Improved tubular reactor

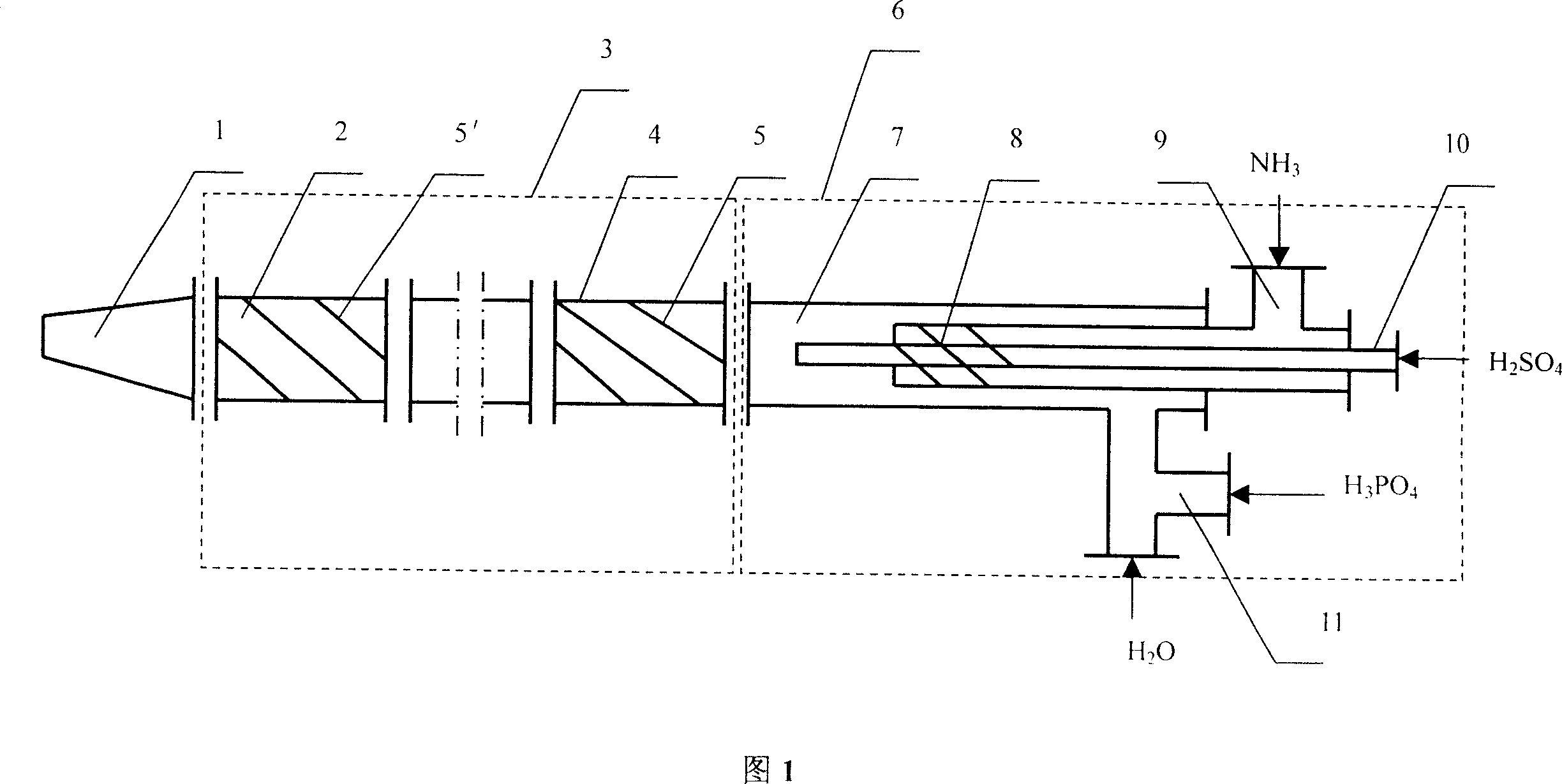

A tubular reactor, reaction technology, applied in chemical/physical/physical chemistry nozzle reactor, application, chemical method of reacting liquid and gas medium, etc., can solve the problem of uneven reaction, incomplete reaction, easy The problems of scarring and blockage can be improved to improve the flexibility of adaptability and operation, improve the stability and safety, and prevent the reaction speed from being too fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

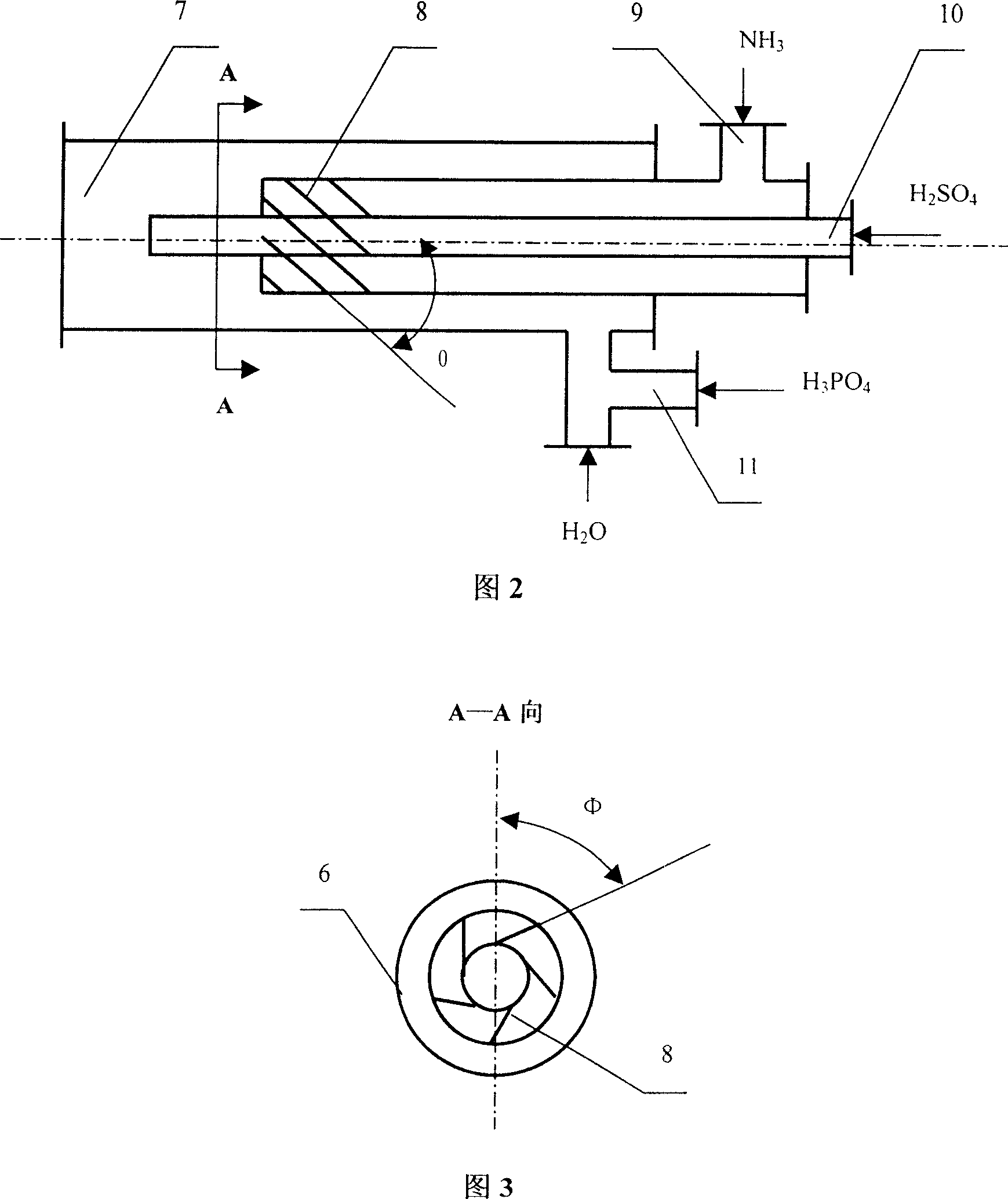

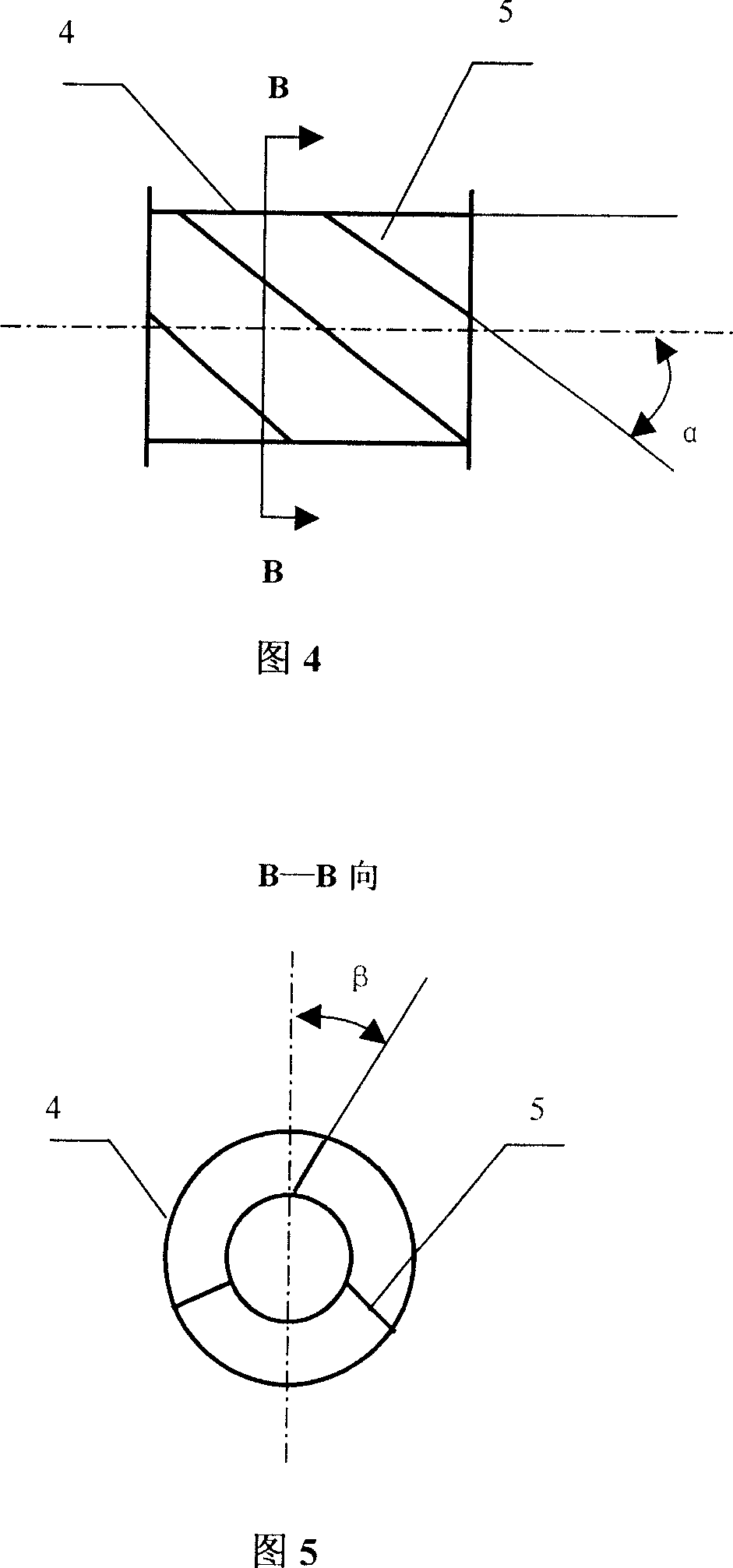

[0078] In the tubular reactor of the present invention, three spiral guide fins are fixed on the outside of the central tube, the direction of rotation is clockwise, the rotation angle θ is 5°, and the inclination angle Ф is 0°. The reaction in the tubular reactor A spiral mixing device 4 is installed at the inlet of the section, and a spiral mixing device 2 identical to the spiral mixing device 4 is installed in front of the reactant output nozzle. There are 3 spiral guide fins, the direction of rotation is clockwise, and the rotation angle α is 5°, the inclination angle β is 0°, under the same dosage, there is no scarring, panting, vibration, and the pressure of the tubular reactor is 3-5kg / cm 2, the pressure is stable, the reaction and injection of the tubular reactor are normal, and the noise is 50 decibels. After 30 days of use, the polytetrafluoroethylene entering the spiral mixer in the reaction section only appears yellow in color and has no cracks. The stainless steel...

Embodiment 2

[0087] The tubular reactor of the present invention is fixed with 10 spiral guide fins on the outside of the central tube, the rotation direction is clockwise, the rotation angle θ is 45°, and the inclination angle Ф is 45°. The reaction in the tubular reactor A spiral mixing device 4 is installed at the entrance of the section, and a spiral mixing device 2 identical to the spiral mixing device 4 is installed in front of the reactant output nozzle. There are 6 spiral guide fins, the direction of rotation is clockwise, and the rotation angle α is 45°, the inclination angle β is 30°, under the same dosage, there is no scarring, panting, vibration, and the pressure of the tubular reactor is 3-5kg / cm 2 , the pressure is stable, the reaction and injection of the tubular reactor are normal, and the noise is 55 decibels. After 30 days of use, the polytetrafluoroethylene entering the spiral mixer in the reaction section only appears yellow in color and has no cracks. The stainless ste...

Embodiment 3

[0091] The tubular reactor of the present invention is fixed with 5 spiral guide fins on the outside of the central tube, the rotation direction is clockwise, the rotation angle θ is 30°, and the inclination angle Ф is 25°. The reaction in the tubular reactor A spiral mixing device 4 is installed at the entrance of the section, and a spiral mixing device 2 identical to the spiral mixing device 4 is installed in front of the reactant output nozzle. There are 4 spiral guide fins, the direction of rotation is clockwise, and the rotation angle α is 10°, the inclination angle β is 15°, under the same dosage, there is no scarring, panting, vibration, and the pressure of the tubular reactor is 3-5kg / cm 2 , the pressure is stable, the reaction and injection of the tubular reactor are normal, and the noise is 50 decibels. After 30 days of use, the polytetrafluoroethylene entering the spiral mixer in the reaction section only appears yellow in color and has no cracks. The stainless stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com