Patents

Literature

56results about How to "Avoid skin effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for composite electromagnetic continuous-casting high-oriented ultra-fine grained materials

The invention relates to a method for continuously producing high-orientated fine-grained metallic material in complex electromagnetic field, pertaining to the technical field of metal casting. The method of the invention is outlined as follows: a pair of self-cooling electrodes are inserted into the upper part of metal melts in a crystallizer, and is electrified with AC power, and a DC induction coil is arranged outside the crystallizer and electrified with DC current to generate a DC magnetic field. The self-cooling electrodes induce the melts near the electrodes to form a crystal core, and combine with electromagnetic oscillation to eject the crystal core into the metal melts, then a core body for the later metal solidification. The crystal core is magnetic orientated during the process of sedimentation, and eventually metal material with highly-orientated fine crystal structure is obtained. The AC current frequency range adopted by the invention is 10 to 10000Hz, AC current intensity range is 0 to 10000A, and magnetic field intensity generated by the DC current is 0 to 10 T and can be continuously tuned. The high-orientated fine-grained metallic material prepared by the invention has uniform casting organizations and can substantially improve the performance and quality of the metal material.

Owner:SHANGHAI UNIV

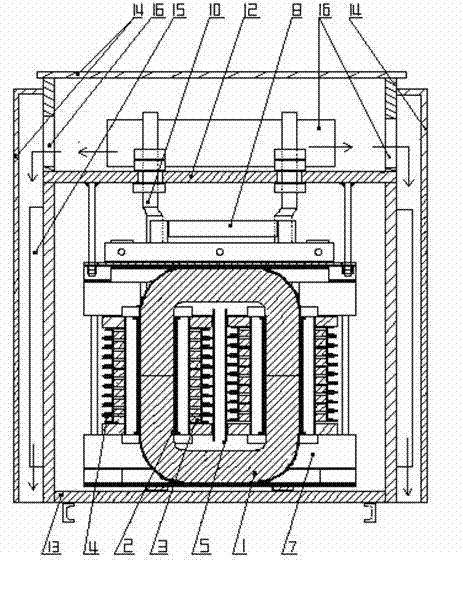

High-power high-frequency high-voltage rectifier transformer

ActiveCN102290222AExtended service lifeReduce lapsTransformers/inductances coolingAc-dc conversion without reversalCapacitanceHigh frequency power

The invention relates to a high-power, high-frequency and high-voltage rectifier transformer, which comprises a core, a plurality of low-voltage windings, a plurality of high-voltage windings, a plurality of rectifier bridges and a transformer oil tank. The core adopts a rectangular ultra-crystalline transformer core, the low-voltage windings are divided into two groups by wide copper foil and are wound on two low-voltage skeletons on the long side column of the core along the same direction, half of the high-voltage windings are sequentially wound on one high-voltage coil skeleton, the otherhalf of the high-voltage windings are sequentially wound on another one high-voltage coil skeleton, the two high-voltage coil skeletons are respectively sleeved on the two low-voltage windings, and the high-voltage windings are respectively connected with the input ends of the matching rectifier bridges. The problem of damage to a high-frequency power supply switch, caused by reflection of distributed capacitance of the secondary winding of the transformer, can be solved, the working frequency can reach 10-50kHz, the rated voltage of direct-current output is 72kv, and the rated output power is no lower than 100kW. The temperature rise in full-load continuous operation is less than 40 DEG C. Therefore, the high-power, high-frequency and high-voltage rectifier transformer is an ideal booster device for a high-voltage power supply of a large electrostatic precipitator.

Owner:NANJING GUODIAN ENVIRONMENTAL PROTECTION TECH

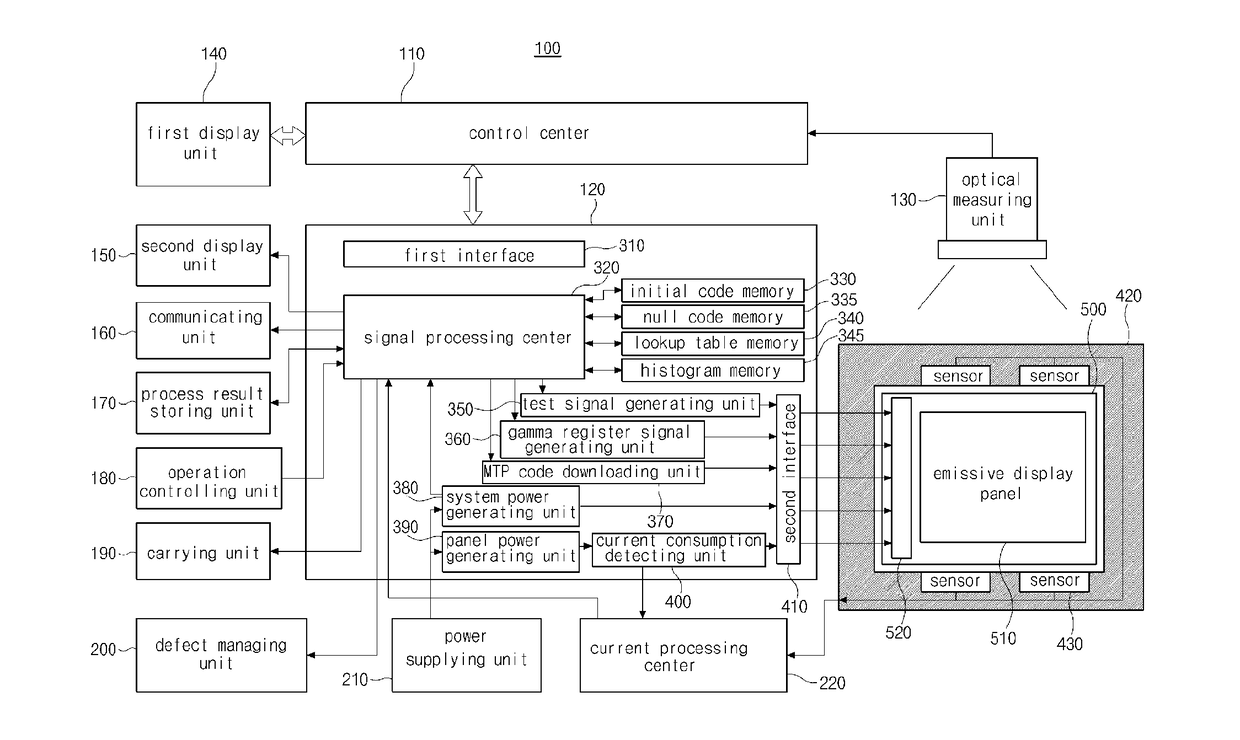

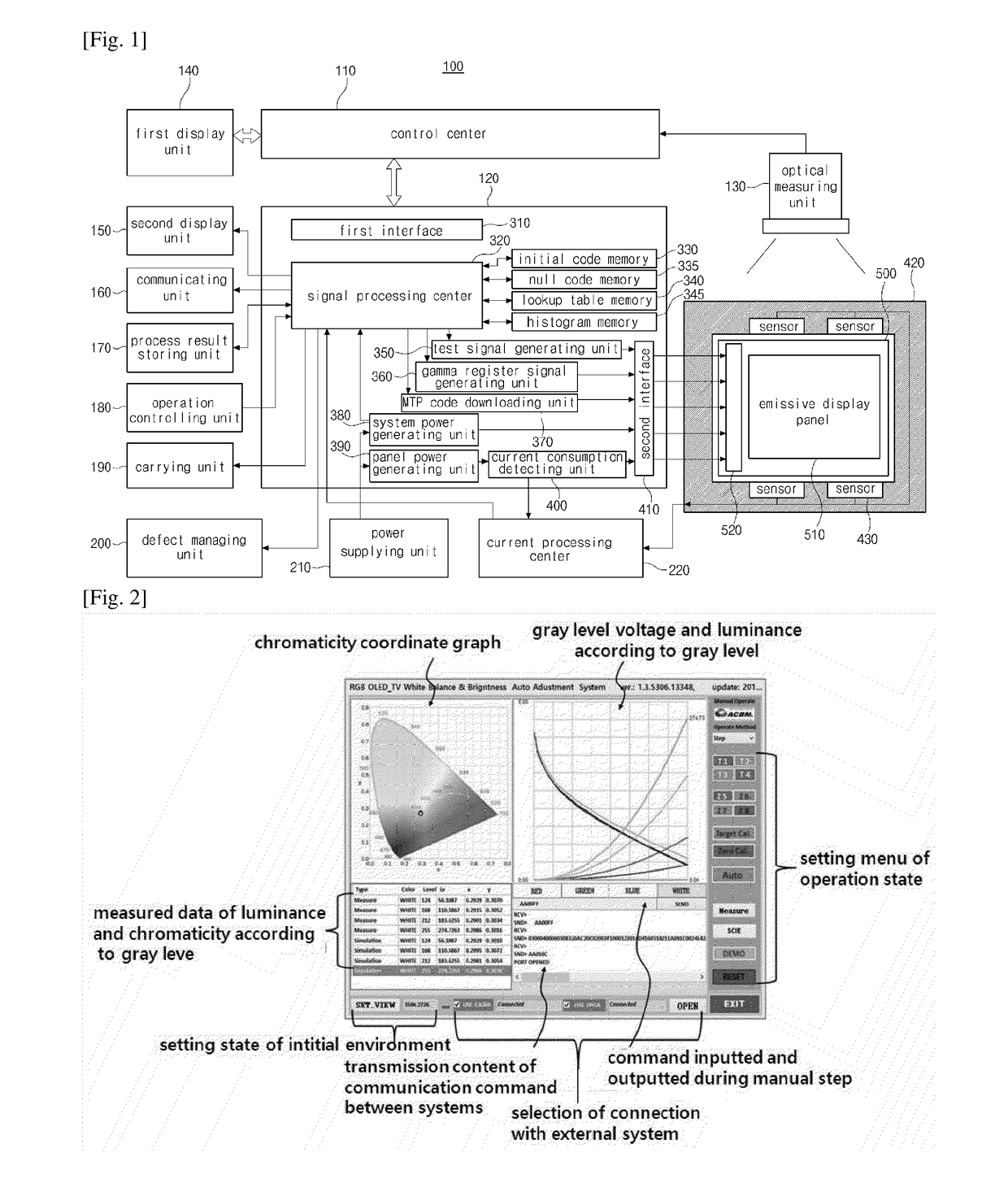

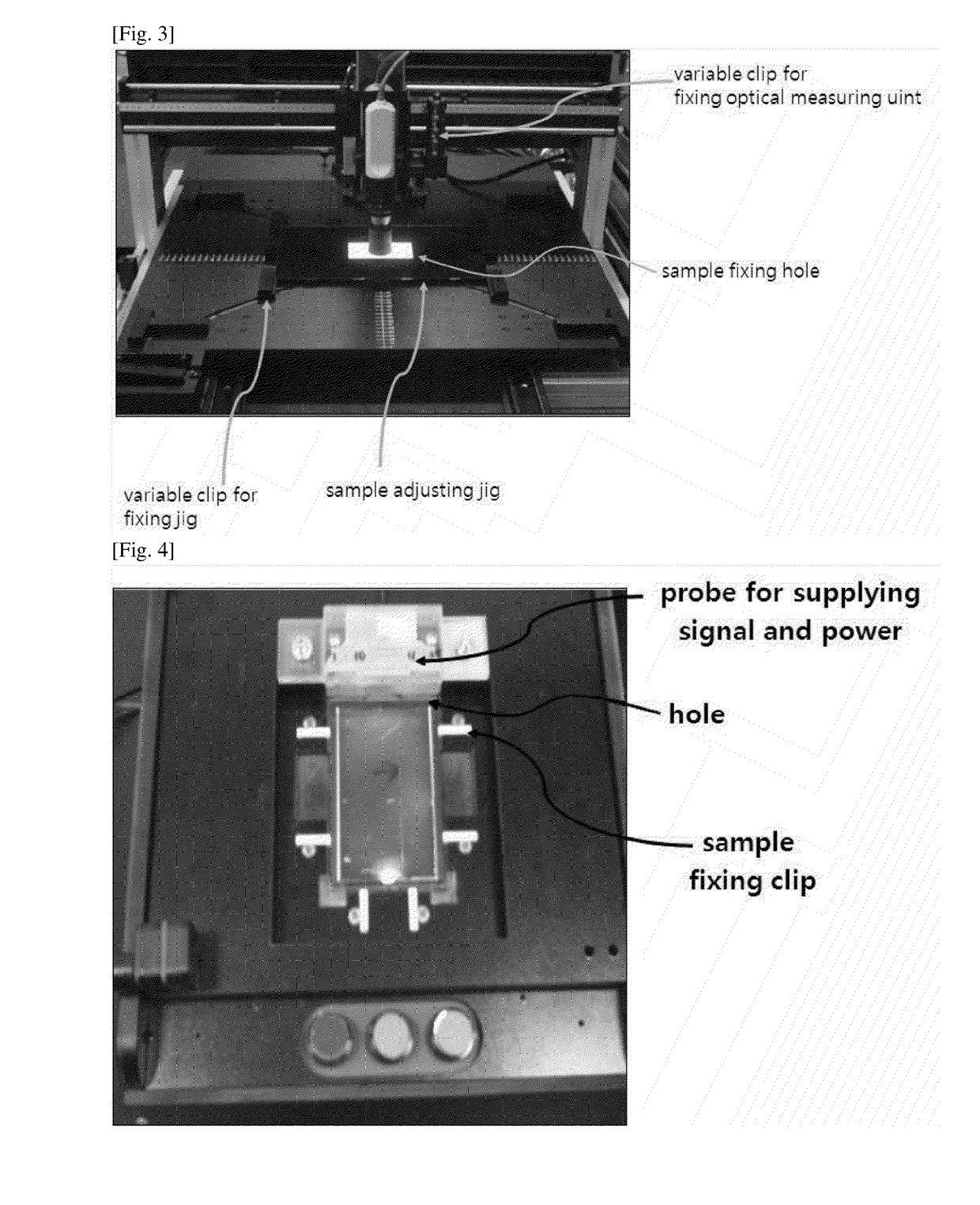

Gamma setting system of display device and gamma setting method thereof

ActiveUS20170223233A1Increase productionImprove accuracyTelevision system detailsCharacter and pattern recognitionDisplay deviceComputer science

The present invention provides a gamma setting system for a display device including: an optical measuring unit measuring an optical property of a display device including an emissive display panel having red, green and blue sub-pixels; a control center performing a null setting step and an automatic setting step using the optical property of the display device; a system driving unit transmitting a result data between the display device and the control center; a first display unit displaying a TW target luminance, a TW target chromaticity and an RGB inherent chromaticity registered for the null setting step and the automatic setting step, a graph of a gray level voltage and a luminance of an RGB and a TW with respect to a gray level, a high level cell driving voltage (PVDD) and a low level cell driving voltage (PVEE) applied to an emitting element, a high level gamma source voltage (VDDH) and a low level gamma source voltage (VDDL) applied to a driving IC, a gamma slope, a contrast ratio, a driving type of the system, a gamma setting, an instruction on an execution command, and a progress state of the display device.

Owner:LIM JUMI

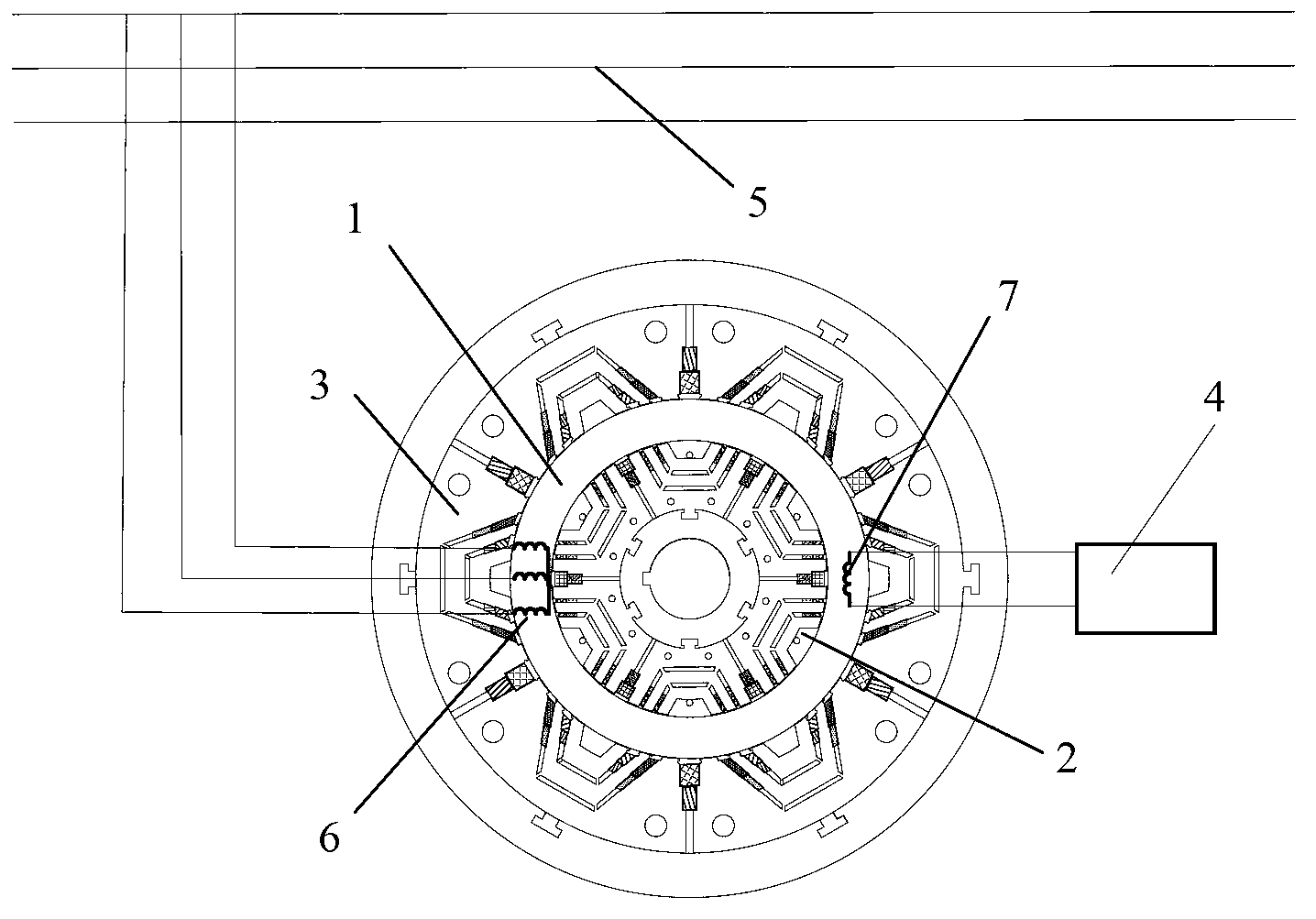

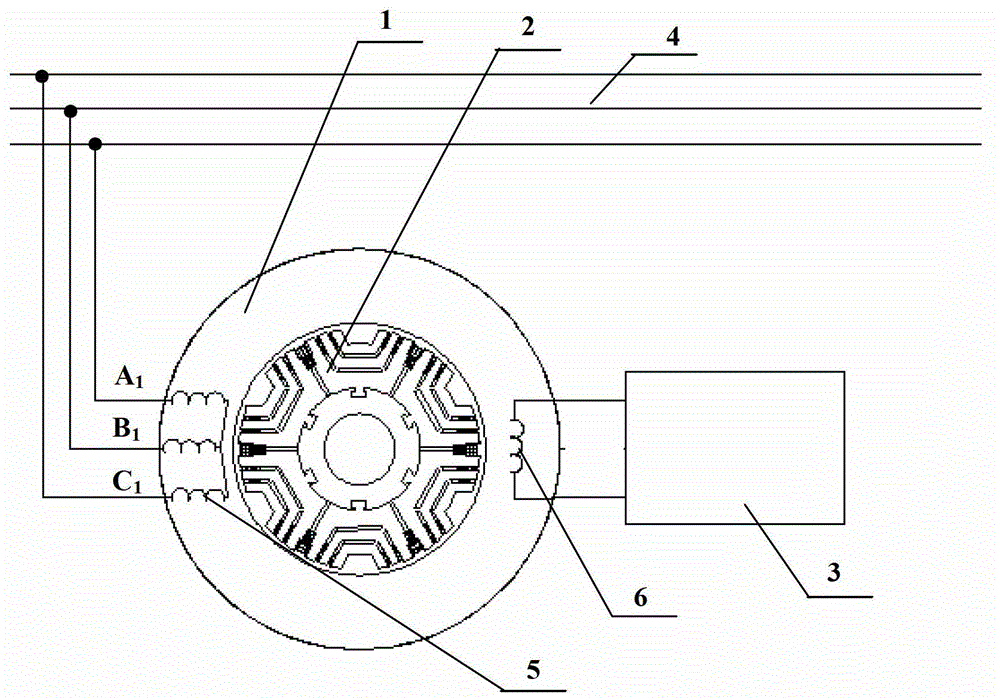

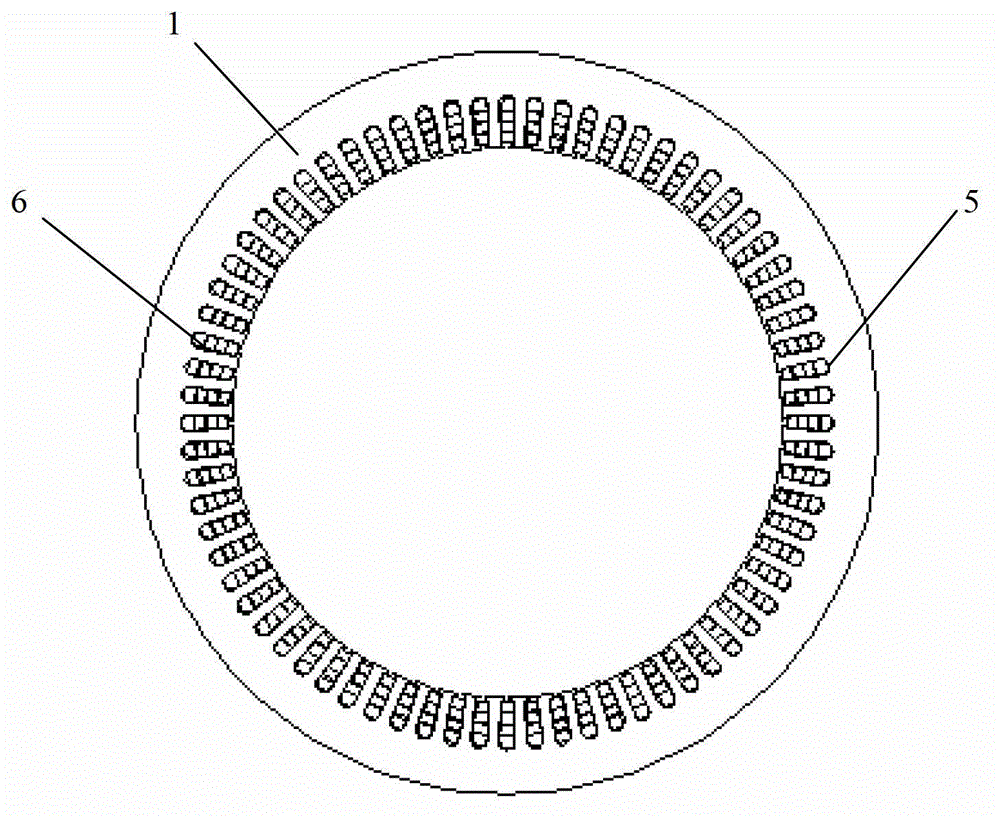

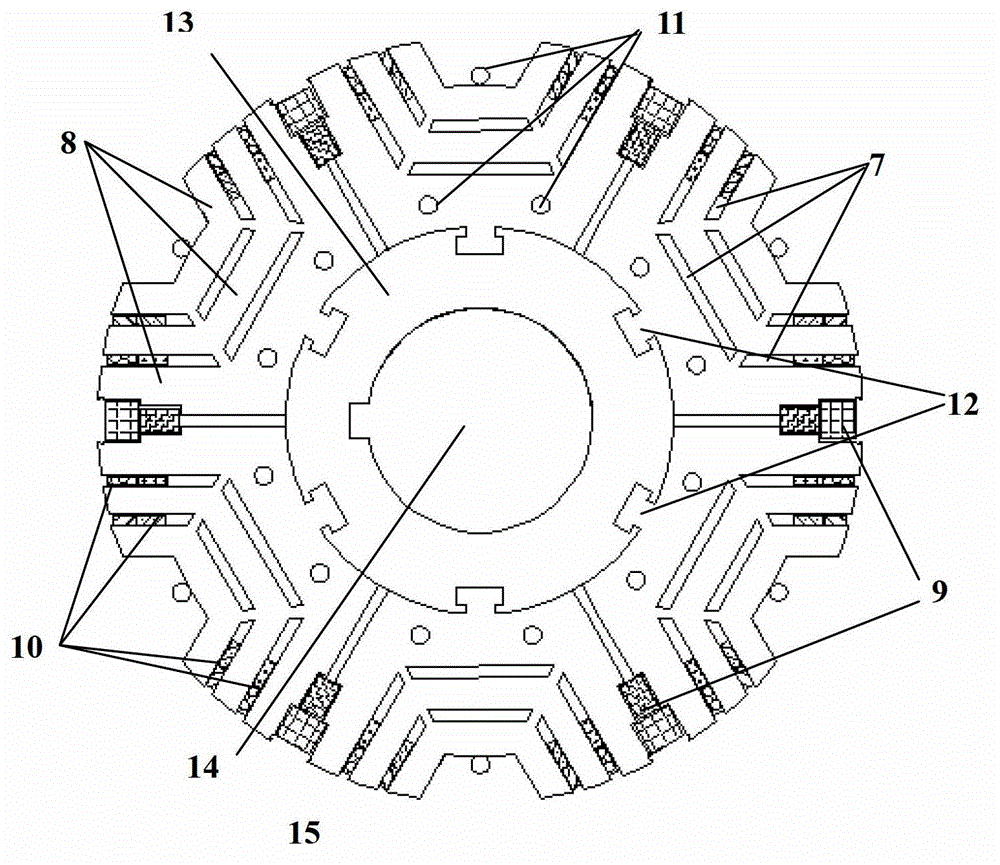

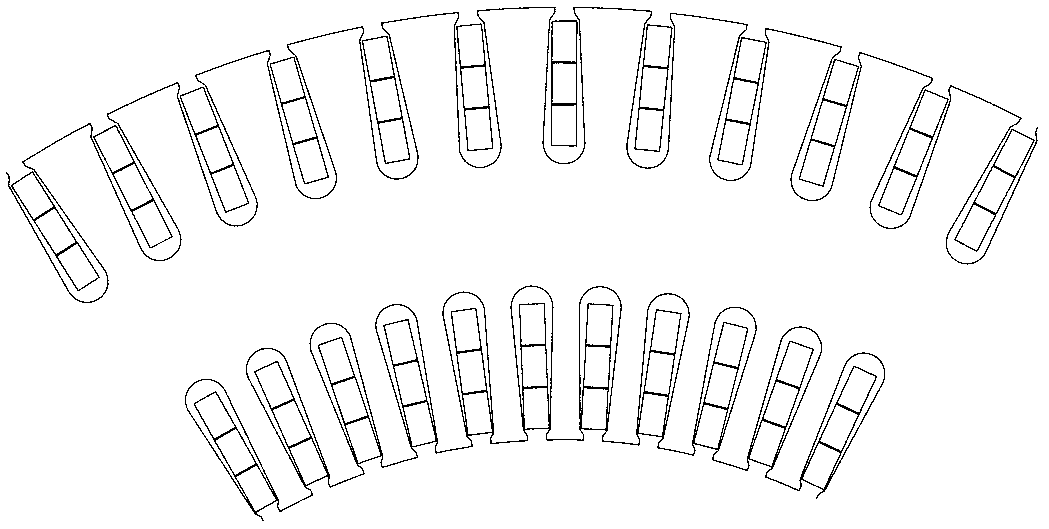

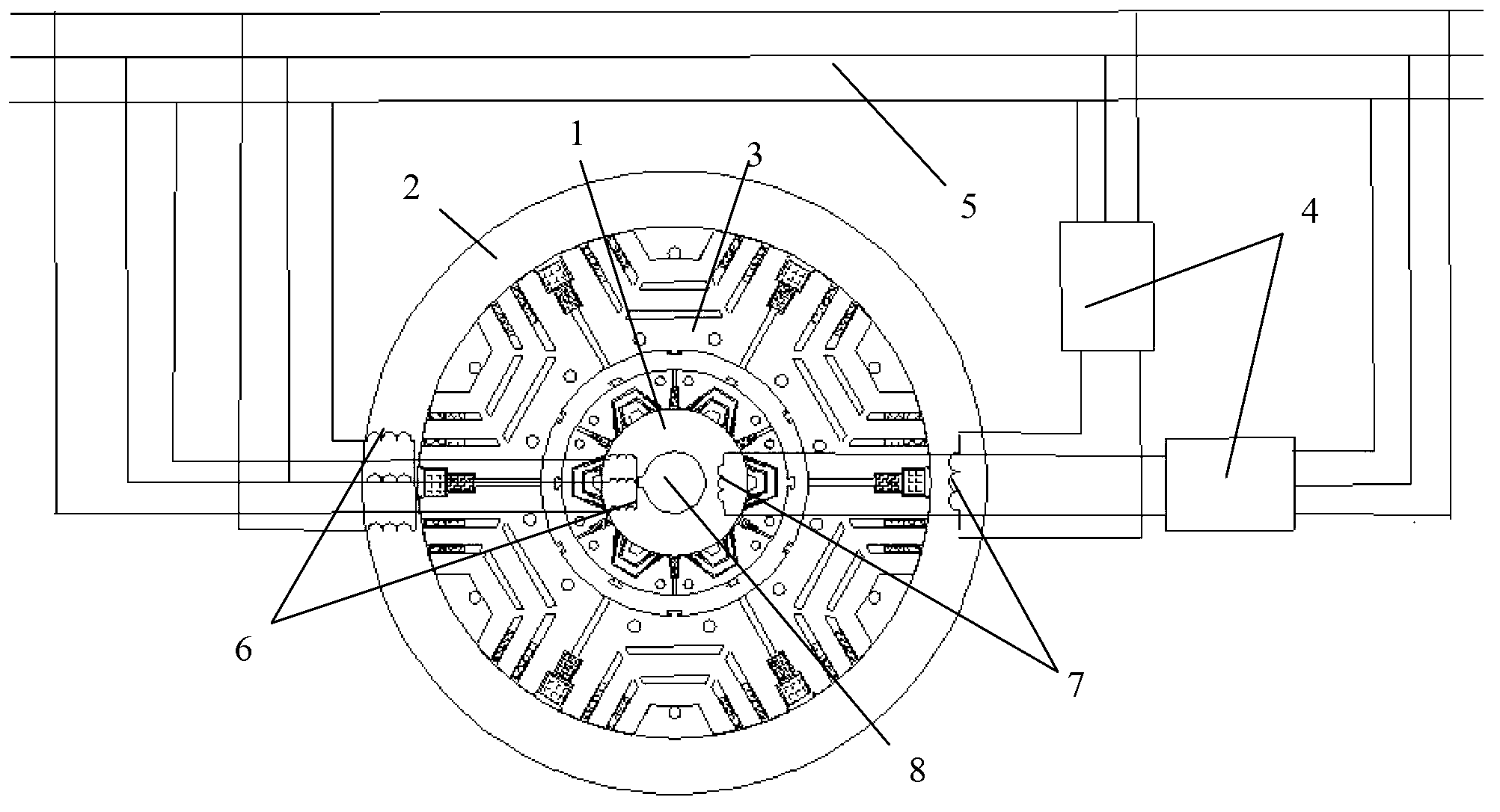

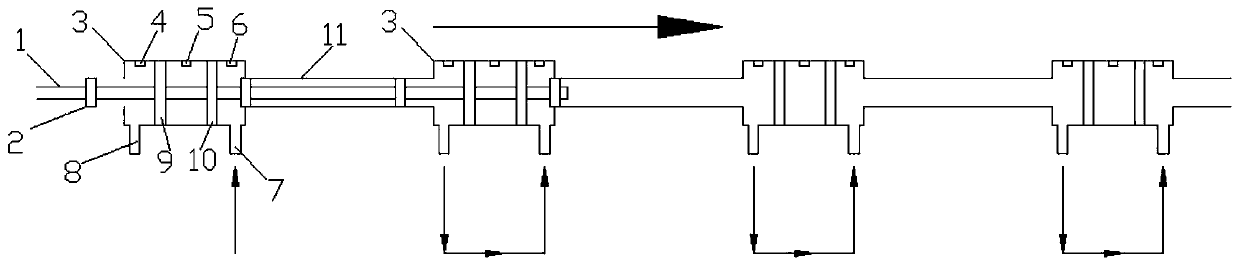

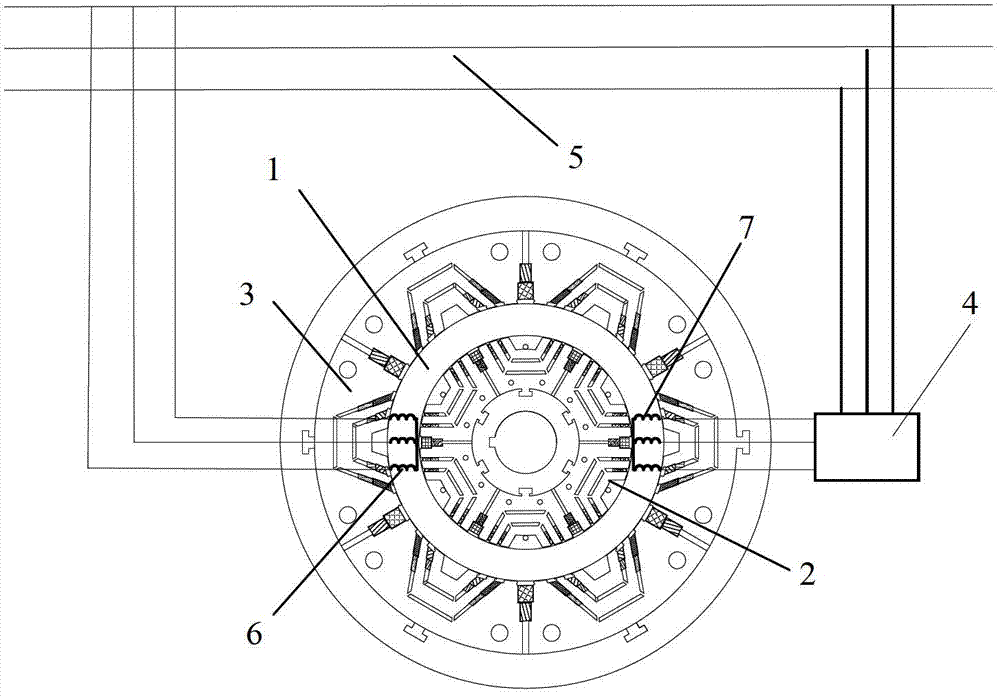

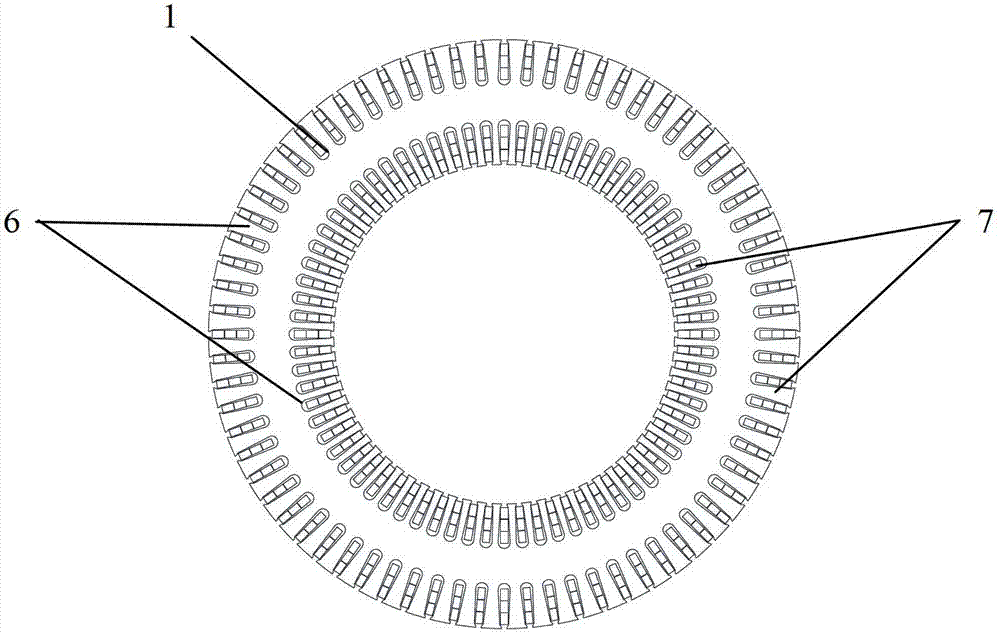

Stator self-excitation synchronous motor with double cage barrier rotors and control method thereof

ActiveCN103166395AHigh electromechanical energy conversion efficiencyModular structureSynchronous generatorsElectronic commutation motor controlSynchronous motorThree-phase

The invention relates to a stator self-excitation synchronous motor with double cage barrier rotors and a control method thereof. The stator self-excitation synchronous motor is characterized in that an inner rotor and an outer rotor are positioned on inner and outer sides of a stator respectively; three-phase symmetry power windings and three-phase symmetry control windings are arranged in grooves on inner and outer surfaces of a stator; the rotors are spliced on the side which is close to the stator along the peripheral direction by using the same cage barrier rotor modules to form a rotor with a salient pole; each cage barrier rotor module is connected with a sleeve by positioning grooves and is provided with a plurality of trapezoid grooves; short-circuit cage bars are put into the trapezoid grooves; a stepped breach is formed in the joint of the adjacent cage barrier rotor modules; and after the adjacent modules are spliced, a public trapezoid groove is formed in the joint of the adjacent modules, the depth of a gap at the bottom of the groove reaches the surface of the sleeve, and public cage bars are put into the grooves. The invention aims to provide the stator self-excitation synchronous motor which is convenient to manufacture, can realize the brushless self-excitation of the stator, is high in power density and steady and dynamic properties and is provided with the double cage barrier rotors.

Owner:SHENYANG POLYTECHNIC UNIV

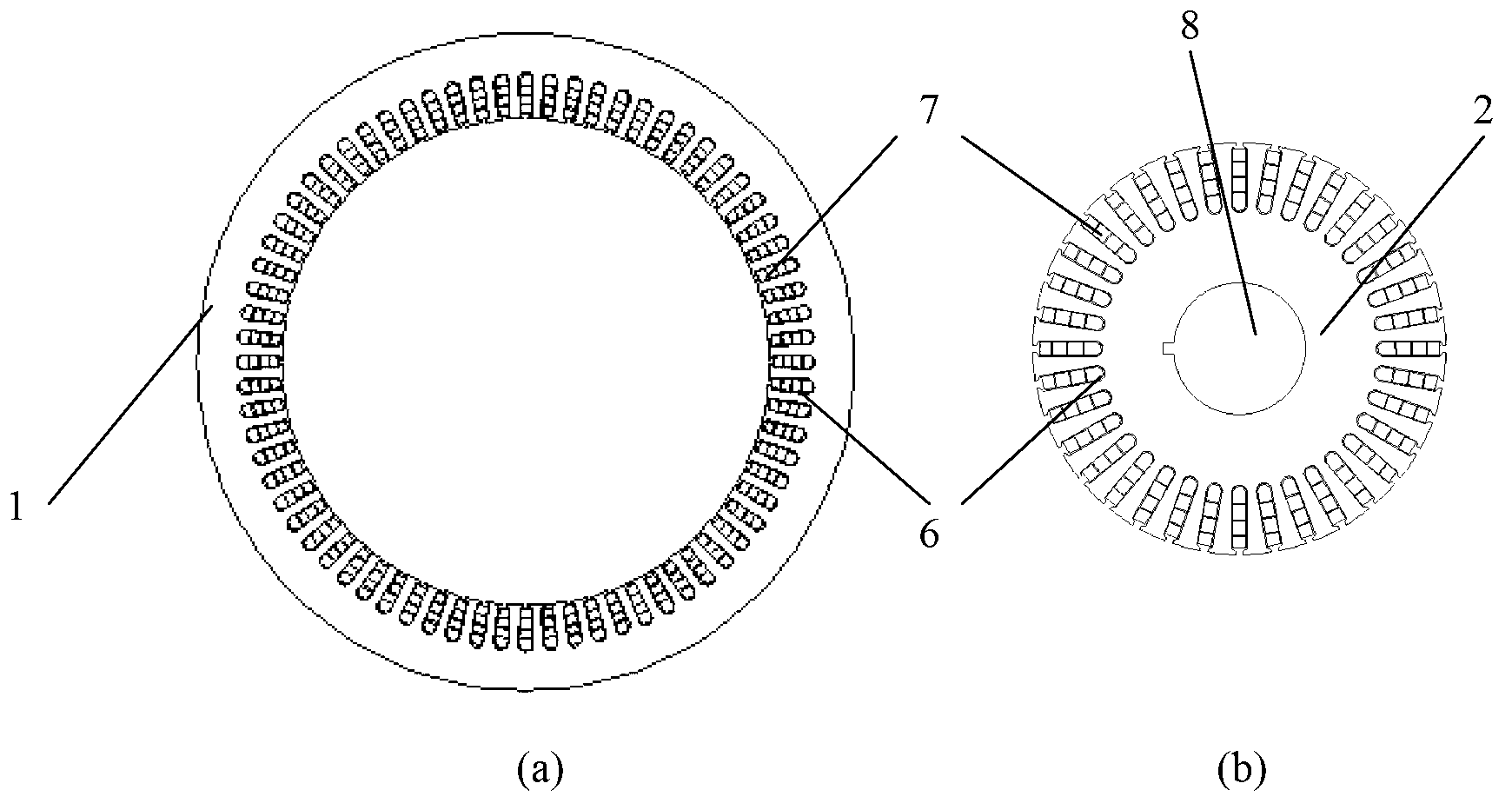

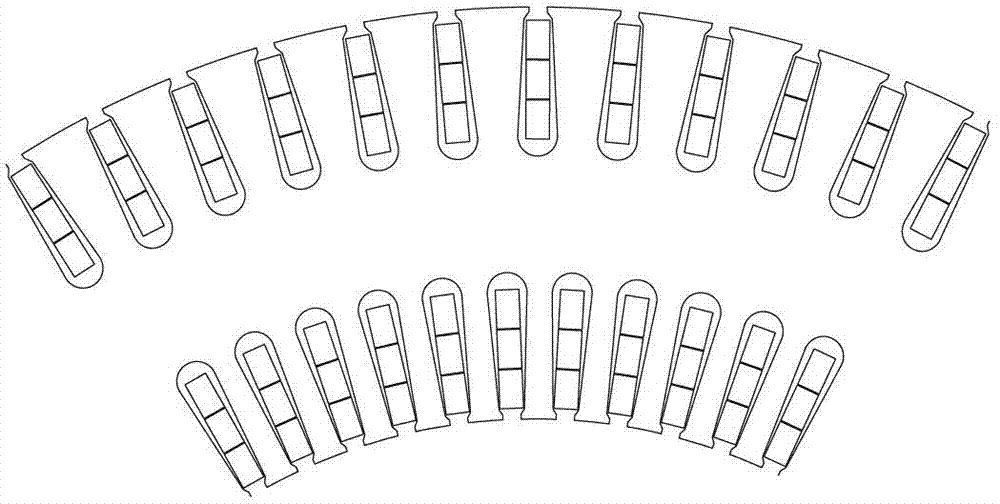

Modularized cage barrier rotor and stator self excitation synchronous motor and control method thereof

ActiveCN103151887AStrong coupling abilityHigh electromechanical energy conversion efficiencySynchronous generatorsElectronic commutation motor controlGroove widthSynchronous motor

The invention relates to a synchronous motor, which is characterized in that a set of 2p electrode three-phase armature winding and a set of 2q electrode single-phase excitation winding are placed on a stator, the stator self excitation is realized on the power supply of the excitation winding, a rotor is split into the rotor with the convex electrode form by cage barrier modules in the circumferential direction, each cage barrier rotor module is connected with a sleeve made of non-magnetic conducting materials through a positioning groove, the cage barrier rotor modules are provided with a plurality of radial trapezoidal grooves, each trapezoidal groove is provided with a plurality of different step groove widths in the radial direction, short circuit cage strips are placed into the trapezoidal grooves, the edges of the adjacent cage barrier rotor modules are step-shaped notches, public trapezoidal grooves are formed after the split joint, the gap depth at the bottoms of the grooves reaches the outer surface of the sleeve, and public cage strips are placed into the grooves. The invention aims at providing the novel modularized cage barrier rotor and stator self excitation synchronous motor structure with the advantages that the processing and the manufacture are convenient, and the coupling capability on the two sets of windings of the stator realizes the maximization, so high power density and good steady and dynaic performance are realized.

Owner:张凤阁

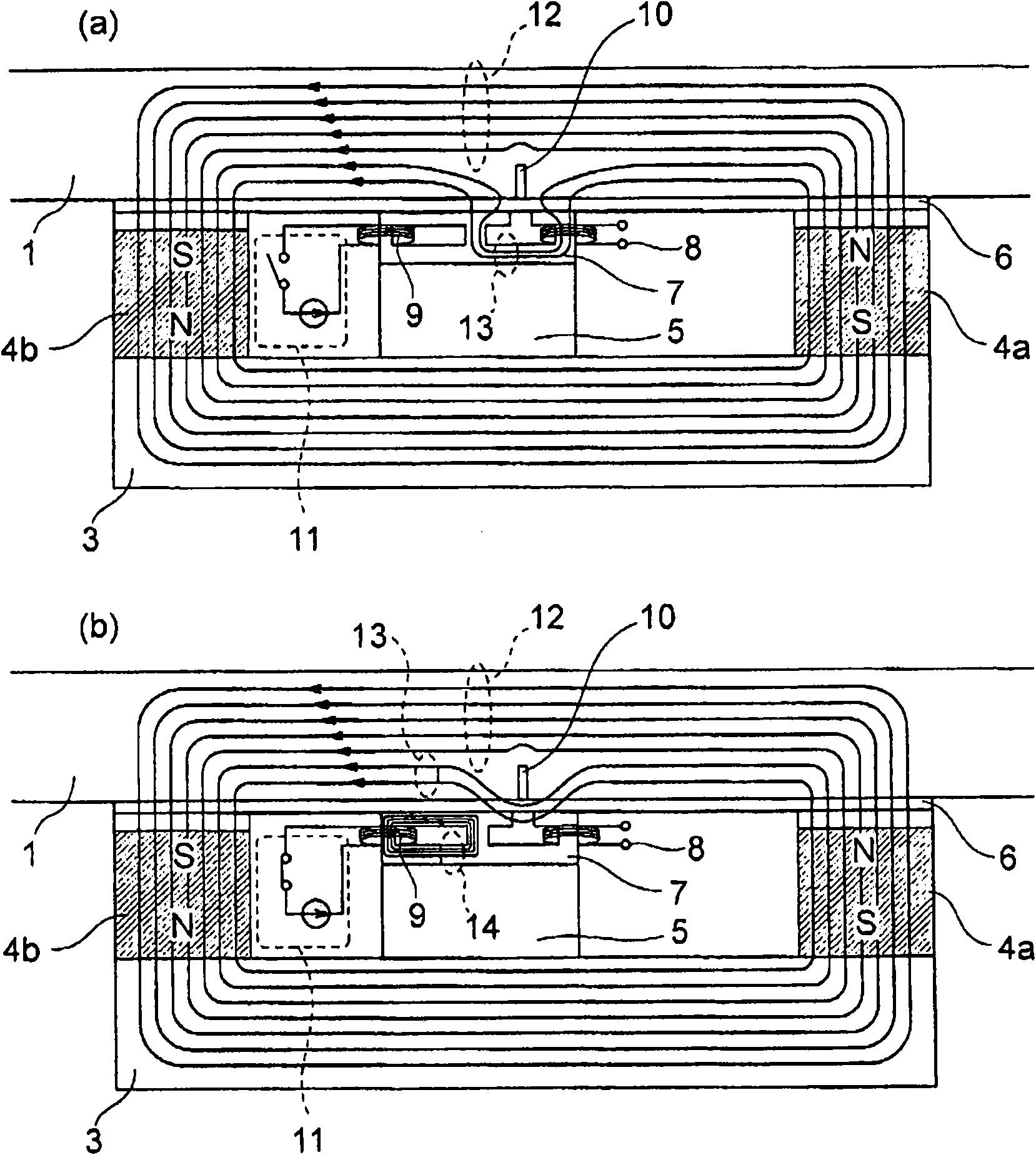

Wire rope flaw detector

ActiveCN101978261ADetect damageAvoid skin effectMaterial magnetic variablesSuperimpositionAmpere-turn

A magnetic flux generated by current excitation is allowed to run over a portion of the magnetic path of a leakage magnetic flux or the entire magnetic path thereof. The amount of the magnetic flux generated by the current excitation is changed in terms of time to change the amount of the leakage magnetic flux crossing a detection coil, an induction voltage is generated in the detection coil, and consequently a flaw can be detected even in the case where there is no relative rate between a wire rope and a wire rope flaw detector. Further, the shape of the magnetic path and the number of ampere turns of the exciting coil are set to be appropriate to prevent the magnetic flux generated by the current excitation from running through the detection coil and make the magnetic flux get balanced out. Thus, noise superimposition to the detection coil generated by current excitation can be prevented.

Owner:MITSUBISHI ELECTRIC CORP

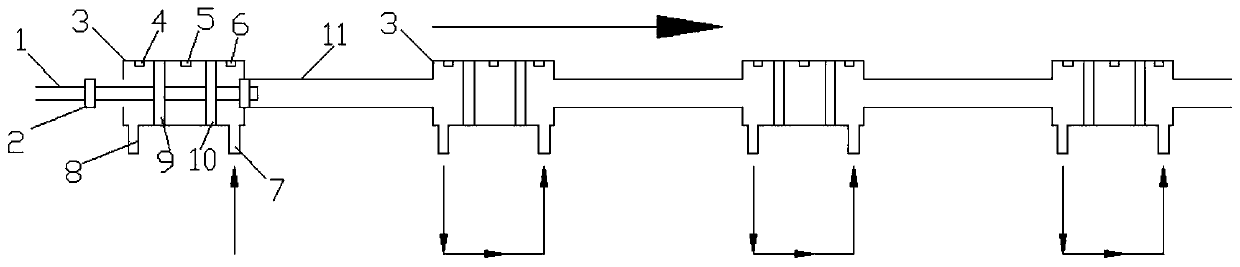

Method of applying electric field energy on molten steel to improve quality of silicon steel billet

The method of applying electric field energy on molten steel to improve quality of silicon steel billet is to introduce electric field energy with the electric field energy generator and the electrodes into molten steel, the electric field energy waveform is duty ratio variable square wave of energy 1000 J-180 MJ, voltage 100-1800V, current 100A-8KA, frequency not higher than 25 Hz and duty ratio of 5-90 %. The electric field energy generator is suitable for use in industrial production and controllable in electric field energy parameters. The treated molten steel results in refined billet structure with obviously increased global crystal, less defaults and high quality.

Owner:ANGANG STEEL CO LTD

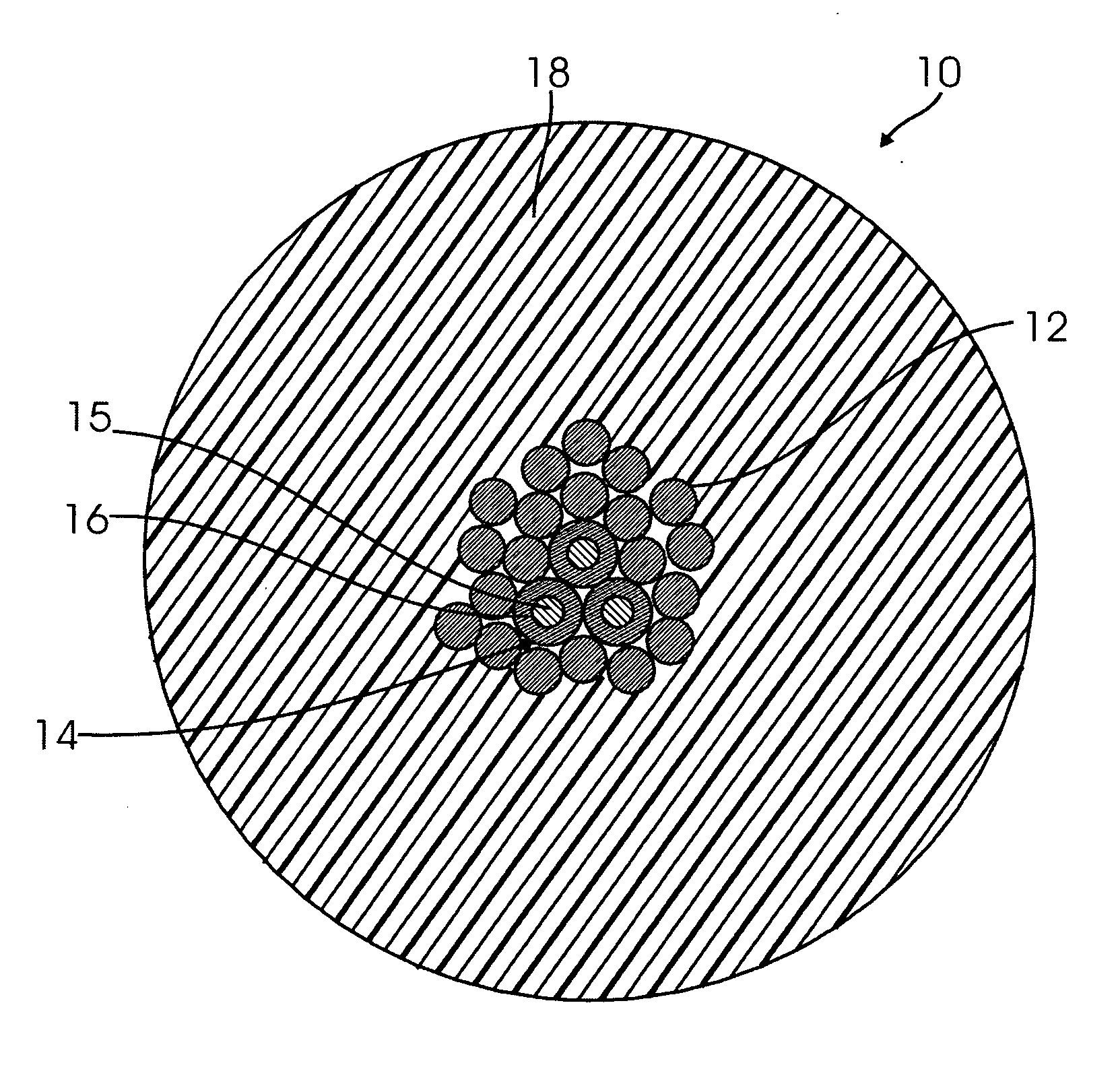

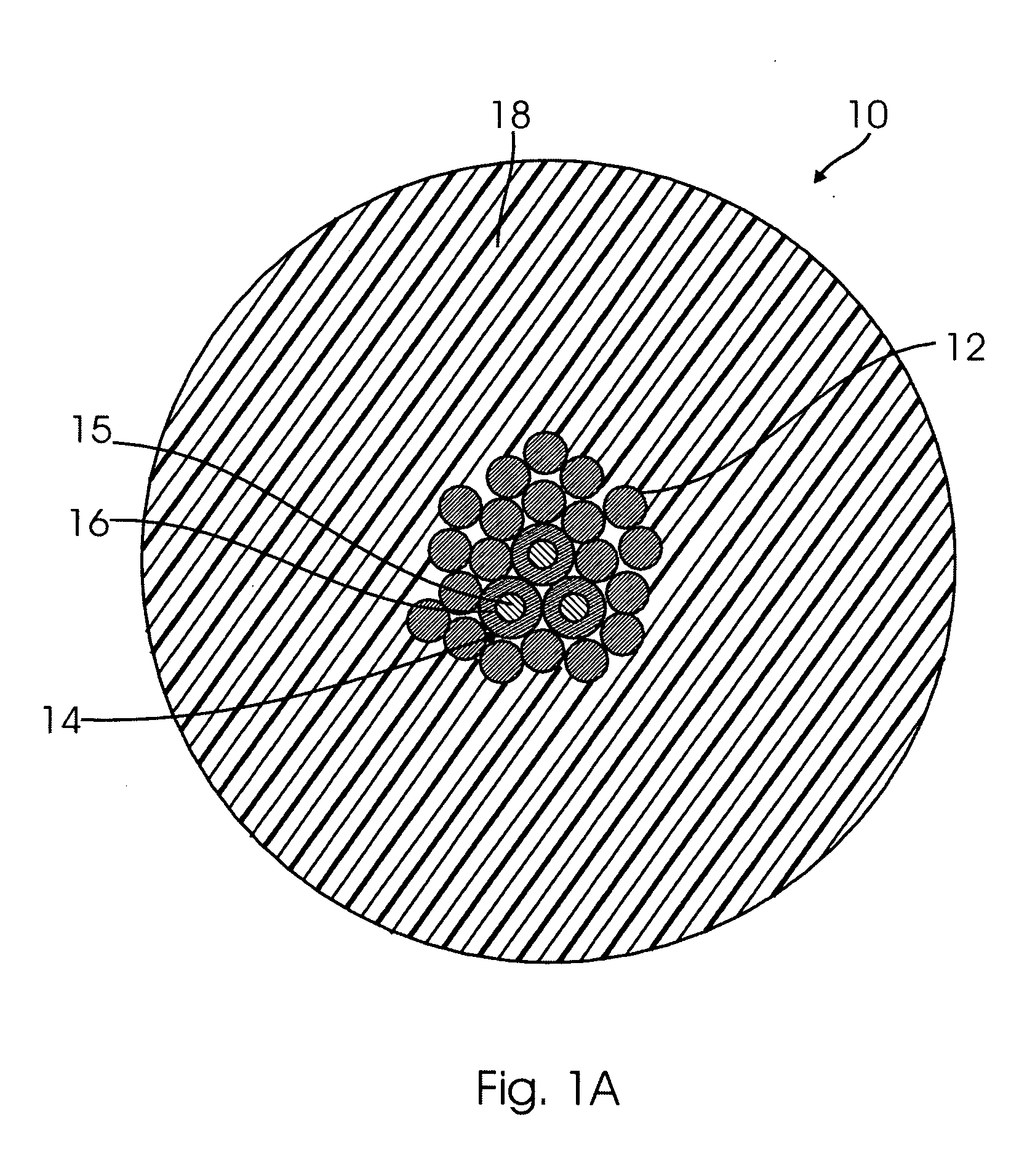

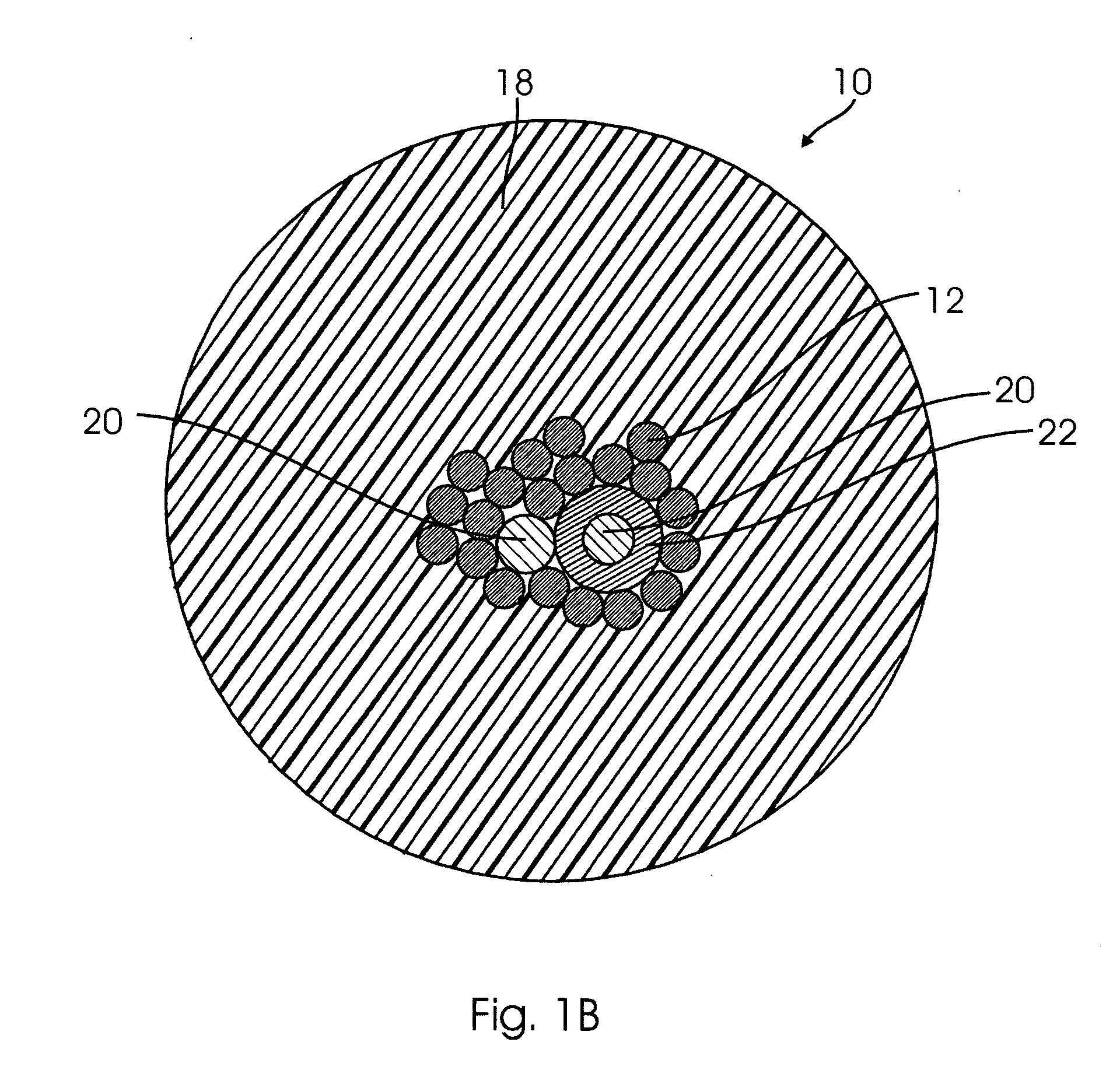

Audio signal cable

InactiveUS20060185886A1Good flexibilityImprove signal qualityInsulated cablesInsulated conductorsElectrical conductorEngineering

An audio signal cable consisting of various combinations of two or more distinct types of conductors. The cable contains at least two conductors of different types. The individual conductors within the cable may be individually insulated or uninsulated. The individual conductors may also be of varying shapes and sizes. The conductors are surrounded by a common insulation. Combining at least two types of different conductors within the cable provides the cable with a versatility to be adaptable to a wide variety of sound applications.

Owner:VICTOR JAY

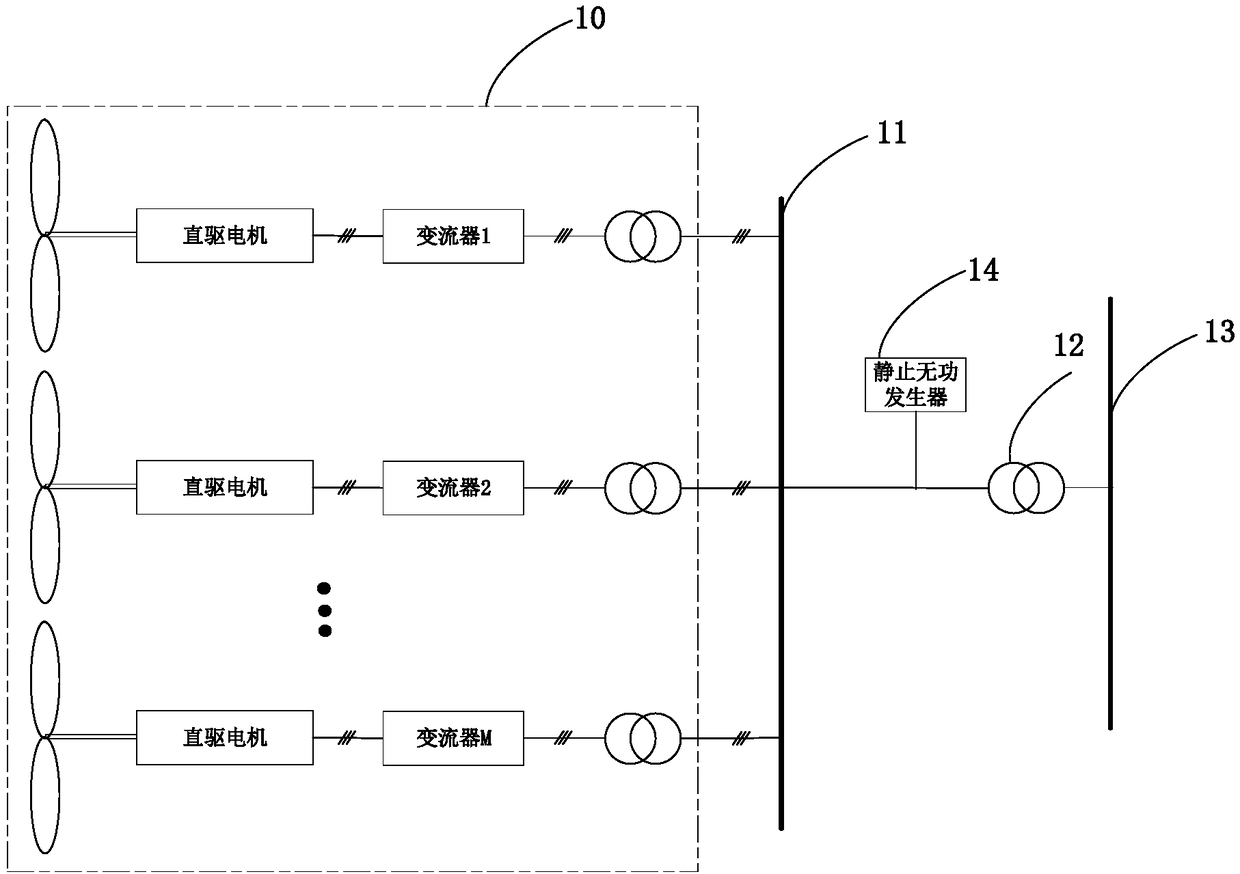

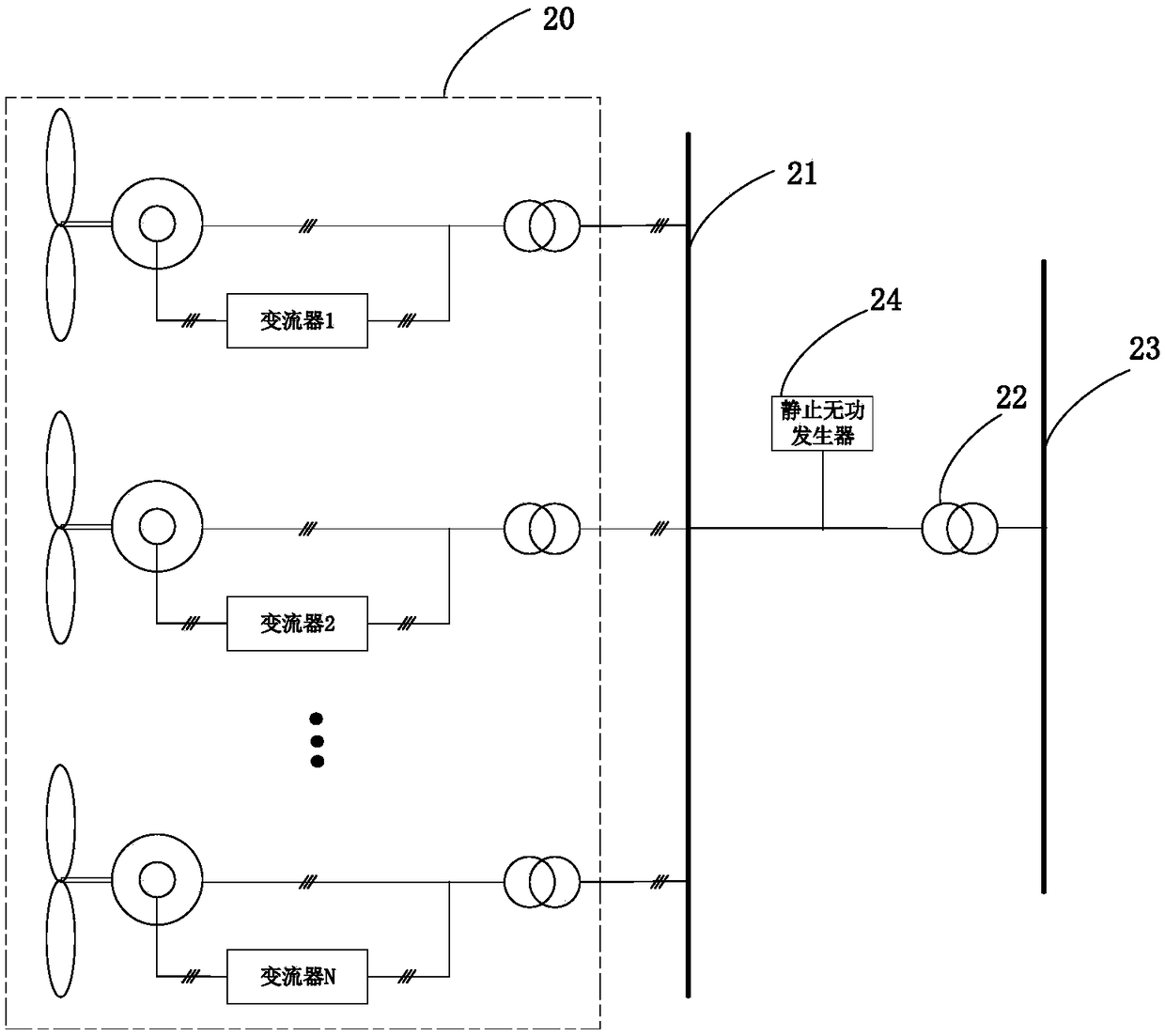

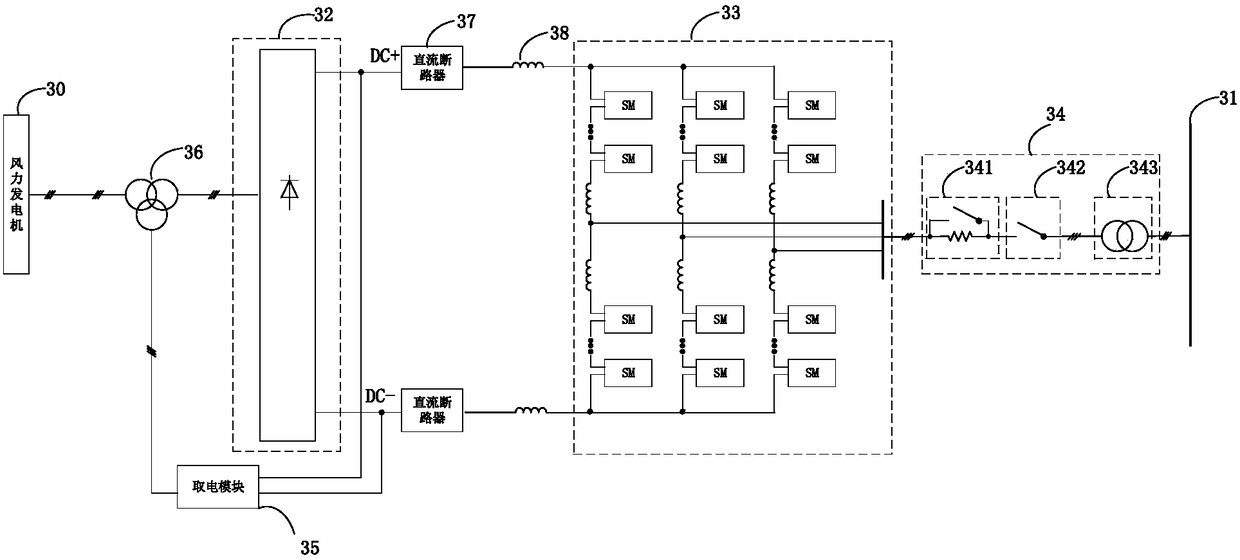

Power transmission system, wind power generator set and wind power plant

PendingCN108512243ALow costReduce lossElectric power transfer ac networkSingle network parallel feeding arrangementsElectric power transmissionTransmitted power

The invention discloses a power transmission system, a wind power generator set and a wind power plant, which are used for transmitting power in a direct current form, reducing construction cost of apower transmission line and line loss during the power transmission process, improving line utilization ratio, extending power transmission distance and simultaneously preventing a skin effect in theline. The power transmission system is used for transmitting electric energy generated by the wind power generator set to a power grid and comprises a machine-side rectification module, grid-side inversion module, a grid-connected module and a power taking module, wherein the machine side rectification module is used for connecting the wind power generator set, the machine-side rectification module, the grid-side inversion module and the grid-connected module are sequentially connected, the grid-connected module is used for connecting the power grid, an input end of the power taking module isconnected with the grid side inversion module, and an output end of the power taking module is used for connecting the wind power generator set.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

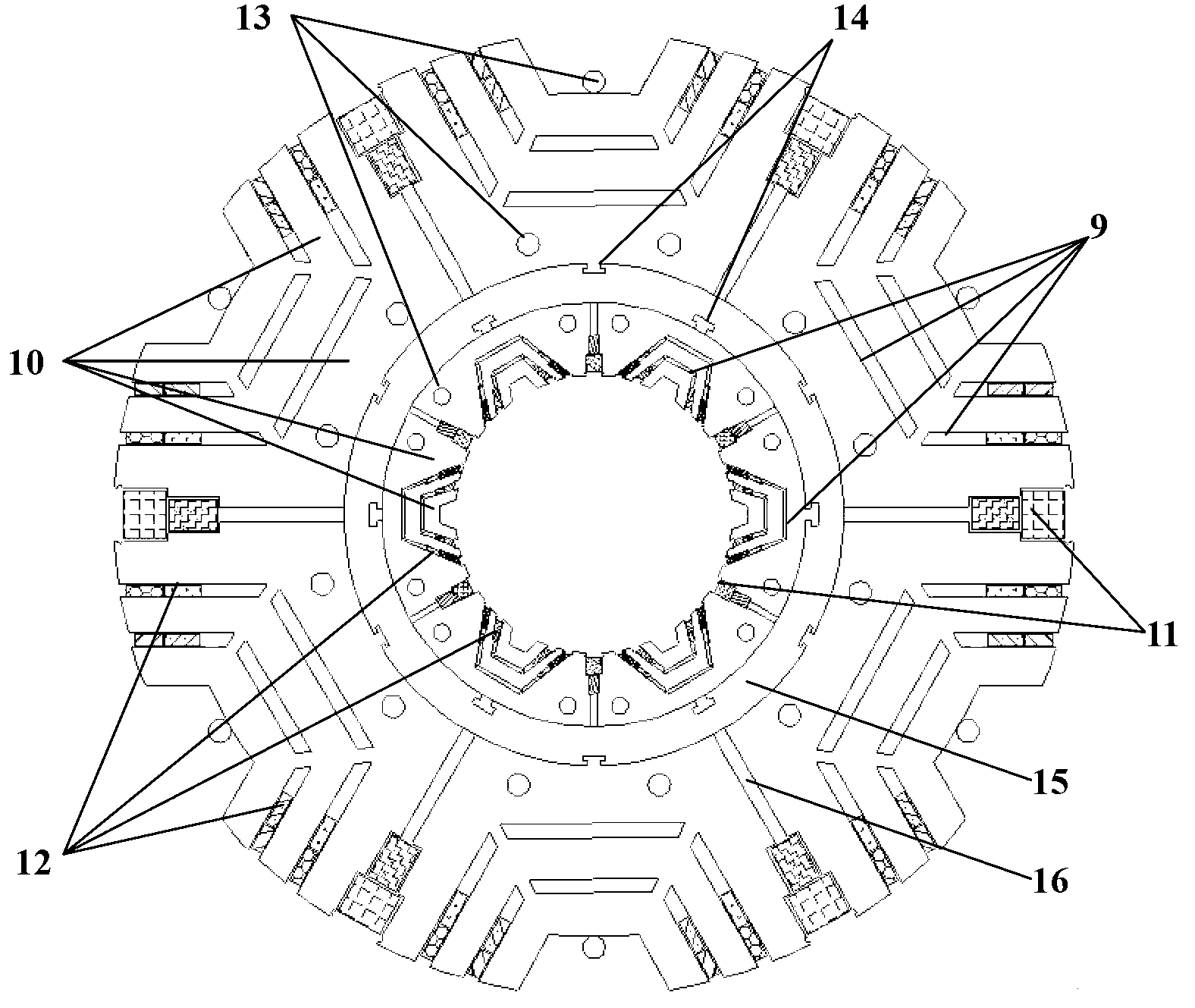

Stator double-winding alternating-current motor with double cage barrier rotors and control method thereof

ActiveCN103166396AStrong coupling abilityHigh electromechanical energy conversion efficiencyElectronic commutation motor controlSynchronous generatorsElectric machineThree-phase

The invention relates to a stator double-winding alternating-current motor with double cage barrier rotors. The stator double-winding alternating-current motor is characterized in that an inner rotor and an outer rotor of the motor are positioned on inner and outer sides of a stator respectively; three-phase symmetry power windings and three-phase symmetry control windings are arranged on the inner and outer sides of the stator; the inner rotor and the outer rotor are spliced along the peripheral direction by using the same cage barrier rotor modules to form a rotor with a salient pole; each cage barrier rotor module is connected with a sleeve by positioning grooves and is provided with a plurality of radial trapezoid grooves; short-circuit cage bars are put into the grooves; a stepped breach is formed in the joint of the adjacent cage barrier rotor modules; and after the adjacent modules are spliced, a public trapezoid groove is formed in the joint of the adjacent modules, a gap at the bottom of the groove reaches the surface of the sleeve, and public cage bars are put into the grooves. The invention aims to provide the stator double-winding alternating-current motor which is convenient to manufacture, can maximize the coupling capacity of the power windings and the control windings on two sides of the stator, is high in power density and dynamic property and is provided with the double cage barrier rotors.

Owner:SHENYANG POLYTECHNIC UNIV

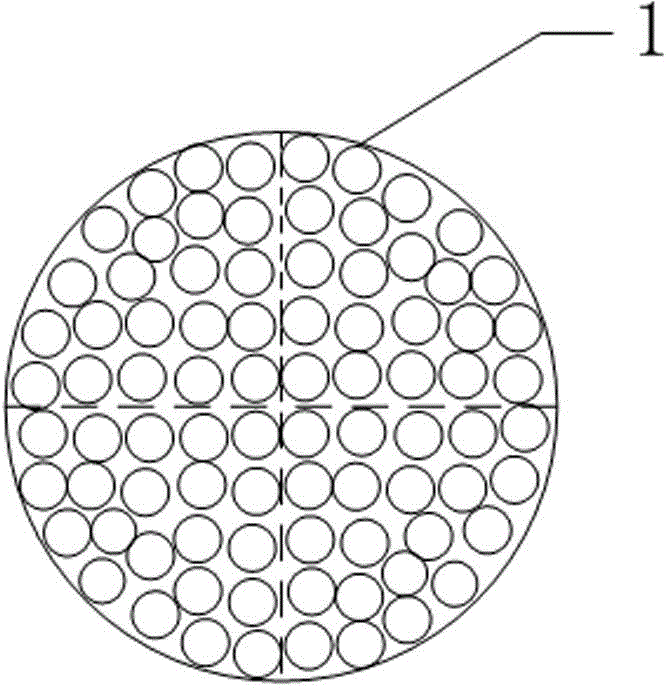

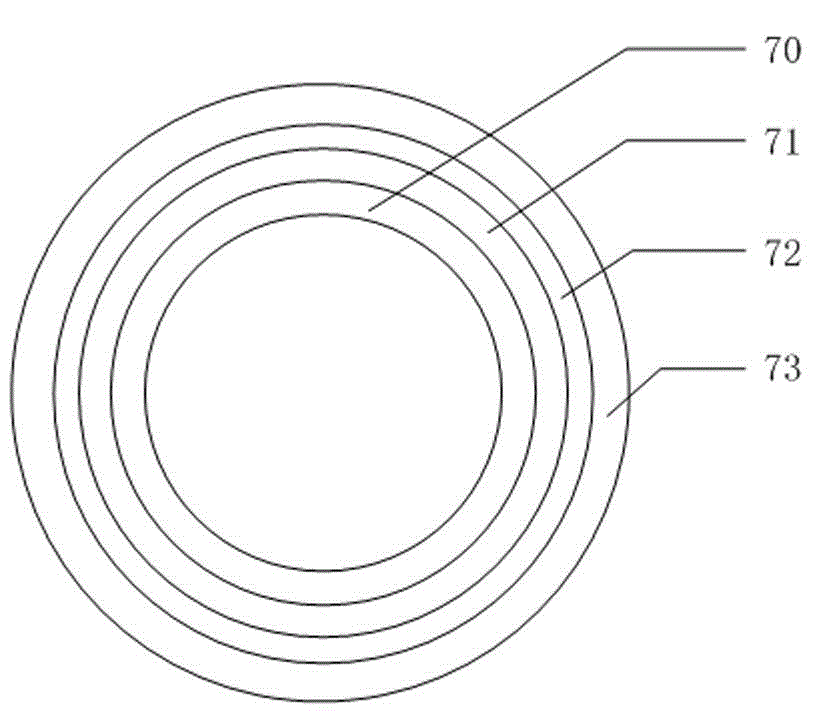

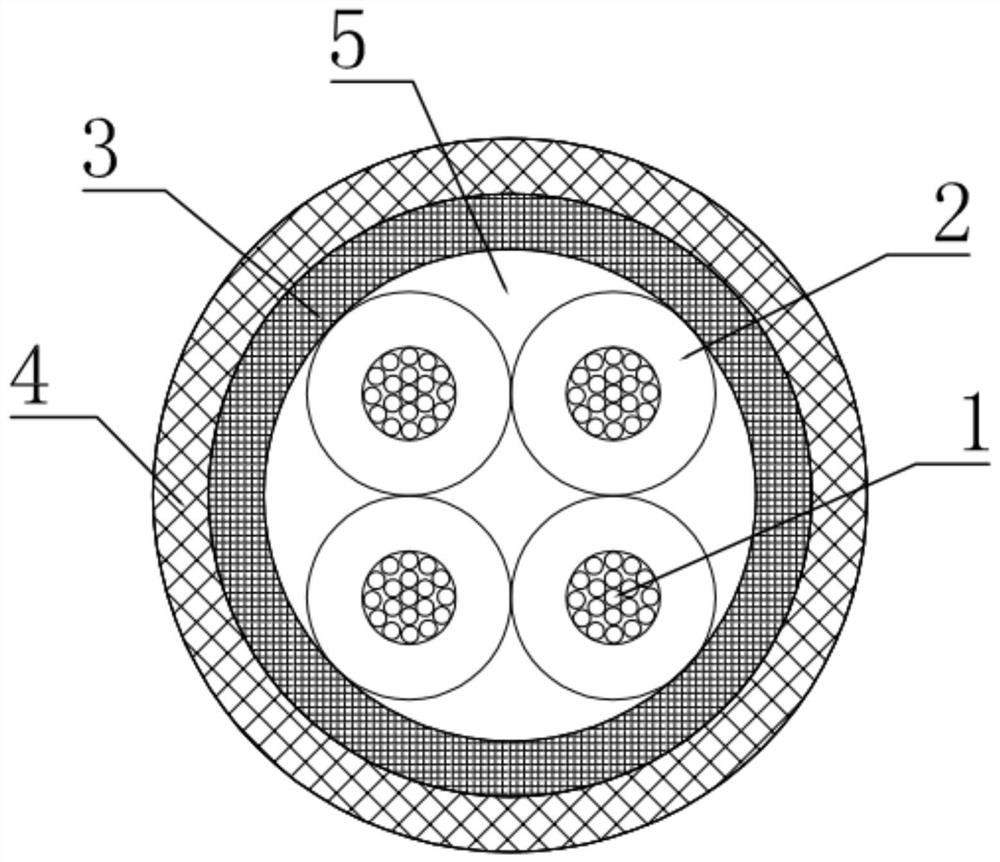

Power cable

ActiveCN104157362AImprove corrosion resistanceImprove flame retardant performancePower cables with screens/conductive layersInsulated cablesPower cableElectrical conductor

A power cable comprises a conductor, a low-smoke halogen-free flame wrapper layer, a conductor shielding layer, an insulating layer, an insulating shielding layer, a butyronitrile flame retardant inner protection sleeve layer, a shielding layer, a corrugated steel protection sleeve and an outer protection sleeve from inside to outside. The cross section of the conductor is round or is a round which is formed by combining multiple sector-shaped conductors. The conductor shielding layer comprises a semi-conduction nylon strip and a conductor shielding material layer, wherein the thickness of the semi-conduction nylon strip is 0.22 mm-0.26 mm, and the thickness of the conductor shielding material layer is 1.3 mm-1.7 mm. The thickness of the insulating layer is 12.0 mm-16.0 mm, and the thickness of the insulating shielding layer is 0.8 mm-1.2 mm. The shielding layer comprises a semiconductor water-blocking strip of which the thickness is 0.8 mm-1.0 mm, a copper wire shield of which the thickness is 2.0 mm-2.4 mm, a sparsely-wound copper strip of which the thickness is 0.1 mm-0.14 mm and a semi-conduction buffering water-blocking strip of which the thickness is 2.5 mm-3.0 mm.

Owner:GUANGZHOU NANYANG CABLE

Modular single-cage barrier rotor double-stator self-excitation synchronous motor and control method thereof

ActiveCN103166399AStrong coupling abilityImprove power densityElectronic commutation motor controlSynchronous generatorsSynchronous motorComputer module

The invention relates to a modular single-cage barrier rotor double-stator self-excitation synchronous motor. The motor is characterized in that an inner stator and an outer stator are arranged inside and outside a rotor; a three-phase symmetry armature winding and a single-phase symmetry exciting winding are arranged in slots of each stator, which are near the rotor; cage barrier rotor modules and a sleeve are combined through positioning slots to form a rotor of which inner and outer sides have salient pole types on each of the inner and outer surfaces of the rotor; a plurality of radial trapezoid-shaped slots are formed on the surface of the side of each cage barrier rotor module, which is near the stators and have multiple different step slot widths, and short circuit cage bars are arranged in the slots; a step-shaped opening is formed on a connection part of the adjacent cage barrier rotor modules; after the modules are spliced, common trapezoid-shaped slots are formed on connection parts of the spliced modules, gaps of bottoms of the slots reach the surface of the sleeve, and common cage bars are arranged in the slots; and the invention aims to provide the novel modular single-cage barrier rotor double-stator self-excitation synchronous motor which is convenient to process and manufacture, can realize stator-side self excitation, and has high reliability, and the excellent steady state and dynamic performance.

Owner:SHENYANG POLYTECHNIC UNIV

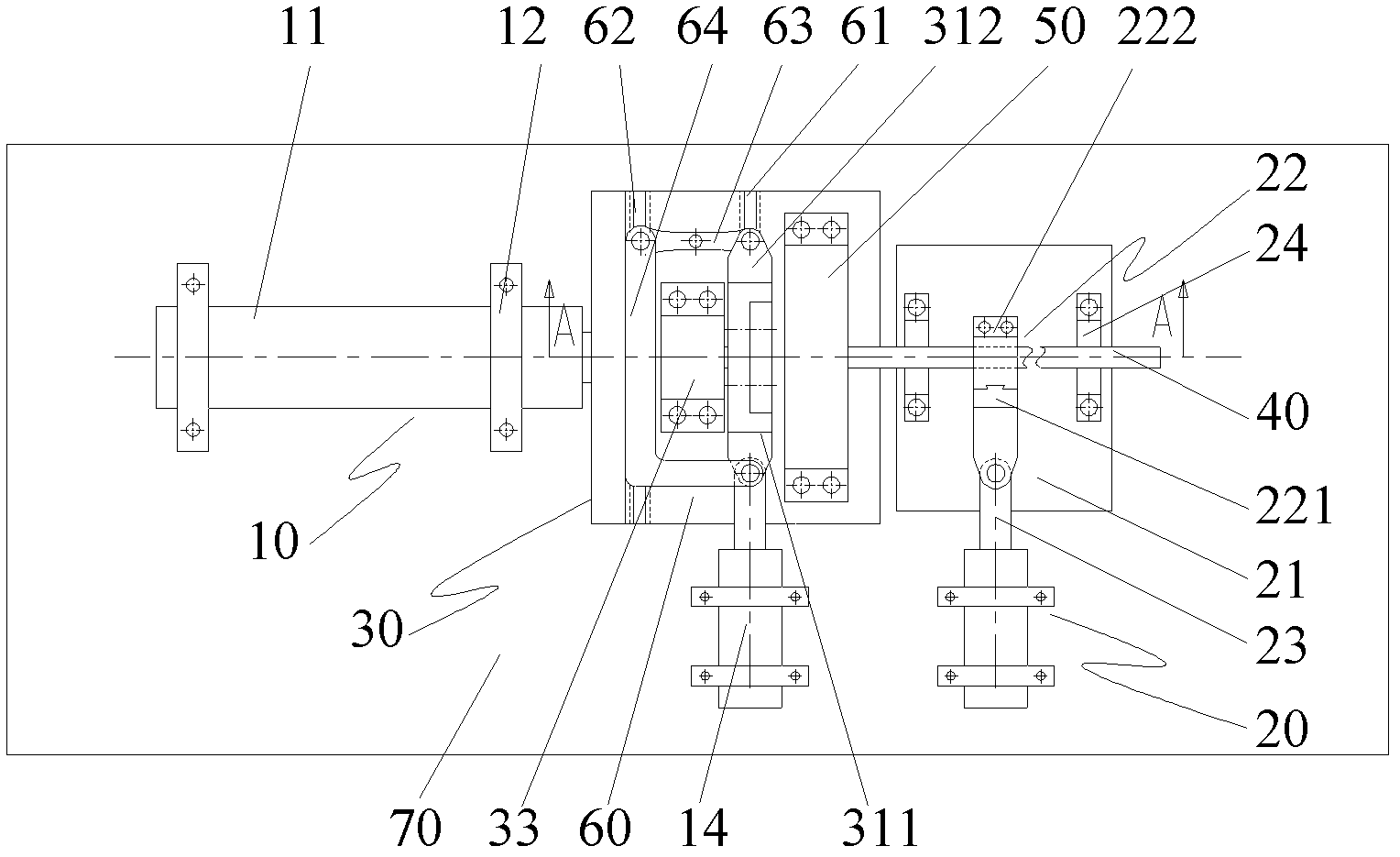

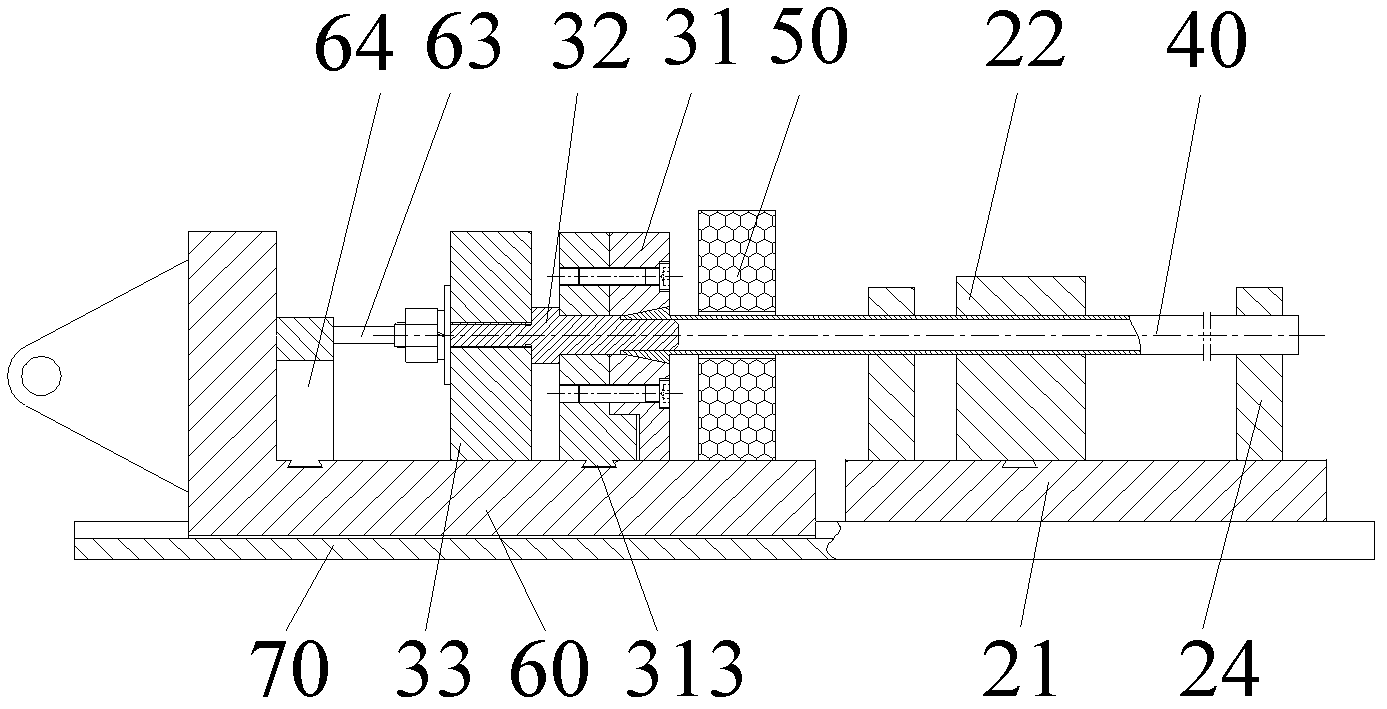

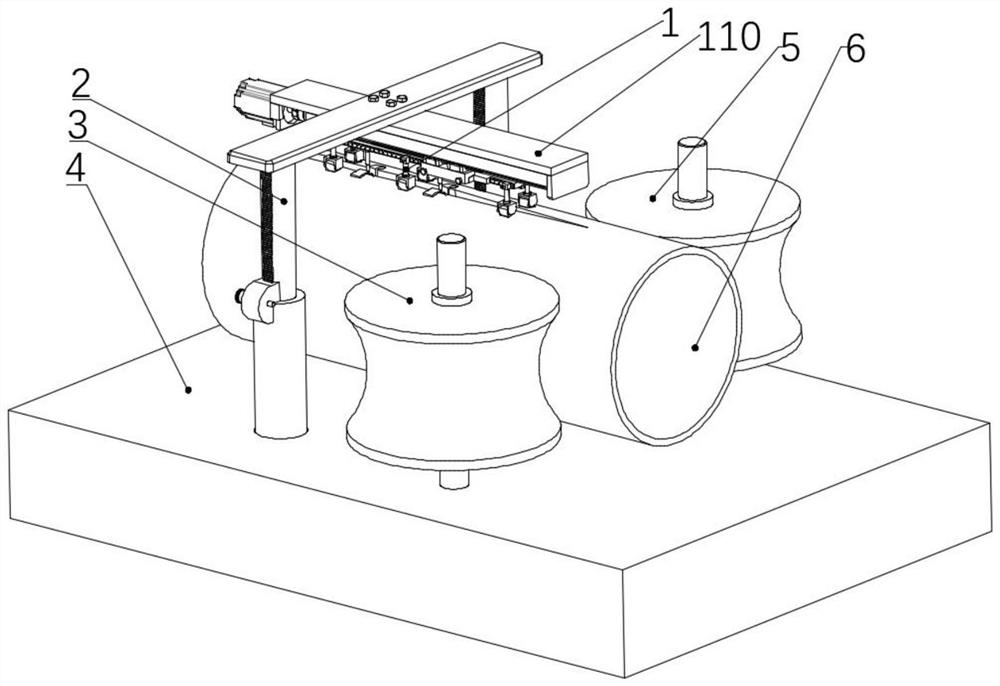

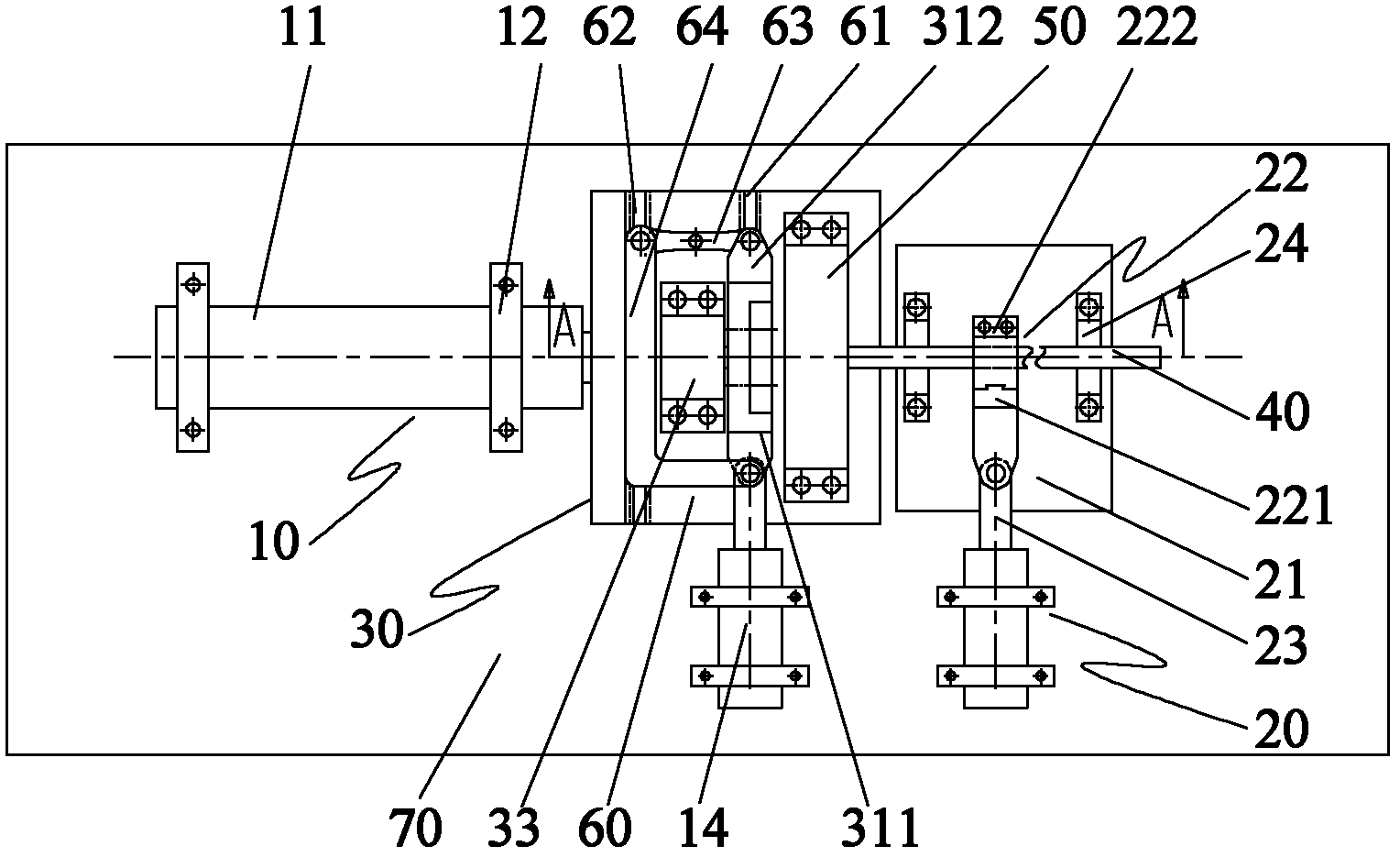

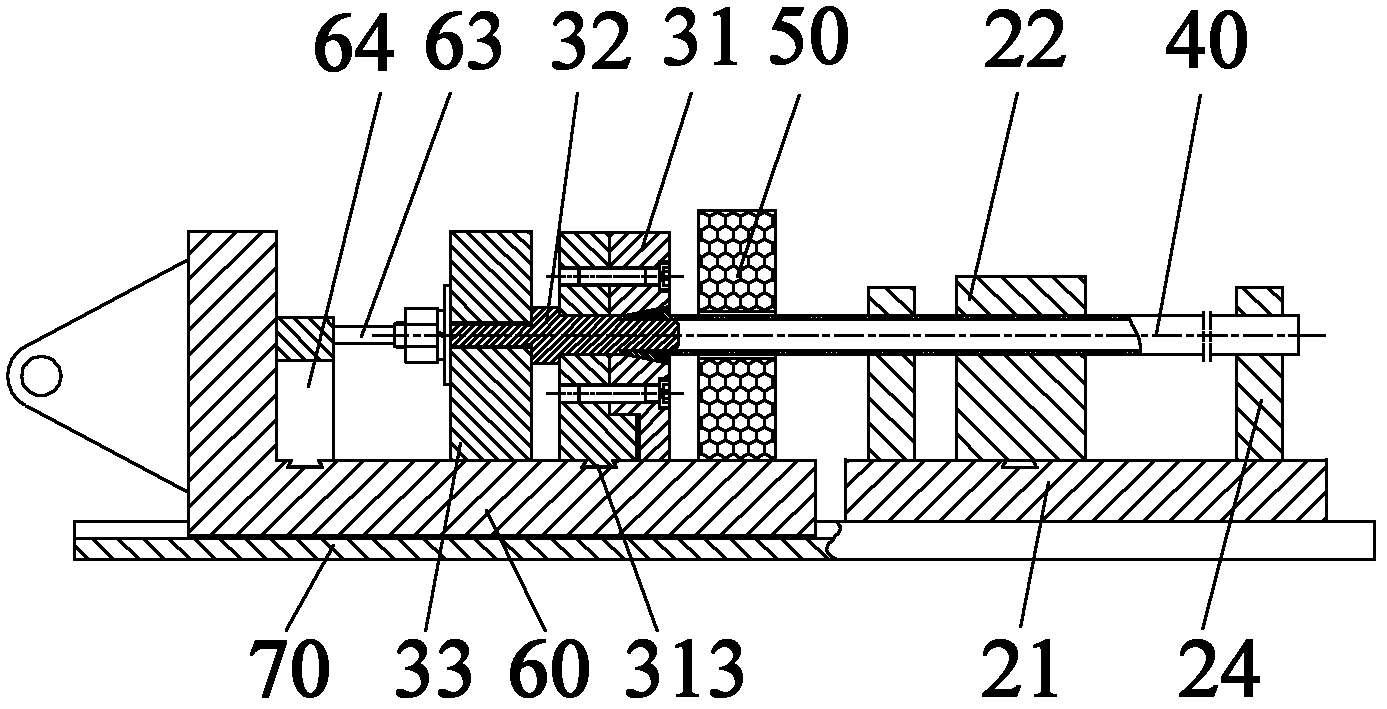

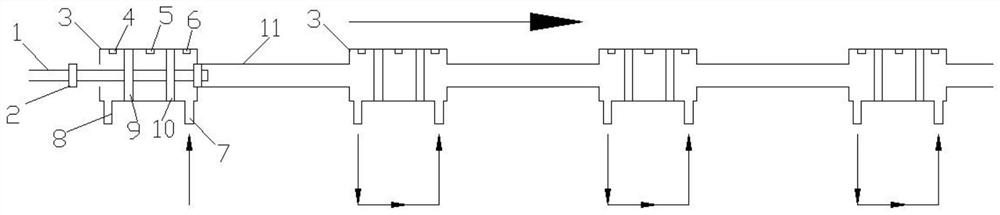

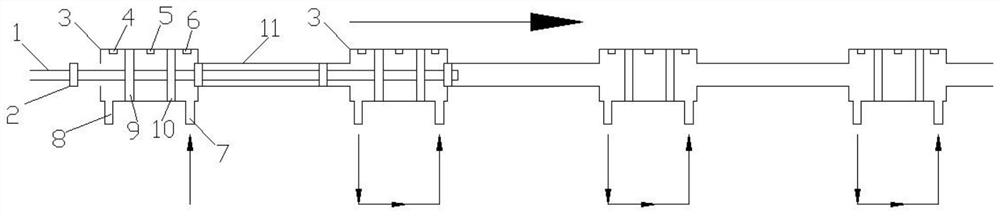

Hard tube end forming equipment and forming method

The invention provides hard tube end forming equipment and a forming method. The hard tube end forming equipment comprises a feeding portion (10), a clamping portion (20) and an extrusion forming portion (30), wherein the clamping portion (20) is used for fixing a hard tube (40) to be formed, and the extrusion forming portion (30) is used for forming a tube end structure of the hard tube (40) to be formed. The hard tube end forming equipment is characterized in that a heating portion (50) is further arranged between the clamping portion (20) and the extrusion forming portion (30). The hard tube end forming equipment is stable in structure, high in reliability, low in cost, high in production efficiency, high in positioning precision and fine in forming quality.

Owner:ZOOMLION HEAVY IND CO LTD

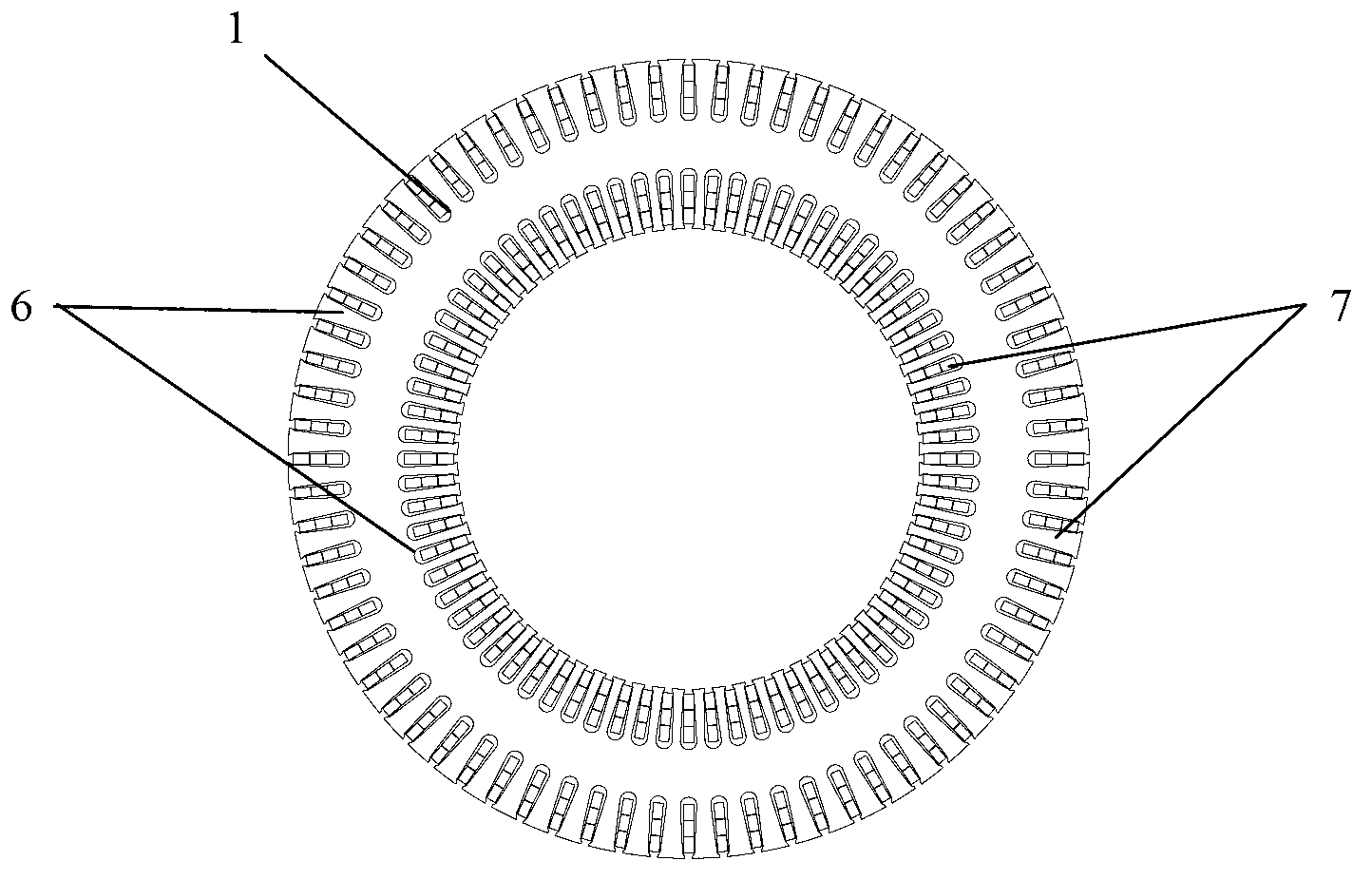

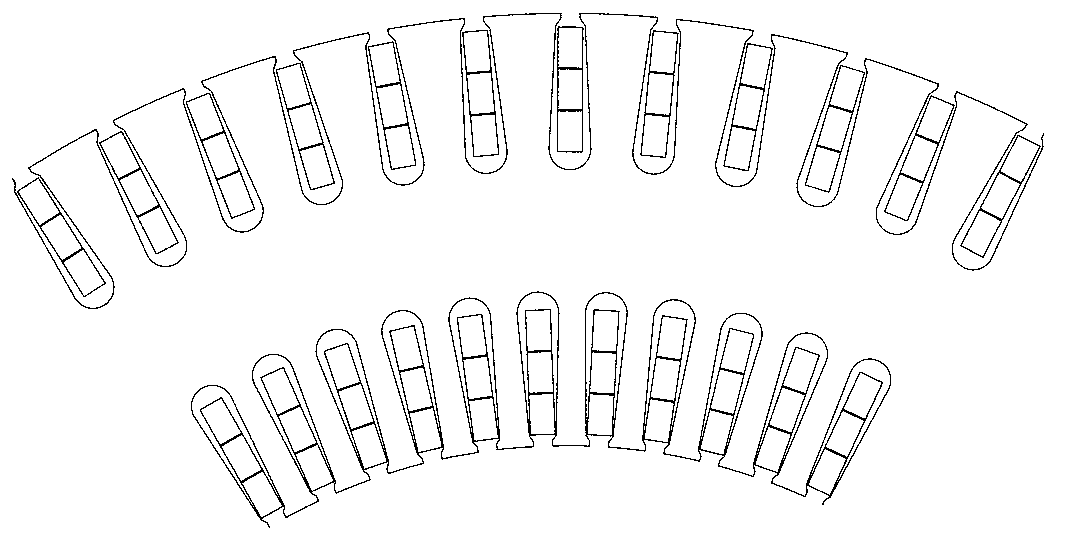

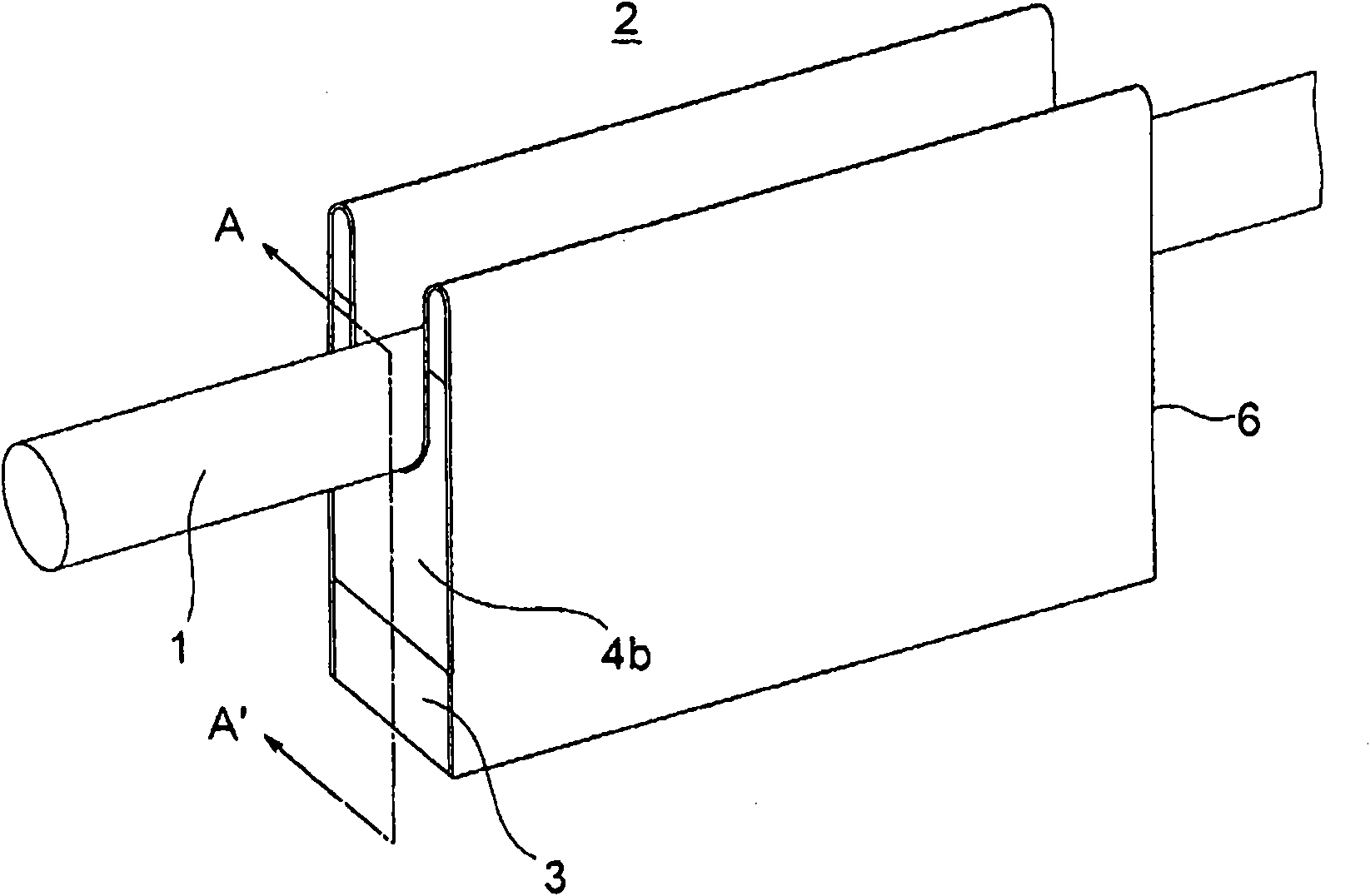

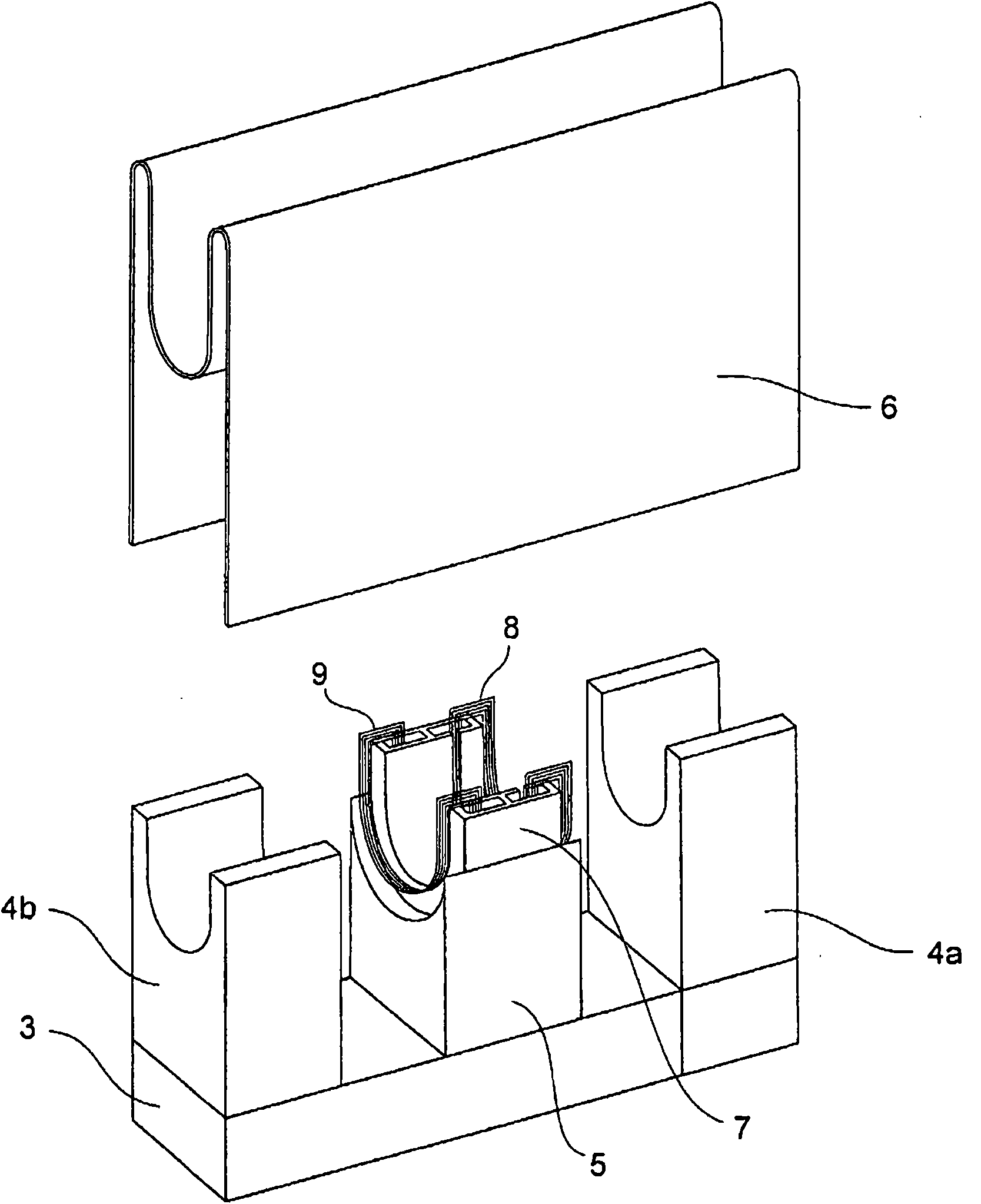

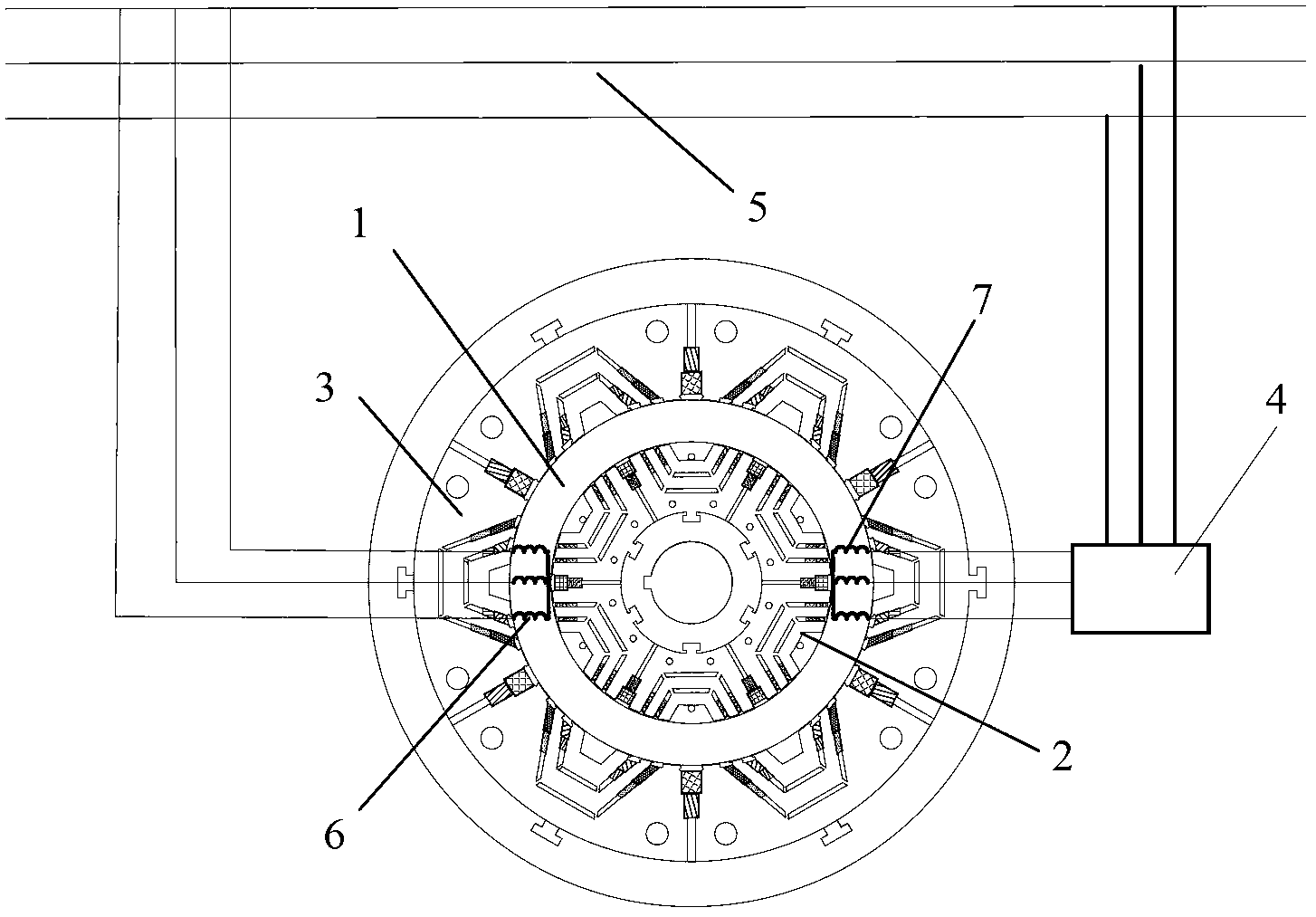

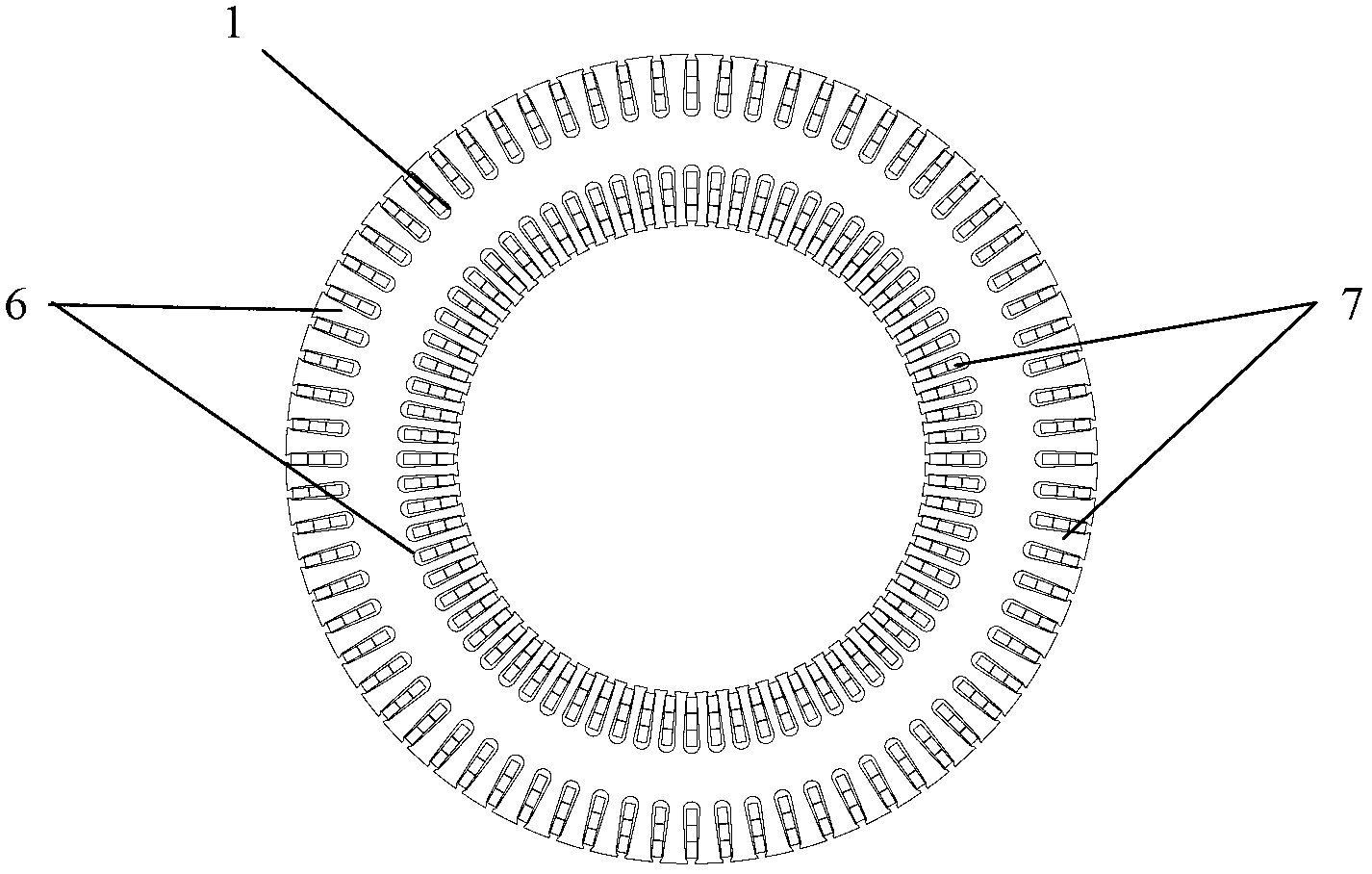

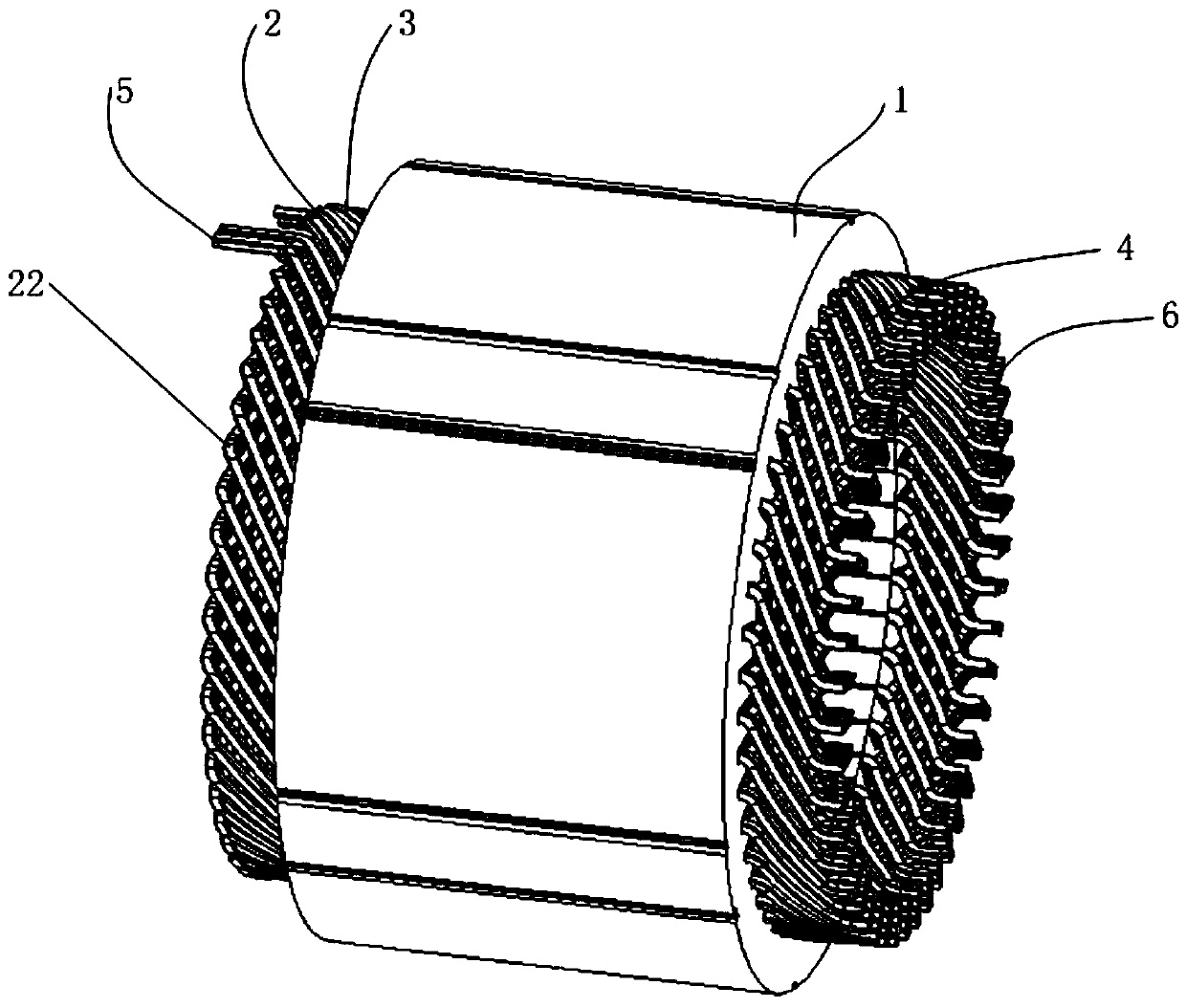

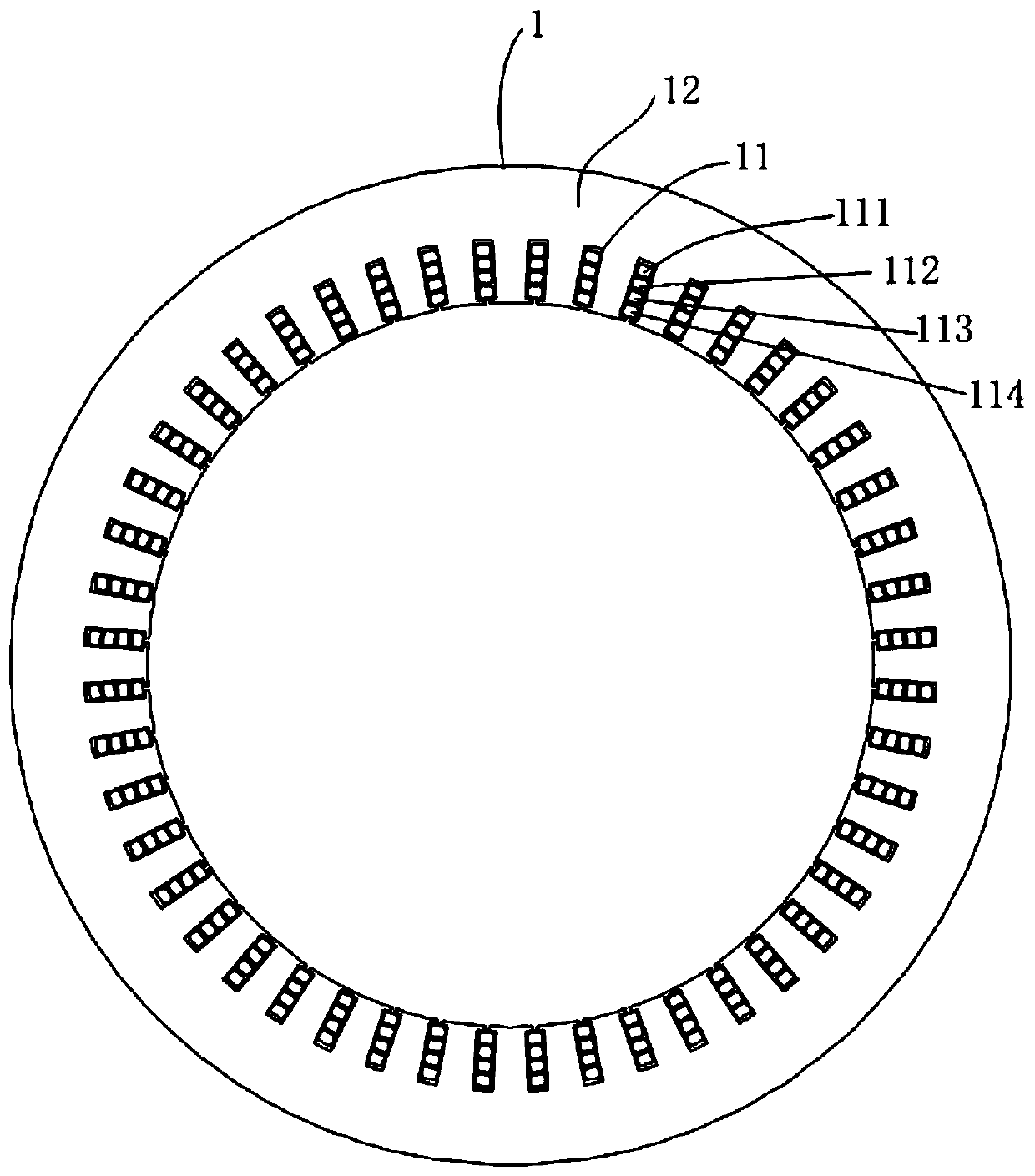

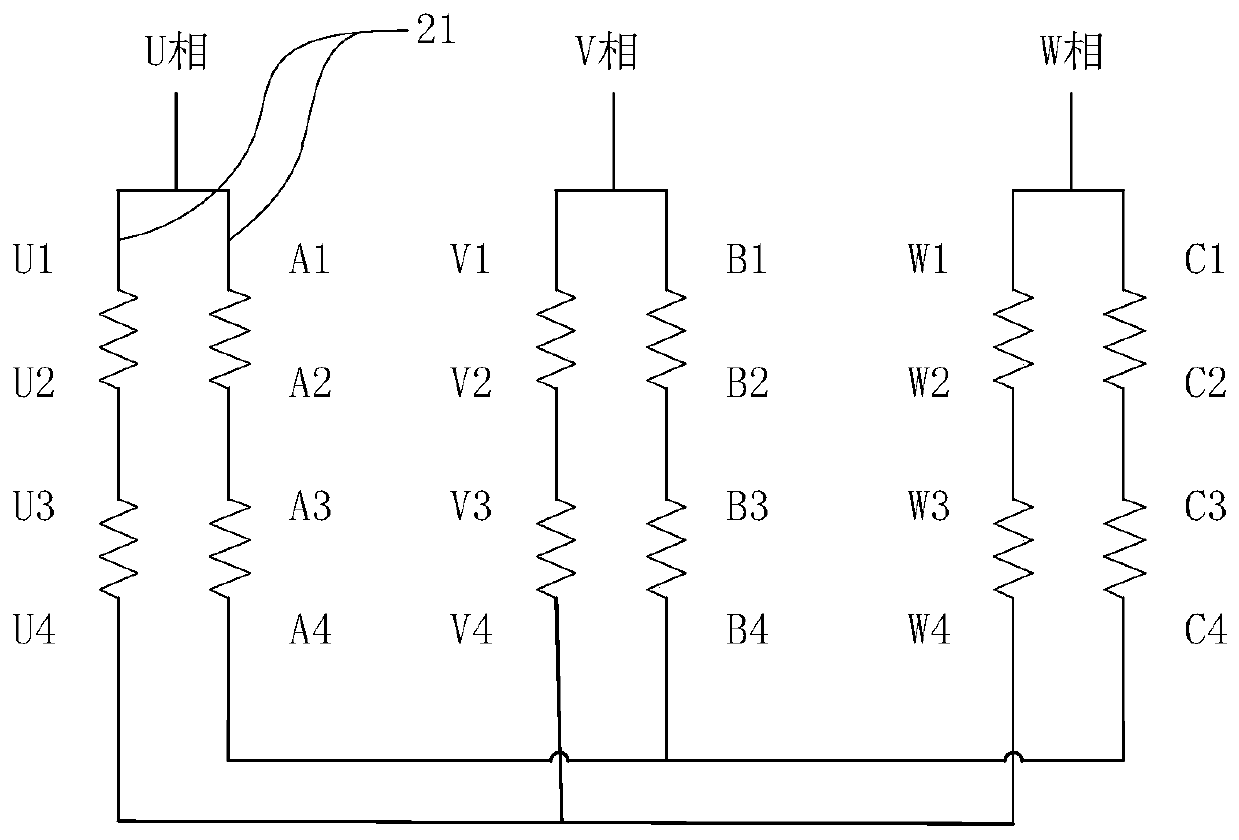

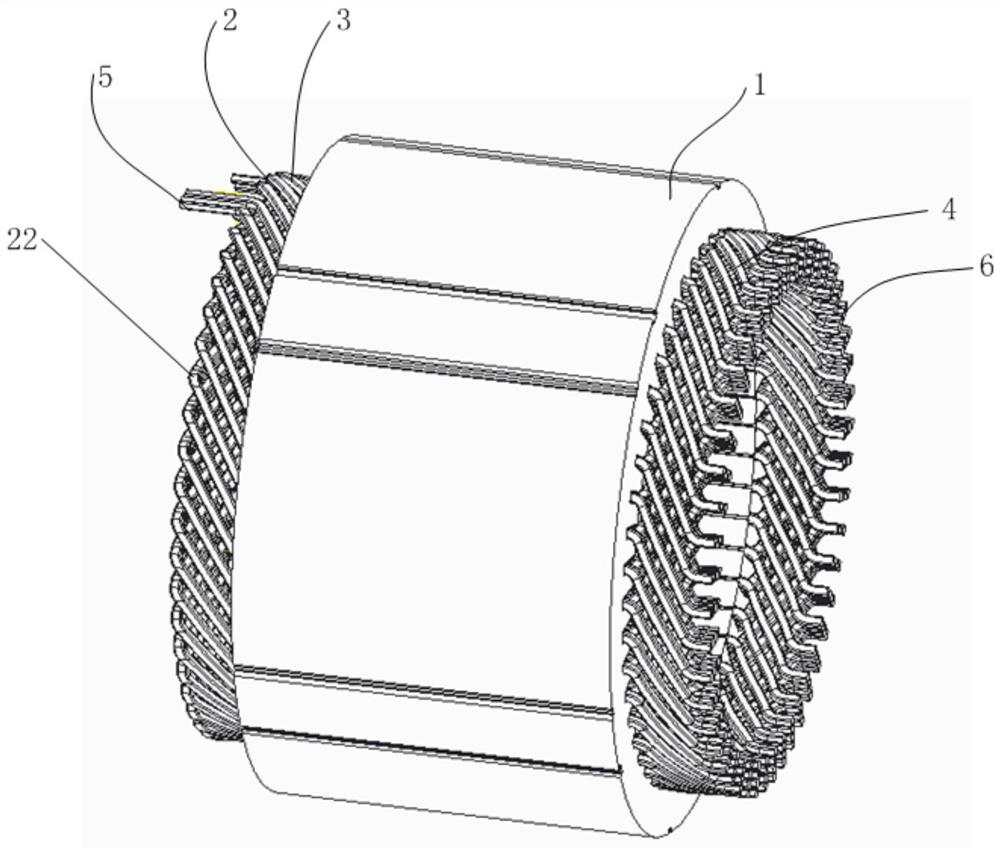

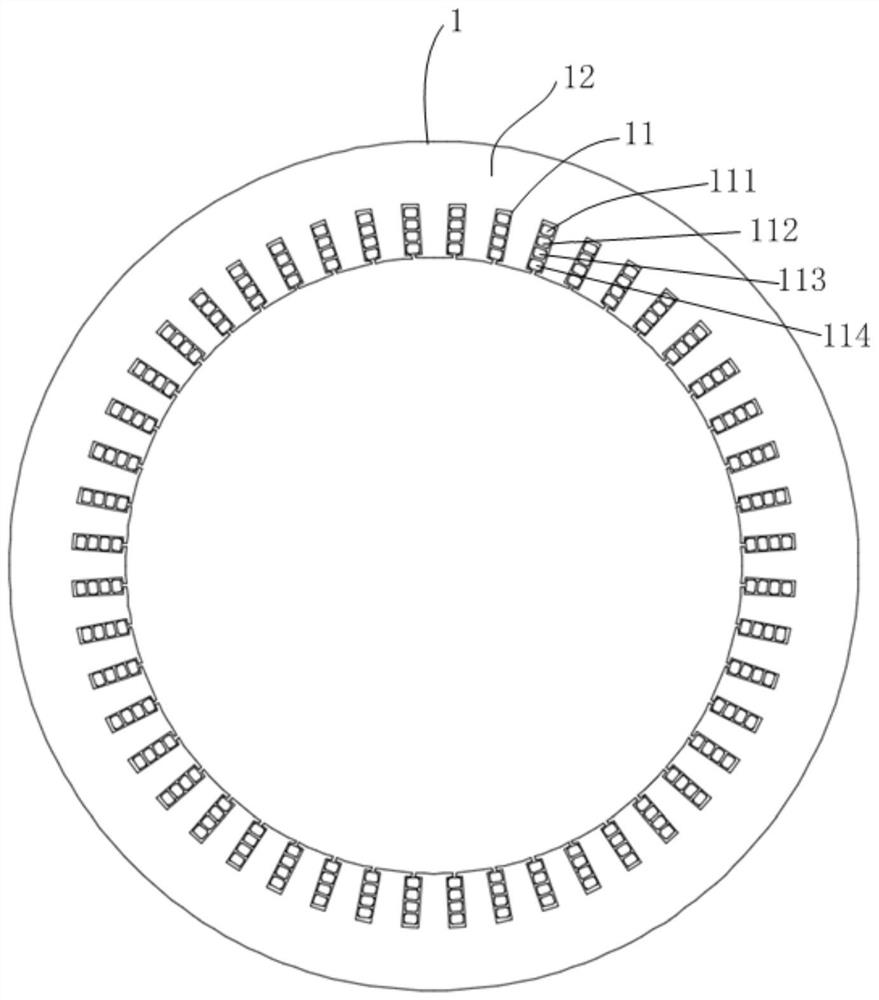

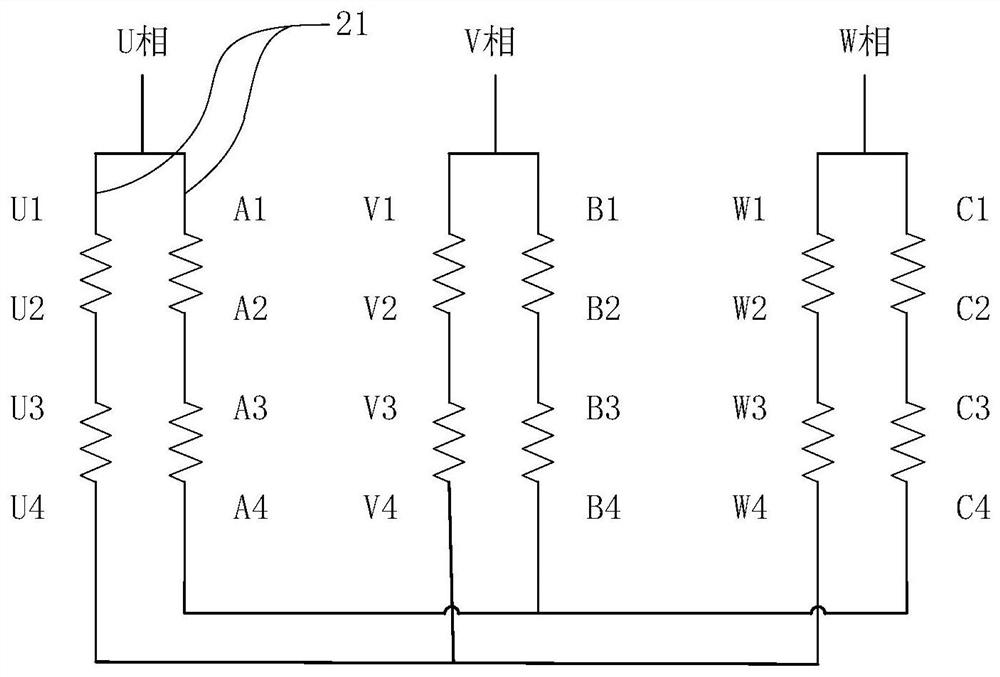

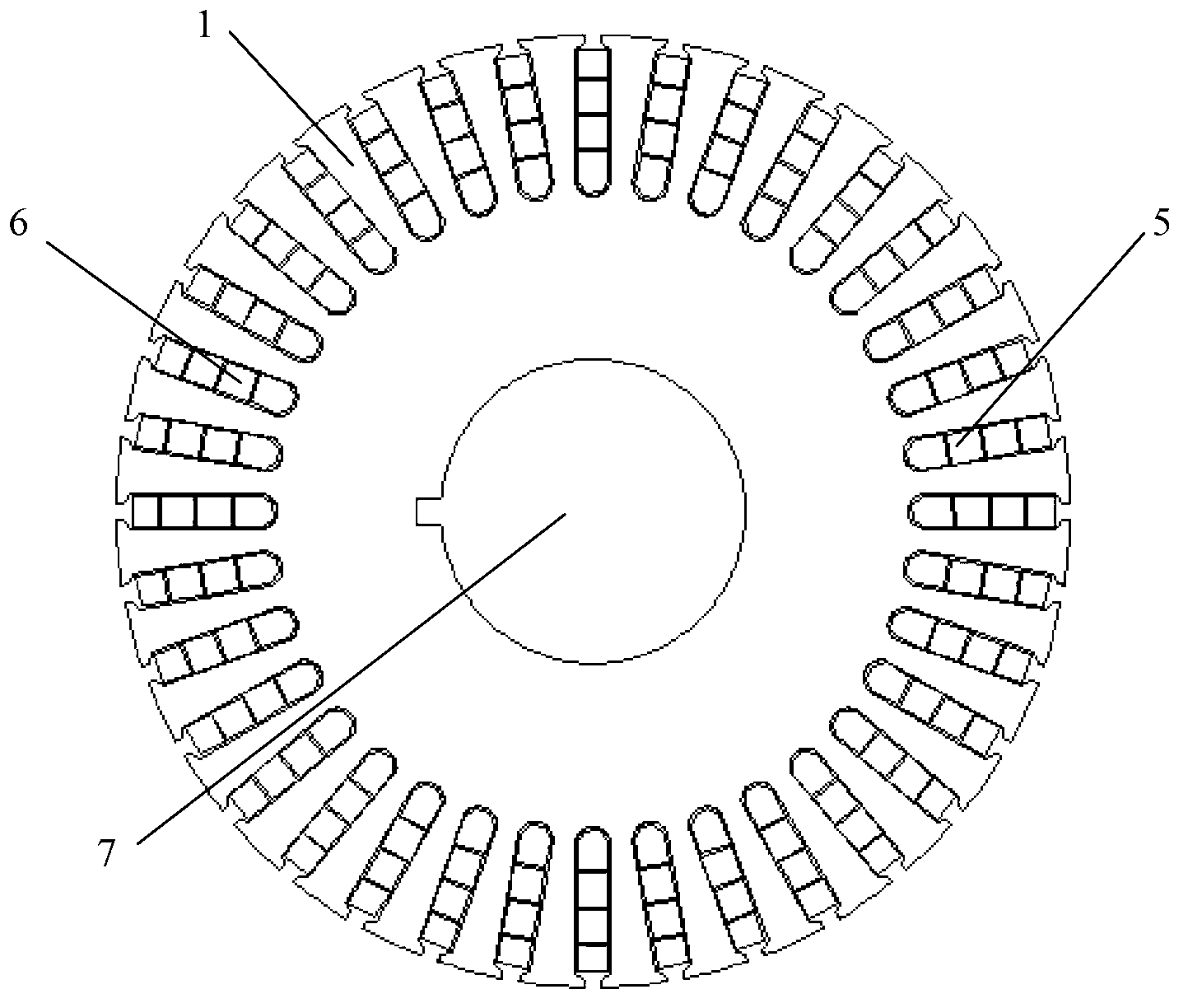

Pin winding type motor stator and motor

ActiveCN111146892AAvoid skin effectImprove work efficiencyMagnetic circuit stationary partsWindings conductor shape/form/constructionElectrical resistance and conductanceElectrical conductor

The invention relates to the technical field of motors, and discloses a pin winding type motor stator and a motor. The pin winding type motor stator comprises a stator iron core, wherein the stator iron core comprises multiple layers of stator grooves and a stator yoke part; pin windings are wound in the stator grooves, each pin winding is provided with three phases, each phase of pin winding comprises two winding units which are connected in parallel, each winding unit is formed by connecting in series in a forward wave winding mode and a reverse wave winding mode, and each winding unit penetrates through the multiple layers of stator grooves. The pin windings of the pin winding type motor stator provided by the invention adopt forward and reverse wave winding modes; a certain phase difference is formed by conductor current distribution in the stator grooves, the skin effect of the motor during high-speed operation is effectively inhibited, the winding connection arrangement is optimized, the half-turn length of all coils in the windings is shortened, the sectional area of a busbar is increased, the alternating current resistance and loss of the winding are obviously reduced, andthe working efficiency of the motor is improved. Compared with the alternating current loss without the phase difference, the winding scheme with the phase difference reduces the alternating current loss by 30W.

Owner:CHINA FIRST AUTOMOBILE

Stator and motor of pin winding type motor

ActiveCN111146892BAvoid skin effectImprove work efficiencyMagnetic circuit stationary partsWindings conductor shape/form/constructionElectrical resistance and conductanceElectrical conductor

The invention relates to the technical field of motors, and discloses a pin winding type motor stator and a motor. The pin winding type motor stator comprises a stator iron core, wherein the stator iron core comprises multiple layers of stator grooves and a stator yoke part; pin windings are wound in the stator grooves, each pin winding is provided with three phases, each phase of pin winding comprises two winding units which are connected in parallel, each winding unit is formed by connecting in series in a forward wave winding mode and a reverse wave winding mode, and each winding unit penetrates through the multiple layers of stator grooves. The pin windings of the pin winding type motor stator provided by the invention adopt forward and reverse wave winding modes; a certain phase difference is formed by conductor current distribution in the stator grooves, the skin effect of the motor during high-speed operation is effectively inhibited, the winding connection arrangement is optimized, the half-turn length of all coils in the windings is shortened, the sectional area of a busbar is increased, the alternating current resistance and loss of the winding are obviously reduced, andthe working efficiency of the motor is improved. Compared with the alternating current loss without the phase difference, the winding scheme with the phase difference reduces the alternating current loss by 30W.

Owner:CHINA FIRST AUTOMOBILE

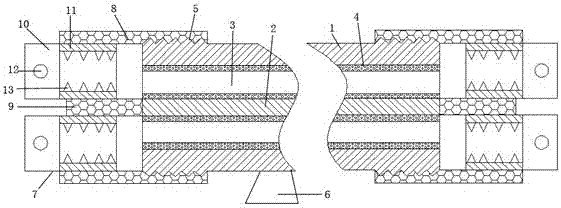

Method for laying ultra long cable

ActiveCN110401142AOvercome high fuel consumptionEliminate the complexity of the joint processInsulating conductors/cablesApparatus for laying cablesHeavy metalsTubes types

The invention discloses a method for laying an ultra long cable. According to a programmed path, multiple cable protection tube type cable channels are arranged on a laying path, multiple hydraulic driving devices are arranged on the cable channels, a cable production workshop is assembled at a cable laying start end, and production preparation is performed; before production, cable section structure design can be performed, and cable density is controlled; the known production process is utilized to prepare heavy metal suspension, and the density of the heavy metal suspension is made to be equal to the density of the ultra-long cable; when the ultra-long cable is laid, through controlling opening and closing of a variable diameter sealing device I and a variable diameter sealing device IIin a hydraulic driving device, through injecting or extracting the heavy metal suspension, the cable is advanced along a protection tube; no front traction power is required in the entire laying process; the entire cable line has no intermediate joint, only an extra long cable is required to complete the entire power cable line, and thereby the stability of subsequent use of the power cable lineis guaranteed.

Owner:XUZHOU LIFANG MECHANICAL & ELECTRICAL EQUIP MFG CO LTD

Cage barrier spliced outer rotor stator double-winding alternating current motor and control method thereof

ActiveCN103166405AStrong coupling abilityHigh electromechanical energy conversion efficiencySynchronous generatorsElectronic commutation motor controlThree-phaseAlternating current

The invention relates to a cage barrier spliced outer rotor stator double-winding alternating current motor. The motor is characterized in that an outer rotor is arranged outside a stator, a three-phase symmetry power winding and a control winding are arranged in slots on the surface of the outer side of the stator, and the same cage outer rotor modules are connected with a sleeve through outside positioning slots and spliced in a circumferential direction to form the outer rotor with salient pole types; the inner surface of each cage barrier outer rotor module is provided with radial trapezoid-shaped slots which have multiple different step slot widths, and short circuit cage bars are arranged in the slots; after the adjacent rotor modules are spliced, common trapezoid-shaped slots are formed on connection parts and have multiple different step slot widths along a radial direction, gaps of the bottoms of the slots reach the inner surface of the sleeve, and common cage bars are arranged in the slots; and the invention aims to provide the novel cage barrier combined outer rotor stator double-feed alternating current motor which is convenient to process and manufacture, ensures that the coupling capacity of two windings of the stator is optimized, and has the high power density and the excellent steady state and dynamic performance.

Owner:SHENYANG POLYTECHNIC UNIV

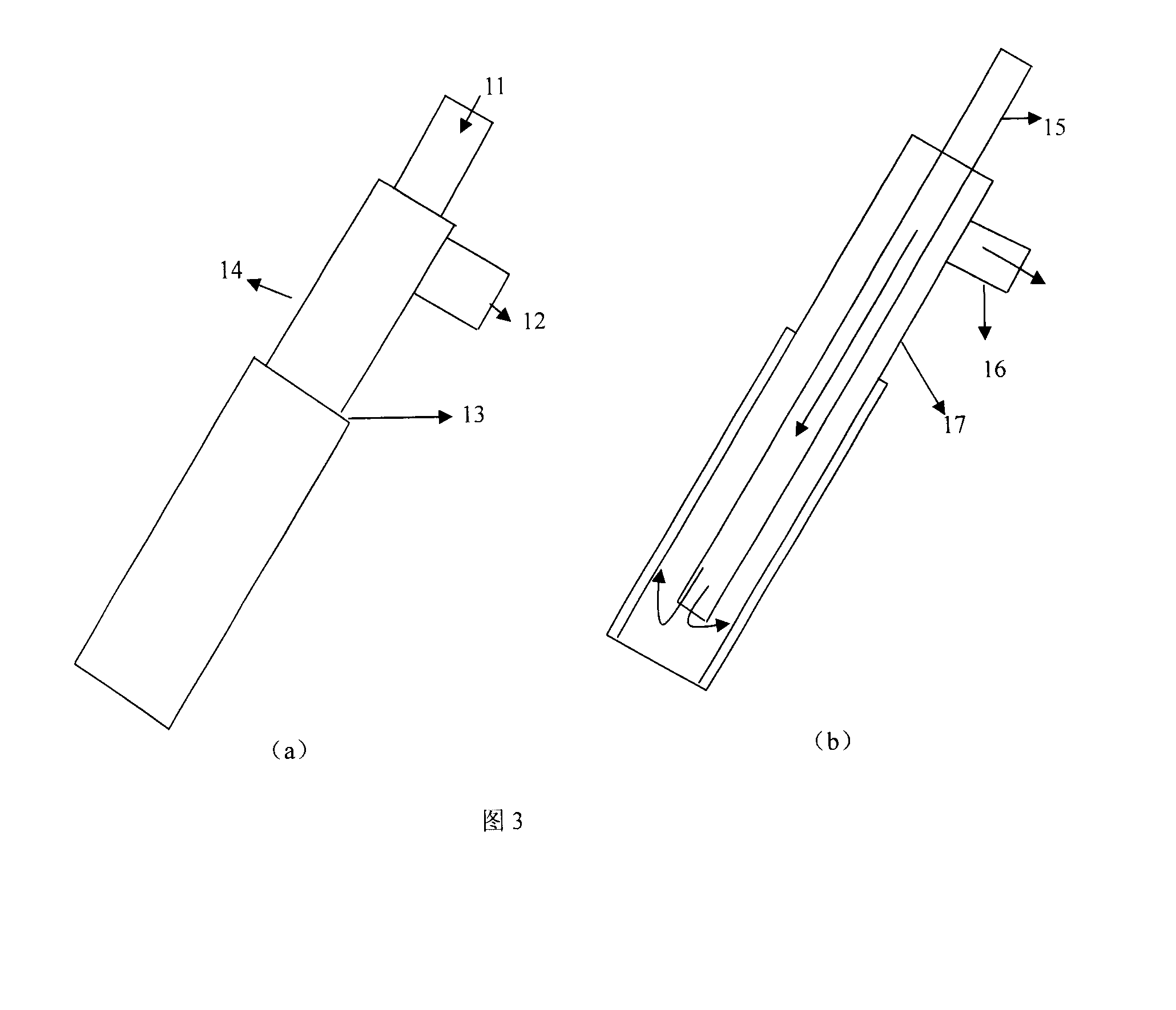

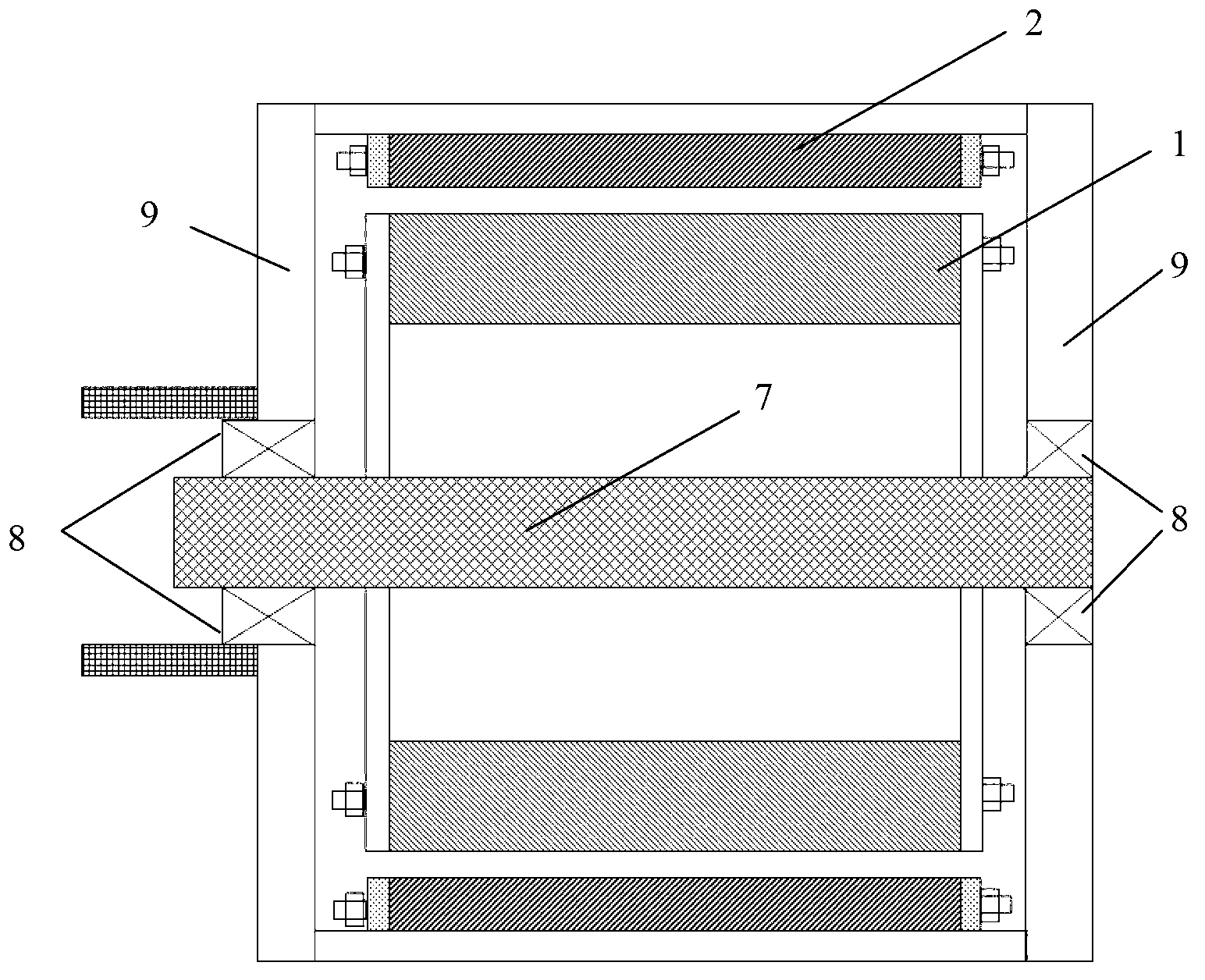

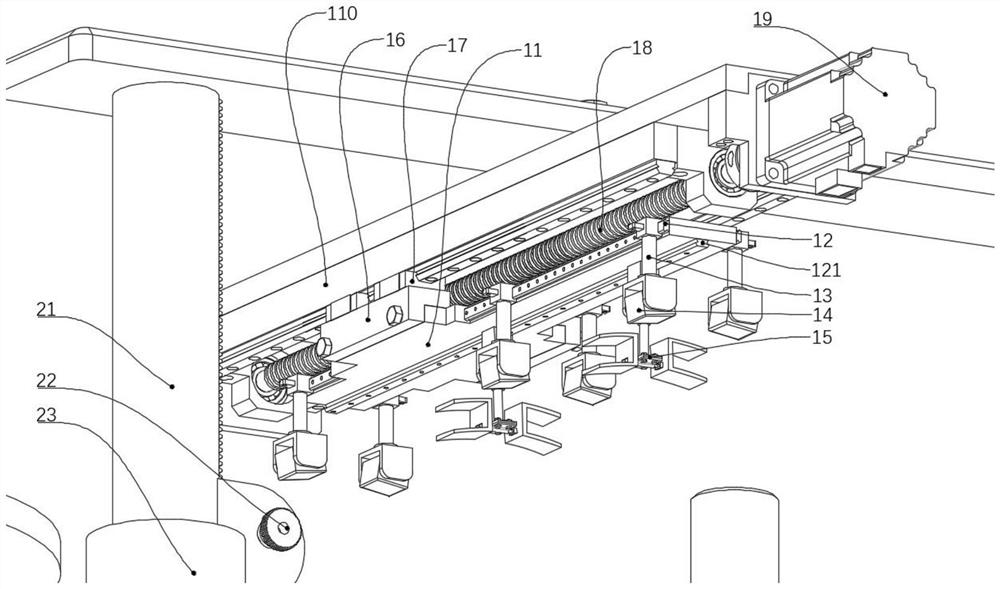

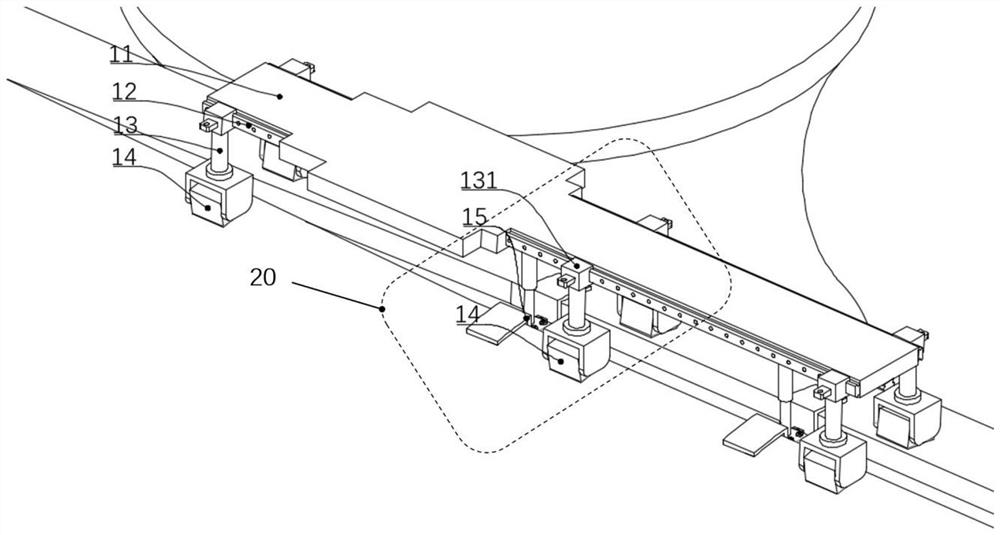

Thick-wall pipeline weld joint multi-stage heating device and heating method

ActiveCN114406534AImprove welding qualityImprove diffusivityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWeld seam

The invention provides a thick-wall pipeline welding seam multi-stage heating device. The thick-wall pipeline welding seam multi-stage heating device comprises an electrode set, a liftable portal frame, a left extrusion roller, a welding platform and a right extrusion roller. And the electrode group is suspended and fixed below the liftable portal frame and is used for carrying out multi-stage heating on a welding seam. And the electrode group comprises a pair of common electrodes positioned near a V-shaped angle notch of the pipe blank and N movable electrode groups arranged at intervals. The invention further provides a method for uniformly heating the thick-wall pipe blank welding seam, the position of the movable electrode group is determined according to production requirements, then the movable electrode group is electrified and heated at the same time, a plurality of heating loops are formed at a plurality of positions on the side face of the pipe blank welding seam, and then a plurality of local heating currents are formed; the welding seam of the pipe blank reaches the peak of the V-shaped angle notch after being subjected to sufficient N times of heat conduction, and the temperature distribution at the welding seam of the pipe blank is more uniform. A multi-stage heating mode is formed through the common electrode and the N movable electrode sets, that is, multi-stage heating is conducted on the weld joint of the pipe blank through the multiple movable electrodes arranged at intervals, and the weld joint of the pipe blank is evenly heated.

Owner:YANSHAN UNIV

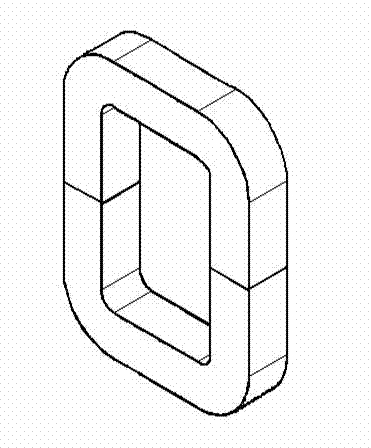

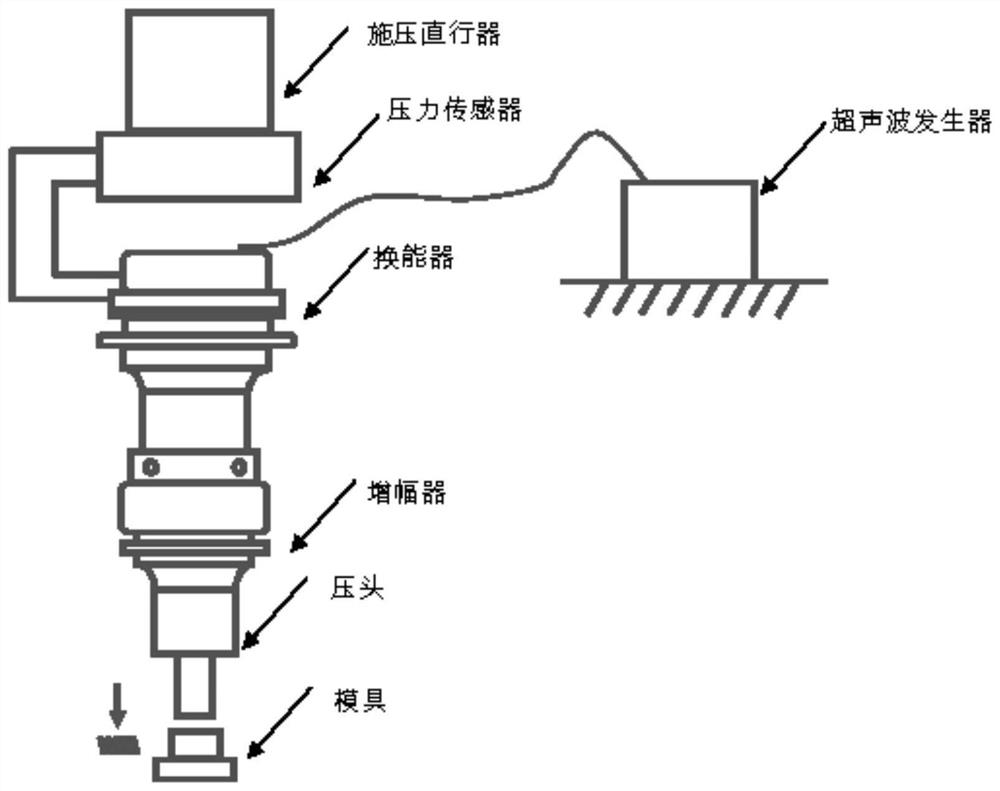

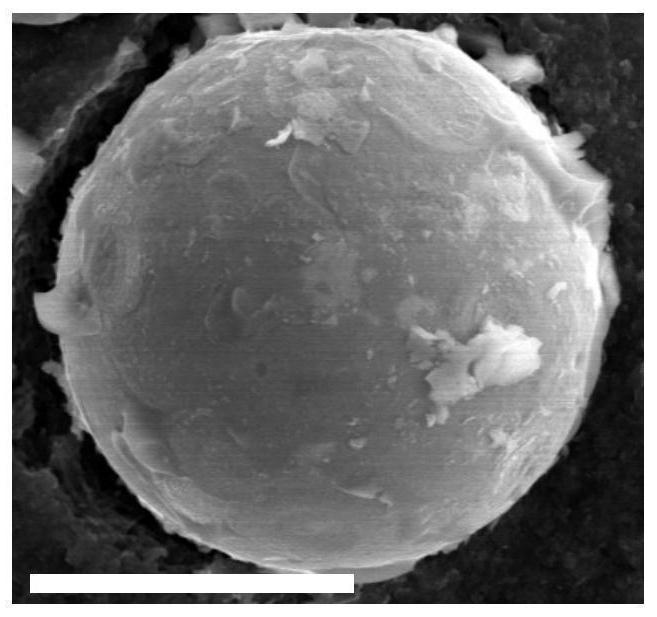

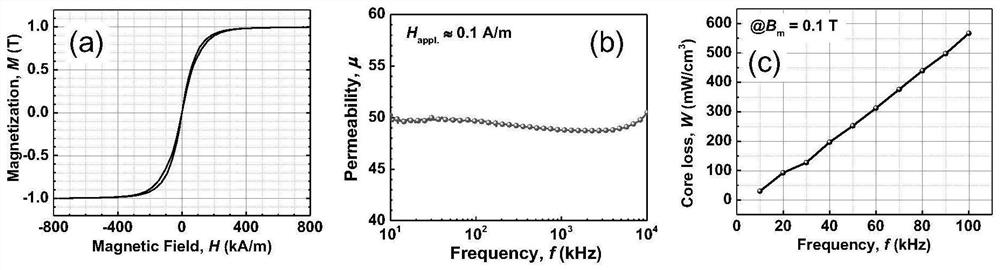

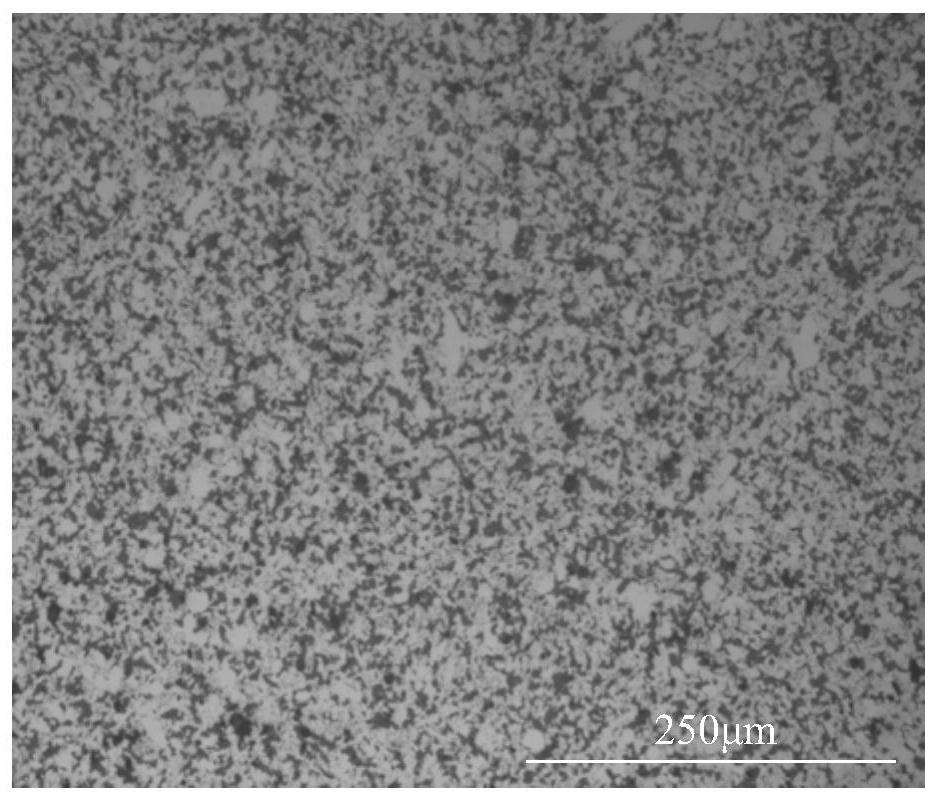

Ultrasonic-enhanced magnetic powder core compression molding method and compressed powder magnetic core

PendingCN113871179APromote sportsFacilitate rearrangementInorganic material magnetismInductances/transformers/magnets manufactureCompression moldingInitial permeability

The invention discloses an ultrasonic-enhanced magnetic powder core compression molding method and a compressed powder magnetic core. The invention discloses an ultrasonic enhanced magnetic powder core compression molding method which comprises the following steps: placing soft magnetic powder (coated) in ultrasonic compression molding equipment, setting the ultrasonic frequency to be 15-60kHz and the vibration amplitude to be 70-90%, and simultaneously starting a pneumatic system to pressurize, wherein the pressure is 0.3-0.9 MPa, the compression time is 0.1-10s and the dwell time is 3-5s, and completing the compression molding of a magnetic powder core. The method / process has the advantages of being small in required pressure, short in completion time, high in powder forming density, simple and efficient. The invention further discloses the magnetic powder core prepared by the ultrasonic enhanced magnetic powder core compression molding method, the magnetic powder core has high saturation flux density, low iron loss and high initial magnetic conductivity, and the magnetic conductivity of the magnetic powder core shows good high-frequency stability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method of applying electric field energy to treat molten steel

The present invention provides method of applying electric field energy to treat molten steel. One electric field energy generator is used to introduce electric field energy into molten steel via electric poles, and the electric field energy is in square wave of variable duty ratio and has energy of 1000J-200MJ, voltage of 100V-2000V, current 100A-10KA, frequency not higher than 25 Hz, and duty ratio of 5-95 %. The electric field energy generator is suitable for industrial production and has properly adjusted parameters. The treated molten steel has changed solidification process and fine solidified structure, and the solidified material has globular crystal structure and isometric branch structure, less macro segregation and other faults, raised physical and mechanical performance.

Owner:ANGANG STEEL CO LTD

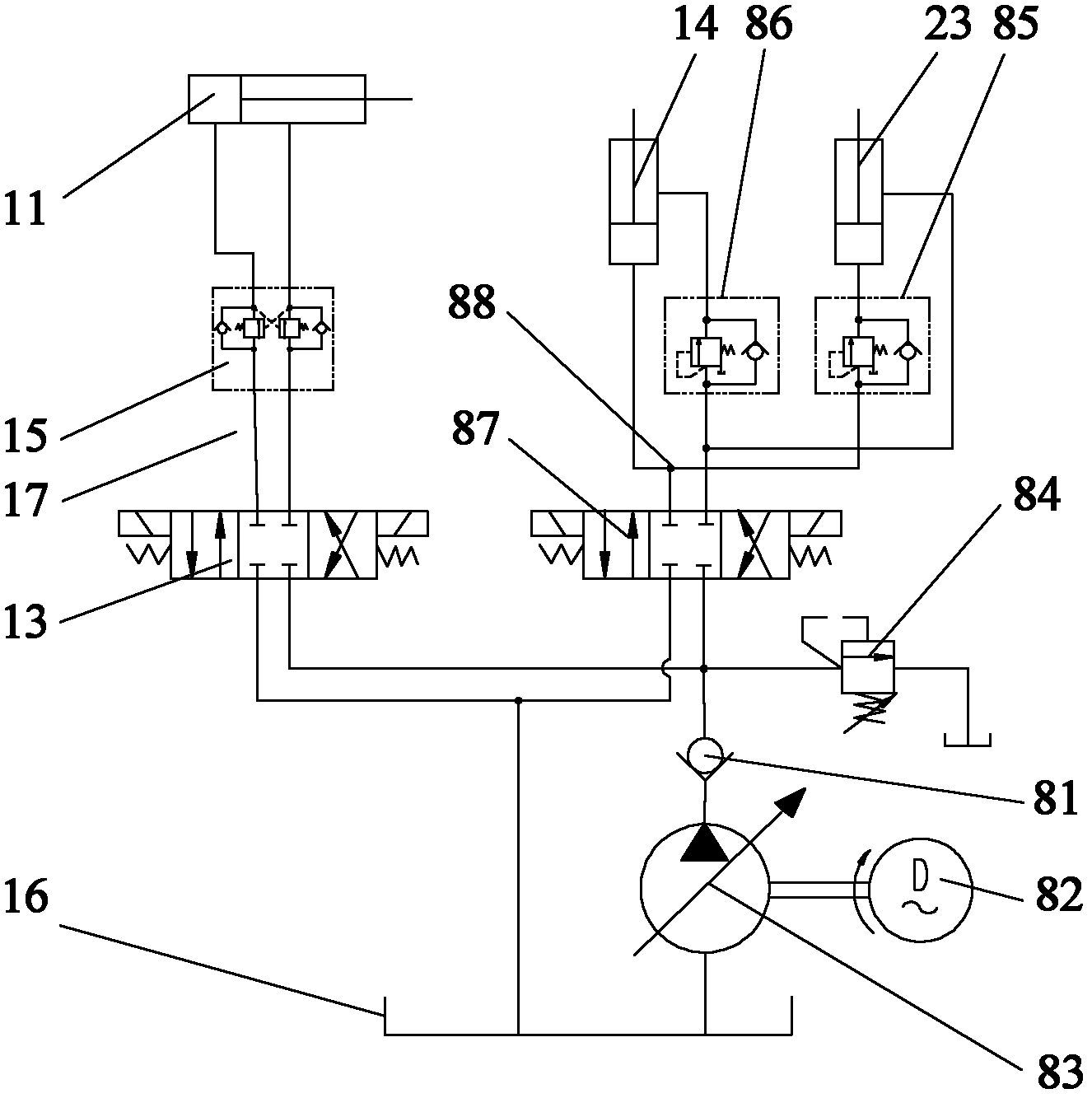

Hard tube end forming equipment and forming method

The invention provides hard tube end forming equipment and a forming method. The hard tube end forming equipment comprises a feeding portion (10), a clamping portion (20) and an extrusion forming portion (30), wherein the clamping portion (20) is used for fixing a hard tube (40) to be formed, and the extrusion forming portion (30) is used for forming a tube end structure of the hard tube (40) to be formed. The hard tube end forming equipment is characterized in that a heating portion (50) is further arranged between the clamping portion (20) and the extrusion forming portion (30). The hard tube end forming equipment is stable in structure, high in reliability, low in cost, high in production efficiency, high in positioning precision and fine in forming quality.

Owner:ZOOMLION HEAVY IND CO LTD

Stator double-winding AC motor with double-cage barrier rotor and its control method

ActiveCN103166396BStrong coupling abilityHigh electromechanical energy conversion efficiencySynchronous generatorsElectronic commutation motor controlComputer moduleThree-phase

The invention relates to a stator double-winding alternating-current motor with double cage barrier rotors. The stator double-winding alternating-current motor is characterized in that an inner rotor and an outer rotor of the motor are positioned on inner and outer sides of a stator respectively; three-phase symmetry power windings and three-phase symmetry control windings are arranged on the inner and outer sides of the stator; the inner rotor and the outer rotor are spliced along the peripheral direction by using the same cage barrier rotor modules to form a rotor with a salient pole; each cage barrier rotor module is connected with a sleeve by positioning grooves and is provided with a plurality of radial trapezoid grooves; short-circuit cage bars are put into the grooves; a stepped breach is formed in the joint of the adjacent cage barrier rotor modules; and after the adjacent modules are spliced, a public trapezoid groove is formed in the joint of the adjacent modules, a gap at the bottom of the groove reaches the surface of the sleeve, and public cage bars are put into the grooves. The invention aims to provide the stator double-winding alternating-current motor which is convenient to manufacture, can maximize the coupling capacity of the power windings and the control windings on two sides of the stator, is high in power density and dynamic property and is provided with the double cage barrier rotors.

Owner:SHENYANG POLYTECHNIC UNIV

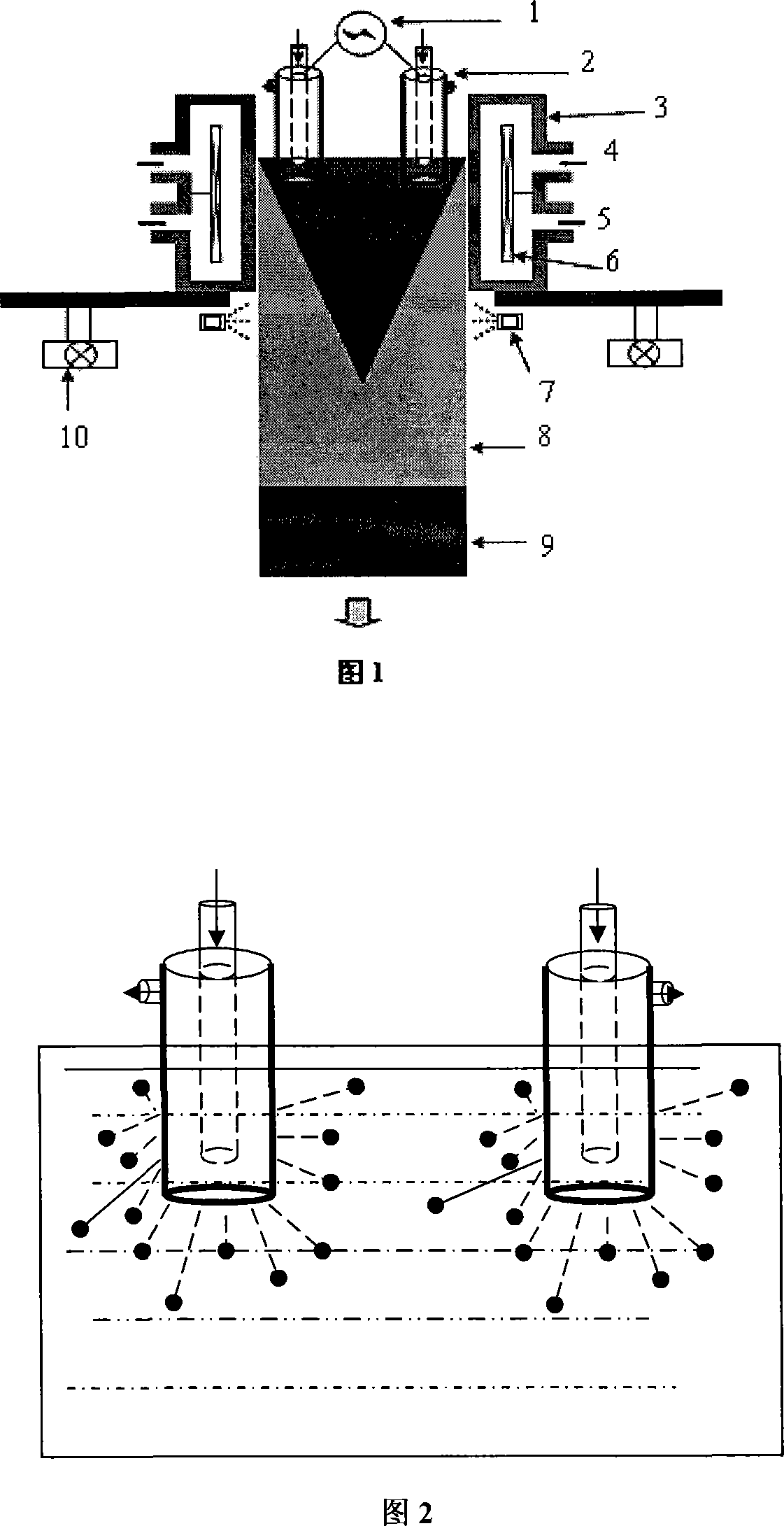

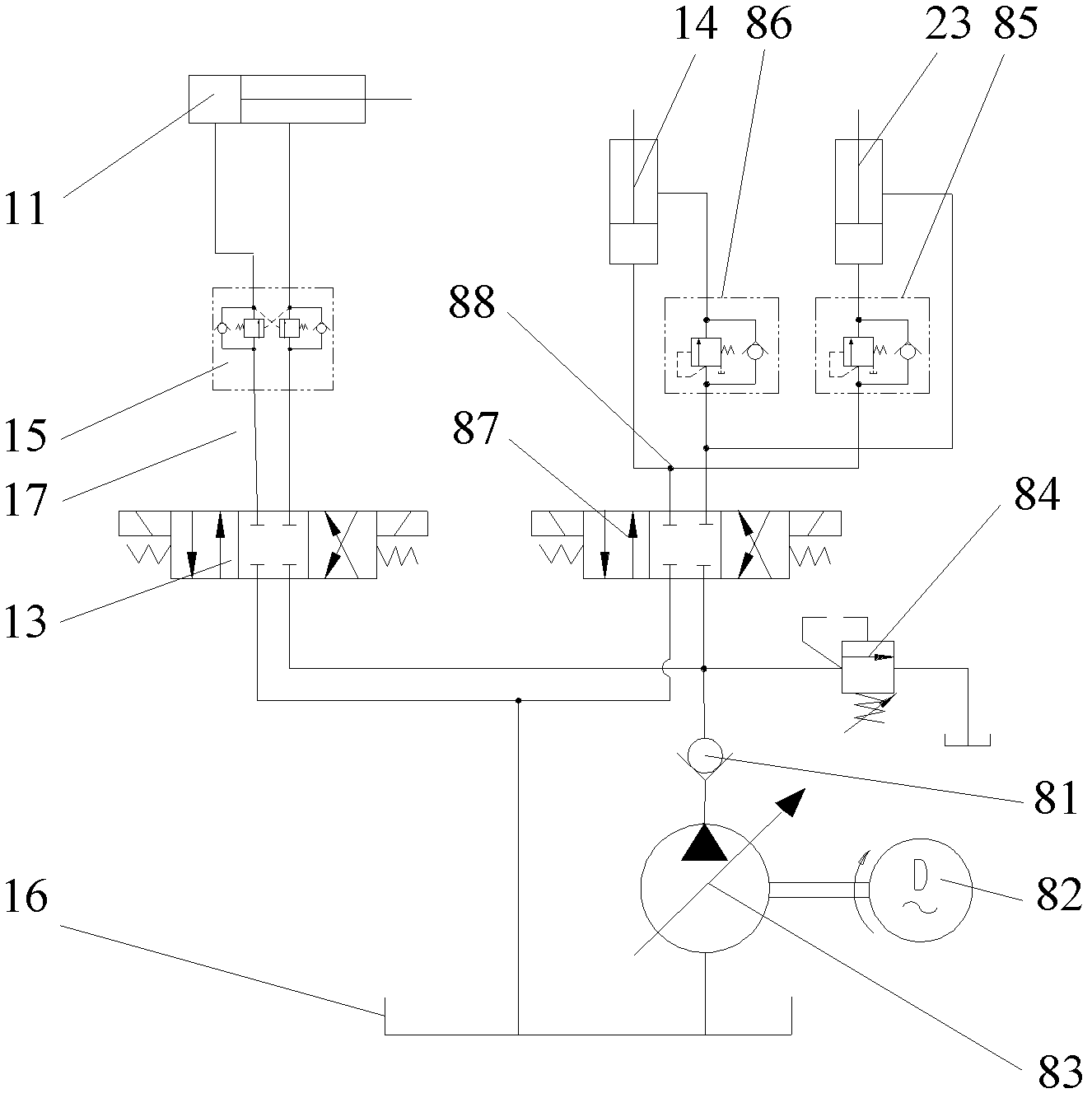

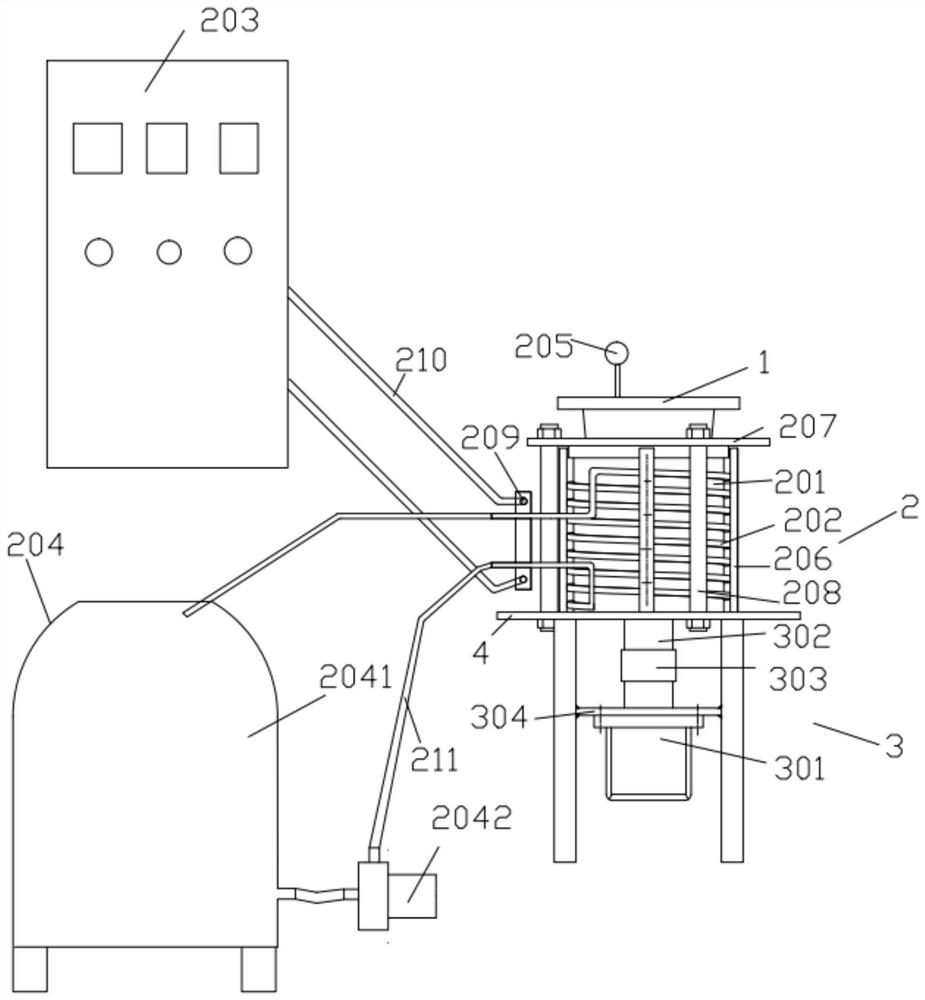

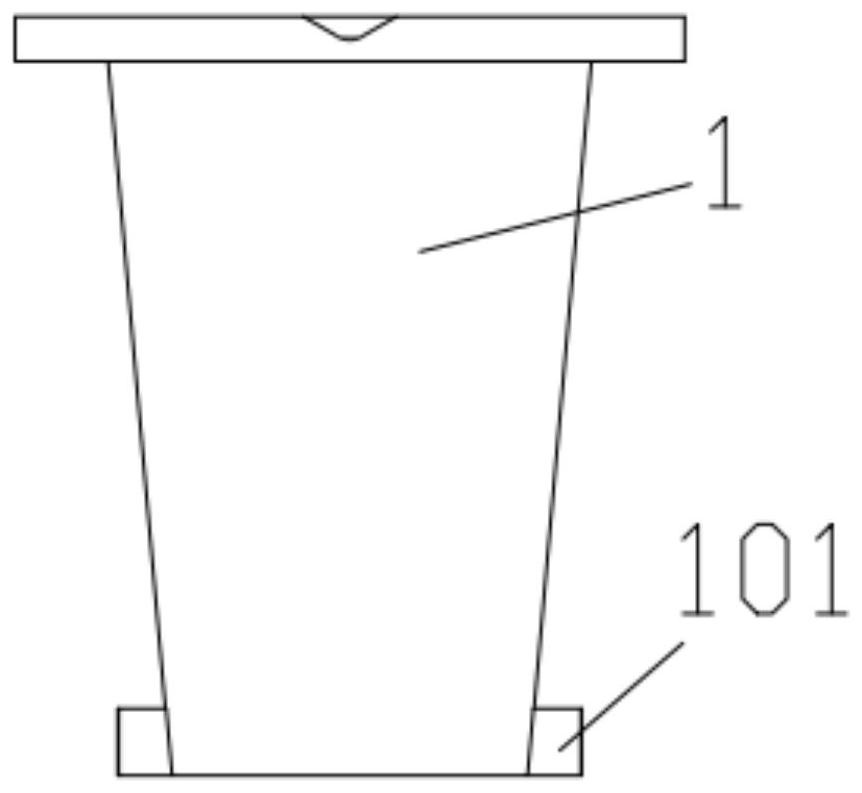

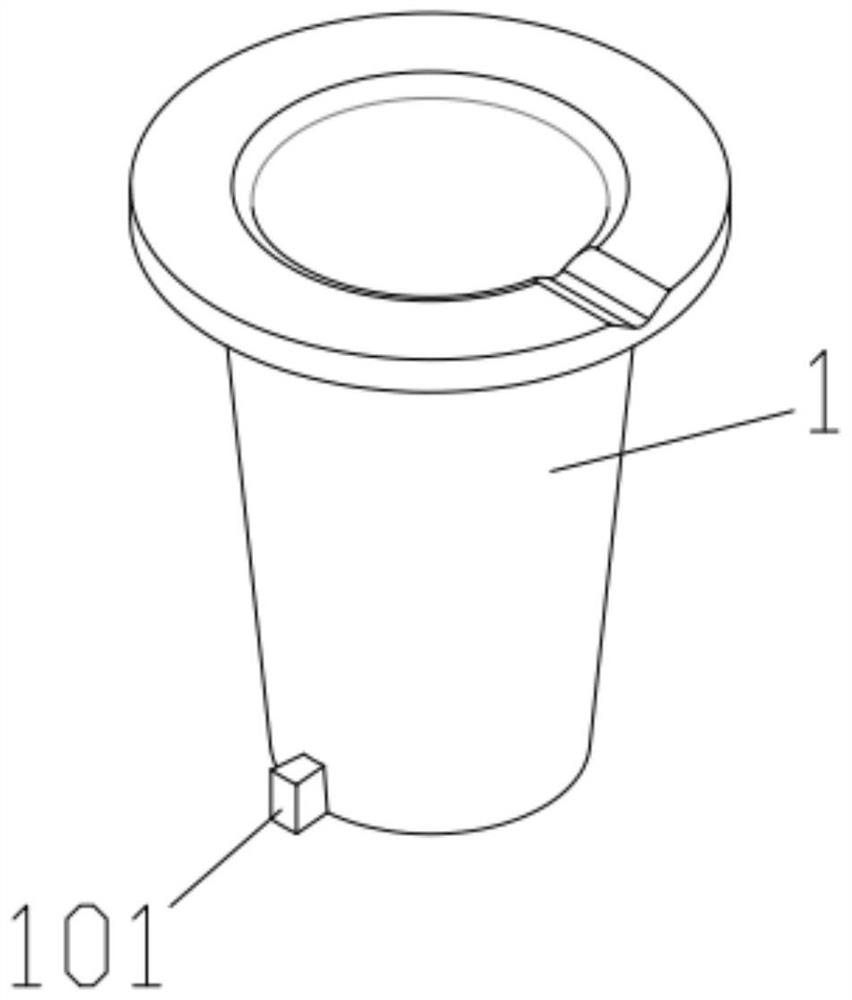

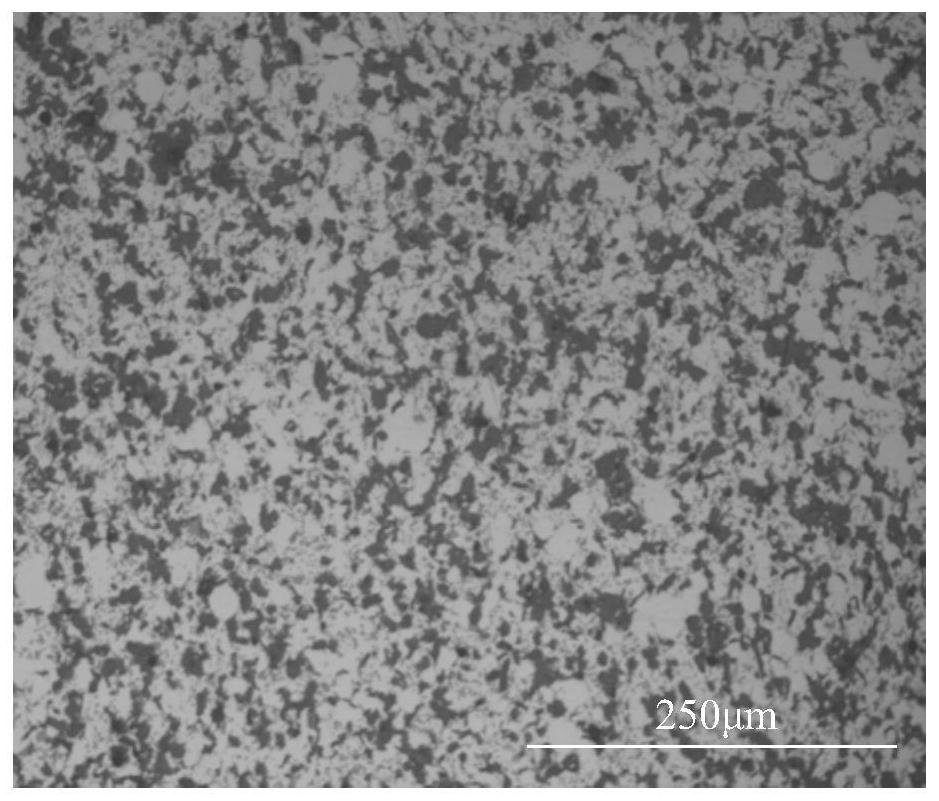

A composite preparation process and equipment for semi-solid metal paste

The invention discloses a composite preparation process and composite preparation equipment for semisolid metal slurry. A weak electromagnetic stirring device and a mechanical stirring device are compounded together to prepare the semisolid metal slurry. Compared with an existing semisolid metal slurry preparation technique, the compound preparation process has the advantages that 1, compared witha rotary magnetic field electromagnetic stirring method, the electromagnetic field can be fully covered to avoid a skin effect and the needed energy consumption is low; 2, compared with a weak electromagnetic stirring method, the stirring force of alloy slurry is enhanced, the time needed to obtain the semisolid metal slurry is shortened, and the efficiency is improved; 3, compared with a mechanical stirring method, no mechanical stirrers are available, so that the defects that the stirrer is corroded and the alloy slurry is polluted are overcome, and meanwhile, the temperature of the slurryis controllable; 4, the composite preparation equipment is simple in structure, low in cost, flexible to control process and convenient to operate; and 5, the composite preparation process solves theproblem of low preparation efficiency of the semisolid slurry in large structural part production in production of large structural parts, the weights of which are over 5 Kg.

Owner:XI AN JIAOTONG UNIV

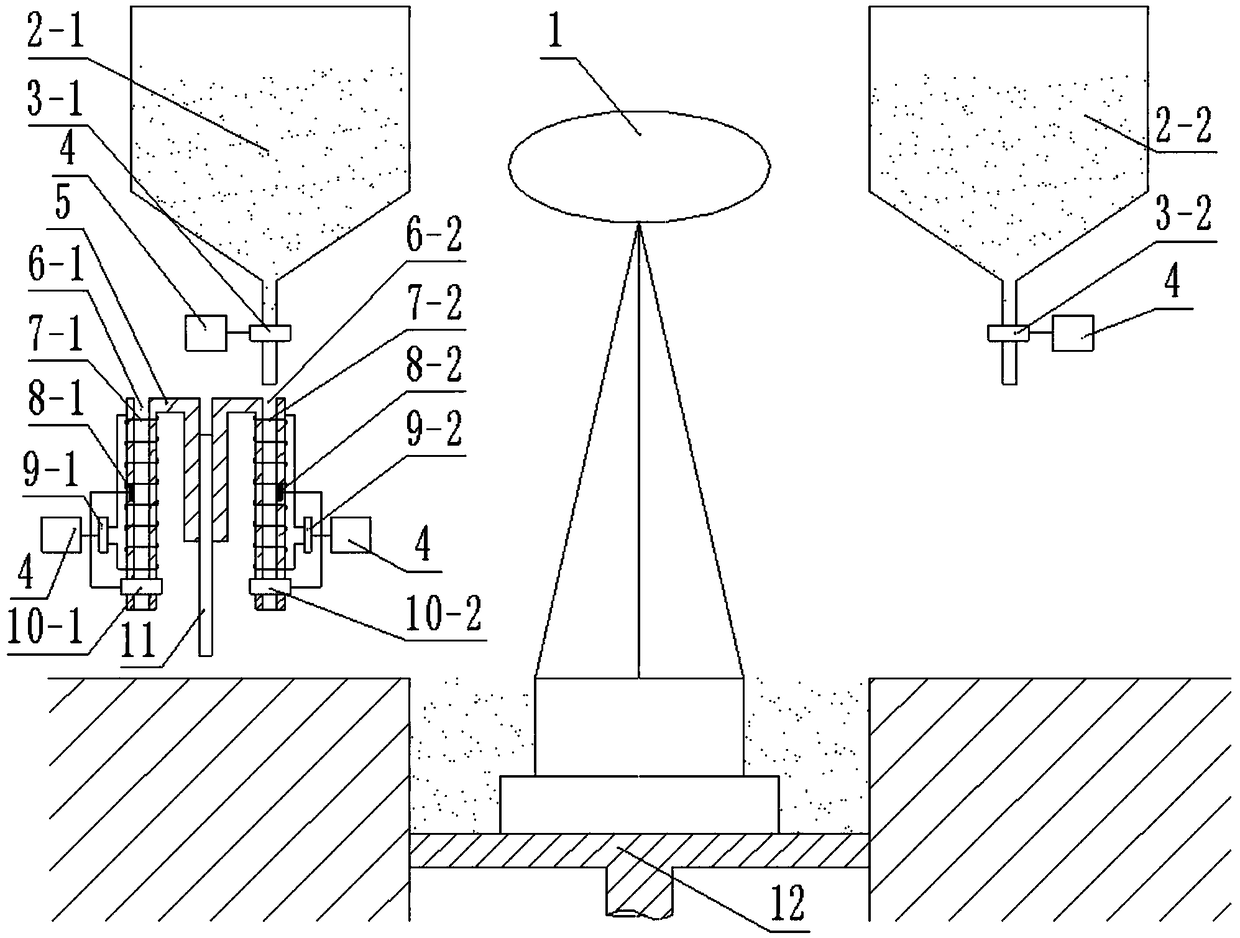

An integrated system of electromagnetic induction heating powder supply and powder bed additive manufacturing

ActiveCN106563806BUniform heating temperatureAchieve the effect of online annealingAdditive manufacturing apparatusIncreasing energy efficiencySolenoid valveProcess engineering

An integrated system of electromagnetic induction heating powder supply and spreading manufactured by powder bed additive manufacturing, including the first and second powder storage cylinders on both sides of the optical path system, and the powder outlet of the powder storage cylinder is equipped with a solenoid valve to control powder leakage And connected with the central controller, the middle part of the powder spreading frame connected to the lifting forming cylinder is connected with a metal powder spreading plate, the first and second powder storage tanks are opened on both sides of the powder spreading frame, and the inner wall of the powder storage tank is embedded with a temperature sensor It is also connected with the central controller. A solenoid valve for controlling powder leakage is installed under the powder outlet of the powder storage tank and connected to the central controller. A metal coil is wound on the outer wall of the powder storage tank, and the metal coil is connected to the electromagnetic induction heating controller. The magnetic induction heating controller is connected with the central controller. The present invention heats the powder required for laying a single layer by electromagnetic induction. The amount of powder heated each time is small and the heating is rapid. A forming layer is heated to reduce residual stress and reduce warpage and cracking of the formed part.

Owner:XI AN JIAOTONG UNIV

A method for laying extra-long cables

ActiveCN110401142BEliminate hidden dangers of failureDelivery length limitInsulating conductors/cablesApparatus for laying cablesPower cableStructural engineering

The invention discloses a method for laying an ultra long cable. According to a programmed path, multiple cable protection tube type cable channels are arranged on a laying path, multiple hydraulic driving devices are arranged on the cable channels, a cable production workshop is assembled at a cable laying start end, and production preparation is performed; before production, cable section structure design can be performed, and cable density is controlled; the known production process is utilized to prepare heavy metal suspension, and the density of the heavy metal suspension is made to be equal to the density of the ultra-long cable; when the ultra-long cable is laid, through controlling opening and closing of a variable diameter sealing device I and a variable diameter sealing device IIin a hydraulic driving device, through injecting or extracting the heavy metal suspension, the cable is advanced along a protection tube; no front traction power is required in the entire laying process; the entire cable line has no intermediate joint, only an extra long cable is required to complete the entire power cable line, and thereby the stability of subsequent use of the power cable lineis guaranteed.

Owner:XUZHOU LIFANG MECHANICAL & ELECTRICAL EQUIP MFG CO LTD

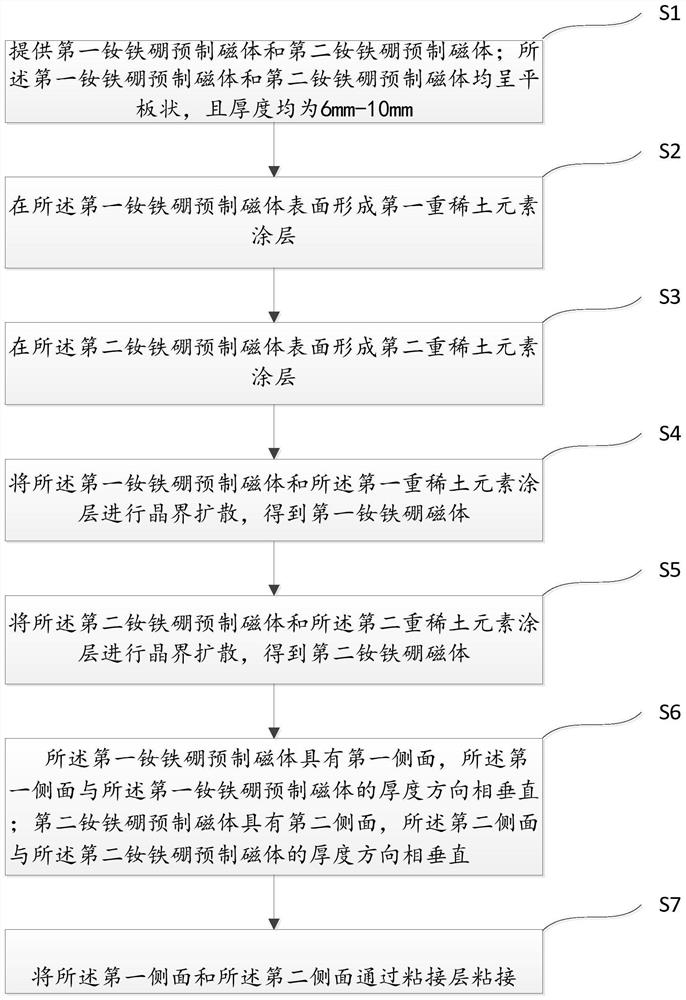

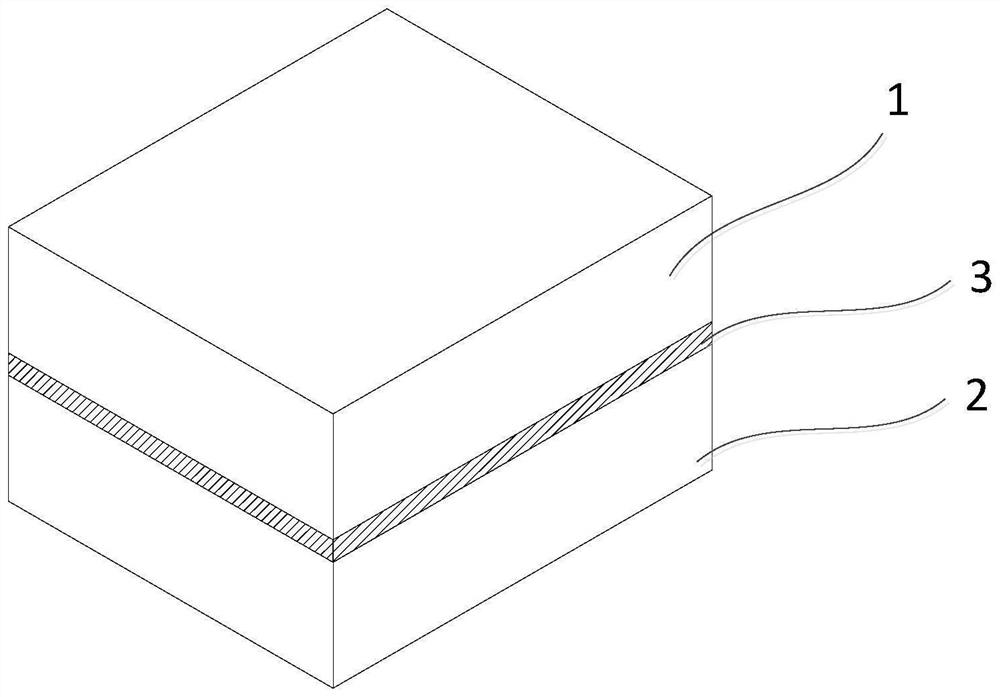

Rare earth magnetic steel of wind driven generator and manufacturing method of rare earth magnetic steel

PendingCN114446629AAvoid skin effectReduce conductivityPermanent magnetsInductances/transformers/magnets manufactureElectric machineEddy current effect

The invention relates to the technical field of magnet preparation, and discloses a rare earth magnetic steel of a wind driven generator and a manufacturing method thereof, and the manufacturing method is characterized in that a first neodymium iron boron magnet and a second neodymium iron boron magnet are bonded through a bonding layer to form the rare earth magnetic steel of the wind driven generator, so that the skin effect of the magnetic steel is effectively avoided, and the magnetic steel has high reliability. The first neodymium-iron-boron magnet and the second neodymium-iron-boron magnet which are thin are bonded through the bonding layer, the conductivity of the rare earth magnetic steel of the wind driven generator can be reduced, the eddy current effect of the magnetic steel is reduced, the service life of a motor can be effectively prolonged, and the service life of the motor is prolonged. In addition, the thickness of the first neodymium iron boron prefabricated magnet and the thickness of the second neodymium iron boron prefabricated magnet are small, so that the use amount of heavy rare earth does not need to be increased to solve the problem of uneven distribution of the heavy rare earth of the magnetic steel, the use amount of the heavy rare earth Tb and the heavy rare earth Dy is effectively reduced, and expensive rare earth resources are saved.

Owner:中国科学院赣江创新研究院

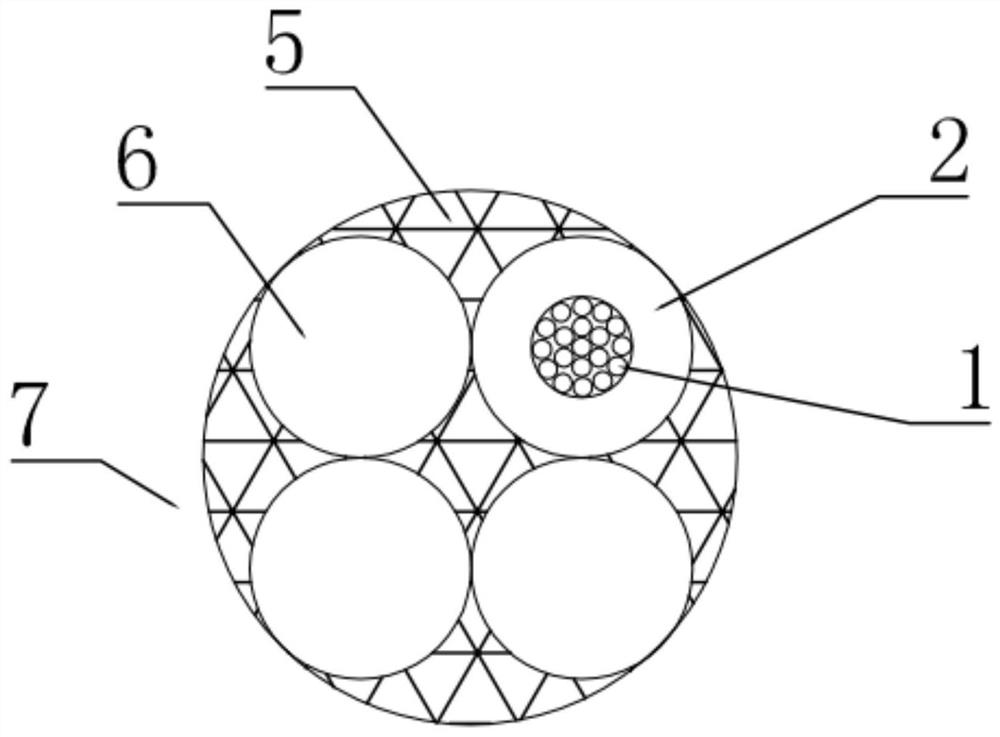

A multi-cable assembly device for power transmission and its use method

ActiveCN105575559BSolve the needs of useAvoid skin effectInsulating bodiesApparatus for laying cablesPower cableSkin effect

The invention discloses a power transmission multi-cable assembly device constituted by conductive joints and sheath pipes. Each of the sheath pipe is constituted by a pipe wall and a differentiation separation board, and the differentiation separation board is connected with the inner surface of the pipe wall, and can be used to divide the inner cavity of each of the sheath pipes into at least two wire passing cavities having the same areas of the cross sections. The conductive joints are parallely connected by connecting lugs, the number of which are equal to the number of the wire cavities, and are disposed on an insulation pedestal. Each of the connecting lugs is constituted by a connecting tongue and a socketed pipe, and the connecting tongue is additionally provided with at least one connecting screw hole, and the inner surface of each of the socketed pipes is uniformly provided with cone-shaped fastening teeth. The use method comprises four steps: determining of total wire diameter, differentiation of cables, assembly, and wiring. The use requirements of the large-cross section cables requiring various diameters can be flexibly and easily satisfied, and the production costs of the large-cross section cables can be reduced. The problem of the frequent occurrence of the skin effect of the large-cross section cables can be effectively solved, and therefore the use performance of the power cables can be greatly improved.

Owner:STATE GRID CORP OF CHINA +1

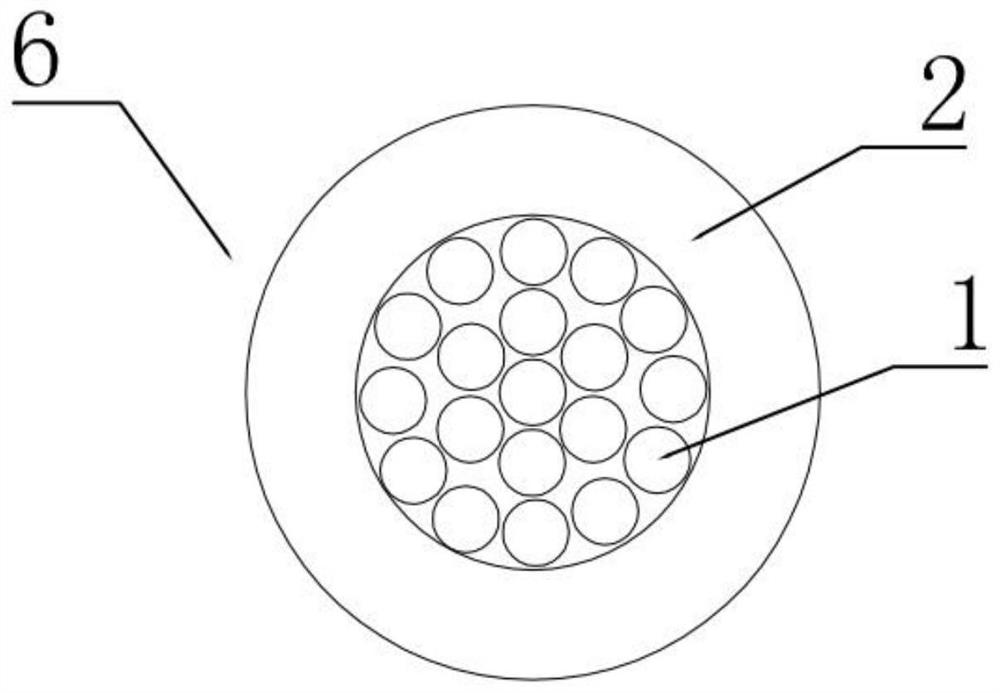

Novel super-soft flame-retardant knitting yarn and manufacturing method thereof

ActiveCN112489855AFully dispersedImprove transmission performanceInsulated cablesInsulated conductorsYarnFiber

The invention discloses a novel super-soft flame-retardant knitting yarn which comprises core wires, a shielding layer and knitting yarn, each core wire comprises a conductor core and an inner insulating layer wrapping the conductor core, the multiple core wires are stranded together to form a signal wire, the shielding layer and the knitting yarn are sequentially arranged outside the signal wire,the conductor core comprises a plurality of wires and a plurality of strands of reinforced fibers, and the plurality of wires and the plurality of strands of reinforced fibers are uniformly distributed and stranded together to form the conductor core; the invention further discloses a manufacturing method of the cable. The manufacturing method comprises the steps of preparing polyphenylene sulfide silk threads, wires, reinforcing fibers, shielding wires and reinforcing wire raw materials, twisting the conductor cores, wrapping the core wires, twisting the core wires, weaving the shielding layer and weaving the yarns. By arranging a specific structure and a corresponding manufacturing method, the strength and the flexibility of the core wire are enhanced while the wire is fully dispersed,a good heat insulation, flame retardance and shielding effect is achieved, the skin effect generated by signals or currents in wire transmission is effectively avoided, and the transmission capacity of the wire is enhanced.

Owner:今皓光电(昆山)有限公司

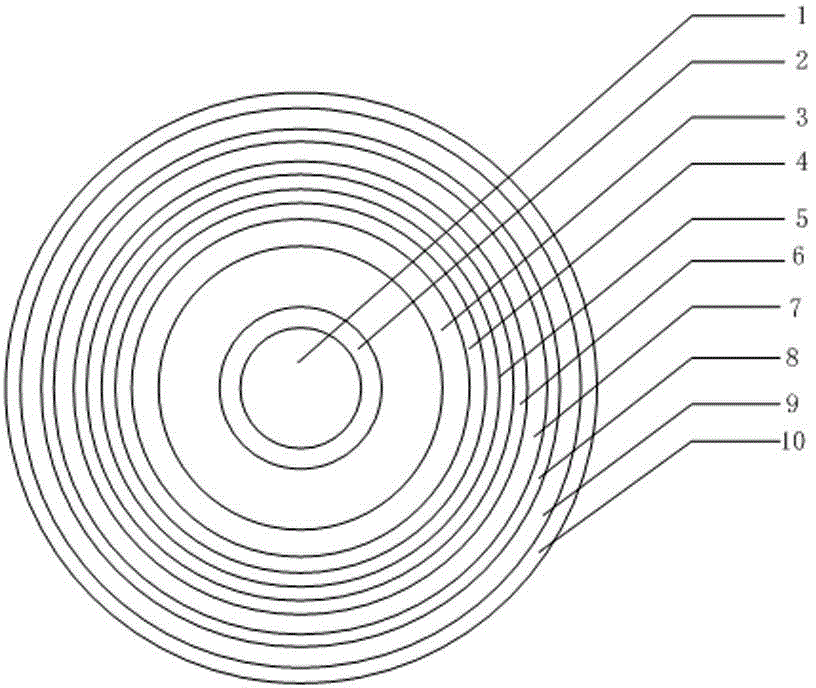

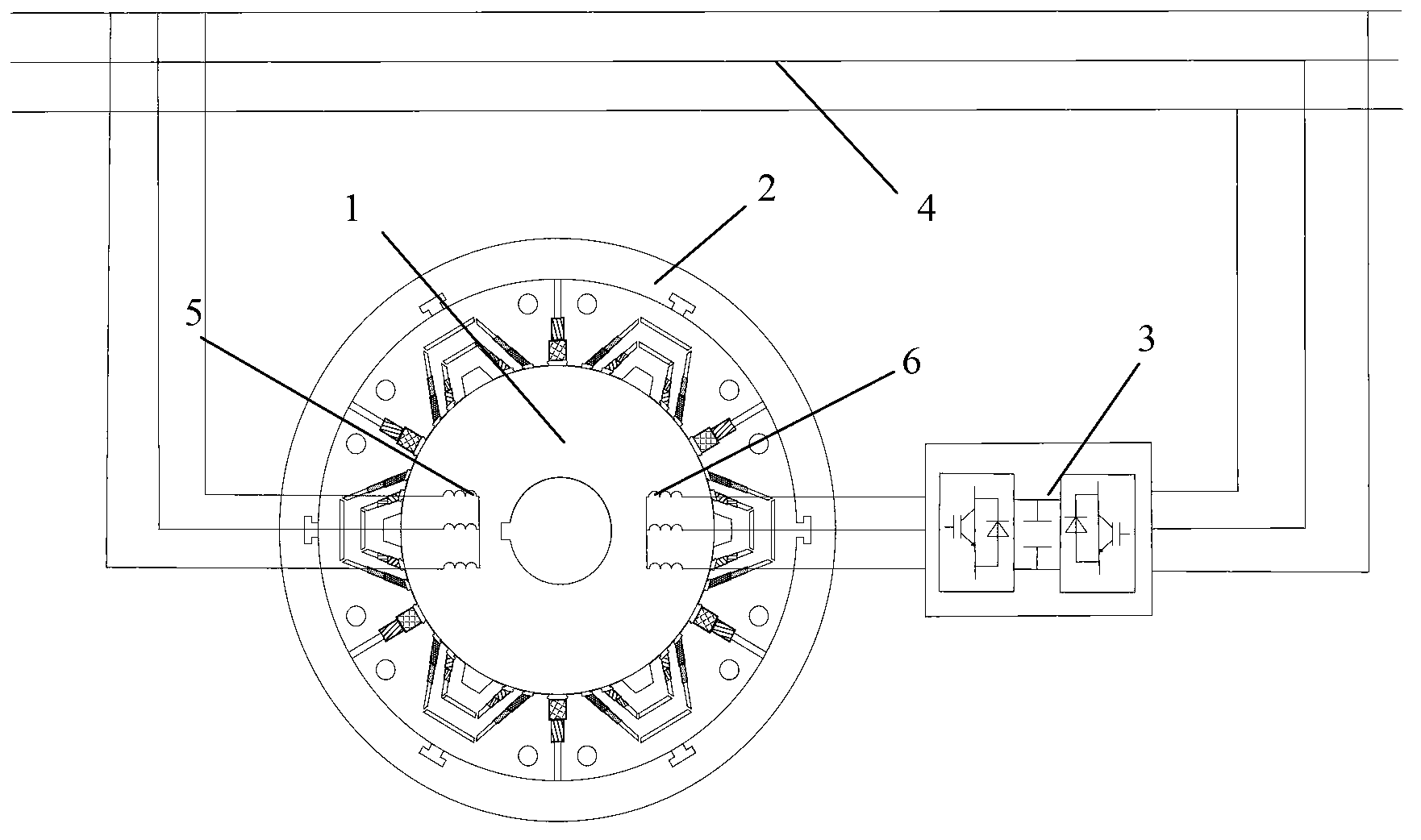

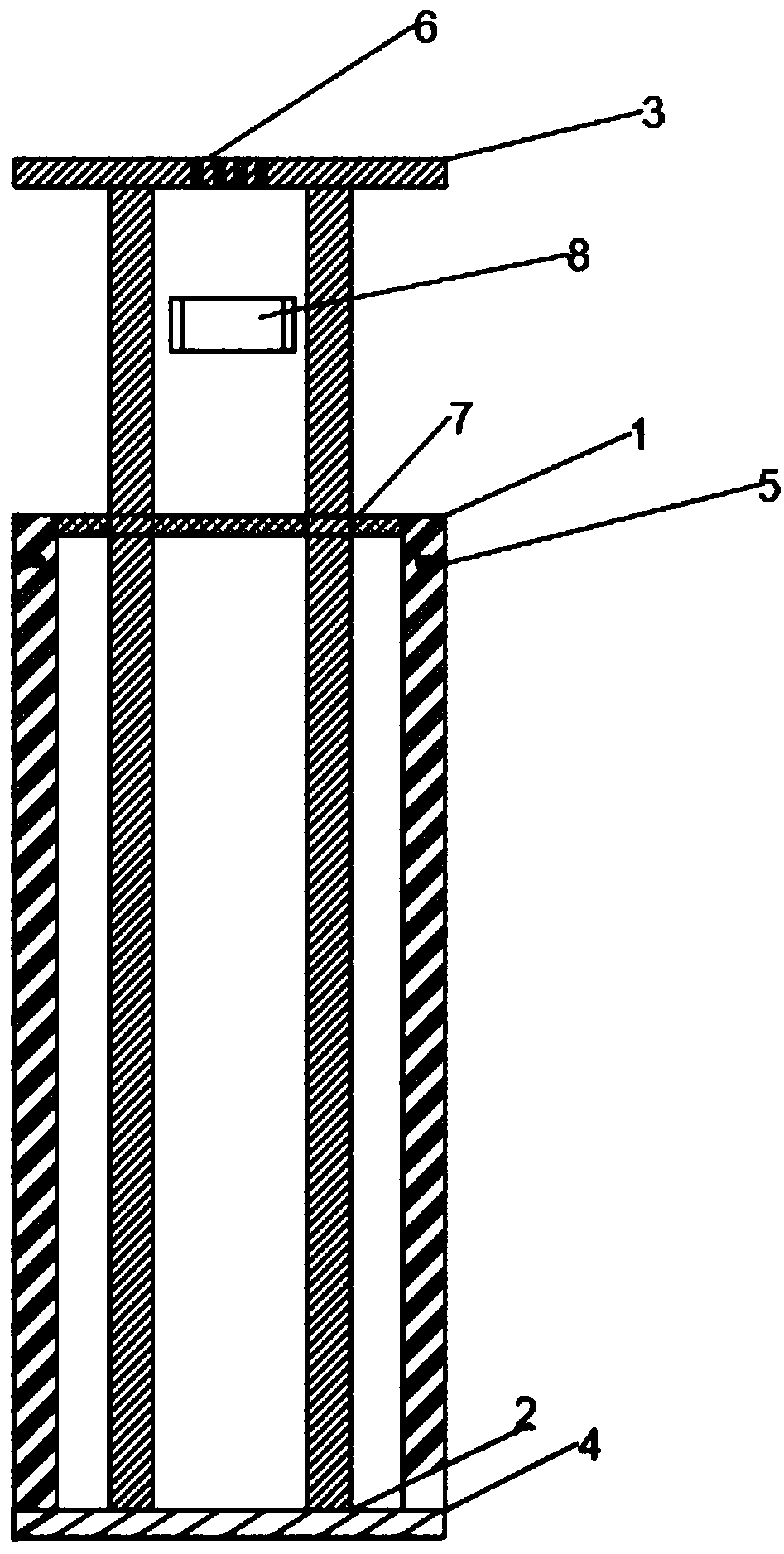

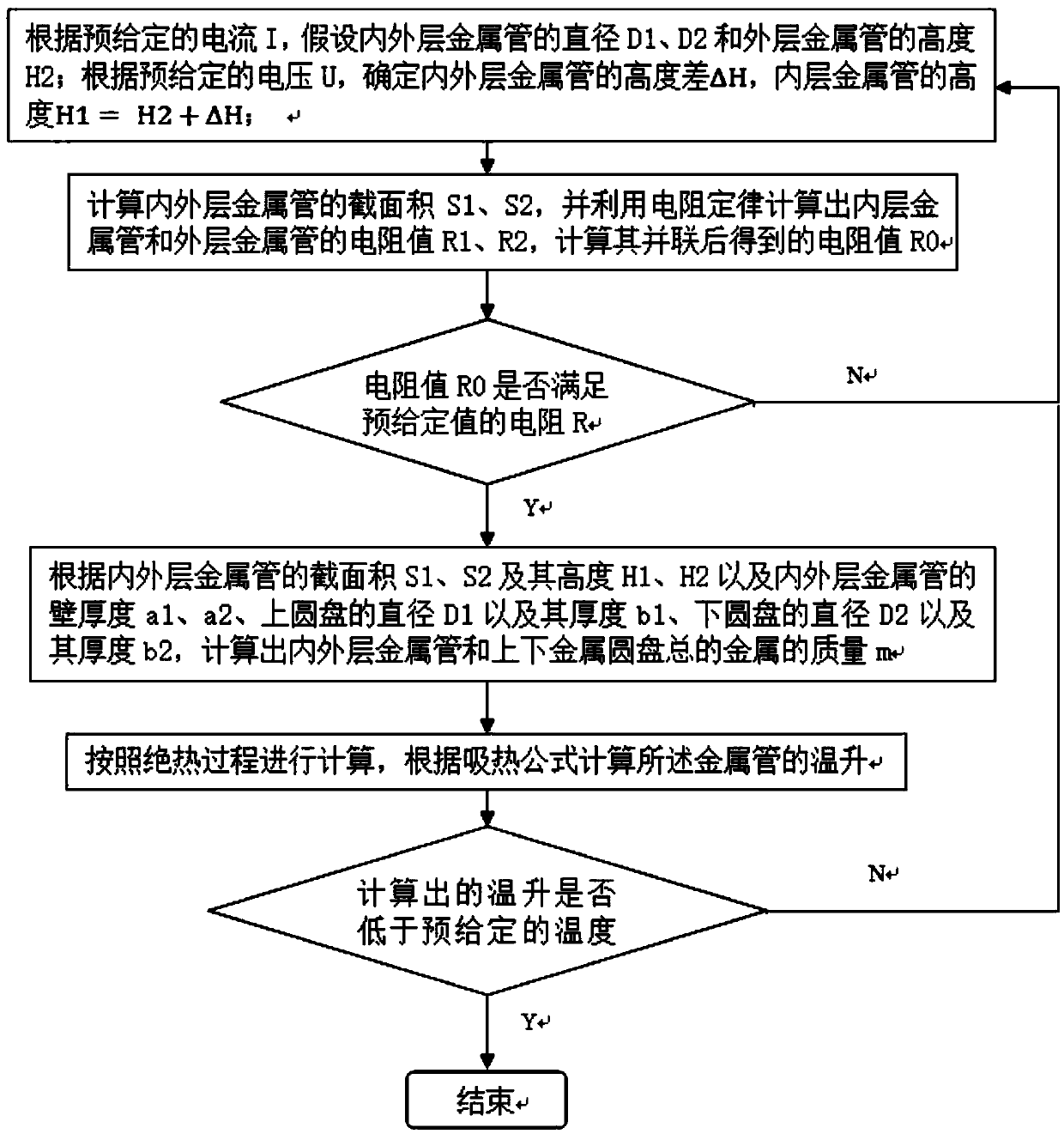

Milliohm-level dummy load used for high power supply system and design method thereof

ActiveCN110391058AEasy to makeAvoid skin effectZig-zag/sinusoidal resistive elementsLoad resistanceSkin effect

The invention discloses a milliohm-level dummy load used for a high power supply system and a design method thereof. The dummy load includes an outer layer metal pipe 1, an inner layer metal pipe 2, ametal upper disc 3, a metal lower disc 4, terminal threaded holes 5, wiring socket threaded holes 6 and a rectangular hole 8; the height of the inner layer metal pipe 2 is greater than that of the outer layer metal pipe 1; the inner layer metal pipe 2 is coaxially put into the outer layer metal pipe 1; the bottoms of the two metal pipes are coaxially welded on the metal lower disc 4; the top of the inner layer metal pipe 2 are welded on the metal upper disc 3; the terminal threaded holes 5 are located in the pipe wall of the outer layer metal pipe 1; the wiring socket threaded holes 6 are located in the metal upper disc 3; and the rectangular hole 8 is located in the pipe wall of the inner layer metal pipe 2, and the height of the rectangular hole is greater than that of the outer layer metal pipe 1. Through the dummy load which is formed through the coaxial welding of the inner and outer metal pipes, skin effects can be avoided; and the dummy load is fast in heat dissipation, compactin structure, small in volume, laborsaving and time-saving in manufacturing and small in dummy load resistance and can reach a milliohm level.

Owner:HUAZHONG UNIV OF SCI & TECH

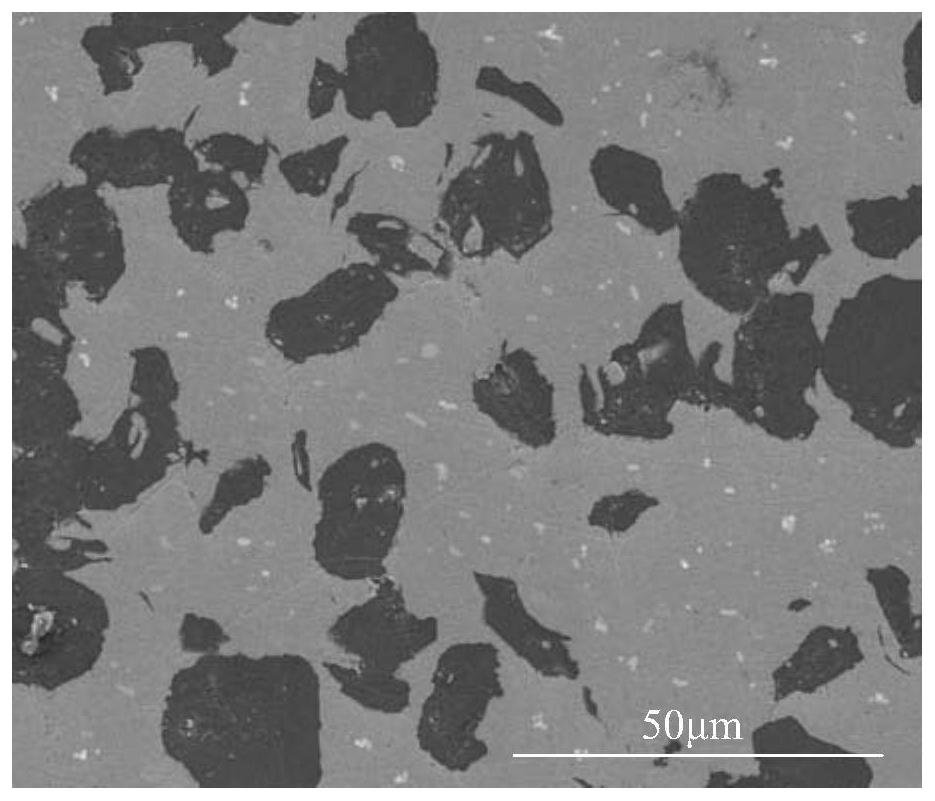

A kind of anti-electric ablation wear-resisting wear-reducing copper-based composite material and preparation method thereof

ActiveCN109136630BEvenly distributedReduce interfacial energyLiquid/solution decomposition chemical coatingCopper platingRaw material

The invention provides a copper-based composite material resistant to electric ablation, wear-resisting and friction-reducing, and the raw materials include Sn, Pb, Cr, C, TiB 2 and copper. The invention also provides a preparation method of the composite material. In the electric ablation-resistant, wear-resistant and friction-reducing copper-based composite material of the present invention, graphite is added by copper-coated graphite powder, because the copper layer on the graphite surface can reduce the interface energy and density difference between it and the copper alloy powder, making it The distribution in the composite is more uniform. In the preparation method, the heating is realized by induction rapid heating, and then the temperature is uniform, which not only shortens the heating time and saves energy consumption, but also realizes uniform temperature heating, avoiding the skin effect and wrapping caused by the long time of ordinary induction heating damage, while avoiding the problem that the cross-sectional temperature cannot be achieved due to the poor thermal conductivity of the powder.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com