Permanent magnet synchronous motor

A permanent magnet synchronous motor technology, applied to synchronous motors with stationary armatures and rotating magnets, synchronous machine parts, electric components, etc., can solve problems such as rotor temperature rise, improve power factor, and reduce eddy current heating , The effect of reducing the risk of demagnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with drawings and embodiments.

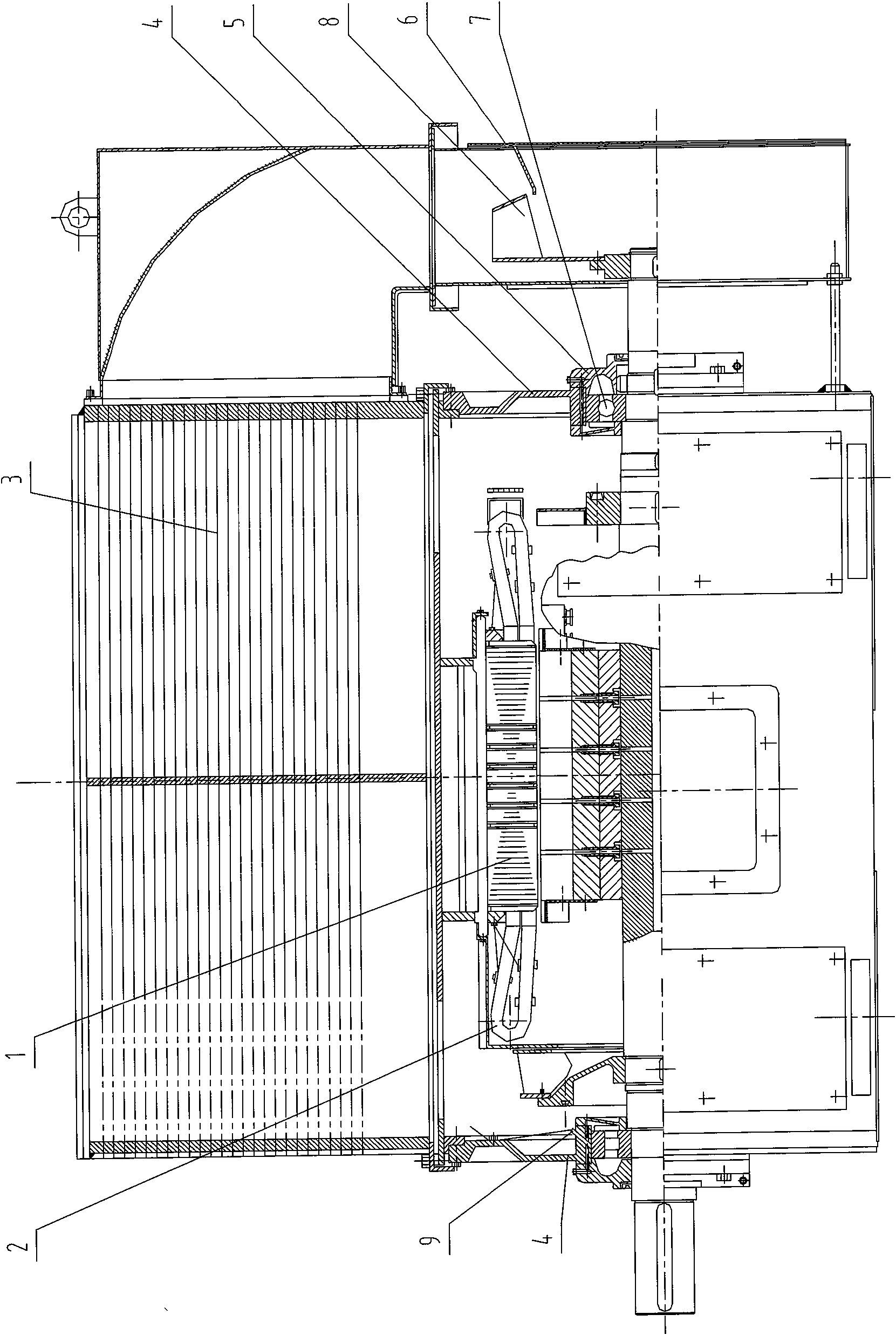

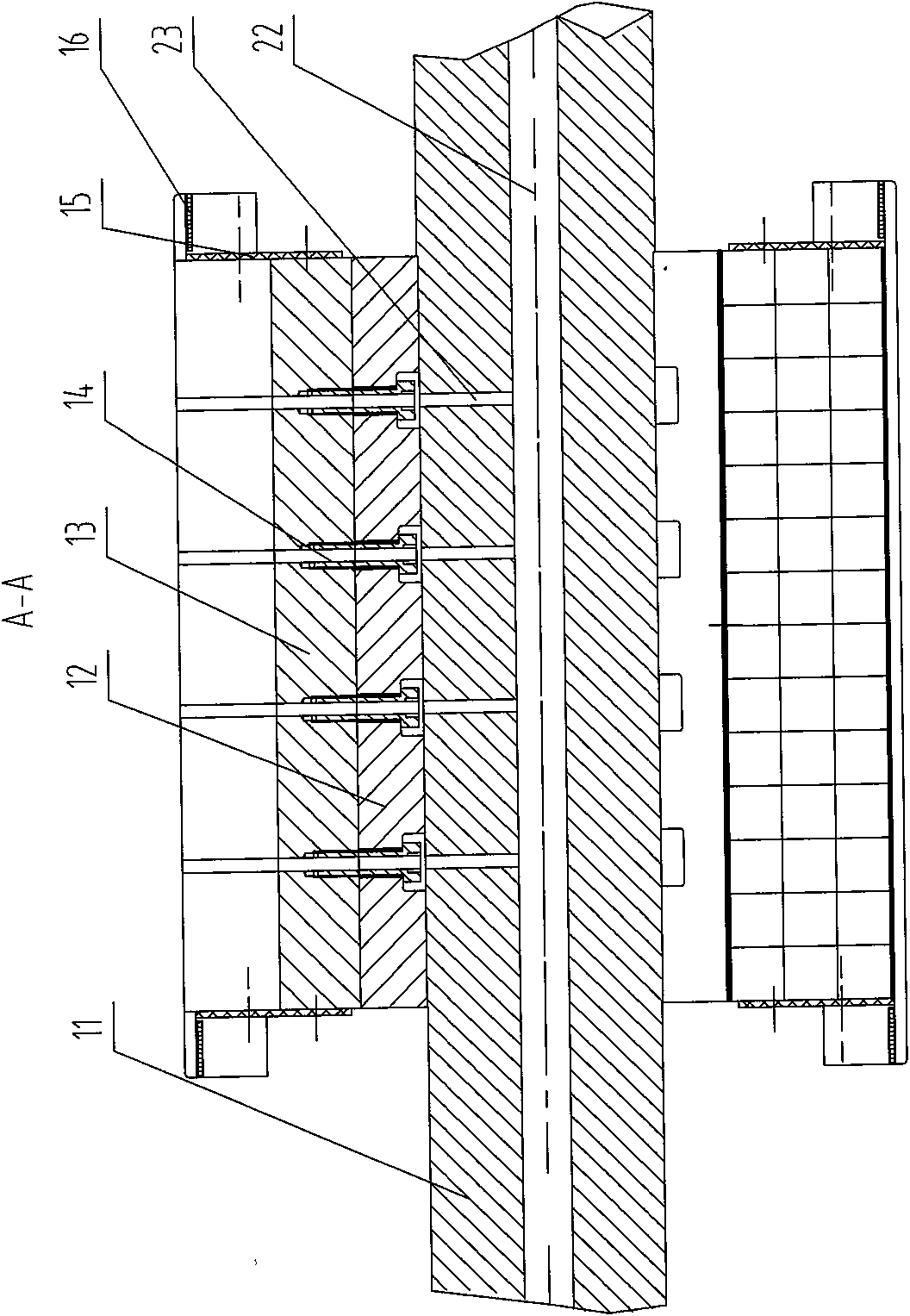

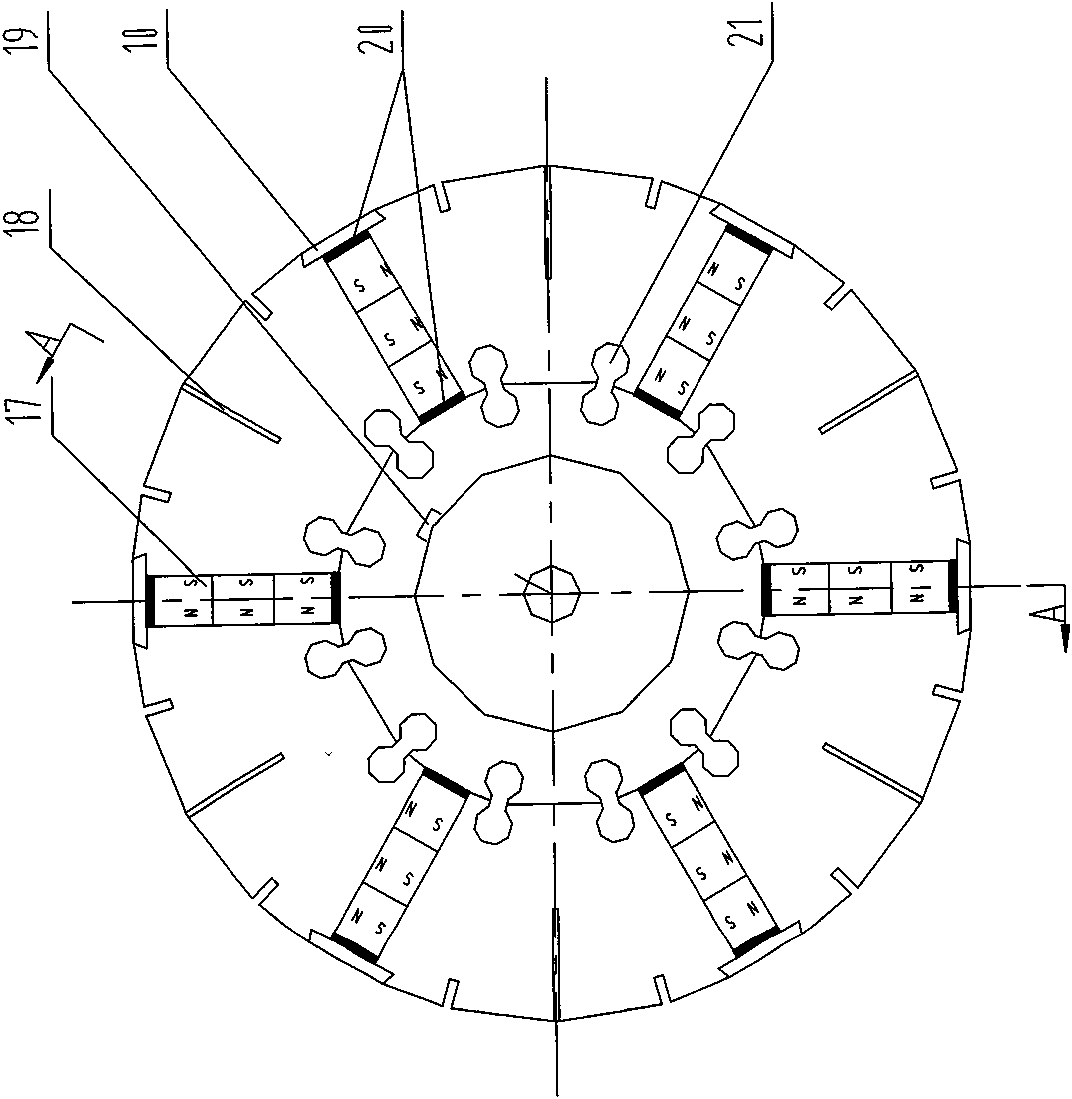

[0036] exist figure 1 Among them, the permanent magnet synchronous motor consists of two major components: the stator and the rotor. The stator part consists of a casing, a stator core 1 and an armature winding 2. The casing is composed of a casing 3, an end cover 4, a bearing cover 5 and a protective cover 6, and its structure is basically the same as that of an ordinary three-phase asynchronous motor. The stator of an ordinary three-phase asynchronous motor can be directly matched with the rotor part of the present invention to form a permanent magnet synchronous motor, which is a major feature of the present invention; another major feature of the present invention is that the structure of the rotor part is changed. figure 2 and image 3 Among them, the hollow core shaft 11, the magnetic isolation sleeve 12, and the split magnetic pole 13 are coaxially assembled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com