Patents

Literature

38 results about "Contact order" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The contact order of a protein is a measure of the locality of the inter-amino acid contacts in the protein's native state tertiary structure. It is calculated as the average sequence distance between residues that form native contacts in the folded protein divided by the total length of the protein. Higher contact orders indicate longer folding times, and low contact order has been suggested as a predictor of potential downhill folding, or protein folding that occurs without a free energy barrier.

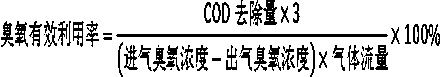

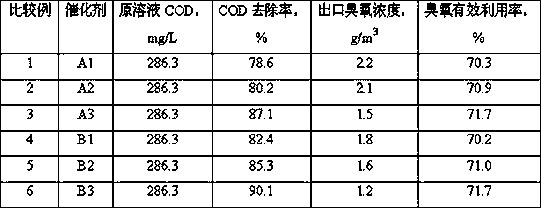

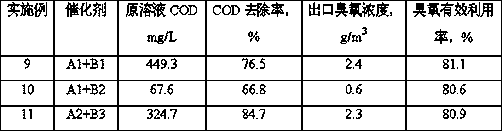

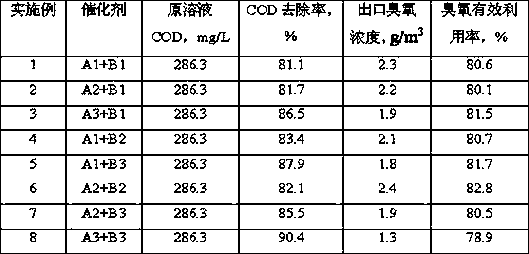

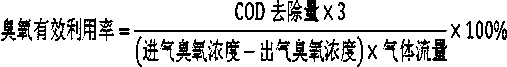

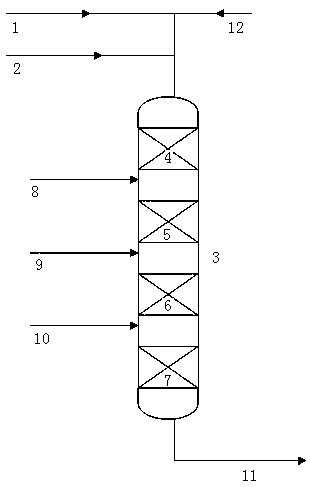

Method for treating wastewater through catalytic wet oxidation of ozone

PendingCN108069499AEasy to handleImprove effective utilizationWater contaminantsHeterogenous catalyst chemical elementsCatalytic oxidationOxidative treatment

The invention relates to the technical field of wastewater treatment and particularly discloses a method for treating wastewater through catalytic wet oxidation of ozone. The method comprises the steps as follows: organic wastewater and ozone enter a reactor to react, and the reactor is sequentially filled with a catalyst A and a catalyst B in the contact sequence with the organic wastewater. Themethod comprises a simple process and has good stability, the COD removal capacity is high, the effective utilization rate of ozone can be increased, and the dosage of ozone can be reduced.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP +1

Technology for treating organic wastewater through catalytic wet ozone oxidation

PendingCN108069496AEasy to handleImprove effective utilizationWater treatment compoundsWater contaminantsWastewaterUtilization rate

The invention relates to the technical field of wastewater treatment, and particularly discloses a technology for treating organic wastewater through catalytic wet ozone oxidation. The technology comprises steps as follows: the organic wastewater and ozone enter a reactor for a reaction, and the reactor is sequentially filled with a catalyst A and a catalyst B according to the contact sequence with the organic wastewater. The technology is simple and good in stability, not only is COD removing capacity high, but also effective utilization rate of ozone can be increased and adding amount of ozone can be reduced.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP +1

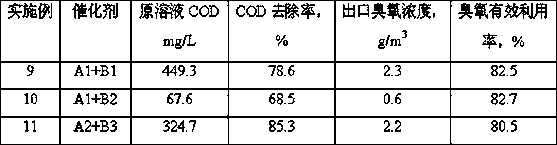

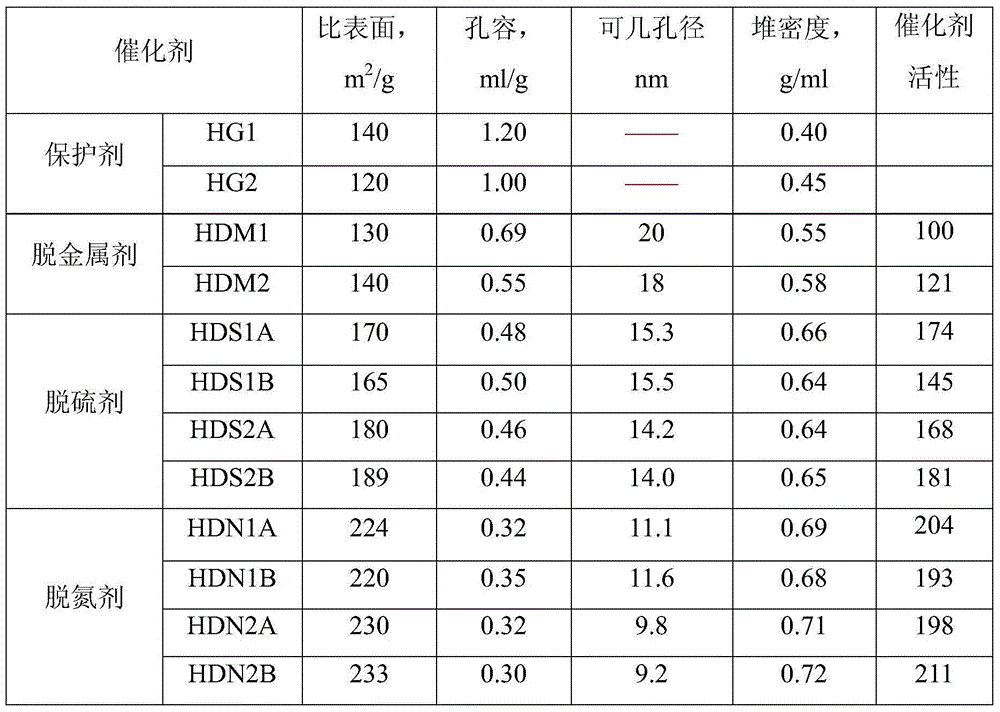

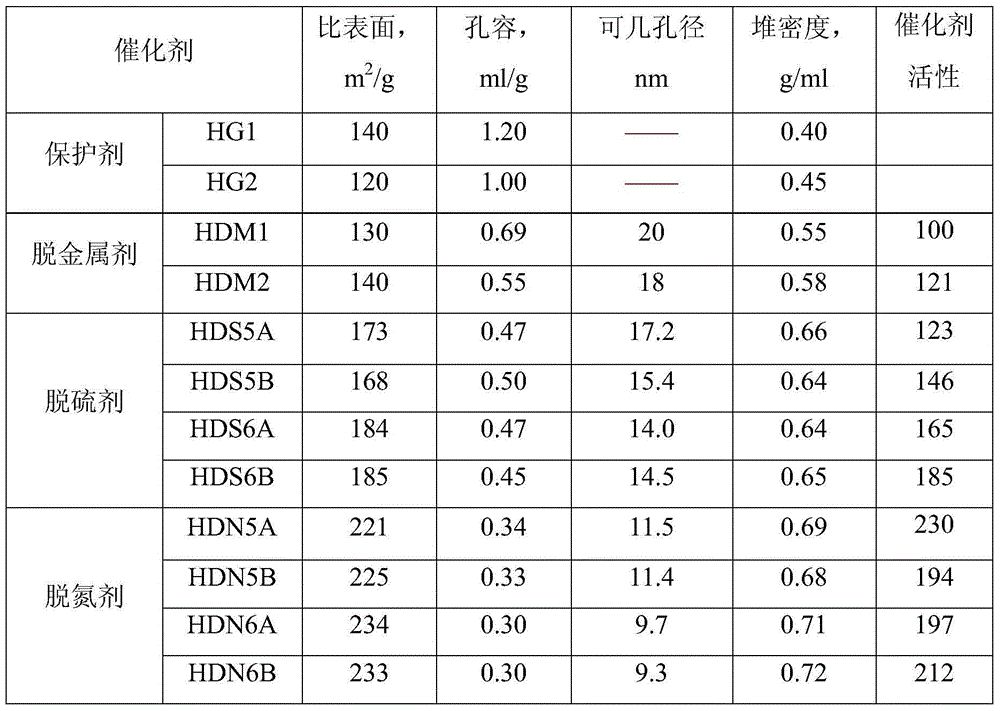

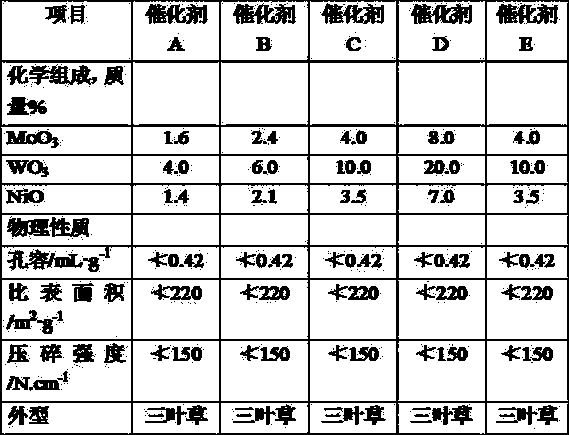

Gradation filling method of heavy oil hydrogenation treatment catalyst

ActiveCN105985805AControl temperature riseRealize an organic relayTreatment with hydrotreatment processesHydrogenation reactionReaction system

A gradation filling method of a heavy oil hydrogenation treatment catalyst. A reaction system includes two or more hydrogenation reactors connected in series. From the second reactor, the activity and probable pore size of the catalyst are both gradually decreased according to the sequence of contact with a reaction material flow in the same reactor. Between two adjacent reactors, according to the sequence of contact with the reaction material flow, the activity of the catalyst at the bottom of one reactor is lower than that at the top of the next one reactor, and the probable pore size of the catalyst at the bottom of one reactor is not more than that at the top of the next one reactor. Meanwhile, the activity of the catalyst at the bottom of one reactor is lower than that at the bottom of the next one reactor, and the probable pore size of the catalyst at the bottom of one reactor is large than that at the top of the next one reactor.

Owner:PETROCHINA CO LTD

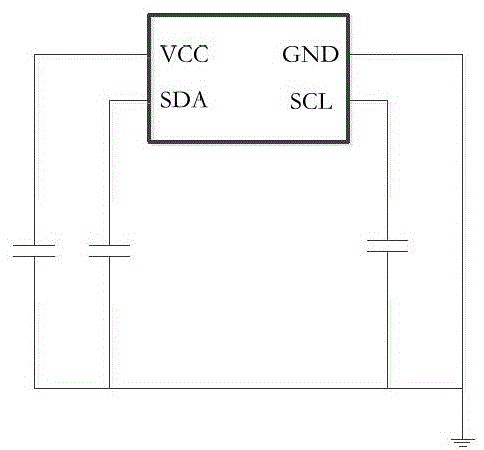

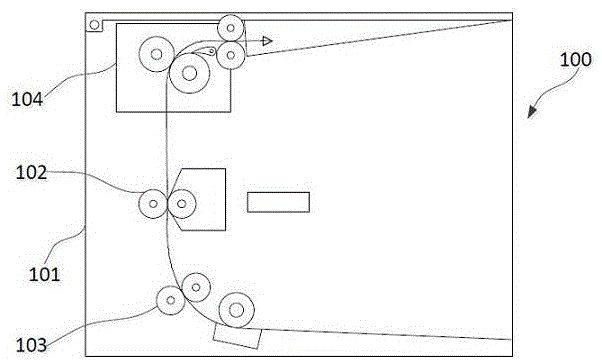

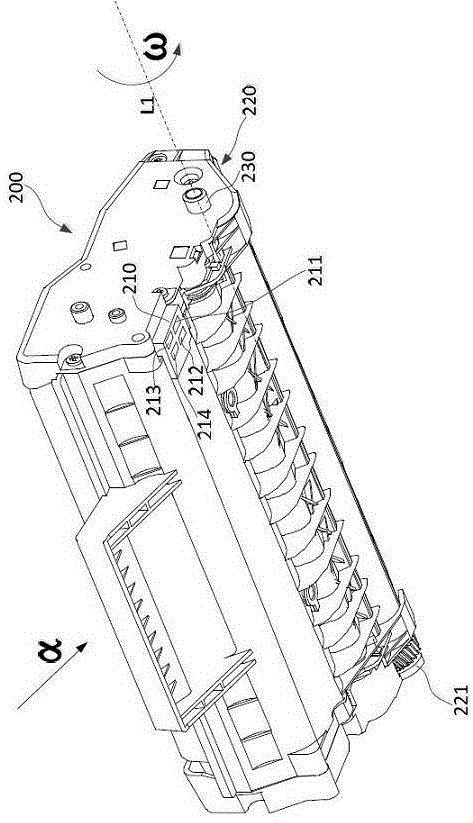

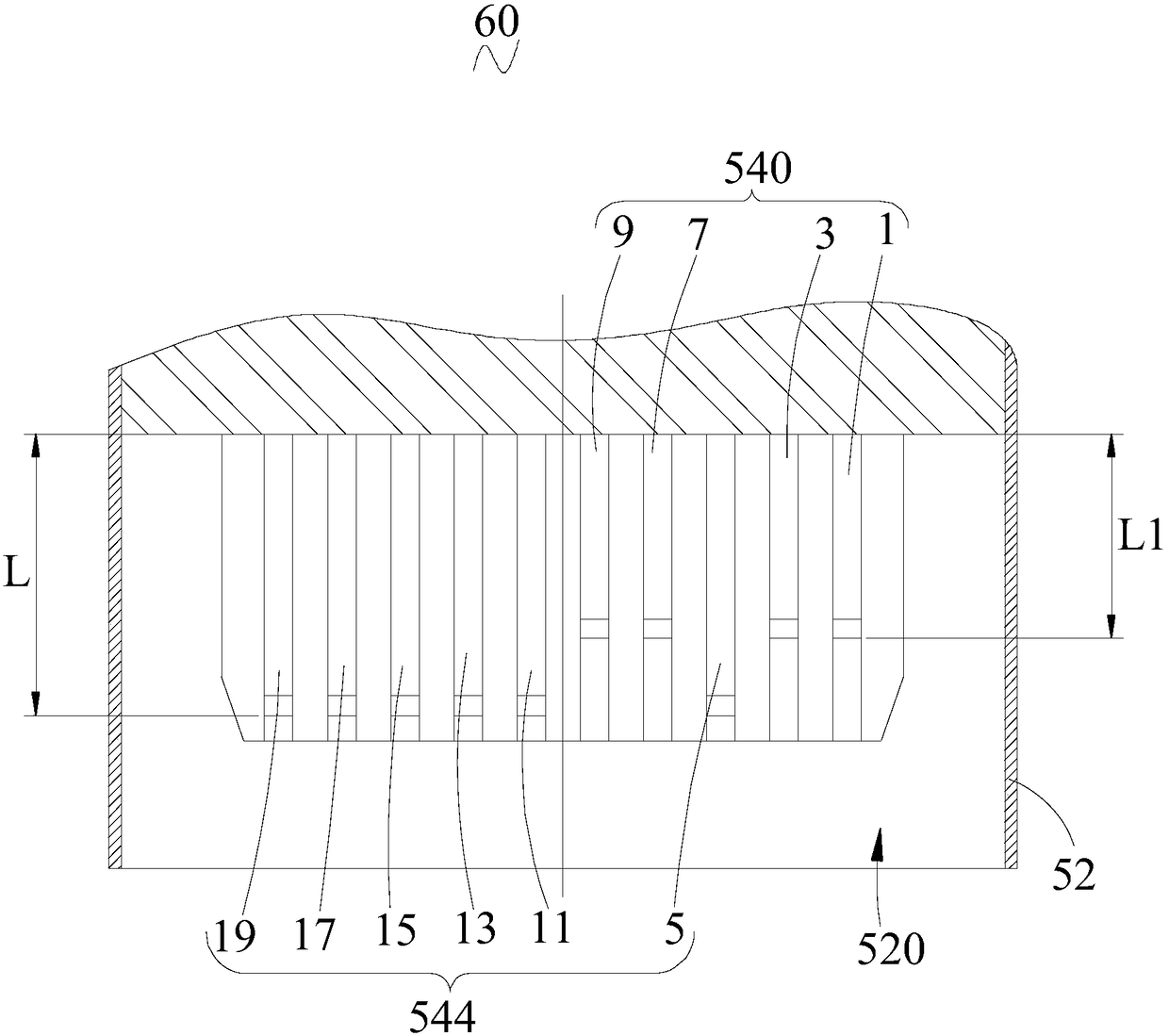

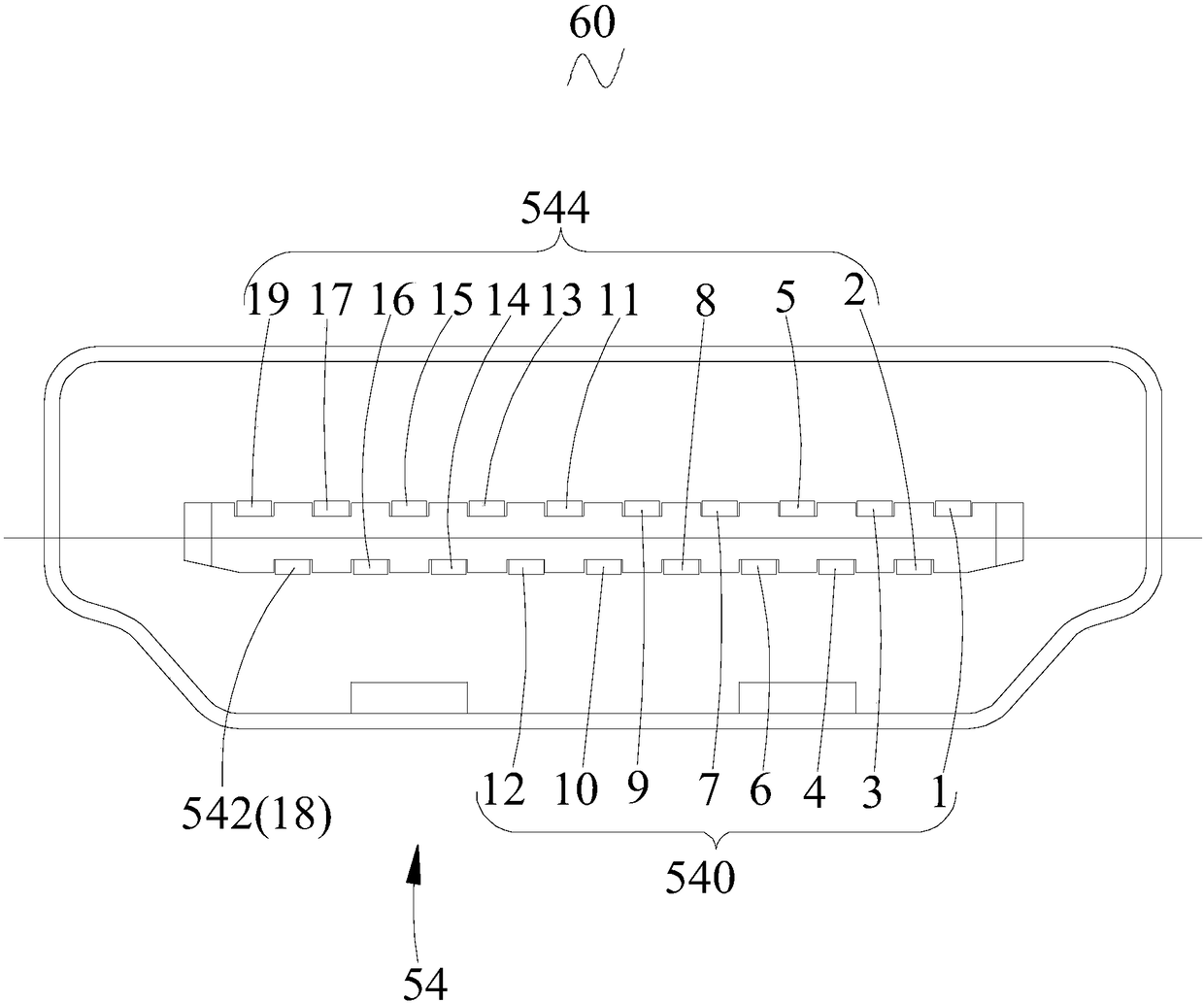

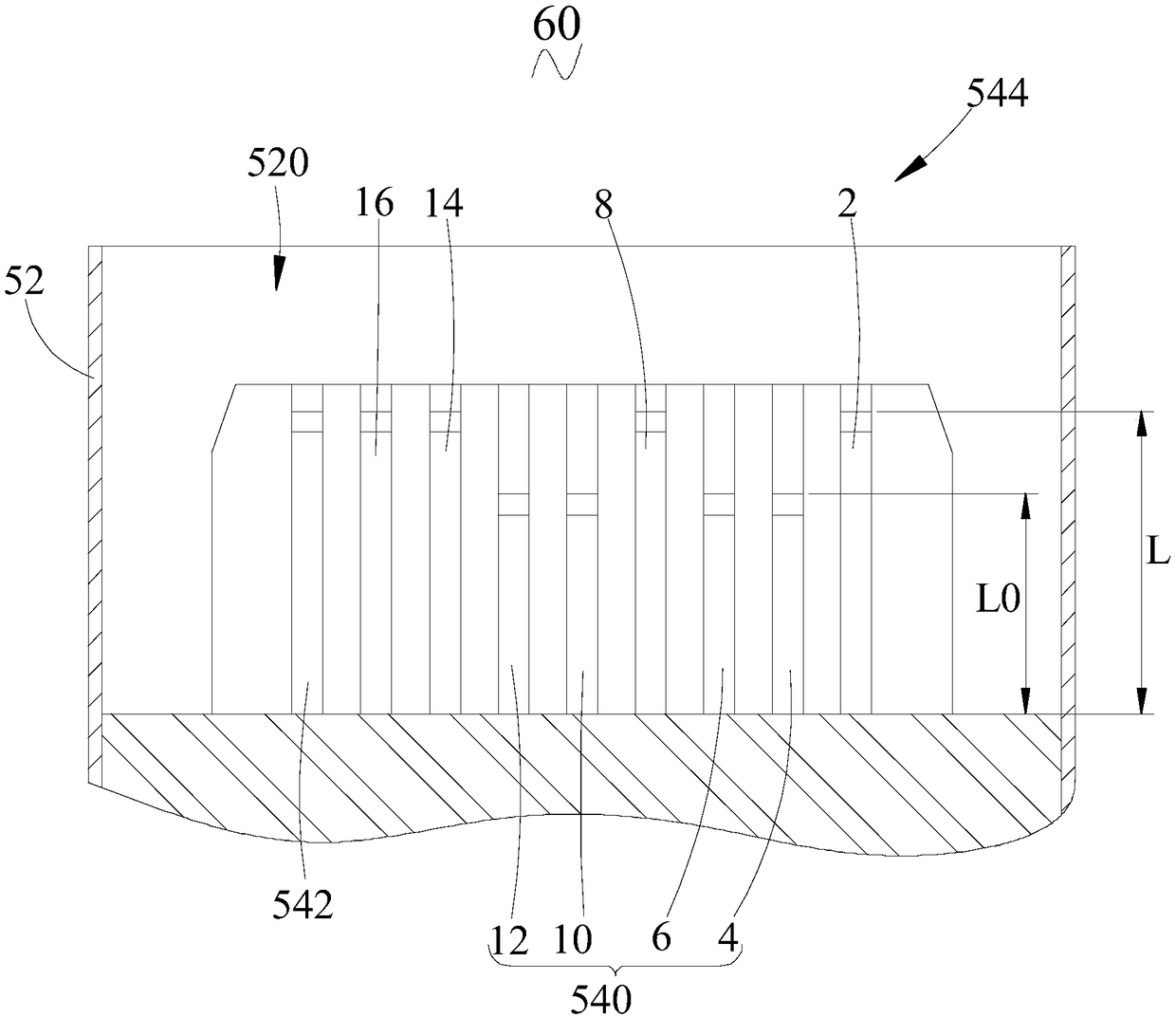

Storage element, developing cartridge employing same and image forming equipment

InactiveCN105549361ASolve technical defects of poor stabilityElectrographic process apparatusGround contactImage formation

The invention discloses a storage element for a developing cartridge, the developing cartridge comprising the storage element and image forming equipment comprising the developing cartridge. When the developing cartridge is arranged on the image forming equipment, conduction of a grounding contact on the storage element and a corresponding contact element in a main body of the image forming equipment is before conduction of a voltage contact on the storage element and the corresponding contact element in the main body; and conduction of the voltage contact on the storage element and the corresponding contact element in the main body is before conduction of a signal contact on the storage element and the corresponding contact element in the main body. The storage element disclosed by the invention can avoid the problem that components on the storage element are damaged due to the fact that high voltages are formed on the contacts on the storage element to discharge; and furthermore, the problem that the storage element of the developing cartridge is poor in stability when working due to the fact that a plurality of contacts on the storage element and a plurality of corresponding contacts on the main body of the image forming equipment do not have a certain successive contact order can be solved.

Owner:ZHUHAI PANTUM ELECTRONICS

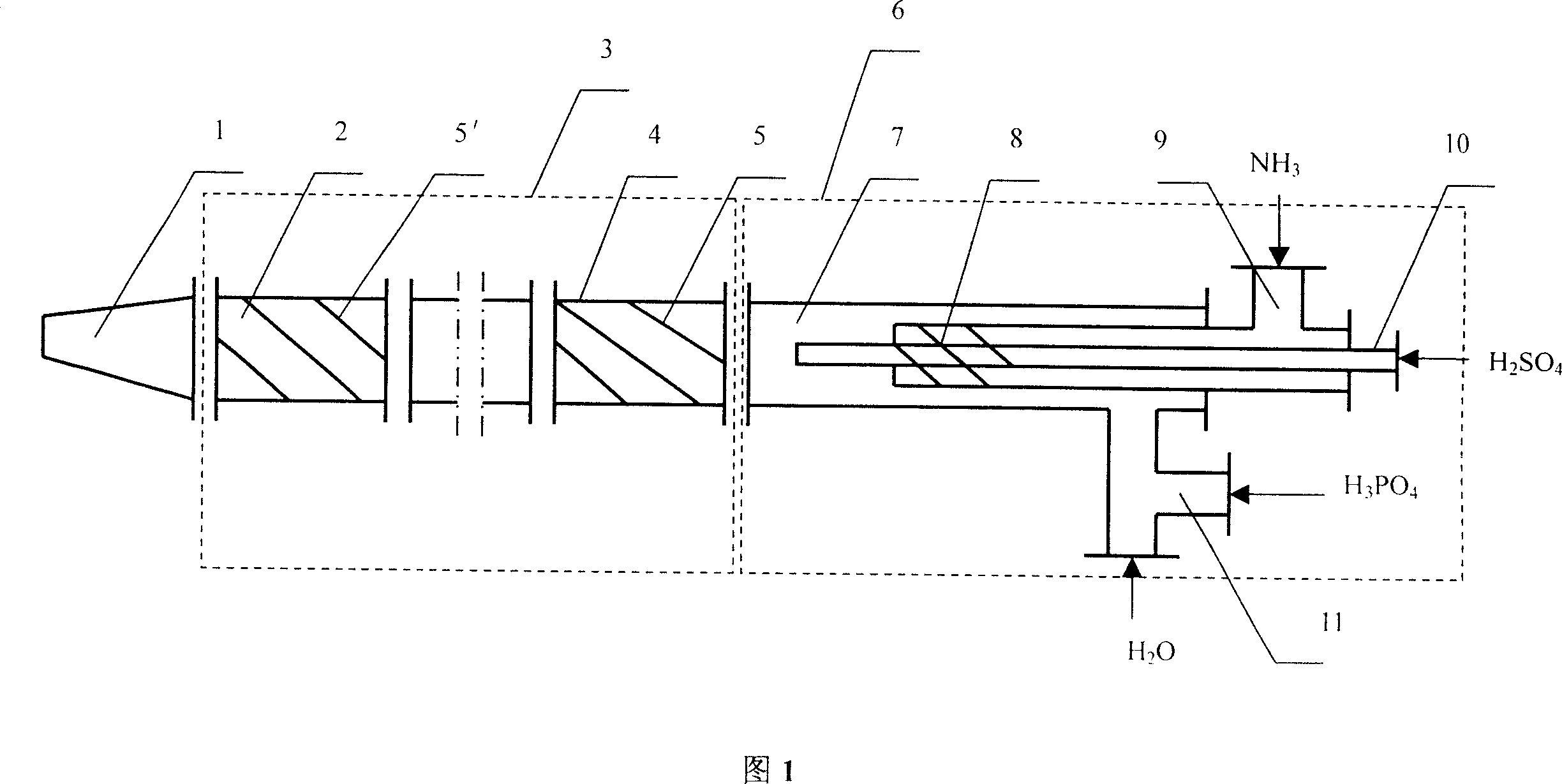

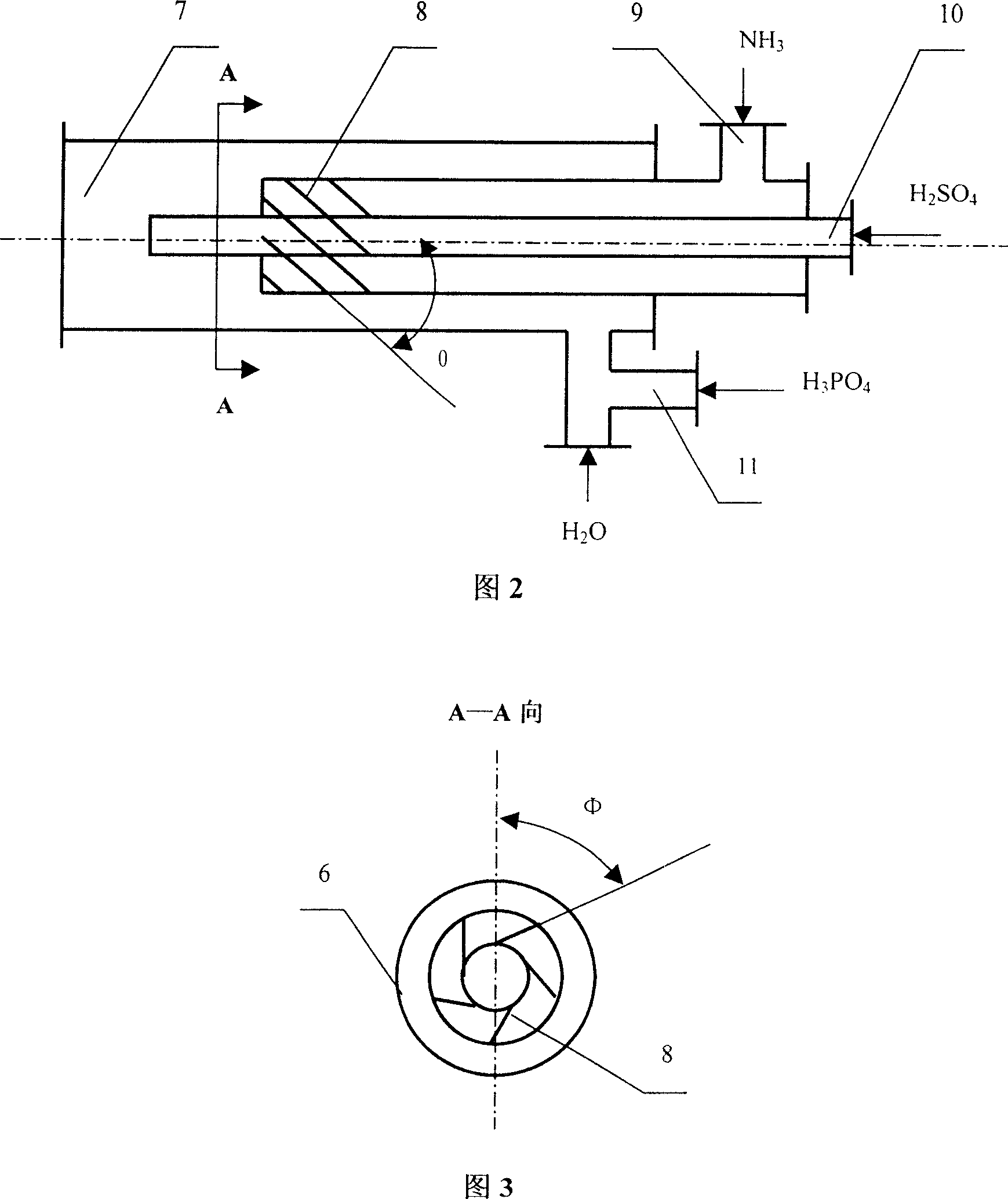

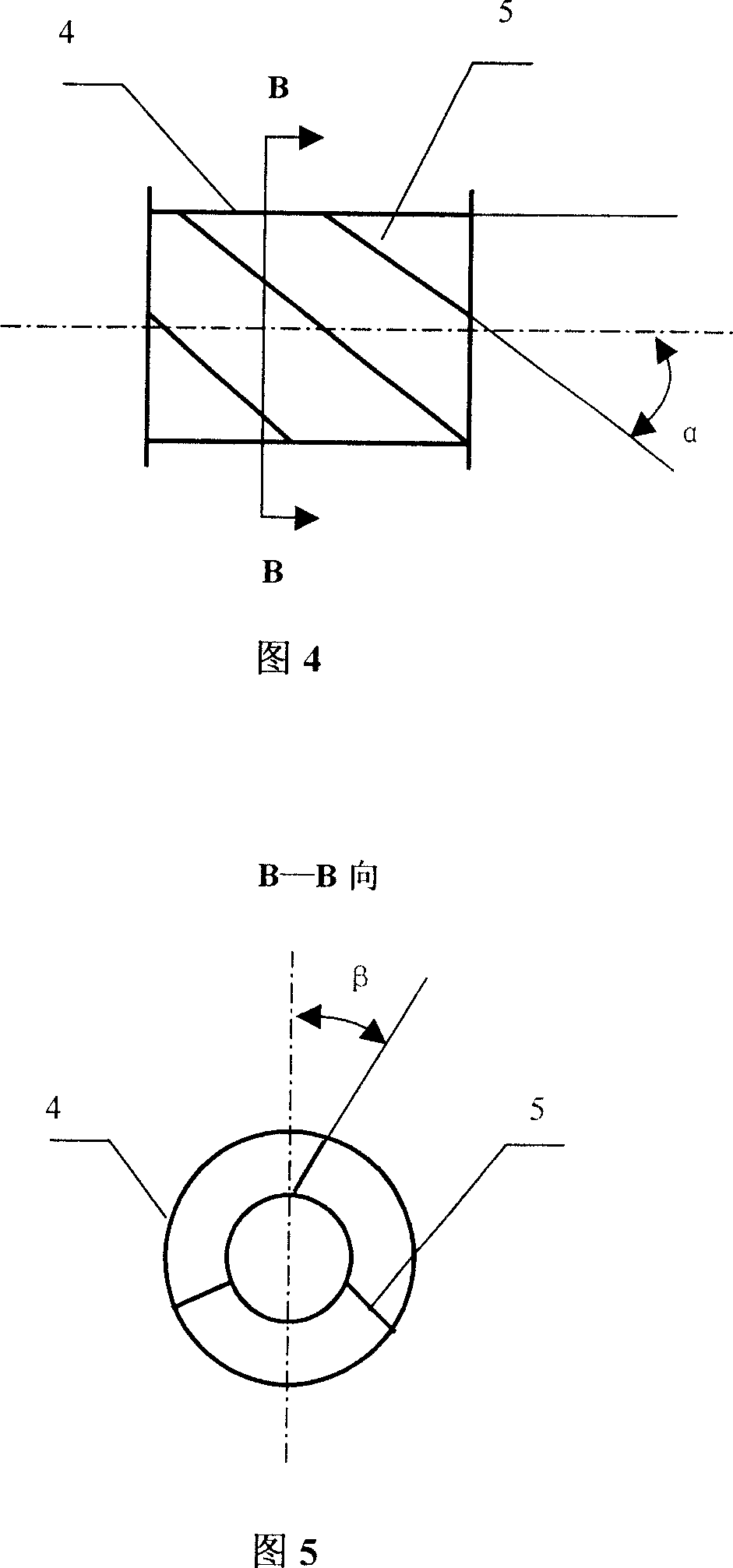

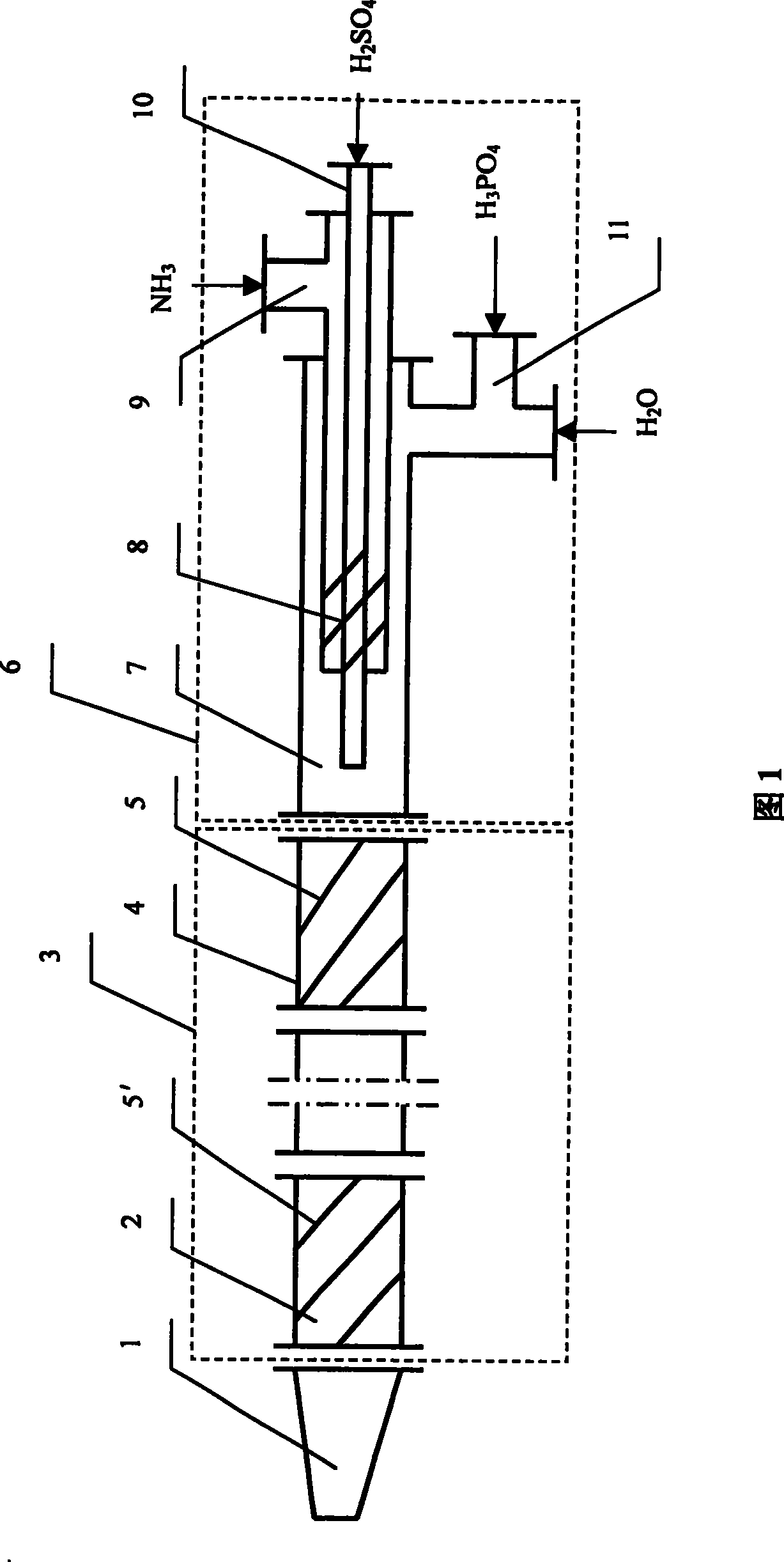

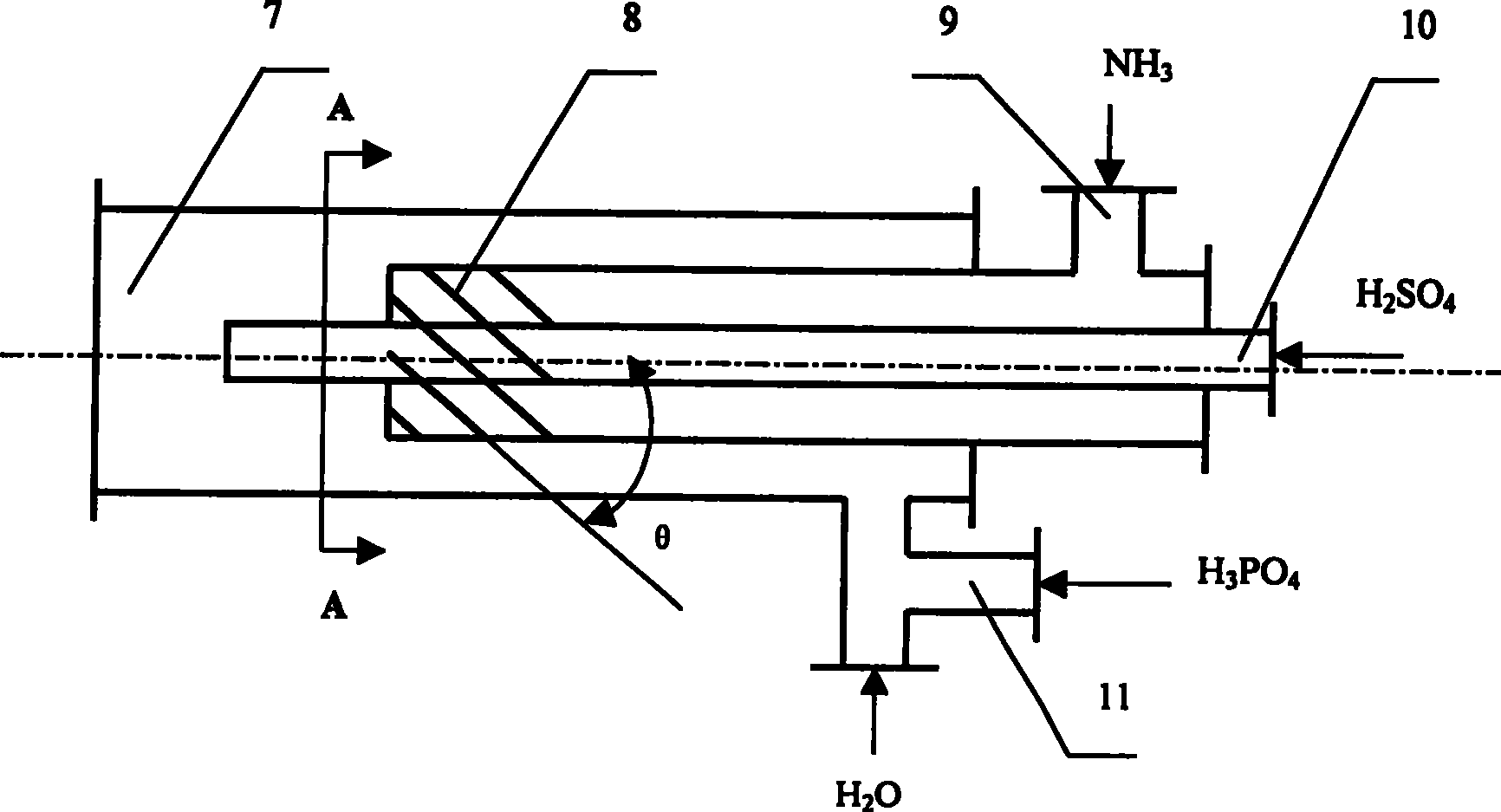

Improved tubular reactor

InactiveCN1986042ADissolve fastLess corrosiveAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersGas phaseSlurry

The improved tubular reactor includes one reactant mixing section, one reactant reacting section and one reaction product outputting nozzle. It features the reactant mixing section with one spiral jetting mixer and the reactant reacting section with one spiral mixer. The material contact order and the spiral jetting mixer in the reactant mixing section are regulated properly to control the mixing degree, contact area and reaction speed to ensure homogeneous mixing of the materials and moderate reaction speed. The spiral mixer in the reactant reacting section mix the gas phase, the liquid phase and the solid phase gradually for homogeneous, smooth, mild and full reaction to form high quality well atomized slurry.

Owner:中国-阿拉伯化肥有限公司

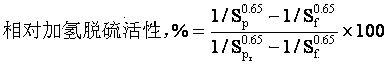

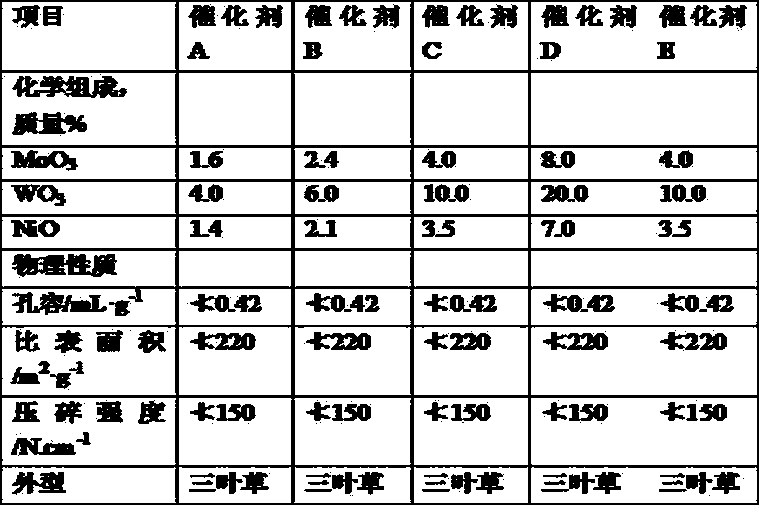

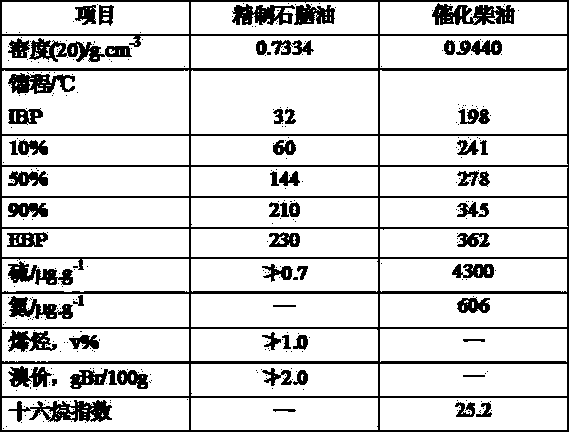

Hydrodesulfurization catalyst grading method

ActiveCN103773437AReduce voidsLarge filling-to-heap ratioRefining to eliminate hetero atomsSulfurHydrodesulfurization

The invention discloses a hydrodesulfurization catalyst grading method, the hydrodesulfurization catalyst grading method is as follows: a hydrogenation reactor comprises at least two catalyst beds, in accordance with the reaction material contact order, an upstream catalyst bed is a low-bulk-ratio catalyst bed, the bulk ratio of a downstream catalyst bed is higher than that of the adjacent upstream catalyst bed, each catalyst bed is loaded with more than two catalysts with different diameters in a grading manner. Compared with a single-diameter catalyst, the physical mixtures have smaller voidage and larger loading bulk ratio, the hydrodesulfurization performance of a whole reaction system can be improved, the operation period is prolonged, on the basis of no addition of fixed investment, production performances of ultra-low-sulfur and low-sulfur clean fuels can be improved in a low cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

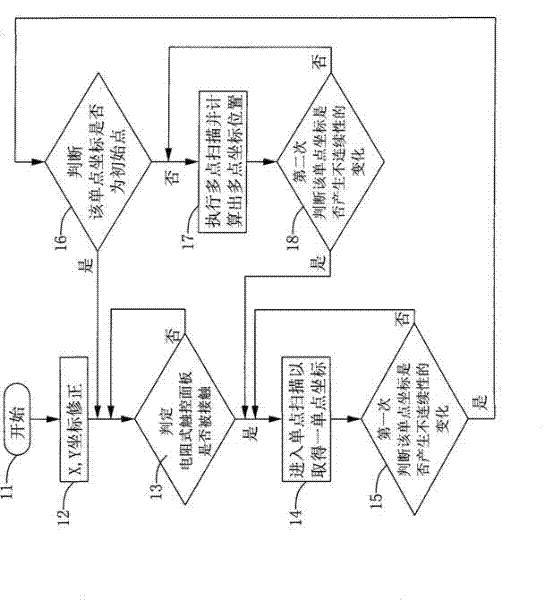

Control method for multi-point touch control controller

InactiveCN101458610ASimple principleSimple structureInput/output processes for data processingContact timeControl theory

The invention relates to a control method of multi-point contact control controller applied to an electric resistance type contact control panel, the electric resistance type contact control panel is provided, a contact order of a first contact body and a second contact body can be determined according to contact times of the first contact body and the at least one second contact body respectively contacted with the electric resistance type contact control panel, one first contact coordinate and at least one actual coordinate can be determined in order based on the voltage value sensed by the electric resistance type contact control panel, and the contact body continuously keeps contact with the electric resistance type contact control panel; at least one control instruction can be determined according to the moving track of the actual coordinate.

Owner:J TOUCH CORPORATION

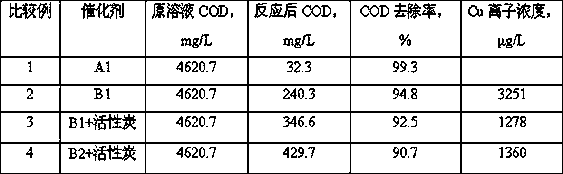

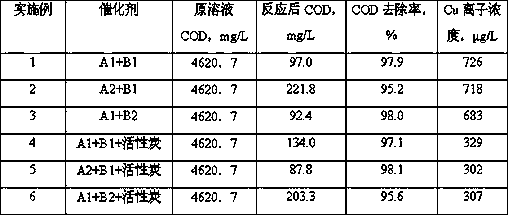

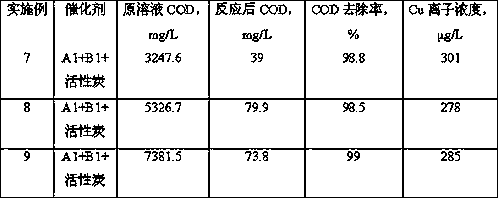

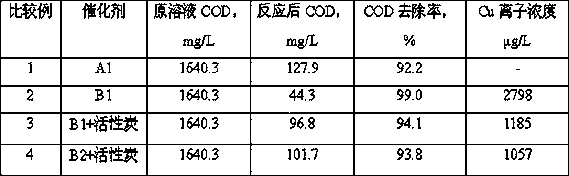

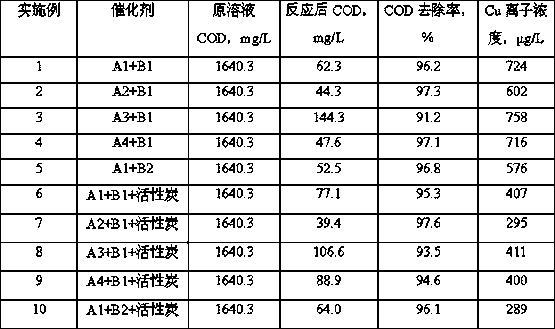

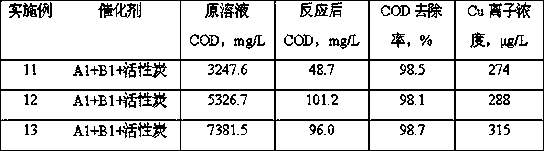

Method for treating organic wastewater through catalytic wet oxidation

ActiveCN108069497AEasy to handleGive full play to the catalytic effectMolecular sieve catalystsWater contaminantsCatalytic oxidationOxidative treatment

The invention relates to the technical field of wastewater treatment, and particularly discloses a method for treating organic wastewater through catalytic wet oxidation. The method comprises steps asfollows: the organic wastewater and an oxidizing agent enter a reactor for a reaction, and the reactor is sequentially filled with a catalyst A and a catalyst B according to the contacted sequence with the organic wastewater. The method adopts a simple technology and is good in stability, not only is COD removing capacity high, but also the problem of metal loss can be solved.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP +1

Catalytic wet oxidation treatment method of organic wastewater

PendingCN108069495AGive full play to the catalytic effectEasy to handleWater treatment parameter controlMolecular sieve catalystsOxidative treatmentOxidizing agent

The invention relates to the technical field of wastewater treatment and particularly discloses a catalytic wet oxidation treatment method of organic wastewater. The treatment method comprises steps as follows: the organic wastewater and an oxidizing agent enter a reactor for a reaction, and the reactor is sequentially filled with a catalyst A and a catalyst B according to the contact sequence with the organic wastewater. The method adopts a simple process, is good in stability and high in COD removal capability and can solve the problem about metal loss.

Owner:FUSHUN RES INST OF PETROLEUM & PETROCHEMICALS SINOPEC CORP +1

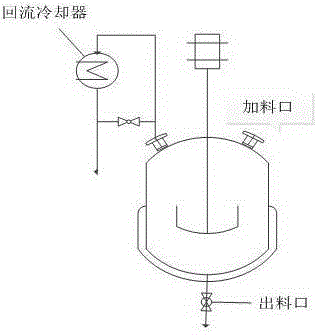

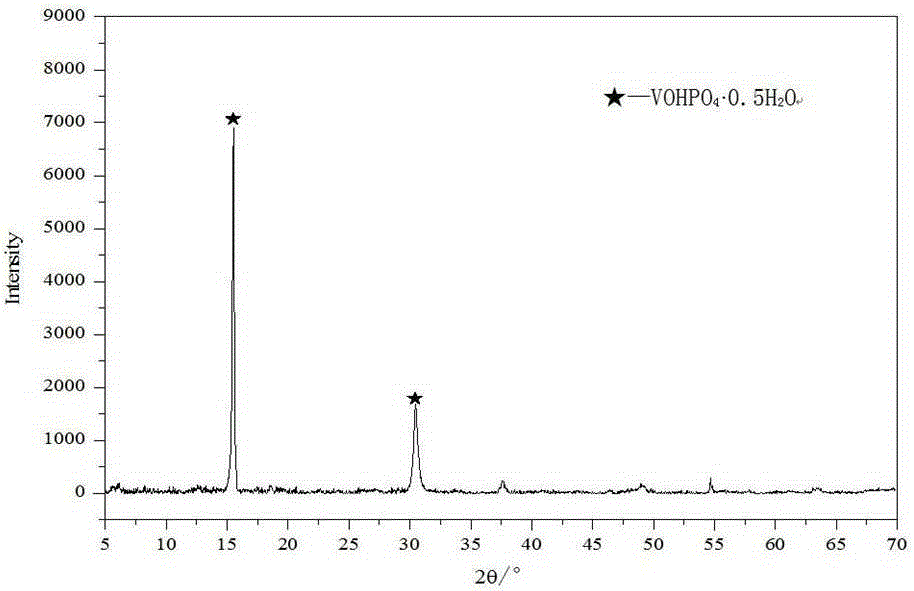

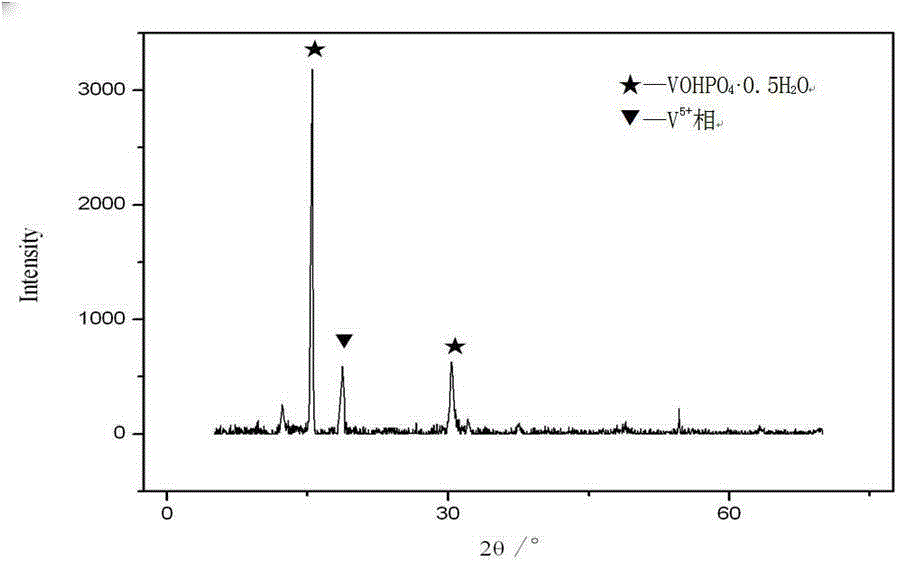

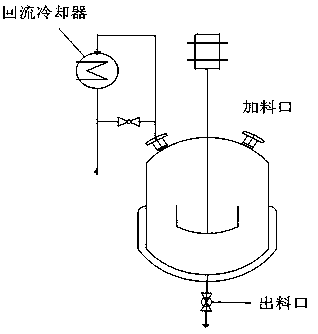

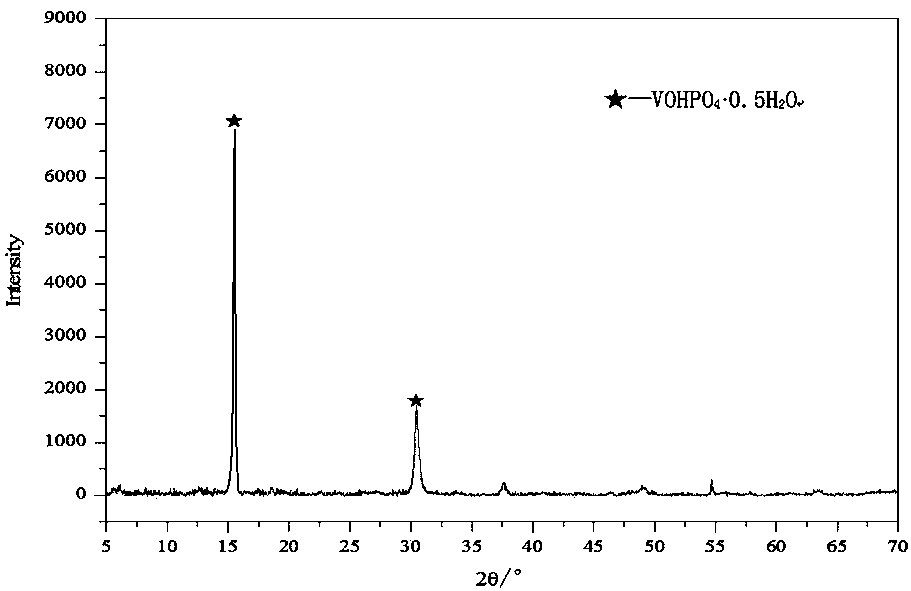

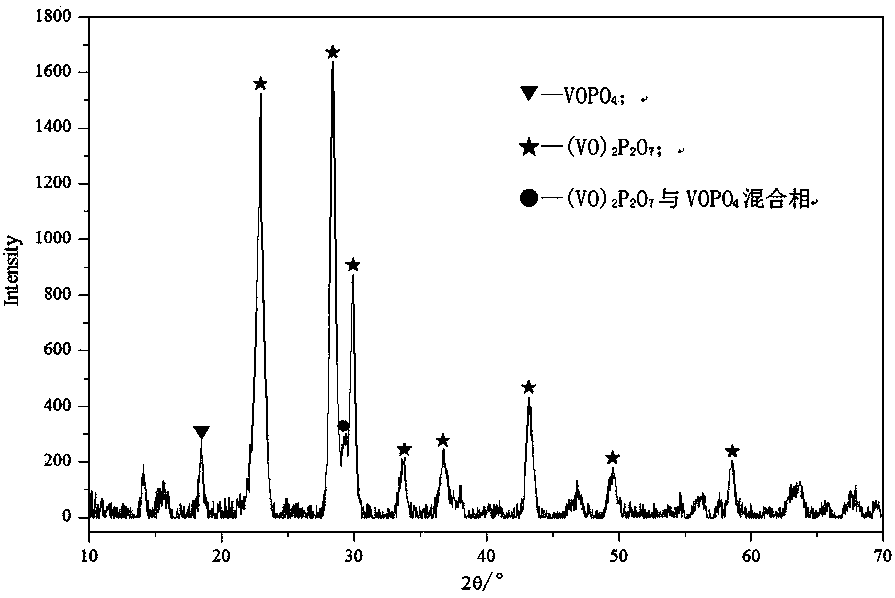

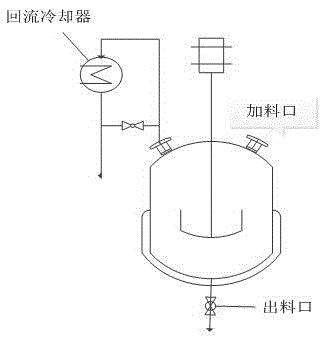

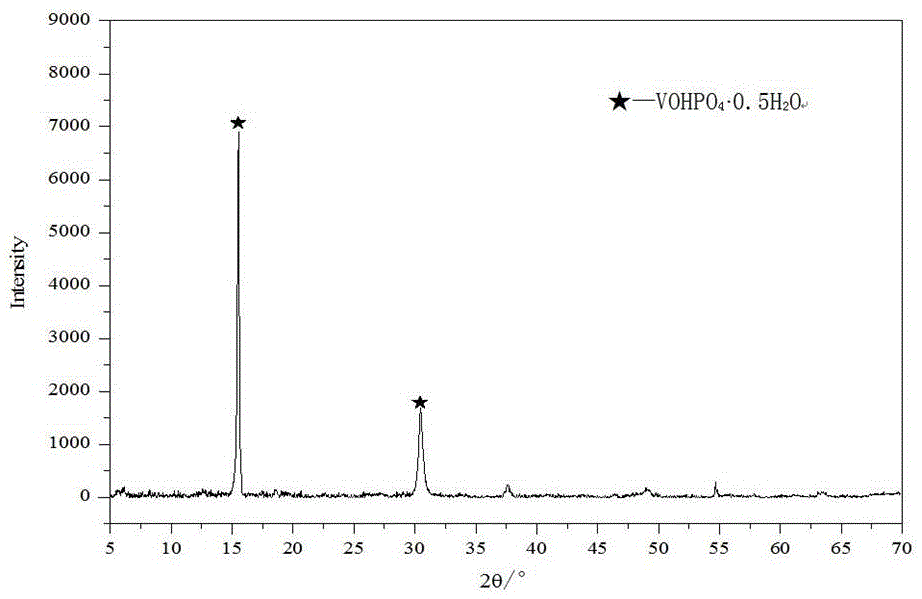

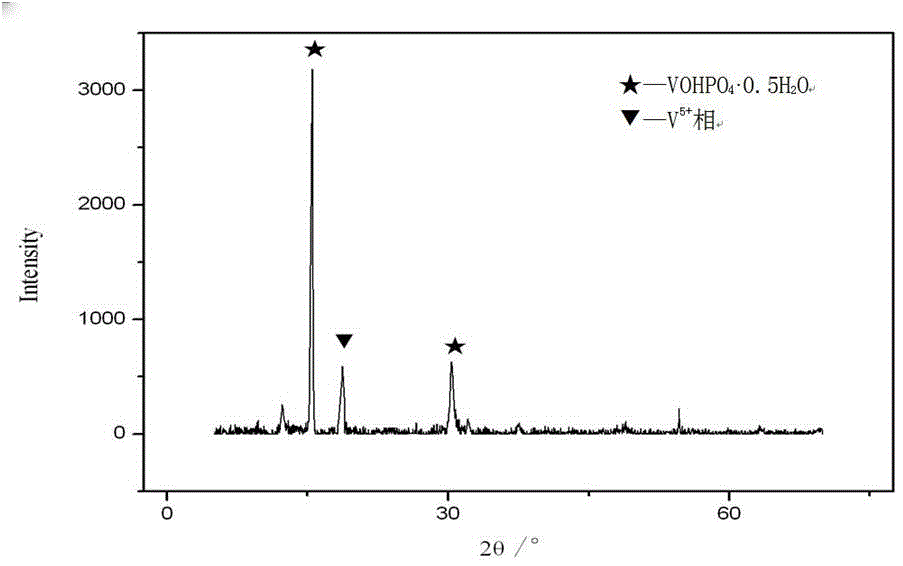

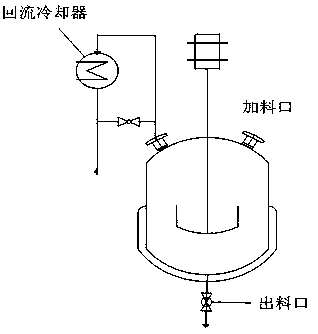

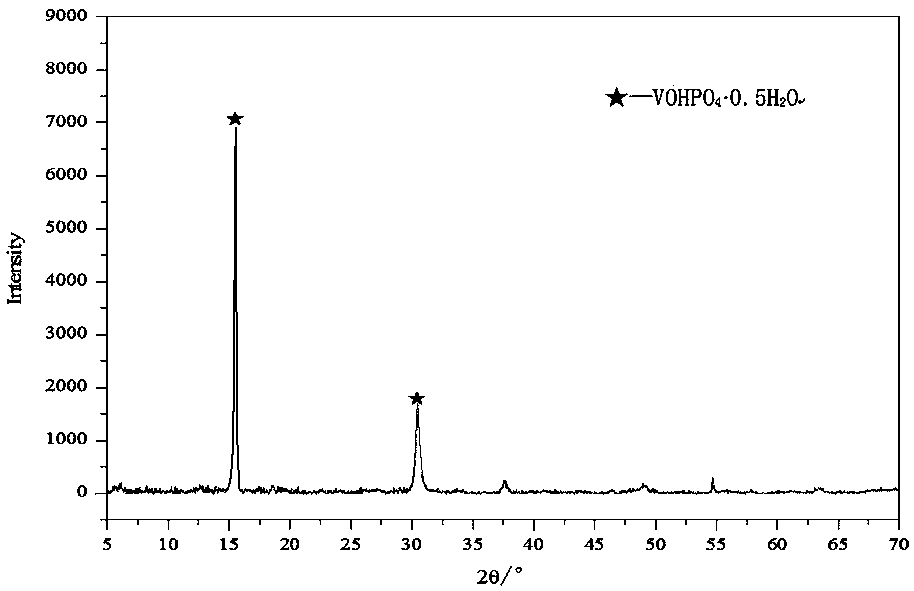

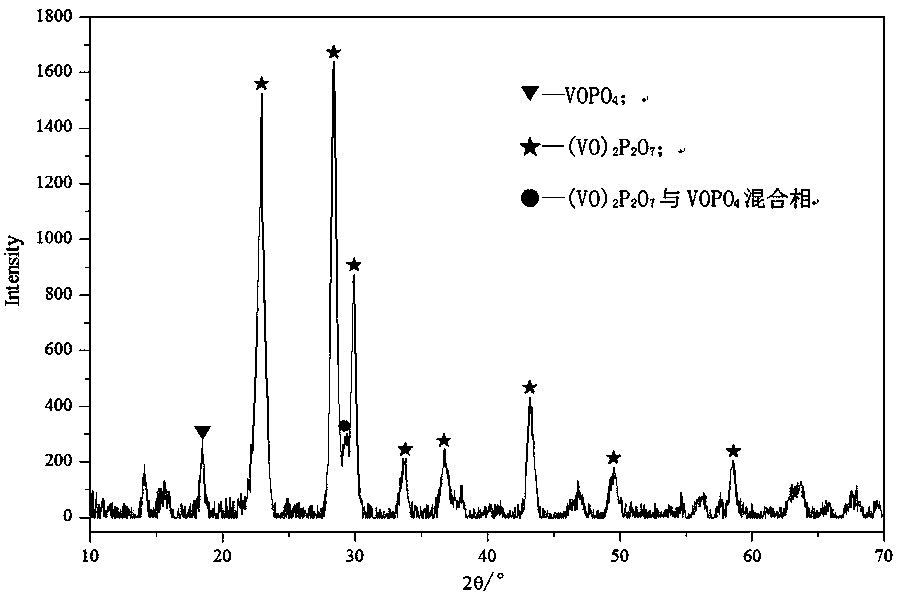

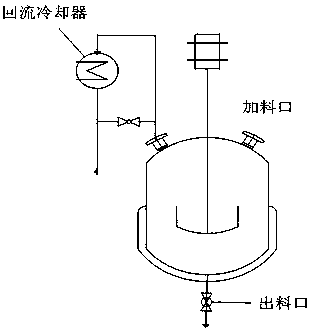

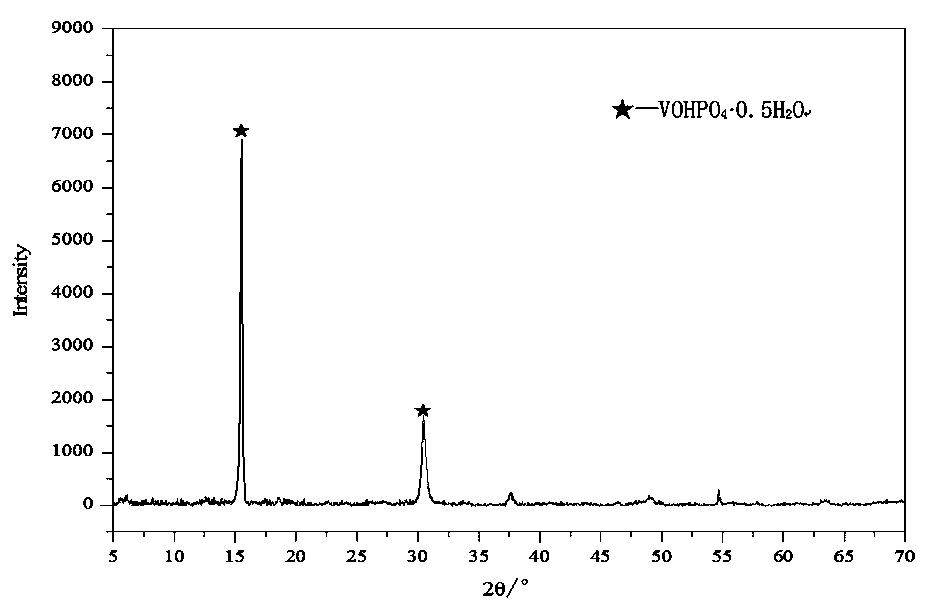

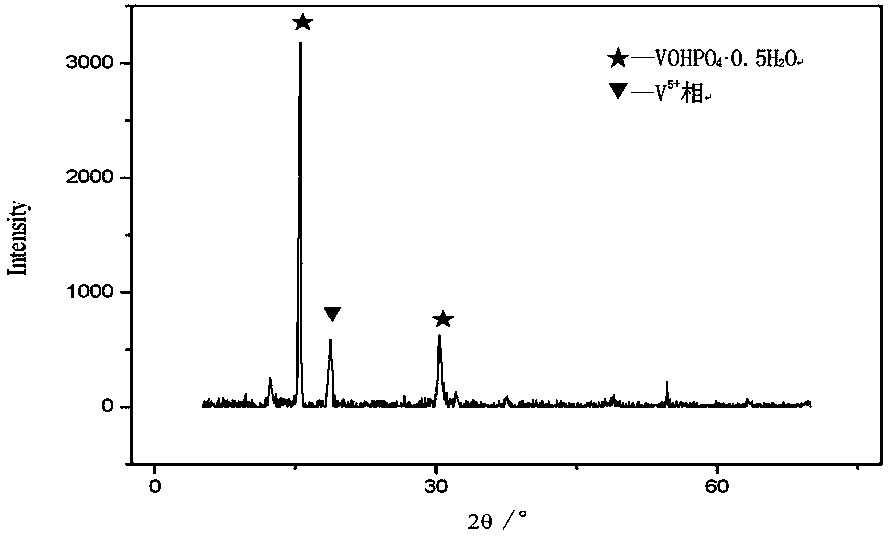

Catalyst grading method for preparing maleic anhydride through oxidation of n-butane

ActiveCN106732702AReduce volume fractionImprove efficiencyPhysical/chemical process catalystsOrganic chemistrySide reactionButane

The invention discloses a method for preparing maleic anhydride through oxidation of n-butane. The method comprises that n-butane and air are mixed, the mixed reaction gas passes through three or more double-tandem vanadium phosphorus oxide catalyst beds in parallel, under oxidative reaction conditions, the reaction gas contacts with the vanadium phosphorus oxide catalyst and undergoes a reaction, and in an order of contact with mixed reaction gas, a grading loading process is carried out according to a tendency of increasing the average valence of vanadium in the three or more tandem catalyst beds, then reducing the average valence and then increasing the average valence so that the activity distribution of the catalyst is balanced and the catalyst produces full activity. The method can improve the concentration of n-butane in the feed, reduce the reaction hot spot of the bed, make the bed temperature distribution average, effectively inhibit the side reaction, improve product selectivity and increase a product maleic anhydride yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Colouring of keratinous fibers using a pretreatment comprising an iron salt and a colour developer comprising hydrolysable tannin

A method of colouring keratinous fibers comprising contacting the keratinous fibers sequentially with a pre-treatment composition and a colour developer wherein: i. the pre-treatment composition comprises: (a) 0.5-25% by weight of an iron salt at a pH below 2 including 0.5-5% by weight of a reducing agent (b) a buffer effective in the pH range 3-6 and (c) a penetration enhancer comprising one or more solvents having Hansen solubility parameter δh between 1-10 (MPa)1 / 2 and δp between 10-25 (MPa)1 / 2 wherein the component (b) is mixed with (a) or (c) not more than 360 minutes prior to contacting the keratinous fibers and ii. the colour developer is selected from one or more of hydrolysable tannin or its breakdown products or derivatives or a mixture thereof obtained from a natural or synthetic source, where the sequence of contact is in any order.

Owner:CONOPCO INC D B A UNILEVER

Catalyst grading method for preparation of maleic anhydride from n-butane by oxidation

ActiveCN108101872APromote conversionIncrease volume fractionOrganic chemistryPhysical/chemical process catalystsSide reactionButane

The invention discloses a catalyst grading method for preparation of maleic anhydride from n-butane by oxidation. N-butane is mixed with air, and obtained mixed reaction gas flows in parallel throughthree or more vanadium phosphorus oxide catalyst beds connected in series, and is contacted with a vanadium phosphorus oxide catalyst for reaction under the oxidation reaction condition, wherein according to the contact sequence with the mixed reaction gas, the three or more catalyst beds connected in series perform graded loading according to the trend of the P / V molar ratio of the catalyst beingfirstly low, high and then low, so that activity distribution of the catalyst is balanced, and the activity of the catalyst is fully exerted. With the method, the n-butane concentration in feed can be increased, the reaction hot spot of the beds is reduced, temperature distribution of the beds is uniform, occurrence of side reactions is effectively inhibited, selectivity of a product is improved,and the yield of the product maleic anhydride is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing maleic anhydride by oxidation of n-butane

ActiveCN106749126AHigh average reaction temperatureHigh reaction conversion rateOrganic chemistryPhysical/chemical process catalystsReaction zoneOxygen content

The invention discloses a method for preparing maleic anhydride by oxidation of n-butane. According to the invention, n-butane, air and cycle tail gas are mixed, a mixture passes through more than two of reaction zones which are connected in series in order, under oxidation reaction condition, the mixture is contacted with a vanadium phosphorus oxide catalyst; besides the most downstream reaction zone, each reaction zone comprises more than two catalyst bed layers; wherein, according to a contact sequence with reaction gas, average valence of vanadium in the catalyst in the downstream reaction zone is higher than the average valence of vanadium in the catalyst in the upstream reaction zone; and, in each reaction zone besides the most downstream reaction zone, average valence of vanadium in the downstream catalyst bed layer is higher than the average valence of vanadium in the upstream catalyst bed layer. The catalyst activity is equally distributed according to reaction requirement, catalytic activity is fully performed, especially in a tail gas cycle utilization technology, influence of decreased conversion rate due to decreased oxygen content in the raw materials can be compensated, reaction hot spot is reduced, and product selectivity is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Improved tubular reactor

InactiveCN1986042BDissolve fastLess corrosiveAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersGas phaseSlurry

The improved tubular reactor includes one reactant mixing section, one reactant reacting section and one reaction product outputting nozzle. It features the reactant mixing section with one spiral jetting mixer and the reactant reacting section with one spiral mixer. The material contact order and the spiral jetting mixer in the reactant mixing section are regulated properly to control the mixingdegree, contact area and reaction speed to ensure homogeneous mixing of the materials and moderate reaction speed. The spiral mixer in the reactant reacting section mix the gas phase, the liquid phase and the solid phase gradually for homogeneous, smooth, mild and full reaction to form high quality well atomized slurry.

Owner:中国-阿拉伯化肥有限公司

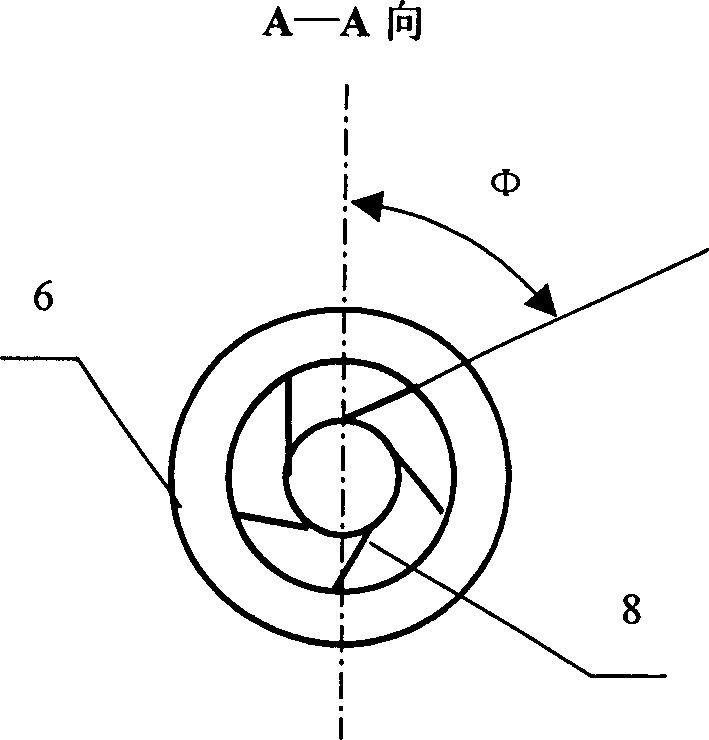

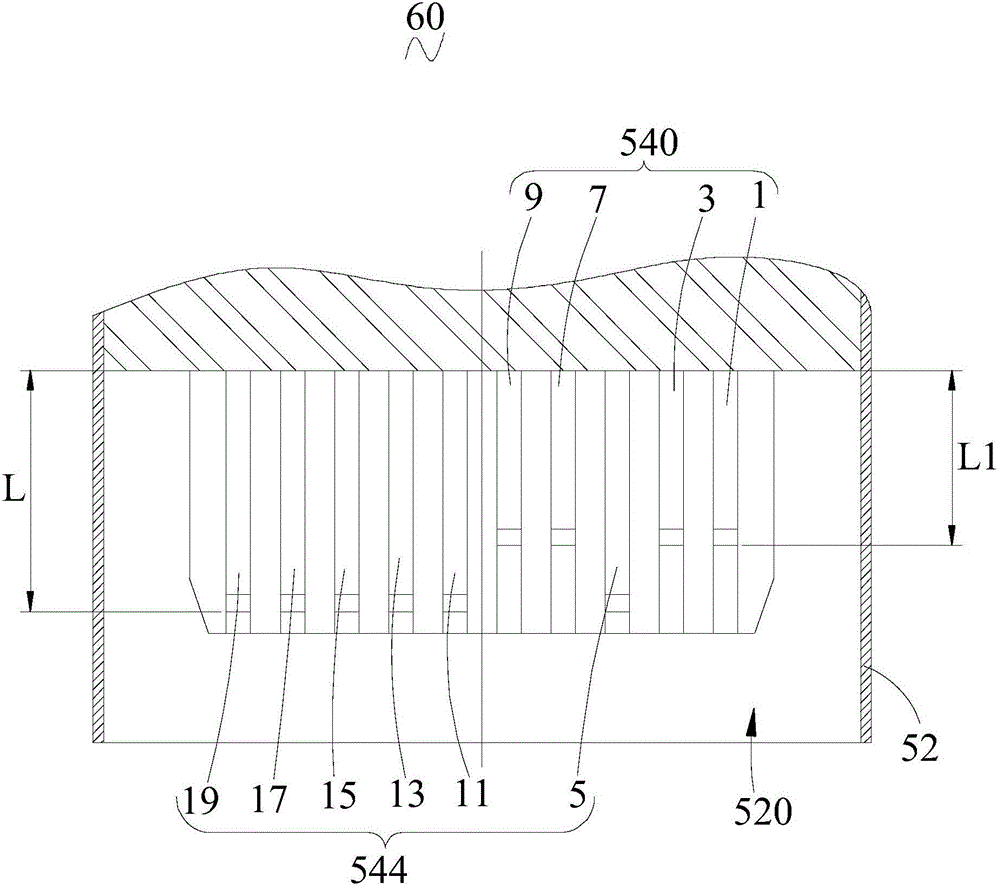

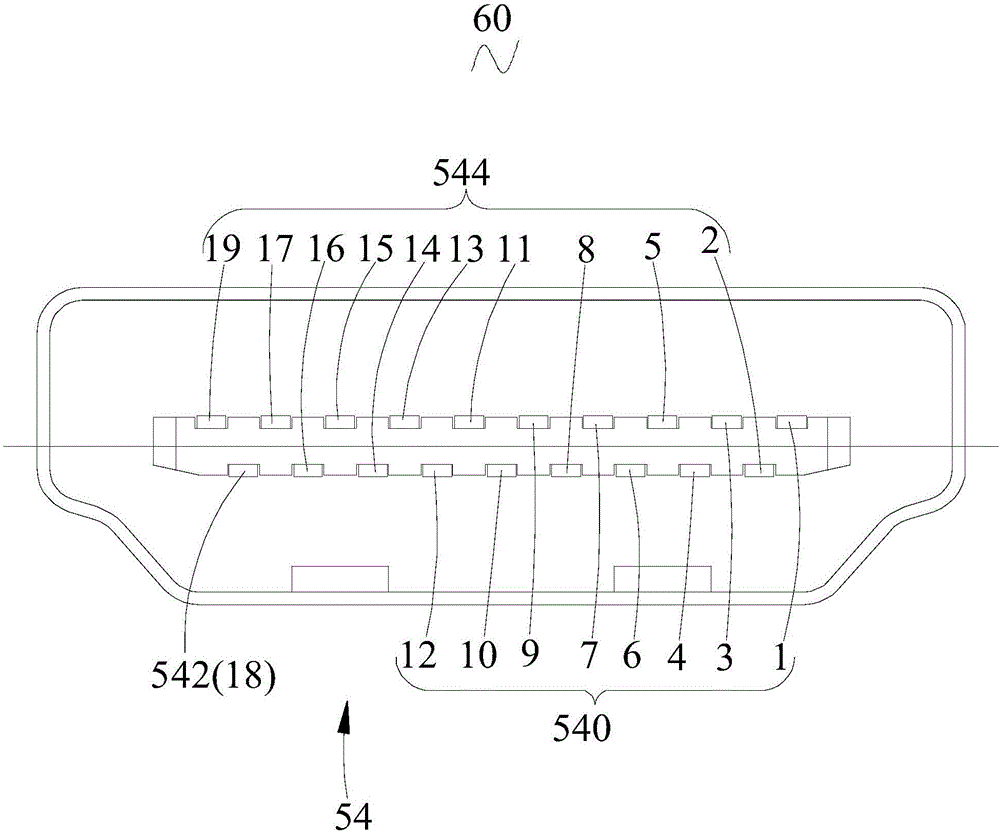

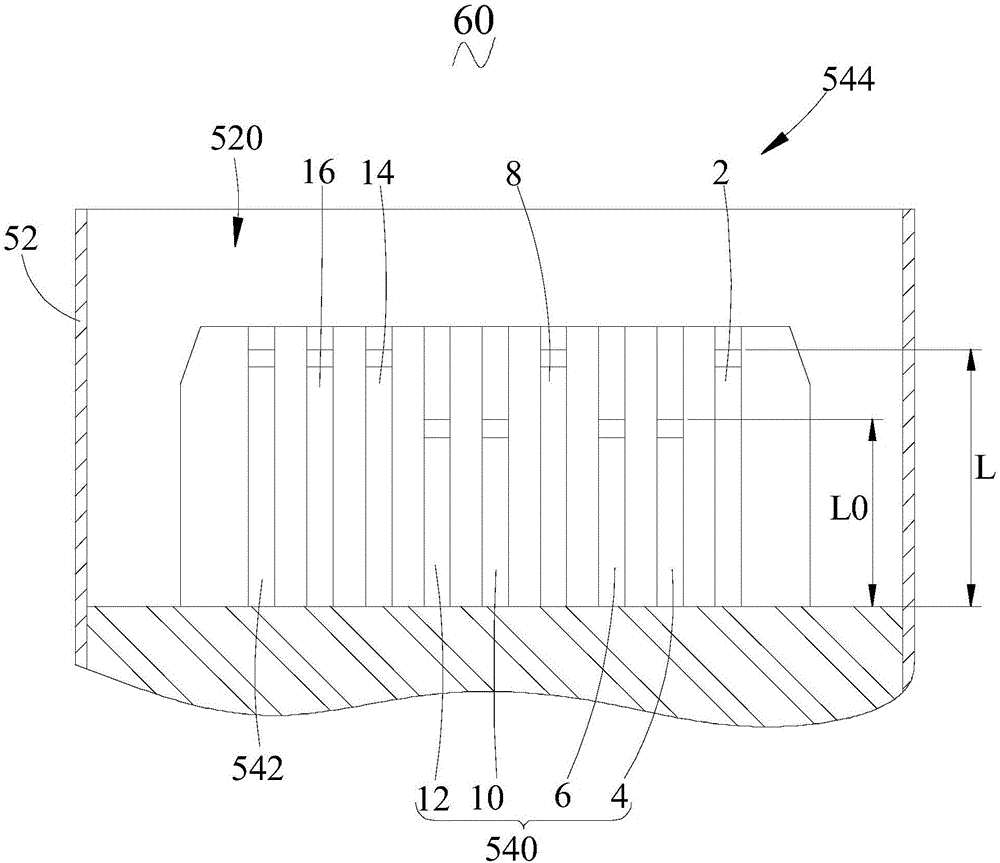

HDMI connector and blue-ray player

The invention is suitable for the technical field of connectors, and provides an HDMI connector. The HDMI connector comprises a plug and a socket, wherein each of the plug and the socket comprises a housing and multiple pins; the pins in the plug correspond to the pins in the socket; each pin comprises an A attribute pin, a power pin and input / output pins; when the plug is inserted into the socket, the contact order of the plug and the socket is as follows: contact of the socket and the housing of the plug is a first contact order; the contact of the input / output pins in the socket and the input / output pins in the plug is a second contact order; the contact of the A attribute pin in the socket and the A attribute pin in the plug is a third contact order; and the contact of the socket and the power pin in the plug is a fourth contact order. According to the HDMI connector, through changing the contact order of the pins when the plug is inserted into the socket, a failure, caused by surge impact, of the A attribute pins in the third contact order can be avoided by priority contact in the second contact order even if in a function failure of the first contact order.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Short-edge cutting broaching finishing broach and short-edge cutting combined broaching finishing broach

The invention discloses a short-edge cutting broaching finishing broach and a short-edge cutting combined broaching finishing broach. The short-edge cutting broaching finishing broach comprises a support part, wherein a broaching part is arranged on the support part; cutting teeth are arranged on the broaching part; the cutting teeth are composed of odd number of cutting teeth and even number of cutting teeth in the sequence of contacting with a processed workpiece; the odd number of cutting teeth and the even number of cutting teeth are composed of cutting edge parts and non-cutting edge parts in mutual connection with each other; the cutting edge parts on the odd number of cutting teeth and the cutting edge parts on the even number of cutting teeth are arranged in a staggered form. The invention has the following beneficial effects: the service life of the broach of a slide sheet slot of a cylinder of a compressor of an air conditioner is prolonged in the manner of designing the tool cutting edge inclination and arranging the tool cutting edge inclinations on different cutting parts so that the phenomena of ultralow depth of parallelism and surface roughness of the slide sheet slot of the cylinder can be avoided.

Owner:CHENGDU GERUN HI TECH MATERIALS

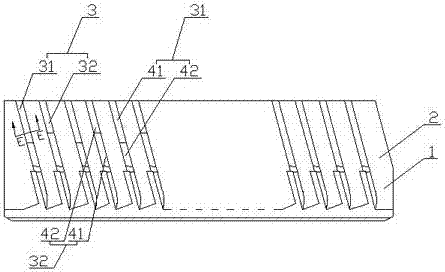

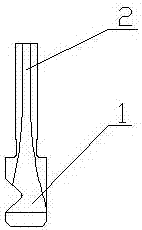

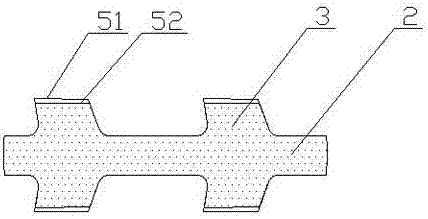

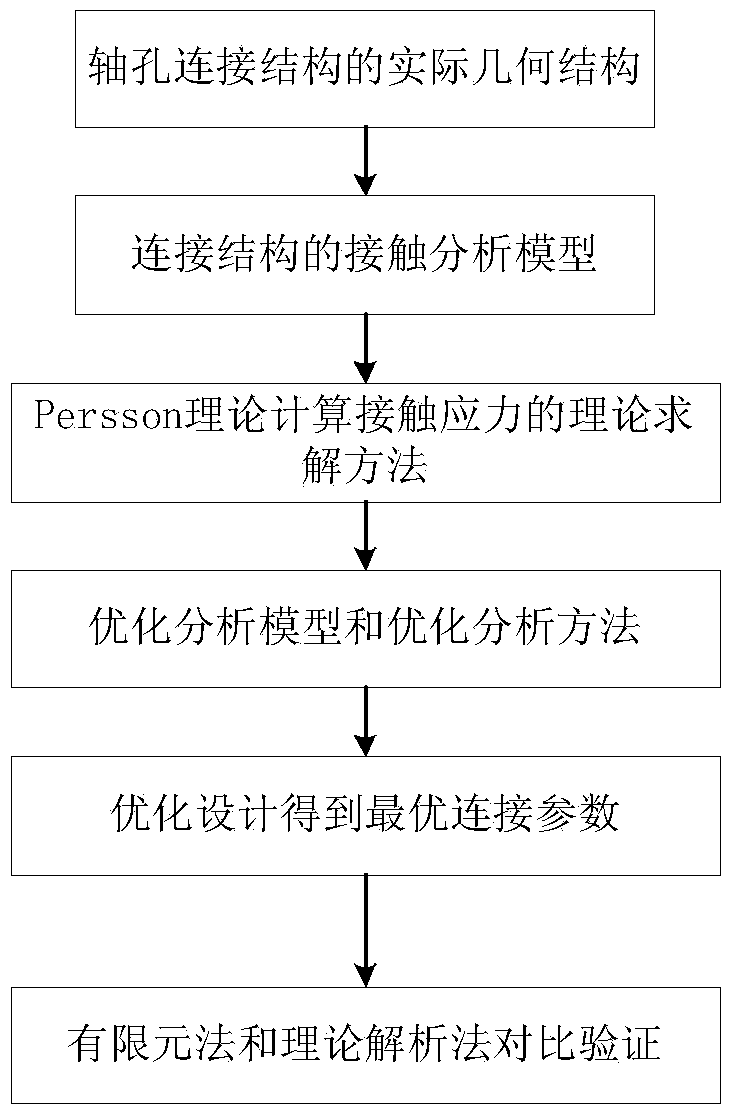

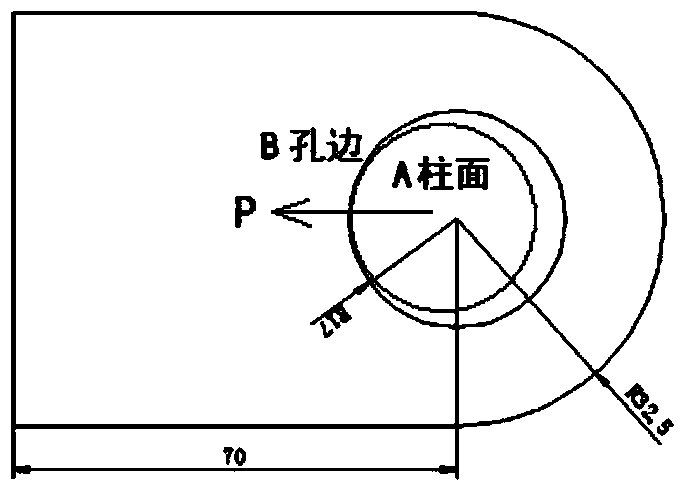

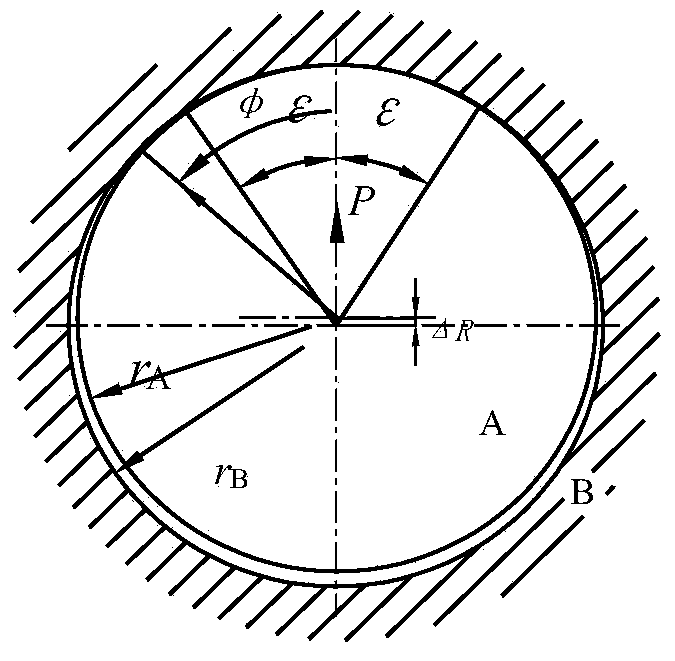

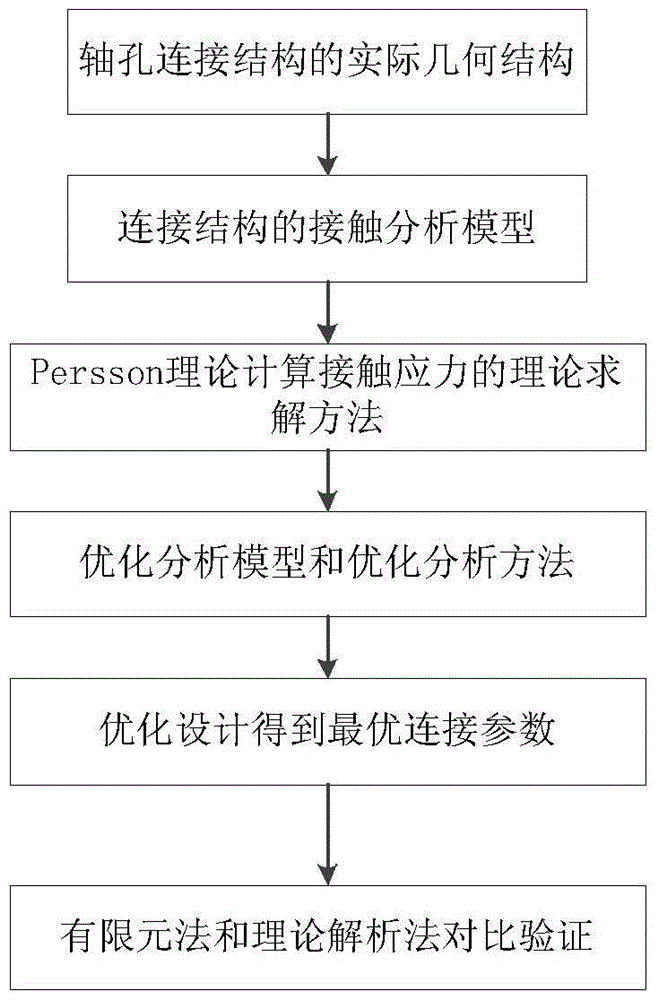

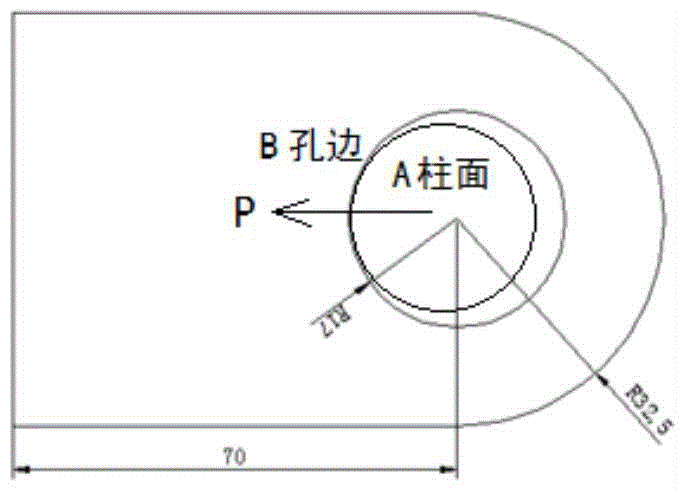

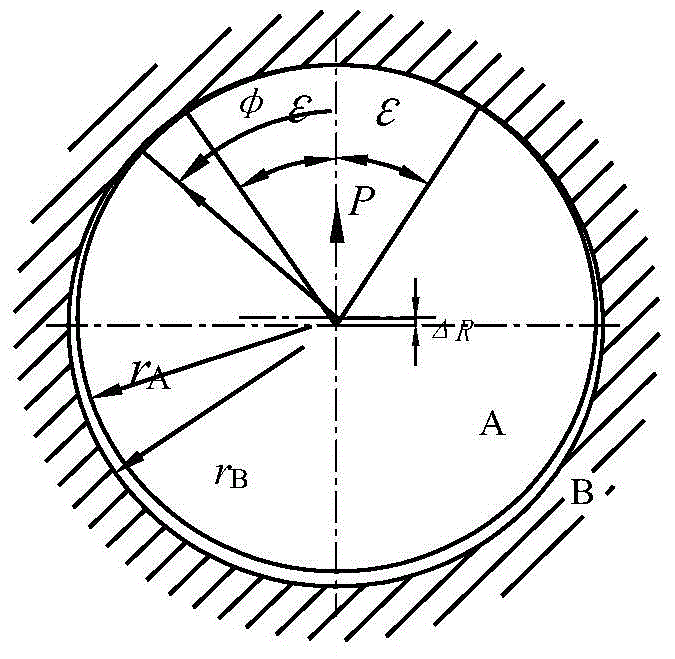

Design method for improving shaft hole connection structure bearing capacity

ActiveCN103838932AImprove carrying capacityLarge distribution areaSpecial data processing applicationsEngineeringFinite element solution

The invention discloses a design method for improving shaft hole connection structure bearing capacity. The design method for improving the shaft hole connection structure bearing capacity comprises the following steps: step (1) a contact stress analysis model and a theoretical calculation method of the shaft hole connection structure are established; step (2) a contact optimization model is established and calculation is designed; step (3) a theoretical solution is compared with a finite element solution error. Traditional shaft hole connection structures do not consider the phenomenon of bigger contact stress existing in shaft hole matching area, so that bearing capacity is not high. The design method for improving the shaft hole connection structure bearing capacity starts from factors influencing the contact stress, increases the number of initial contact points, and optimizes contact surface curvature through changing hole interface curved surface shape and optimizing the curved surface parameters, so that shaft hole contact order extends gradually from two sides to the middle part, contact area is increased, the maximum contact stress is reduced, and bearing capacity is improved. The design method for improving the shaft hole connection structure bearing capacity is unique in method, clearly in thought, feasible in operation, high in universal applicability, and is capable of being popularized and applied in other connection structure designs.

Owner:BEIHANG UNIV

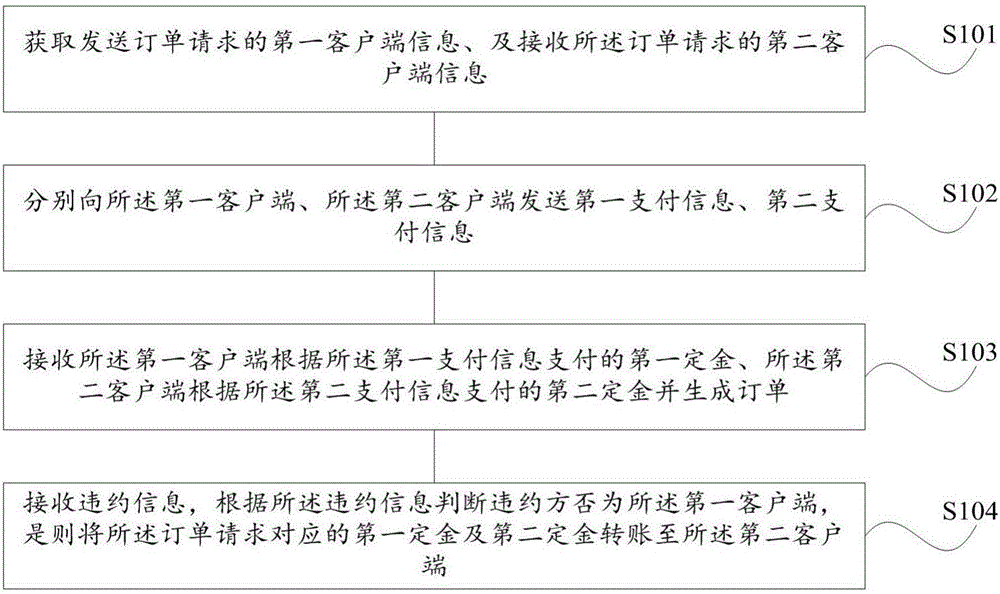

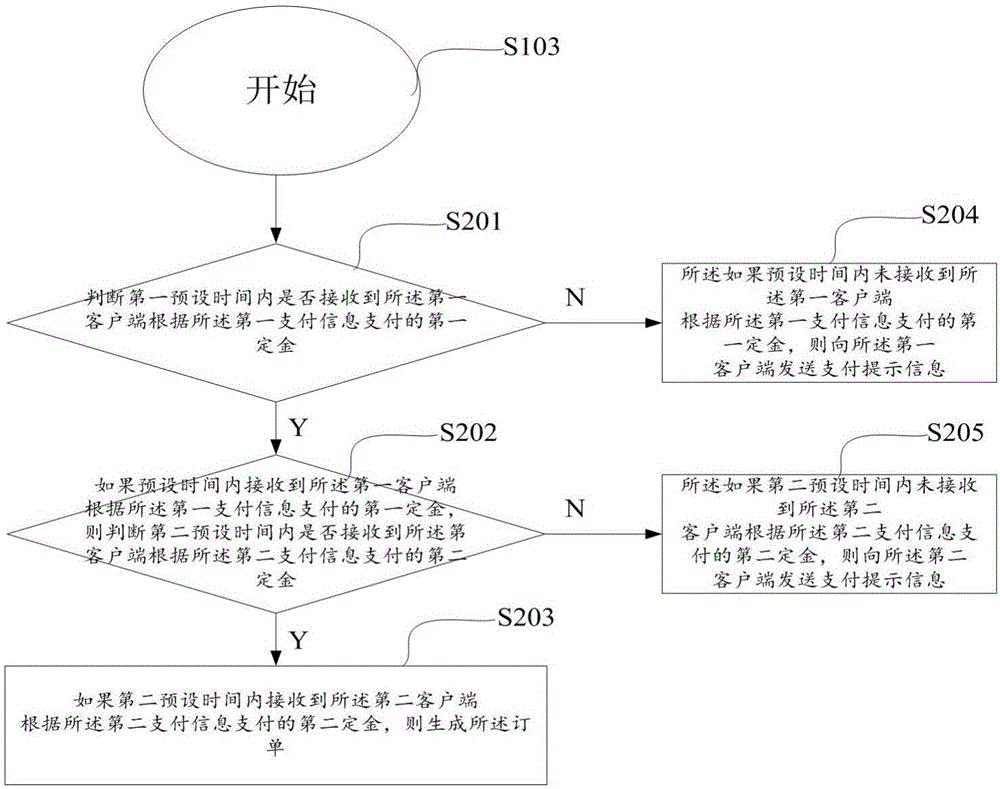

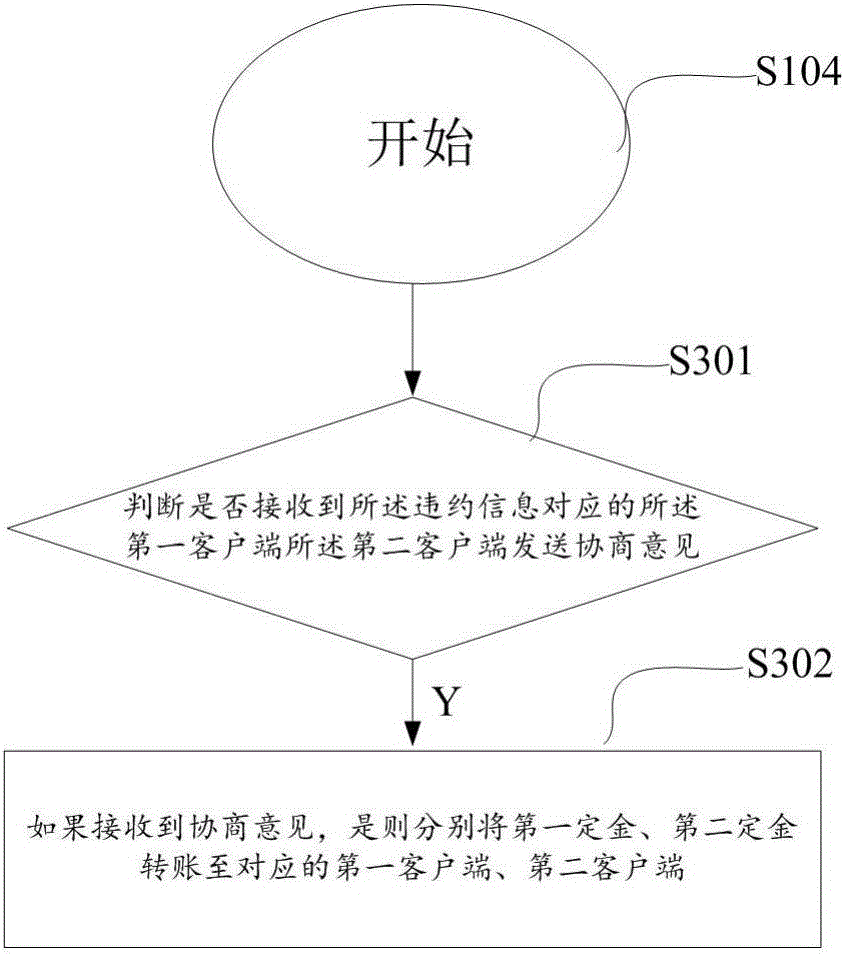

Third party-based contract management method and system

InactiveCN106228430AImprove reliabilityGuaranteed reliabilityBuying/selling/leasing transactionsThird partyPayment

The present invention discloses a third party-based contract management method and system, wherein the method comprises the following steps of obtaining the information of a first client for sending order requests and the information of a second client for receiving the order requests; sending the first payment information and the second payment information to the first client and the second client respectively; receiving the first earnest money paid by the first client according to the first payment information and the second earnest money paid by the second client according to the second payment information, and generating orders; receiving the default information, determining whether a default party is the first client according to the default information, if yes, transferring the first and second earnest moneys corresponding to the order requests to the second client. According to the present invention, by obtaining the earnest moneys of the transaction two parties according to the contact orders, thereby comprising the reliability of the contacts of the transaction two parties, and reducing the loss of the transaction two parties.

Owner:徐晖

Process method for preparing maleic anhydride from n-butane by oxidation

ActiveCN108101871AHigh reaction conversion rateHigh yield of maleic anhydrideOrganic chemistryReaction zoneOxygen content

The invention discloses a process method for preparing maleic anhydride from n-butane by oxidation. N-butane and air are mixed with circulating tail gas, and obtained mixed reaction gas flows in parallel through two or more reaction zones connected in series sequentially, and is contacted with a vanadium phosphorus oxide catalyst for reaction under the oxidation reaction condition, wherein each reaction zone comprises two or more of catalyst beds except the most downstream reaction zone, according to the contact sequence with the mixed reaction gas, the P / V molar ratio of the catalyst in the downstream reaction zone is lower than that of the catalyst in the upstream reaction zone, and the P / V molar ratio of the downstream catalyst bed is higher than that of the upstream catalyst bed in allthe reaction zones except the most downstream reaction zone. With the method, activity of the catalyst can be fully played, especially in the tail gas recycling process, the influence from the decrease of conversion rate due to the decrease of oxygen content of raw materials can be better avoided, reaction hot spots are reduced, and product selectivity is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

hdmi connector and blu-ray player

The invention is suitable for the technical field of connectors, and provides an HDMI connector. The HDMI connector comprises a plug and a socket, wherein each of the plug and the socket comprises a housing and multiple pins; the pins in the plug correspond to the pins in the socket; each pin comprises an A attribute pin, a power pin and input / output pins; when the plug is inserted into the socket, the contact order of the plug and the socket is as follows: contact of the socket and the housing of the plug is a first contact order; the contact of the input / output pins in the socket and the input / output pins in the plug is a second contact order; the contact of the A attribute pin in the socket and the A attribute pin in the plug is a third contact order; and the contact of the socket and the power pin in the plug is a fourth contact order. According to the HDMI connector, through changing the contact order of the pins when the plug is inserted into the socket, a failure, caused by surge impact, of the A attribute pins in the third contact order can be avoided by priority contact in the second contact order even if in a function failure of the first contact order.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

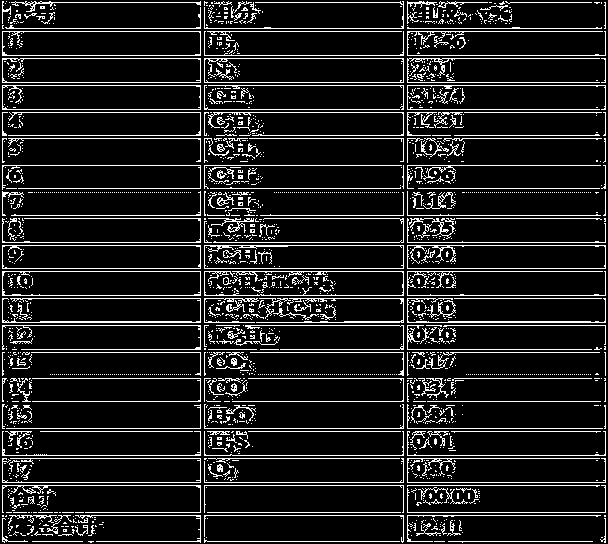

Method for producing ethylene cracking material by hydrogenation of liquefied gas

ActiveCN108085061BImprove hydrogenation activityAverage reaction speedGaseous mixture working upHydrocarbon oils treatment productsHydrogenReaction speed

The invention discloses a method for producing an ethylene cracking material through liquefied gas hydrogenation. The method is characterized in that liquefied gas and hydrogen pass through a hydrogenation reactor through a cocurrent flowing mode, then are contacted with a hydrogenation catalyst under hydrogenation technical condition and subjected to a reaction; the hydrogenation reactor comprises more than two reaction segments, and according to a contact sequence with a reaction material, the activity of the catalyst in a downstream reaction segment is higher than the activity of the catalyst in an upstream reaction segment. The method reduces the relative average reaction speed at an entrance of a catalyst bed layer, changes problem of large relative average reaction speed at the entrance of the catalyst bed layer, a difference of the average reaction speed of each segment of the catalyst bed layer is greatly reduced, and the relative average reaction speed of each segment of the catalyst bed layer is more uniform.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing ethylene cracking material by hydrogenation of dry gas

ActiveCN106753558BReduced Relative Average Reaction SpeedSlow reaction speedGaseous mixture working upReaction rateFixed bed

The present invention discloses a method for producing an ethylene cracking material through dry gas hydrogenation. According to the method, olefin-containing dry gas and optional supplemented hydrogen enter a fixed bed hydrogenation reactor in a co-current flow manner, and contact a hydrogenation catalyst under a hydrogenation process condition, a reaction is performed, and the obtained reaction products are separated to obtain the dry gas having the saturated olefin; and the hydrogenation reactor comprises four reaction sections, and according to the sequence of the contact between the material and the catalyst, the law of the hydrogenation activity metal contents in the catalysts in each reaction section is the low content, the high content, the low content and the high content. According to the present invention, with the method, the relatively average reaction rate of the inlet section of the catalyst bed layer is reduced, the problem that the relatively average reaction rate of the inlet section of the catalyst bed layer is high is solved, the difference among the average reaction rates of each section of the bed layer is substantially reduced, and the relatively average reaction rates of each section are uniform; and with the method, the deep oxygen removal can be ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

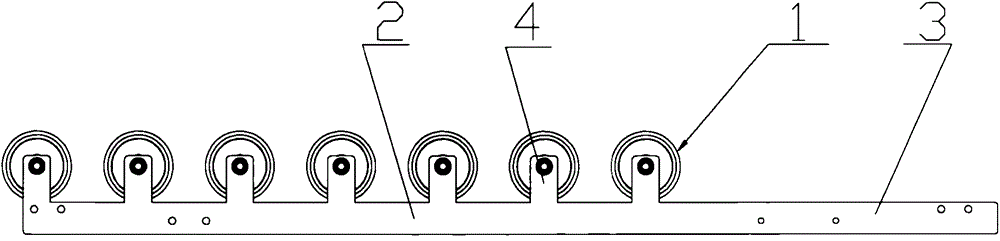

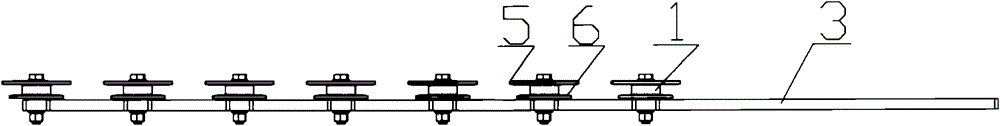

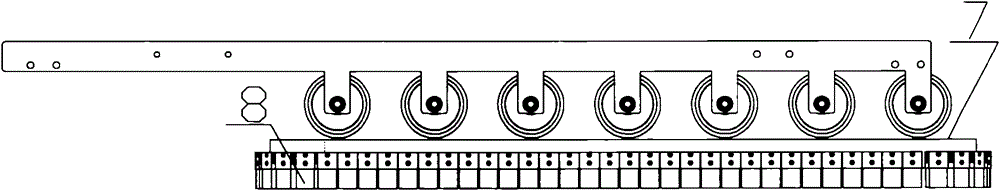

Guide pulley set for chamfer deburring machine

ActiveCN102366920BAdjustable contact sizeEasy to wear and replaceBelt grinding machinesConvex structureEngineering

The invention relates to a guide pulley set for a chamfer deburring machine, which can be used for downwards pressing a grinding belt in a relative motion state and comprises a pressing plate and a guide pulley, wherein the pressing plate is in an equal-space or unequal-space concave-convex structure; and the guide pulley is arranged at the lug boss part of the pressing plate. The guide pulley set has the advantages that: firstly, the grinding belt can downwards move along with the downward adjustment of the pressing plate by a lifting mechanism and is in rolling fit with the guide pulley on the pressing plate, so that the friction coefficient is small, the aim that the contact order between a grinding head and a workpiece face is adjustable is achieved and the guide pulley set can be used for polishing and deburring workpieces in different thicknesses and has favorable suitability; secondly, the guide pulley set lays a feasible foundation for driving the grinding belt for one time, polishing for two times and realizing the deburring and has high polishing and deburring efficiency; and thirdly, the guide pulley set brings convenience for replacement of the grinding head in the grinding belt and can be used for avoiding the embarrassment of the wear of the grinding head and the scrap of a grinding base band of the guide pulley set; and in addition, the manufacturing cost is saved and the waste of raw materials is avoided.

Owner:HANGZHOU XIANGSHENG ABRASIVE MACHINE MFG

A kind of method that n-butane oxidation prepares maleic anhydride

ActiveCN106749125BAverage temperature distributionMild severity of reactionOrganic chemistryPhysical/chemical process catalystsSide reactionButane

The invention discloses a method of producing maleic anhydride by oxidizing n-butane. The method includes the following steps: mixing the n-butane with air; co-currently enabling the mixed reaction gas to pass through at least two vanadium-phosphorous oxide catalyst bed layers in series to perform a contact reaction with a vanadium-phosphorous oxide catalyst under an oxidizing reaction condition. The average valence of vanadium in a downstream catalyst bed layer is higher than that of vanadium in an upstream catalyst bed layer according to the contact sequence of the catalyst with the mixed reaction gas. The method reduces reaction hot spots in the bed layers and enables temperature distribution in the bed layers to be balanced, thus effectively inhibiting side-reactions, increasing product selectivity and increasing yield of the product, maleic anhydride.

Owner:CHINA PETROLEUM & CHEM CORP +1

A Design Method for Improving the Bearing Capacity of Shaft-hole Connection Structure

ActiveCN103838932BAvoid the defects of low carrying capacityImprove scienceSpecial data processing applicationsEngineeringFinite element solution

The invention discloses a design method for improving shaft hole connection structure bearing capacity. The design method for improving the shaft hole connection structure bearing capacity comprises the following steps: step (1) a contact stress analysis model and a theoretical calculation method of the shaft hole connection structure are established; step (2) a contact optimization model is established and calculation is designed; step (3) a theoretical solution is compared with a finite element solution error. Traditional shaft hole connection structures do not consider the phenomenon of bigger contact stress existing in shaft hole matching area, so that bearing capacity is not high. The design method for improving the shaft hole connection structure bearing capacity starts from factors influencing the contact stress, increases the number of initial contact points, and optimizes contact surface curvature through changing hole interface curved surface shape and optimizing the curved surface parameters, so that shaft hole contact order extends gradually from two sides to the middle part, contact area is increased, the maximum contact stress is reduced, and bearing capacity is improved. The design method for improving the shaft hole connection structure bearing capacity is unique in method, clearly in thought, feasible in operation, high in universal applicability, and is capable of being popularized and applied in other connection structure designs.

Owner:BEIHANG UNIV

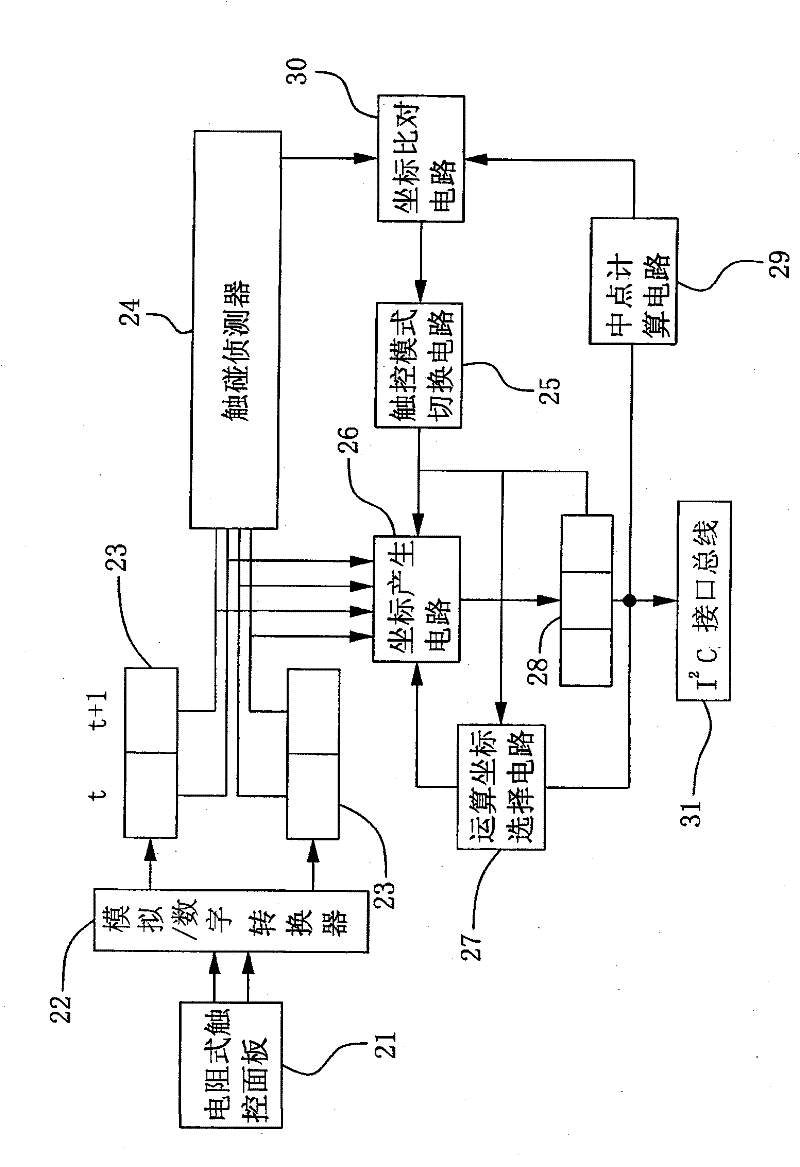

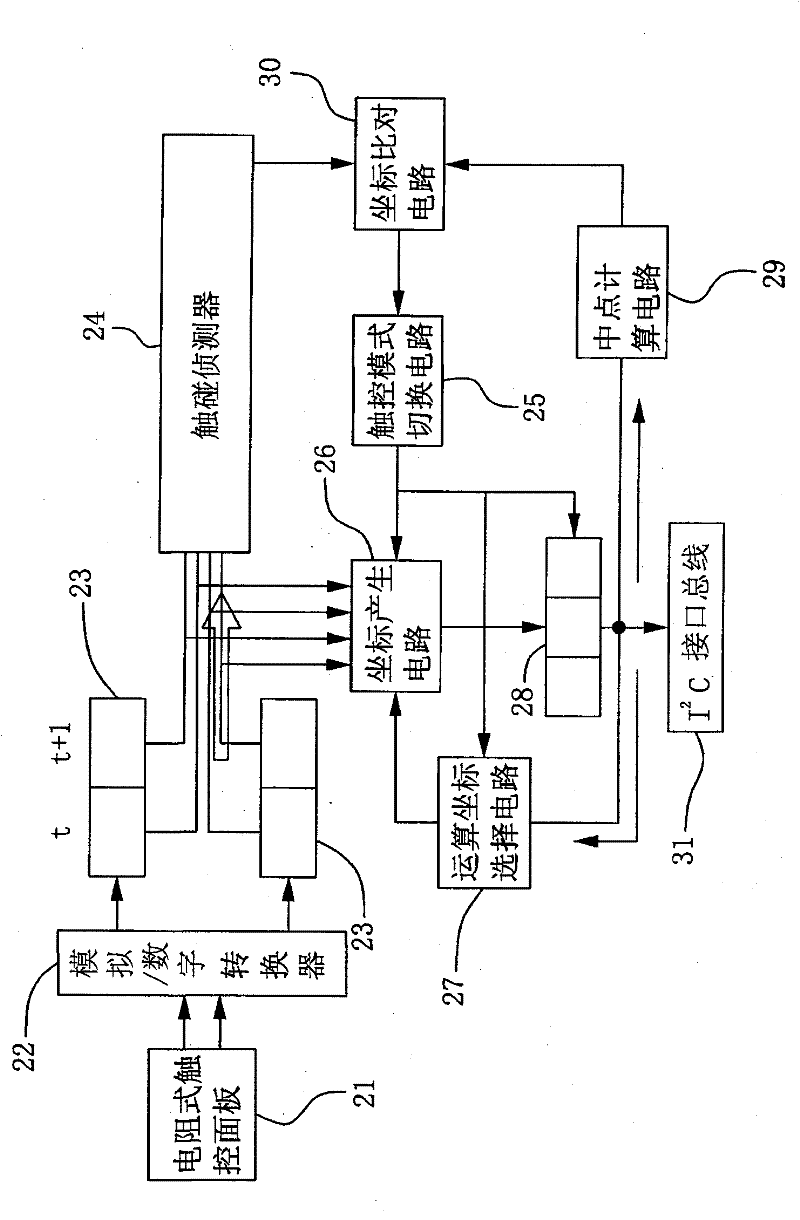

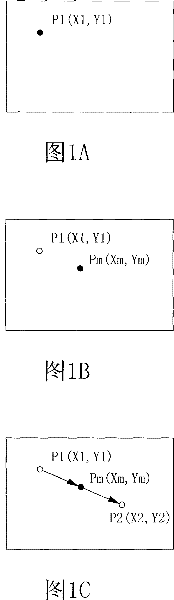

Resistance type touching control panel controller structure and method for discriminating and operating multi-point coordinates

InactiveCN101373416BLow costInput/output processes for data processingController architectureContact time

The invention discloses a controller framework applied to a resistance type touch panel and a coordinate method for calculating and judging multi-touch. The method comprises the steps as follows: providing a resistance type touch panel; according to a contact time difference between a first contact body and at least a second contact body which is in separate contact with the resistance type touchpanel, determining a contact order of the first contact body and the second contact body, and determining a first contact coordinate and at least a middle point coordinate in sequence through a voltage value sensed by the resistance type touch panel, wherein the first contact body is in continuous contact with the resistance type touch panel; determining at least a second contact coordinate in sequence according to the first contact coordinate and the middle point coordinate, wherein the middle point coordinate and the second contact body have the same quantity as the second contact coordinate.

Owner:J TOUCH CORPORATION

Colouring of keratinous fibers using a pretreatment comprising an iron salt and a colour developer comprising hydrolysable tannin

A method of coloring keratinous fibers comprising contacting the keratinous fibers sequentially with a pre-treatment composition and a color developer wherein: i. the pre-treatment composition comprises: (a) 0.5-25% by weight of an iron salt at a pH below 2 including 0.5-5% by weight of a reducing agent (b) a buffer effective in the pH range 3-6 and (c) a penetration enhancer comprising one or more solvents having Hansen solubility parameter δh between 1-10 (MPa)1 / 2 and δp between 10-25 (MPa)1 / 2 wherein the component (b) is mixed with (a) or (c) not more than 360 minutes prior to contacting the keratinous fibers and ii. the color developer is selected from one or more of hydrolysable tannin or its breakdown products or derivatives or a mixture thereof obtained from a natural or synthetic source, where the sequence of contact is in any order.

Owner:CONOPCO INC D B A UNILEVER

Control method for multi-point touch control controller

InactiveCN101458610BImprove the shortcoming of only outputting single-point coordinate dataInput/output processes for data processingContact timeControl theory

Owner:J TOUCH CORPORATION

A method for dry gas hydrogenation to produce ethylene cracking material

ActiveCN106753559BImprove hydrogenation activityAverage reaction speedGaseous mixture working upHydrogenation reactionFixed bed

The invention discloses a method for producing an ethylene cracking feed by hydrogenation of dry gas. The dry gas containing olefins and optional supplemented hydrogen enter a fixed bed hydrogenation reactor in a parallel flow manner and are in contact with hydrogenation catalysts under a process condition of hydrogenation for reacting; an obtained reaction product is separated to obtain olefin-saturated dry gas; two or more reaction sections are arranged in the hydrogenation reactor; according to the contact sequence of the catalysts and materials, the activity of the hydrogenation catalyst in a downstream reaction section is higher than that of the hydrogenation catalyst in an upstream reaction section. According to the method disclosed by the invention, the speed of the hydrogenation reaction of the olefins can be controlled, and the conversion rate of the hydrogenation reaction of the olefins is enabled to be steadily and gradually improved along a catalyst bed layer; reaction heat is gradually and gently released rather than be centrally released, so that reaction temperature rise of the catalyst bed layer is reduced, a temperature bulb of the catalyst bed layer is greatly gentle, and further the service life of the catalysts is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

A Catalyst Graded Heavy Oil Hydrogenation Upgrading Method

ActiveCN103059980BImprove fouling capacityHigh porosityTreatment with hydrotreatment processesParticulatesPorosity

The invention discloses a heavy oil hydro-upgrading method using catalyst grading. The method comprises: mixing a heavy oil raw material with hydrogen, passing the mixture through an ebullated bed reactor loaded with solid matters in an up-flow mode, and performing a hydrogenation reaction under a hydrotreating condition. Specifically, the solid matters include two matters of different specifications: stainless steel cages for keeping a fixed bed and particulate ebullated bed catalysts positioned in the space formed by the stainless steel cages. According to the contact order of a hydrocarbon raw material and the catalysts, the hydrogenation activity of the particulate catalysts gradually increases. The method provided in the invention uses the technological characteristics of fixed bed hydrogenation and ebullated bed hydrogenation for reference at the same time, provides greater porosity than the prior art, enhances the dirt-holding capacity of the catalyst bed, and can ensure stable operation of the device, thus being in favor of improving the hydrogenation reaction effects.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com