A composite preparation process and equipment for semi-solid metal paste

A technology of semi-solid metal and slurry, which is applied in the compound preparation process and equipment field of semi-solid metal slurry, which can solve the problems of impure components of slurry, gas entrapment, corrosion of agitator, etc., and achieve good uniformity of structure and shape , Stirring force is enhanced, and the effect of avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

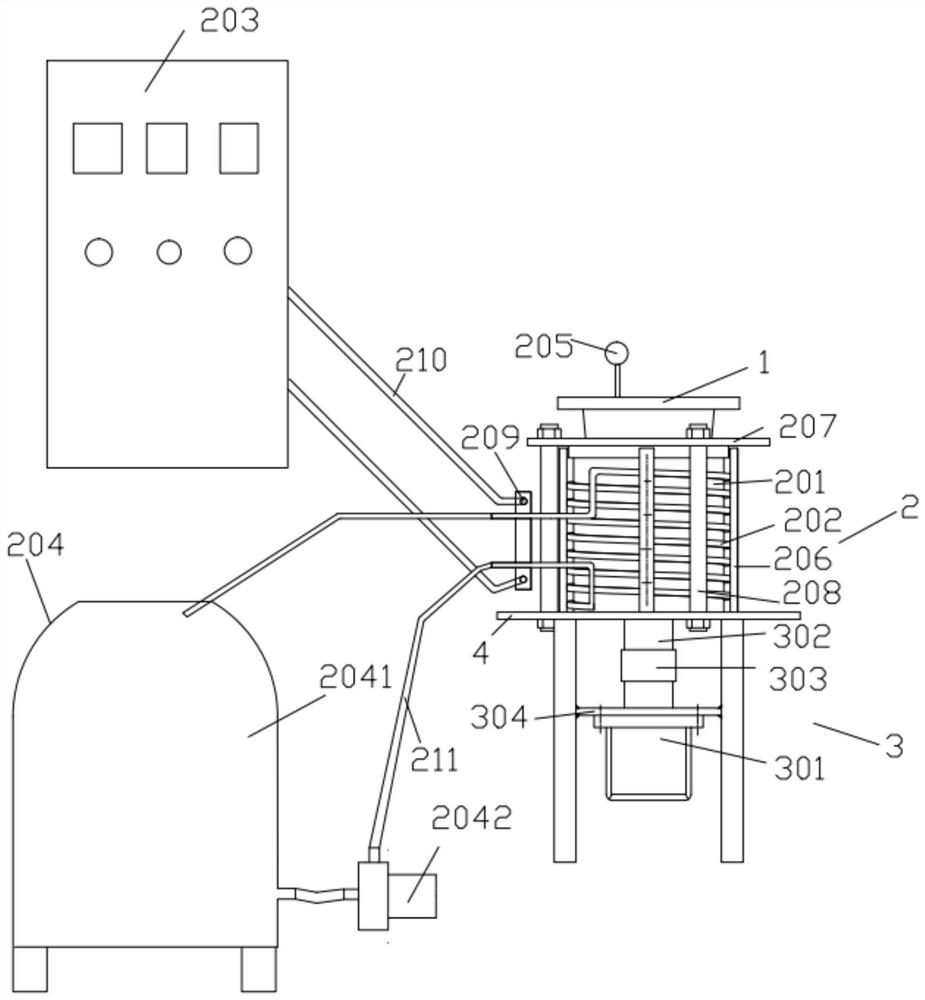

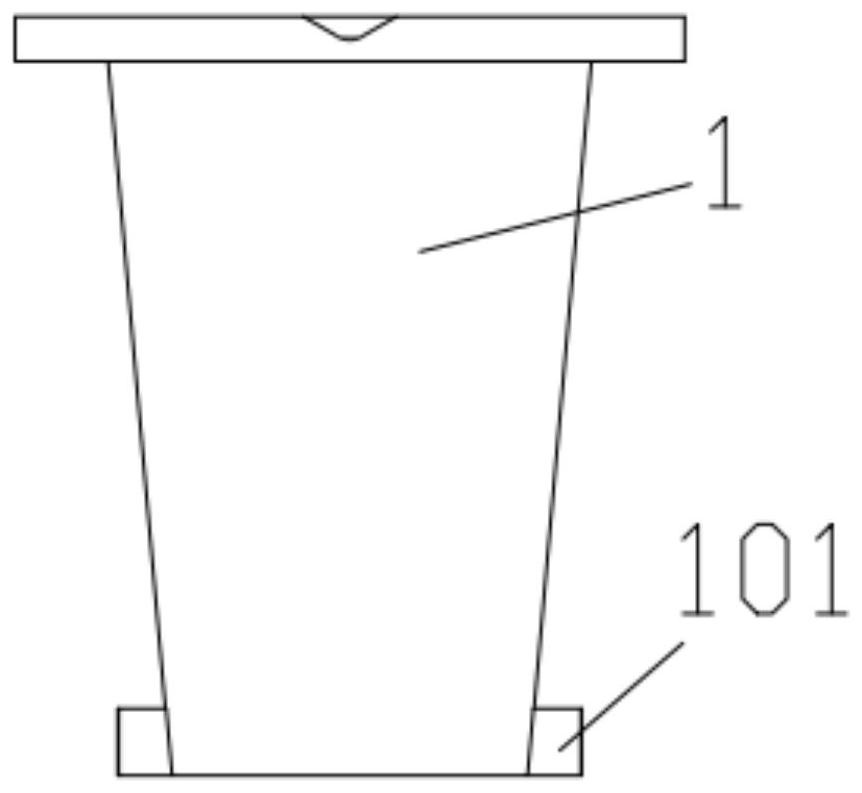

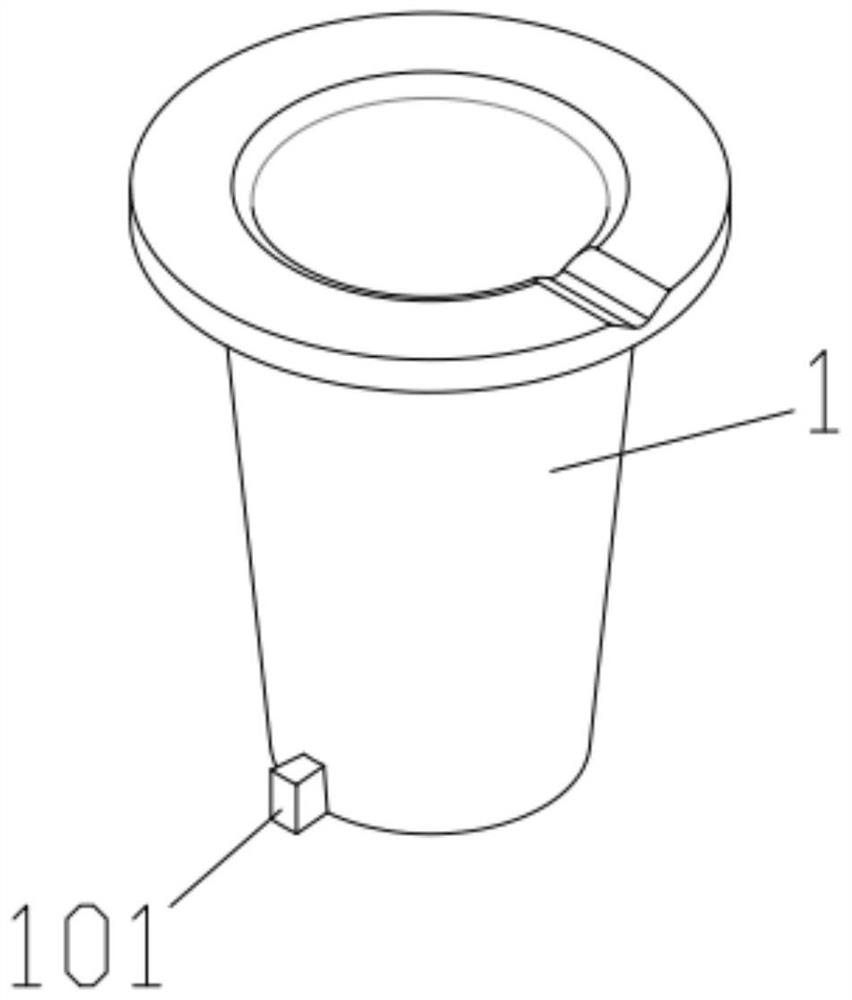

[0042] A compound preparation equipment for semi-solid metal paste, such as figure 1 As shown, it includes a slurry preparation container 1, a weak electromagnetic stirring device 2, a mechanical stirring device 3, and a support 4. The mechanical stirring device 3 is located under the weak electromagnetic stirring device 2, and the slurry preparation container 1 is a crucible, such as figure 2 and 3 shown;

[0043]Weak electromagnetic stirring device comprises insulation layer 201, electromagnetic induction coil 202, electric control device 203, cooling device 204, temperature measuring element 205, electromagnetic induction coil fixed rod 206, pressure plate 207, bolt 208, and temperature measuring element 205 is platin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com