Guide pulley set for chamfer deburring machine

A technology of deburring machine and belt pressing wheel, applied in abrasive belt grinders, grinding machines, metal processing equipment, etc., can solve the problems of poor applicability, inability to adjust up and down movement, low grinding efficiency, etc., achieving good applicability and saving manufacturing costs. , avoid wasteful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

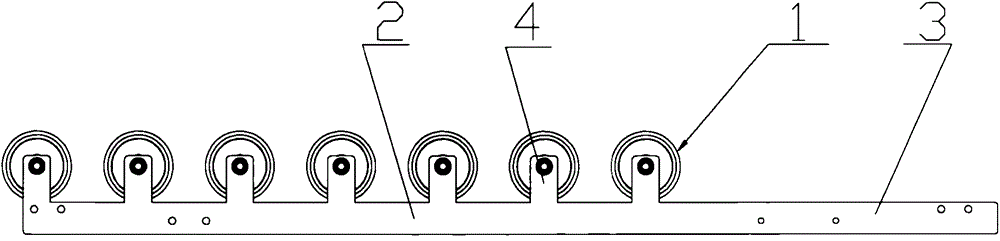

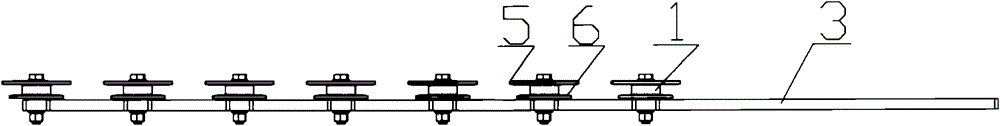

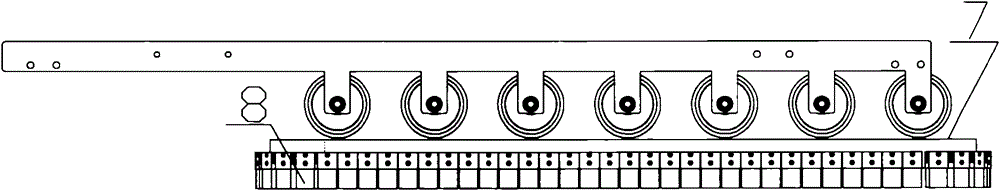

[0015] Embodiment 1: with reference to attached Figure 1-4 . A pinch wheel set for chamfering and deburring machines, consisting of a pinch plate 2 and a pinch wheel 1, the pinch plate 2 has a convex-concave structure with equal or non-equal intervals and one end is a connecting plate 3 of a lifting mechanism, and the boss portion 4 is equipped with Pressure pulley 1. The diameter of the outer rim 5 of the pinch wheel 1 is greater than the diameter of the inner rim 6 . The pressing plate 2 is made of metal or non-metal material. The pinch roller 1 is made of metal or non-metal material. The wheel surface of the pressure belt wheel 1 is in rolling fit with the upper end surface of the grinding belt 7, that is, the grinding belt 7 rotates horizontally and is pressed down under the action of the grinding belt 7, and automatically resets under the action of the 9 surfaces of the grinding belt 7 drum, Grinding belt 7 sides are equipped with a plurality of grinding heads 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com