Monocrystal high temperature alloy electric field directional freeze apparatus

A high-temperature alloy and directional solidification technology, which is applied in single crystal growth, self-solidification, crystal growth, etc., can solve the problems of unfavorable DC electric field, increase of radial temperature gradient of directional solidification solid-liquid interface, super heat loss, etc., to achieve Good protective effect, refine metal solidification structure, reduce segregation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

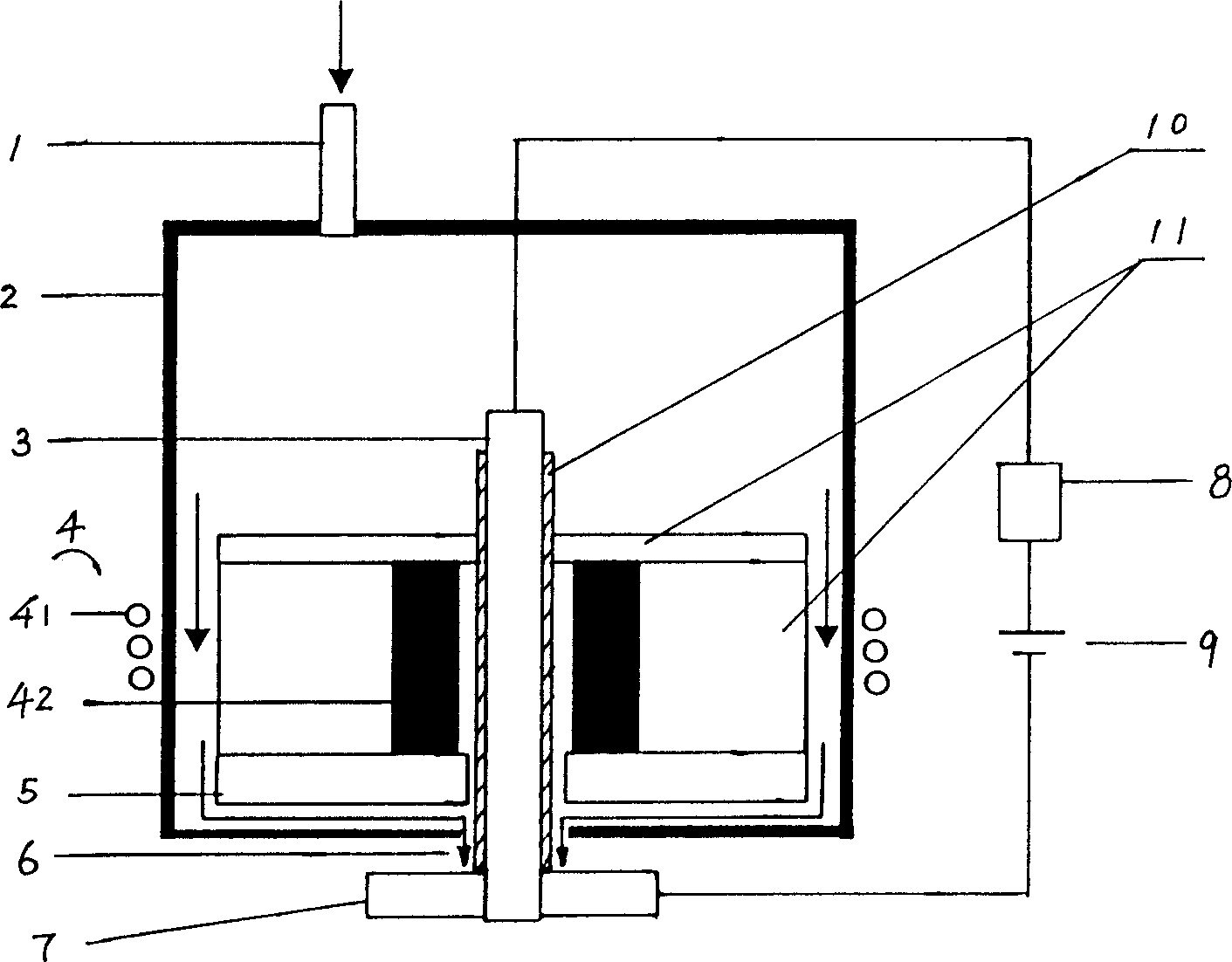

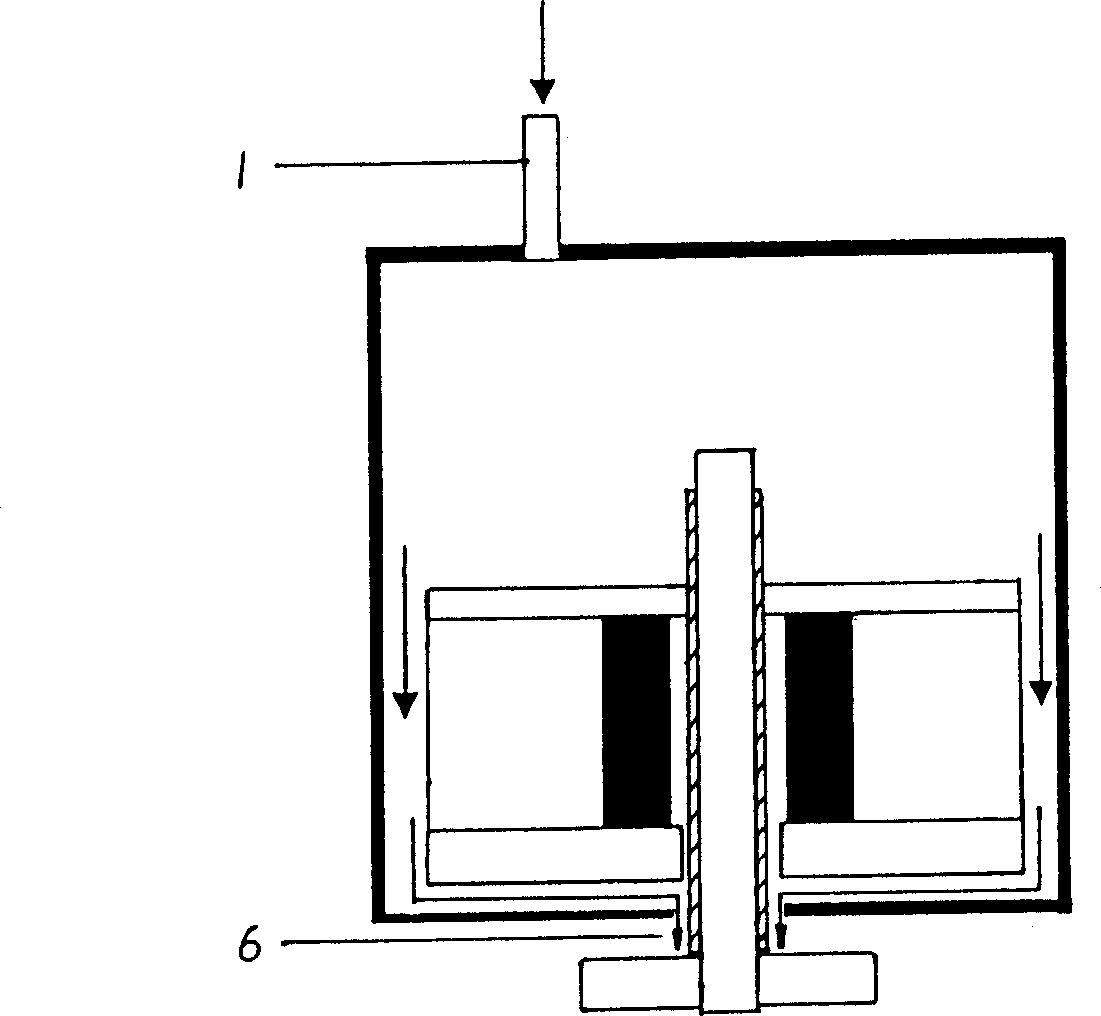

[0019] like figure 1 As shown, the structure of the single crystal superalloy electric field directional solidification equipment includes three parts: a heating device 4, a clamping mechanism 7 and a DC electric field generating device. This is described in detail below.

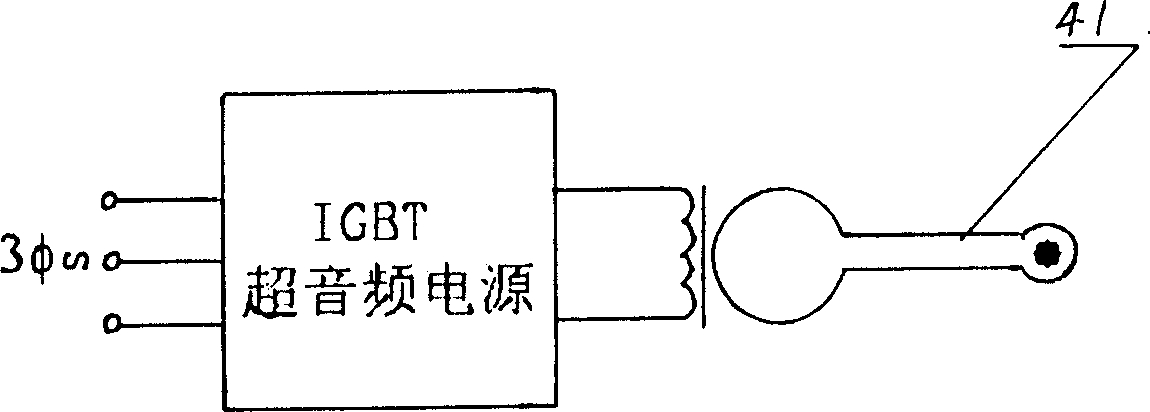

[0020] The heating device 4 uses an IGBT super-audio power supply to generate single-phase alternating current, which is sent to the induction heater 41 after being stepped down by the transformer. The induction heater 41 heats the graphite induction body 42, and the graphite induction body 42 heats the sample 3 by radiation. principle such as figure 2 shown.

[0021] High-purity Al is used around the graphite induction body 42 2 o 3 Insulation cotton 11 insulation, Al 2 o 3 Insulation cotton 11 has a refractoriness higher than 1700°C and has a good heat preservation effect. After the heating furnace works at 1550°C for two hours, the temperature of the quartz glass cover (shell) 2 is still lower tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com