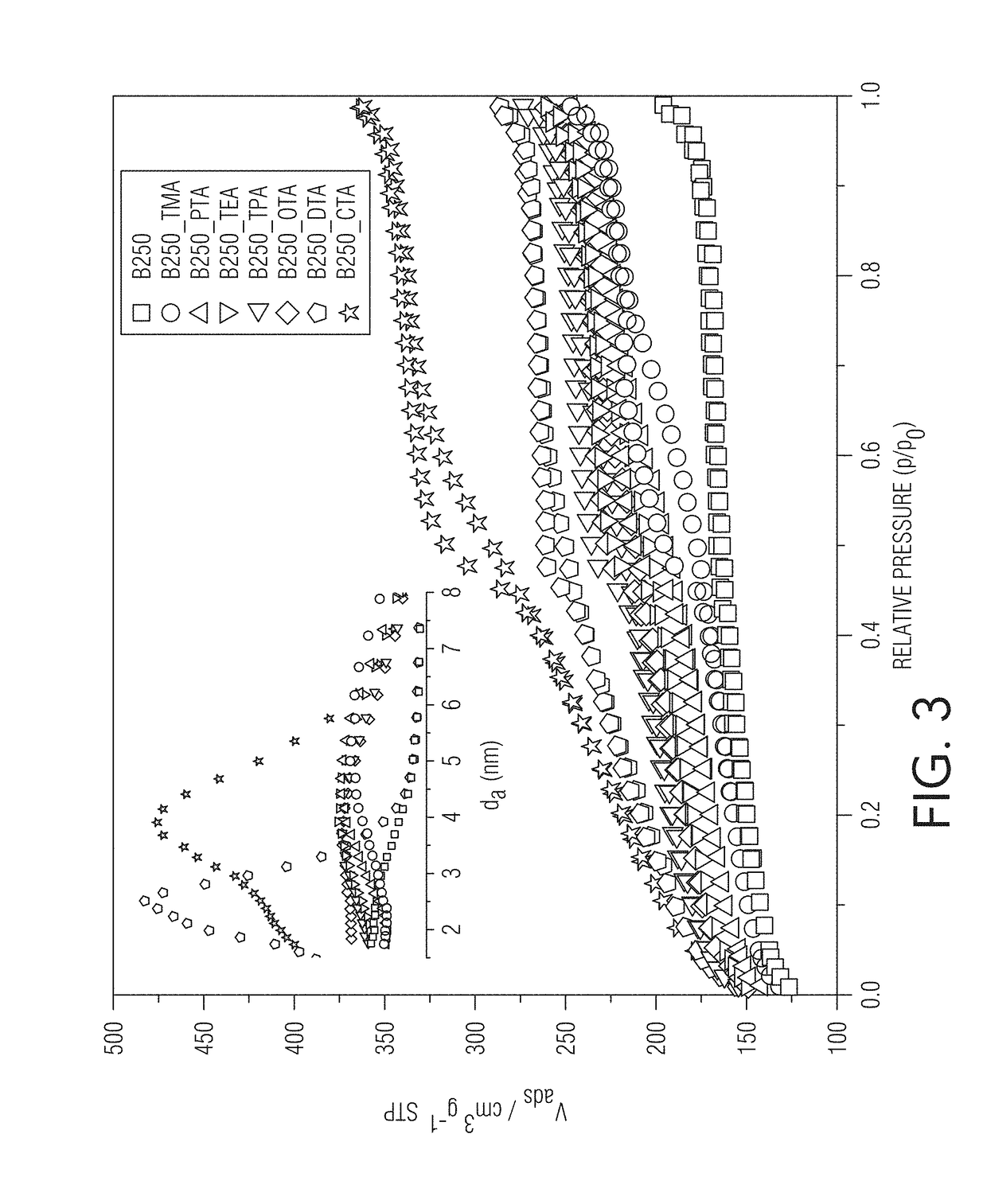

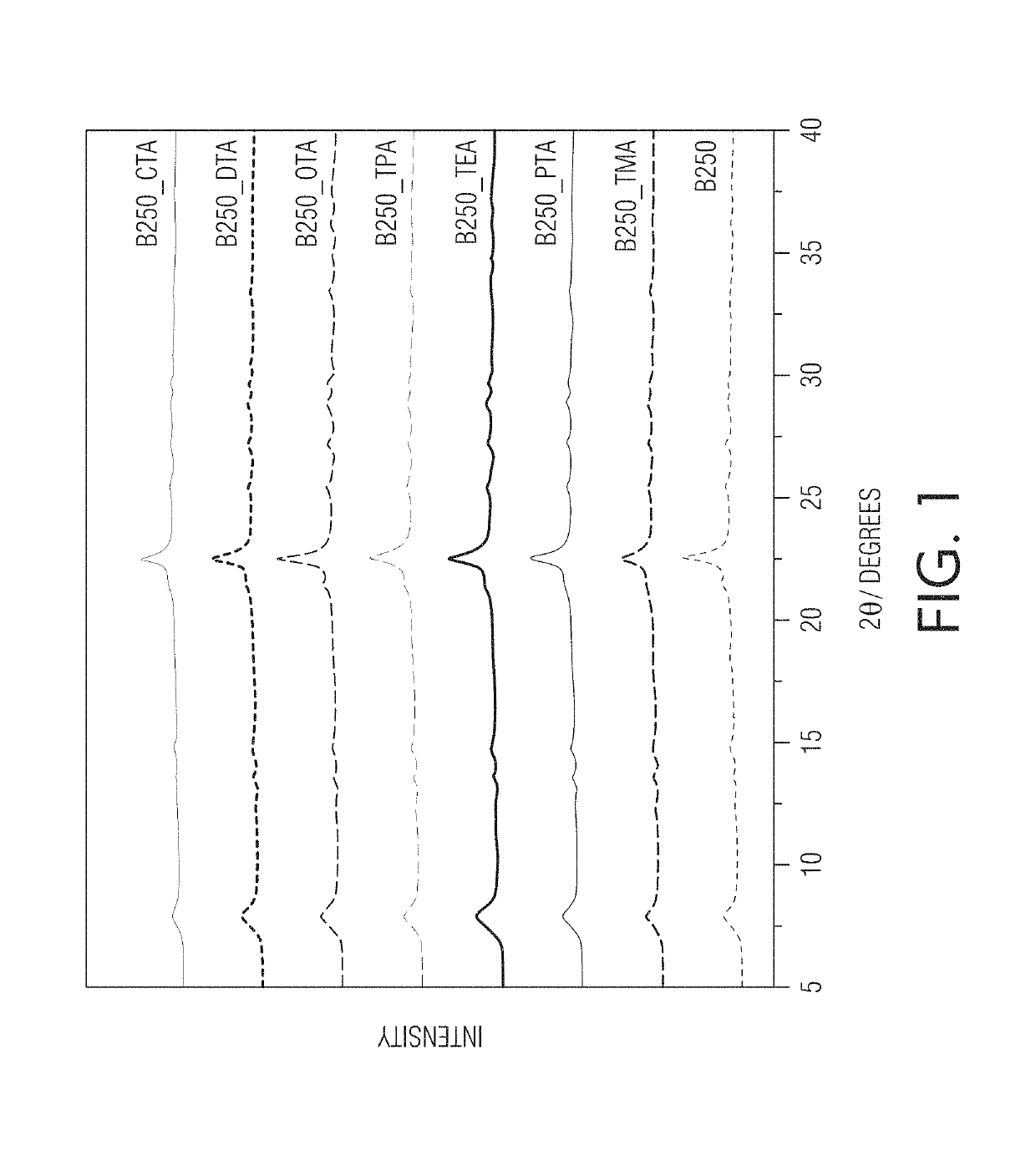

Methods of producing hierarchical beta zeolites with tunable mesoporosity through pore directing agent assisted base leaching

ActiveUS20180311652A1Reduce crystallinityEliminate microporosityHydrocarbon by isomerisationMolecular sieve catalystsGramOrganic chemistry

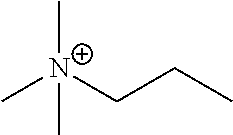

Methods for producing mesoporous beta zeolites from parent beta zeolites having a Si / Al molar ratio of at least 10 comprise selecting a target average mesoporous size between 2 nm and 8 nm for the parent beta zeolites, selecting a pore directing agent (PDA) based on the target average mesopore size, where a non-ionic surfactant, a small cationic surfactant has a molecular weight of greater than 100 grams / mole, or both may be selected as the PDA when the target average mesopore size is at least 5 nm, and a large cationic surfactant having a molecular weight of less than 100 grams / mole may be selected as the PDA when the target average mesopore size is less than 5 nm. The method further comprises adding the selected PDA to an alkaline solution to form a PDA-base mixture, and adding the parent beta zeolites to the PDA-base mixture to produce the mesoporous beta zeolites.

Owner:SAUDI ARABIAN OIL CO

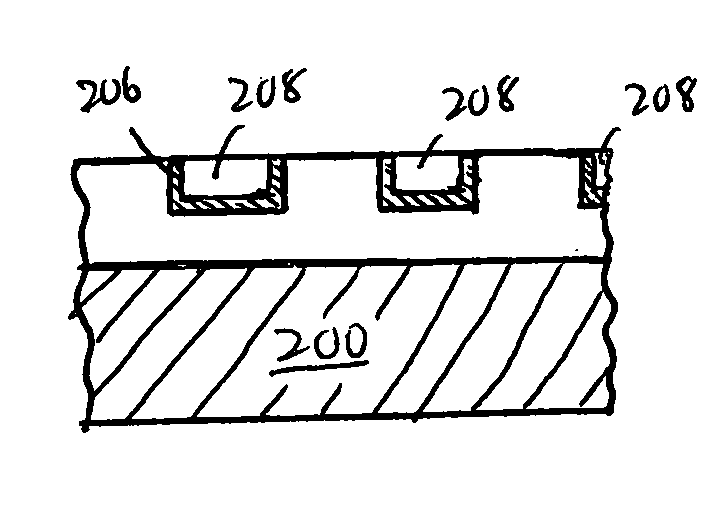

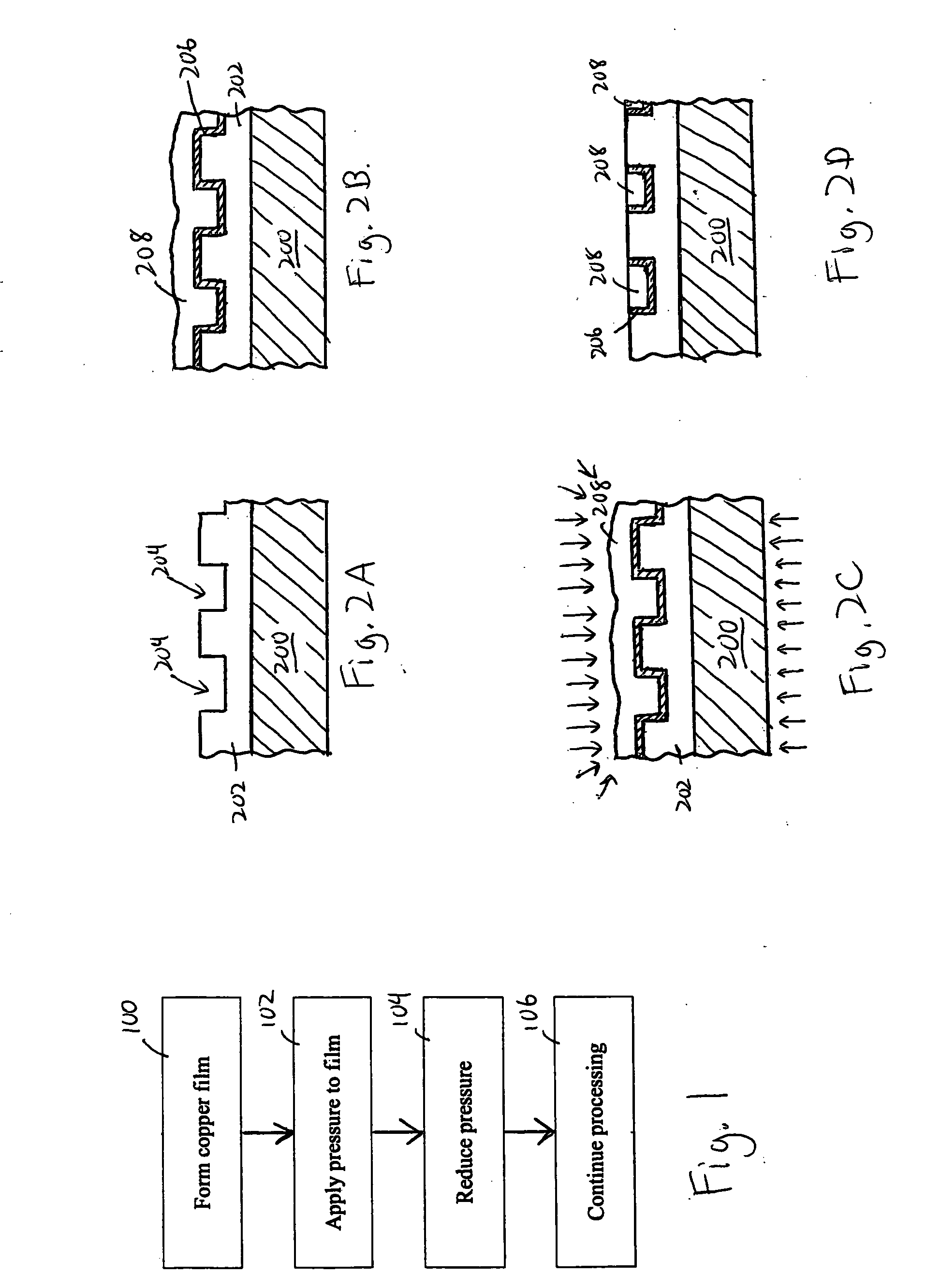

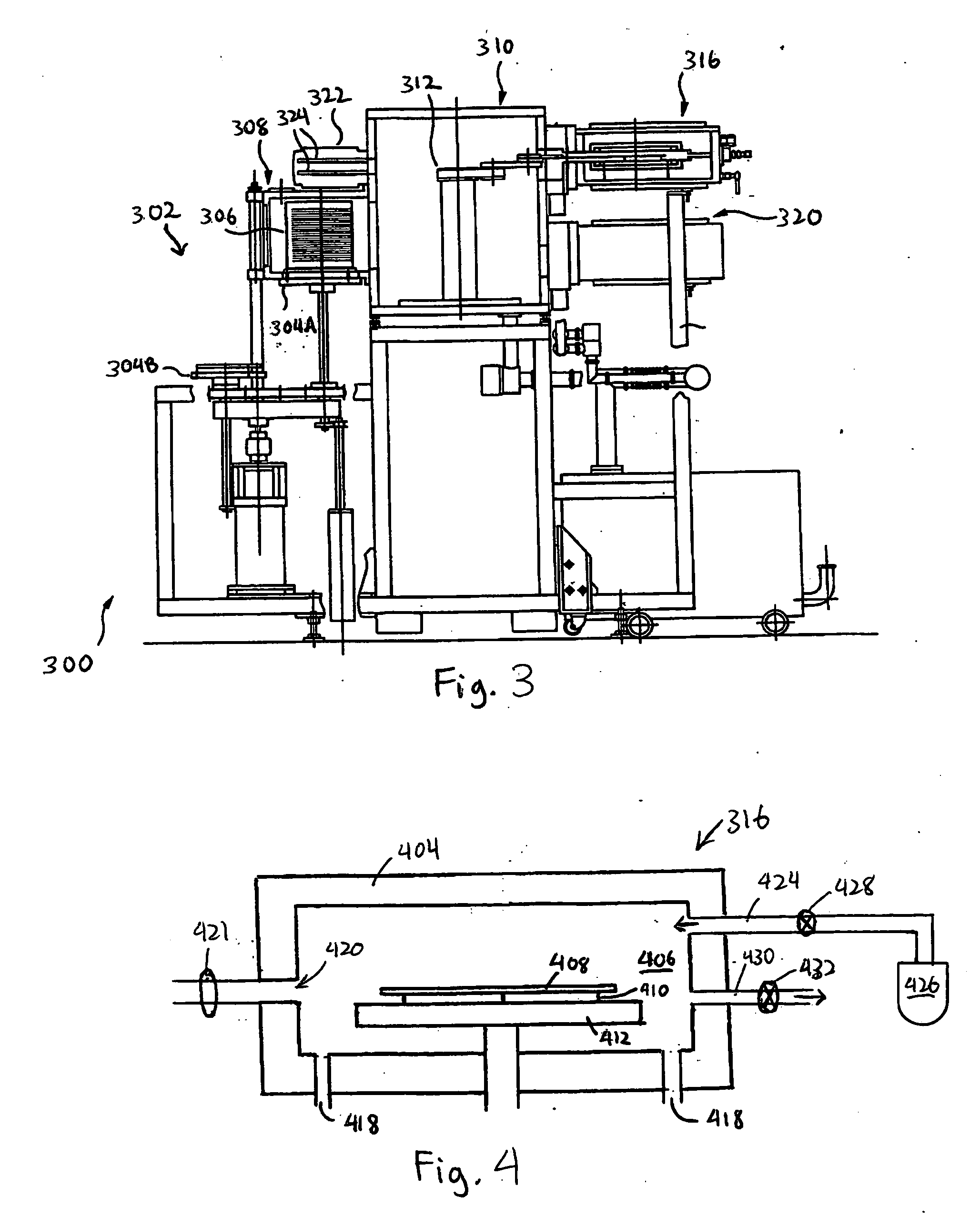

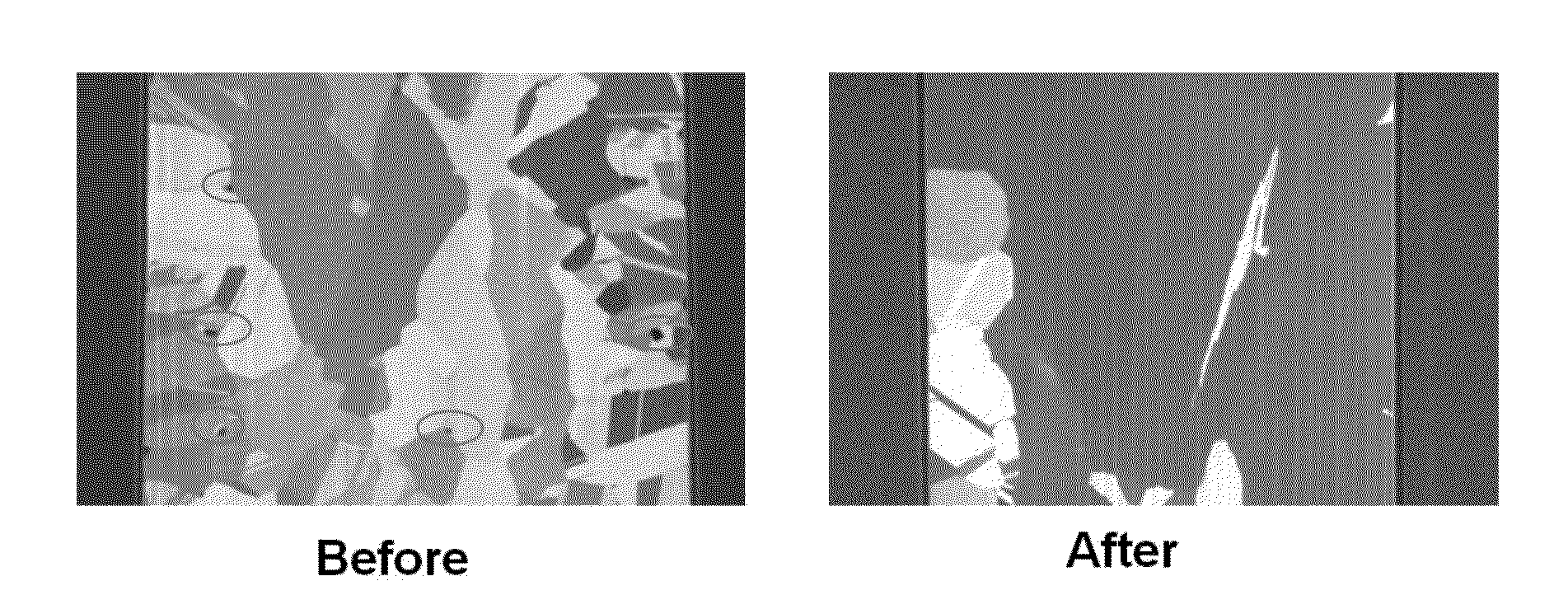

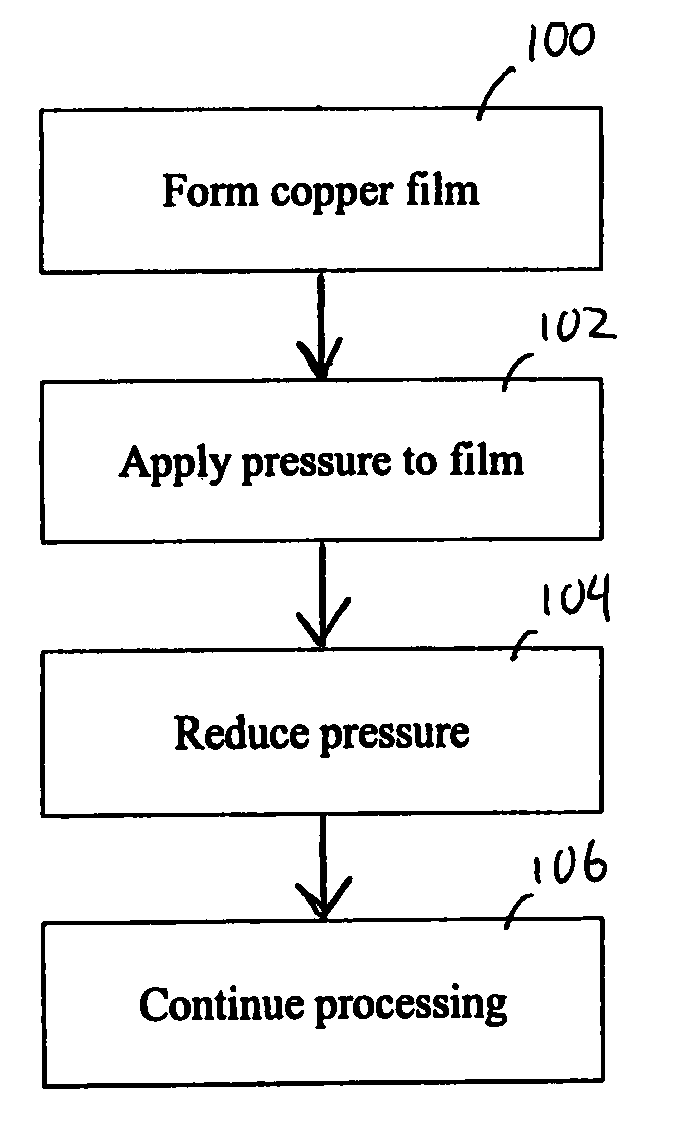

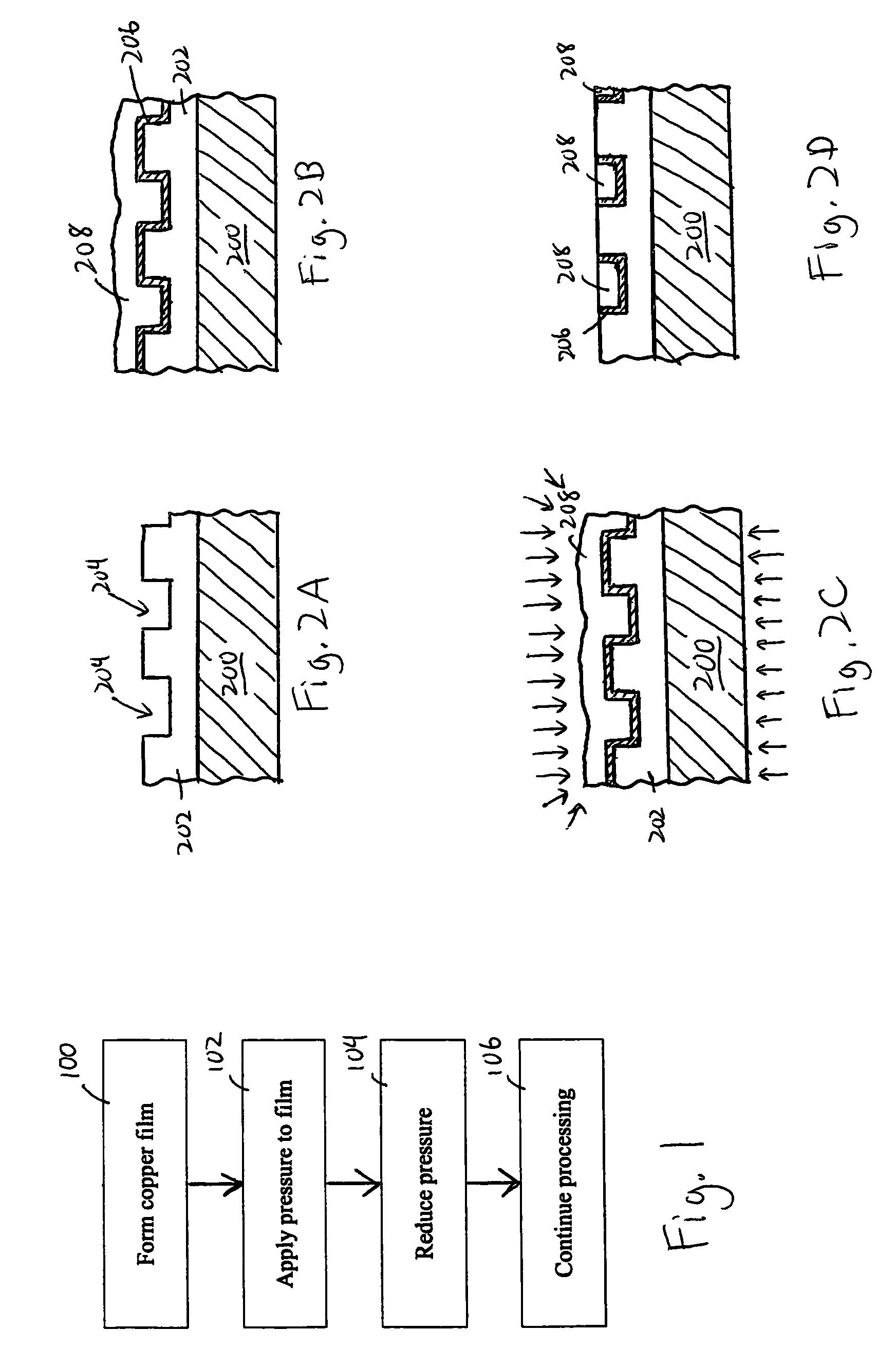

High pressure treatment for improved grain growth and void reduction

InactiveUS20060183326A1Fine grainEliminate microporositySemiconductor/solid-state device manufacturingDielectricRoom temperature

A copper film is annealed at high pressure to enhance grain growth and remove voids. Other films, such as dielectrics, may also be suitable. High pressure can be used in conjunction with temperatures lower than room temperature for annealing or higher temperatures may be used to further enhance grain growth.

Owner:WAFERMASTERS

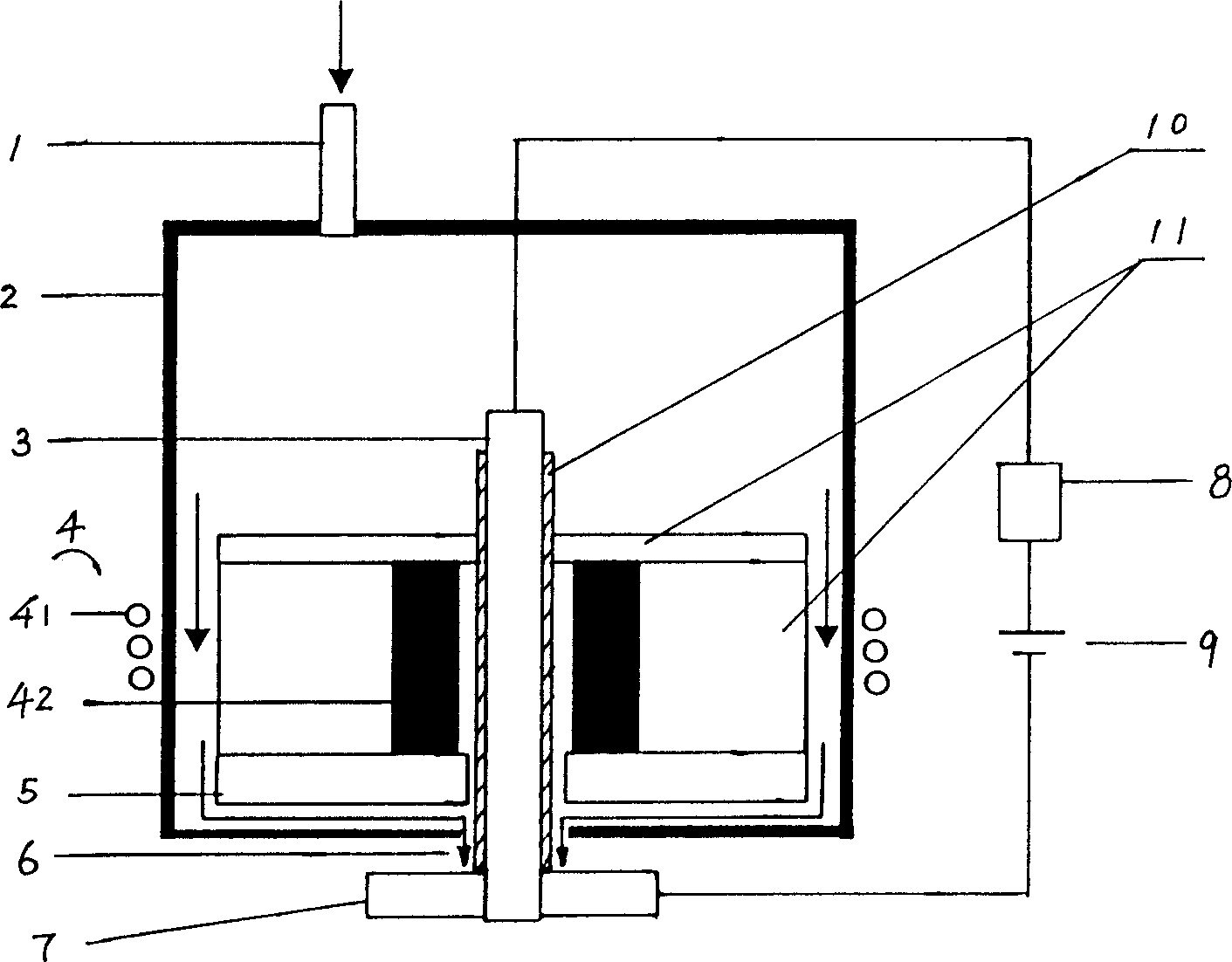

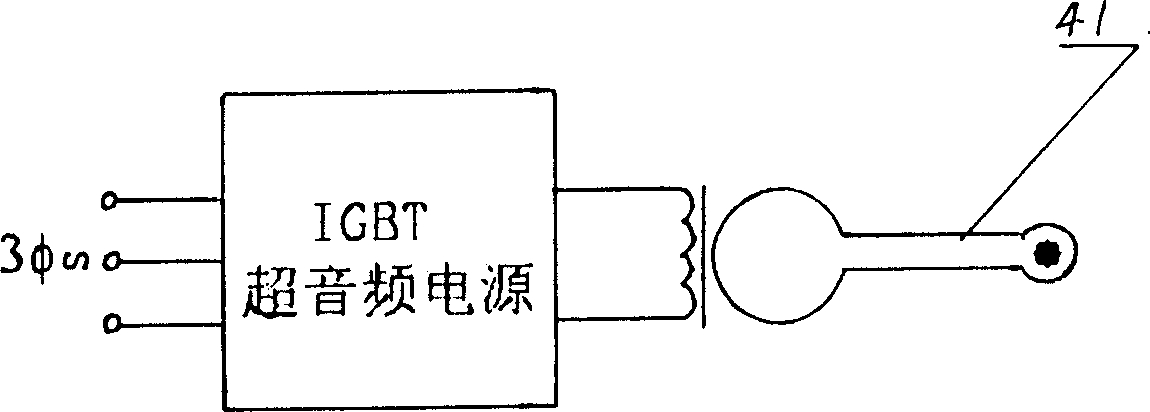

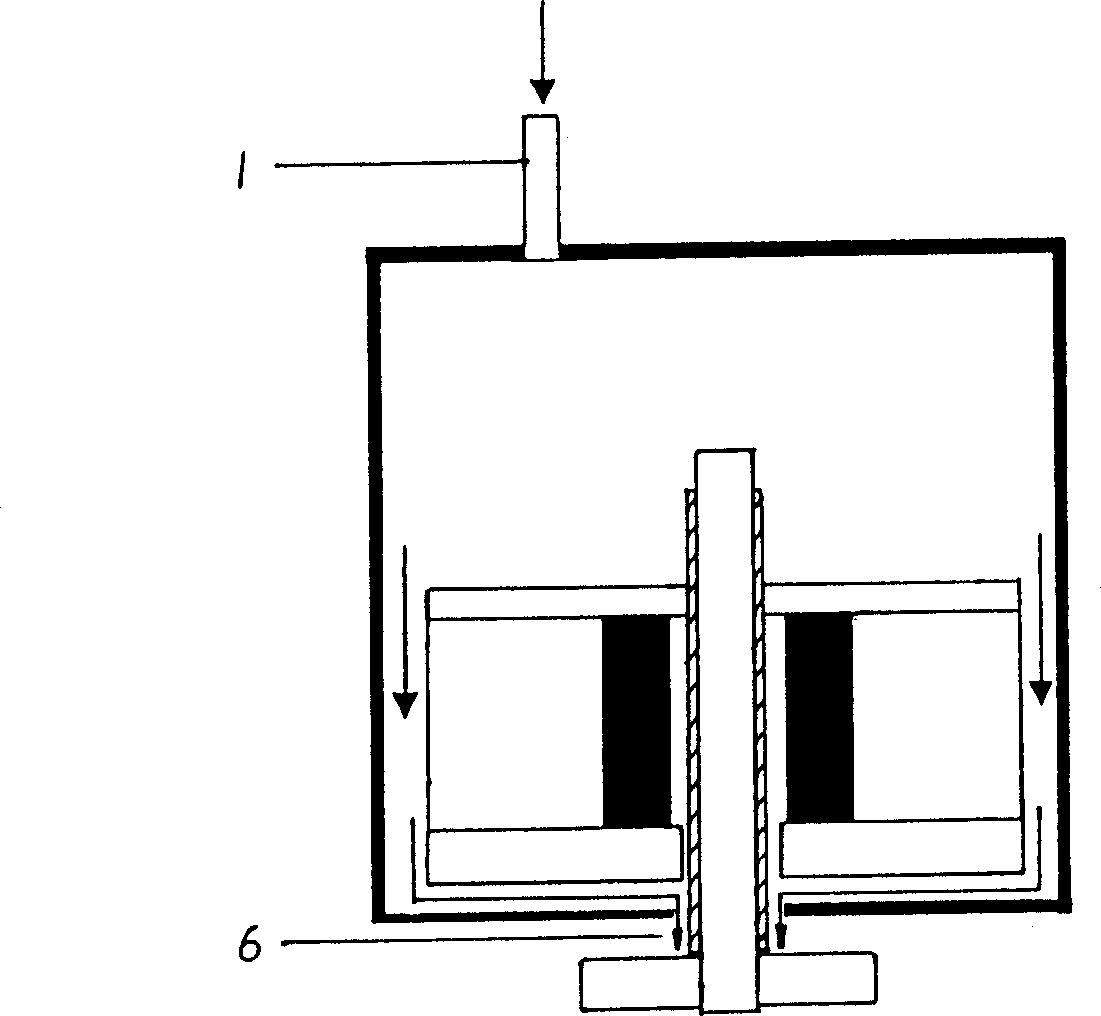

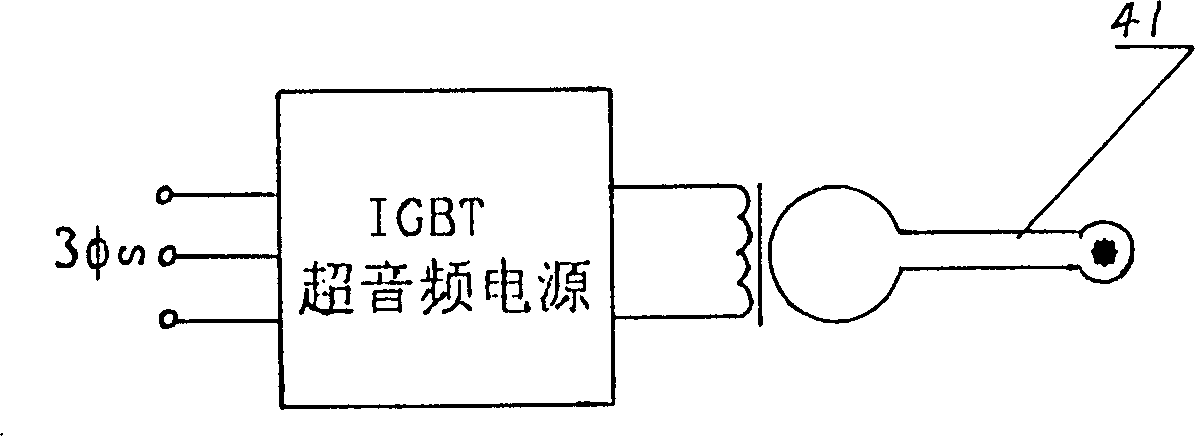

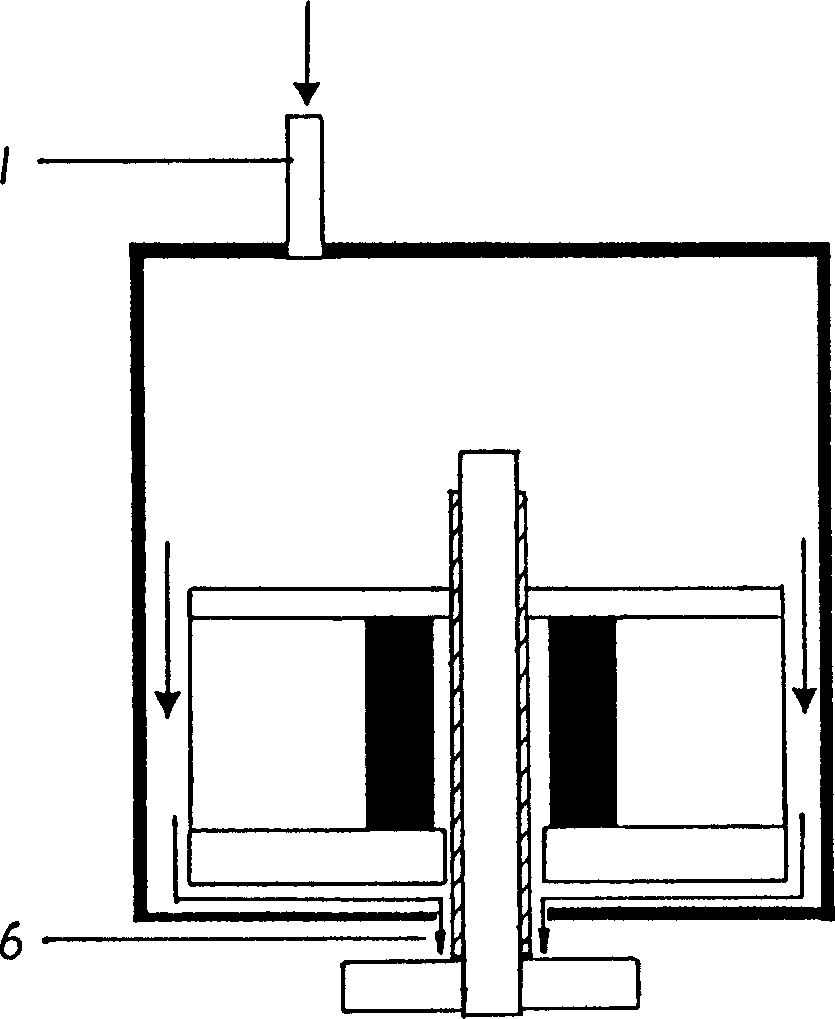

Monocrystal high temperature alloy electric field directional freeze apparatus

InactiveCN1508297ARefining solidified tissueEasy to useFrom frozen solutionsSingle crystal superalloySingle crystal

The invention relates to the single crystal high-temperature alloy solidifying technique, including case, heating set, sample clamping framework and DC electric field generating set. The clamping framework is set under the case, composed of two clamping bars set on the bracket, one end of each clamping bar linked with the rotation shaft on the bracket, the other end linked through fastener, and the outer side of each clamping bar installed with tension spring, the other end of each tension spring fixed on the bracket, and the bracket opened with a through hole to make the sample pass through; the generating set is a close loop, formed by setting a programmable functional module in series between one end of the sample and one pole of the voltage-stailized source, and connecting the other end with the other pole through the clamping tool.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

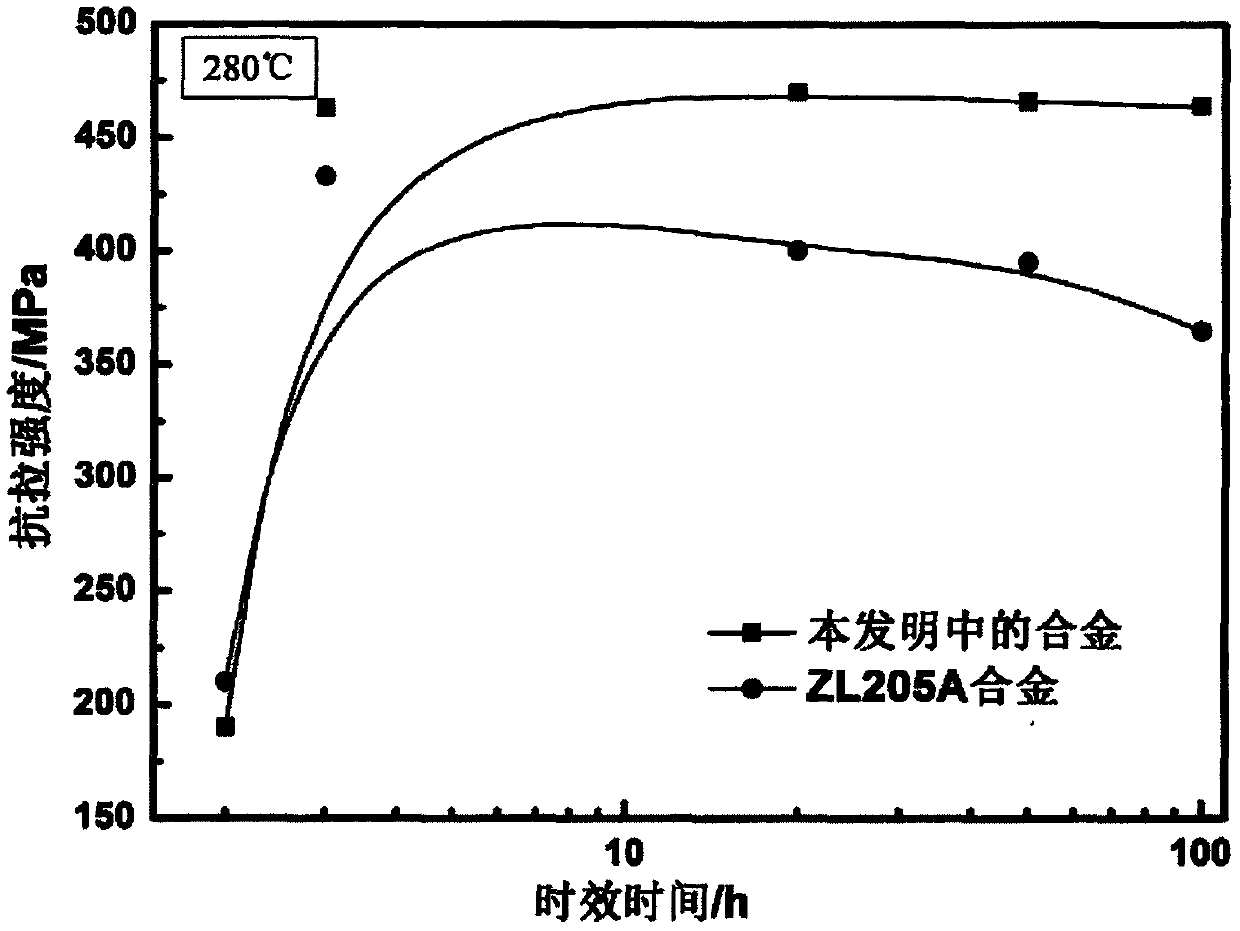

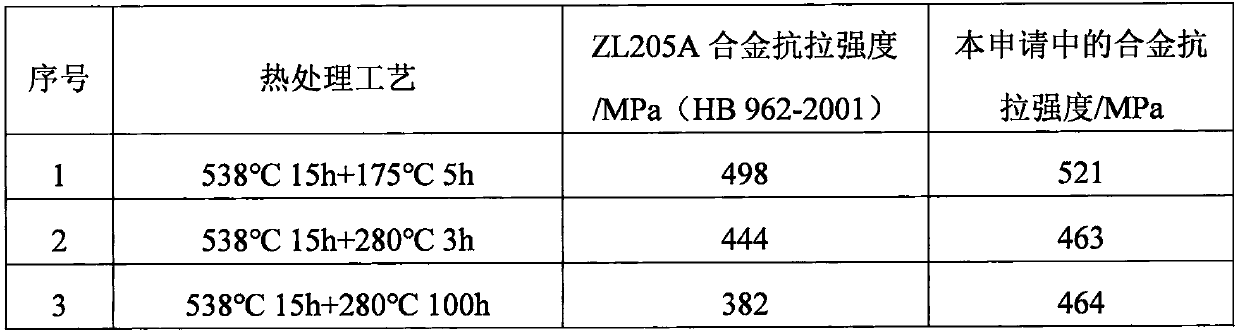

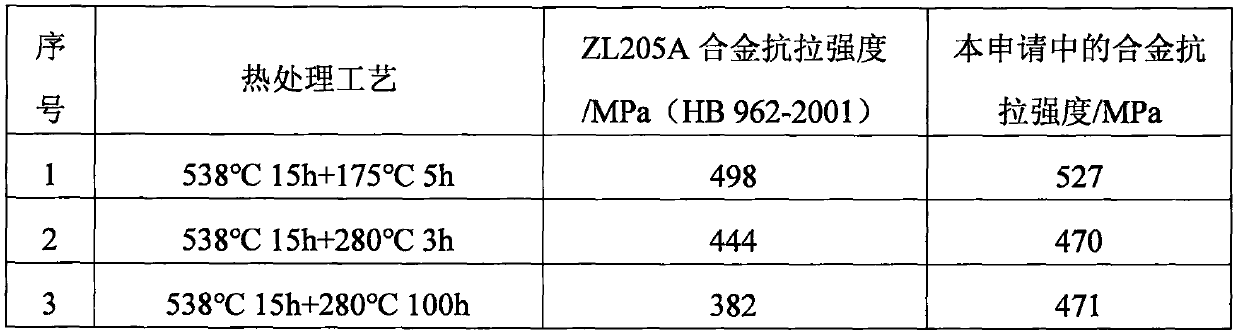

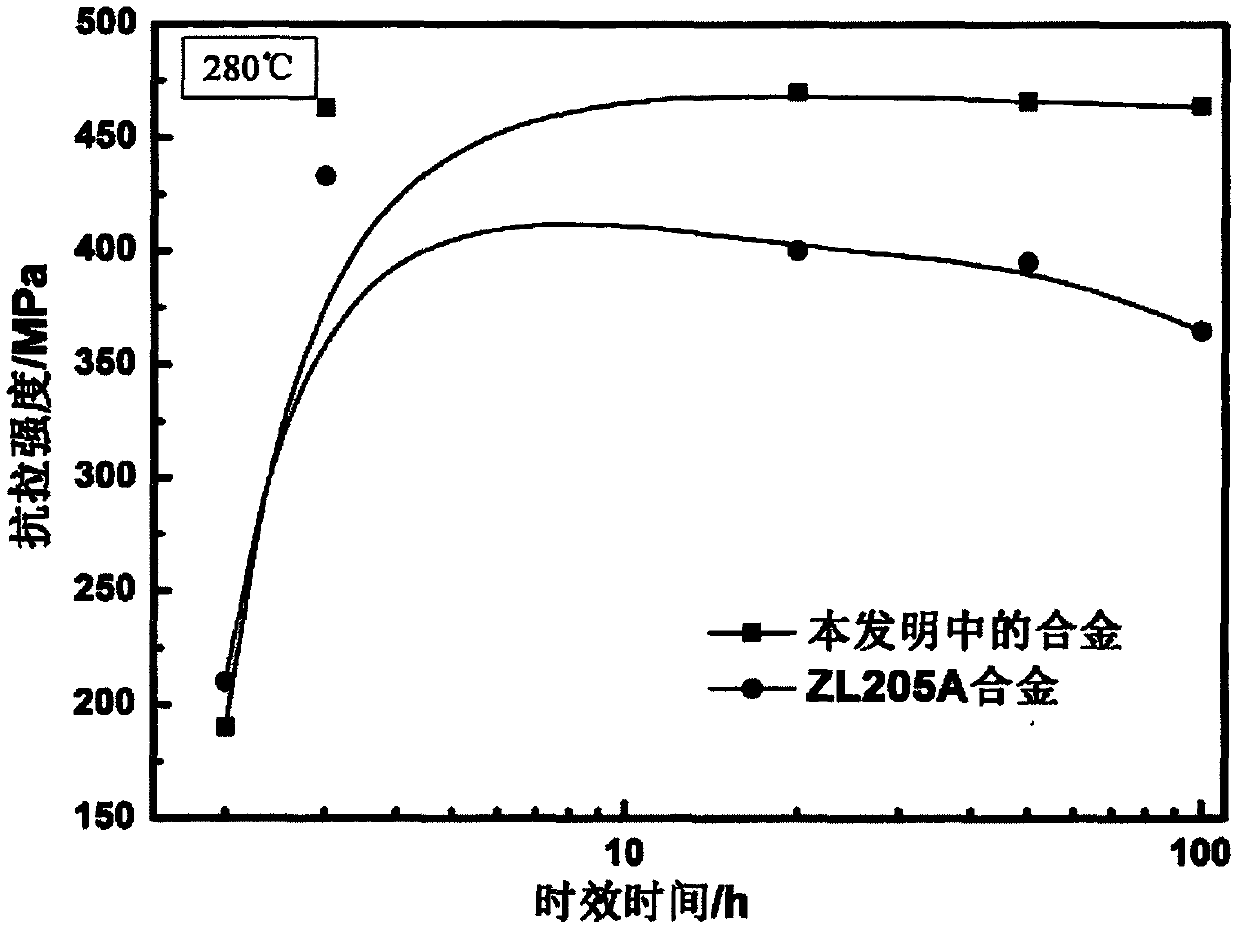

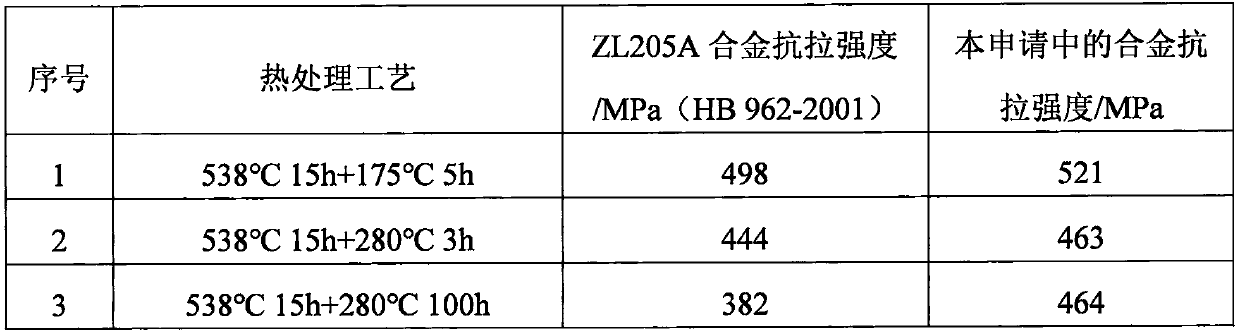

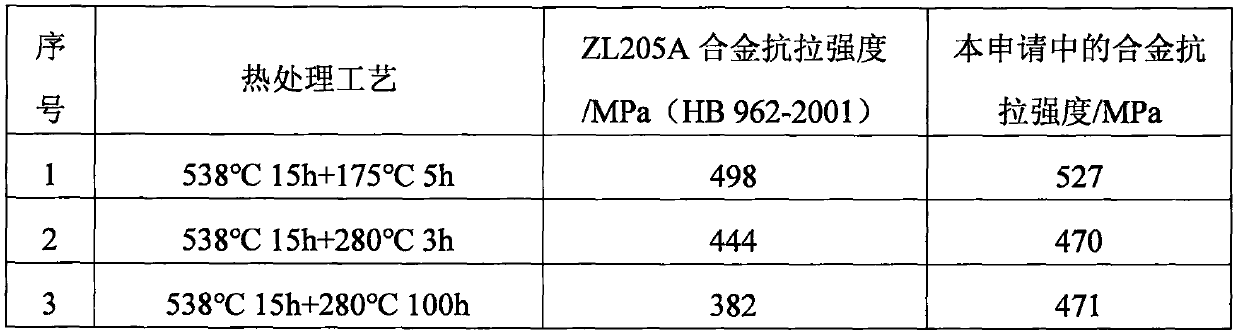

Heat-resisting casting Al-Cu alloy and preparation method

The invention discloses a heat-resisting casting Al-Cu alloy. The heat-resisting casting Al-Cu alloy comprises, by mass, 2.0-3.5% of Cu, 0.5-0.8% of Mn, 0.2-0.6% of Ti, 0.2-0.5% of Sc, 0.1-0.3% of Zr,0.2-0.35% of Cd, less than or equal to 0.1% of impurities, and the balance Al. The heat-resisting casting Al-Cu alloy is high in strength, good in ductility, and can be used for a long time at the high temperature of 280 DEG C. Compared with a traditional high copper ZL205A alloy, under the same T6 heat treatment condition (538 DEG C 15h+indoor temperature water quenching+175 DEG C 3h), the extension strength of the heat-resisting casting Al-Cu alloy is 20-30 MPa higher, and the strength is not declined at the temperature of 280 DEG C for 100h.

Owner:北京世联信诺科技有限公司

Refining agent for waste aluminum to improve performance of aluminum castings

InactiveCN108179298AEliminate microporosityImprove production yieldAluminum magnesium silicateHydroxypropyltrimethyl ammonium chloride chitosan

The invention belongs to the technical field of waste aluminum smelting refining agents, and particularly relates to a refining agent for waste aluminum to improve the performance of aluminum castings. The refining agent comprises, by weight, 3-6 parts of modified graphite, 6-10 parts of nanometer calcium nitride, 2-4 parts of titanium dioxide, 1-3 parts of ammonium tetraborate, 0.8-1.6 parts of stellerite powders, 0.4-0.8 parts of aluminum oxide, 0.1-0.3 parts of sulphur, 4-6 parts of H-mordenite powders, and 0.1-0.3 parts of aluminum magnesium silicate; the modified graphite is modified by 2-hydroxypropyltrimethyl ammonium chloride chitosan as a modifying agent. Compared with the prior art, the refining agent for the waste aluminum to improve the performance of the aluminum castings hasthe advantages that the refining agent can obtain high-quality waste aluminum alloy molten fluid and reduce the microporosity of the obtained castings, and mechanical properties of the refining agentcan also be increased significantly.

Owner:安徽玉成光华铝业有限公司

Methods of producing hierarchical beta zeolites with tunable mesoporosity through pore directing agent assisted base leaching

ActiveUS10391480B2Impart mesoporosityReduce crystallinityHydrocarbon by isomerisationMolecular sieve catalystsGramOrganic chemistry

Methods for producing mesoporous beta zeolites from parent beta zeolites having a Si / Al molar ratio of at least 10 comprise selecting a target average mesoporous size between 2 nm and 8 nm for the parent beta zeolites, selecting a pore directing agent (PDA) based on the target average mesopore size, where a non-ionic surfactant, a small cationic surfactant has a molecular weight of greater than 100 grams / mole, or both may be selected as the PDA when the target average mesopore size is at least 5 nm, and a large cationic surfactant having a molecular weight of less than 100 grams / mole may be selected as the PDA when the target average mesopore size is less than 5 nm. The method further comprises adding the selected PDA to an alkaline solution to form a PDA-base mixture, and adding the parent beta zeolites to the PDA-base mixture to produce the mesoporous beta zeolites.

Owner:SAUDI ARABIAN OIL CO

Silicon nitride ceramic piece and processing method thereof

ActiveCN114230349AReduce porosityAvoid the problem of uneven pore distributionComposite materialSilicon nitride

The invention discloses a silicon nitride ceramic part and a processing method thereof. The silicon nitride ceramic part comprises a first cylinder, and two ends of the first cylinder are respectively provided with a first end face and a second end face; a first fixing seat is arranged in the first cylinder body, and the first fixing seat is connected with the first end face in a penetrating manner; a second fixing base is arranged on the upper surface of the second end face and connected with the second end face in a penetrating mode. The preparation method of the silicon nitride ceramic part comprises the following steps: granulating, carrying out cold isostatic pressing molding to obtain a primary green body, carrying out finish machining to obtain a second green body, pre-sintering to obtain a third green body, and finally sintering to obtain the silicon nitride ceramic part. The silicon nitride ceramic piece is uniform in internal density distribution, high in strength, low in density, large in size, easy to process and high in finished product percent of pass.

Owner:BEIJING SINOMA SYNTHETIC CRYSTALS CO LTD +1

A New Process for Microstructure and Performance Optimization of Low Rhenium Single Crystal Castings

ActiveCN107460419BEliminate microporosityHigh strengthHeat treatment process controlRheniumSingle crystal

The invention belongs to the field of nickel-base high temperature alloy, and particularly relates to a novel process for optimizing the microstructure and performance of a low-rhenium single-crystal casting. The novel process is characterized in that an experimental means of combining a computer simulation software with differential thermal analysis is adopted, so that a heat treatment process system is determined more accurately; meanwhile, the hot isostatic pressing technology and the heat treatment technology are combined, the defects such as microporosity and shrinkage in the single-crystal casting are effectively eliminated, the surface recrystallization problem of the casting in the conventional method is avoided through complementary advantages, and both the strength and the endurance property of the single-crystal casting are improved; moreover, as a stepped temperature rising method is adopted, the phenomenon that the conventional heat treatment process can easily cause incipient melting in the casting is avoided; and besides, three times of aging treatment is adopted, the novel process has the advantage that more gamma' strengthening phases are precipitated compared with the conventional aging treatment, the strengthening phases are uniform in distribution, appropriate in sizes, and regular in shapes, and the anti-fatigue and anti-deformation performances of the alloy are further improved.

Owner:JIANGSU UNIV

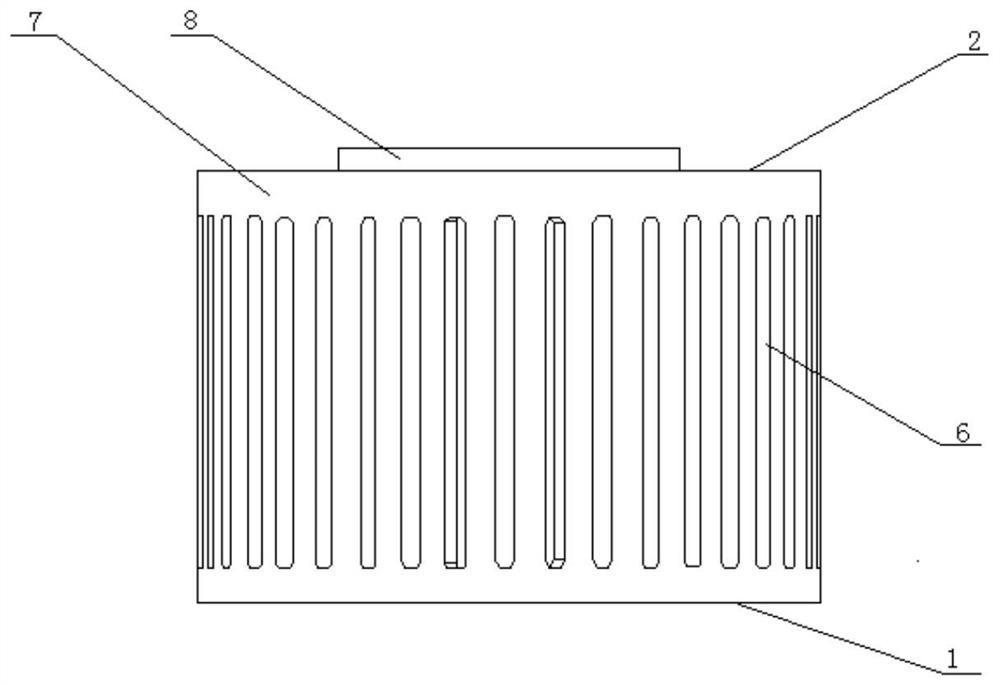

Preparation method of high-strength and high-plasticity Inconel718 alloy based on SLM

ActiveCN113477942AIncrease profitLow costAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSolution treatment

A preparation method of a high-strength and high-plasticity Inconel 718 alloy based on SLM comprises the following steps: S1, selective laser melting forming is conducted, specifically, an Inconel 718 alloy blank is printed through a selective laser melting method; and the Inconel 718 alloy blank is sequentially subjected to step S2: isostatic pressing heat treatment, step S3: stress relief annealing treatment, step S4: solution treatment and step S5: two-stage aging treatment, specifically, the temperature of isostatic pressing heat treatment is 1165-1170 DEG C, the pressure intensity is 125-135 Mpa, and the time is 210-270 min; the temperature of stress relief annealing is 790-810 DEG C, and the time of stress relief annealing is 20-40 min; the temperature of solution treatment is 940-960 DEG C, and the time of solution treatment is 20-40 min; and in two-stage aging treatment, the temperature of first-stage aging treatment is 750-770 DEG C, the time of first-stage aging treatment is 470-490 min, the temperature of second-stage aging treatment is 640-660 DEG C, and the time of second-stage aging treatment is 470-490 min. The Inconel 718 alloy prepared by the method has strength, plasticity and hardness and has excellent comprehensive mechanical properties, and the application of the Inconel 718 alloy can be expanded to the field of more precise and complex structures.

Owner:SOUTHWEST JIAOTONG UNIV

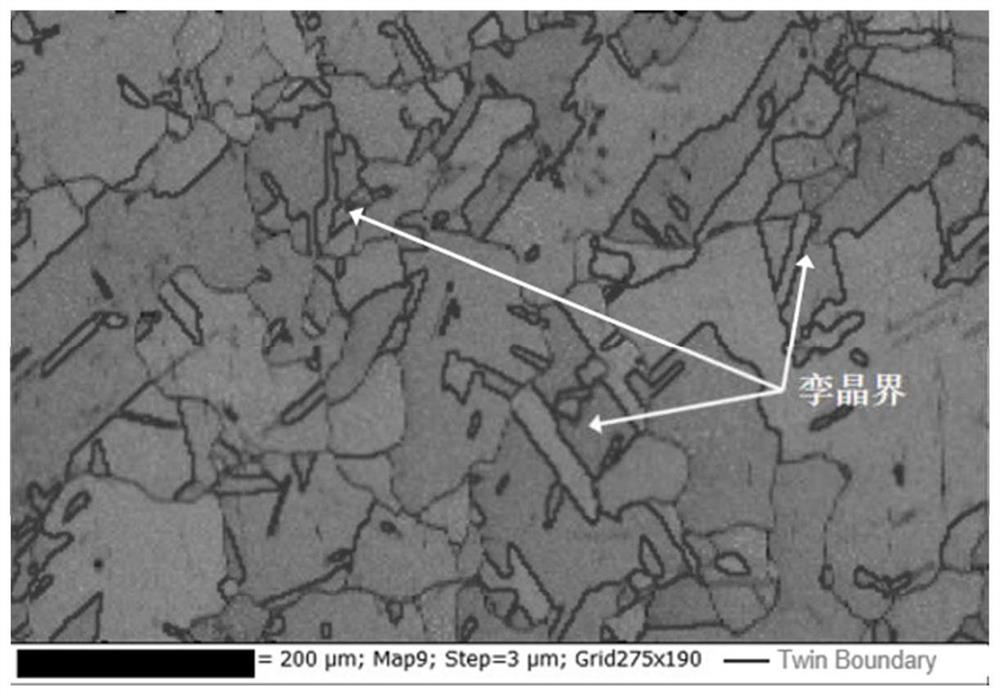

Additive for Reducing Voids after Annealing of Copper Plating with Through Silicon Via

ActiveUS20160168738A1Simple formulaEasy to operateSemiconductor/solid-state device manufacturingInksSulfonateCopper plating

An additive for reducing voids after annealing of copper plating with through silicon via. The additive contains by weight percent: 0.05-1% of one or more of quaternized polyethylene imine and derivatives thereof having different molecular weights, and 1-10% of polyethylene glycol with an average molecular weight of 200-20000. The additive is used in combination with an electroplating solution of a copper methyl sulfonate system. The electroplating solution of a copper methyl sulfonate system contains 1-5 ml / L of the additive by volume ratio. The electroplating solution of a copper methyl sulfonate system contains by quality volume ratio: 50-110 g / L of copper ions, 5-50 g / L of methanesulfonic acid and 20-80 mg / L of chlorine ions. The electroplating solution also contains by volume ratio: 0.5-5 ml / L of accelerator, 5-20 ml / L of inhibitor and 5-10 ml / L of levelling agent. The additive for reducing voids after annealing of copper plating with through silicon via provided in the present invention can solve the problem of micro-voids between grain boundaries after high temperature annealing of copper plating.

Owner:SHANGHAI SINYANG SEMICON MATERIALS

Epoxy protective coating system for high-power nuclear power station

ActiveCN101781508BImprove corrosion resistanceGood radiation protectionAnti-corrosive paintsShieldingNuclear gradeNuclear power

The invention relates to an epoxy protective coating system for a high-power nuclear power station. Priming coat comprises a component A1 and a component B with the weight ratio of 4-6, and finishing coat comprises a component A2 and the component B with the weight ratio of 3-5:1.. The component A1 comprises 20 to 50% of epoxy resin, 10 to 40% of anti-corrosion paint, 10 to 25% of radiation-resistant stuffing, 0.1 to 3% of addition agent and the balance of menstruum by weight percent. The component A2 comprises 20 to 50% of the epoxy resin, 10 to 40% of the anti-corrosion paint, 5 to 20% of the radiation-resistant stuffing, 0.1 to 3% of the addition agent and the balance of the menstruum by weight percent. The component B is a radiation-resistant epoxy-amine adduct curing agent, and is synthesized by 10 to 30% of liquid epoxy resin, 30 to 70% of polyamine with primary amine groups and 20 to 60% of the menstruum. The corrosion resistance and radiation resistance can meet the requirements of nuclear grade paint and can pass simulation DBA tests when the coating system is used for a high-power nuclear power station.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Method for improving metallurgical quality of large-specification 2000 series aluminum alloy cast ingot

ActiveCN112974747AReduce the degree of component segregationReduce crackingCasting cleaning apparatusWater flowIngot

The invention provides a method for improving the metallurgical quality of a large-specification 2000 series aluminum alloy ingot, and is suitable for a large-specification flat ingot with the size of 520mm (thickness) x 1620mm (width) and a large-specification round ingot with a diameter of 1000mm. The method comprises the following steps of: jointly applying ultrasonic waves and electromagnetic waves to molten aluminum (such as molten aluminum in a front groove) during casting; and selecting ultrasonic frequency, coupling parameters of electromagnetic waves, casting temperature, casting speed and water flow according to alloy components. According to the method, the casting stress of the large-specification cast ingot can be effectively reduced, cracks are reduced, the composition segregation degree of the cast ingot is reduced, microporosity is reduced, the cast ingot is prevented from cracking, and the casting forming rate is increased.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Solvent-tolerant acrylate composition and applications thereof

ActiveCN111087526AImprove anti-agingImprove adhesionNitrile polymer adhesivesEster polymer adhesivesPolymer scienceAdhesive

The invention discloses a solvent-tolerant acrylate composition and applications thereof, wherein the components of the composition do not contain a tackifying resin, a multifunctional phosphorus hydroxyl compound is used as a cross-linking agent, and the solvent tolerance is good. With the application of the adhesive film prepared from the solvent-tolerant acrylate composition to an acrylate pressure-sensitive adhesive, the adhesive film can tolerate permeation and the like of polar and non-polar solvents on a bonding interface of the acrylate pressure-sensitive adhesive, and can be applied to places with more chemical solvents.

Owner:SUZHOU SHIHUA NEW MATERIAL TECH

A heat-resistant cast aluminum-copper alloy and its preparation method

Owner:北京世联信诺科技有限公司

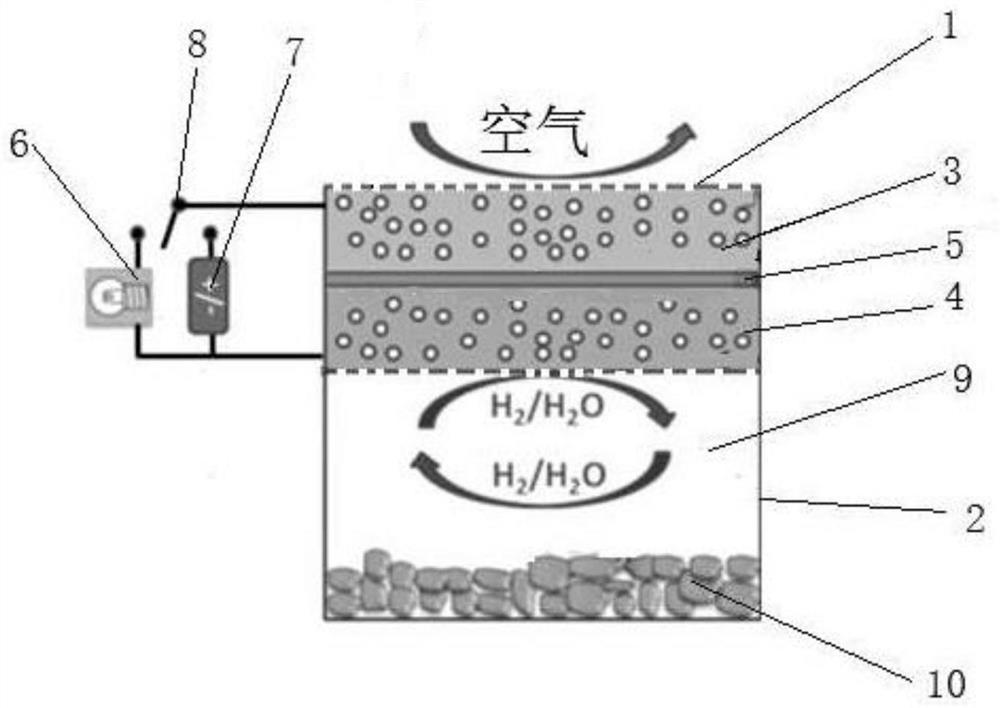

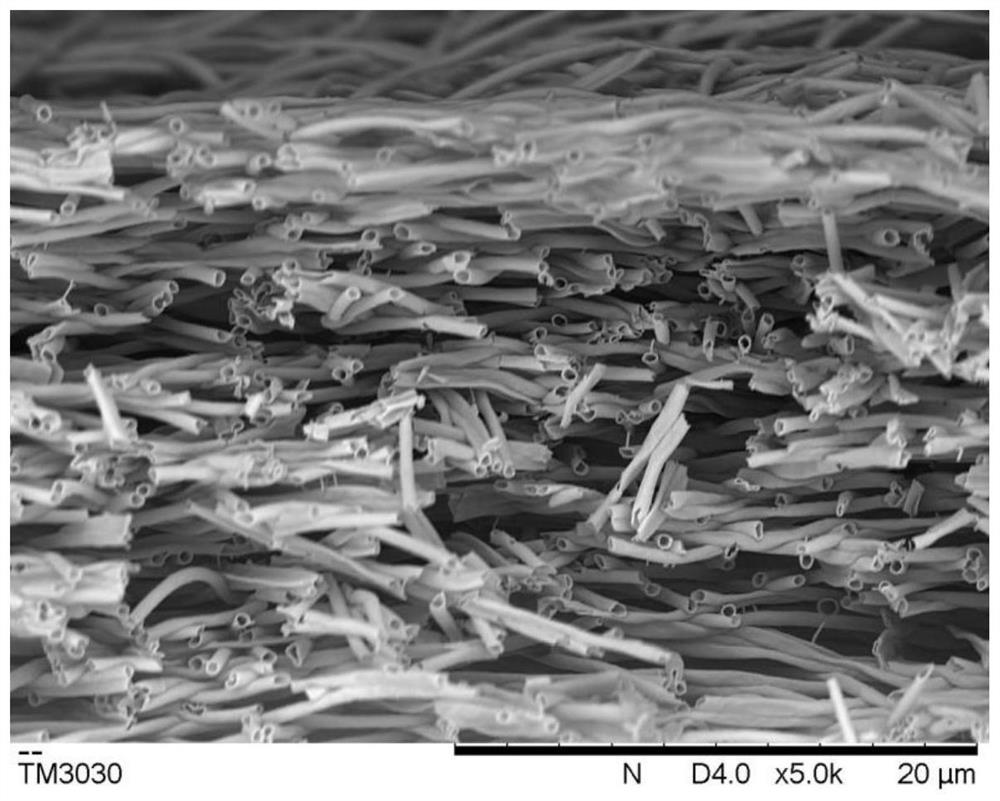

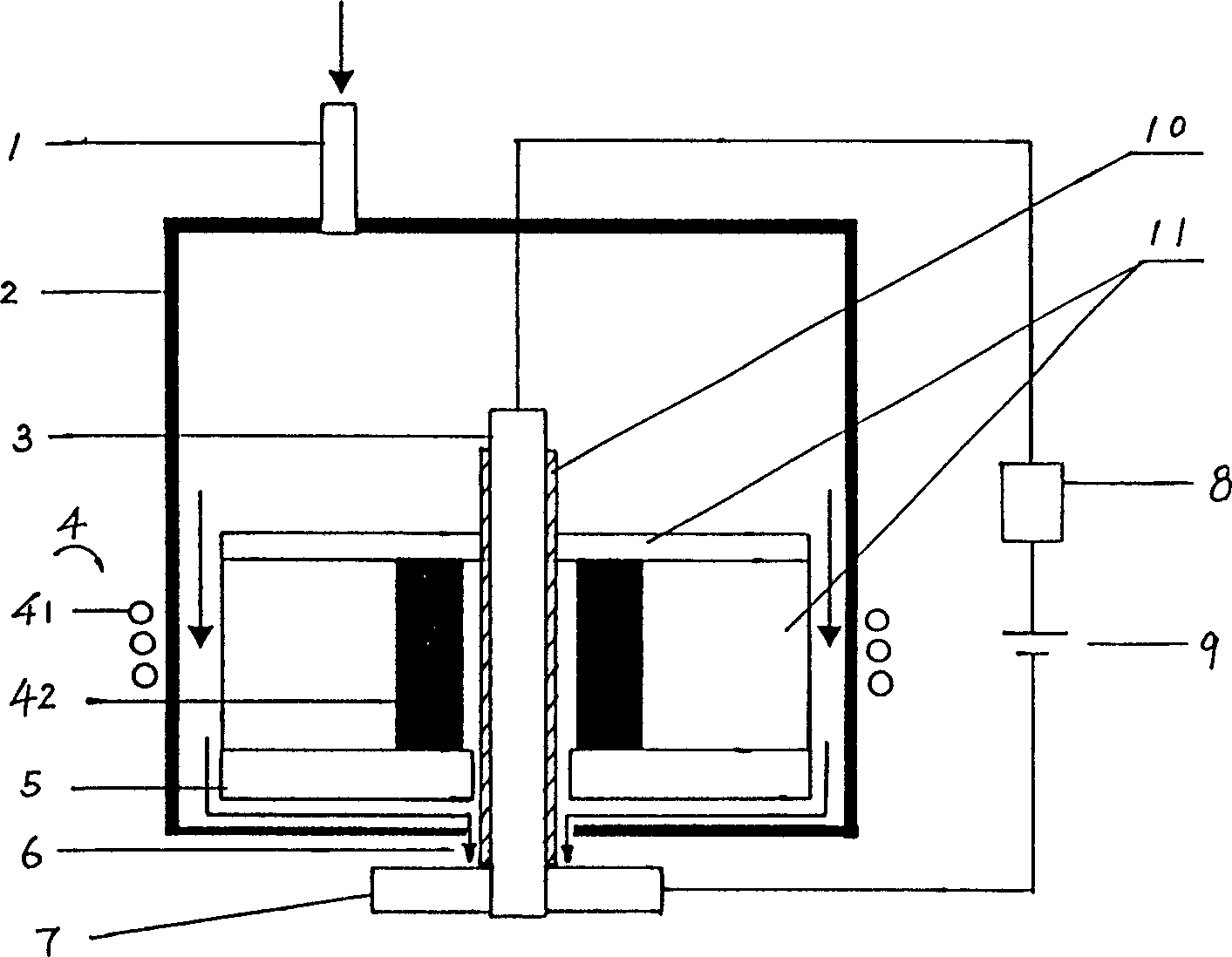

Hollow fiber pore-forming agent and application thereof in fuel cells

ActiveCN112853530AReduce activation polarizationLower internal resistanceHollow filament manufactureCell electrodesElectrochemical responseFiber

The invention relates to a hollow fiber pore-forming agent and application thereof in fuel cells. The pore-forming agent is PAN-PVP coaxial hollow fiber prepared from peroxyacetyl nitrate and polyvinylpyrrolidone as raw materials, and a preparation method of the pore-forming agent comprises the following steps of preparing a PAN-PVP mixed solution from peroxyacetyl nitrate and polyvinylpyrrolidone; and then operating on a coaxial high-voltage electrostatic spinning machine, placing methyl silicone oil in an inner needle hole, placing the PAN-PVP mixed solution in an outer needle hole, and rotating a roller collector to collect the PAN-PVP coaxial hollow fiber. The PAN-PVP hollow fiber can form a three-dimensional network cross-linked cavity after a fuel cell anode is fired to remove the fiber, so that the connection of the anode in the hole is improved, the internal specific surface area of an electrolyte is increased, the activation polarization of the cell is integrally reduced, the electrochemical reaction area is increased, the internal resistance of the cell is reduced, and the substance diffusion is accelerated, and therefore, the output performance of the cell is finally improved, and attenuation of specific capacity is slowed down.

Owner:XIAMEN UNIV

A kind of solvent-resistant acrylate composition and its application

ActiveCN111087526BImprove anti-agingImprove adhesionNitrile polymer adhesivesEster polymer adhesivesPolymer scienceAdhesive

Owner:SUZHOU SHIHUA NEW MATERIAL TECH

Monocrystal high temperature alloy electric field directional freeze apparatus

InactiveCN1226470CRefining solidified tissueEasy to useFrom frozen solutionsSingle crystal superalloySingle crystal

The invention relates to the single crystal high-temperature alloy solidifying technique, including case, heating set, sample clamping framework and DC electric field generating set. The clamping framework is set under the case, composed of two clamping bars set on the bracket, one end of each clamping bar linked with the rotation shaft on the bracket, the other end linked through fastener, and the outer side of each clamping bar installed with tension spring, the other end of each tension spring fixed on the bracket, and the bracket opened with a through hole to make the sample pass through; the generating set is a close loop, formed by setting a programmable functional module in series between one end of the sample and one pole of the voltage-stailized source, and connecting the other end with the other pole through the clamping tool.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A Method for Improving the Metallurgical Quality of Large Size 2000 Series Aluminum Alloy Ingots

ActiveCN112974747BReduce the degree of component segregationReduce crackingCasting cleaning apparatusWater flowIngot

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

High pressure treatment for improved grain growth and void reduction

InactiveUS7344979B2Fine grainEliminate microporositySemiconductor/solid-state device manufacturingDielectricRoom temperature

A copper film is annealed at high pressure to enhance grain growth and remove voids. Other films, such as dielectrics, may also be suitable. High pressure can be used in conjunction with temperatures lower than room temperature for annealing or higher temperatures may be used to further enhance grain growth.

Owner:WAFERMASTERS

Method for reducing microporosity of casting silicon-aluminum alloy

InactiveCN108315607AImprove liquidityEliminate Casting Performance DropsAcetic anhydrideNitrogen gas

The invention belongs to the technical field of casting silicon-aluminum alloy, and particularly relates to a method for reducing microporosity of casting silicon-aluminum alloy. The method comprisesthe following steps that raw materials are prepared, the raw materials are added into a melting pool at 740 DEG C for melting, after keeping 5-10 minutes, the raw materials are heated up to 800-820 DEG C; when the raw materials are cooled down to 650-670 DEG C, acetic anhydride with the weight counting for 0.8-1.2% of furnace burden is added, slagging-off, discharging from a furnace and casting are carried out after treatment for 6-10 minutes, and heat treatment is carried out after the casting is completed. Compared with the prior art, the method has the following advantage that through scientifically proportioning the content of each element, refining process of a refining agent is omitted, the fluidity of the materials is improved by introducing nitrogen, the problem that the casting performance is lowered due to the content of silicon is solved, addition of dysprosium can effectively reduce the microporous rate of the alloy, surface tension of the alloy during the casting process is improved, and the mechanical properties of the alloy are improved.

Owner:安徽玉成光华铝业有限公司

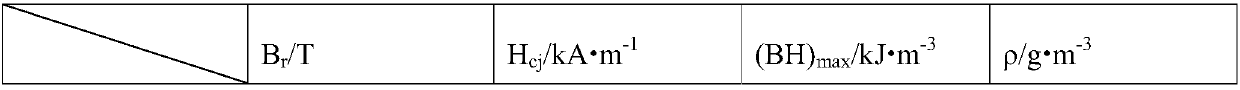

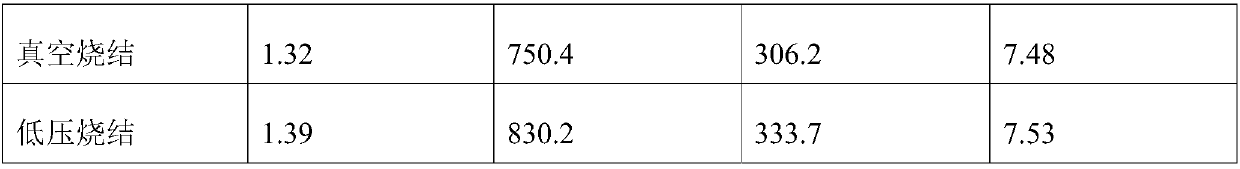

High performance NdFeB rare earth permanent magnet material and preparation method thereof

ActiveCN106920617BPrevent oxidationEasy to operateTransportation and packagingMetal-working apparatusLow voltageRare earth

A preparation method of a high-performance NdFeB rare earth permanent magnet material: (1) batching; (2) melting and casting; (3) preparing magnetic powder; (4) preparing a magnetic field forming green body; (5) cold isostatic pressing; (6) ) low-pressure sintering, put the cold isostatic pressing green body obtained in step (5) into a low-pressure sintering furnace, and when the vacuum is evacuated to the furnace pressure≤1×10 ‑2 Start to heat up at Pa, when the temperature rises to 900-1000°C and keep it warm for 0.5-1.0h, keep vacuuming during the above-mentioned heating and heat preservation process, stop vacuuming after the heat preservation is over, continue to maintain the temperature in the furnace at 900-1000°C and feed High-purity inert gas until the pressure in the furnace is 0.5-4MPa and heat-preservation and pressure-holding sintering for 5-30 minutes. After sintering, stop heat preservation and pass high-purity inert gas at room temperature to cool to room temperature to obtain a sintered magnet; (7) Two-stage heat treatment. The above method can obtain the NdFeB rare earth permanent magnet material with excellent comprehensive magnetic properties and reduce the cost.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com