Patents

Literature

75results about How to "Increase fill ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

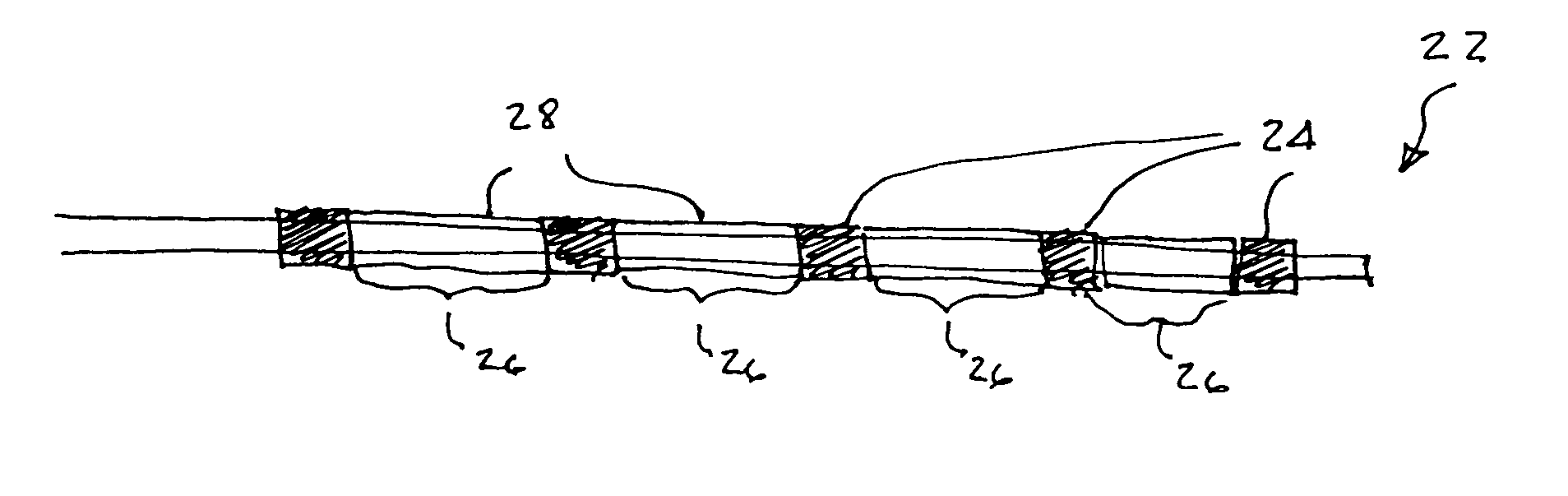

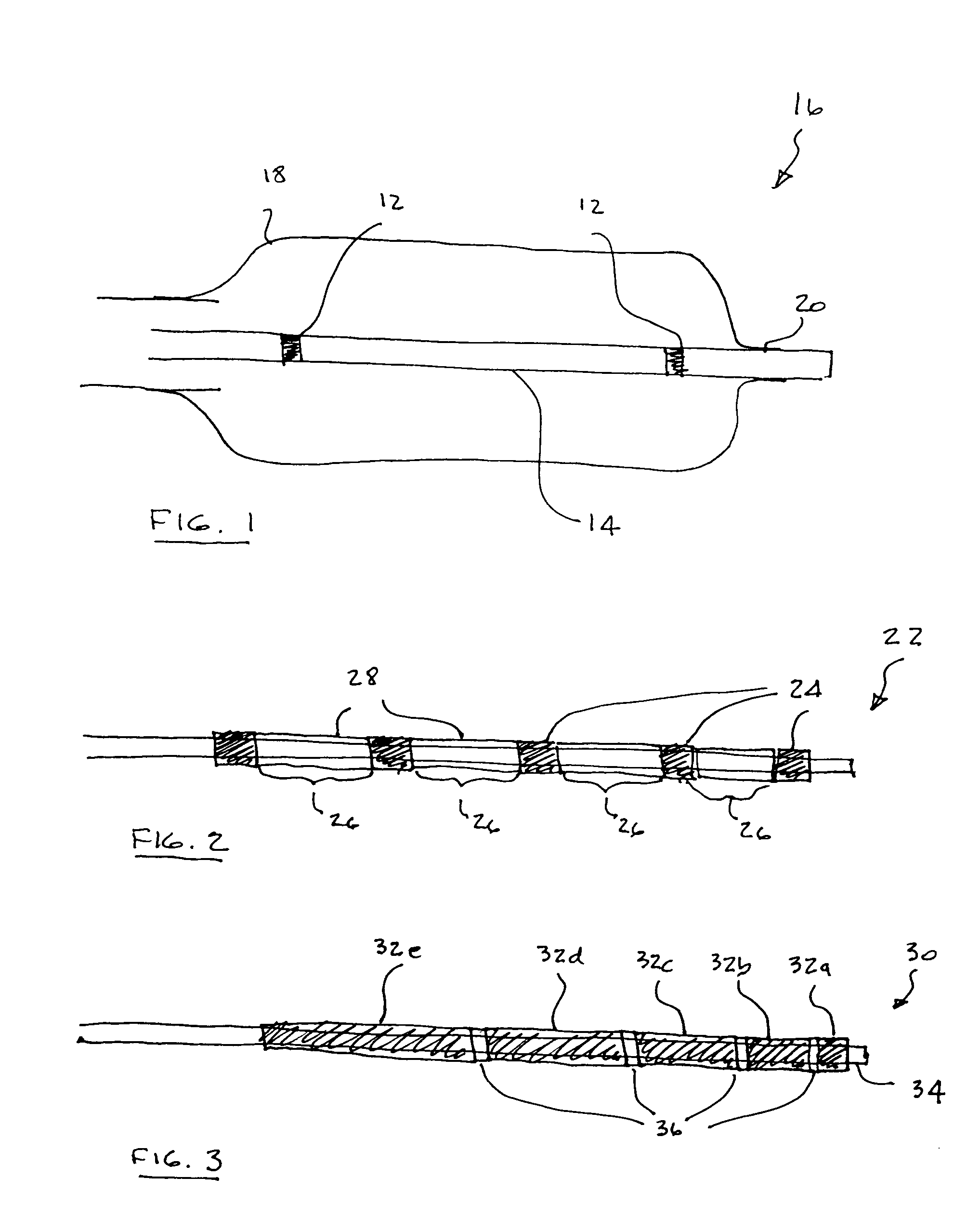

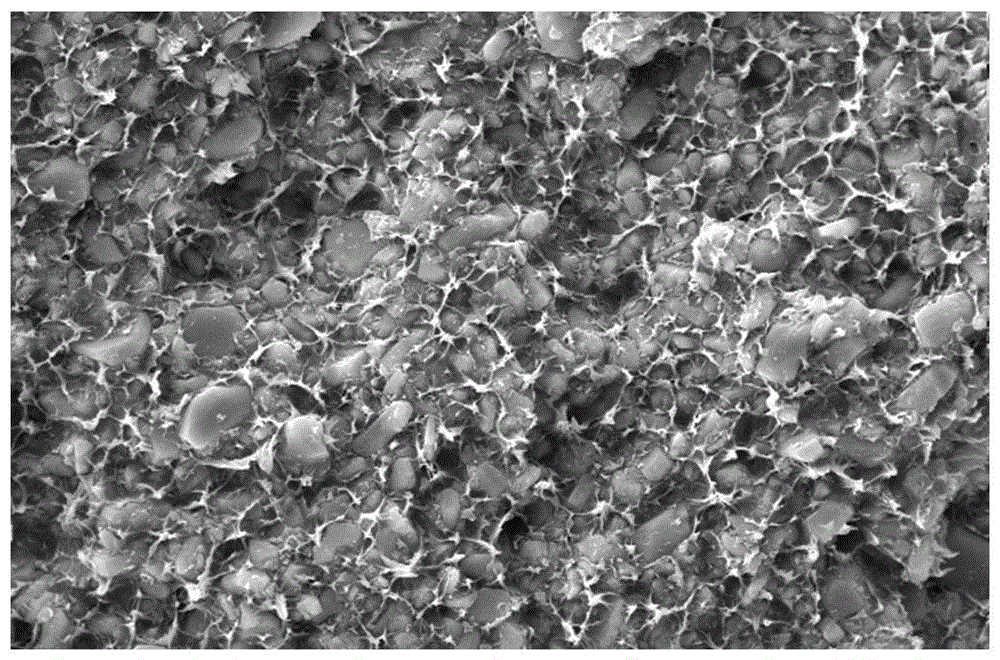

Polymeric marker with high radiopacity

InactiveUS20050064223A1Overcomes shortcomingImprove fill rateSurgeryConductive materialPolymer resinRadiopaque agent

High radiopacity is achieved in a polymeric marker by combining a polymeric resin, a powdered radiopaque agent having uniformly shaped particles of a specific particle size distribution and a vetting agent. The method to produce the marker calls for the blending and pelletization of these materials followed by extrusion onto support beading. The resulting supported tubing is subsequently cut to length with the beading still in place. After ejection of the beading remnant the marker is slipped into place on the device to be marked and attached by melt bonding. Marking of a guidewire allows lesions to be measured while the marking of balloon catheters allow the balloon to be properly positioned relative to a lesion.

Owner:ABBOTT CARDIOVASCULAR

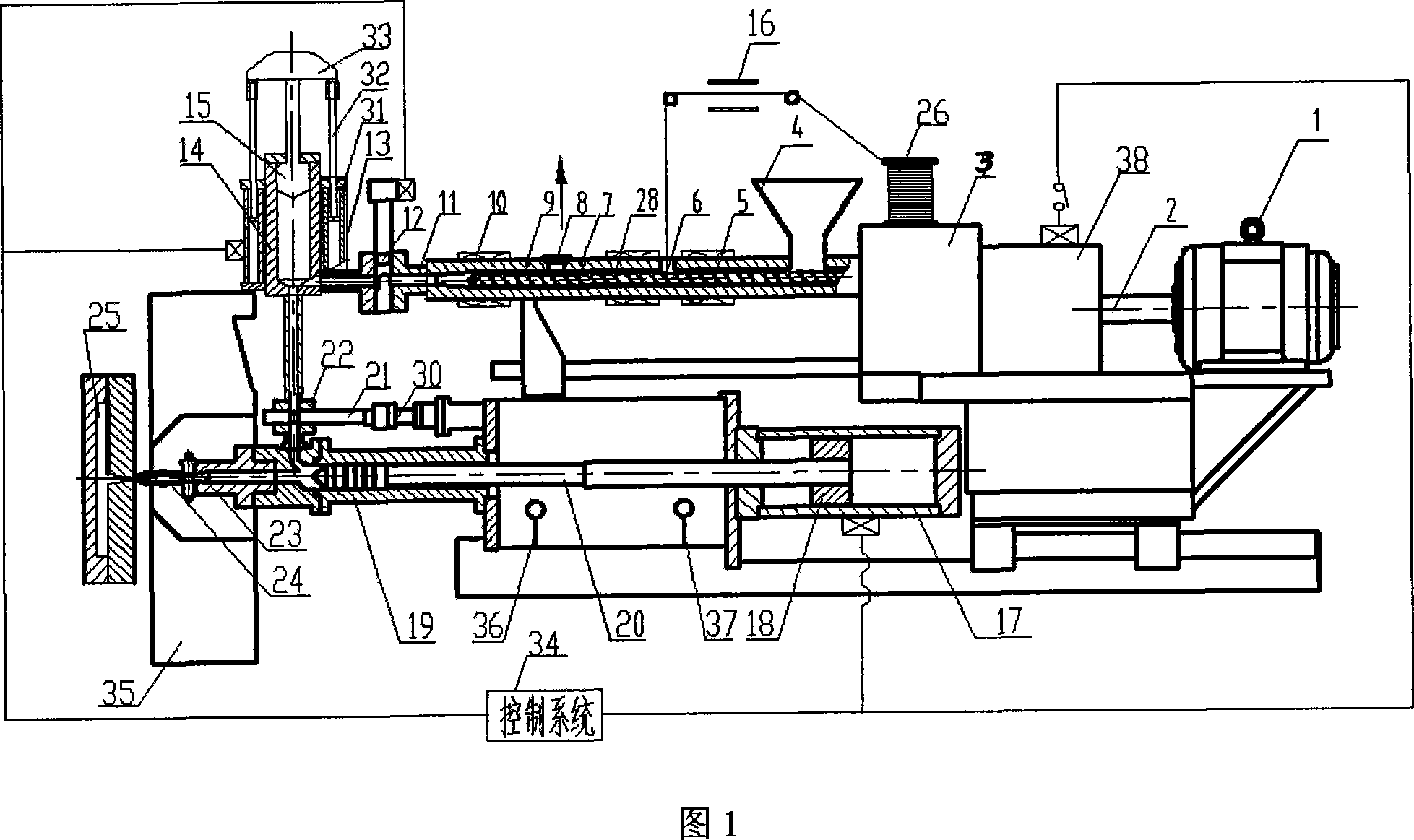

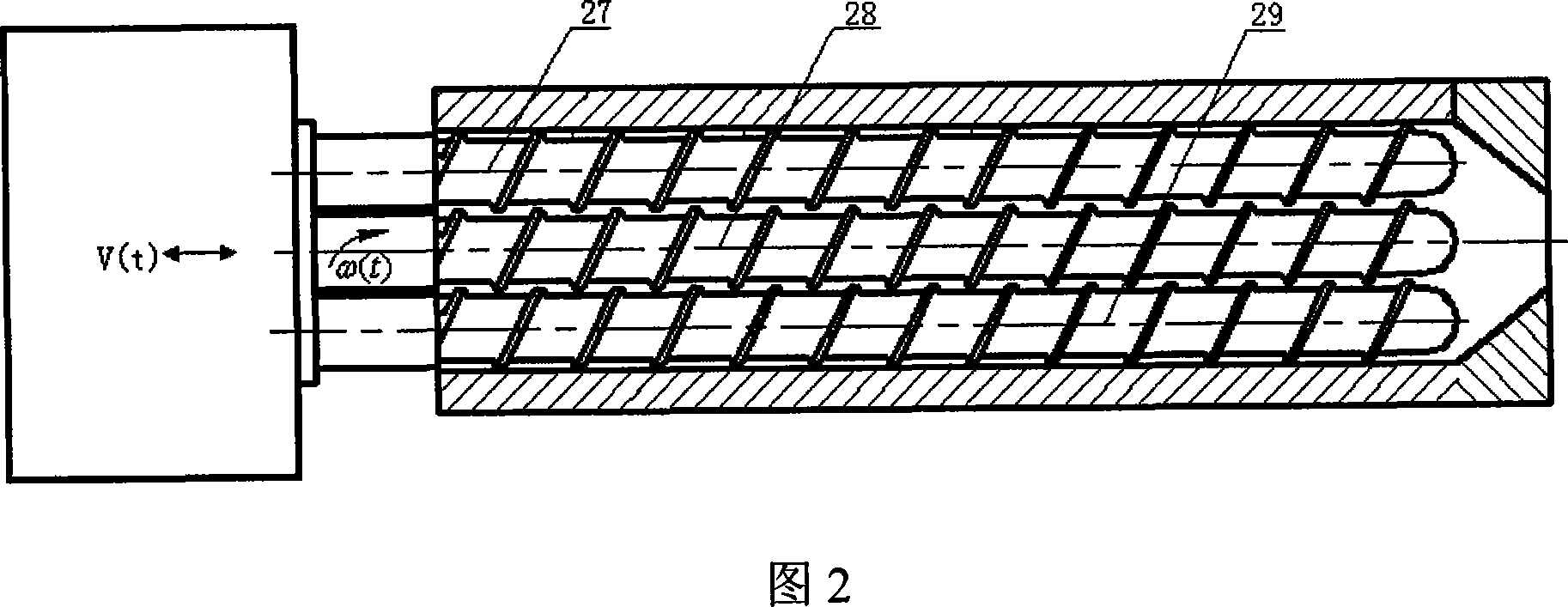

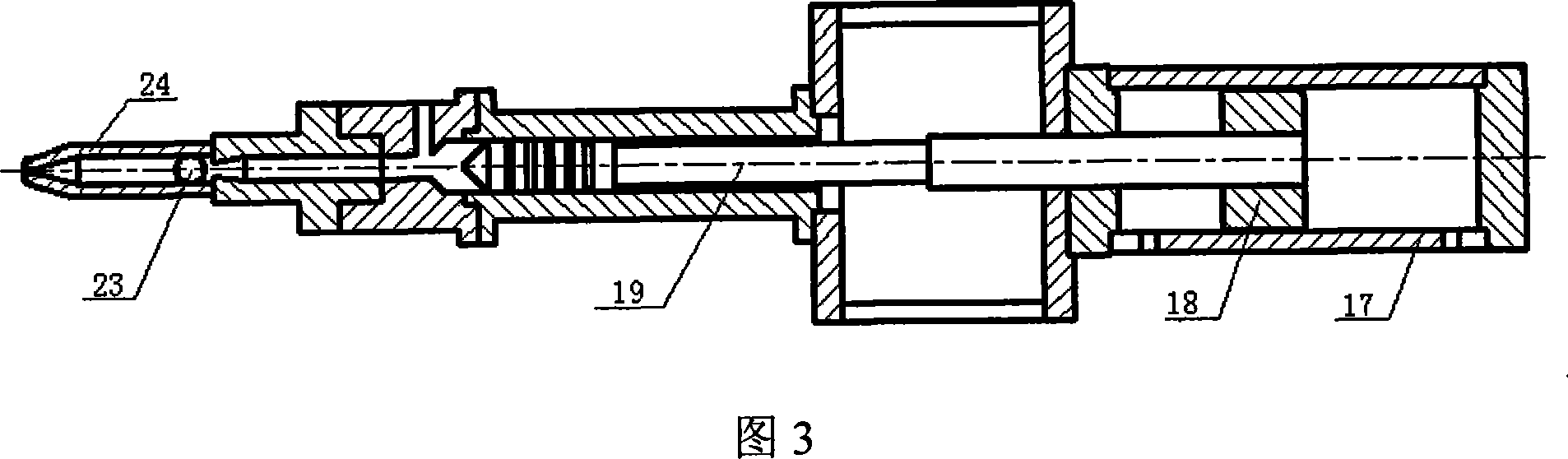

Pulse type shock processing on-line compound injection molding method and its equipment

InactiveCN101077611AIncrease fill ratioImprove interface compatibilityEngineeringFiber-reinforced composite

The present invention discloses pulse type shock reinforced in-line mixing and injecting forming method and apparatus. Pulse type shock is introduced into the whole in-line mixing and injecting forming process of producing fiber reinforced composite polymer material. The apparatus includes one plasticizing extruder with three screws arranged in one line and including one main screw capable of generating periodical axial pulse shock, one buffering storing device, and one pulse type shock pressure reinforcing plunger injecting device. The present invention can lower melt viscosity, raise mixing and homogenizing effect, raise the compatibility between fiber and polymer, lower the processing power consumption and raise product quality.

Owner:SOUTH CHINA UNIV OF TECH

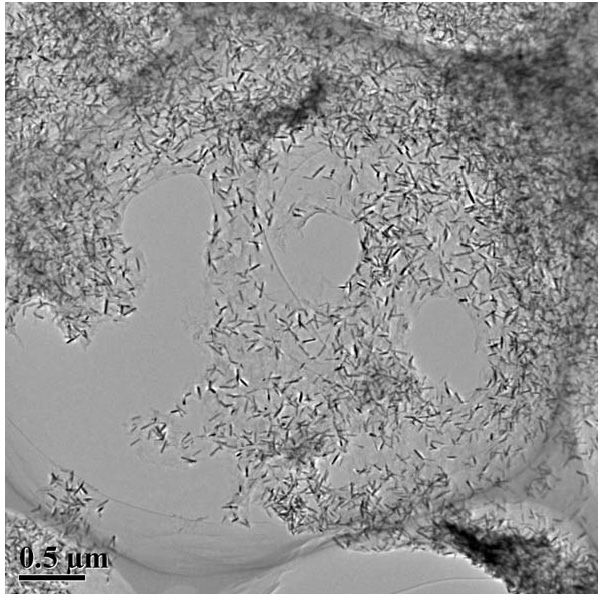

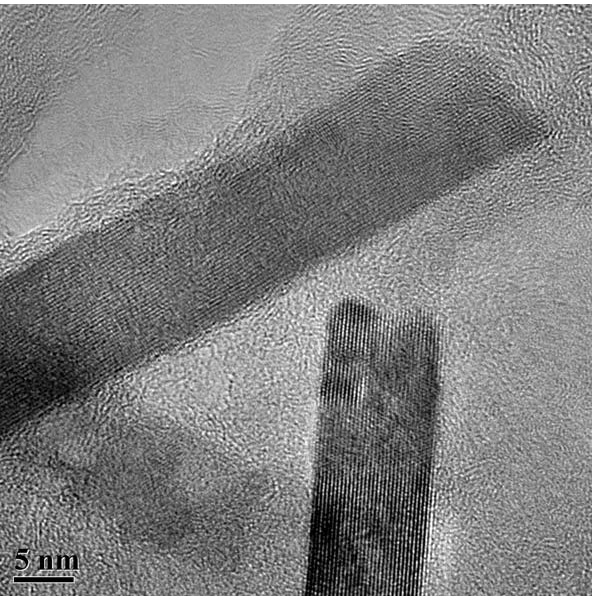

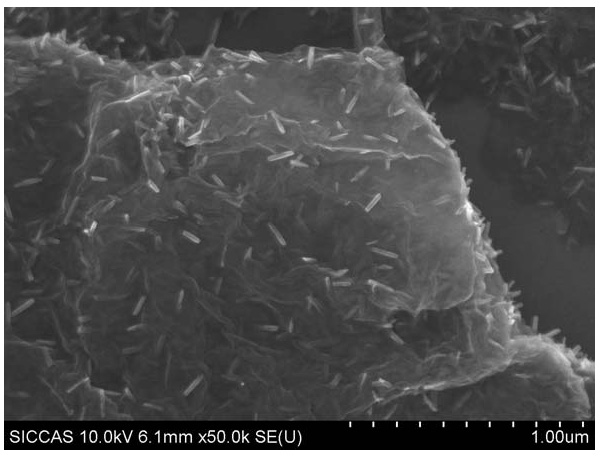

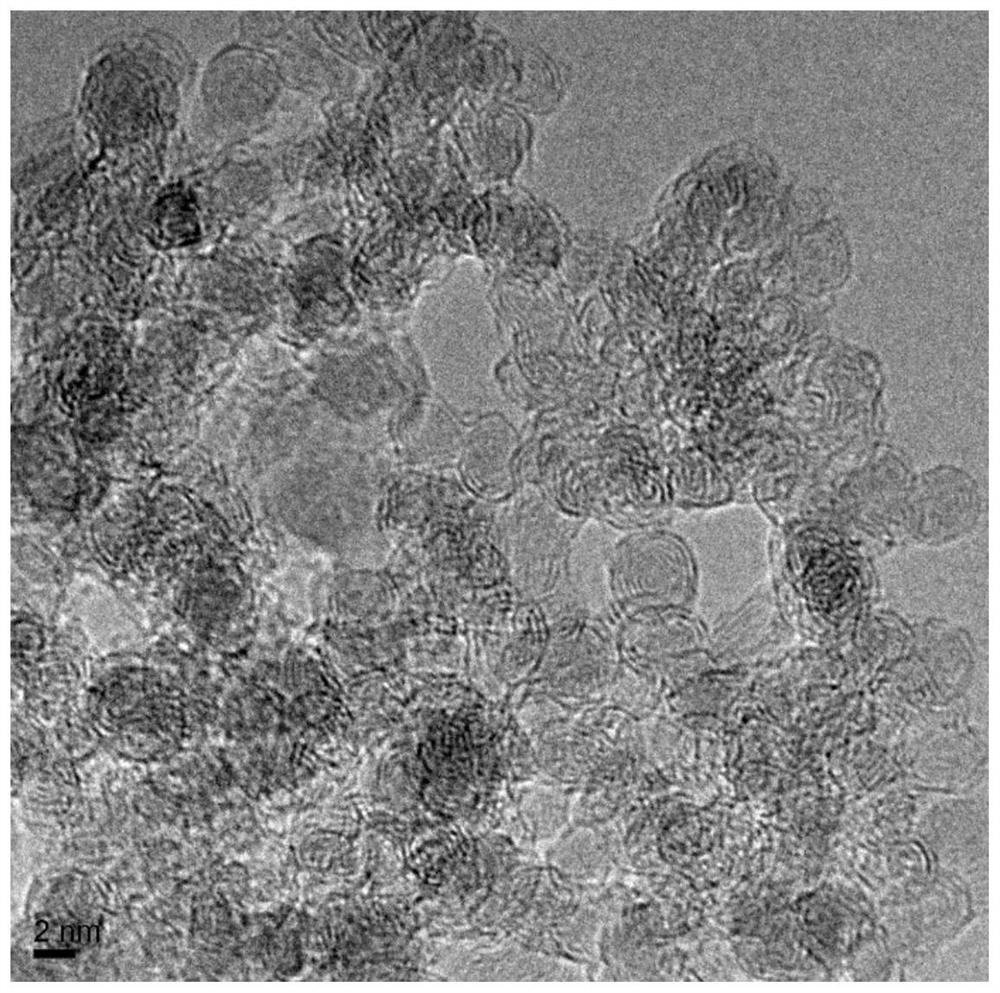

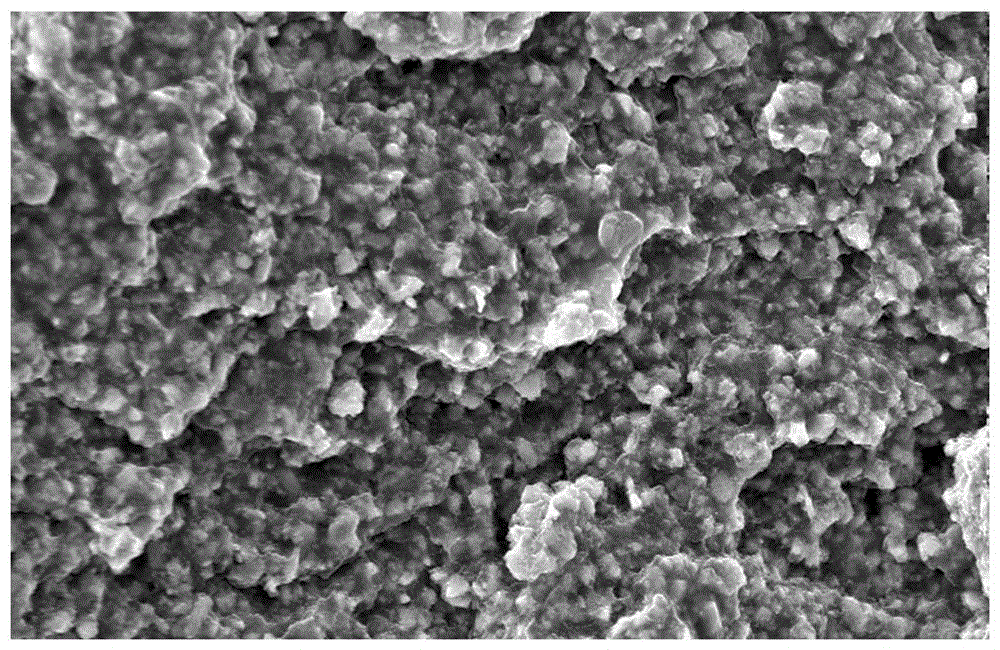

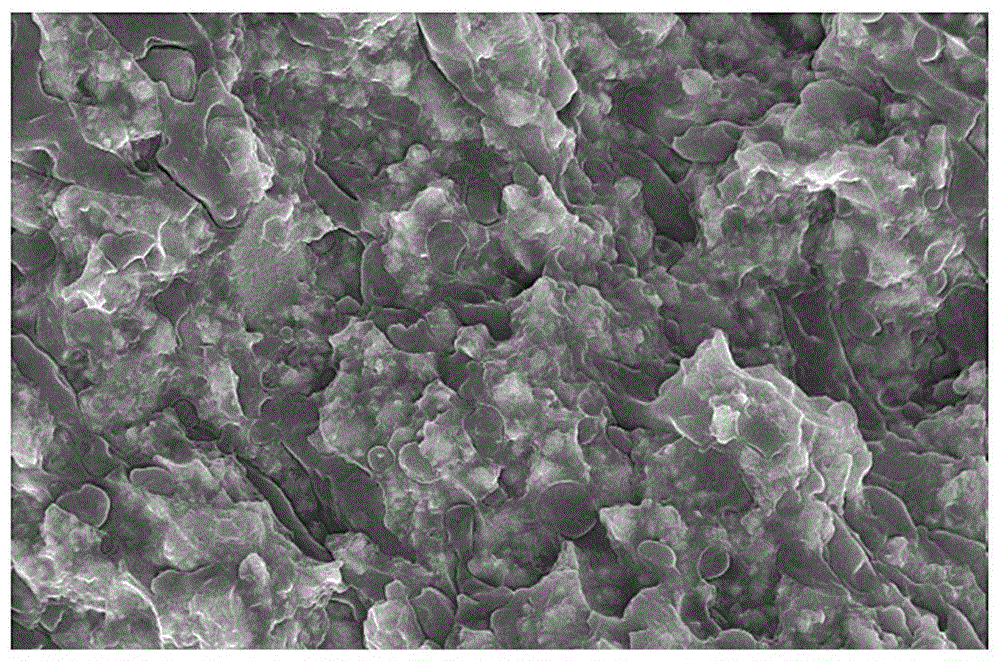

Nitrogen-doped graphene/tin oxide nano composite material and preparation method thereof

InactiveCN102324522ALarge specific surface areaImprove conductivityCell electrodesLithiumDoped graphene

The invention relates to a nitrogen-doped graphene / tin oxide nano composite material and a preparation method thereof. The nitrogen-doped graphene / tin oxide nano composite material comprises graphene and tin oxide nanocrystals loaded on the surface of the graphene. The doping content of the nitrogen in the composite material is 0 to 8 percent. Due to the doping effects of the nitrogen and the dispersive action of tin oxide nanoparticles in the graphene, the composite material has the characteristics of large specific area surface and high conductivity, and exhibits high electrochemical lithium storage performance.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for preparing hollow steel ingot for protection ring of large power generator by adopting electroslag remelting

ActiveCN104164574AIncrease profitReduce heating timesCasting parameters measurement/indication devicesTransformerProtection ring

The invention discloses a method for preparing a hollow steel ingot for a protection ring of a large power generator by adopting electroslag remelting. The method comprises the following steps: (1) preparing consumable electrode groups; (2) melting slag into liquid molten slag; (3) inserting the consumable electrode groups into an electroslag remelting hollow ingot crystallizer; (4) starting two transformers; (5) injecting the liquid molten slag into the electroslag remelting hollow ingot crystallizer; (6) when the consumable electrode groups are in contact with the liquid molten slag, forming an electrifying loop among fake electrodes, the consumable electrode groups and a bottom water tank; (7) when the liquid molten slag is in contact with an upper section, forming a loop among the upper section, the bottom water tank and the transformers connected with the bottom water tank; (8) adjusting the output currents and voltages of the two transformers; (9) when a metal melt is in contact with a molten steel liquid level detection device, starting an ingot stripping device for ingot stripping; (10) exchanging the consumable electrode groups; and (11) inserting subsequent consumable electrode groups into the liquid molten slag, and repeating the steps (8 to 10) until the ingot stripping is finished.

Owner:NORTHEASTERN UNIV LIAONING

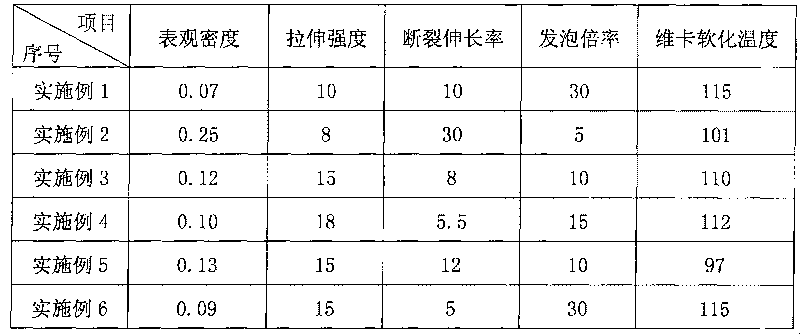

Complete biodegradation foam material and preparation method thereof

The invention discloses a complete biodegradation foam material and a preparation method thereof; the complete biodegradation foam material mainly comprises polyhydroxy alkanoate, starch and foaming agent; the complete biodegradation foam material is characterized in that: the complete biodegradation foam material does not comprise polylactic acid, and 20-80 parts of the polyhydroxy alkanoate, 20-60 parts of starch and 0.5-5 parts of the foaming agent are included by weight. The foam material takes the starch and the polyhydroxy alkanoate as main raw materials, has good physical properties, can carry out complete biodegradation and greatly reduces the manufacturing cost of the foam material.

Owner:SHENZHEN ECOMANN BIOTECH

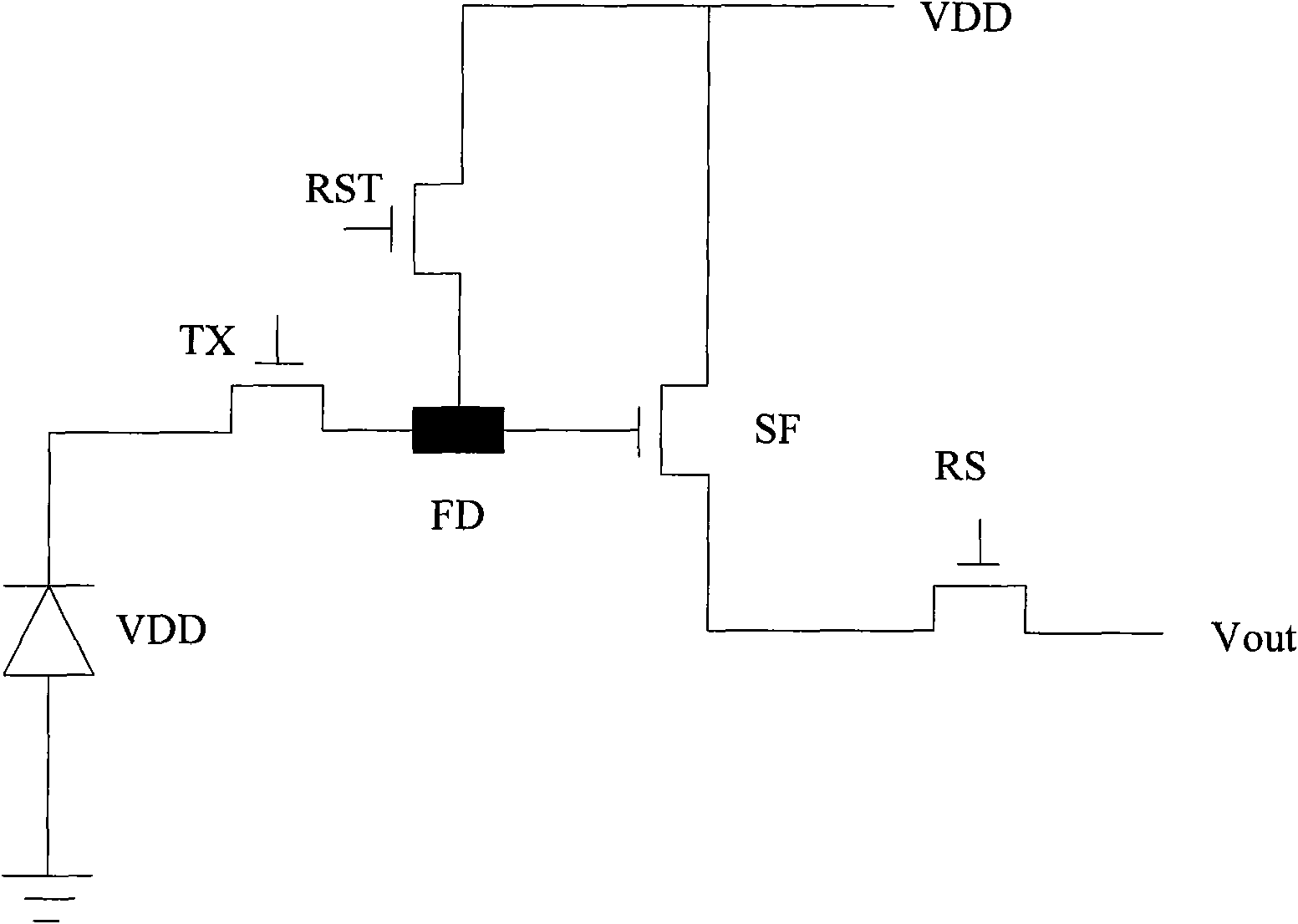

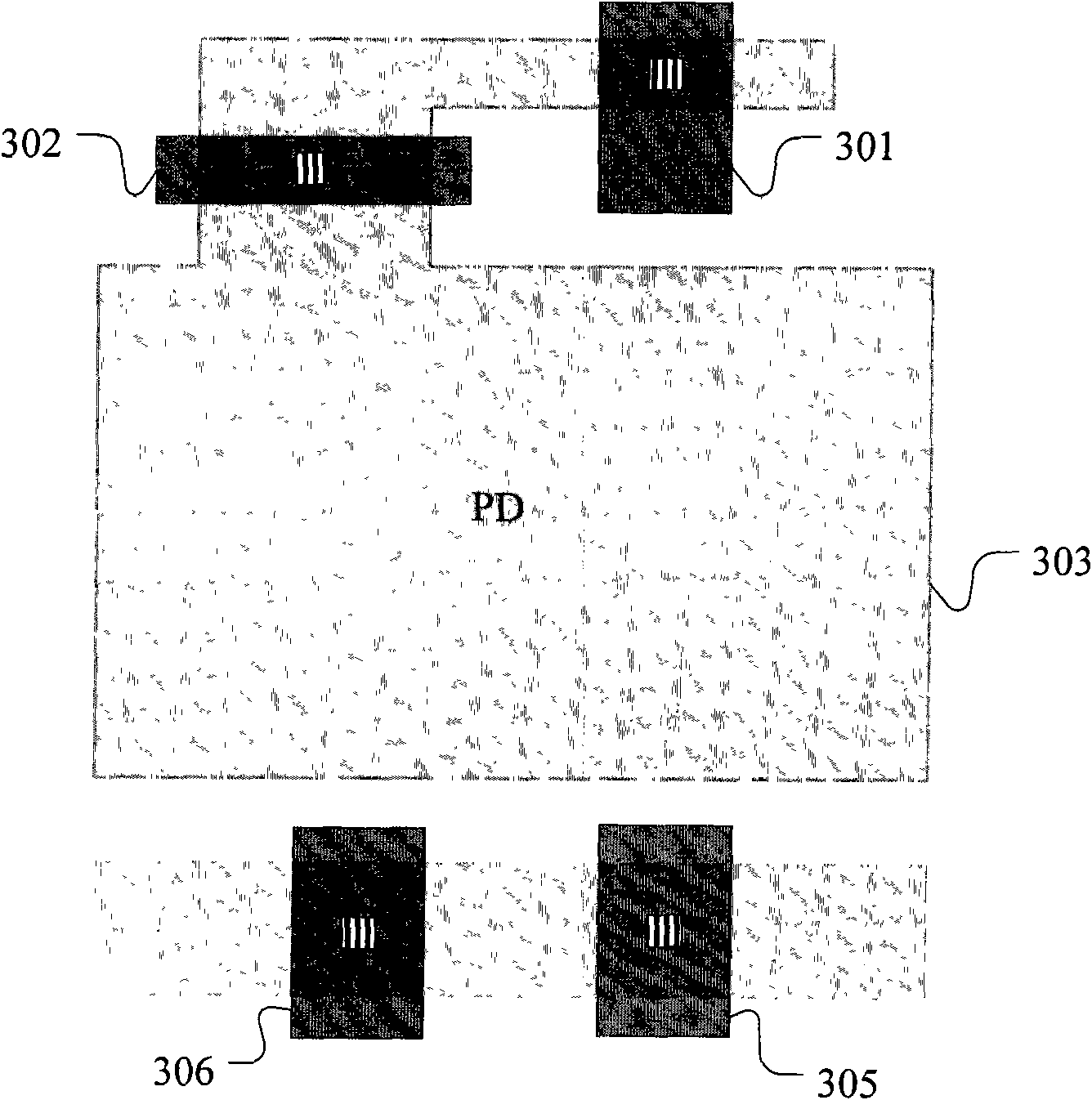

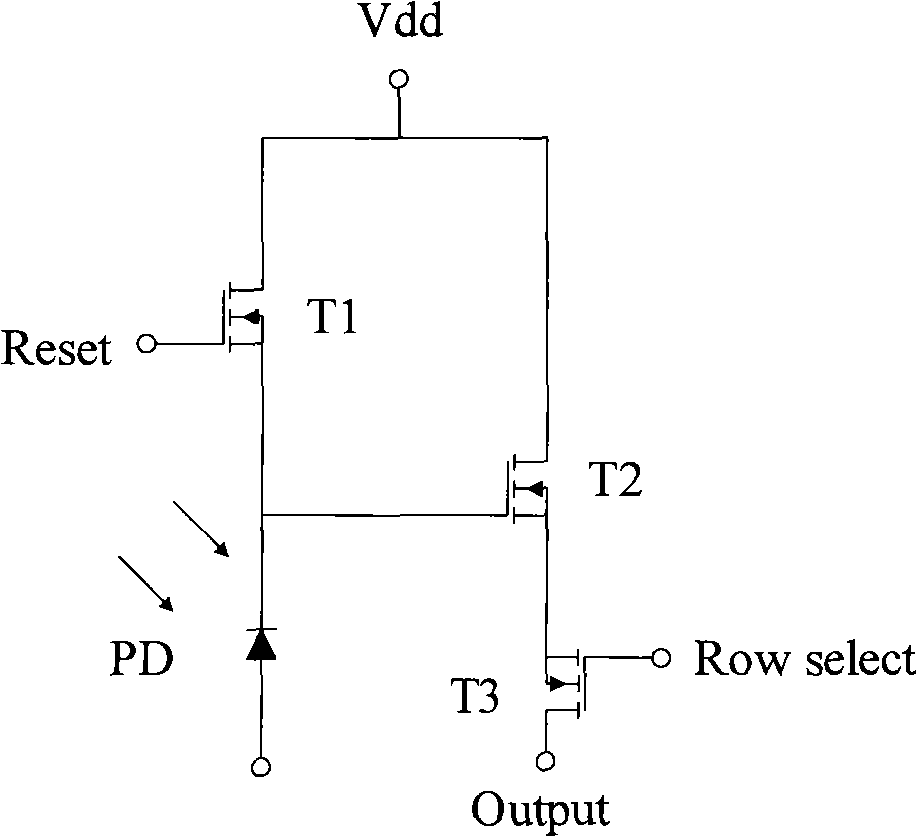

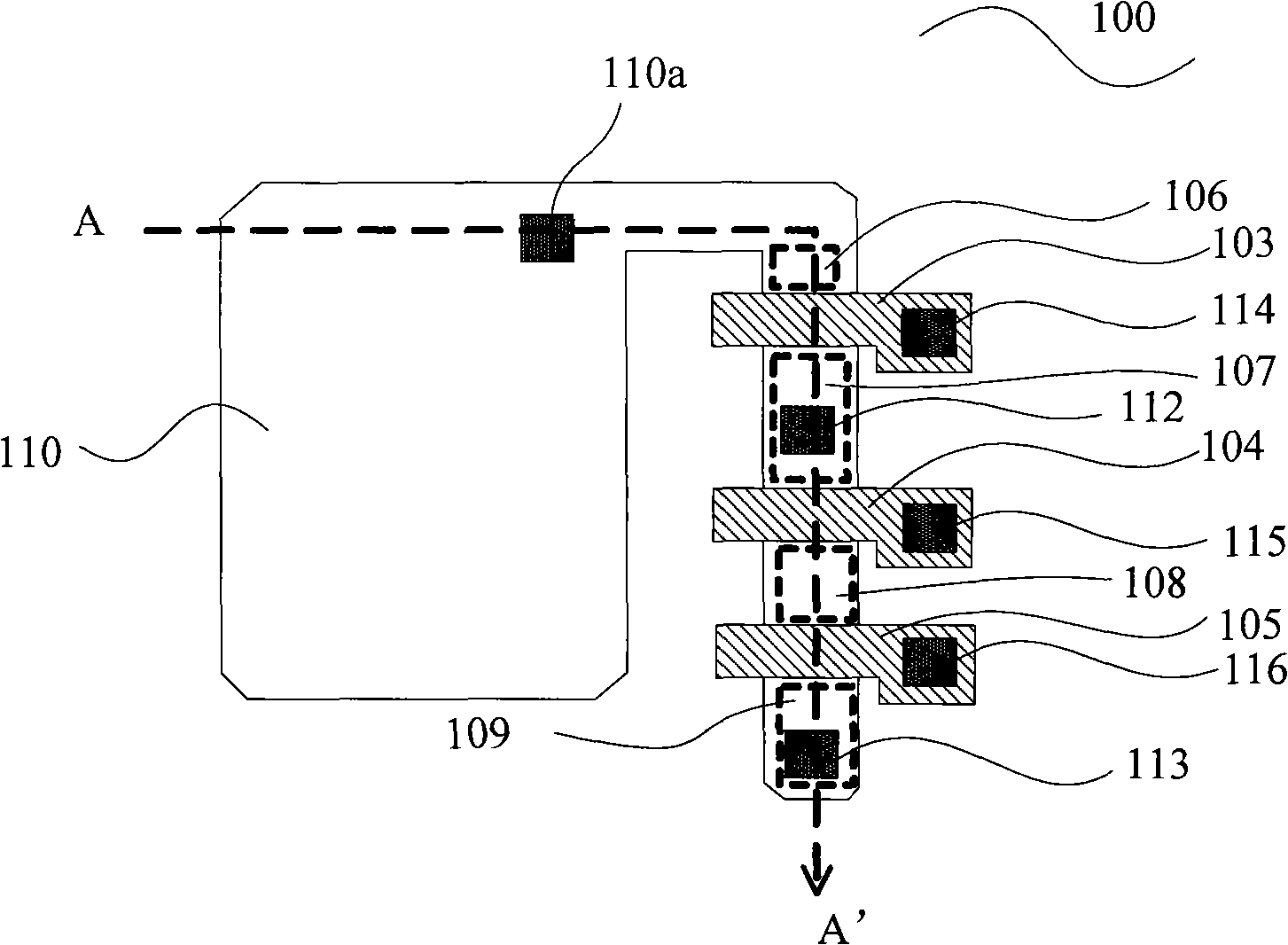

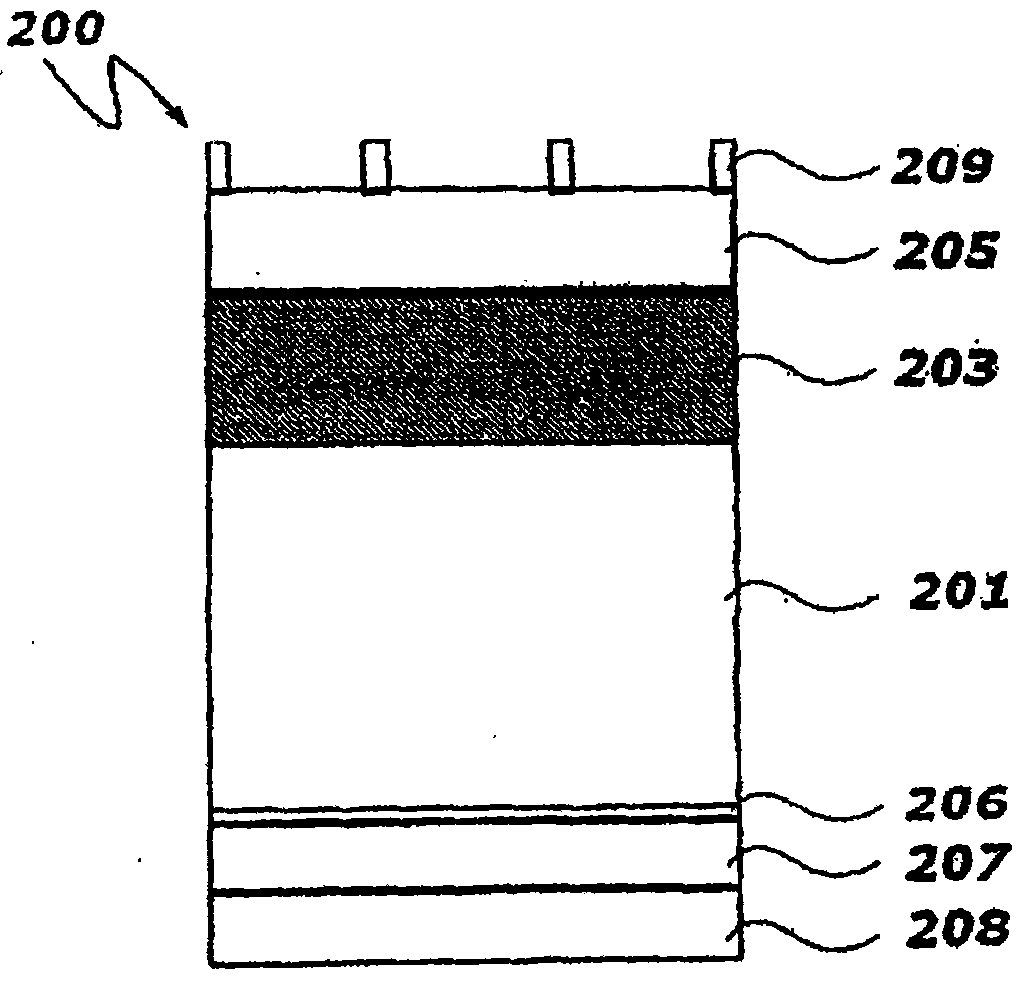

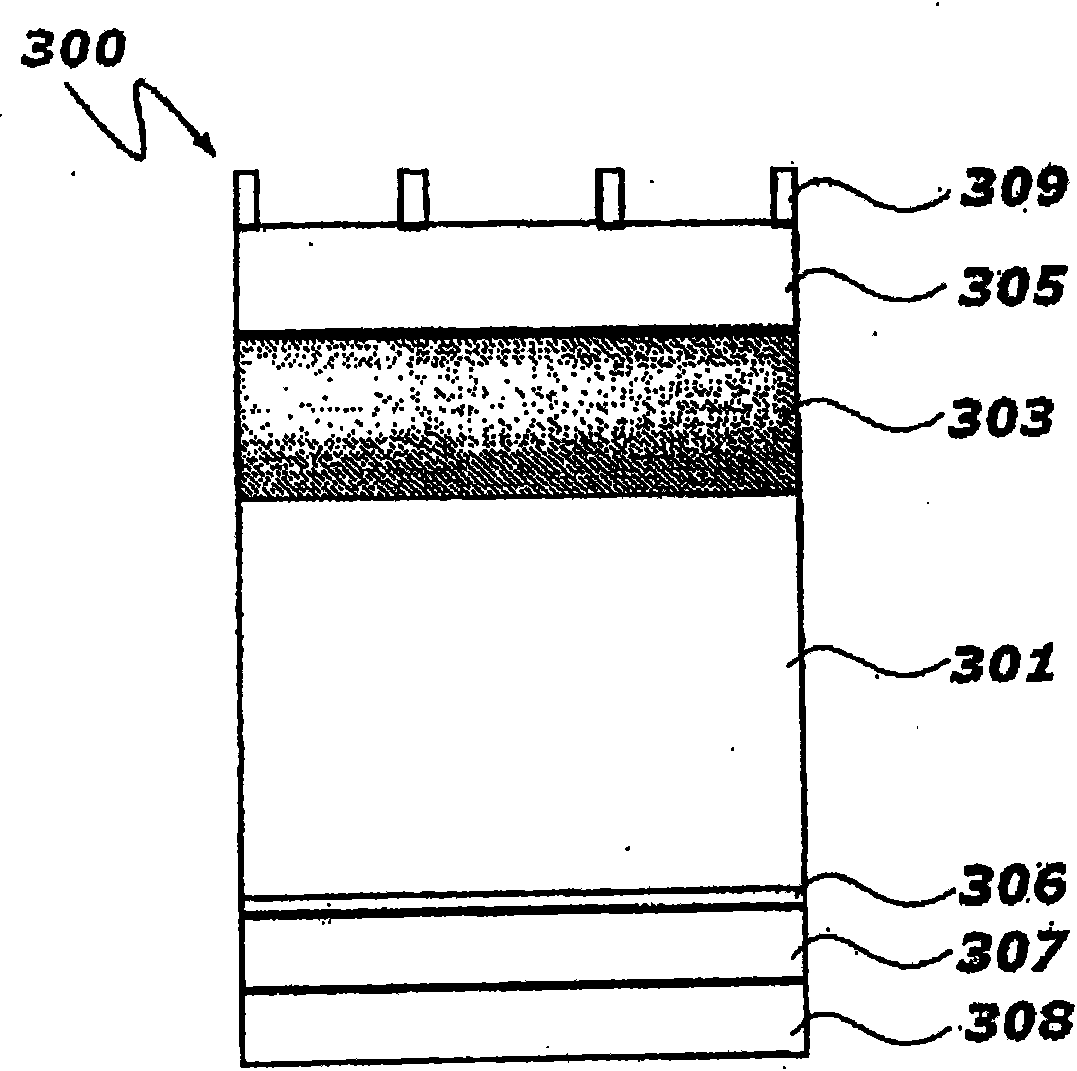

Pixel unit and image sensor with high dynamic range

ActiveCN102387316AIncreased ability to store chargeLarge dynamic rangeTelevision system detailsColor television detailsPhotodiodeComputer science

The invention provides a pixel unit with a high dynamic range. The pixel unit is provided with a 4T structure; a reset transistor grid part of the pixel unit and a photodiode region are overlapped to form a first charge storage grid; and a row strobe transistor grid part and the photodiode region are overlapped to form a second charge storage grid. The invention also provides an image sensor with a high dynamic range. According to the pixel unit disclosed by the invention, the reset transistor grid part and the photodiode region are overlapped to form the first charge storage grid; the row strobe transistor grid part and the photodiode region are overlapped to form a second charge storage grid; and the first charge storage grid is controlled by using a reset signal and the second charge storage grid is controlled by using a row selection signal. The capability of a storage charge of the pixel unit is enhanced and the dynamic range of the pixel unit is widened; meanwhile, the difficulty of metal wire distribution is also reduced, the packing ratio of the pixel unit is increased and the chip area of the pixel unit is reduced.

Owner:BYD SEMICON CO LTD

Epoxy resin encapsulating material composition

ActiveCN101173159ALow initial viscosityLow coefficient of linear expansionOther chemical processesSemiconductor/solid-state device detailsEpoxyChemical composition

An epoxy resin encapsulation material composition, the composition contains epoxy resin, a curing agent and inorganic filler particles containing a coupling agent, wherein the particle diameter of the inorganic filler particles containing a coupling agent is 0.1-200 microns , wherein the inorganic filler particles containing a coupling agent whose particle diameter is not more than 3 microns account for 5-20% by volume of the total amount of the inorganic filler particles containing a coupling agent. The epoxy resin encapsulating material composition provided by the present invention can greatly increase the filling ratio of the inorganic filler, thus making the epoxy resin encapsulating material composition provided by the present invention have low initial viscosity, excellent fluidity, and linear expansion coefficient Low, the production cost of obtaining epoxy resin encapsulation materials with the same initial viscosity is greatly reduced. In addition, the composition provided by the invention has excellent dielectric properties and is suitable for the packaging of various electronic components sensitive to stress, especially for automatic packaging of electronic components requiring high precision.

Owner:靖江德方科技服务有限公司

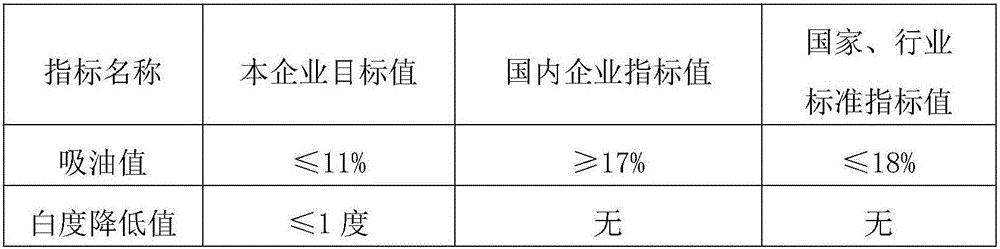

Surface modification method of special ground calcium carbonate for silicone adhesive and surface-modified ground calcium carbonate

InactiveCN106751864AImprove bindingQuality is not affectedPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsStearic acidSilicone adhesive

The invention belongs to the field of research on a surface modification method of calcium carbonate, and aims at solving the problem that common modified ground calcium carbonate cannot be well applied to a silicone adhesive packing. The surface modification method of the special ground calcium carbonate for the silicone adhesive comprises the following steps of (1) heating stearic acid, and mixing the stearic acid with the ground calcium carbonate for surface modification; (2) mixing a product obtained in the step (1) with a silane coupling agent for surface modification; and (3) drying and filtering the product obtained in the step (2). According to the method, ground calcium carbonate powder can be relatively fully modified, so that the ground calcium carbonate powder has good compatibility with the silicone adhesive; the filling ratio of the ground calcium carbonate is improved on the premise of ensuring the quality of the silicone adhesive; the production cost of the silicone adhesive is reduced; and the thixotropy of the silicone adhesive is improved. Meanwhile, the invention further provides the ground calcium carbonate employing the method.

Owner:广西贺州市科隆粉体有限公司

CMOS image sensor and method for forming same

ActiveCN101312201AFree spaceReduced output contact holesSemiconductor/solid-state device detailsSolid-state devicesOptical pathCMOS

A CMOS image sensor comprises at least one CMOS image sensor pixel unit pair which comprises a first pixel unit and a second pixel unit. Each pixel unit in the CMOS image sensor comprises a photodiode area and a drive circuit area, wherein the drive circuit area comprises output transistors. Drain electrodes of the two output transistors adjacent to the first pixel unit and the second pixel unit are connected to be a common output end. The invention further provides another CMOS image sensor, wherein the amount of effective contact holes can be reduced through an output contact hole and a power contact hole of a common output transistor of the adjacent pixel units, thereby effectively decreasing the amount of the contact holes. The structure enables pixel units with smaller dimension to be designed under the condition of unreduced technical nodes without modifying a peripheral circuit and the processing parameter, which can not increase the mask and processing cost, but reduces the output capacitance and increases the filling ratio and the optical path.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

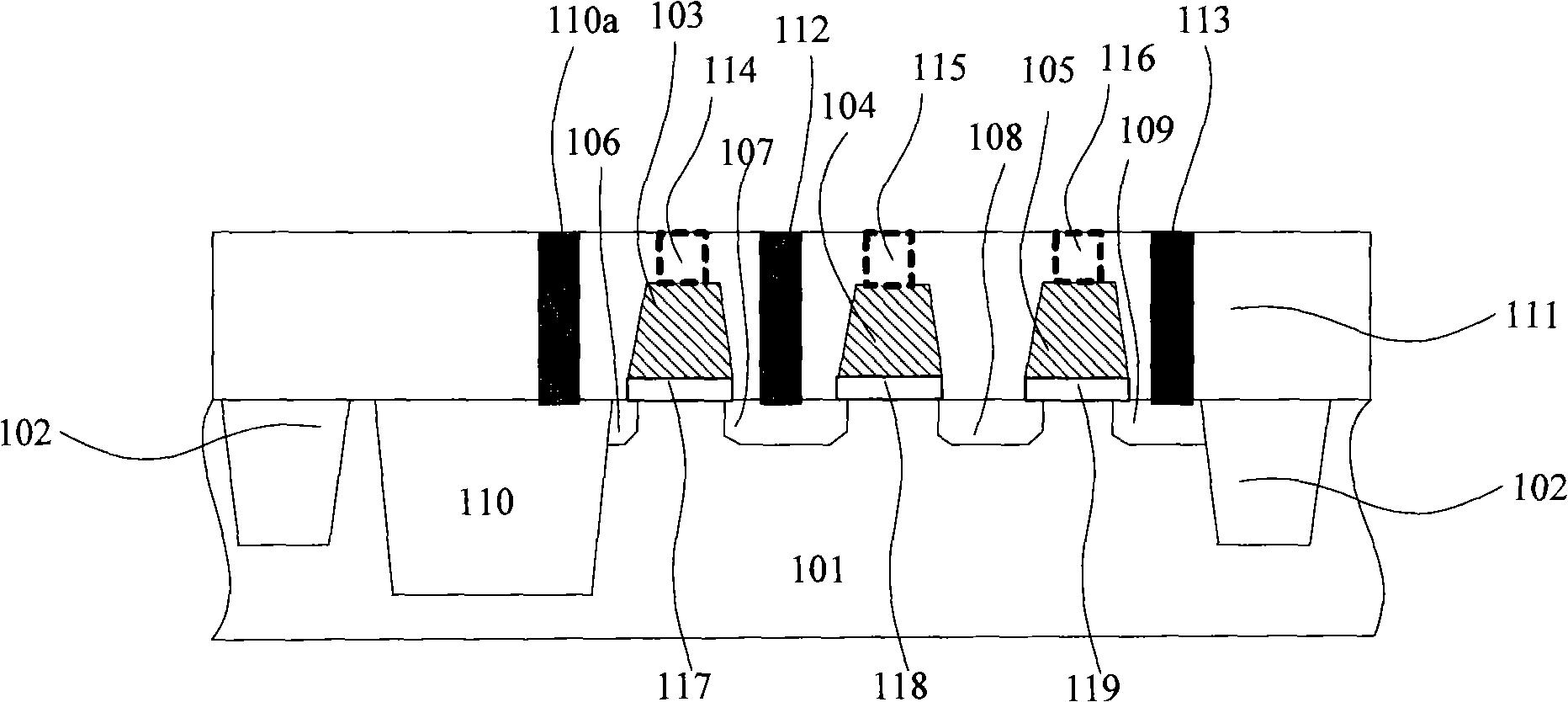

Hydrodesulfurization catalyst grading method

ActiveCN103773437AReduce voidsLarge filling-to-heap ratioRefining to eliminate hetero atomsSulfurHydrodesulfurization

The invention discloses a hydrodesulfurization catalyst grading method, the hydrodesulfurization catalyst grading method is as follows: a hydrogenation reactor comprises at least two catalyst beds, in accordance with the reaction material contact order, an upstream catalyst bed is a low-bulk-ratio catalyst bed, the bulk ratio of a downstream catalyst bed is higher than that of the adjacent upstream catalyst bed, each catalyst bed is loaded with more than two catalysts with different diameters in a grading manner. Compared with a single-diameter catalyst, the physical mixtures have smaller voidage and larger loading bulk ratio, the hydrodesulfurization performance of a whole reaction system can be improved, the operation period is prolonged, on the basis of no addition of fixed investment, production performances of ultra-low-sulfur and low-sulfur clean fuels can be improved in a low cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

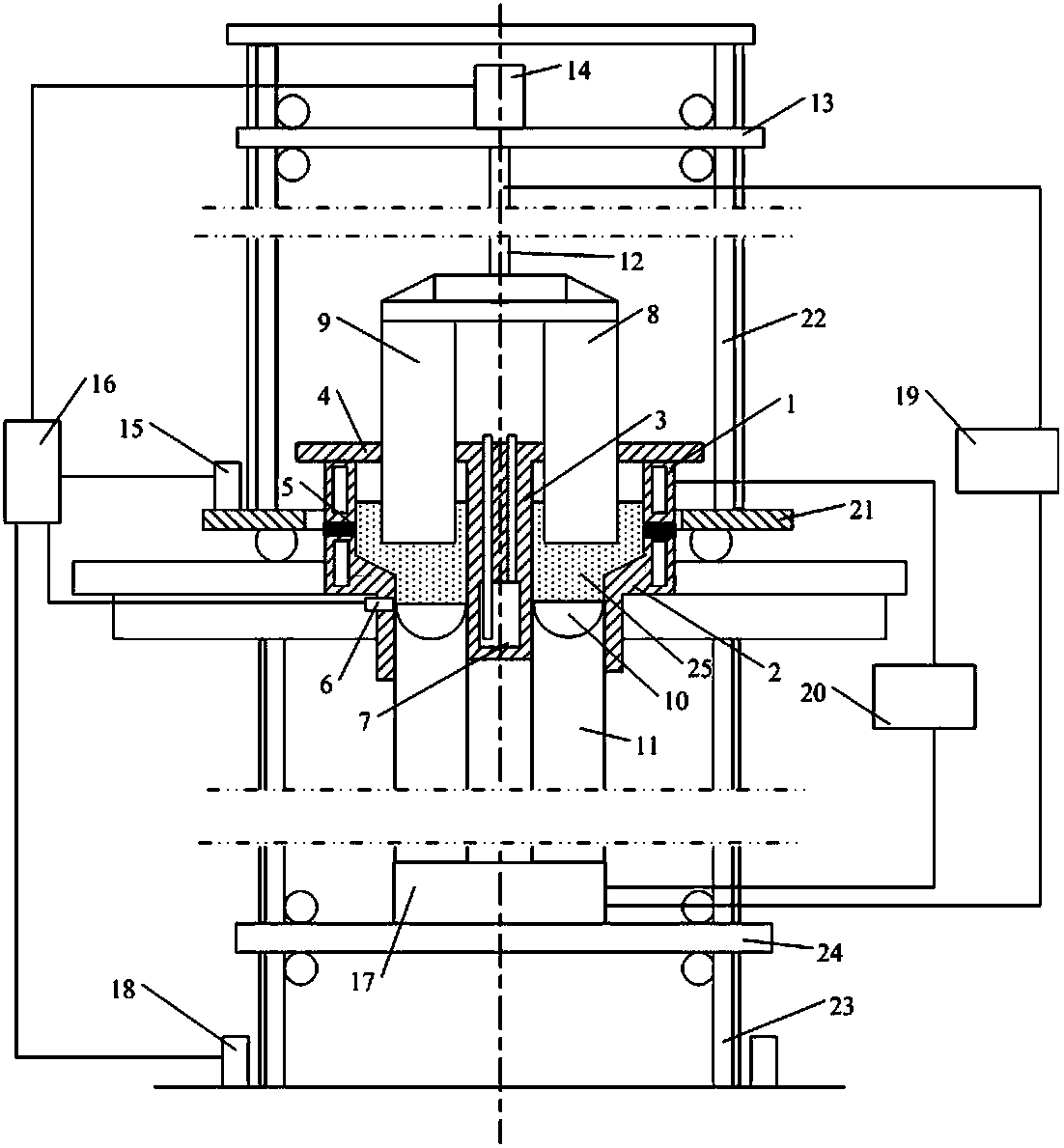

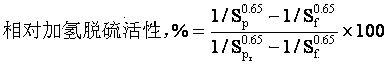

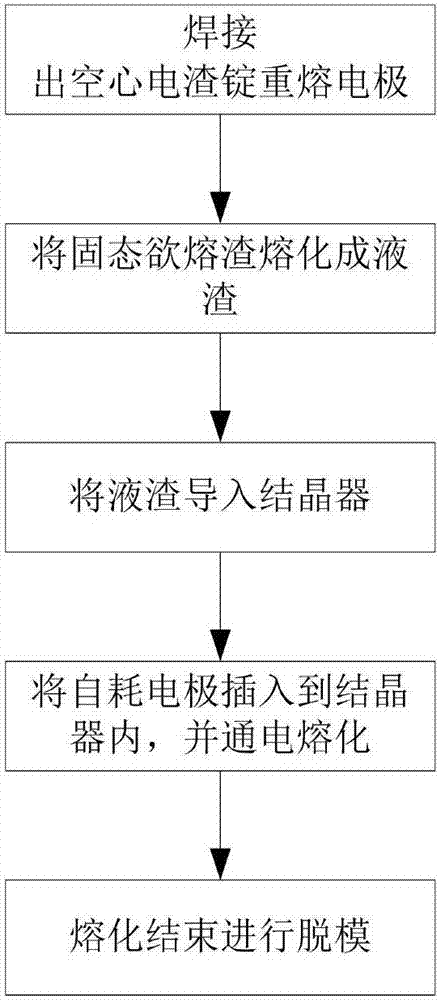

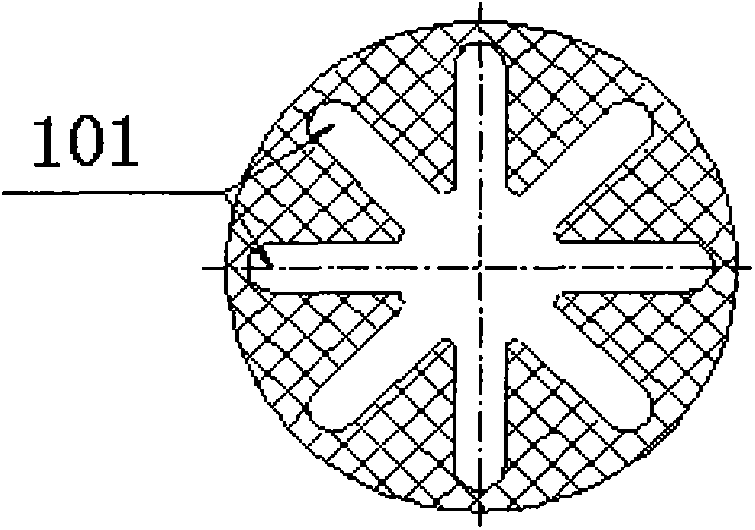

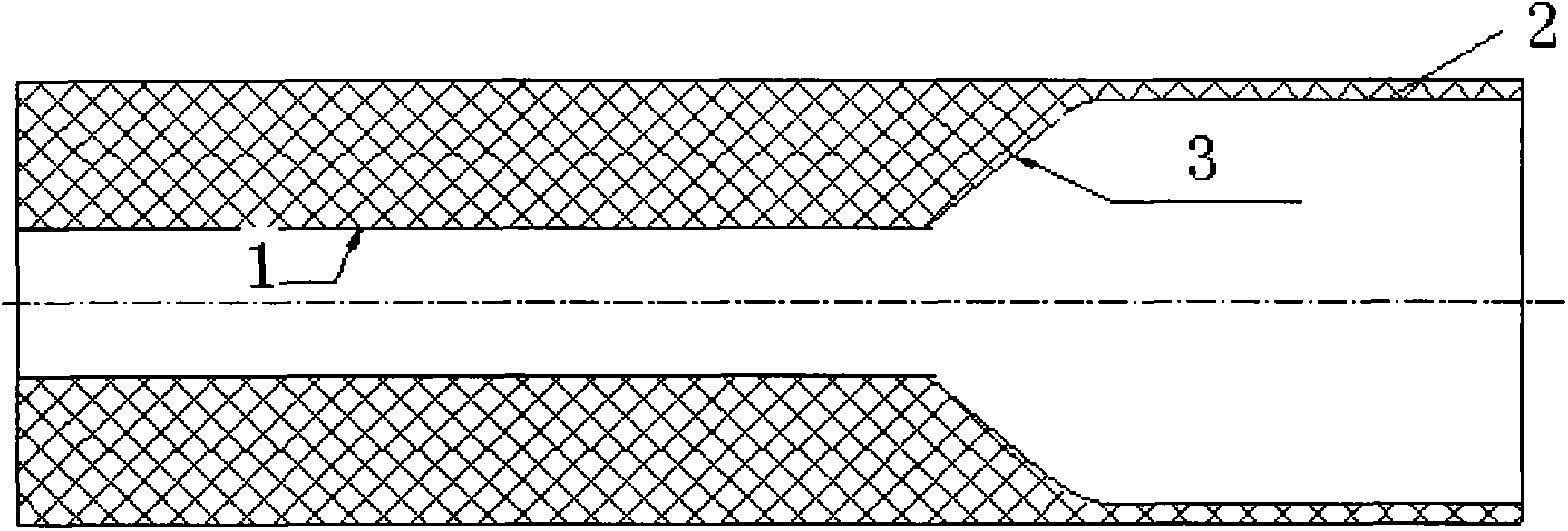

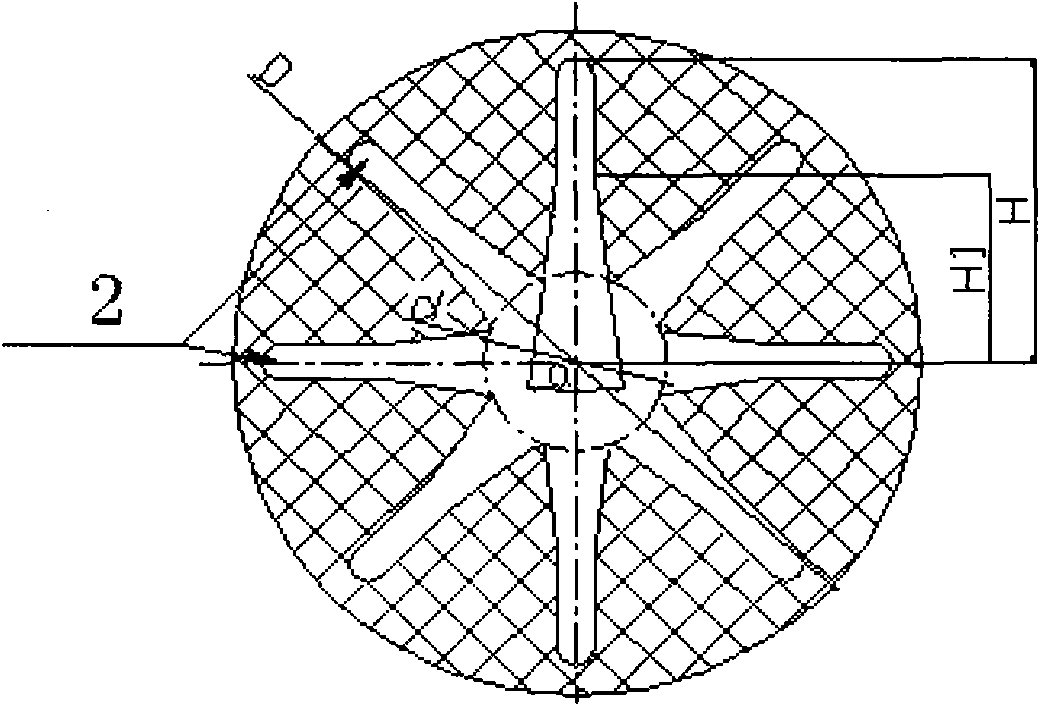

Device and method for producing small hollow electroslag ingot

The invention discloses a device and a method for producing a small hollow electroslag ingot, belongs to the technical field of hollow electroslag ingot melting, and solves the technical problems of incapacity of ensuring the concentricity of the hollow electroslag ingot, incapacity of ensuring a high filling ratio, complex structure, high production cost and inapplicability to a small hollow electroslag ingot in the prior art. According to the device disclosed by the invention, an inner crystallizer is fixed to a bottom water tank, and an outer crystallizer is of a movable structure. The method disclosed by the invention comprises the following steps: welding a re-melting electrode of the hollow electroslag ingot; melting a solid pre-melting slag; pouring the liquid slag into the crystallizers in the invention, and carrying out electrifying melting; and carrying out die release after the melting is concluded. The device disclosed by the invention has the advantages of being simple in structure, easy to produce, simple to operate during a melting process, and low in production cost.

Owner:凌远科技股份有限公司

Low-density halogen-free flame retardant type high-strength composite material as well as preparation method and use thereof

InactiveCN102924870AHigh strengthImprove toughnessSynthetic resin layered productsMetal layered productsEpoxyMicrosphere

The invention relates to a low-density halogen-free flame retardant type high-strength composite material and a preparation method thereof. The low-density halogen-free flame retardant type high-strength composite material is characterized in that the composite material comprises the following components in parts by mass according to 300 mass parts: 70-100 parts of multifunctional epoxy resins, 20-30 parts of phenoxy resins, 40-60 parts of phosphorus-containing curing agent, 0.05-0.5 part of imidazole accelerant, 0.1-0.6 part of ammonia accelerant, 10-60 parts of porous silicon dioxide, 10-60 parts of hollow microspheres, 0.3-5 parts of amine terminated coupling agents and 3-20 parts of ethanol, wherein the substance components are mixed according to the proportion and are uniformly dispersed to prepare the low-density halogen-free flame retardant type high-strength composite material. The low-density halogen-free flame retardant type high-strength composite material is simple in process, low in cost and wide in application prospect in fields of splicing sheets and composite materials; and the prepared composite material is low in density, halogen-free flame retardant and high in strength.

Owner:广东裕丰威禾新材料科技股份有限公司

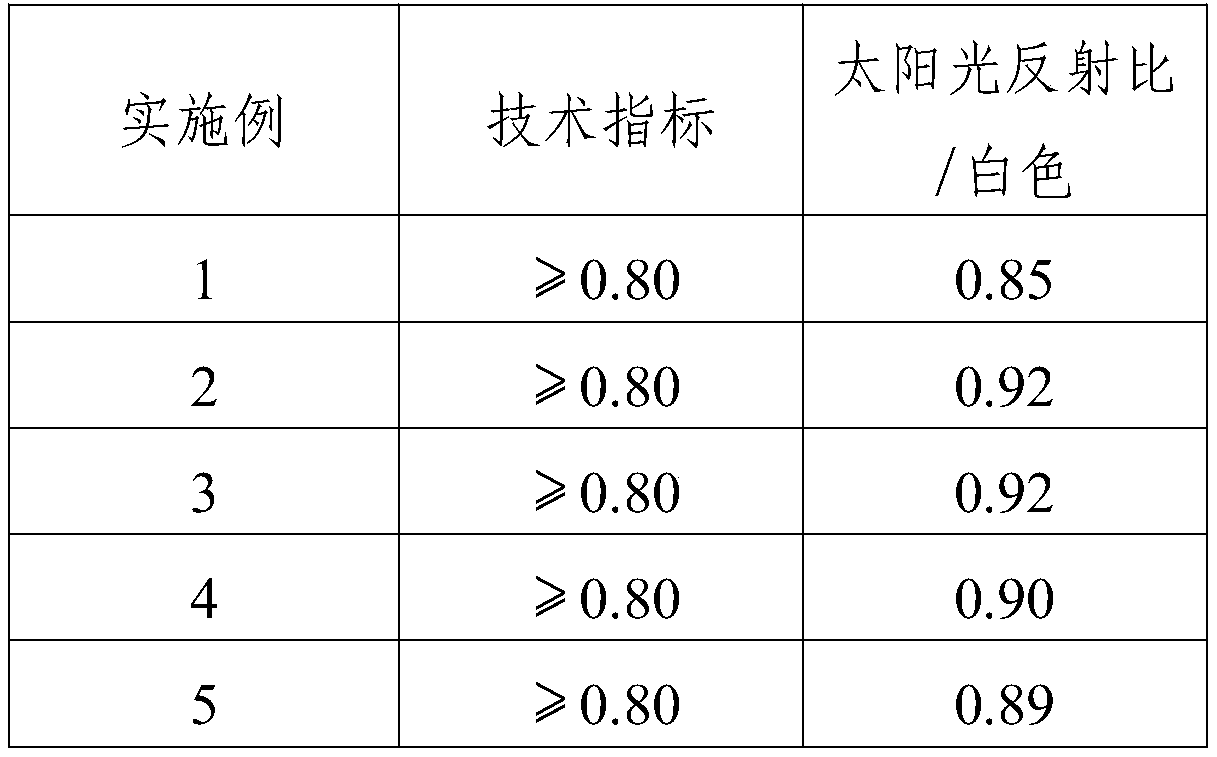

Vanadium dioxide series sun heat reflection intelligent temp./control high molecular sheet (plate) material

InactiveCN1624041AImprove reflection efficiencyImprove penetration efficiencySolar heat devicesSolar thermal energy generationVanadium dioxideOptoelectronics

A high-molecular plate (or sheet) with intelligent temp controlling function by reflecting sun-heat or not is prepared from high-molecular material, composite pigment, organic glass, polycarbonate, modified terylene fibres and terylene fibres. Its features that full-band infrared light can be reflected when the temp is higher than its phase-change temp, or not when the temp is lower than its phase-change temp. It can be used for building, car, ship, etc.

Owner:SUN YAT SEN UNIV

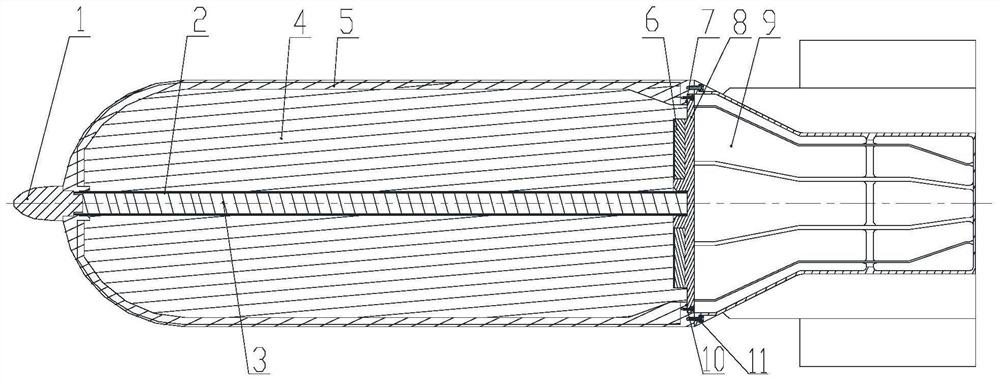

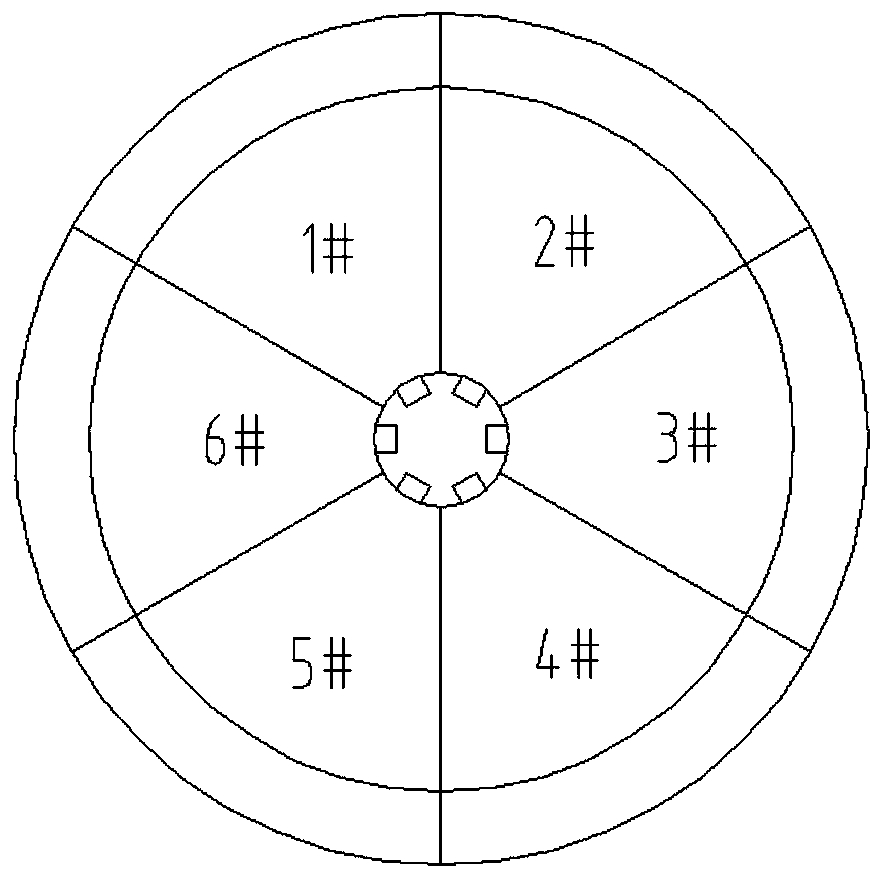

Charging grain structure of solid rocket engine

ActiveCN103644046AIntegrity guaranteedIncrease fill ratioRocket engine plantsGroove widthCombustion chamber

The invention relates to a charging grain structure of a solid rocket engine, and belongs to the technical field of solid rocket engines. Under the conditions that a design limiting boundary is constant, the total grooving depth is equal to or larger than four fifths the outer radius of a grain, and the inner tube diameter of the grain is smaller than or equal to one fourth the outer diameter of the grain, the tube diameter and the grooving width can be reduced substantially through the coordination action of a variable-width groove part on the premise that integrity of the charging structure is ensured, so that the charge-weight ratio of a charging combustion chamber of the solid rocket engine adopting the propellant type is improved, and the purpose of improving the overall performance namely the volume energy density of the solid rocket engine is achieved.

Owner:BEIJING POWER MACHINERY INST

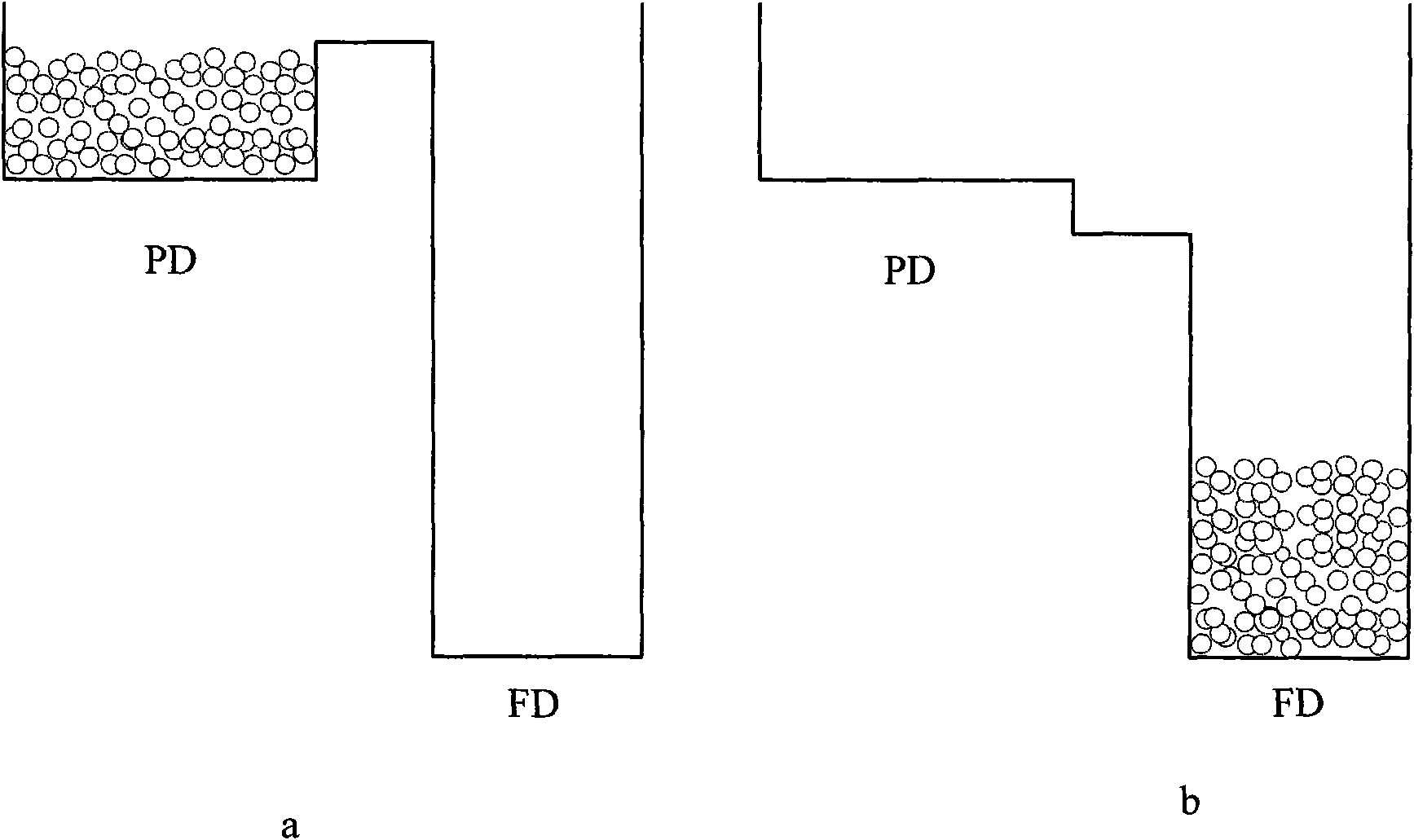

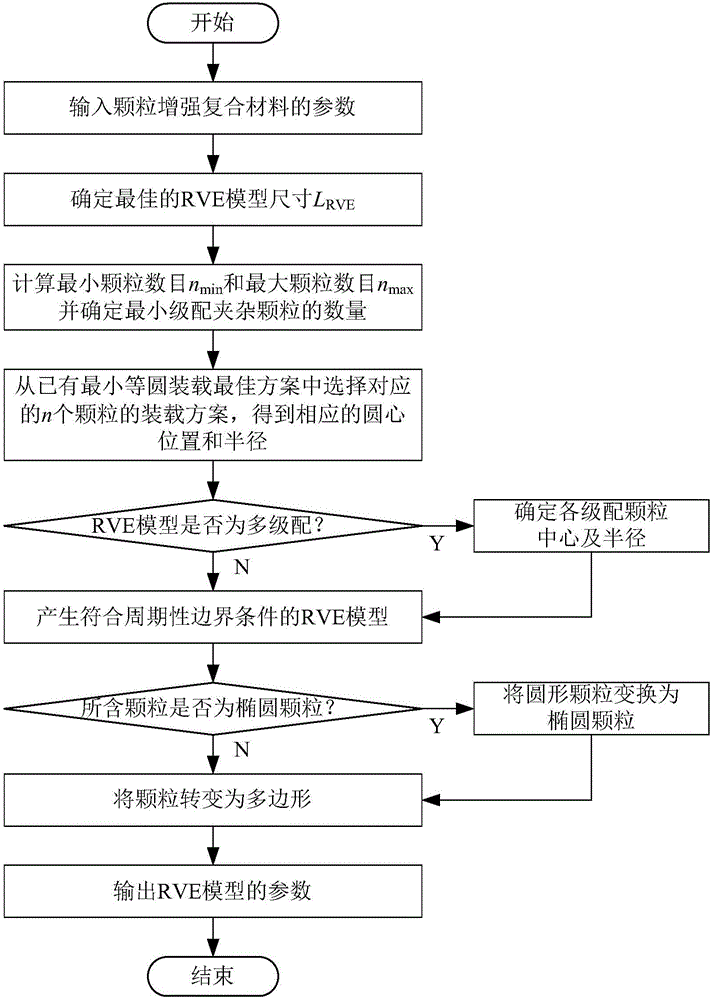

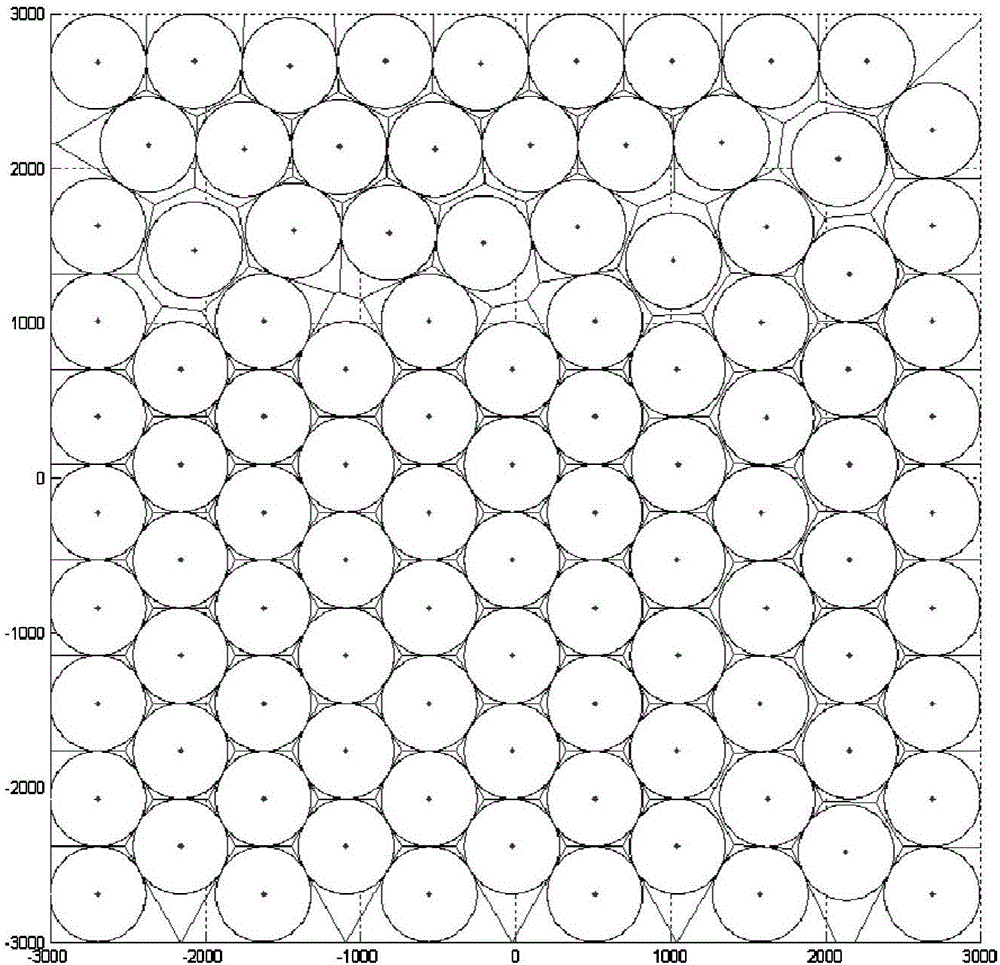

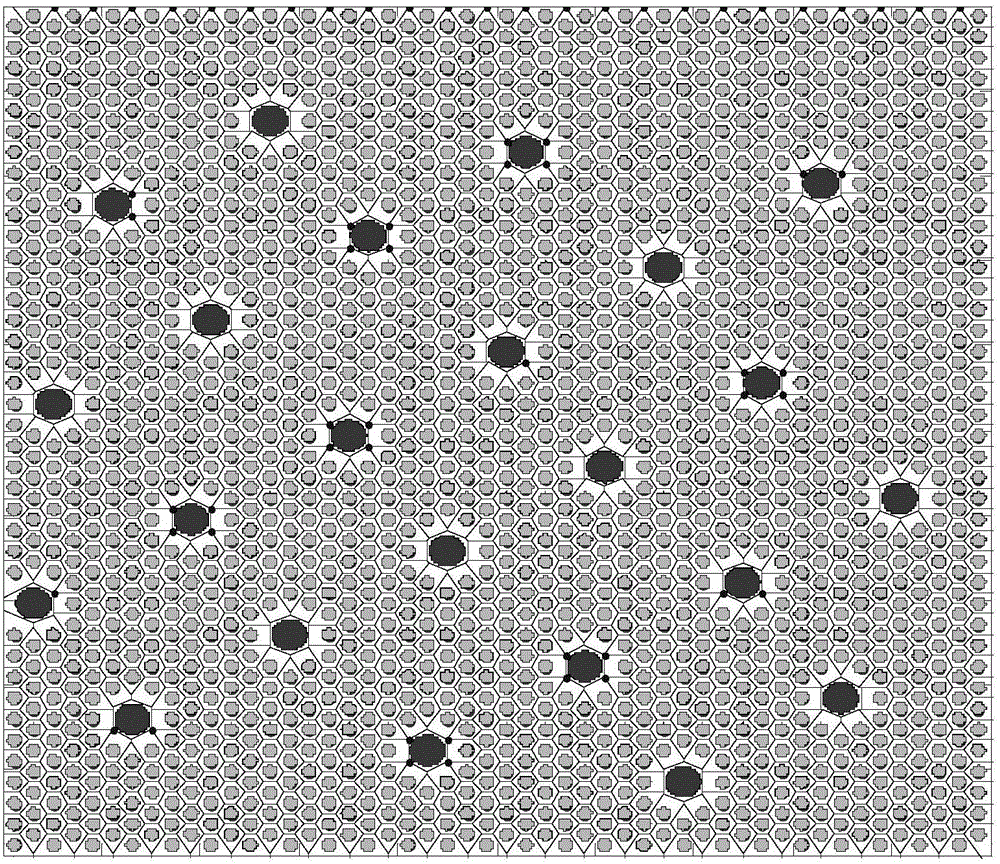

High volume fraction RVE (Representative Volume Element) model generation method used for VCFEM (Voronoi Cell Finite Element Method) analysis

ActiveCN106650018AGenerate efficientlyPromote generationDesign optimisation/simulationSpecial data processing applicationsAnalysis modelsMethod of undetermined coefficients

The invention discloses a high volume fraction RVE (Representative Volume Element) model generation method used for VCFEM (Voronoi Cell Finite Element Method) analysis. The method comprises the following steps of: inputting a parameter of a particle reinforcement composite material, estimating the dimension of a RVE model, determining an amount of minimum grading inclusion particles, selecting a corresponding loading scheme of n particles from existing minimum equal circle / sphere loading optimal schemes to obtain a corresponding circle / sphere center position and radius and generate the RVE model which conforms to a periodic boundary condition, transforming circular / spherical particles into elliptical / spherical particles according to whether the particles of the RVE model are circular / spherical particles or not, transforming the particles into a polygon / polyhedron, obtaining an optimal dimension of the RVE model through multi-time calculation, and finally, outputting the parameters of the RVE model. By use of the method, according to the volume fraction and the topological parameter of the size grading of the particle reinforcement composite material, a periodic numerical analysis model used for VCFEM analysis can be efficiently and simply generated, and the method can be used for the trans-scale analysis of composite materials with a high packing ratio, multiple grading and different particle shapes.

Owner:NAT UNIV OF DEFENSE TECH

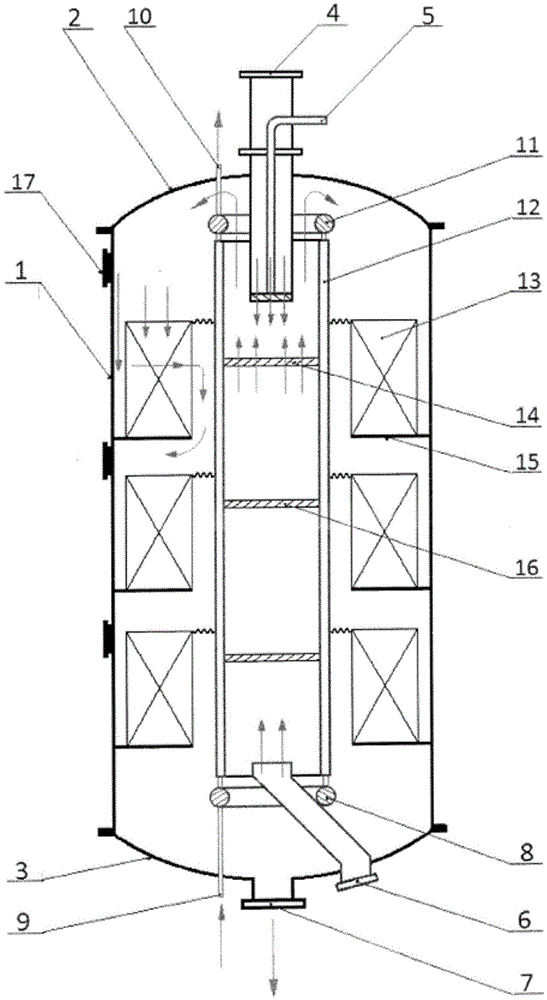

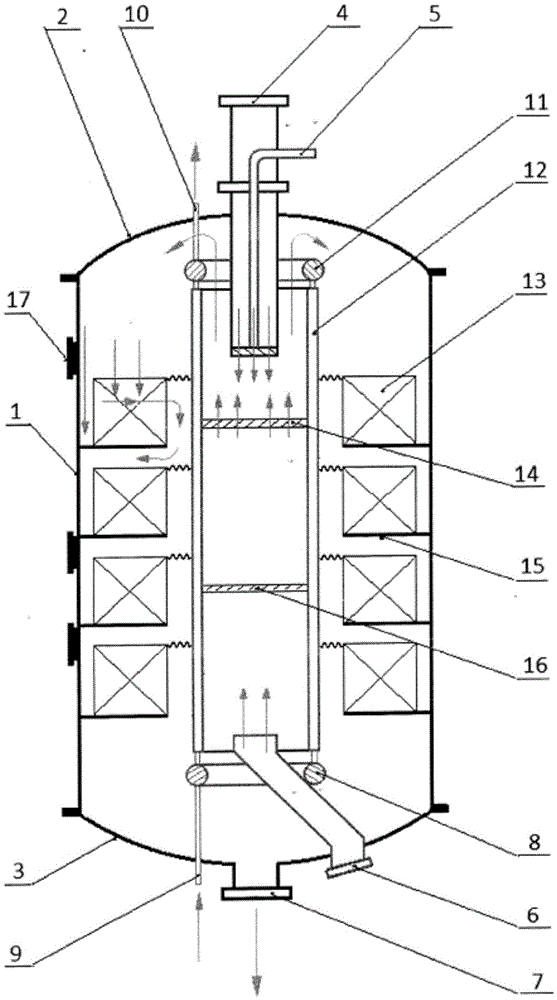

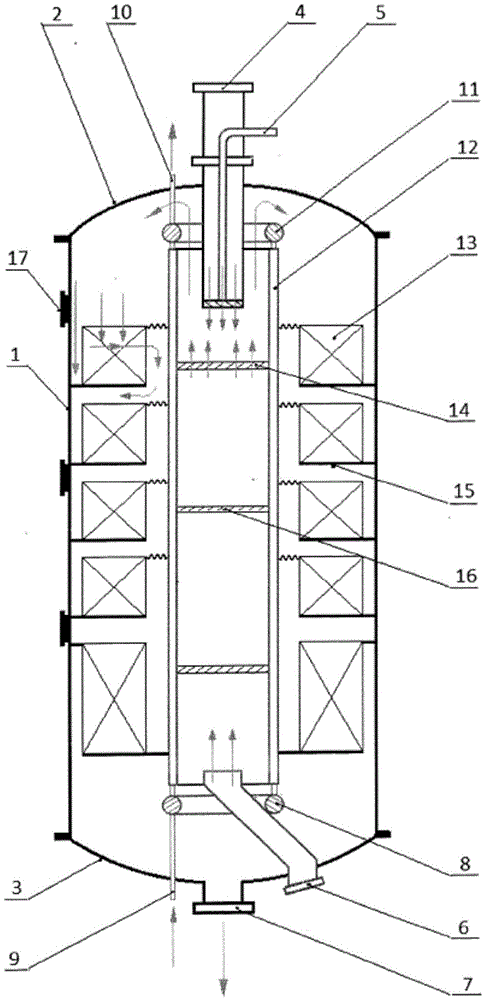

Multi-section indirect heat exchange type radial fixed bed reactor

InactiveCN105457564AImprove efficiencyImprove the filling ratioChemical/physical processesInlet temperatureProcess engineering

The invention relates to a multi-section indirect heat exchange type radial fixed bed reactor which is used for a heat release chemical reaction. The multi-section indirect heat exchange type radial fixed bed reactor comprises a cylindrical shell, a catalytic reaction device, a sleeve type heat exchanger and a fin arranged on the sleeve type heat exchanger. Inlet temperatures and outlet temperatures of different reaction regions of the reactor with the type, provided by the invention, are controlled in a limited range close to a pre-set optimal value. Compared with the prior art, the multi-section indirect heat exchange type radial fixed bed reactor has the advantages that the temperature of a catalyst bed layer can be steadily controlled to be close to the pre-set optimal value in a relatively large range by using a simple method; the utilization efficiency of a catalyst is high, the filling ratio is great and the catalyst is easy to load and unload; the multi-section indirect heat exchange type radial fixed bed reactor has a simple structure, relatively low requirements on manufacturing and installation processes, and low capital construction cost and operation cost; and the heat loss is small and the utilization coefficients are high.

Owner:张淮海

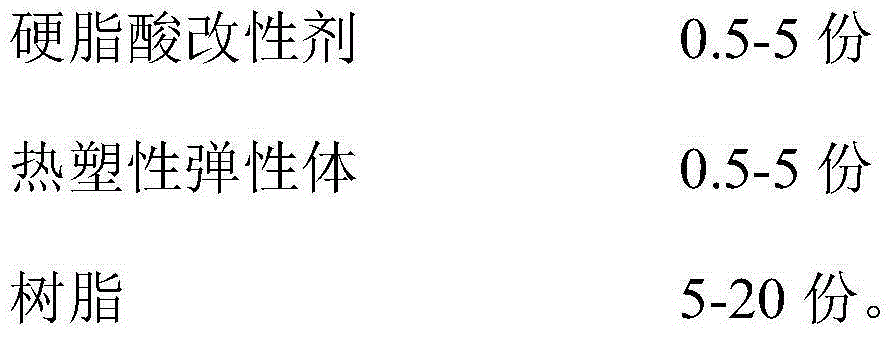

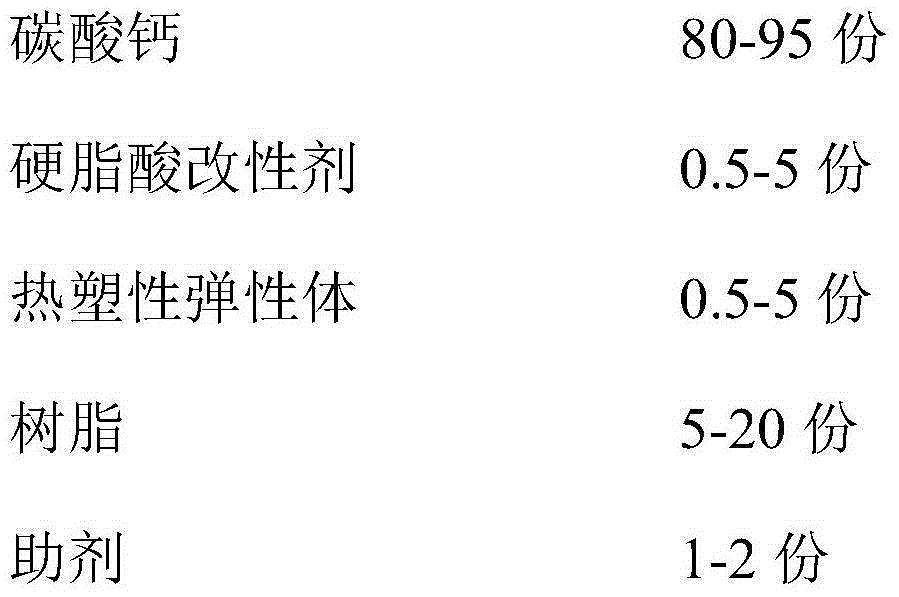

High-performance masterbatch with high loading calcium carbonate and preparation method for masterbatch

The invention discloses a high-performance masterbatch with high loading calcium carbonate and a preparation method for the masterbatch. The preparation raw materials of the masterbatch comprise the following components in parts by weight: 80 to 95 parts of calcium carbonate, 0.5 to 5 parts of stearic acid modifier, 0.5 to 5 parts of thermoplastic elastomer and 5 to 20 parts of resin; the preparation method for the masterbatch comprises the following steps: A, weighing the calcium carbonate and assistants and putting in a high-speed mixer, and stirring for 8 to 12 minutes; B, weighing the stearic acid modifier and putting in a mixture obtained in the step A, and stirring for 8 to 12 minutes; C, weighing the thermoplastic elastomer, the resin and a mixture obtained in the step B and putting in an internal mixer, and performing for banburying for 15 to 30 minutes; D, putting a mixture obtained in the step C in a screw extruder, and performing extrusion pelletization to obtain the finished product of the masterbatch. The masterbatch with high loading calcium carbonate disclosed by the invention has a higher filling proportion, and is capable of effectively reducing the cost of plastic products; the plastic products are obviously enhanced in shock strength and flexural modulus.

Owner:赵晓华

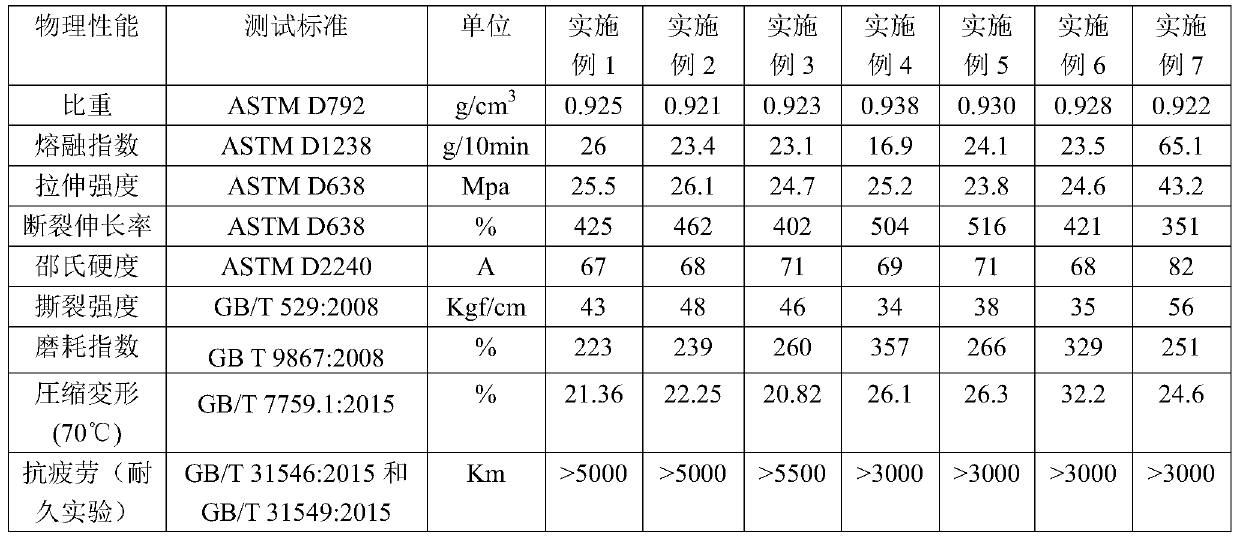

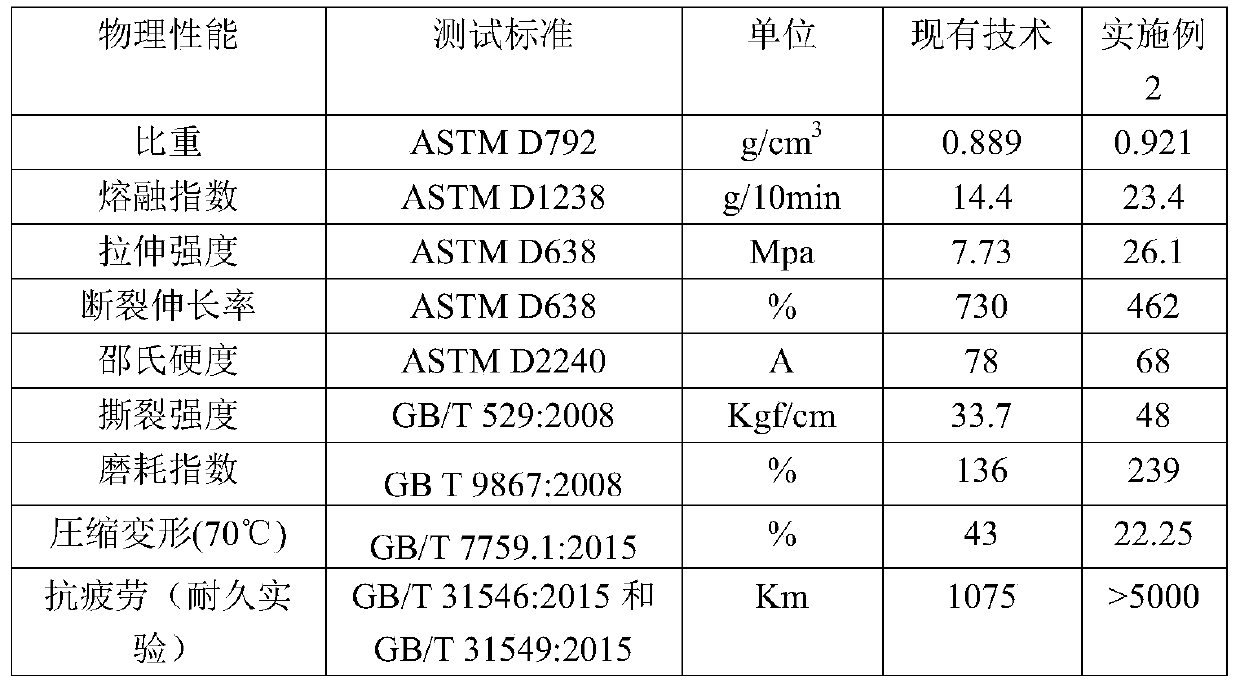

Non-pneumatic tire material taking thermoplastic vulcanized (TPV) as base material and preparation method of same

The invention discloses a non-pneumatic tire material taking thermoplastic vulcanized rubber as a base material and a preparation method of the non-pneumatic tire material, and belongs to the field ofmodified polymer materials and non-pneumatic tires. The material mainly comprises thermoplastic vulcanized rubber, a styrene elastomer, a hydrogenated styrene elastomer, a plasticizer, polypropylene,polyethylene, a filler, a hyperbranched polymer, a compatilizer, an antioxidant, a wear-resistant anti-slip agent and an ultraviolet light absorber. The preparation method comprises the following steps: mixing and stirring the thermoplastic vulcanized rubber, the styrene elastomer, the hydrogenated styrene elastomer and the plasticizer, mixing the rest materials, and carrying out melt mixing to obtain the target product. The non-pneumatic tire material prepared by the preparation method has the advantages of wear resistance, skid resistance, fatigue resistance, high toughness, high elasticity, low possibility of compressive deformation and the like, can effectively reduce the safety risks of air leakage, tire burst and the like in the driving process of a vehicle, can be recycled, and hasthe characteristics of greenness and environmental protection.

Owner:DONGGUAN JISU PLASTIC TECH

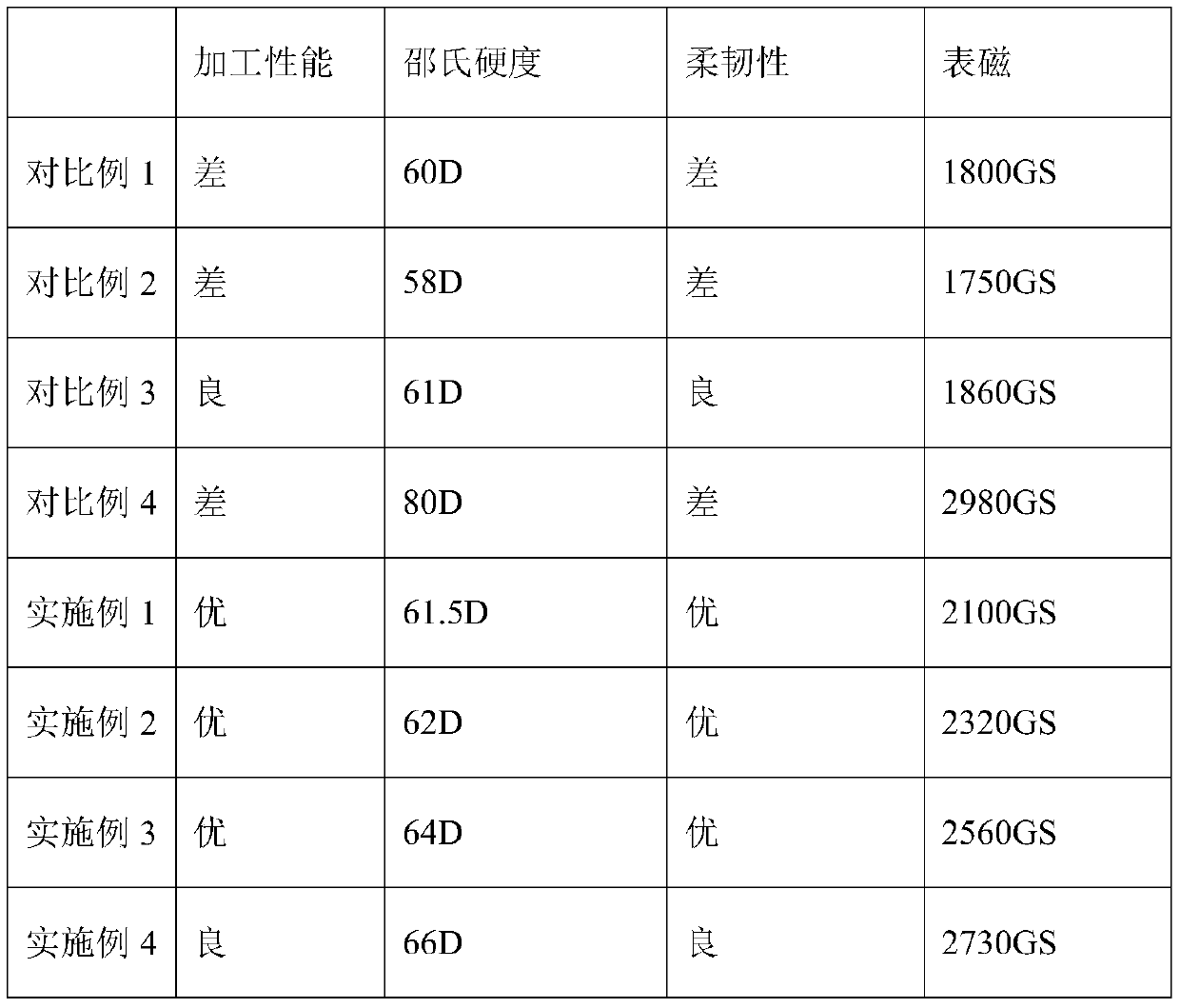

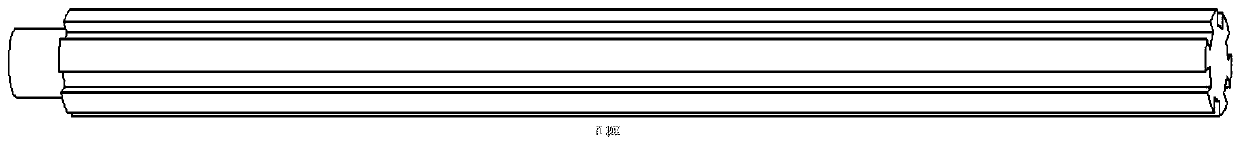

Preparation method for flexible rubber neodymium iron boron magnet with high filling ratio

ActiveCN109786098AIncrease fill ratioImprove magnetismInductances/transformers/magnets manufactureMagnetic materialsSilane couplingNeodymium iron boron

The invention relates to the field of rubber magnets, in particular to a preparation method for a flexible rubber neodymium iron boron magnet with a high filling ratio. The preparation method comprises the following steps that: adding neodymium iron boron powder into organic solvent containing silane coupling agent and epoxy resin to obtain surface modified neodymium iron boron powder; then, evenly mixing the surface modified neodymium iron boron powder, rubber type binder and auxiliary materials, and then, carrying out banburying to obtain a rubber neodymium iron boron granule material; carrying out compression molding on the obtained rubber neodymium iron boron granule material to obtain a semi-finished product; and cutting and magnetizing the obtained semi-finished product, and packaging to obtain a flexible rubber neodymium iron boron magnet finished product. By use of the preparation method, the defects in the prior art that the neodymium iron boron magnet has a small neodymium iron boron magnet powder filling amount, poor magnetic property and poor mechanical property can be overcome, so that the preparation method has the advantages that the filling ratio of the neodymium iron boron powder is high, the magnetic property is good, the mechanical property of the flexible rubber neodymium iron boron magnet is effectively improved and the processing difficulty of the flexiblerubber neodymium iron boron magnet is lowered.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

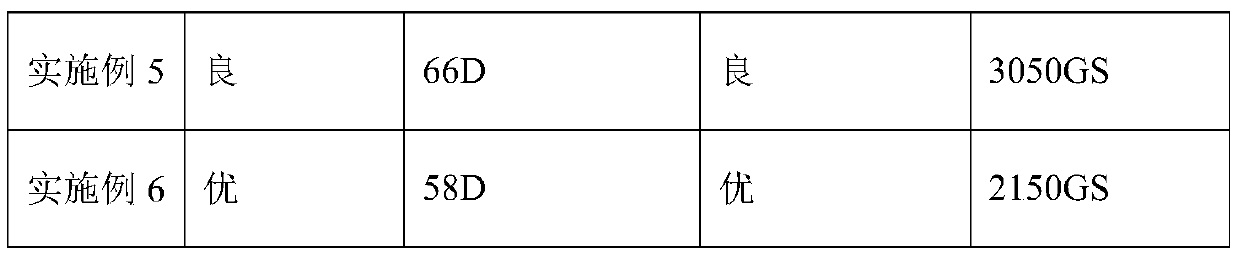

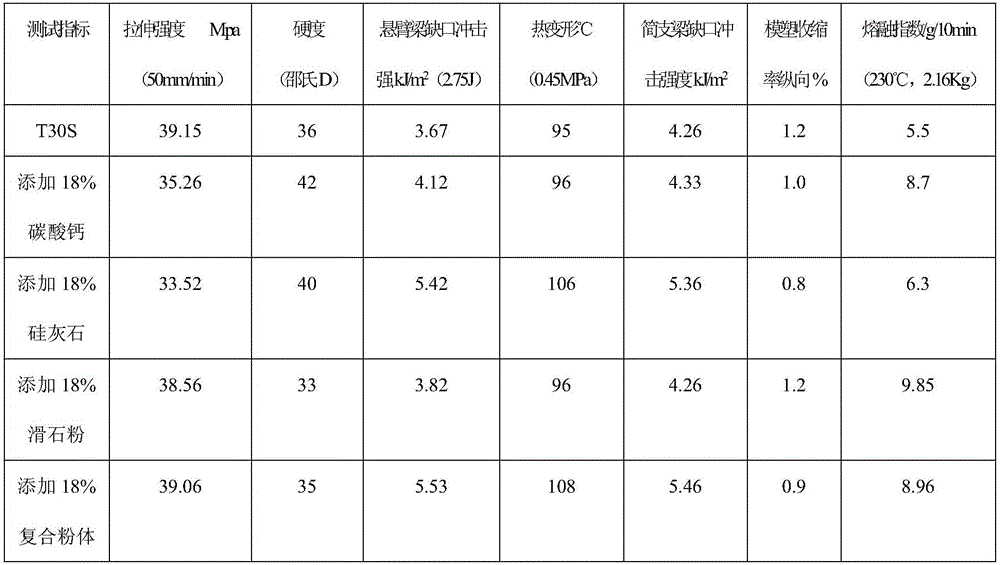

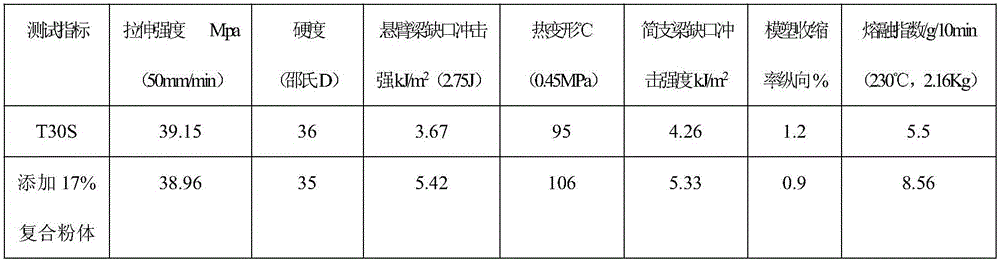

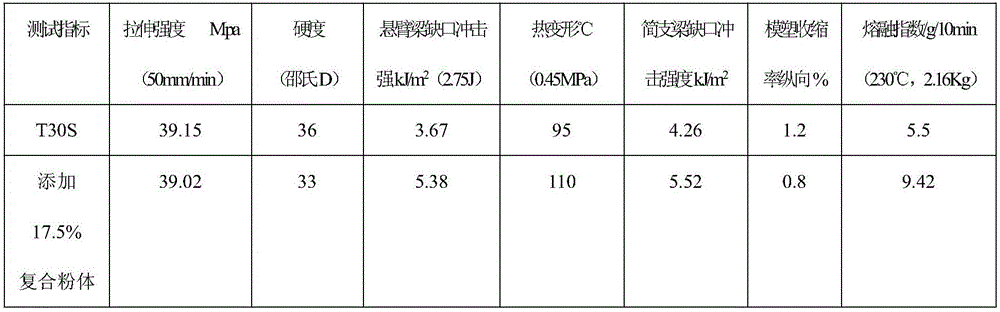

Compound powder for modified polypropylene and preparation method thereof

The invention aims at providing compound powder for modified polypropylene. The compound powder is characterized by being prepared from the following components in parts by weight: 1 part of calcium carbonate subjected to surface treatment by stearic acid, 2-5 parts of wollastonite treated by a silane coupling agent and 2-5 parts of talcum powder treated by a titanate coupling agent. The invention further provides a preparation method of the compound powder for modified polypropylene. By adopting the compound powder provided by the invention, the compatibility of powder filling and polypropylene can be improved, and performances of modified polypropylene are comprehensively improved.

Owner:JIANGXI HONGYI POLYMERIC MATERIALS

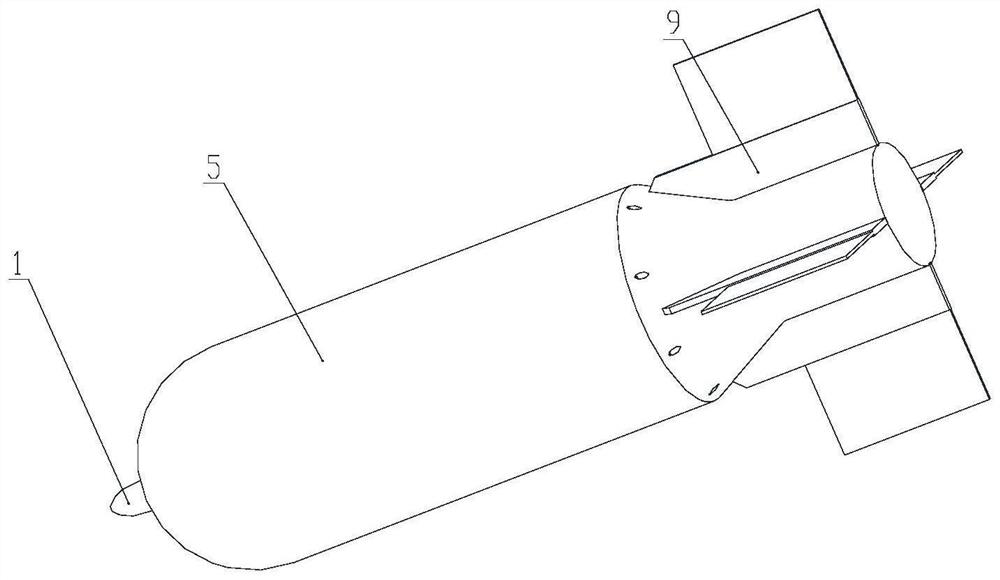

Forest aviation fire extinguishing bomb thrown through gravity and using method

ActiveCN112604210AThe overall structure is simple and reliableNo secondary damageAircraft componentsClimate change adaptationAviationEngineering

The invention discloses a forest aviation fire extinguishing bomb thrown through gravity and a using method, and belongs to the field of technical design of fire extinguishing bombs. The forest aviation fire extinguishing bomb comprises a fuse, a central charging pipe, a central grain, a fire extinguishing agent, a fire extinguishing bomb shell, a tail grain, a sealing ring, a tail end cover, a fastening screw and a tail fin. The fire extinguishing bomb is mounted by a forest aviation fire-fighting helicopter and is thrown at a certain height above a fire scene, when a distance between the fire extinguishing bomb and the ground reaches a preset explosion height, the fire extinguishing bomb is ignited and detonated by firing the fuse, the fire extinguishing agent is uniformly and quickly thrown to the surface of comburent under the action of central charging and tail charging, so that the fire extinguishing purpose is achieved. The forest aviation fire extinguishing bomb is thrown through gravity, and the problem that an existing fire extinguishing bomb is low in hit precision is solved. By means of the charging structure and a large fire extinguishing agent filling ratio, the problems that an existing fire extinguishing bomb is small in coverage area, uneven in fire extinguishing agent distribution and the like are effectively solved. The fire extinguishing bomb can be used for forest fire extinguishing and grassland fire extinguishing.

Owner:湖北航天飞行器研究所

Hetero-junction silicon solar cell and fabrication method thereof

InactiveCN101821857AMinimize efficiencyIncrease the open circuit voltageFinal product manufacturePhotovoltaic energy generationSilicon solar cellCrystalline silicon

Owner:LG ELECTRONICS INC

High-thermal-conductivity composite gel and preparation method thereof

PendingCN111826132AImprove thermal conductivityNo pollution in the processHeat-exchange elementsGel preparationPtru catalystGel based

The invention relates to a high-thermal-conductivity composite gel, which is prepared from a gel base material, a heat-conducting filler and a coupling agent under the action of a catalyst. The heat-conducting filler is prepared from graphitized diamond particles and a heat-conducting auxiliary material, layered graphene grows on the surfaces of the graphitized diamond particles, and the heat-conducting auxiliary material is selected from at least one of aluminum oxide, zinc oxide, beryllium oxide and hexagonal boron nitride; the mass ratio of the gel base material to the heat-conducting filler is 1:9.5-15.2, the mass ratio of the heat-conducting filler to the coupling agent is 125-200:1, and the mass ratio of the graphitized diamond particles to the heat-conducting auxiliary material in the heat-conducting filler is 4-5:1. The invention further provides a preparation method of the high-thermal-conductivity composite gel.

Owner:彗晶新材料科技(张家港)有限公司

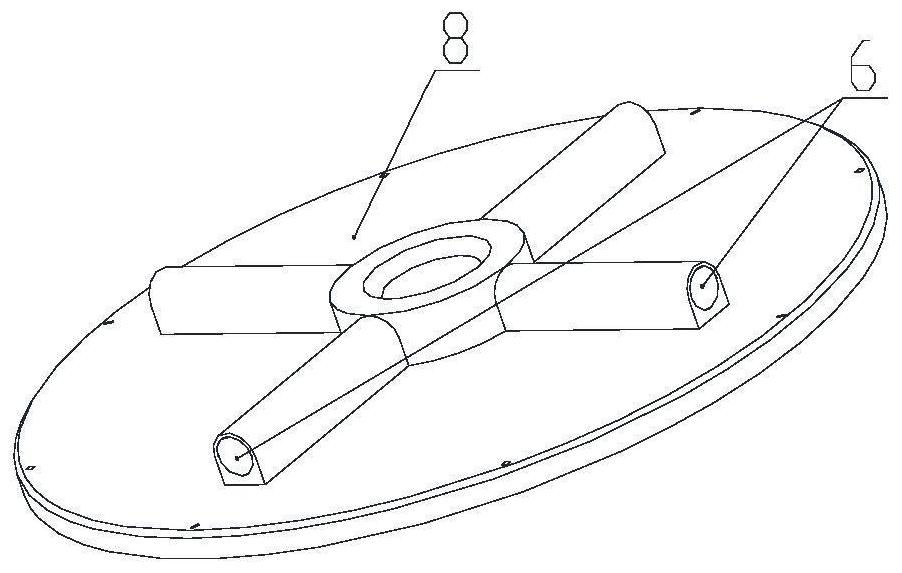

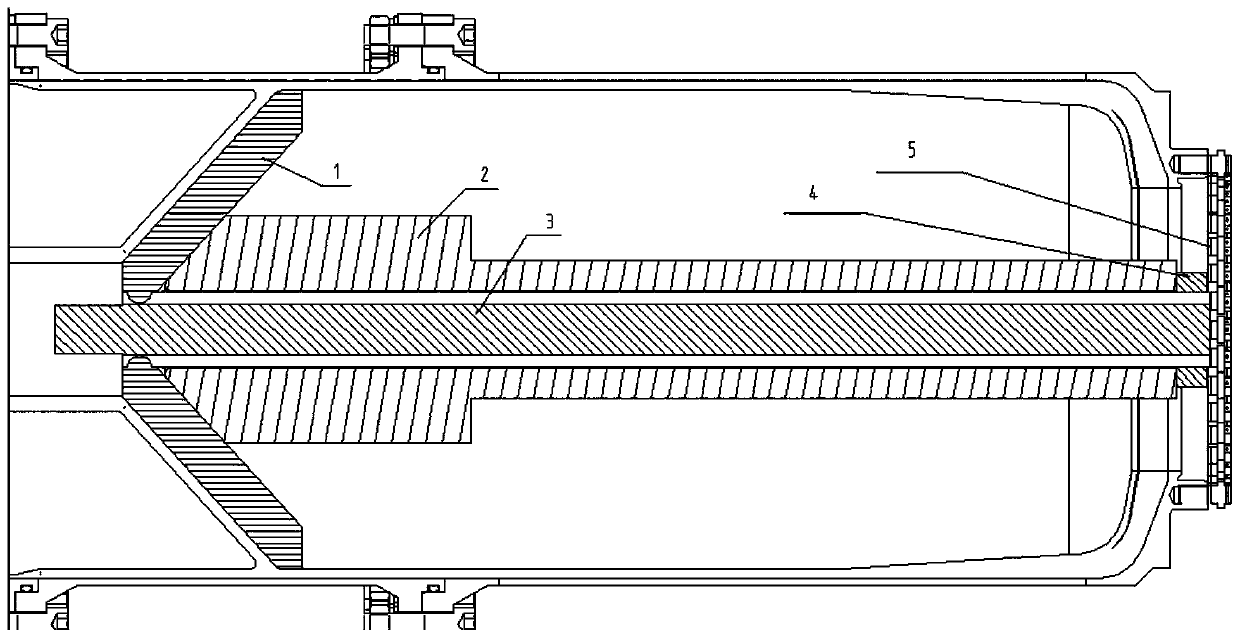

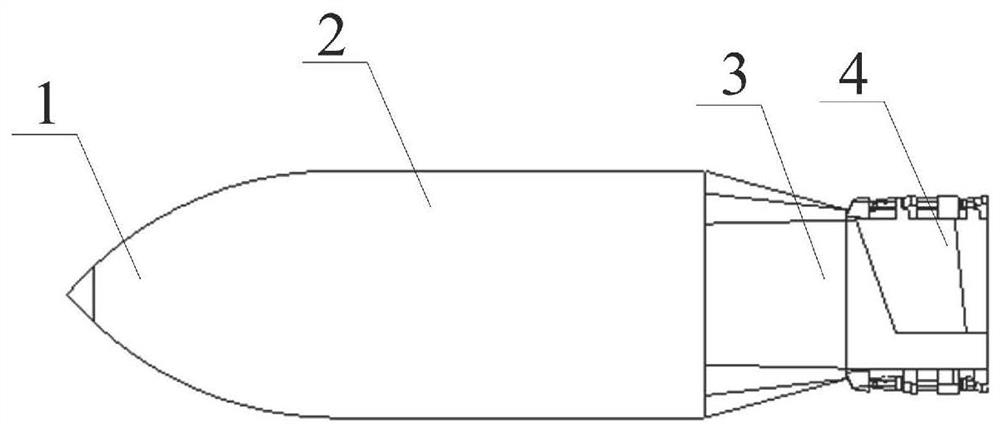

Charging supporting structure

ActiveCN110792527ASimple designReduce the size of the opening diameterRocket engine plantsEngineeringMechanical engineering

The invention discloses a charging supporting structure. The structure comprises a core mold (1), a supporting rod (2), an inner cylinder (3), a fastening device (4) and a supporting plate (5). The core mold (1) comprises multiple fan rings, a circular ring shape is formed by the fan rings, the core mold is used for supporting a soft interlayer of an outer engine, the supporting rod (2) is used for supporting the core mold (1), the inner cylinder (3) is connected with an outer structure to position and guide the core mold (1), the fastening device (4) is used for connecting the supporting rod(2) and the inner cylinder (3), and the supporting plate (5) is connected with the seal head end of the outer engine and meanwhile provides supporting force for the inner cylinder (3) and the supporting rod (2). Through the structure, association of the opening diameter and the whole size of the supporting structure does not need to be considered, the opening diameter size of the engine is reduced, charging can be more effective, the higher filling ratio is achieved, and the whole design of the engine is facilitated.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

A kind of magnetic plastic composite material and preparation method thereof

ActiveCN103258610BHigh strengthEvenly distributedInorganic material magnetismMaterials preparationNylon 6

The invention discloses a magnetic plastic composite material. The magnetic plastic composite material includes the following components, by mass, 4-8 % of nylon 6 powder, 90-95% of neodymium iron boron magnetic powder, 0-5% of caprolactam, 0.5-1.5% of lubricant and 0.3-1% of silane coupling agent. The invention further discloses a magnetic plastic composite material preparation method. The magnetic plastic composite material is good in strength due to the fact that content of the neodymium iron boron magnetic powder reaches 90-95%. Through fully mixing of the neodymium iron boron magnetic powder and the nylon 6 powder, the neodymium iron boron magnetic powder is even in distribution and magnetism. Therefore, the magnetic plastic composite material can be more stable in quality.

Owner:XIAMEN RUNNER IND CORP

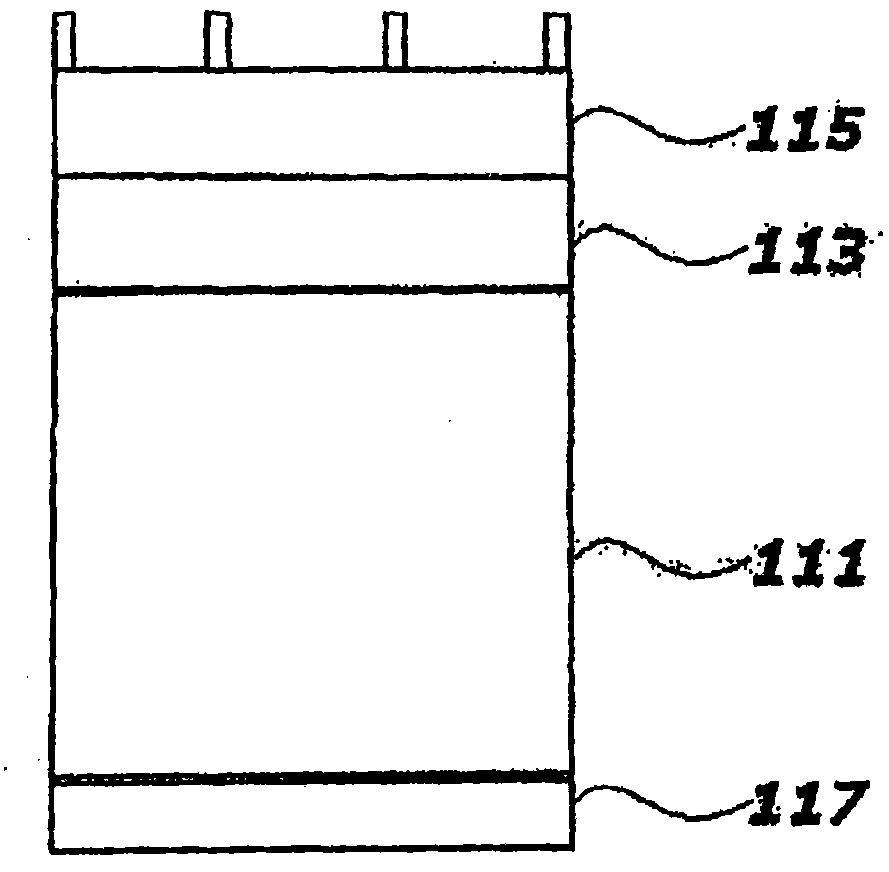

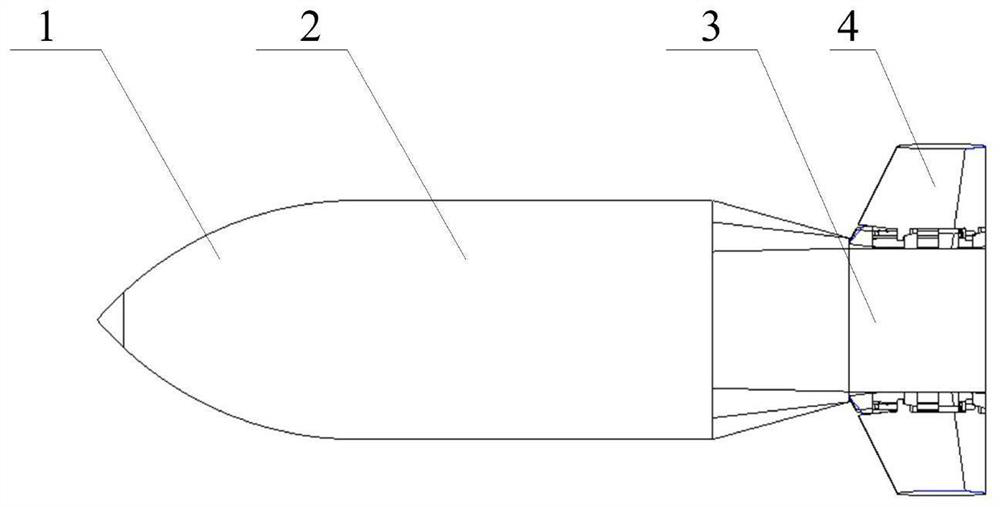

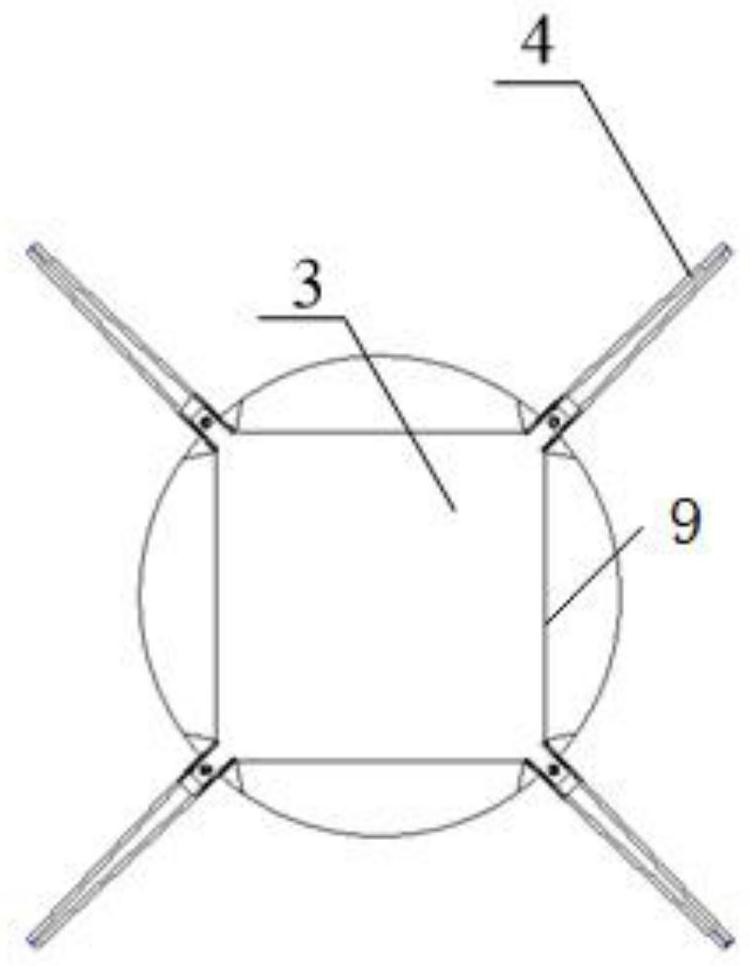

Compact high aspect ratio aerodynamic configuration layout structure of fire extinguishing bomb and design method

ActiveCN112461057ACompact structureIncrease the bearing areaAmmunition projectilesSustainable transportationStructural engineeringMechanical engineering

The invention discloses a compact high aspect ratio aerodynamic configuration layout structure of a fire extinguishing bomb. The compact high aspect ratio aerodynamic configuration layout structure comprises a warhead, a bomb body, a bomb tail and four foldable empennages; the warhead is arranged at the front end of the bomb body; the bomb body is a standard cylinder; the bomb tail main body adopts a square body design, the front end of the bomb tail is in smooth transition with the bomb body cylinder, the smoothness of the aerodynamic configuration is guaranteed, the square outer surface is beneficial to fin folding, and the square body further increases the internal volume of the bomb; and the four foldable empennages are folded in the circumferential direction of the bomb tail main body, the envelope size after folding does not exceed the bomb body, the four foldable empennages can adapt to a circular launch canister, it can be guaranteed that wings are more compact in structure when folded and can completely protrude out of the surface of the bomb body when unfolded, the stress area of the wings is increased to a greater extent, and the stability of the bomb is better improved.The aerodynamic configuration layout structure is high in stability, high in filling ratio, compact in structure and particularly suitable for barreled launching.

Owner:湖北航天飞行器研究所

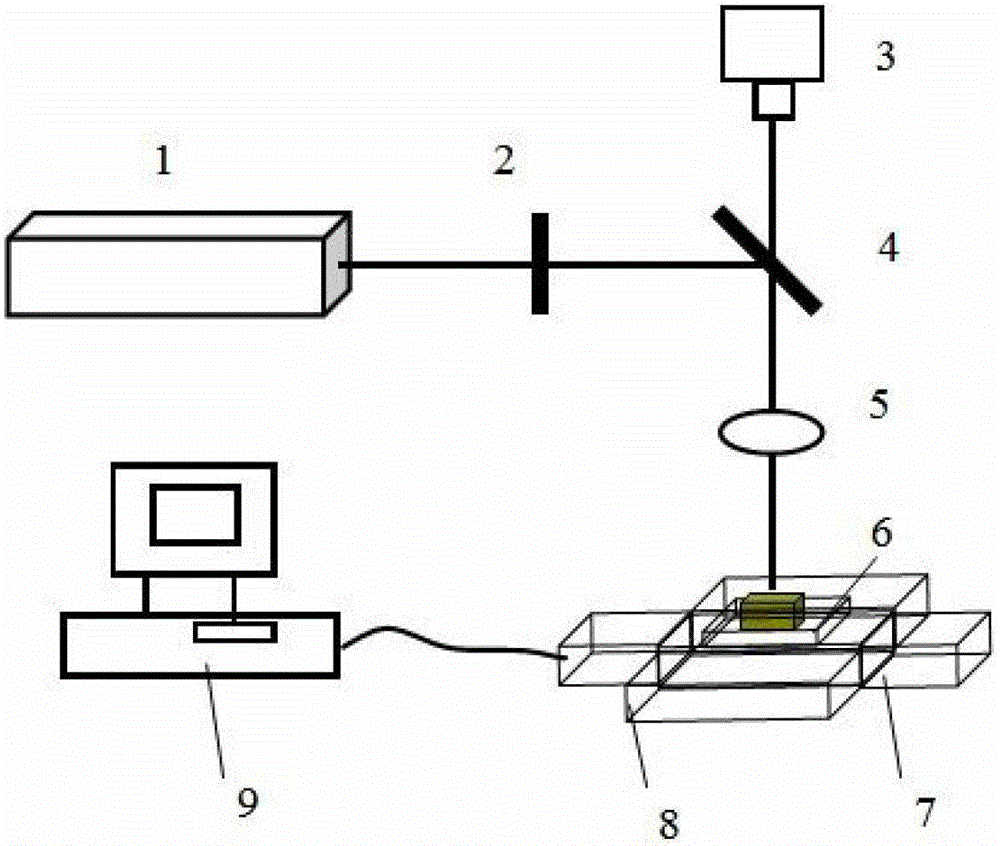

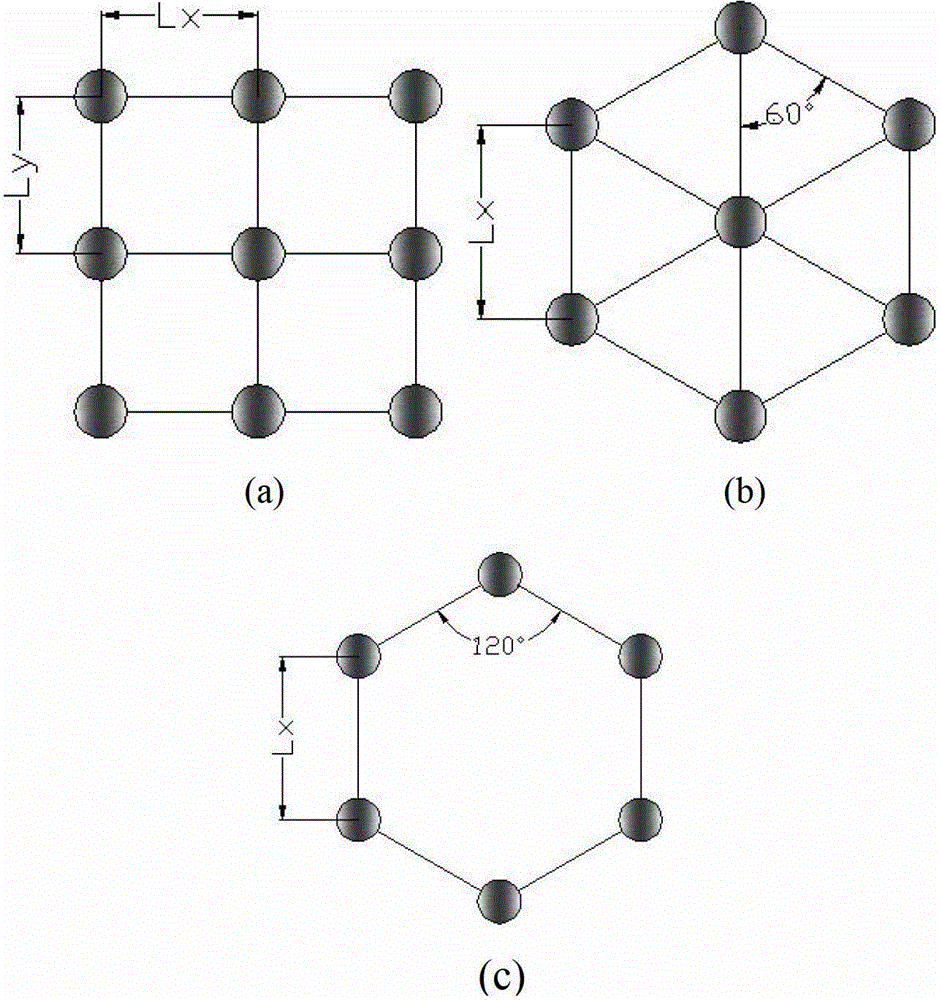

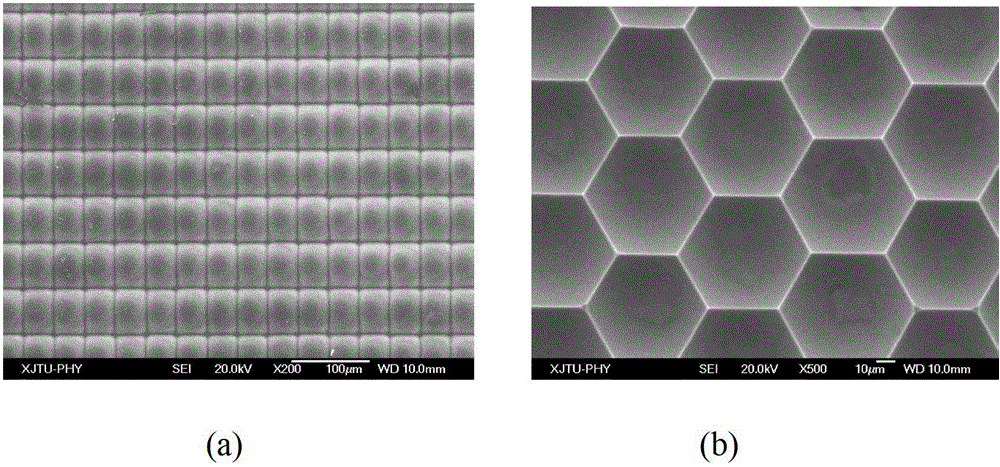

Method for fabricating microlens array beam shaper by femtosecond laser enhanced chemical etching

The invention discloses a method for preparing a microlens array beam shaper through femtosecond laser reinforced chemical etching. The method comprises the steps of: selecting quartz glass a sample material, carrying out surface processing through femtosecond laser to obtain a microlens array dead hole; and placing a hydrogen fluoride solution in the processed microlens array dead hole for carrying out auxiliary etching to complete the preparation of the microlens array beam shaper. A microlens array is prepared by using femtosecond laser reinforced chemical etching, and the advantage of controllable morphology of the prepared microlens array is obtained, wherein the morphology of a microlens can be controlled through reasonable arrangement of laser pulse acting points, and the focus length of the microlens can be controlled through a laser parameter. The method can realize high-efficiency processing of a high packing ratio and large-area microlens array; and the prepared microlens array can simply and conveniently realize space light intensity uniform distribution of a gauss beam.

Owner:XI AN JIAOTONG UNIV

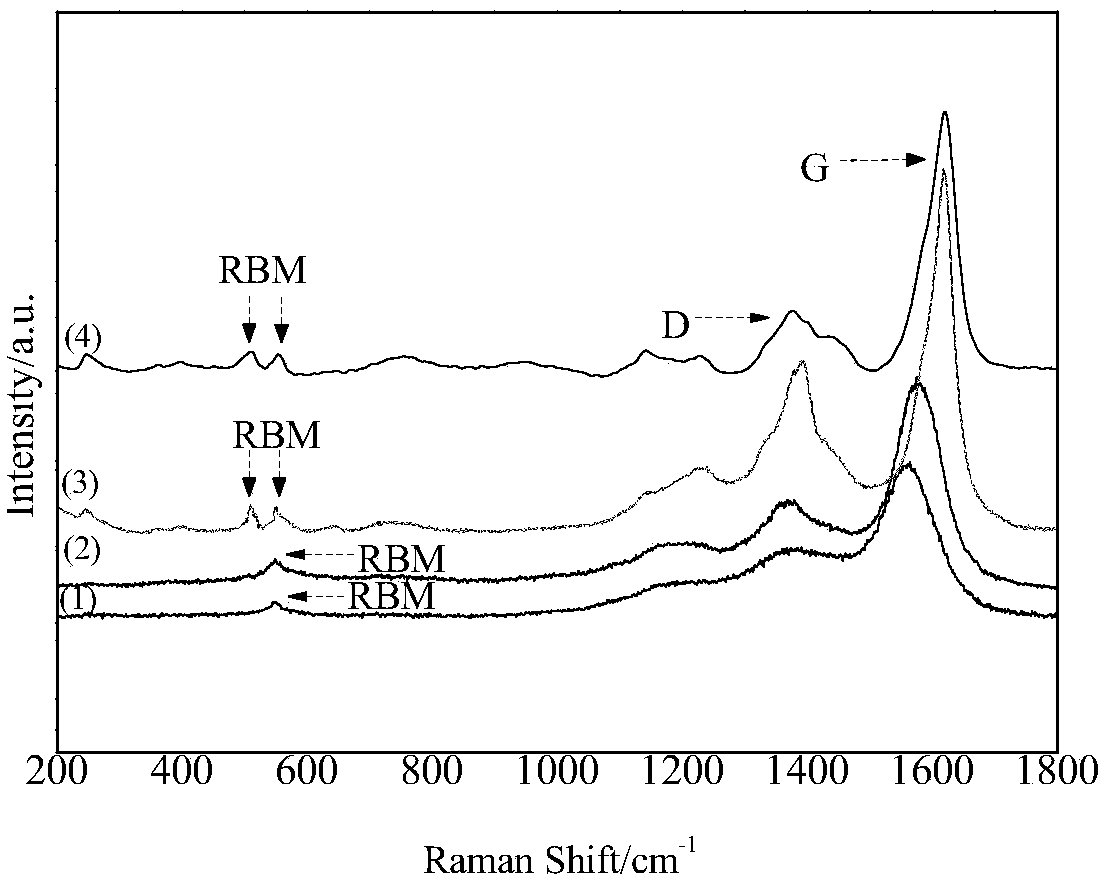

Preparation method of single-walled carbon nanotube-metal hybrid AlPO4-5 molecular sieve composite membrane

ActiveCN110575759AEfficient preparationGood repeatabilitySemi-permeable membranesMembranesMolecular sieveReaction temperature

The invention discloses a preparation method of a single-walled carbon nanotube-metal hybrid AlPO4-5 molecular sieve composite membrane. Single-walled carbon nanotubes (SWCNTs) are prepared in pores of an AlPO4-5 molecular sieve membrane by utilizing a positive streamer discharge technology, so the time, the reaction temperature and the energy consumption in the preparation process are greatly reduced, and the content of the SWCNTs in membrane pores, the completeness of the composite molecular sieve membrane and the membrane forming efficiency are effectively improved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Decorative reflective coating and preparation method thereof

InactiveCN111100517AIncrease deposition rateGood synergyReflecting/signal paintsAcrylic resinLight reflection

The invention provides a decorative reflective coating and a preparation method thereof. The decorative reflective coating comprises the following components in parts by weight: 5-10 parts of modifiedglass beads, 60-80 parts of acrylic resin and 5-10 parts of an emulsifier, the emulsifier being sodium dodecyl benzene sulfonate, 2-3 parts of ceramic beads, 1-2 parts of nano silicon dioxide, 1-2 parts of phenolic resin and 10-15 parts of deionized water, wherein the ratio of the modified glass beads to the ceramic beads is (2-3):1. According to the invention, the hollow glass beads and titaniumtetrabromide react to obtain the modified glass beads; the modified glass beads are coated with a layer of titanium oxide, the titanium oxide has a good thermal isolation effect, so that the coatinghas good light reflection and heat preservation properties at the same time, the added ceramic beads and the modified glass beads act together, the reflection and isolation effects are brought into full play, and the performance of the coating is improved.

Owner:湖南太子化工涂料有限公司

Surface modification process of waste epoxy molding compound

The invention discloses a surface modification process of a waste epoxy molding compound. The process comprises the following steps: (1) ball-milling the strip waste epoxy molding compound in a ball mill to obtain powder; (2) mixing ethanol and water according to a certain proportion to manufacture a mixed solvent, and dissolving a silane coupling agent in the mixed solvent to prepare a solution; (3) adding a certain amount of waste epoxy molding compound powder into the prepared solution, and stirring in refluxing for 1 hour at a certain temperature; (4) filtering reaction liquid, and drying an obtained filter cake in a blast drying oven for 24 hours; (5) grinding the dried product, and screening by screen cloth to obtain the waste epoxy molding compound powder modified by the silane coupling agent. The process disclosed by the invention is simple in operation and low in cost, the modified waste epoxy molding compound powder and high-density polyethylene are good in interfacial compatibility, and the process is beneficial to recycling of the waste epoxy molding compound.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com