Ultrasonic-enhanced magnetic powder core compression molding method and compressed powder magnetic core

A press forming and ultrasonic technology, applied in the field of press forming, can solve the problems of reducing the local and even macro resistivity of the green compact, controlling the local density and resistivity of the green compact, and the promotion of mass production needs to be investigated, so as to improve the macro resistivity. , The effect of reducing pinning phenomenon and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

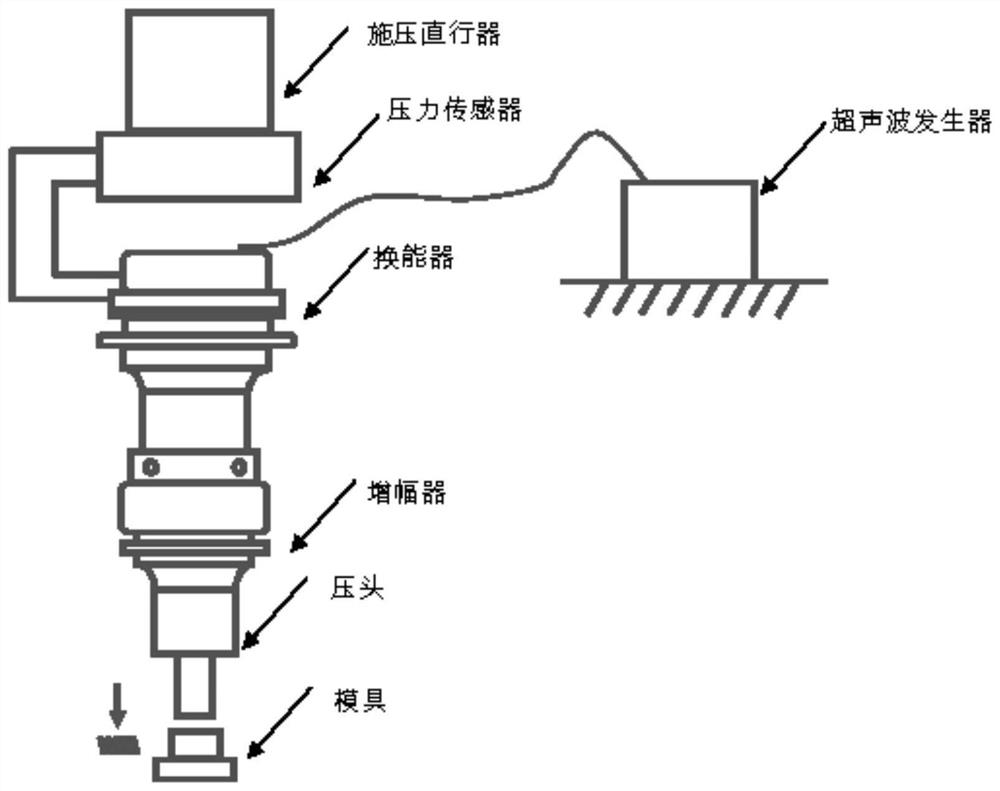

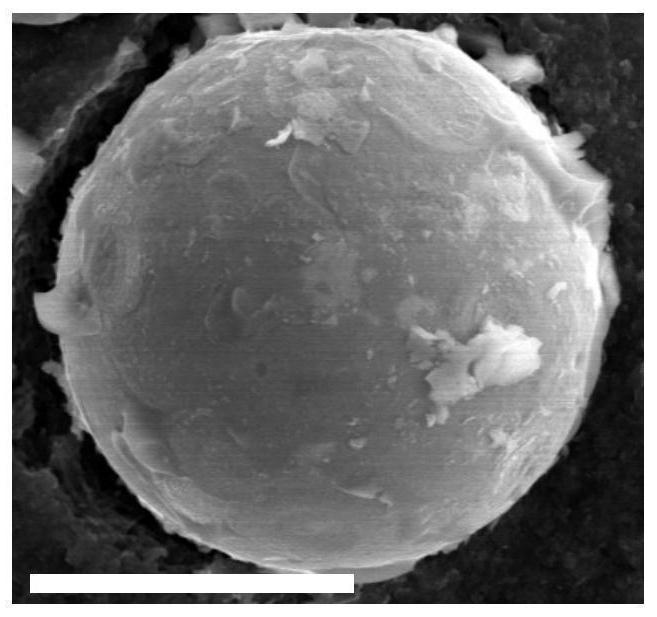

[0061] In the present embodiment, the soft magnetic powder material used is Ni-Fe powder, and the insulating material is organic silicon resin, wherein, the mass ratio of organic silicon resin and soft magnetic powder is 1.5:100, and organic silicon resin is dissolved in acetone, After adding the magnetic material, stir until the acetone is completely volatilized, then take out the mixed powder, dry it and put it into an ultrasonic mold for pressing. Such as figure 2 As shown, the insulating material and soft magnetic powder are evenly distributed.

[0062] The pressure of the pneumatic system is set to 0.6MPa, the pressing time is 0.5s, the holding time is 5s, the ultrasonic frequency of the ultrasonic generator is 15kHz, the vibration amplitude of the ultrasonic amplifier is 80%, and the pneumatic system and the ultrasonic generator are started at the same time. The magnetic powder core is obtained after compression molding.

[0063] Using a vibrating sample magnetometer ...

Embodiment 2

[0068] The difference from Example 1 is that the soft magnetic powder material used is Fe-Si-B-C-Cr amorphous powder, wherein the mass ratio of the silicone resin to the amorphous soft magnetic powder is 1.5:100, and the silicone resin is dissolved in acetone , add the magnetic material and stir until the acetone volatilizes completely, then take out the mixed powder, put it into the ultrasonic mold for pressing after drying, the ultrasonic time is 0.5s, and the holding time is 5s; Figure 4 As shown, the insulating material and soft magnetic powder are evenly distributed.

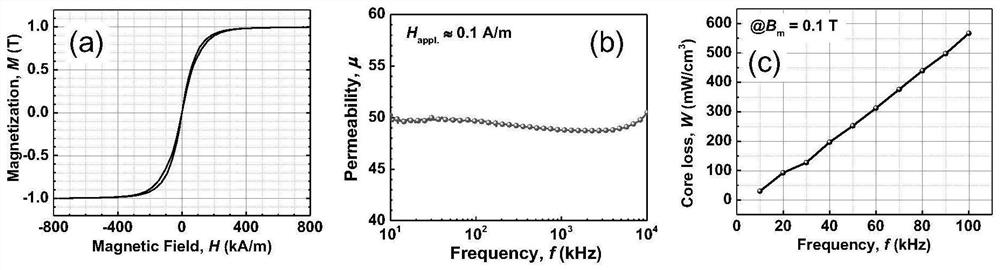

[0069] Using a vibrating sample magnetometer to measure the magnetic properties of magnetic powder cores, such as Figure 5 As shown in (a), measured B s It is 0.92T.

[0070] The 2335A broadband energy analyzer of Hunan Lianzhong Company is used to measure the iron loss of the magnetic powder core, such as Figure 5 As shown in (c), the measured iron loss is W 0.1 / 100k Less than 620mW / cm 3 ;

[0071...

Embodiment 3

[0075] The difference from Example 1 is that the soft magnetic powder material used is Fe-Si-Al powder, the insulating substance is epoxy resin, the mass ratio of epoxy resin to soft magnetic powder is 2:100, and the epoxy resin is dissolved in acetone , add soft magnetic powder and stir until the acetone volatilizes completely, then take out the mixed powder, put it into an ultrasonic mold for pressing after drying, the ultrasonic time is 0.5s, and the holding time is 5s; Figure 6 As shown, the insulating material and soft magnetic powder are evenly distributed.

[0076] Using a vibrating sample magnetometer to measure the magnetic properties of magnetic powder cores, such as Figure 7 As shown in (a), measured B s 0.99T;

[0077] The 2335A broadband energy analyzer of Hunan Lianzhong Company is used to measure the iron loss of the magnetic powder core, such as Figure 7 As shown in (c), measure the iron loss W 0.1 / 100k Less than 659.4mW / cm 3 ;

[0078] The electrical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saturation magnetic induction | aaaaa | aaaaa |

| core loss | aaaaa | aaaaa |

| saturation magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com