Gradation filling method of heavy oil hydrogenation treatment catalyst

A hydrotreating and grading packing technology, which is applied in hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems of out-of-sync deactivation of catalysts of different brands and large bed temperature rise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

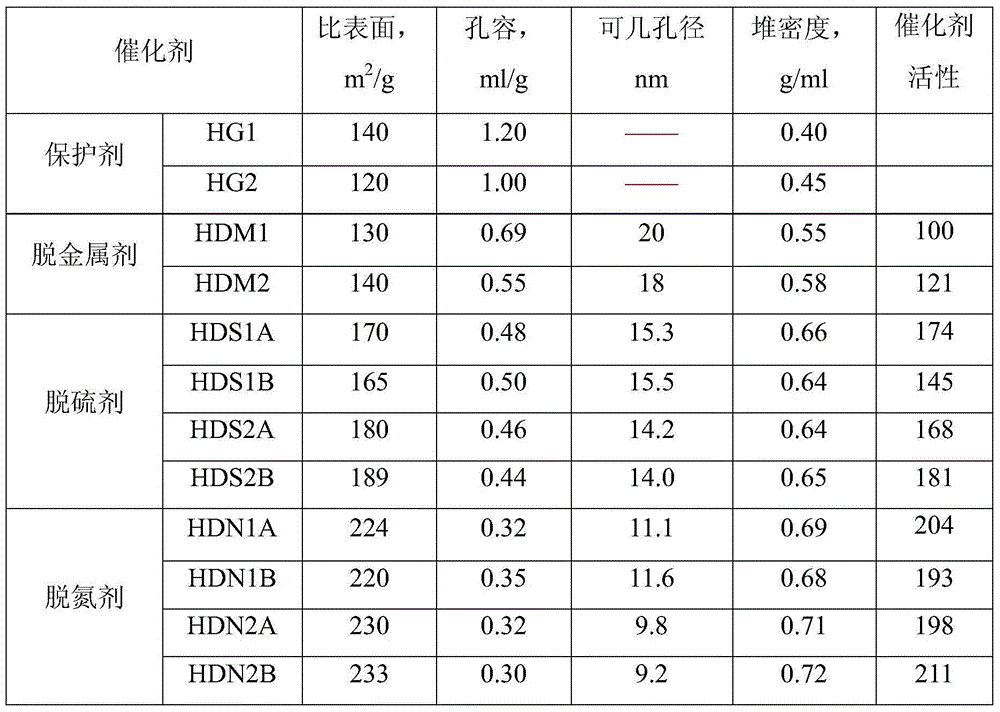

Embodiment 1

[0056] The first reactor is loaded with protective agents HG1 and HG2 and demetallization catalysts HDM1 and HDM2 from top to bottom, and the volume ratio of the four agents is 1:1:4:4; the second reactor is loaded with desulfurization catalysts HDS1A and HDM2 from top to bottom. HDS2A, the volume ratio of the two agents is 1:1; the third reactor is loaded with denitrification catalysts HDN1A and HDN2A from top to bottom, and the volume ratio of the two agents is 1:1. The volume ratio of demetallization catalyst, desulfurization catalyst and denitrification catalyst is 3:4:3. The above-mentioned protective agent and catalyst are all independently developed by China Petroleum and Petrochemical Research Institute. The catalyst carrier is alumina, and the supported metals are nickel and molybdenum. The properties are shown in Table 1. The operating conditions of the device are as follows: the inlet temperature of the first reactor is 380°C, and the volume ratio of hydrogen to oil...

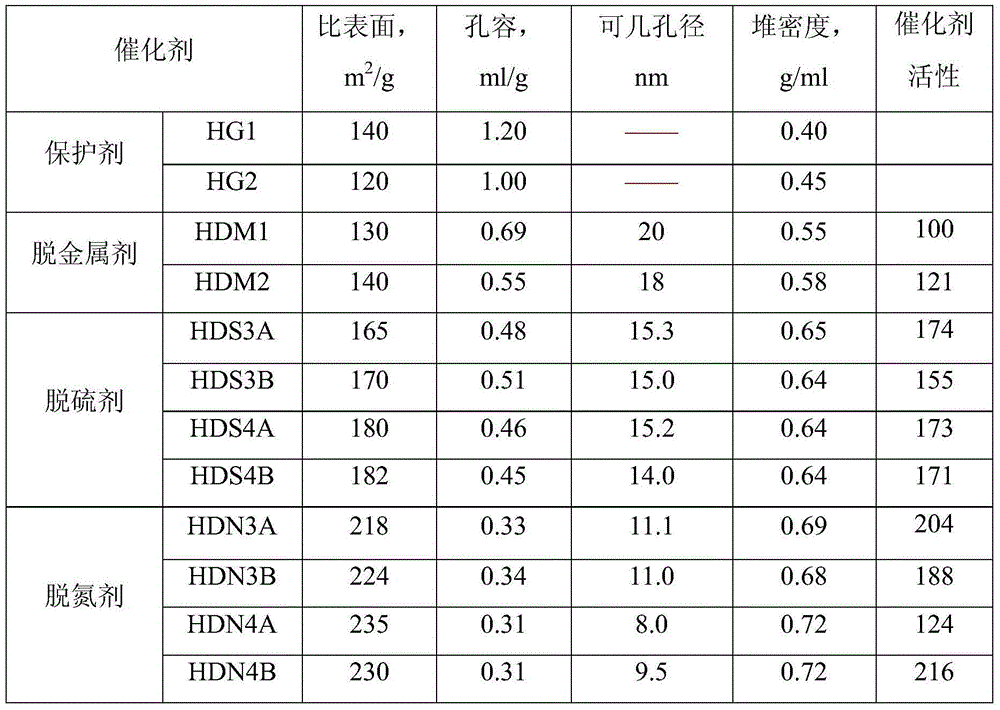

Embodiment 2

[0061] The first reactor is filled with protective agents HG1 and HG2 and demetallization catalysts HDM1 and HDM2 from top to bottom, and the volume ratio of the four agents is 1:1:4:4; the second reactor is loaded with desulfurization catalysts HDS3A and HDS3A from top to bottom. HDS4A, the volume ratio of the two agents is 1:1; the third reactor is loaded with denitrification catalysts HDN3A and HDN4A from top to bottom, and the volume ratio of the two agents is 1:1. The volume ratio of demetallization catalyst, desulfurization catalyst and denitrification catalyst is 3:4:3. The above-mentioned protective agent and catalyst are all independently developed by China Petroleum and Petrochemical Research Institute. The catalyst carrier is silicon oxide, and the supported metals are nickel and molybdenum. The properties are shown in Table 2. The operating conditions of the device are as follows: the inlet temperature of the first reactor is 300°C, and the volume ratio of hydrogen...

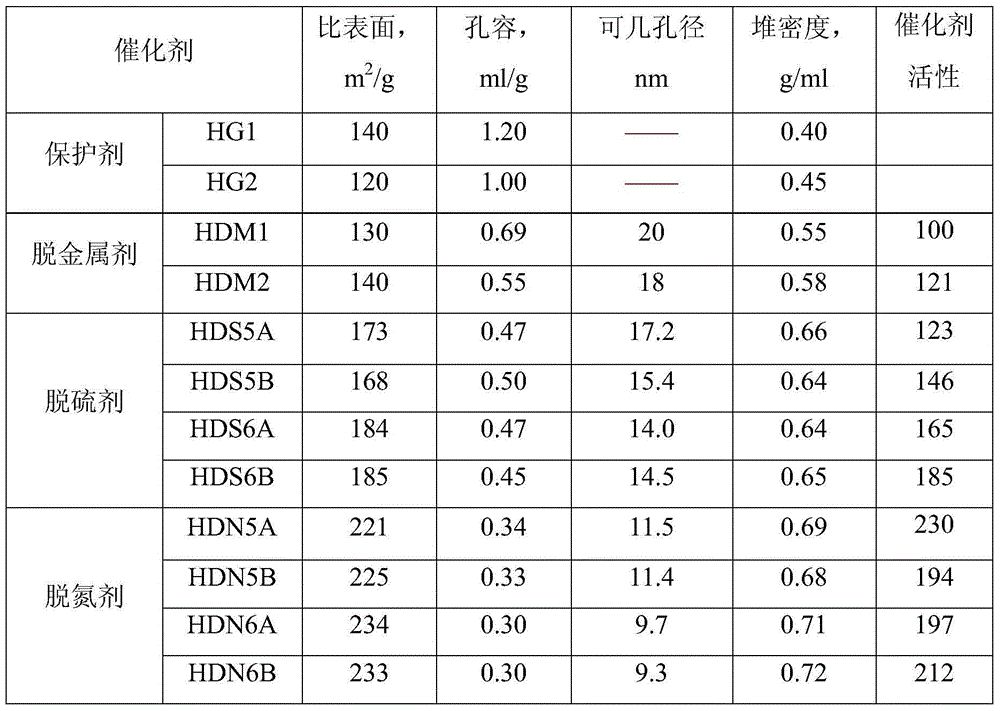

Embodiment 3

[0066] The first reactor is filled with protective agents HG1 and HG2 and demetallization catalysts HDM1 and HDM2 from top to bottom, and the volume ratio of the four agents is 1:1:4:4; the second reactor is filled with desulfurization catalysts HDS5A and HDS6A, the volume ratio of the two agents is 1:1; the third reactor is filled with denitrification catalysts HDN5A and HDN6A from top to bottom, and the volume ratio of the two agents is 1:1. The volume ratio of demetallization catalyst, desulfurization catalyst and denitrogenation catalyst is 3:4:3. The above protective agents and catalysts were all developed by China Petroleum and Petrochemical Research Institute. The catalyst carrier is alumina-silicon oxide, and the supported metals are cobalt and tungsten. The properties are shown in Table 3. The operating conditions of the device are: the inlet temperature of the first reactor is 490°C, the volume ratio of hydrogen to oil is 800:1; the inlet temperature of the second re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com