Patents

Literature

32results about How to "Flux leakage coefficient is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

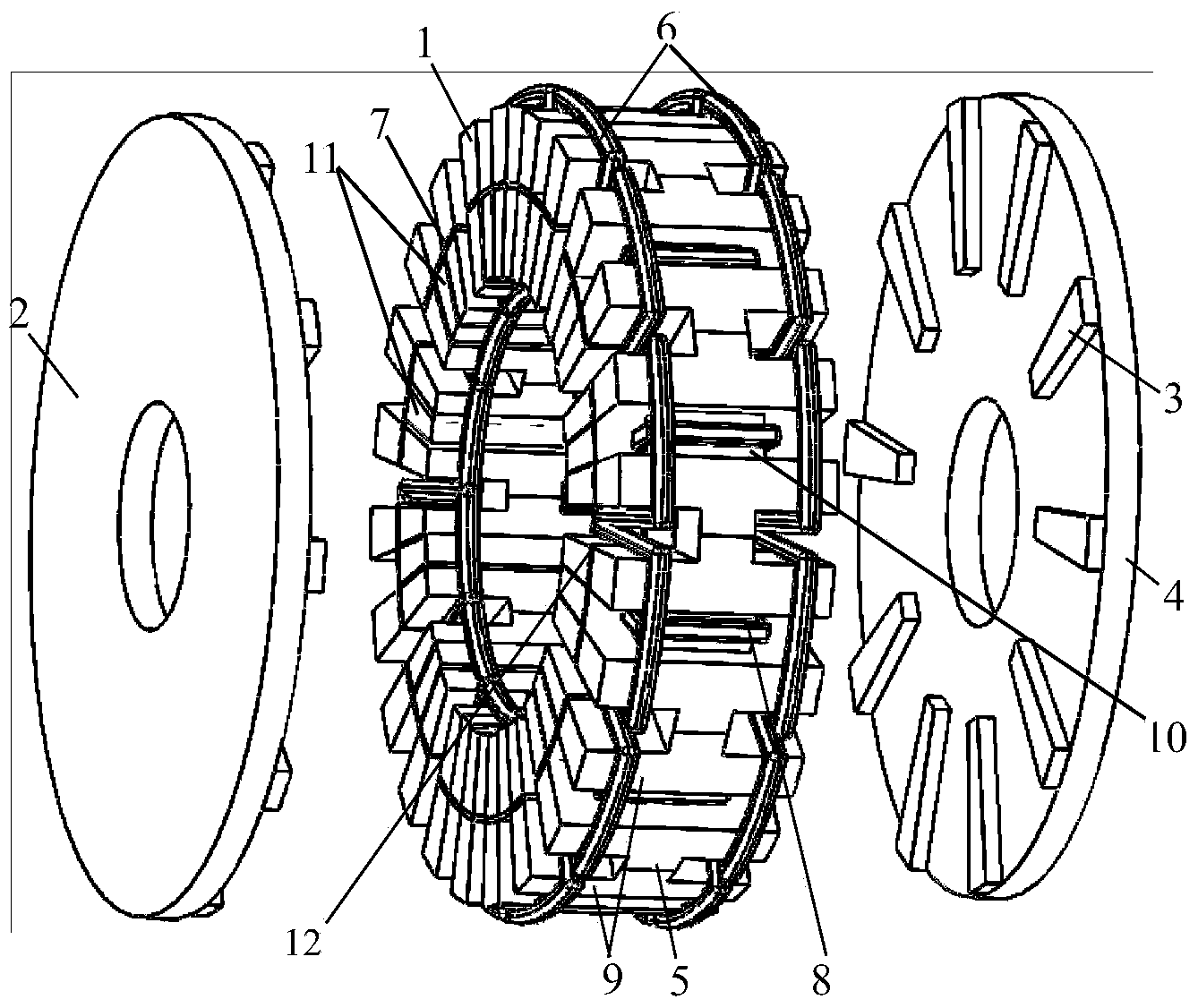

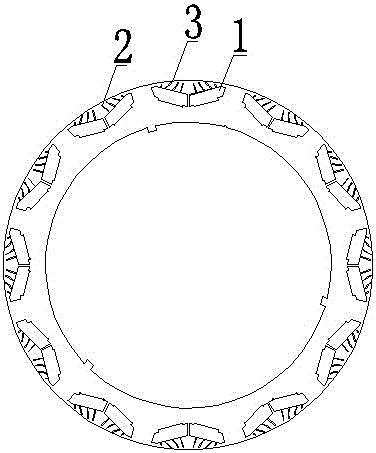

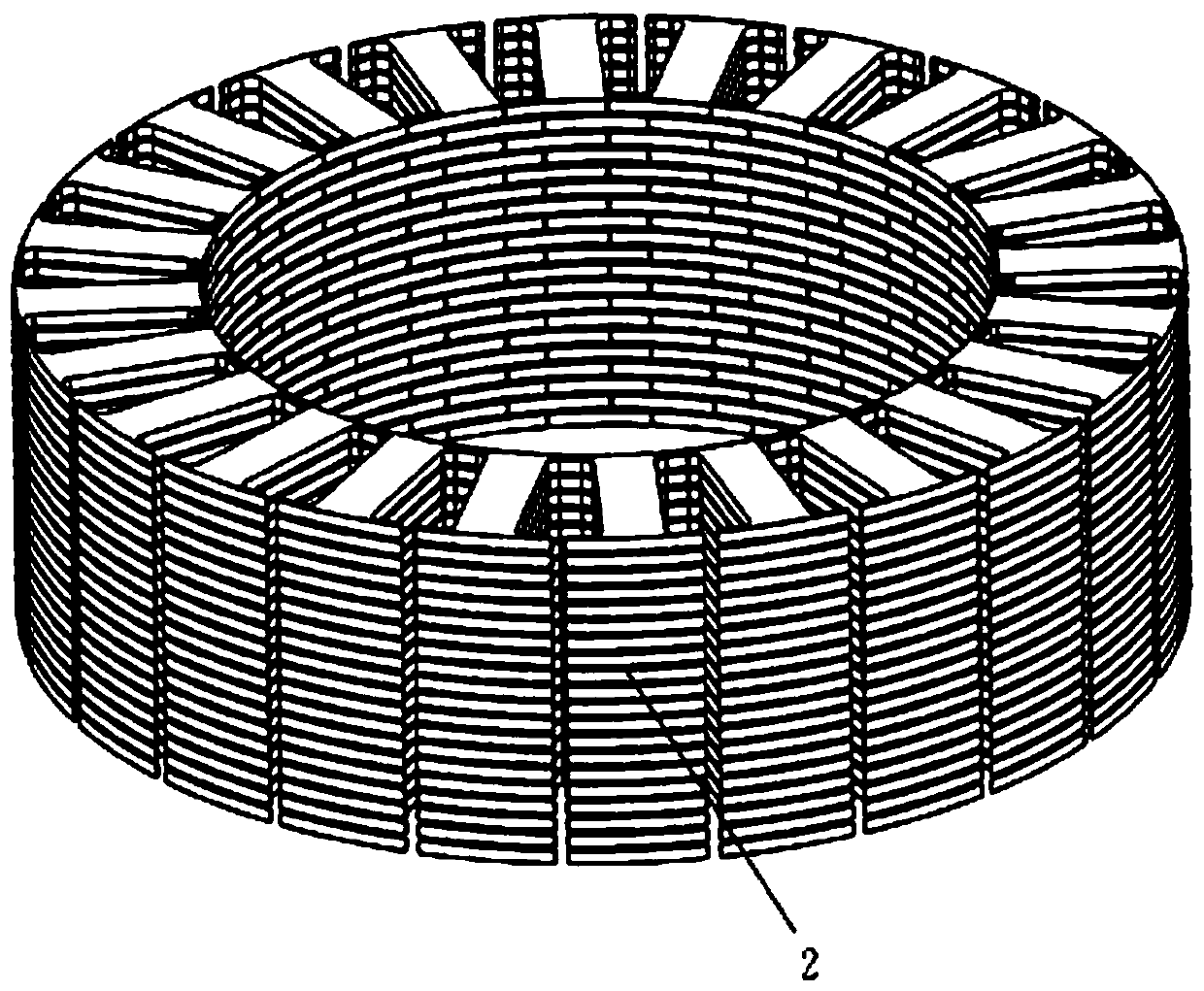

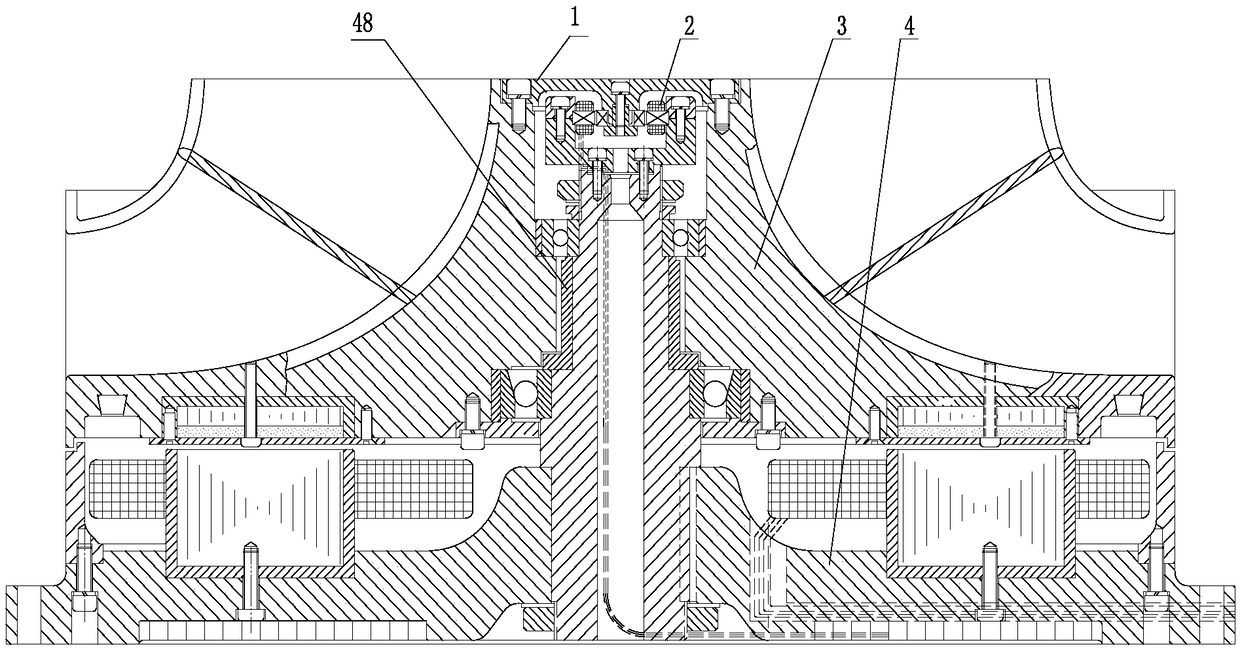

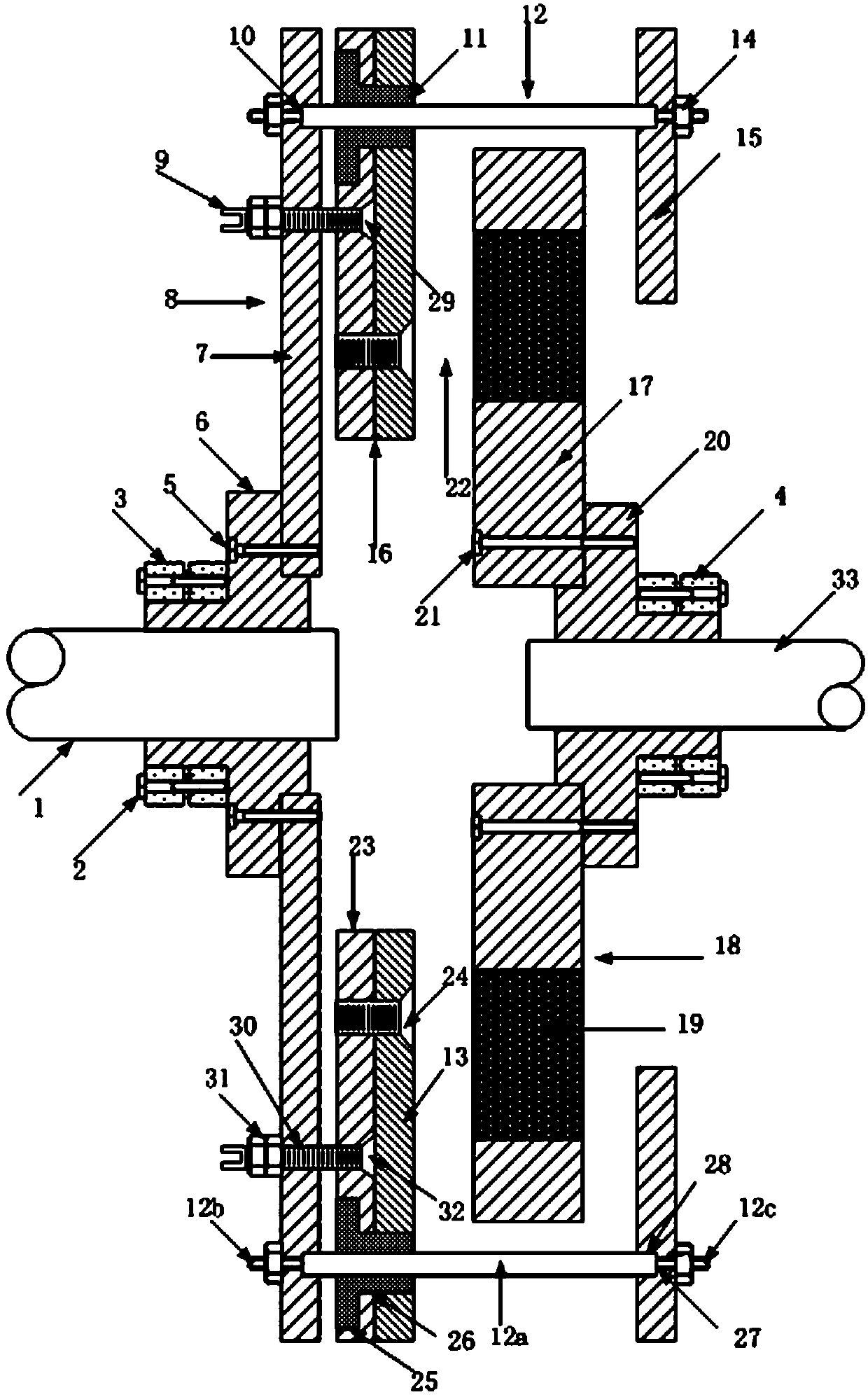

Stator division type axial flux switching type mixed excitation synchronous motor

InactiveCN103490583ALower resistanceReduced risk of demagnetizationDynamo-electric machinesPhysicsSynchronous motor

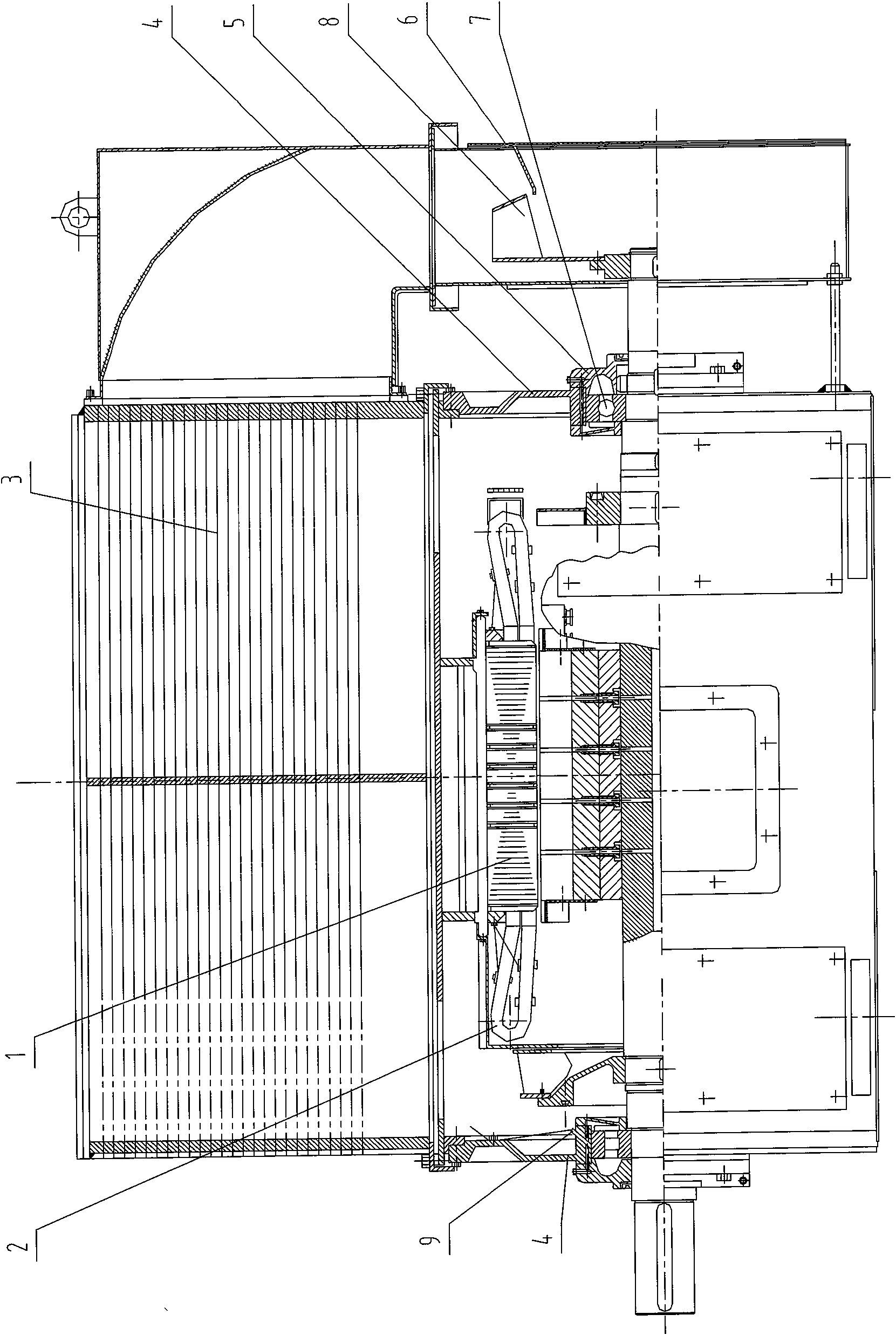

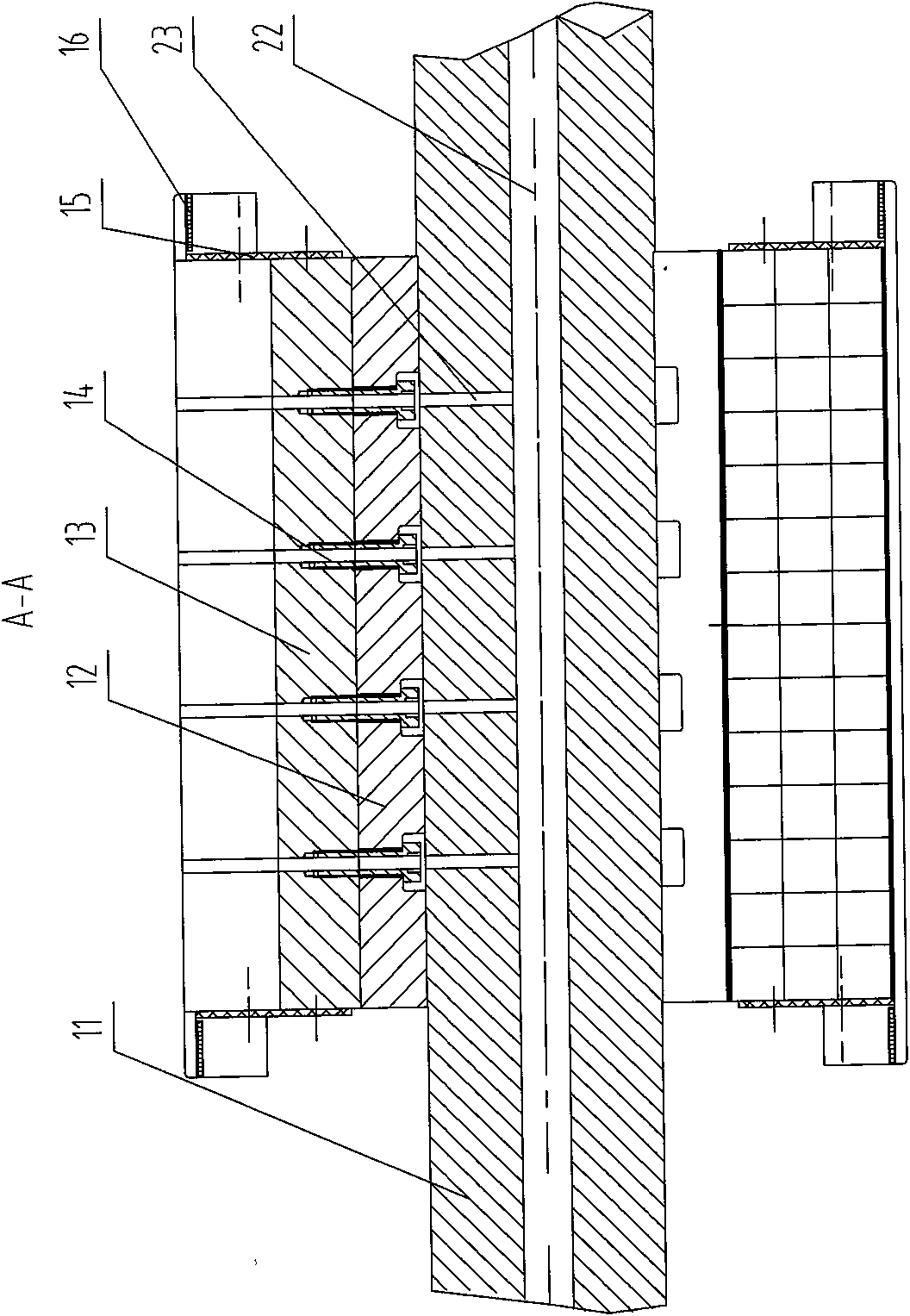

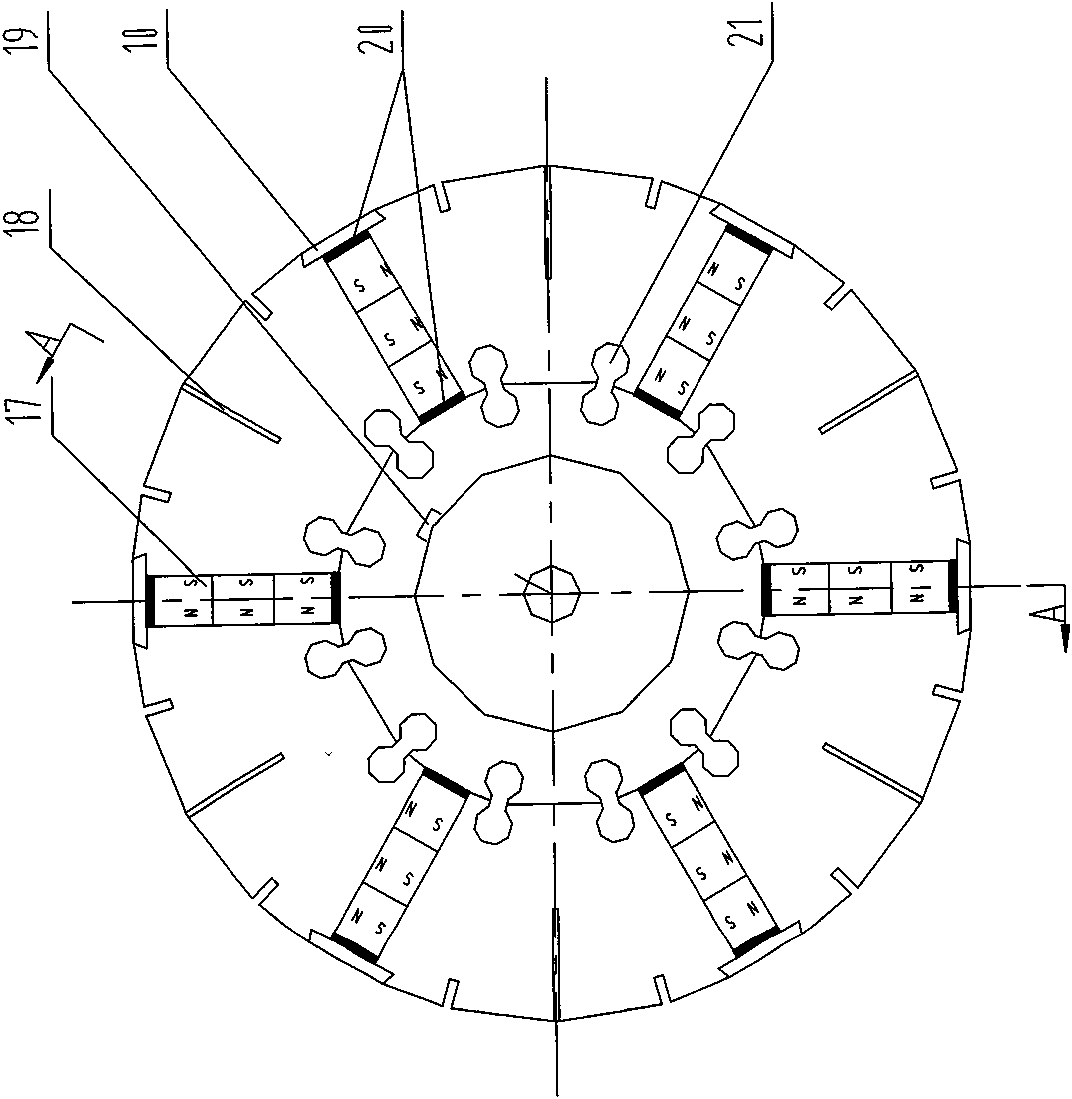

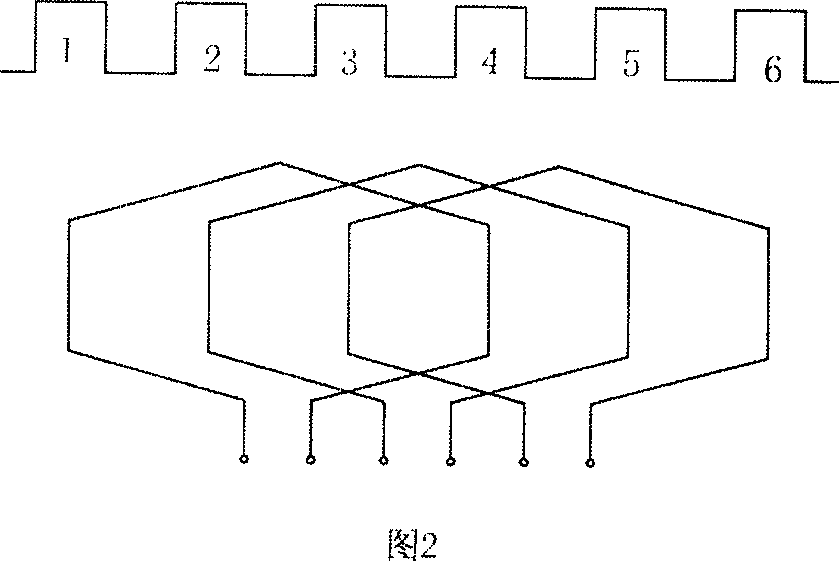

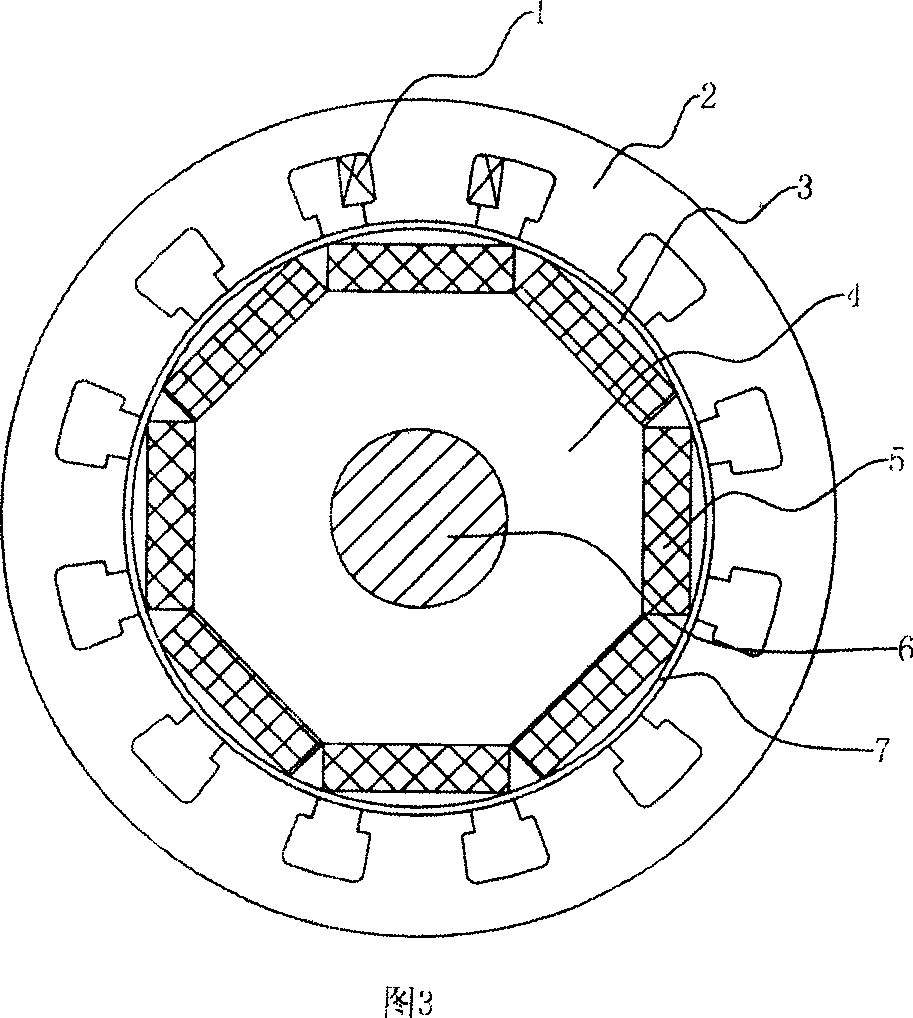

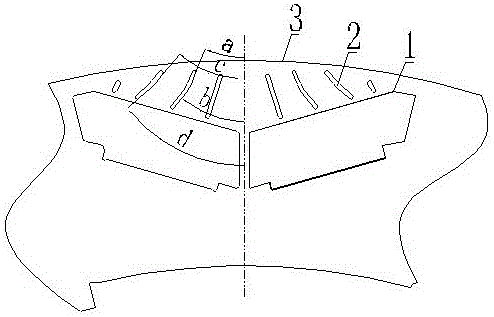

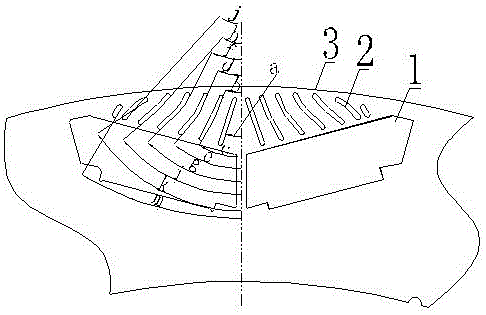

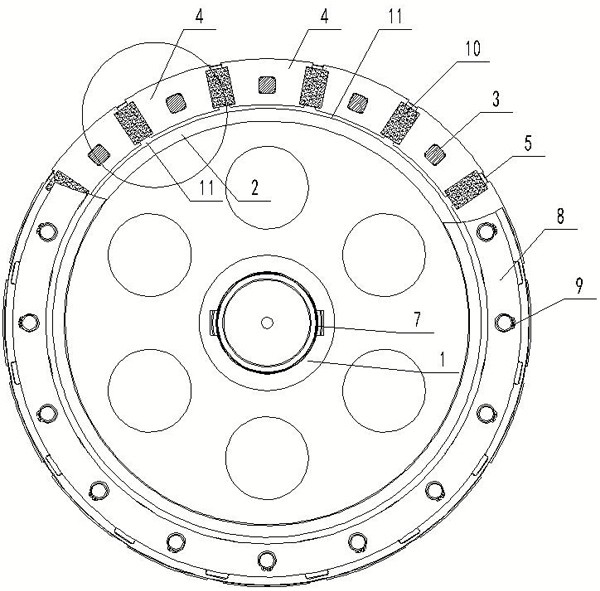

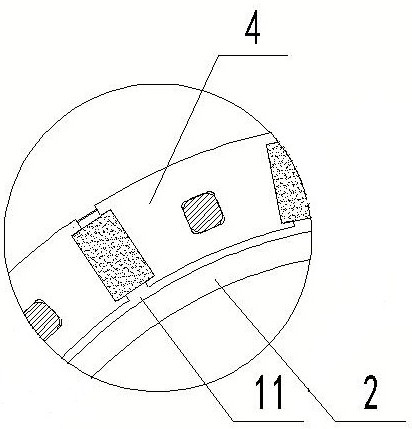

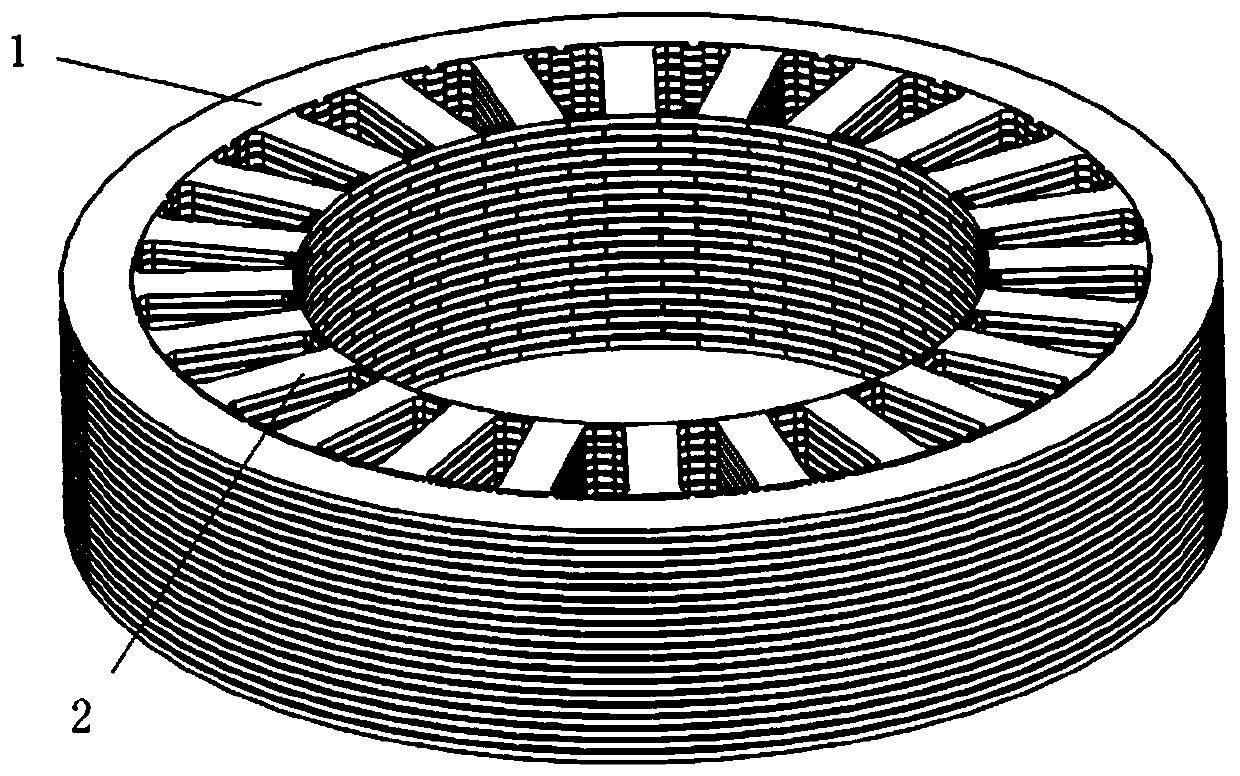

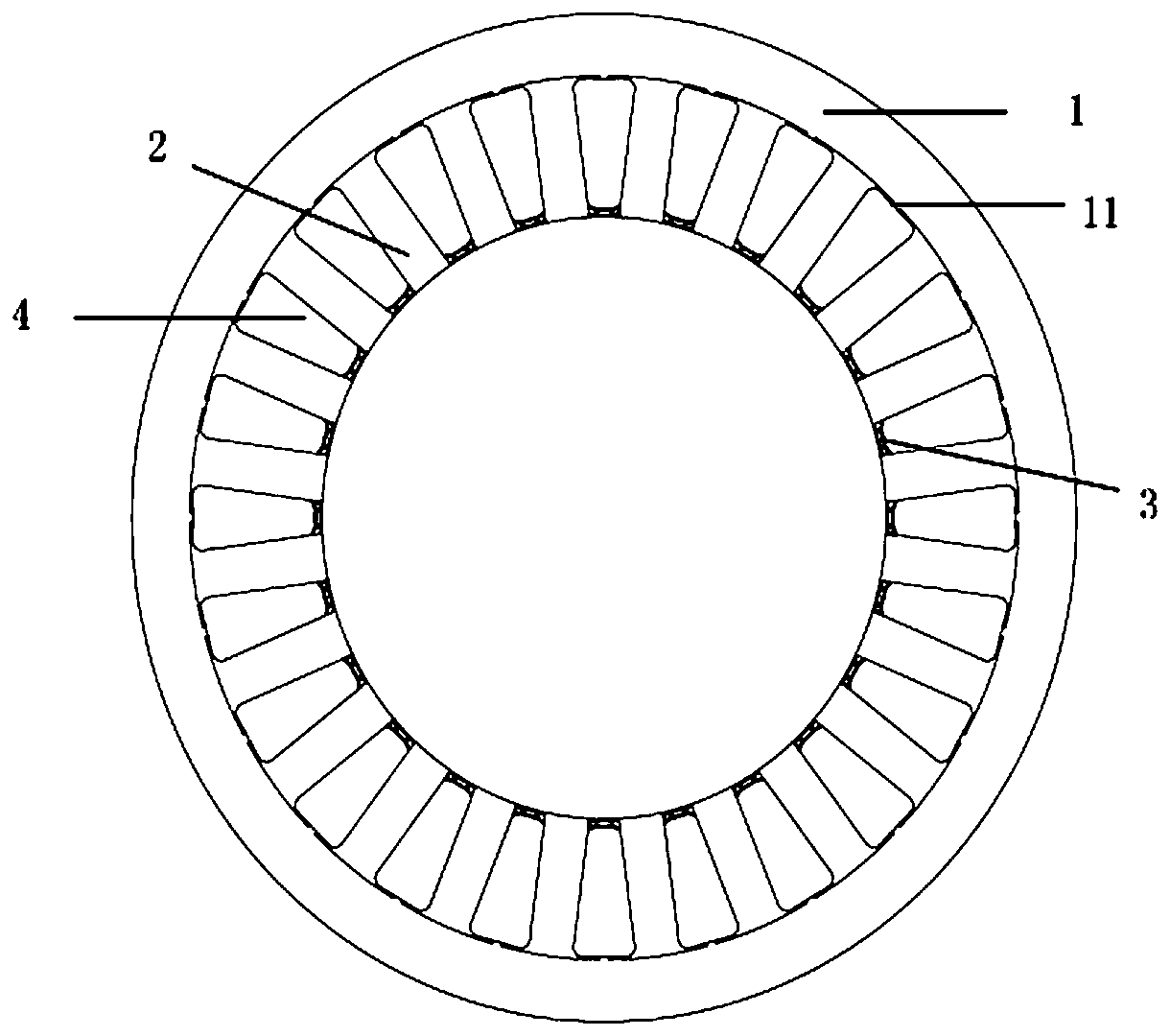

A stator division type axial flux switching type mixed excitation synchronous motor comprises a stator and a rotor. According to the stator, an inner layer H-shaped unit stator iron core and an outer layer H-shaped unit stator iron core are connected to form two wound concentric rings in a splicing mode, a magnetism separation ring separates the two concentric rings, armature windings are concentrated windings and wind stator teeth of the two adjacent H-shaped unit stator iron cores, permanent magnets are distributed between the adjacent H-shaped unit stator iron cores in an N-pole-and-S-pole-alternating mode. The permanent magnets and a stator groove are of a rectangular structure. An excitation support is placed right above the permanent magnets and is separated by the magnetism separation ring. An excitation winding winds the excitation support axially. The rotor is of a disc type structure and comprises a rotor magnet yoke and rotor poles which are evenly fixed on the surface of the rotor magnet yoke in a radial mode. The stator and the rotor are connected coaxially. The magnetism separation ring is used for separating the stator into an inner portion and an outer portion, so that an electro-magnetic circuit and a permanent magnet magnetic circuit are completely connected in parallel, coupling of the two magnetic circuits is lowered, using rate of the permanent magnets is greatly improved, and motor efficiency is obviously improved.

Owner:JIANGXI UNIV OF SCI & TECH

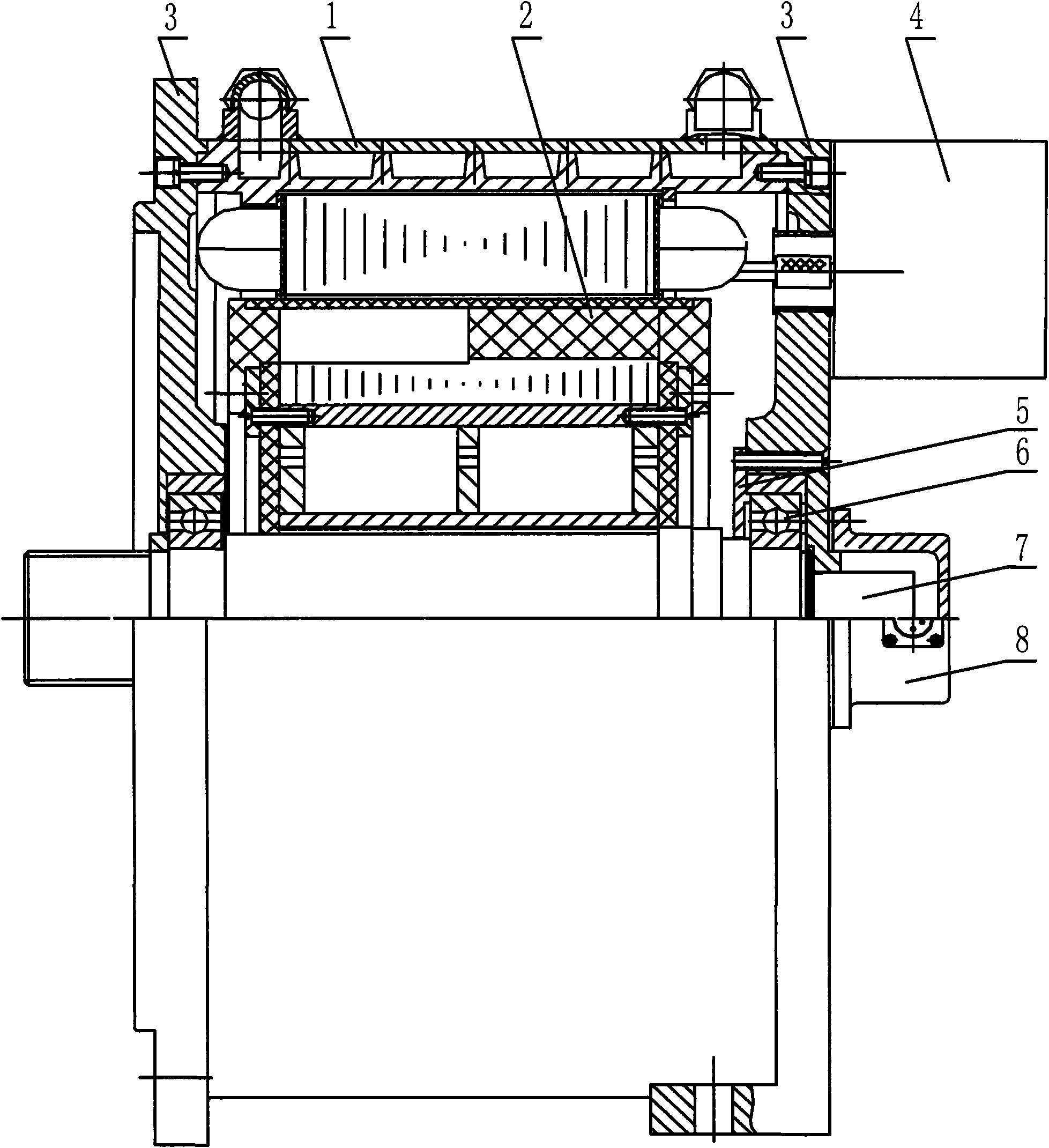

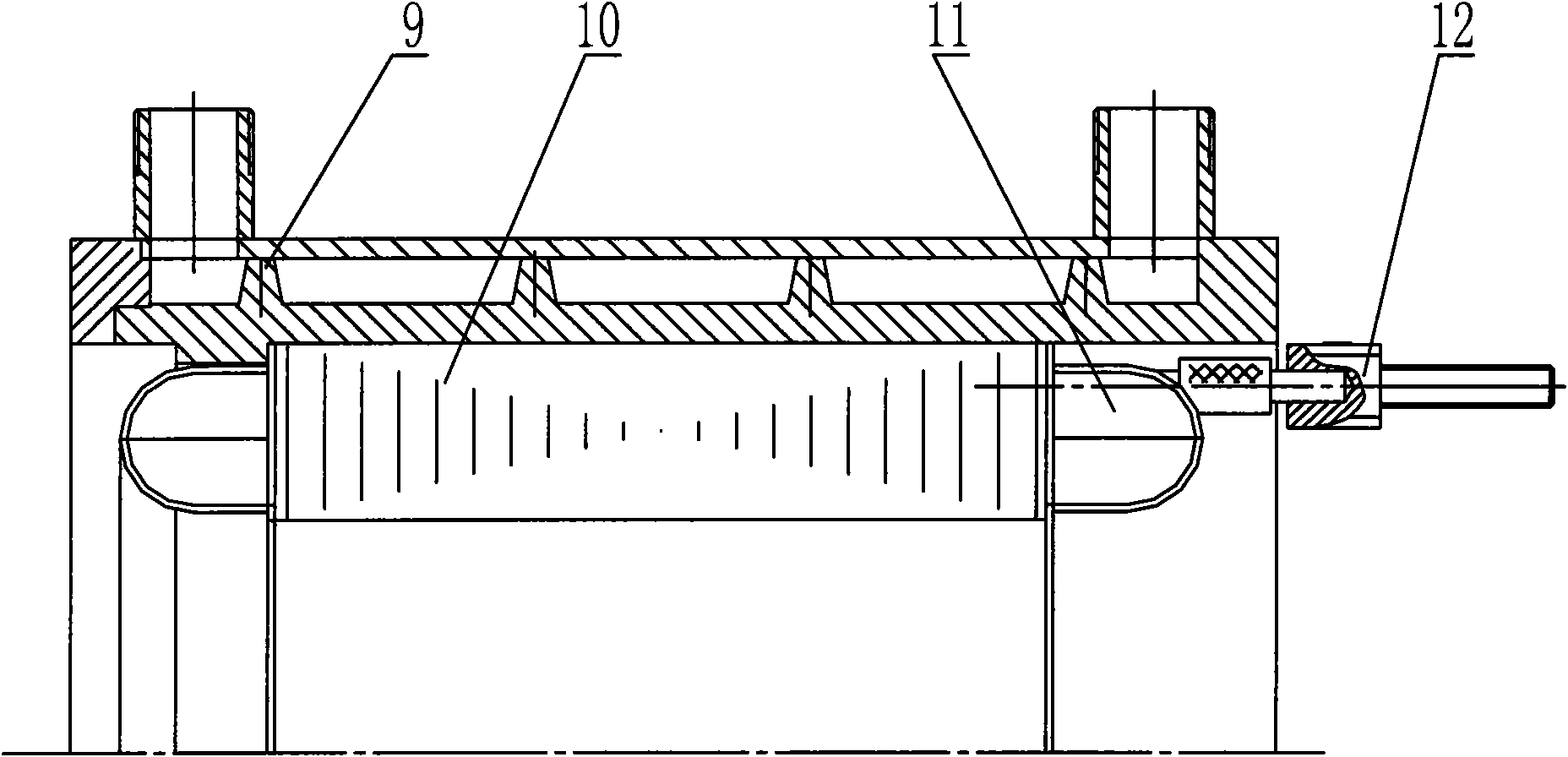

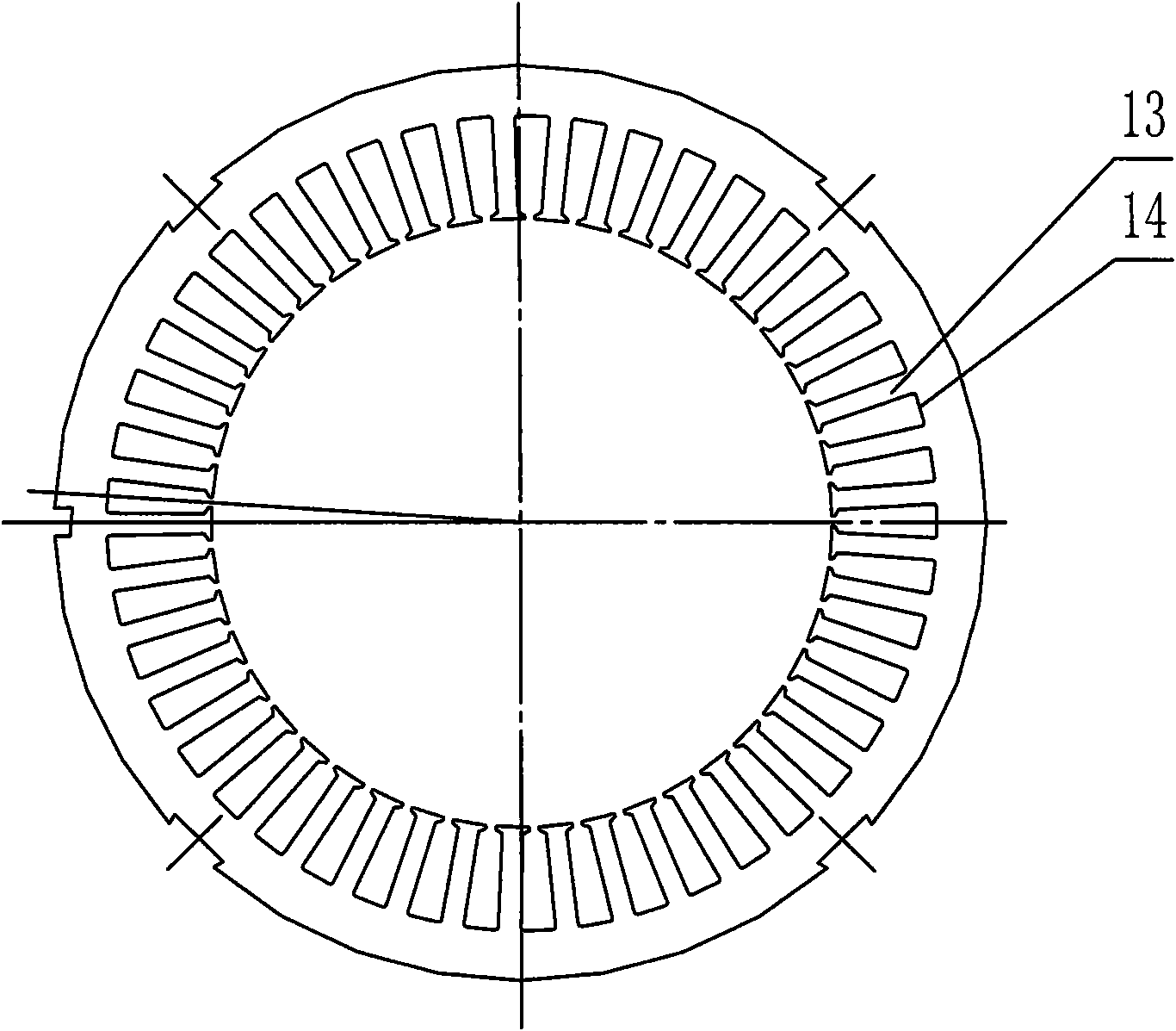

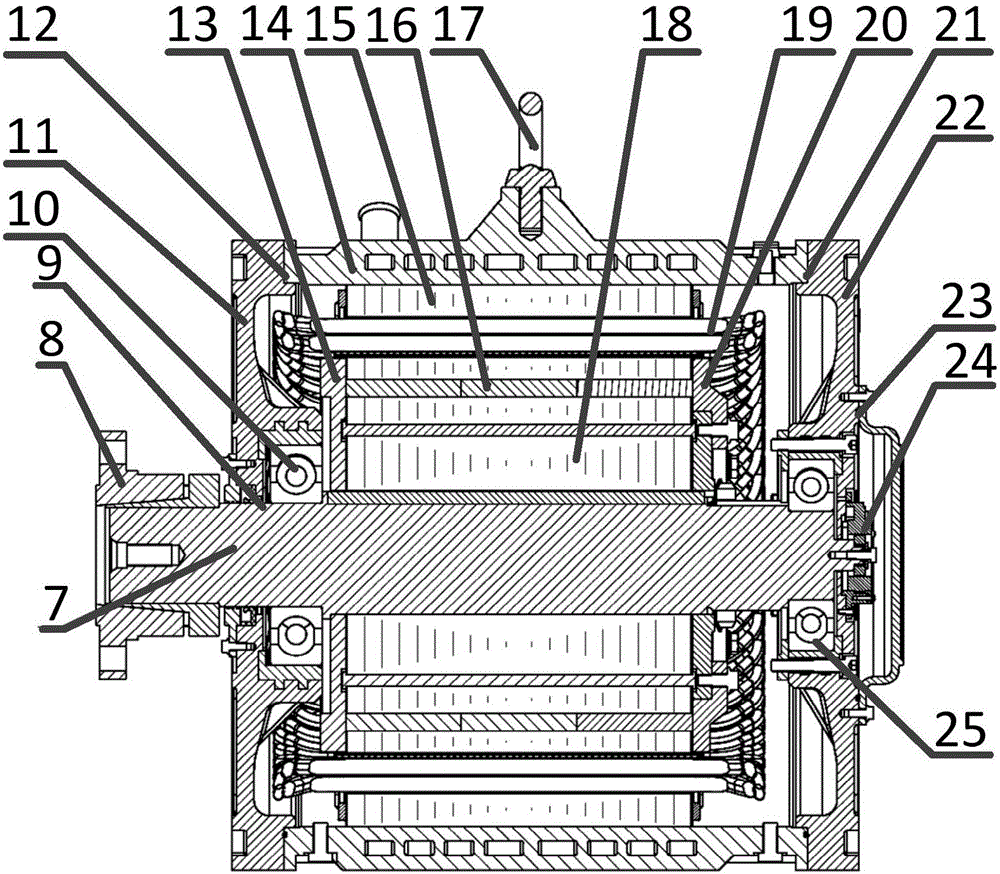

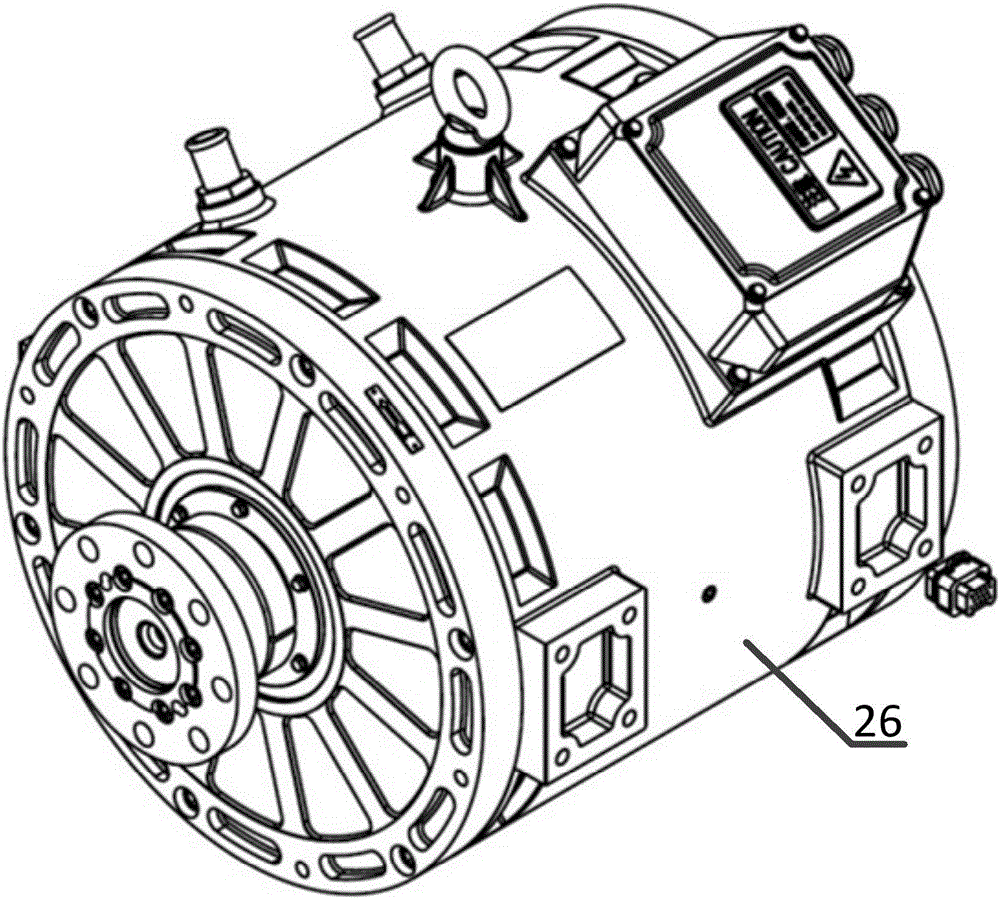

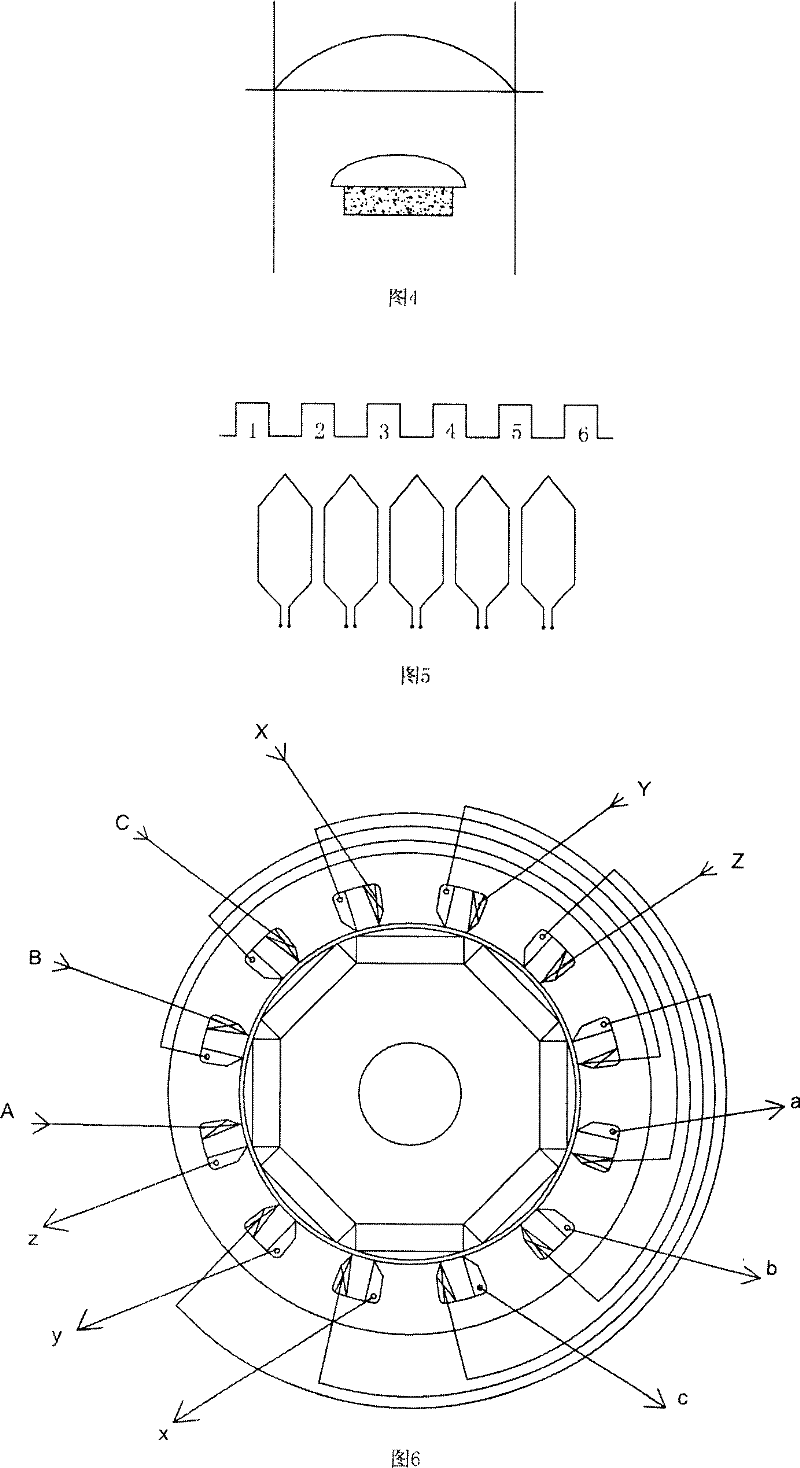

Three-phase water-cooling permanent magnet synchronous motor

InactiveCN101577454AEven heat dissipationHigh mechanical strengthMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet rotorPermanent magnet synchronous motor

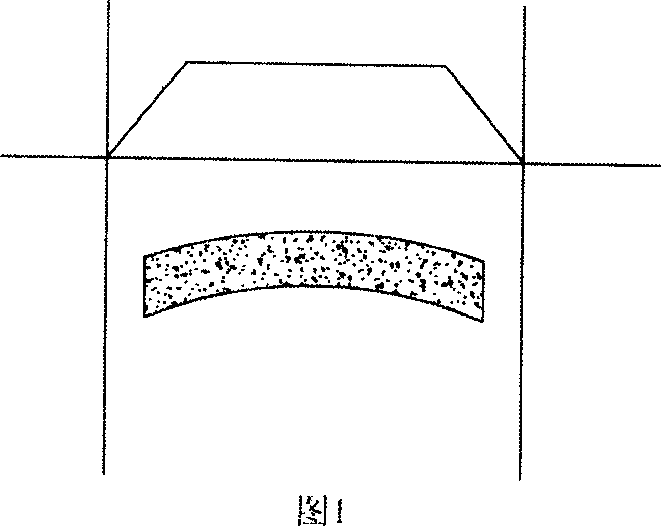

The invention relates to a three-phase water-cooling permanent magnet synchronous motor which comprises a base, a permanent magnet rotor, an end cover, an outlet box, a bearing inner cover and a bearing, wherein the base comprises a water-cooling casing and a stator winding, and the water-cooling casing comprises a casing outer wall and a casing inner wall. The invention is characterized in that a helical groove is made on the surface of the casing inner wall, and helical convex ribs are formed in the groove and form a helical water groove with the casing outer wall. The permanent magnets of the permanent magnet rotor are arc permanent magnets with sections being crown faces, the arc permanent magnets are fixedly pasted on the surface of a rotor iron core in an equidistant manner according to the polarity along the circumference of the permanent magnet rotor and are mutually separated by insulation partition boards, both ends of each arc permanent magnet are fixed by insulation baffles, and an insulation sheath wraps the permanent magnet rotor outside. The invention has the advantages of uniform heat dissipation of the casing, high mechanical strength of the casing and low leakage coefficient of the permanent magnets, thereby improving the utilization rate of the permanent magnets, increasing the accumulation energy of air gaps, reducing copper loss and facilitating wire connection.

Owner:BAOTOU TIANSHAN MOTOR

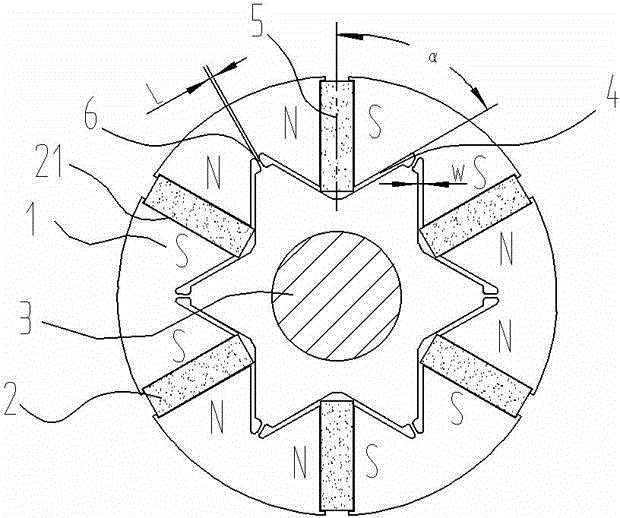

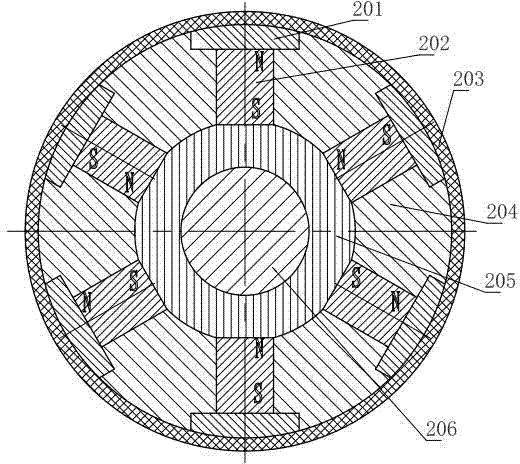

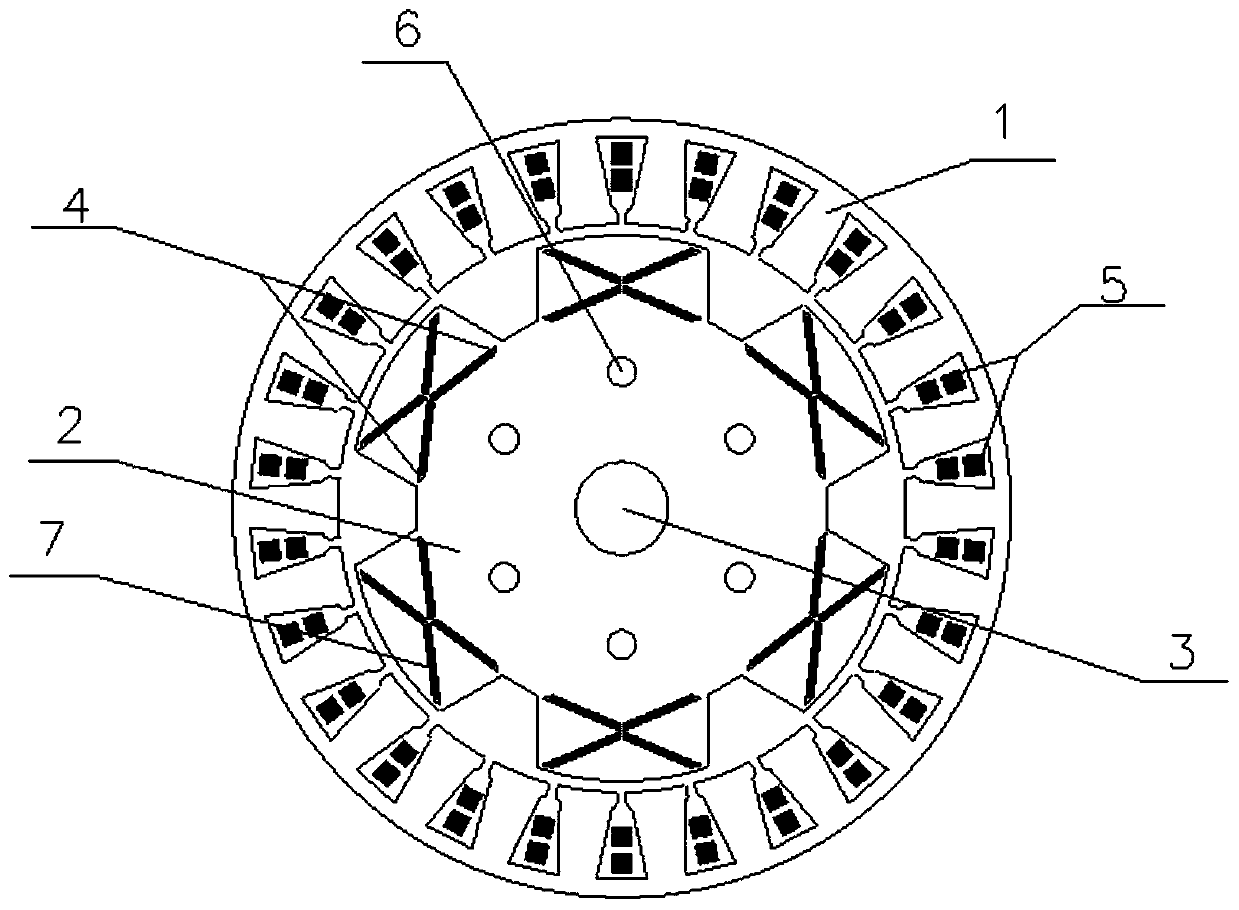

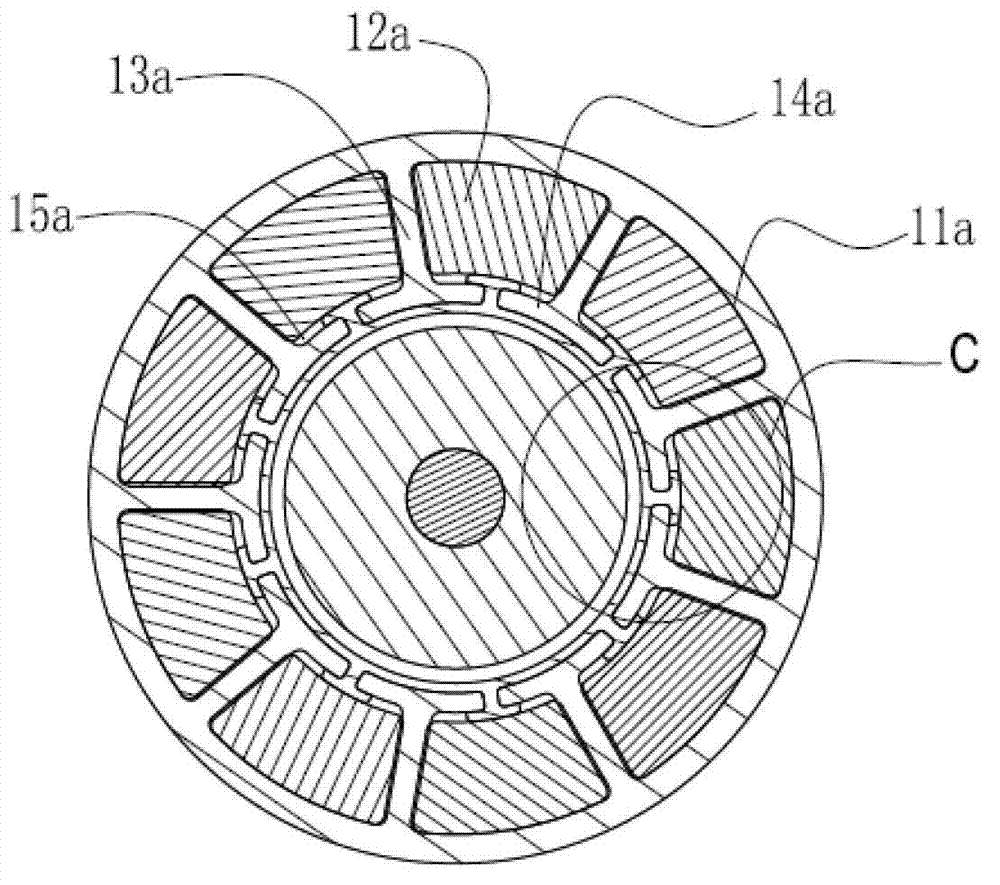

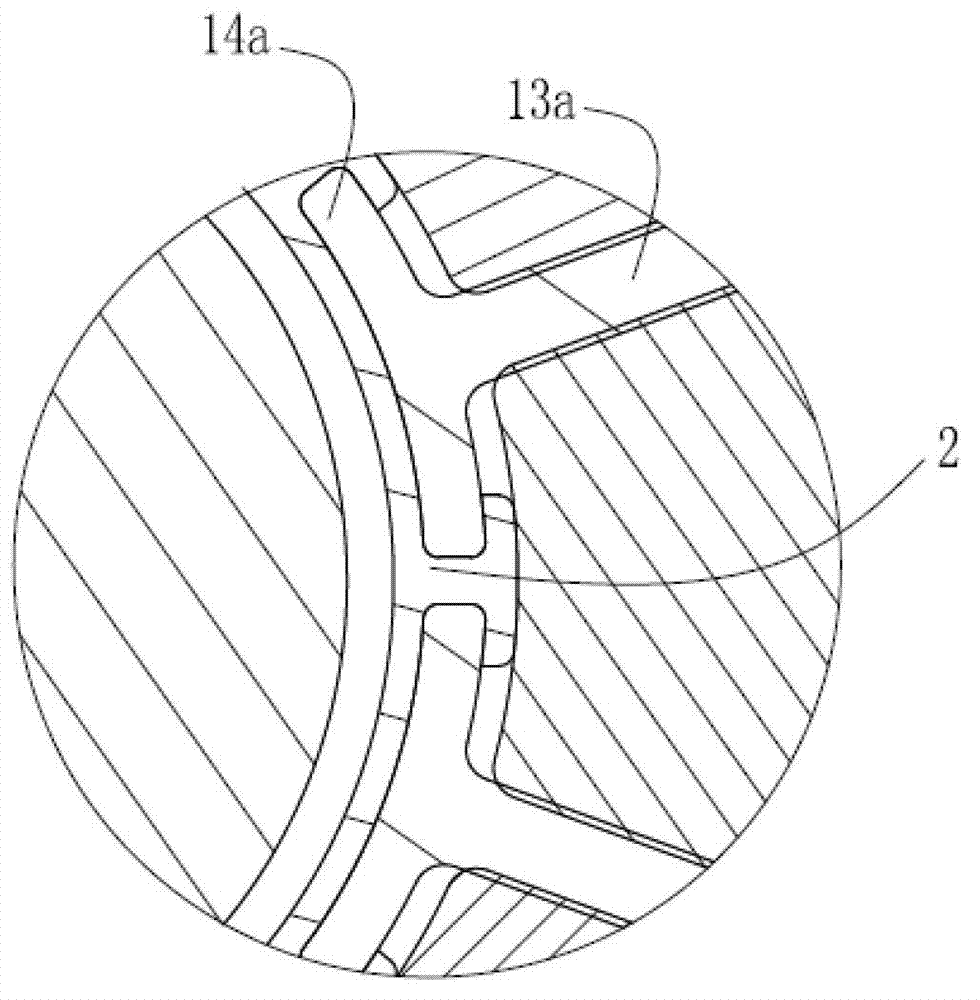

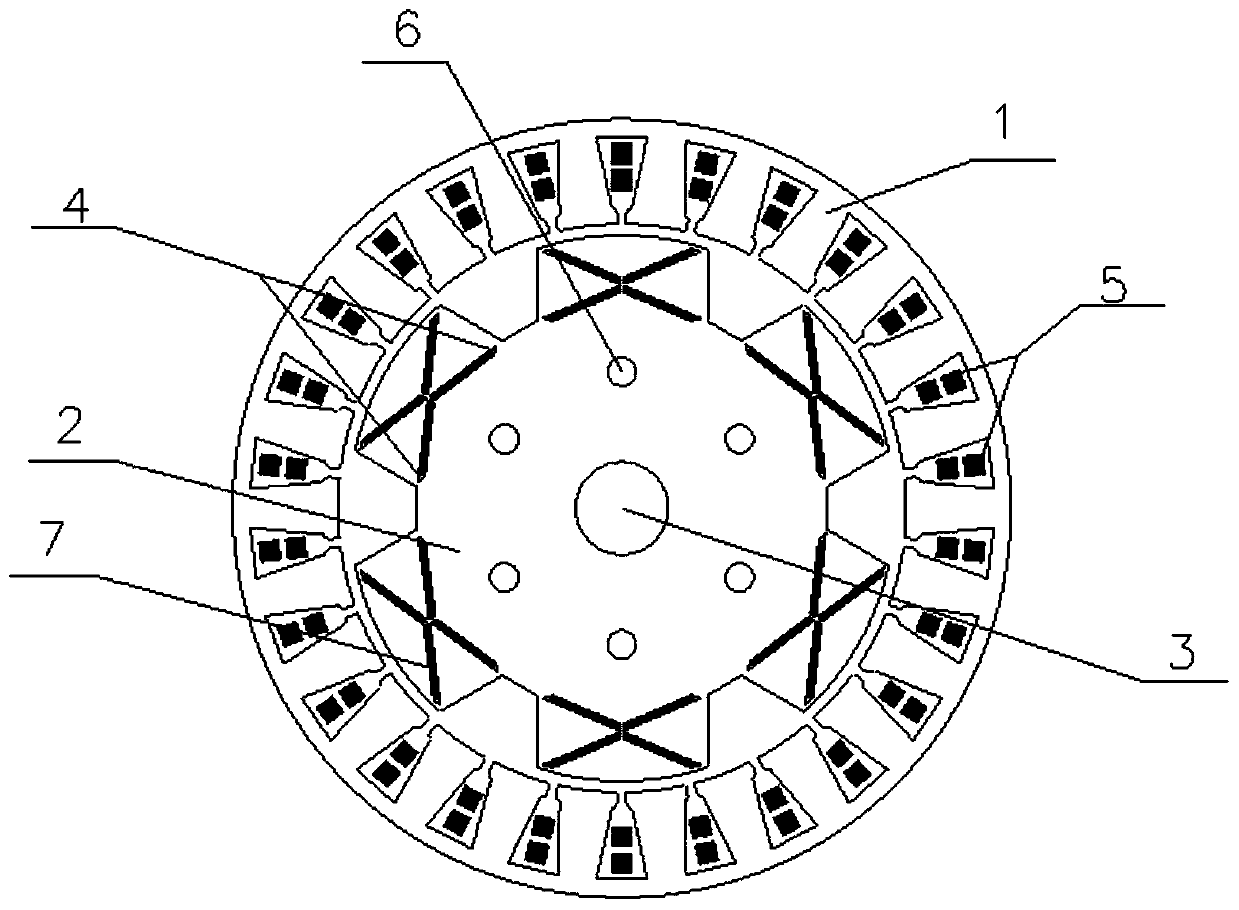

Hybrid magnetic circuit rotor of permanent magnet synchronous motor

InactiveCN106451859AWide range of constant power operationHigh mechanical strengthMagnetic circuit rotating partsConstant powerPower factor

The invention discloses a hybrid magnetic circuit rotor of a permanent magnet synchronous motor. The hybrid magnetic circuit rotor comprises a rotor structure body, a built-in permanent magnet and surface-mounted permanent magnets. The rotor structure body is provided with a plurality of permanent magnet grooves. The built-in permanent magnet is embedded in the permanent magnet grooves. Each surface-mounted permanent magnet is provided with a permanent magnet groove directly facing to the surface-mounted permanent magnet. The surface-mounted permanent magnet is fixed on the outer circumference face of the rotor structure body. One surface-mounted permanent magnet and the built-in permanent magnet in the permanent magnet grooves which directly faces to the surface-mounted permanent magnet form one magnetic pole. The polarities of the neighboring magnetic poles are opposite. The rectangular axis inductance difference of the hybrid magnetic circuit rotor generates the reluctance torque, and the constant power operation range of the motor is widened. The surface-mounted permanent magnet provides the magnetic circuit capable of hinging a stator winding to the original leakage magnetic flux, the magnetic flux leakage coefficient is reduced, the power factor and the power density are improved, the width and the thickness of a magnetic separating bridge are increased, and the mechanical strength during the high speed running of the motor is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

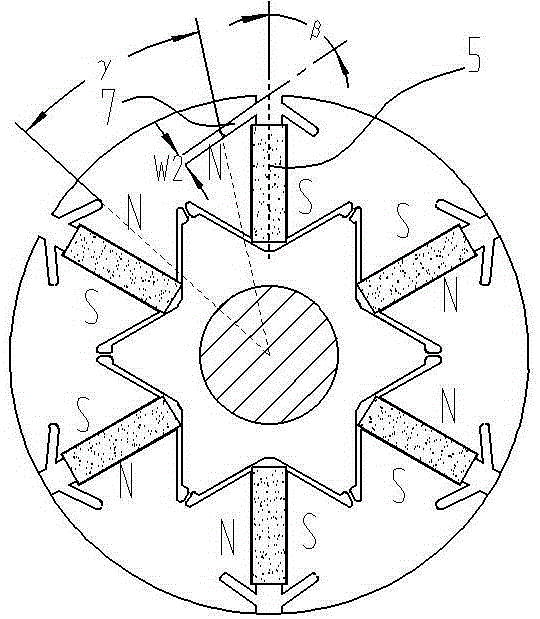

Rotor structure used for tangential permanent magnet direct current brushless motor, and tangential permanent magnet direct current brushless motor

InactiveCN105305760AIncrease working pointHigh torque/current ratioMagnetic circuit rotating partsBrushless motorsElectric machine

The invention discloses a rotor structure used for a tangential permanent magnet direct current brushless motor, and the tangential permanent magnet direct current brushless motor. The rotor structure comprises a rotor iron core, tangential permanent magnets and a rotation shaft; an even number of tangential permanent magnet grooves are formed in the circumference of the rotor iron core radially at the equal intervals; the tangential permanent magnets with the opposite polarities are arranged in the adjacent tangential permanent magnet grooves; the tangential permanent magnets are connected with or disconnected from the near air gap side; the central symmetry of the rotor iron core is maintained; the sides, close to the rotation shaft, of the tangential permanent magnet grooves are communicated with flux-insulation grooves on the two sides of the tangential permanent magnet grooves; the near air gap side of the flux-insulation grooves and the central line of the corresponding tangential permanent magnet grooves extend outwardly at an angle of alpha; and a radially-distributed flux-insulation bridge is formed between the adjacent flux-insulation grooves. The rotor structure used for the tangential permanent magnet direct current brushless motor is simple and compact in structure, small in magnetic leakage factor, high in mechanical strength, convenient to produce, low in manufacturing cost, higher in resistance to demagnetization, and high in overload capacity, so that the tangential permanent magnet direct current brushless motor is higher in torque / current ratio, torque / volume ratio and motor efficiency; and therefore, the rotor structure used for the tangential permanent magnet direct current brushless motor, and the tangential permanent magnet direct current brushless motor are brighter in the application prospects.

Owner:NANJING KANGNI ELECTRONICS TECH

Permanent magnet synchronous motor

InactiveCN101626185AControl temperature riseExtend your lifeMagnetic circuit rotating partsSynchronous machine detailsPermanent magnet synchronous motorMagnetic poles

The invention discloses a permanent magnet synchronous motor consisting of a stator component and a rotor component. The stator component consists of a casing, a stator iron core and a armature winding, wherein a rotor shaft is a hollow shaft, and an internal ventilation hole with two communicated ends are arranged inside the hollow shaft; the rotor shaft is provided with an external ventilation hole communicated with the internal air through hole in the hollow shaft along a radial direction of the rotor shaft; a magnetic shield is provided with a ventilation hole of the magnetic shield along the radial direction; a magnetic pole is provided with a ventilation hole of the magnetic pole along the radial direction; the ventilation hole of the magnetic shield and the ventilation hole of the magnetic pole are communicated with the internal ventilation hole, and the three ventilation holes form a radiant-type radiating structure with the axial direction crossed with the radial direction. Compared with the prior art, the invention excellently controls the temperature rise of the motor in operation, reduces the demagnetization danger of an Nd-Fe-B permanent magnet, and reduces vortex heating and prolongs the service life of the normal operation of the motor at the same time.

Owner:NANTONG JINCHI MECHANICAL ELECTRIC

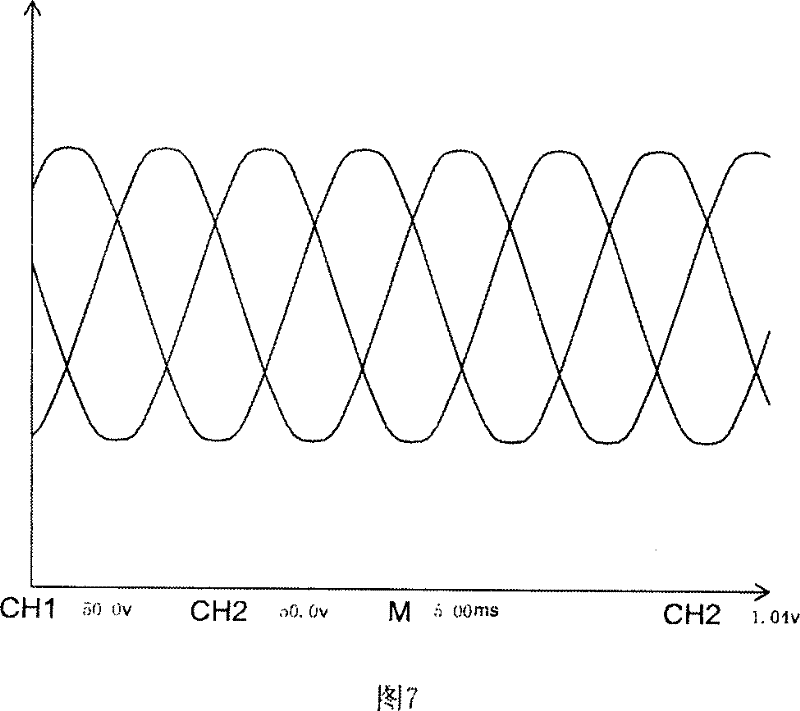

Permanent magnetic brushless DC four-quadrant electric machine

InactiveCN1933286ASimple structure and processWork reliablyMagnetic circuit rotating partsMagnetic circuit stationary partsPhysicsMagnetic core

This invention relates to a new type of permanent magnet brushless DC 4-quadrant motor, in which, magnetic poles of the stator and rotor are in a symmetric geometrical structure with salient poles at either side and 3:2 tooth pole ratio, the groove number of the stator winding is the pole number of the rotor plus 2 or 4, centralized excitation windings serial to each other are mounted on the two symmetric salient poles of the stator to form a phase, said rotor is composed of an axis, a soft magnetic core, a permanent magnet, a magnetic shoe and a ringer, the magnet is installed on the subsurface of soft core of the rotor to form a magnetic pole rotating synchronously and an opposite vertical angle is formed to a column rotor at the outer circle of the pole shoe of the magnet by the non-magnetism ringer and an interference method.

Owner:林祥钟

Novel permanent magnetism auxiliary exciter rotor structure

InactiveCN102497047AIncrease profitImprove performanceMagnetic circuit rotating partsFilling materialsEngineering

The invention discloses a novel permanent magnetism auxiliary exciter rotor structure. An annular magnet yoke is internally provided with a rotating shaft, and a permanent magnet and a pole shoe are locked on the magnet yoke tightly at peripheral of the annular magnet yoke through a stainless steel screw. According to the invention, the stainless steel screw is employed to directly fix the pole shoe and the permanent magnet on the magnet yoke together, compared with a present rotor structure of a bound permanent magnetism auxiliary exciter, weftless glass riband and nonmagnetic filling materials are cancelled, not only are component processing and assembling operation convenient, but also air gap is small, a magnetic leakage coefficient is small, magnetic steel utilization rate is high, and performance is good, stable and reliable.

Owner:SEC ELECTRIC MACHINERY

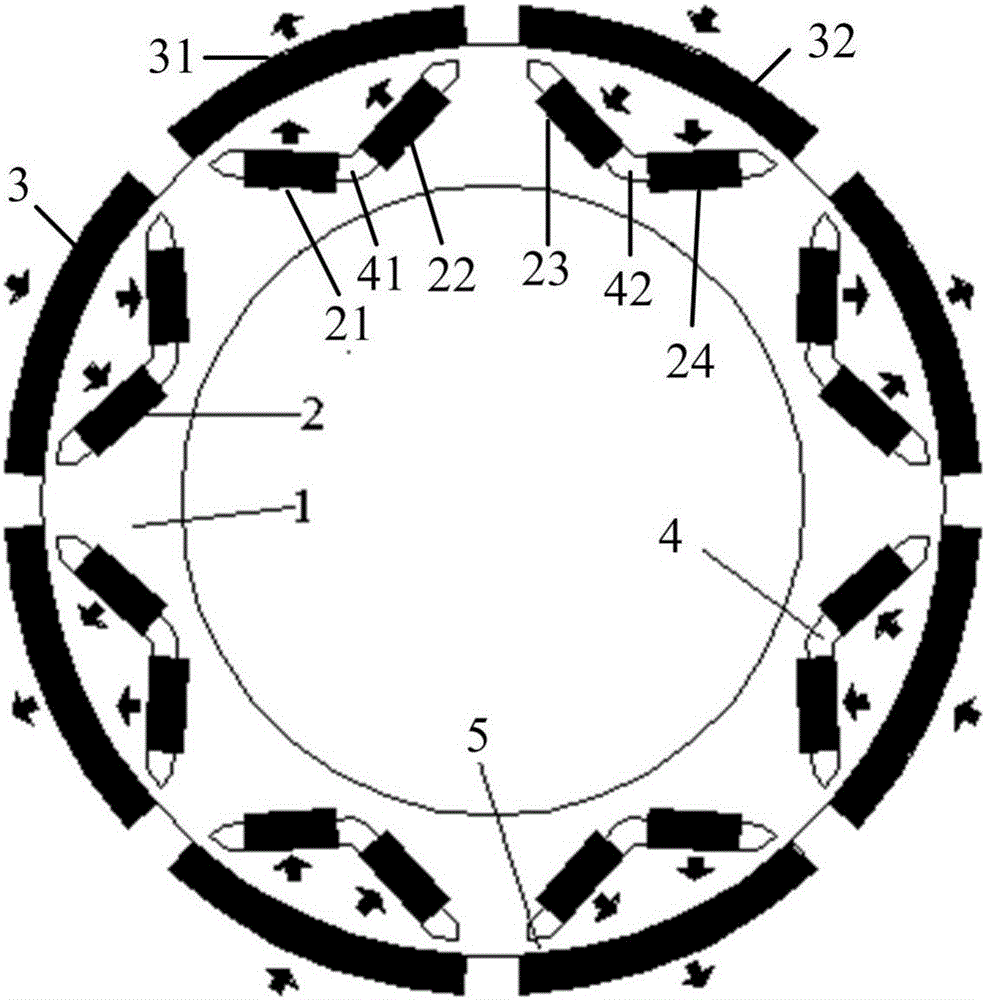

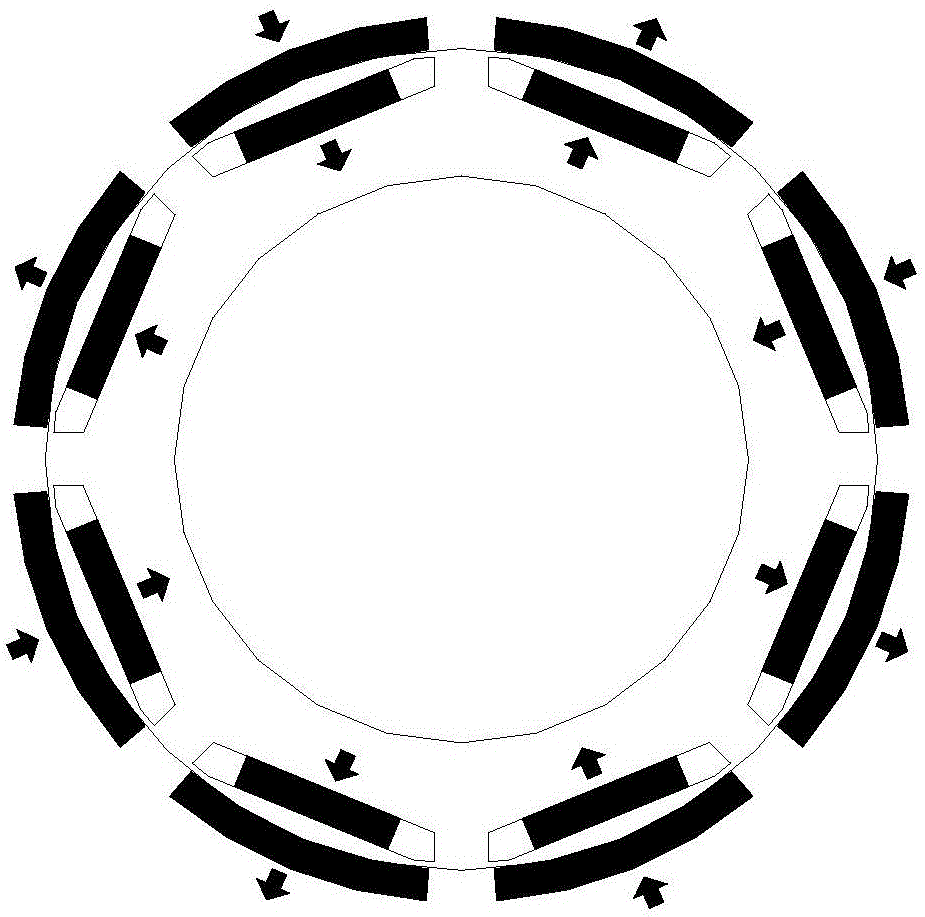

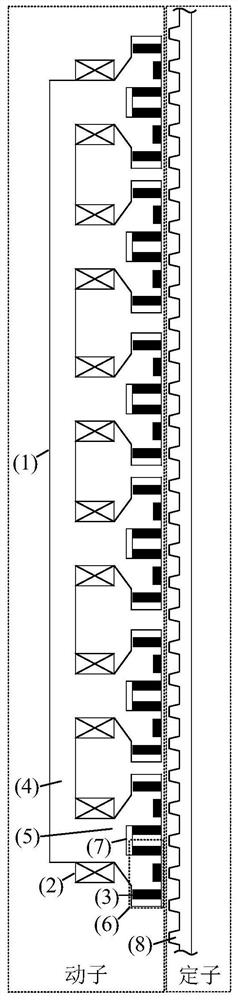

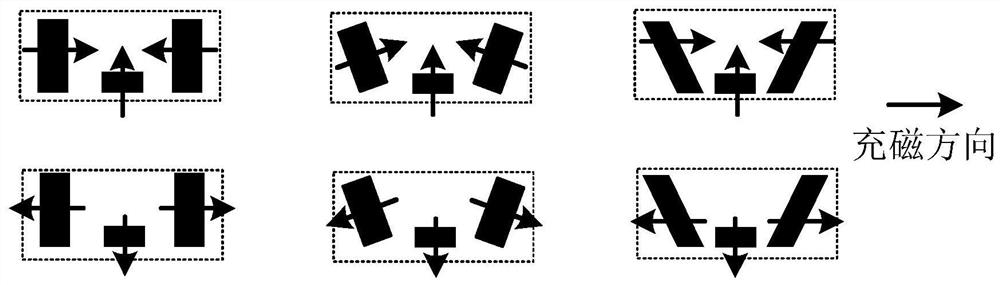

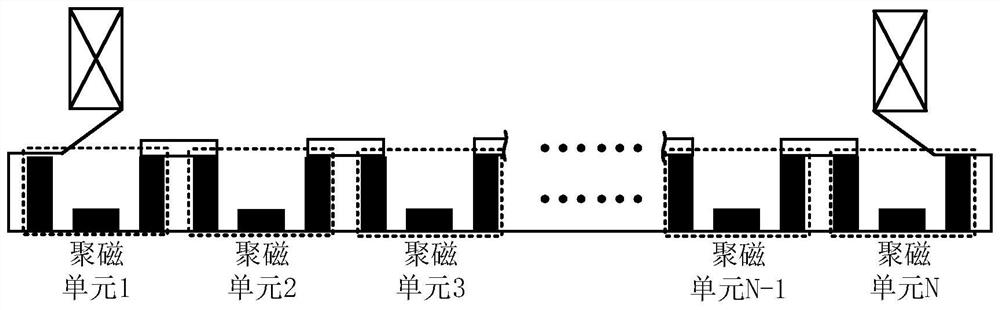

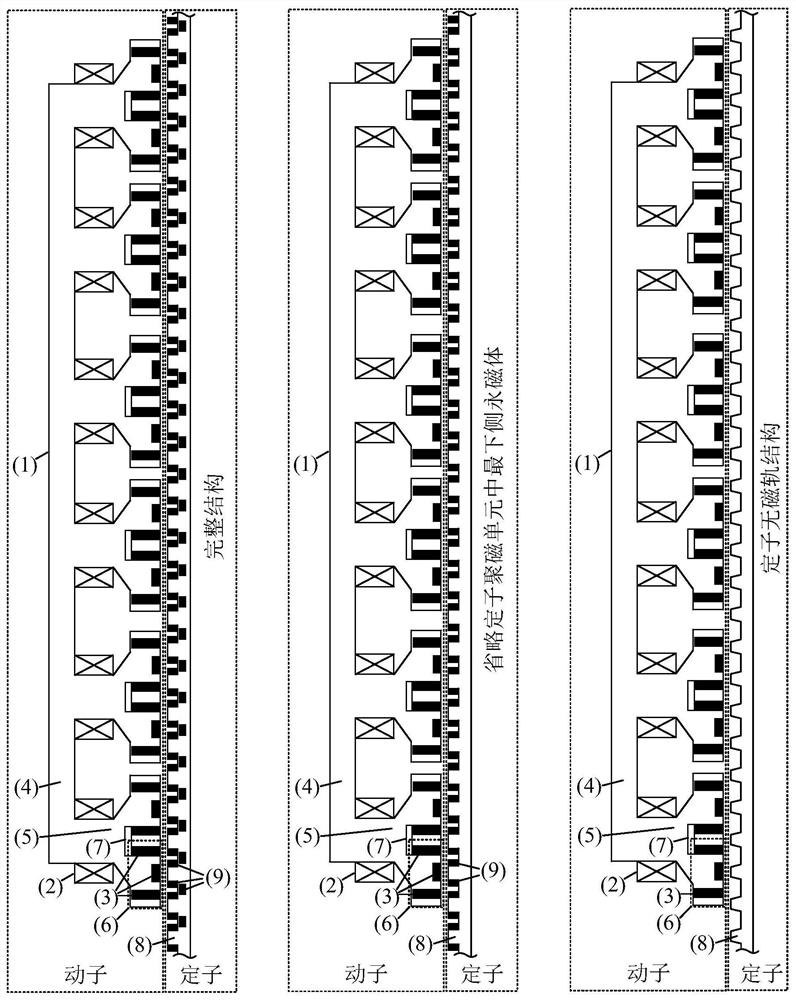

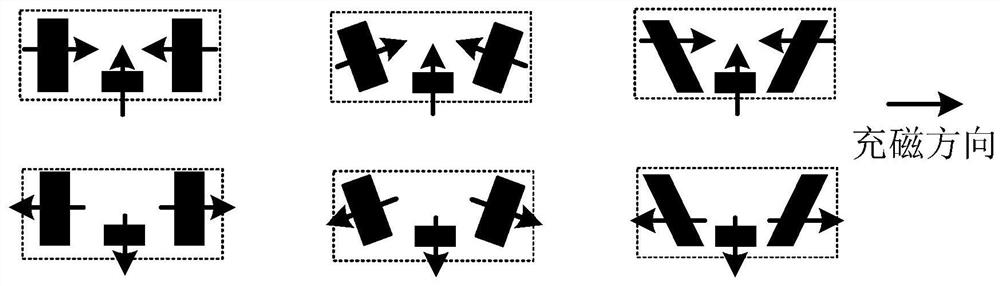

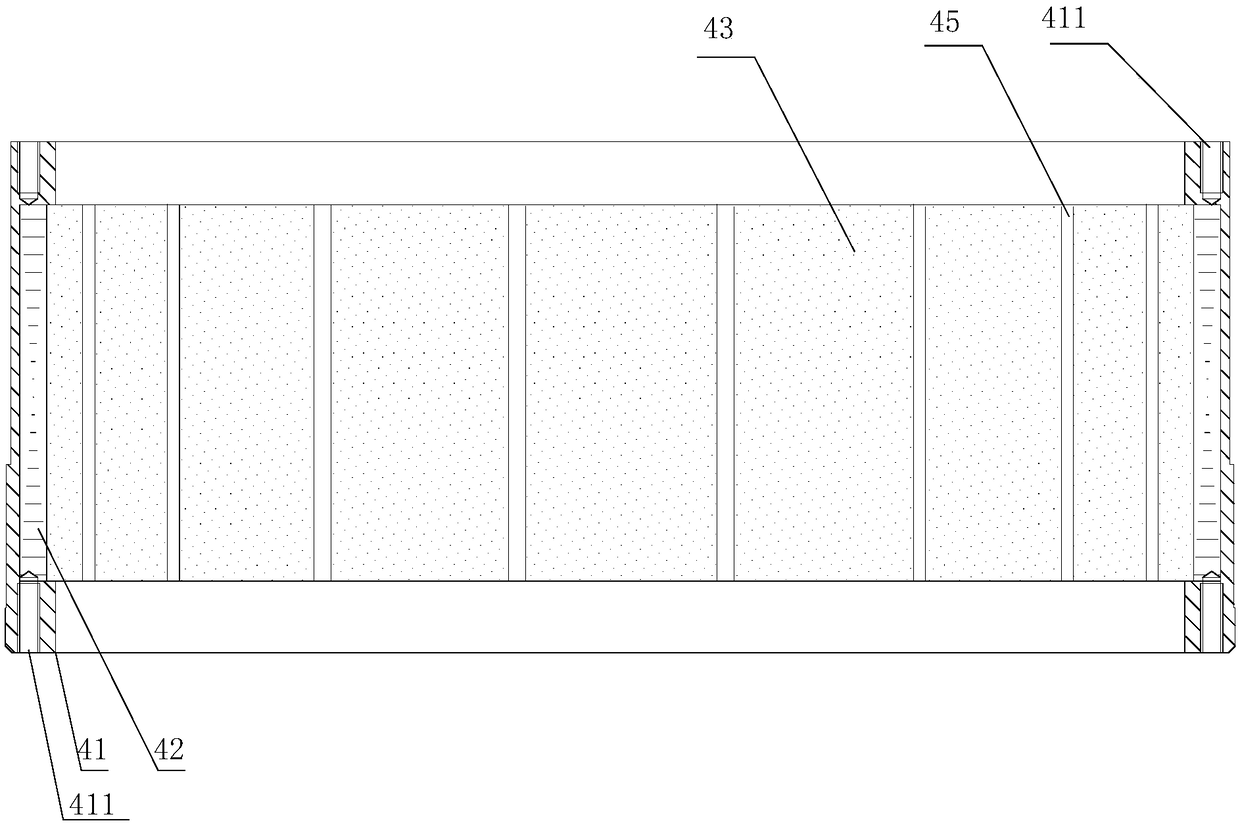

Magnetic gathering type non-magnetic track linear motor

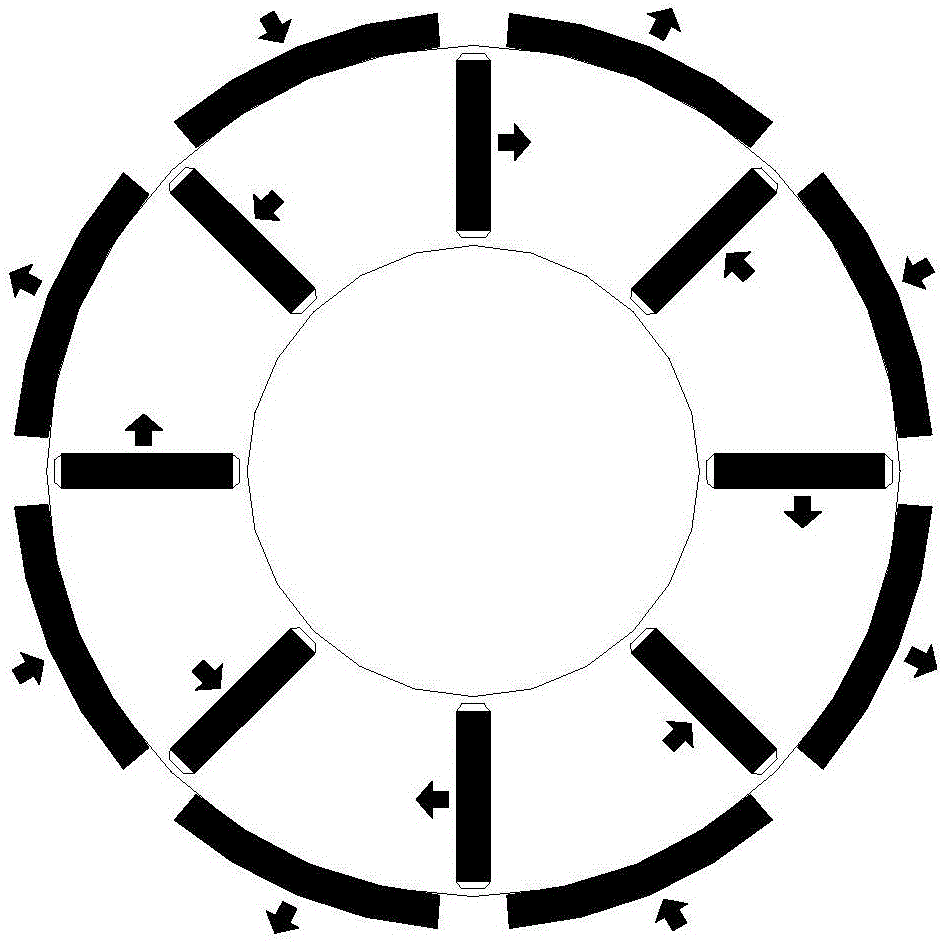

InactiveCN112803620AFully utilize the magnetic energyTake advantage ofMagnetic circuit stationary partsPropulsion systemsMagnetic effectElectric machine

The invention discloses a magnetic gathering type non-magnetic track linear motor. The main structure of the magnetic gathering type non-magnetic track linear motor comprises a rotor and a stator. The motor is mainly characterized in that a plurality of permanent magnets in an iron core of the rotor are mounted in a specifically designed mounting mode and magnetizing directions, and the rotor and the stator are assembled at specific relative positions, so that the magnetic gathering effect of the plurality of permanent magnets is remarkable, a relatively high permanent magnetic field utilization rate and a relatively small magnetic leakage coefficient are obtained, and the thrust density is obviously increased. The magnetism gathering type non-magnetic-track linear motor has the advantages of being high in thrust density, small in thrust fluctuation, low in cost, easy to machine and assemble, reliable in operation, easy to expand multiple modules and the like.

Owner:SUZHOU SEIDAL INTELLIGENT TECH CO LTD

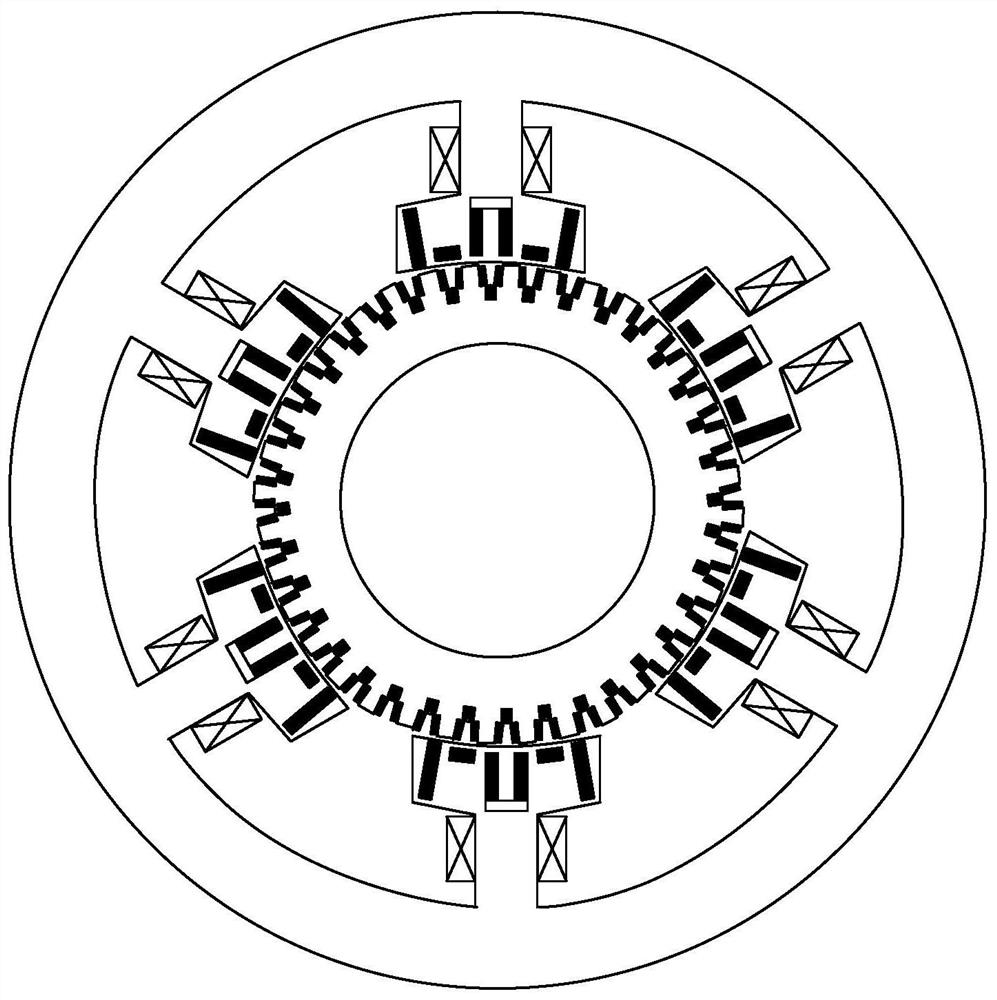

Magnetism gathering type direct-driven permanent magnet motor

ActiveCN113054762AFully utilize the magnetic energyTake advantage ofMagnetic circuit stationary partsPropulsion systemsMagnetic effectElectric machine

Owner:SUZHOU SEIDAL INTELLIGENT TECH CO LTD

Motor blank

InactiveCN106026466AReduce noiseImprove efficiencyMagnetic circuit rotating partsElectric machineEngineering

The invention belongs to the technical field of motors, and particularly relates to a new permanent magnet variable frequency motor rotor blank structure. According to the adopted technical scheme, the motor blank comprises a blank body; at least one magnetic steel hole group is arranged in the blank body; each magnetic steel hole group is composed of two V-shaped holes; and a magnetic line guide hole is arranged between each magnetic steel hole group and the edge of the blank body. After the magnetic steel is mounted, the direction of the magnetic line can be guided through the magnetic line guide hole, the magnetic flux leakage coefficient is reduced, and the motor efficiency is improved. Meanwhile, the magnetic line guide hole can reduce noise generated when the motor operates.

Owner:青岛海联金汇电机有限公司

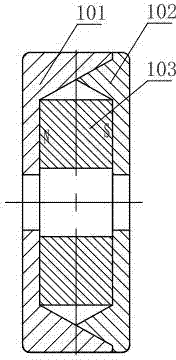

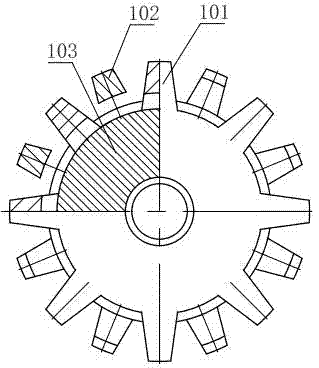

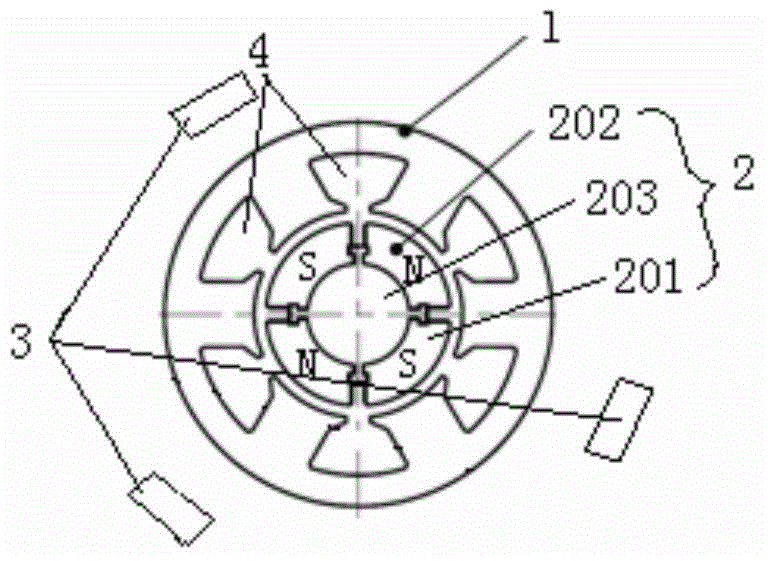

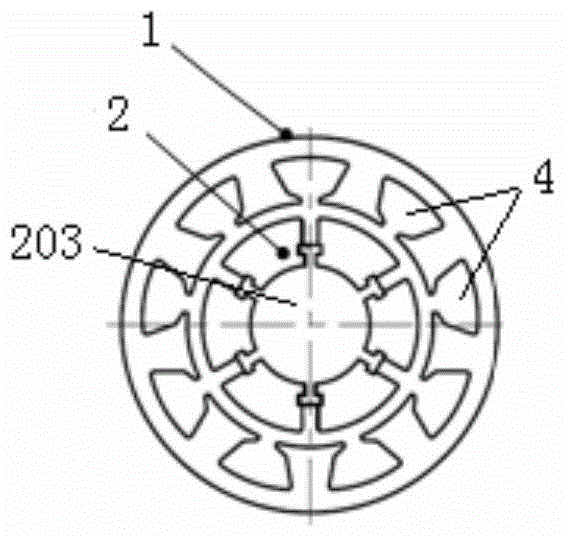

Steering engine and multi-pole-pair permanent magnetic direct-current brushless motor for same

InactiveCN104795954AHigh precisionIncreased torque densitySynchronous machine detailsMagnetic circuit rotating partsBrushless motorsElectric machine

The invention discloses a steering engine and a multi-pole-pair permanent magnetic direct-current brushless motor for the same. The multi-pole-pair permanent magnetic direct-current brushless motor comprises a stator fixed in a motor shell, a rotor arranged in the stator and sensors arranged along the periphery of the rotor and used for sensing magnetic pole changes in the rotation process of the rotor so as to send out signals. The rotor comprises multiple tile type permanent magnets used for increasing magnetic flux density of the steering engine so as to improve steering engine rotation control accuracy; the tile type permanent magnets are arranged equidistantly along the periphery of the rotor and fixedly connected to a rotor core of the rotor, the tile type permanent magnets identical in appearance are south-pole permanent magnets or north-pole permanent magnets, one permanent magnets and one north-pole permanent magnet form a pair of magnetic poles, and the rotor comprise at least two pairs of magnetic poles. The tile type permanent magnets can be magnetized at one time along the periphery of the rotor after being assembled and can be magnetized separately prior to being assembled, the assembly process is simple, magnetic leakage factors are small, gap flux density is high, and utilization rate of the permanent magnets is higher.

Owner:CHANGSHA METRIC ELECTRIC TECH CO LTD

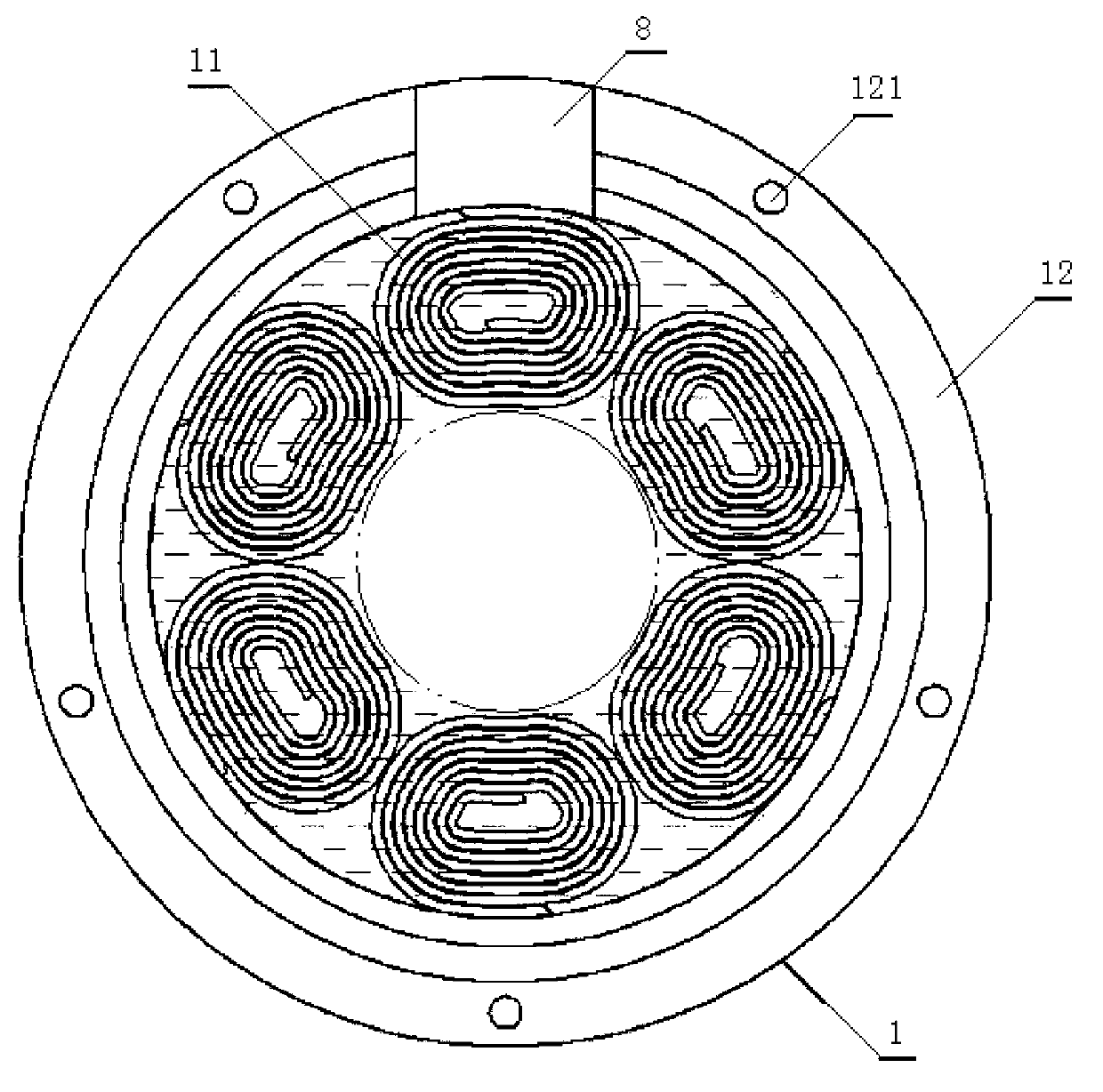

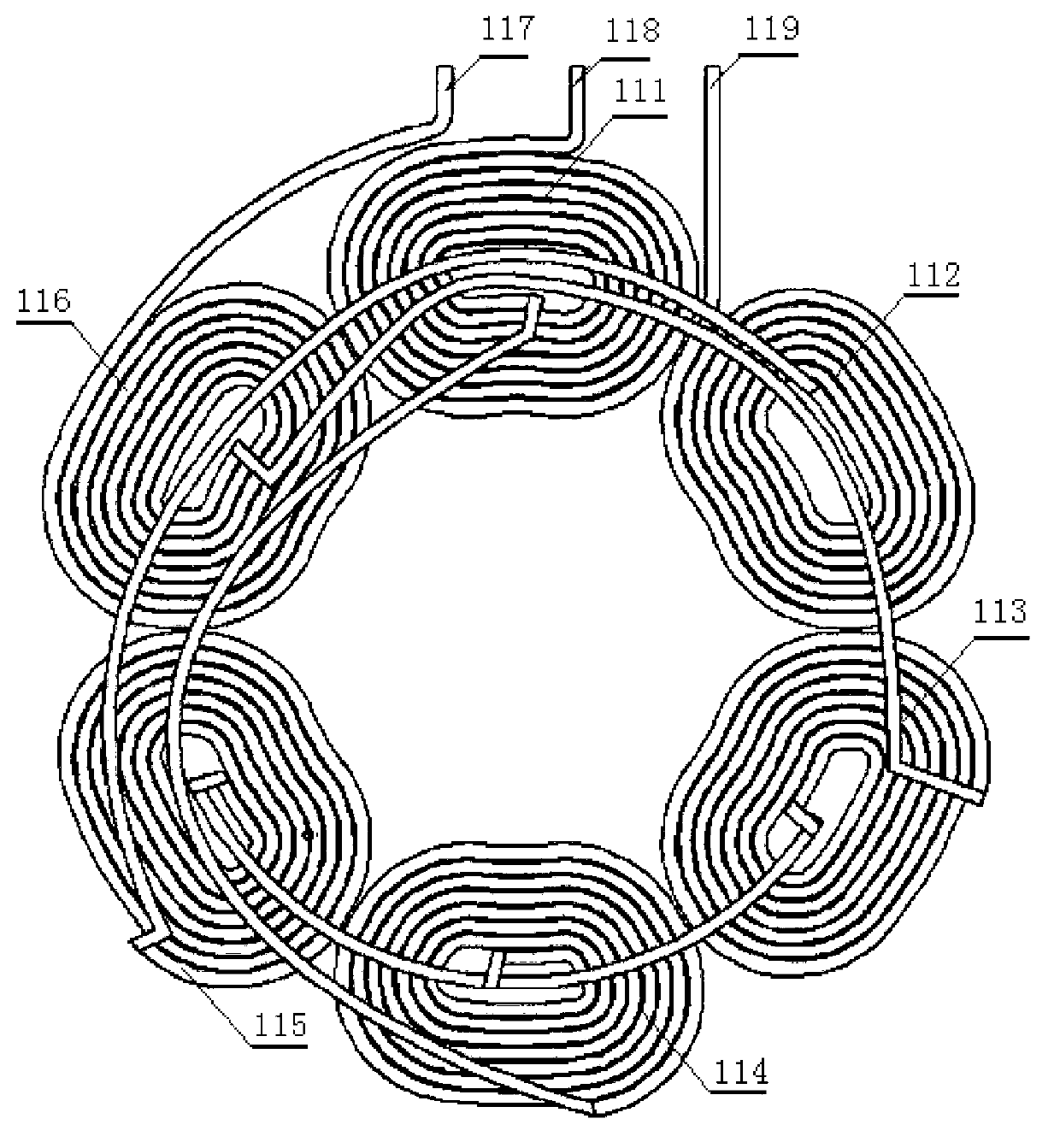

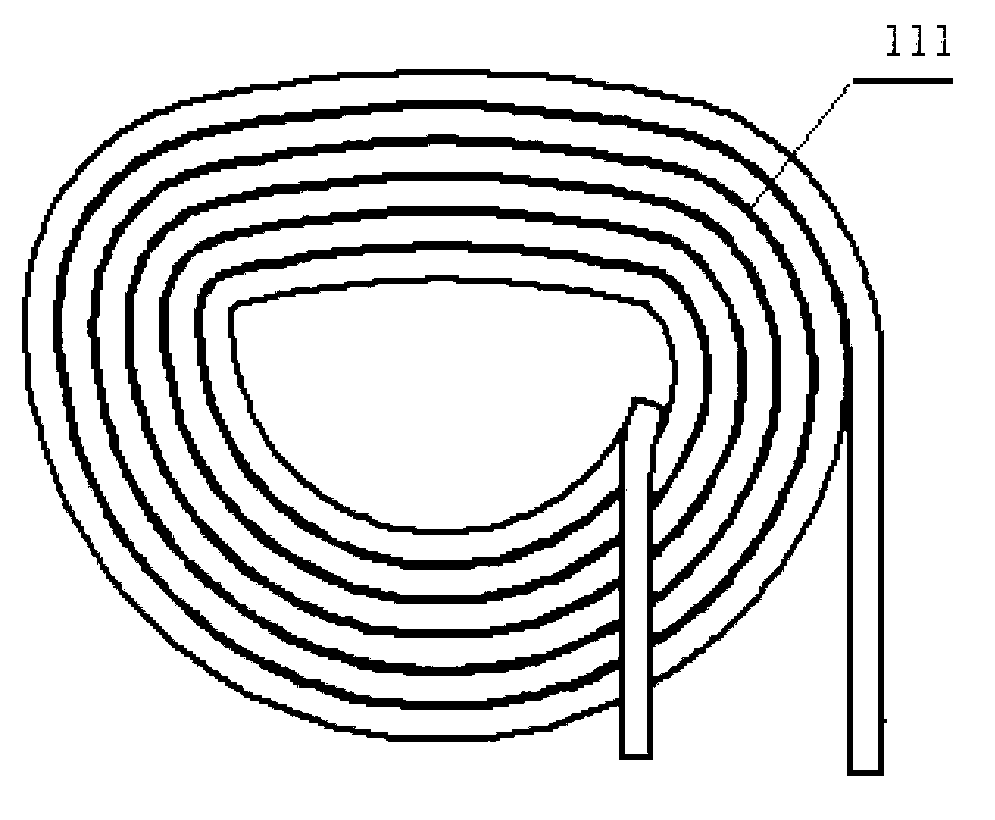

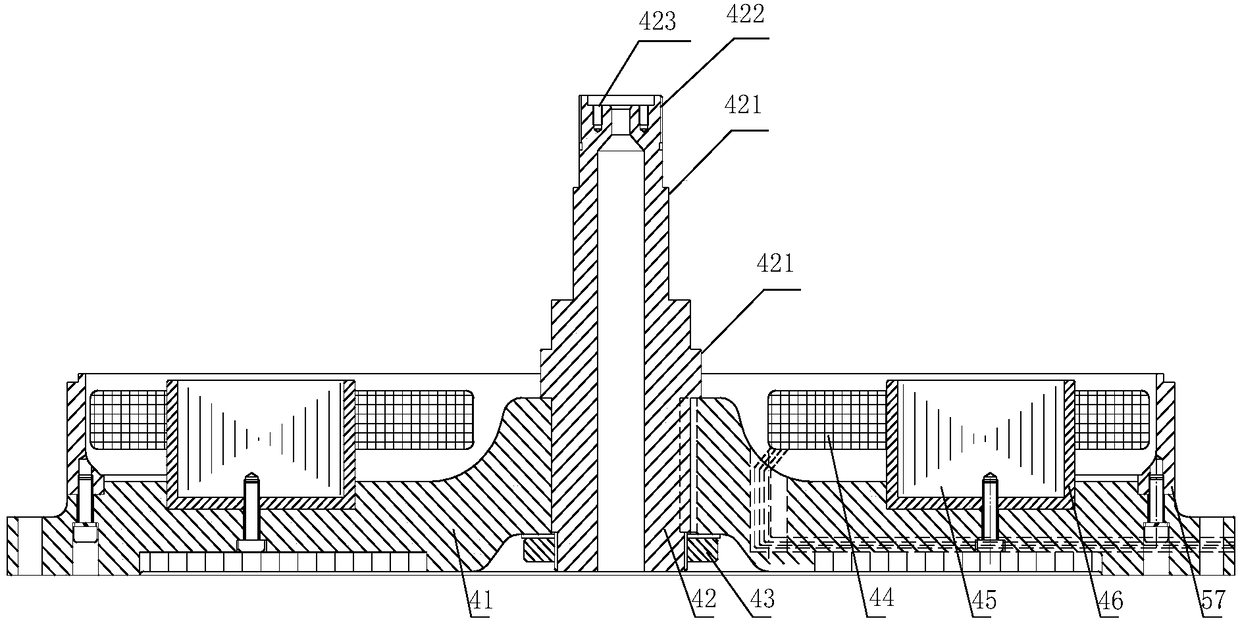

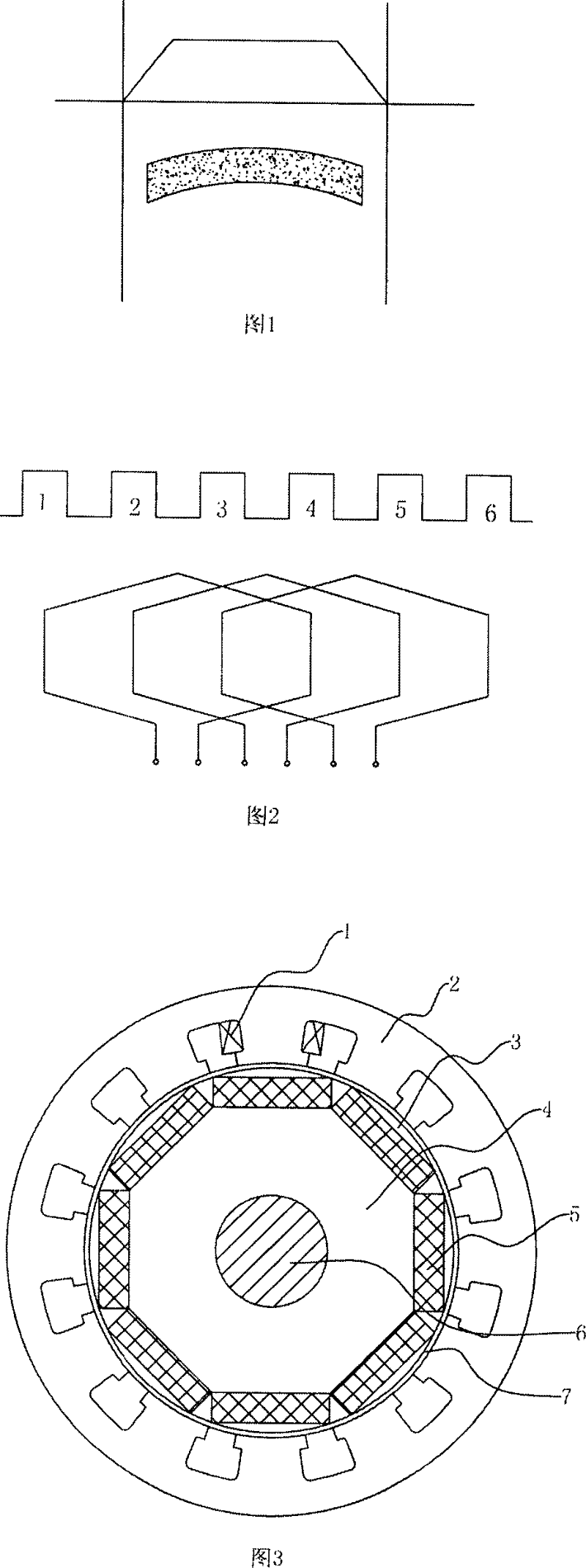

Armature plate and synchronous motor suitable for plate type coreless permanent magnet synchronous motor

InactiveCN103107664AReduce weightReduce speedSynchronous machine detailsSynchronous machines with stationary armatures and rotating magnetsLeft halfSynchronous motor

The invention relates to an armature plate and a synchronous motor suitable for a plate type coreless permanent magnet synchronous motor. The armature plate is provided with an armature. The armature is provided with an armature body and a coil winding. The coil winding is installed in an inner round of the armature body. The coil winding is composed of multiple winding coils. Each winding coil is formed by winding enamel covered sheet wires in a single row mode. The multiple winding coils are wound and arranged to be a round structure in a single layer mode without overlapping. The winding coils and the armature plate body are pressed and then form an annular body with a hole at the center. The armature of the synchronous motor is clamped between a left half shell body and a right half shell body which are installed oppositely. With the armature plate and the synchronous motor suitable for the plate type coreless permanent magnet synchronous motor, the tough situation that when an exiting plate type coreless permanent magnet synchronous motor is manufactured, multiple rows and multiple layers of windings are required is avoided. The armature plate and the synchronous motor suitable for the plate type coreless permanent magnet synchronous motor have the advantages of being simple in winding manner and manufacture technology, high in production efficiency and low in rejection rate. Meanwhile, the motor with the armature plates is light in weight and stable in rotation speed and yield is improved.

Owner:常州市吉士电器有限公司

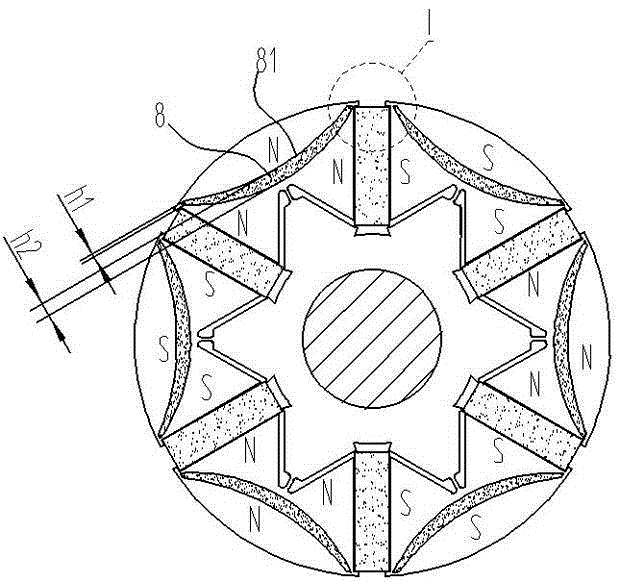

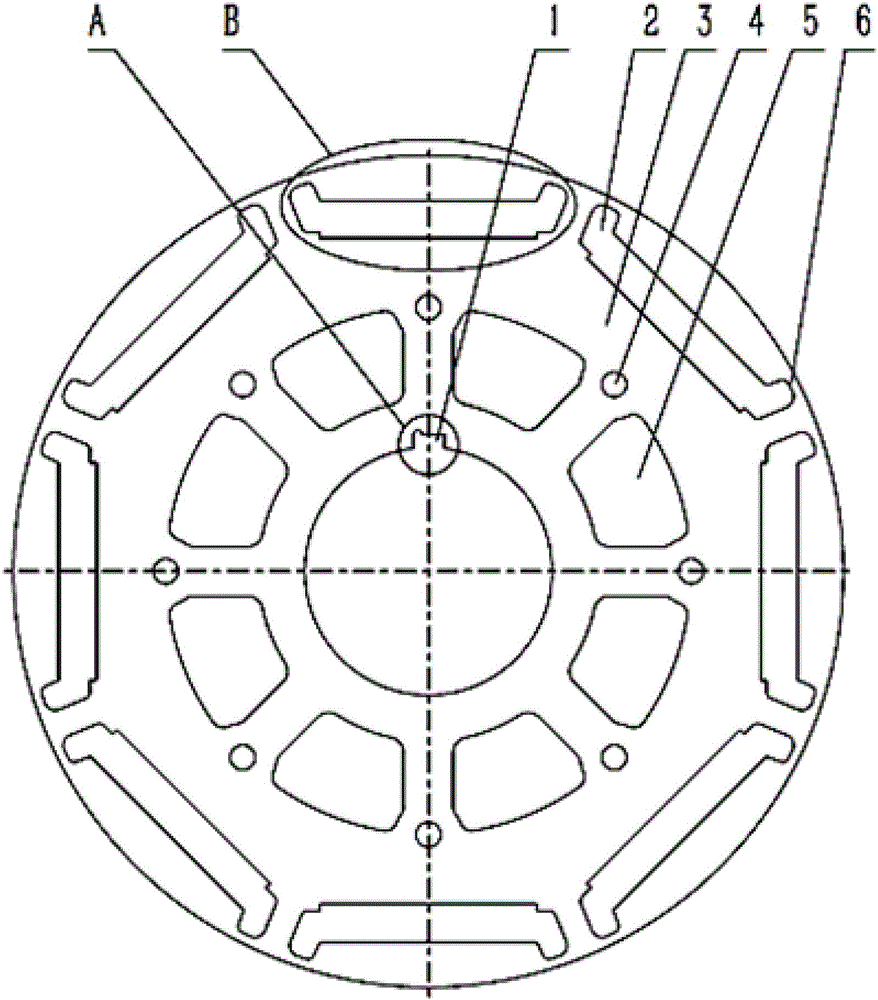

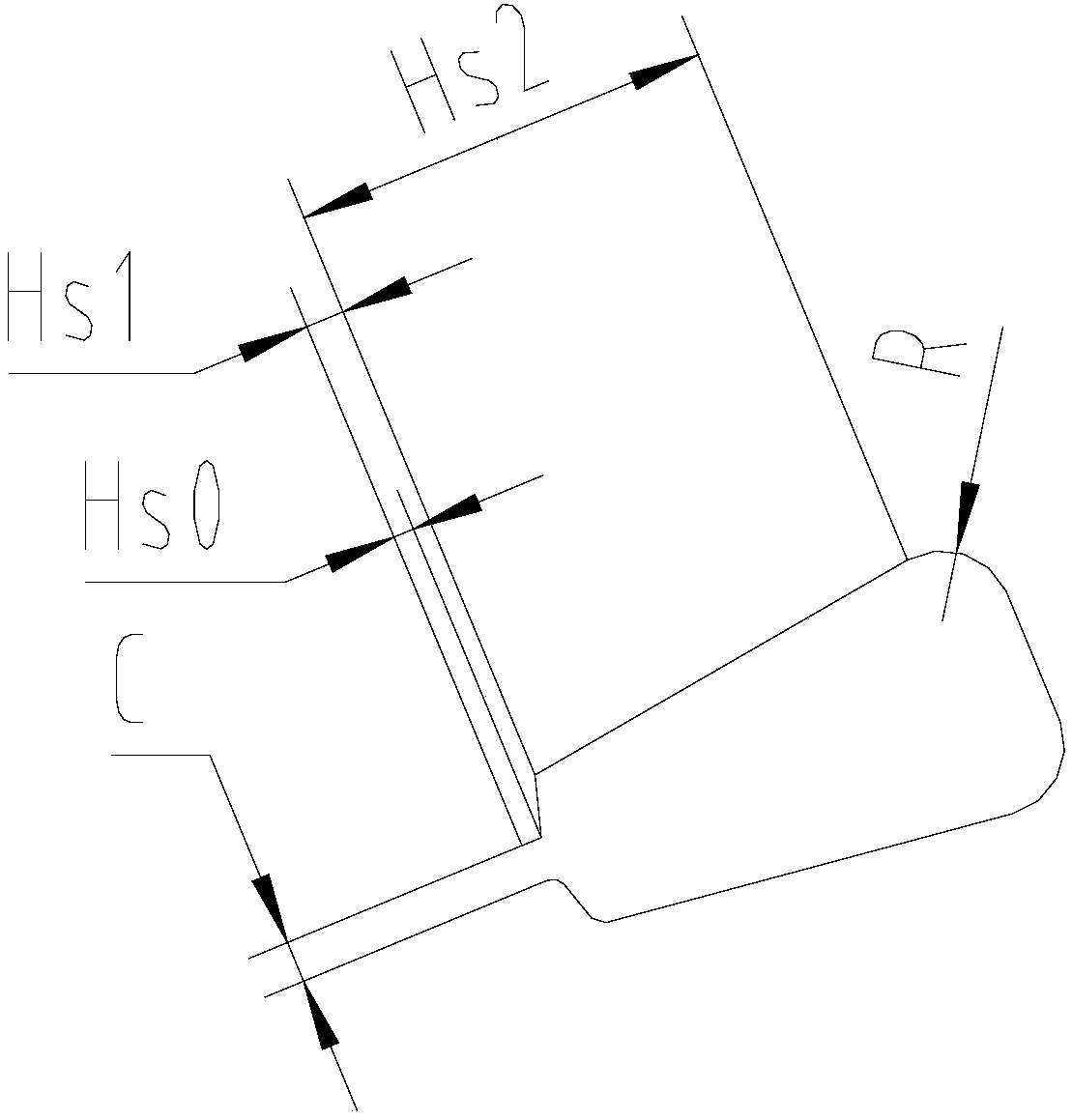

Double V-type permanent magnet hub motor magnetic circuit structure

InactiveCN109831080AFlux leakage coefficient is smallPolar arc coefficient is easy to controlMagnetic circuit rotating partsMagnetic circuit stationary partsPhysicsMagnetic flux

The invention discloses a double V-type permanent magnet hub motor magnetic circuit structure and relates to the technical field of motor structure. The double V-type permanent magnet hub motor magnetic circuit structure comprises a stator, a rotor, a rotor shaft, a permanent magnet, a magnetic isolation bridge, a winding slot and a ventilation hole. The permanent magnet hub motor has good runningcharacteristics. The rotor is an embedded radial rotor and has a low magnetic flux leakage coefficient. No magnetic isolation measures are required on a rotating shaft. A pole-arc coefficient is easyto control. Rotor punching pieces have high mechanical strength. The ventilation hole reduces the magnetic flux at the alignment position. The magnetic circuit structure has low noise performance, reduces the core loss of the rotor, and enhances a heat dissipation effect.

Owner:HARBIN UNIV OF SCI & TECH

Punching sheet, rotor, motor and air conditioning system

InactiveCN109510349APlay the role of magnetic isolationReduce eddy currentMagnetic circuit rotating partsSynchronous machine detailsPunchingEddy current

The invention provides a punching sheet, a rotor, a motor and an air conditioning system. The punching sheet comprises a body, wherein the body has a plurality of magnetic isolation grooves and a plurality of magnetic steel grooves, two kinds of magnetic steel of different magnetic properties are correspondingly arranged in the plurality of magnetic steel grooves, at least one magnetic isolation groove is arranged between the magnetic steel grooves corresponding to the two kinds of magnetic steel of different magnetic properties, and at least part of each magnetic isolation groove is communicated to the edge of the punching sheet so as to form an open groove. The punching sheet, the rotor, the motor and the air conditioning system solve the problem of high eddy current on the surface of the rotor in the prior art.

Owner:GREE ELECTRIC APPLIANCES INC +1

Permanent magnet speed regulation automobile driving electric motor

InactiveCN106130224AFlux leakage coefficient is smallImprove efficiencyMagnetic circuit rotating partsStructural associationCar drivingElectromagnetic noise

The invention provides a permanent magnet speed regulation automobile driving electric motor which is provided with a rotating shaft, a rotor iron core, a rotor magnetic steel member, a wire coil, a stator iron core and a casing that are all order arranged from an inner layer to an outer layer; the rotor iron core consists of a plurality of overlapping rotor punching sheets, the rotor punching sheets comprise rotor punching sheet bodies and magnetic steel grooves arranged on the rotor punching sheet bodies; each magnetic steel groove comprises a central groove, a magnetic steel spigot groove, a first extending wing groove and a second extending wing groove that are all communicated with each other. On one hand, in the permanent magnet speed regulation automobile driving electric motor, a magnetic flux leakage coefficient can be effectively reduced via the rotor punching sheets, magnetic steel demagnetization risk can be reduced, great mechanical performance can be realized, electric motor efficiency can be improved, electromagnetic noise can be lowered, a starting current can be reduced, and torque and limit speed of the electric motor can be increased. On the other hand, design of magnetism isolating bridges on the rotating punching sheets can help effectively prevent two ends of the magnetic steel member can be prevented from being magnetically short-circuited.

Owner:南京高传电机制造有限公司

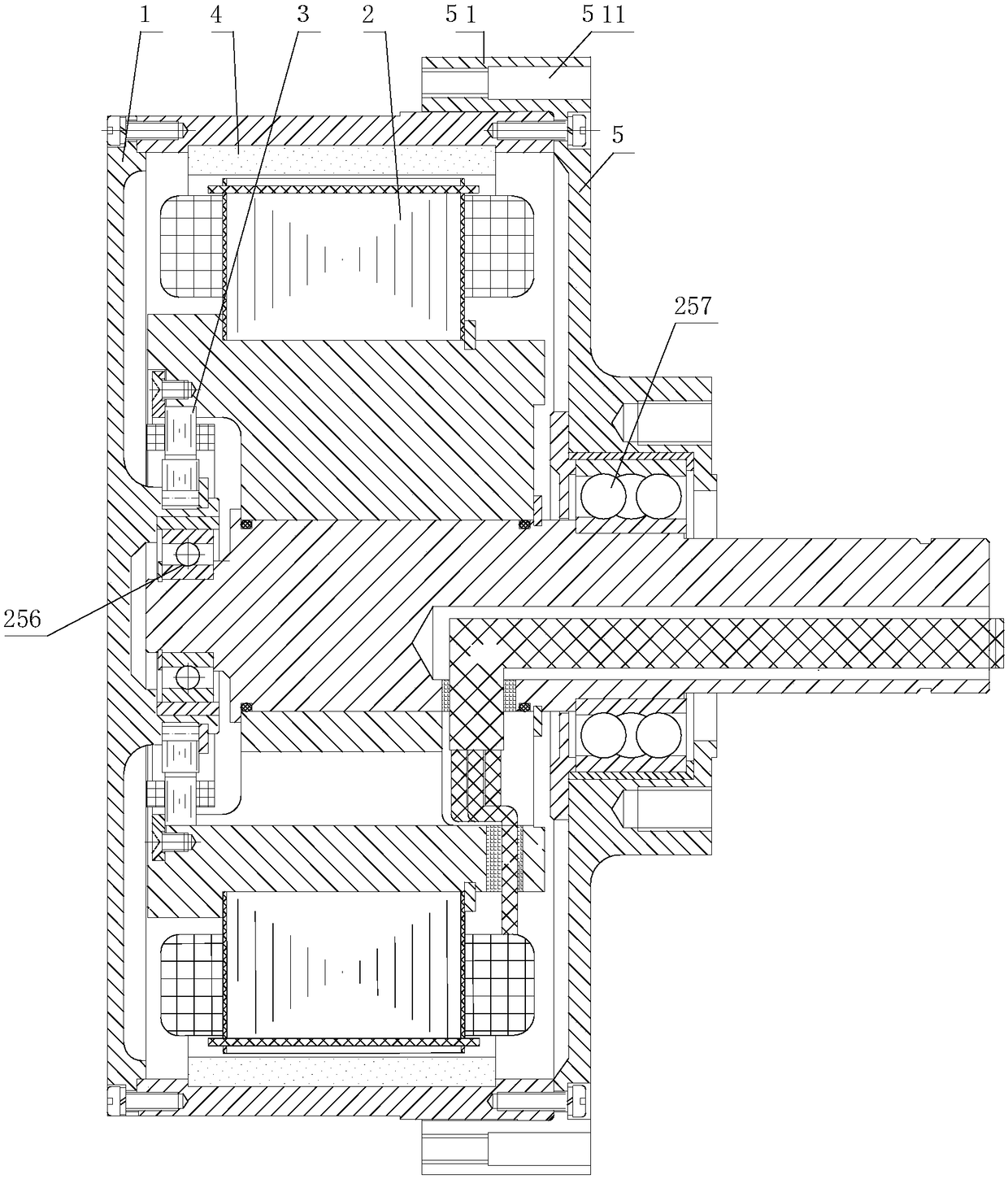

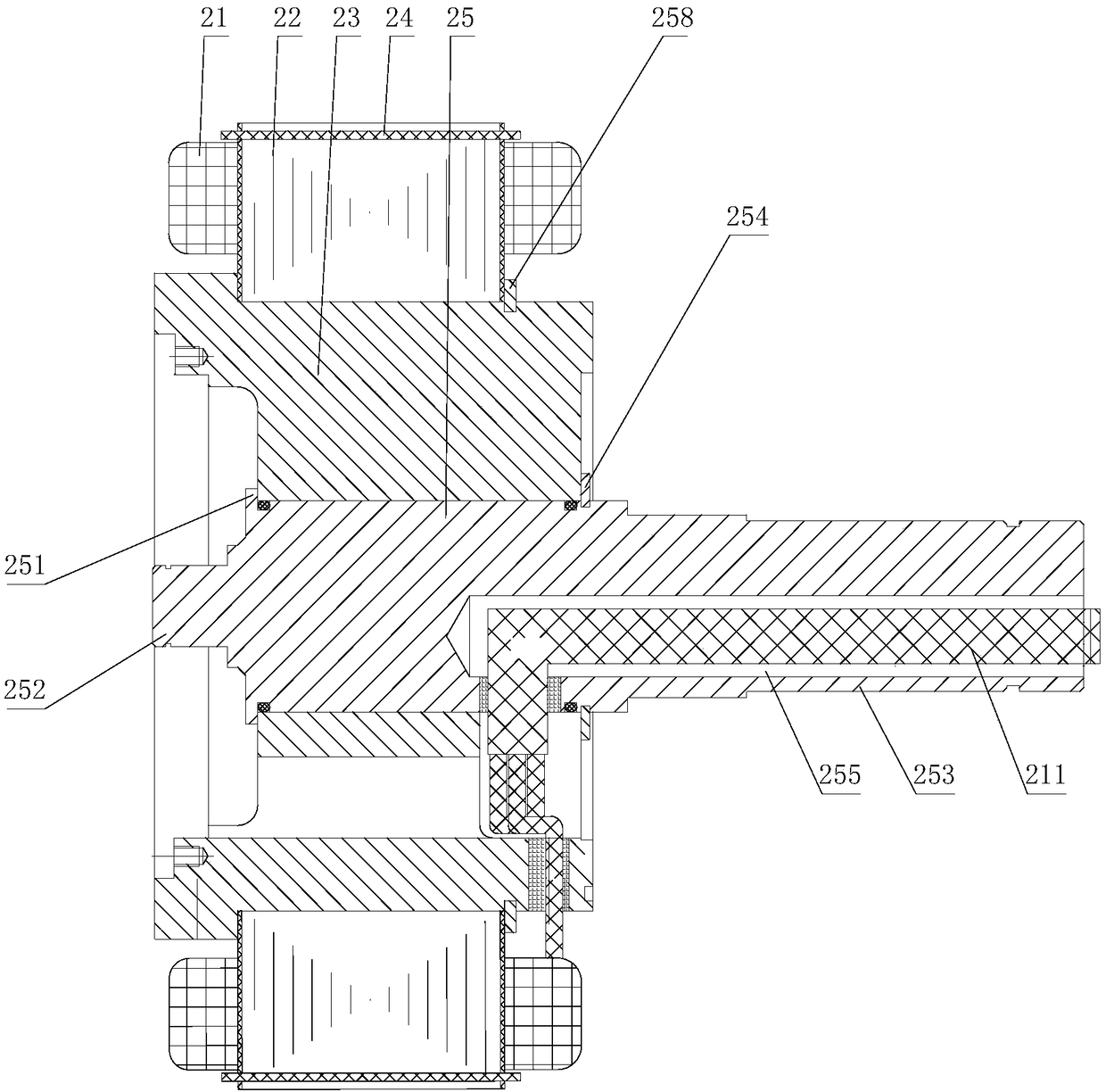

Wheel hub permanent magnet synchronous motor

PendingCN108429422AFast startupGood low speed performanceMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsPermanent magnet rotorPermanent magnet synchronous motor

The invention discloses a wheel hub permanent magnet synchronous motor. The motor comprises a front end cover, a stator, a rotary transformer, a permanent magnet rotor and a rear end cover; the frontend cover and the rear end cover are installed at the two ends of the permanent magnet rotor respectively, one end of the stator is movably connected to the inner side of the front end cover, the other end of the stator protrudes out from a shaft hole of the rear end cover, and the rotary transformer is fixed to the end of the stator; the front end cover, the permanent magnet rotor, the rear end cover and the stator are coaxially installed. The motor has the advantages of high starting speed, good low-speed performance, high overload capacity, stable high-speed running, wide speed regulation range, wide efficient working area and the like.

Owner:包头天工电机有限公司

Built-in radial permanent magnet rotor structure

PendingCN108566003AImproved ability to start asynchronouslyImprove power densityMagnetic circuit rotating partsSynchronous machinesPermanent magnet rotorPunching

The invention provides a built-in radial permanent magnet rotor structure, which comprises a rotation shaft, and a rotor core sleeved on the rotation shaft. The rotor core is an integrated body formedby connecting at least two iron core sections through cage bars and end rings. Each iron core section comprises a hollow rotor section and at least two permanent magnets in opposite poles, wherein the permanent magnets are arranged on the hollow rotor section. The magnetic poles of the permanent magnets of the adjacent two iron core sections are same. The hollow rotor section is formed by superposing a plurality of rotor punching sheets. The cage bars comprise a plurality of cage bars 1 and more than two cage bars 2. The cross section of the cage bar 1 is circular; the cross section of the cage bar 2 comprises a circular portion and a rectangular portion connected with the circular portion. The cage bars 1 are arranged between the circular portions of the adjacent two cage bars 2. The permanent magnets are arranged between the rectangular portions of the adjacent two cage bars 2. The rectangular portion of the cage bar 2 is a magnetic isolation bar, which carries out magnetic isolation on the left and right two permanent magnets, and replaces conventional air gap magnetic isolation, thereby achieving a purpose of carrying out magnetic isolation on the adjacent permanent magnets. The built-in radial permanent magnet rotor structure has the advantages of compact structure, large power density, reliable performance and long service life.

Owner:XIANGYANG HANGLI ELECTROMECHANICAL TECH DEV

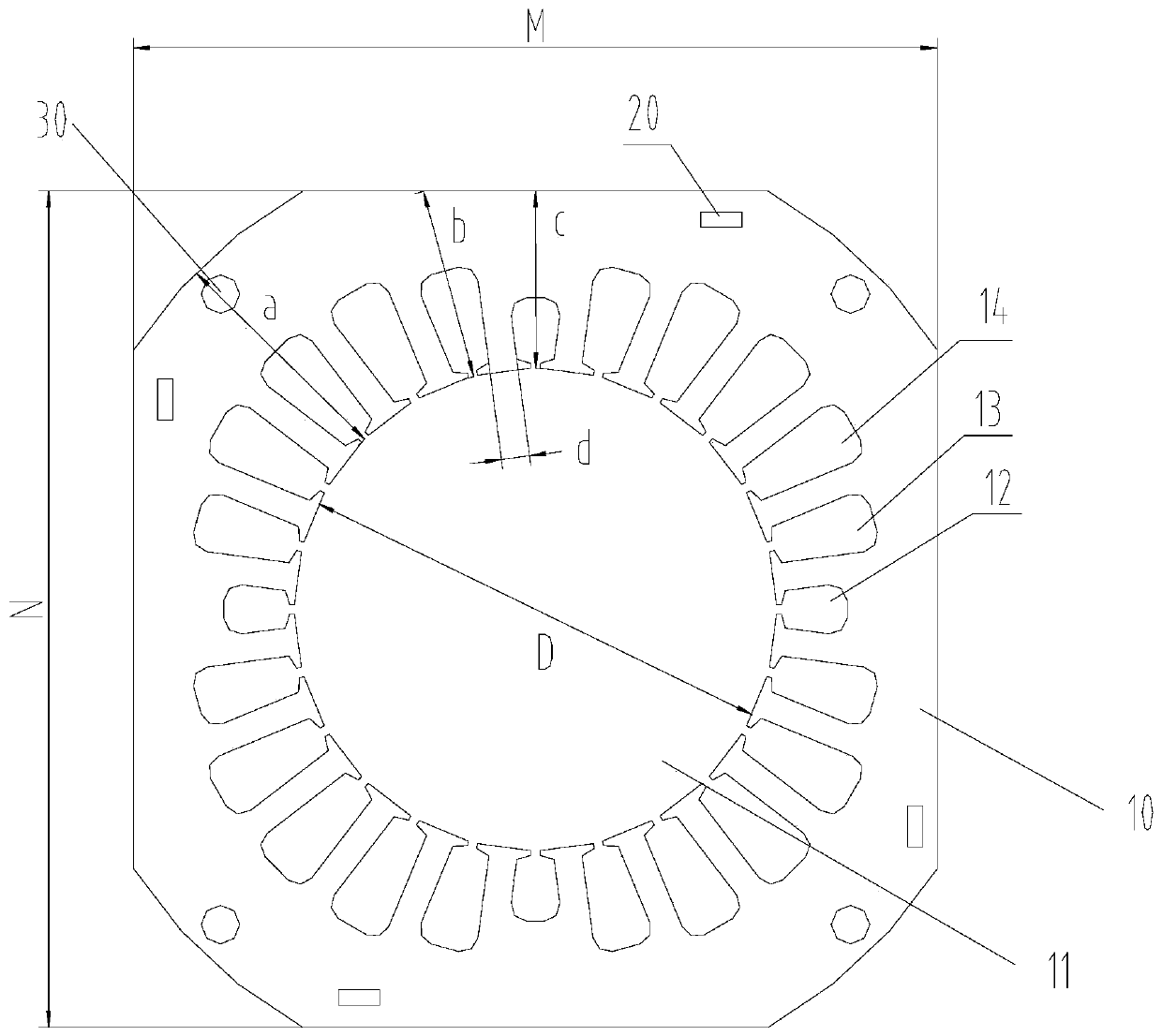

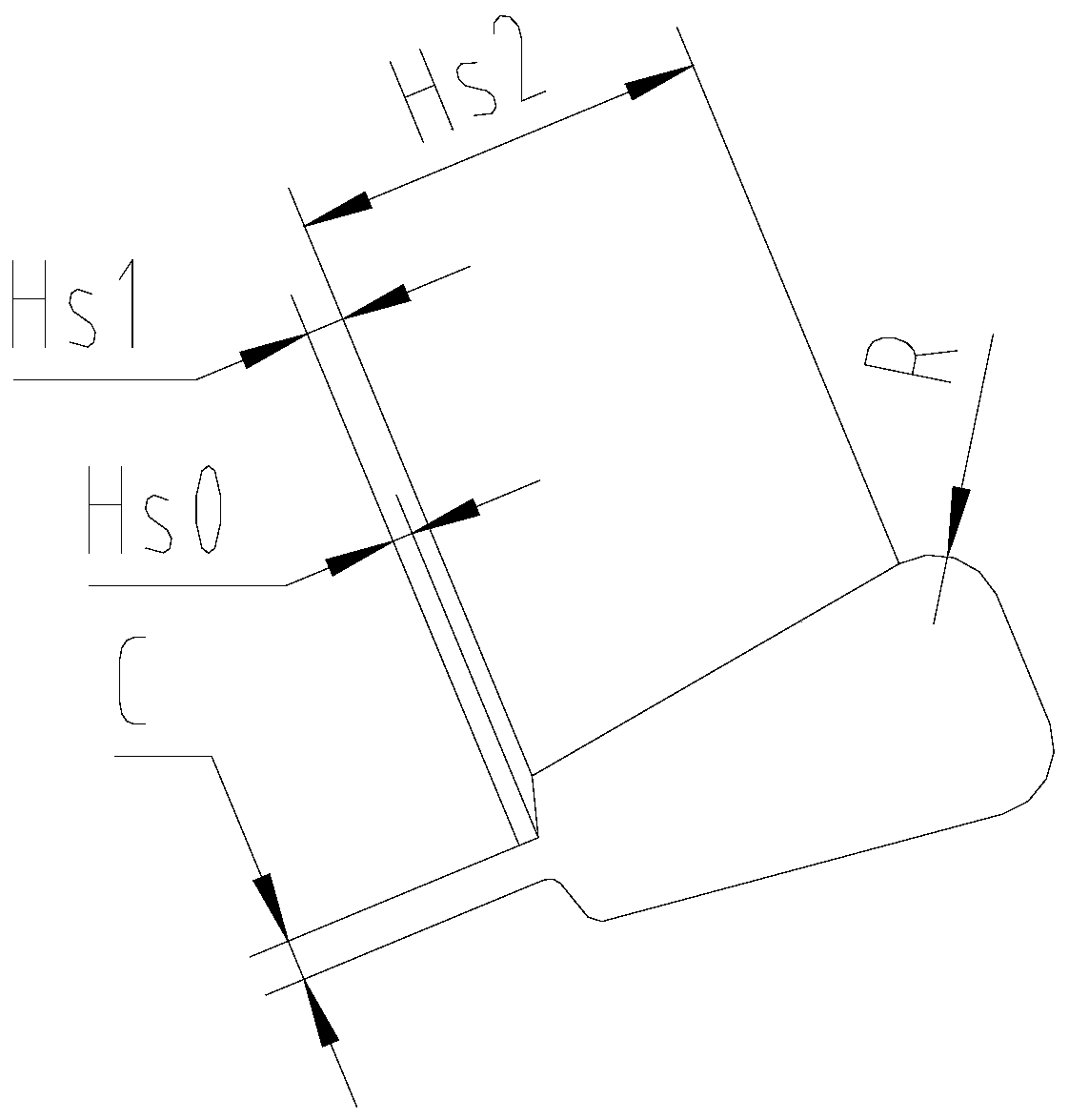

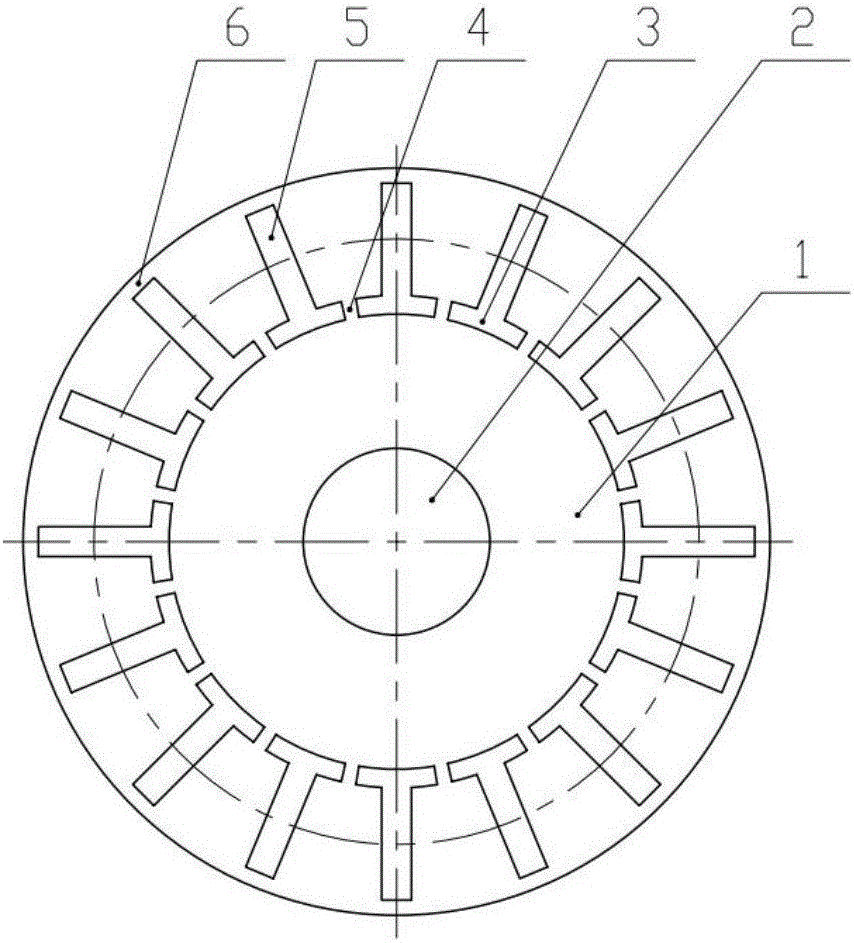

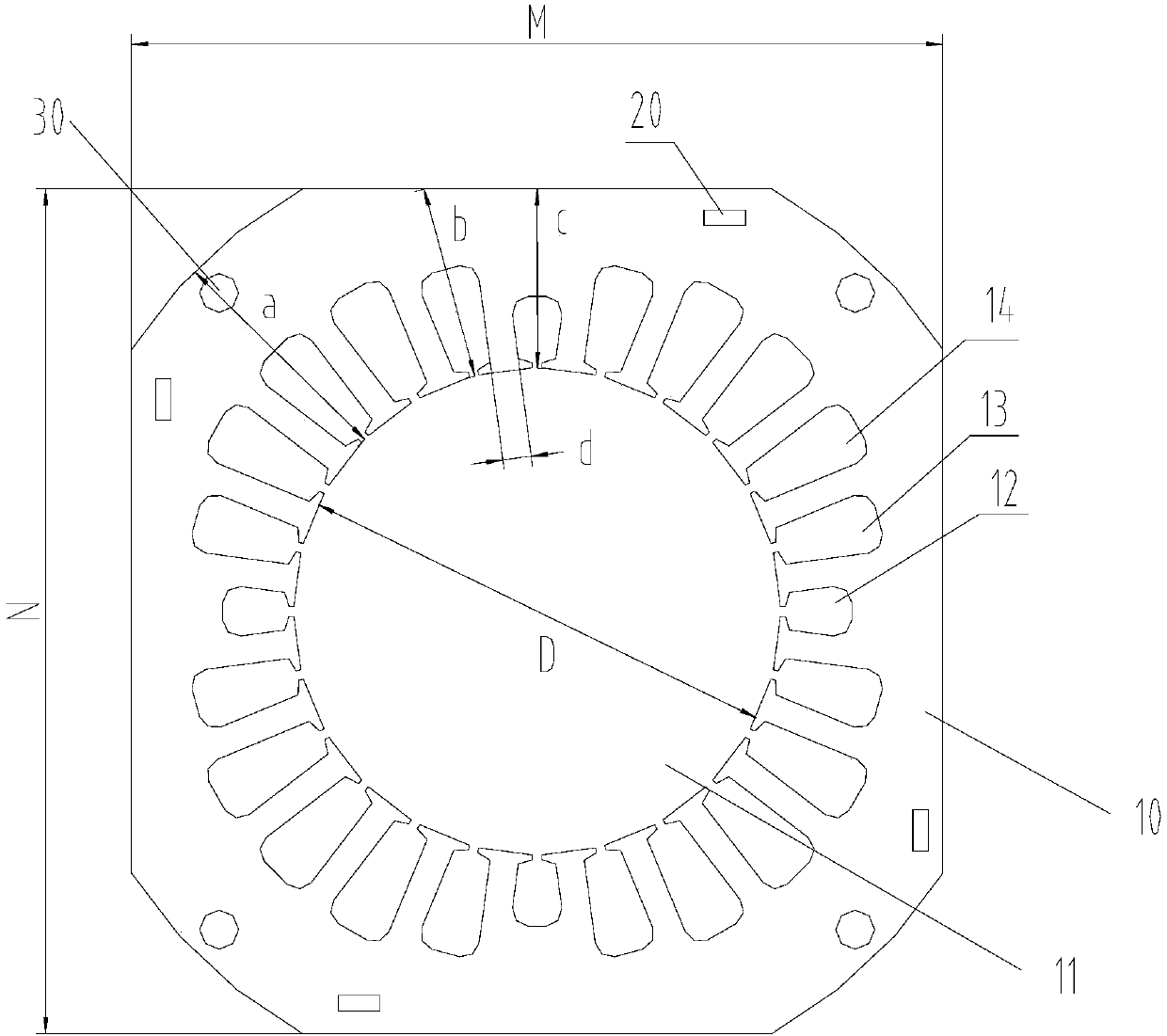

Stator punching, stator and motor

ActiveCN107872107BImprove slot area utilizationFast temperature riseMagnetic circuit stationary partsPunchingElectric machine

The invention provides a stator punching sheet, a stator and a motor. The stator punching sheet comprises a punching sheet body; a central hole is formed in the punching sheet body; small grooves andbig grooves are formed in the punching sheet body in the circumferential direction of the central hole; and the punching sheet body is in symmetrical arrangement by taking the central line of the groove openings of the small grooves as the axis. By virtue of the stator punching sheet, the problem of increasing of the motor cost caused by the stator punching sheet in the prior art is solved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

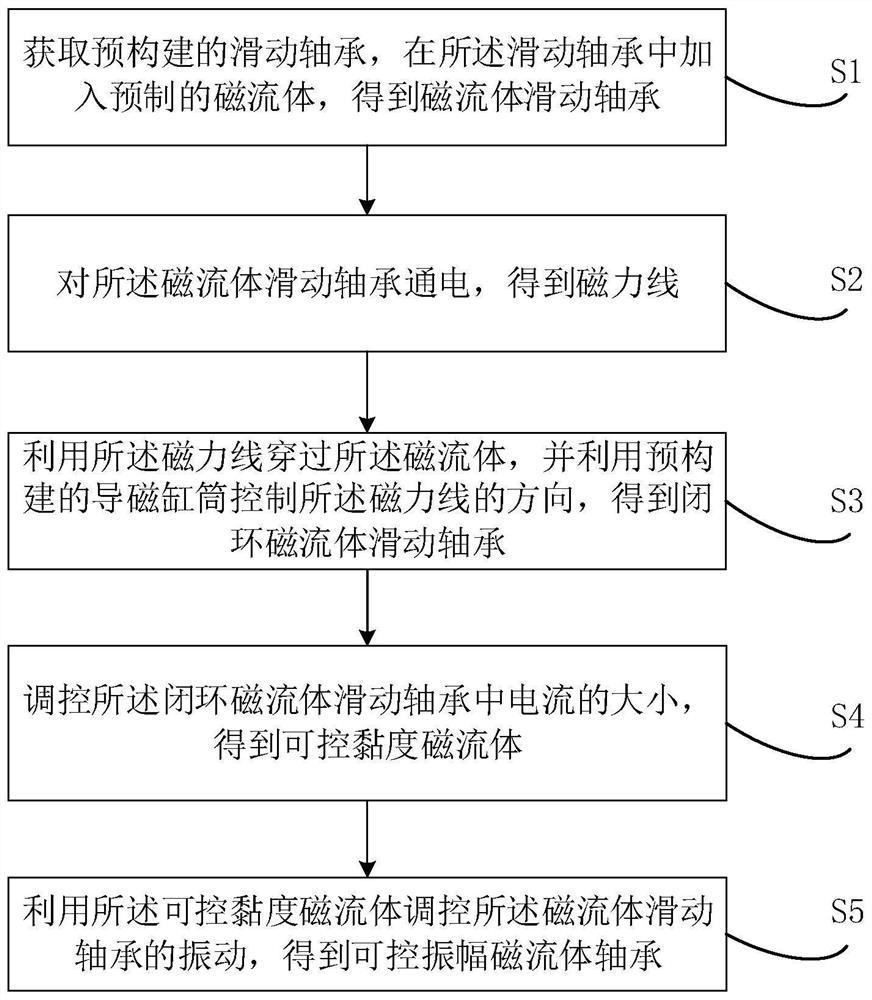

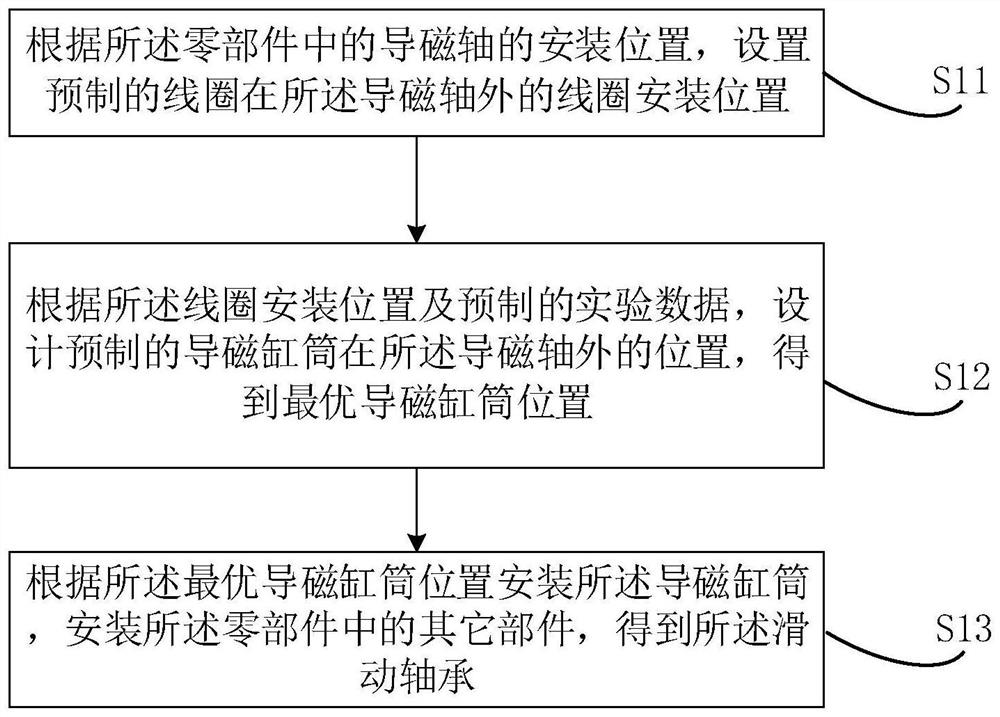

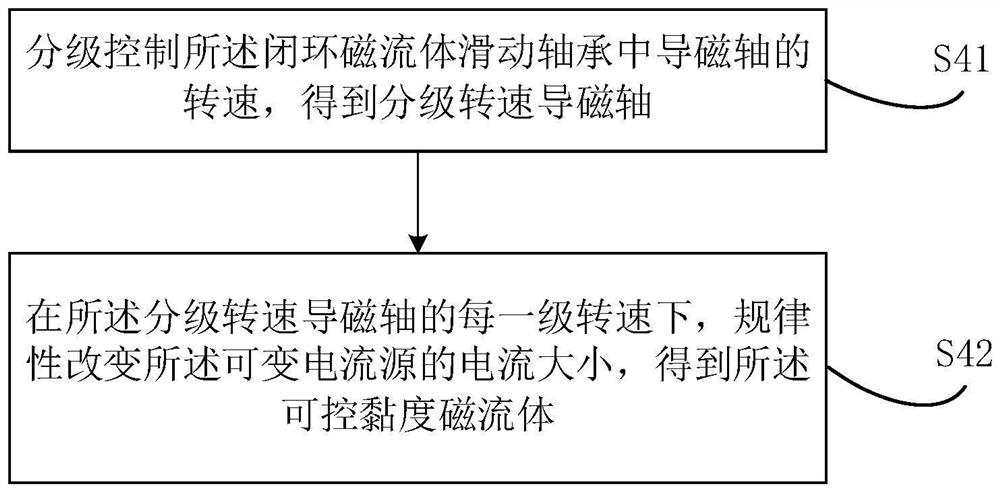

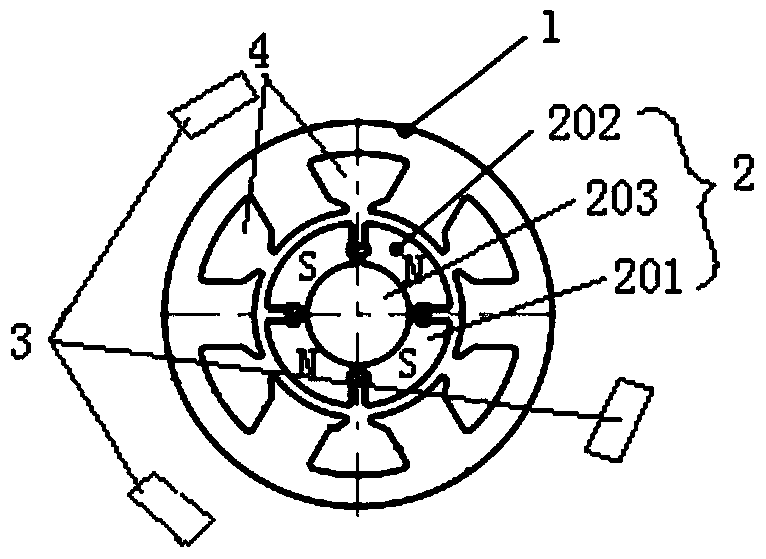

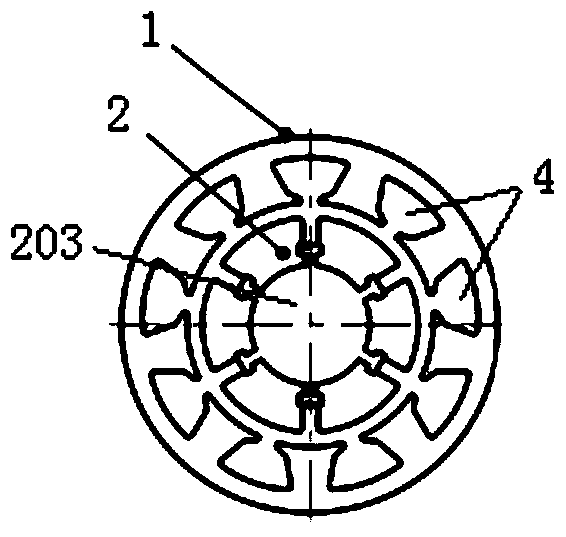

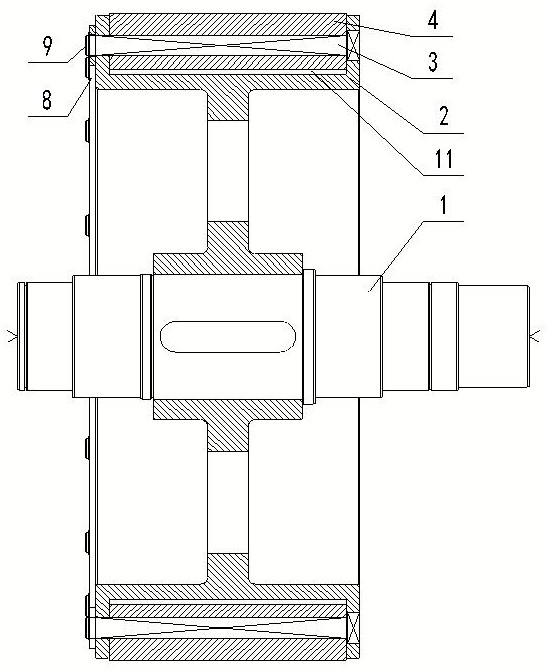

Vibration control method and device of fluid bearing, electronic equipment and medium

PendingCN114462193AResolve amplitudeSolve the noiseGeometric CADDesign optimisation/simulationVibration amplitudeVibration control

The invention relates to the technical field of bearings, and discloses a vibration control method of a fluid bearing, which comprises the following steps: acquiring a pre-constructed sliding bearing, and adding a prefabricated magnetofluid into the sliding bearing to obtain a magnetofluid sliding bearing; electrifying the magnetic fluid sliding bearing to obtain a magnetic line of force; the magnetic lines penetrate through the magnetic fluid, the direction of the magnetic lines is controlled through a pre-constructed magnetic conductive cylinder barrel, and a closed-loop magnetic fluid sliding bearing is obtained; the magnitude of current in the closed-loop magnetofluid sliding bearing is regulated and controlled, and controllable-viscosity magnetofluid is obtained; and regulating and controlling the vibration of the magnetic fluid sliding bearing by using the controllable viscosity magnetic fluid to obtain the controllable amplitude magnetic fluid bearing. The invention further provides a vibration control device of the fluid bearing, electronic equipment and a computer readable storage medium. The problem that the amplitude and noise of the bearing are difficult to control well can be solved.

Owner:TAIZHOU HUANGYAN TONHE PLASTIC IND

Multi-pole permanent magnet brushless DC motor and steering gear for steering gear

InactiveCN104795954BHigh precisionIncreased torque densityMagnetic circuit rotating partsSynchronous machine detailsBrushless motorsElectric machine

The invention discloses a multi-pole permanent magnet DC brushless motor used for steering gear and the steering gear. A multi-pole permanent magnet brushless DC motor for steering gear, including a stator fixed in the motor housing, a rotor set in the stator, and a sensor arranged along the circumference of the rotor and used to sense the pole change during the rotation of the rotor and send out signals The sensor, the rotor includes a plurality of tile-type permanent magnets used to increase the magnetic induction density of the steering gear to improve the rotation control accuracy of the steering gear, and the multi-piece tile-type permanent magnets are arranged equidistantly along the circumference of the rotor and fixed to the rotor of the rotor On the core, the shapes of the tile-type permanent magnets are the same. The tile-type permanent magnets are south pole permanent magnets or north pole permanent magnets. One south pole permanent magnet and one north pole permanent magnet form a pair of magnetic poles, and the rotor contains at least two pairs of magnetic poles. The tile-type permanent magnet can be assembled and then magnetized along the rotor circumference at one time, or it can be magnetized separately and then assembled. The assembly process is simple, the magnetic flux leakage coefficient is small, the air gap magnetic density is high, and the utilization rate of the permanent magnet is higher.

Owner:CHANGSHA METRIC ELECTRIC TECH CO LTD

Screw-free air magnetic isolation rotor

PendingCN111864945AAchieve axial positioningPrevent axial movementSynchronous machine detailsMagnetic circuit rotating partsPermanent magnet synchronous motorMagnetic poles

The invention provides a screw-free air magnetic isolation rotor, and relates to the technical field of permanent magnet synchronous motors. The problems that a conventional rotor is unstable in structure due to a connecting and fixing structure, the rotor magnetic isolation effect is poor, rotor magnetic leakage occurs, and a magnetic isolation bridge has defects are solved. The screw-free air magnetic isolation rotor comprises a rotating shaft, a rotor support, magnetic poles and permanent magnets. The rotor support is fixedly installed on the rotating shaft through a key, the magnetic polesare arranged in the rotor support and assembled into a rotor core, the magnetic poles and the rotor support are inserted and fixed through positioning rods, one end of each positioning rod located outside the rotor support is axially positioned through a check ring, and the other end of each positioning rod is clamped at the rotor support. An air gap used for magnetic isolation is arranged between the magnetic poles and the rotor support, and the gap is larger than an air gap between the stator and the rotor. When the structure is used for positioning and fixing the magnetic poles, no screw connection structure is adopted, the phenomenon that the rotor structure is unstable due to structural looseness and the like is avoided, and the magnetism isolation performance is better due to the adoption of the air magnetism isolation structure.

Owner:山西维达传动科技有限公司

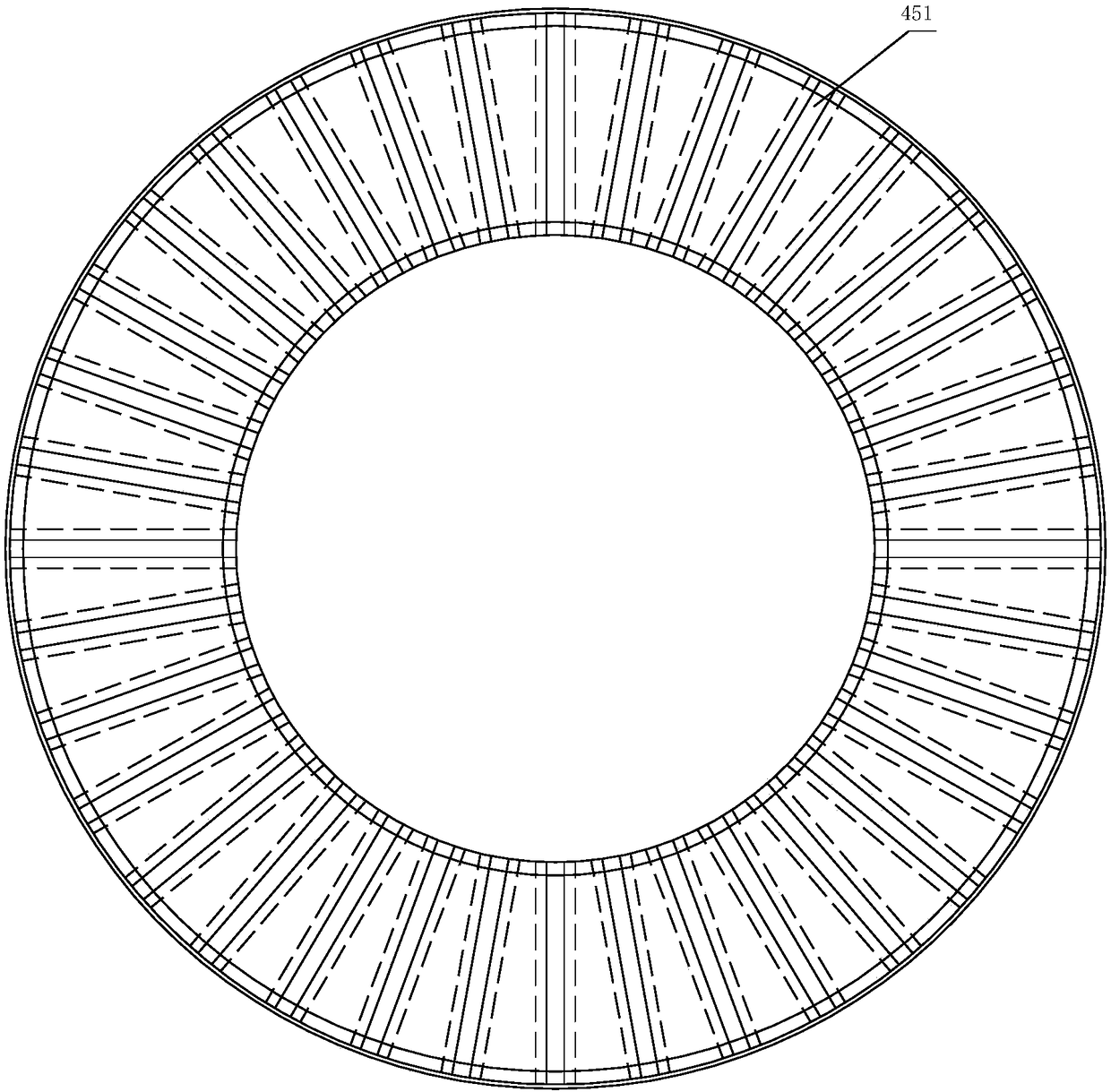

Motor stator core

PendingCN109861411AIncrease magnetic densityImprove power densityMagnetic circuit stationary partsAir gap flux densityMagnetic flux leakage

The invention relates to a motor stator core. The stator core is formed by nesting an annular oriented silicon steel core and an annular non-oriented silicon steel core arranged at the external of theannular oriented silicon steel core; the annular oriented silicon steel core is formed by superposing two kinds of oriented silicon steel sheets, and is provided with oriented grooves; the oriented grooves and the annular non-oriented silicon steel core are fitted with each other to form enclosing grooves; and notch magnetic bridges are arranged between the oriented grooves and the inner side wall of the annular oriented silicon steel core and provided with magnetic bridge through holes, so that magnetic circuits of the notch magnetic bridges can be saturated. During usage, the magnetic bridge through holes can saturate the magnetic circuits of the notch magnetic bridges, so that air-gap flux density can be enhanced, magnetic flux leakage coefficients can be reduced, and motor power density can be increased; and dovetail grooves can effectively reduce notch magnetic flux leakage and air gap flux pulsation, so that the output torque of motors can be enhanced.

Owner:苏州英磁新能源科技有限公司

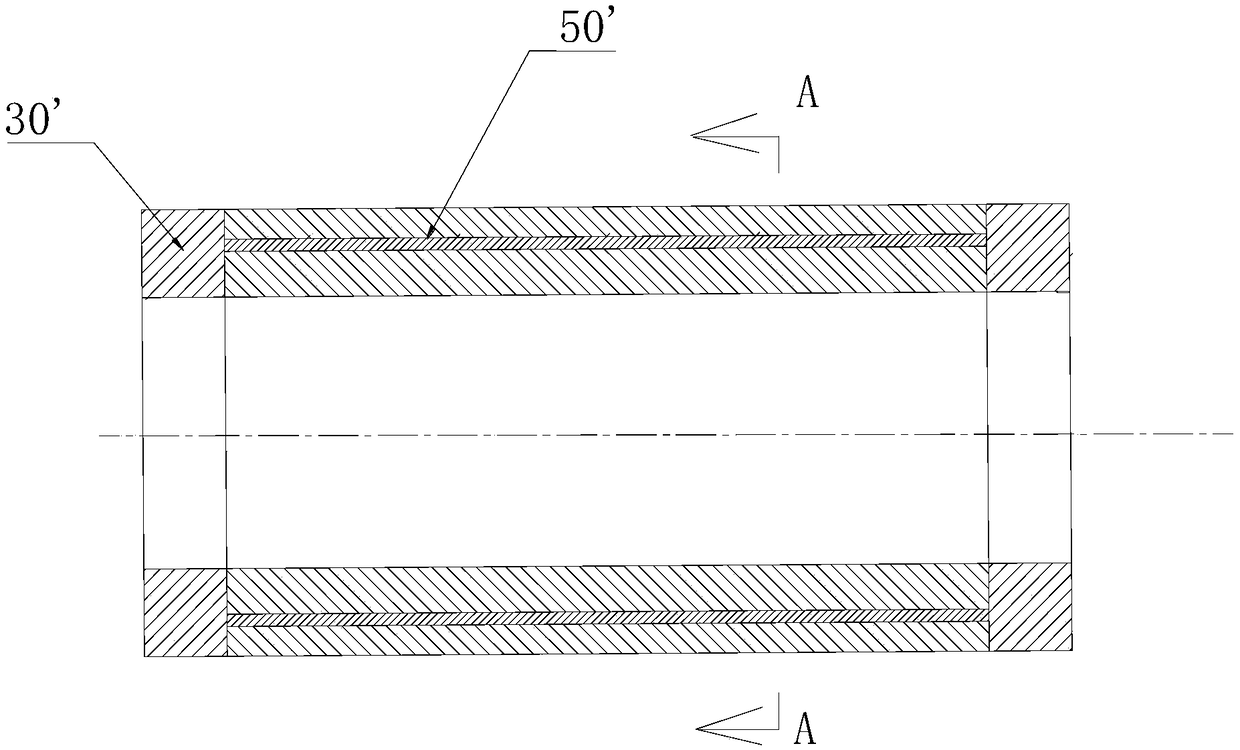

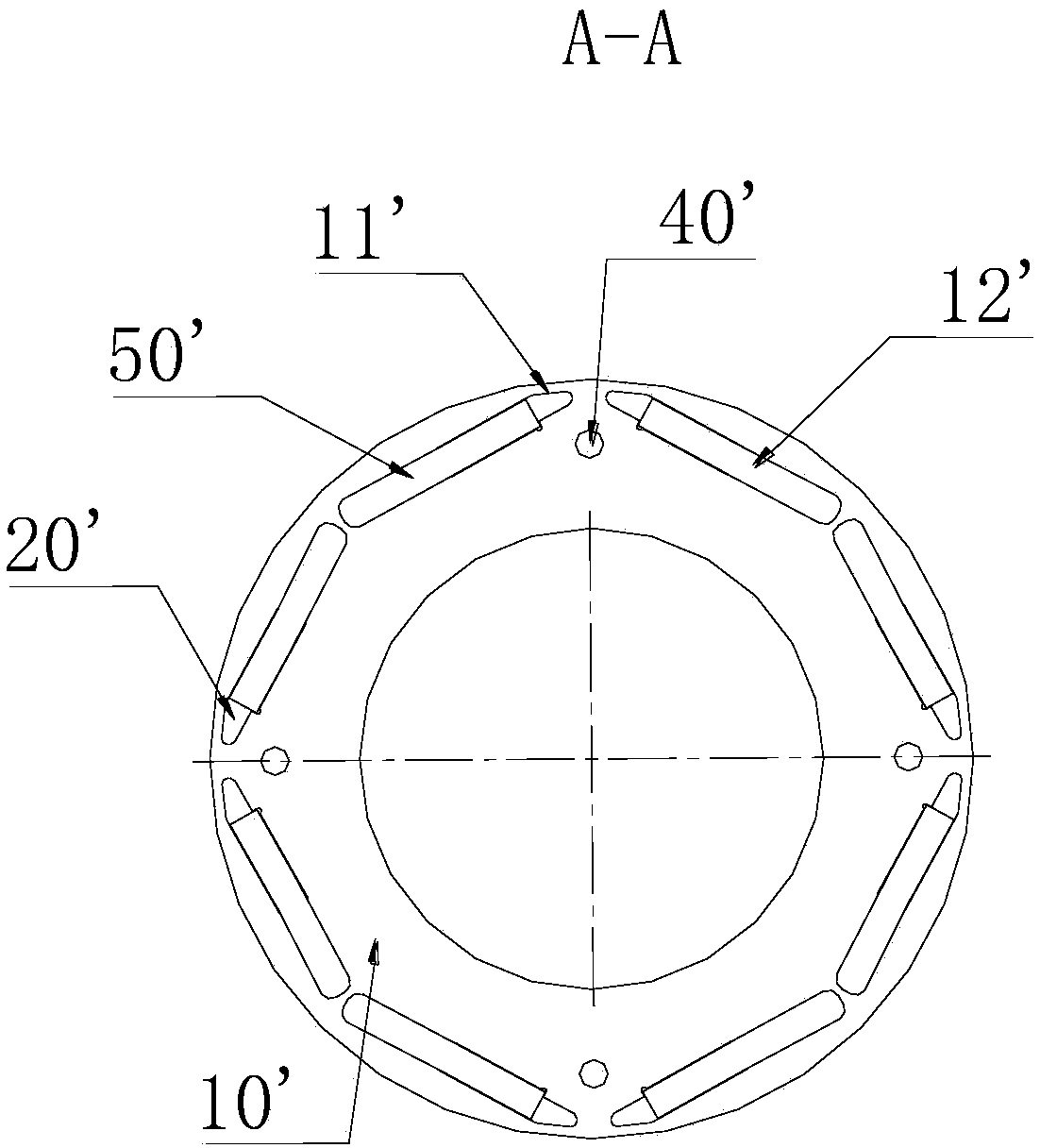

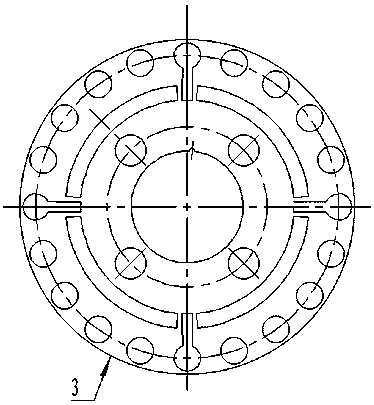

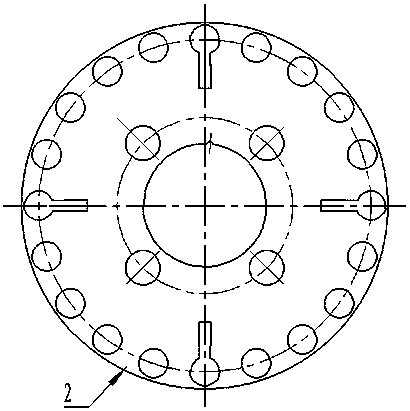

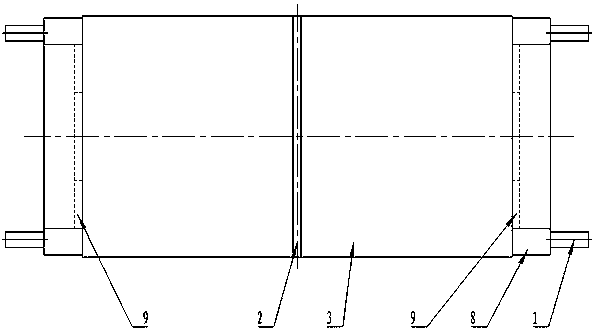

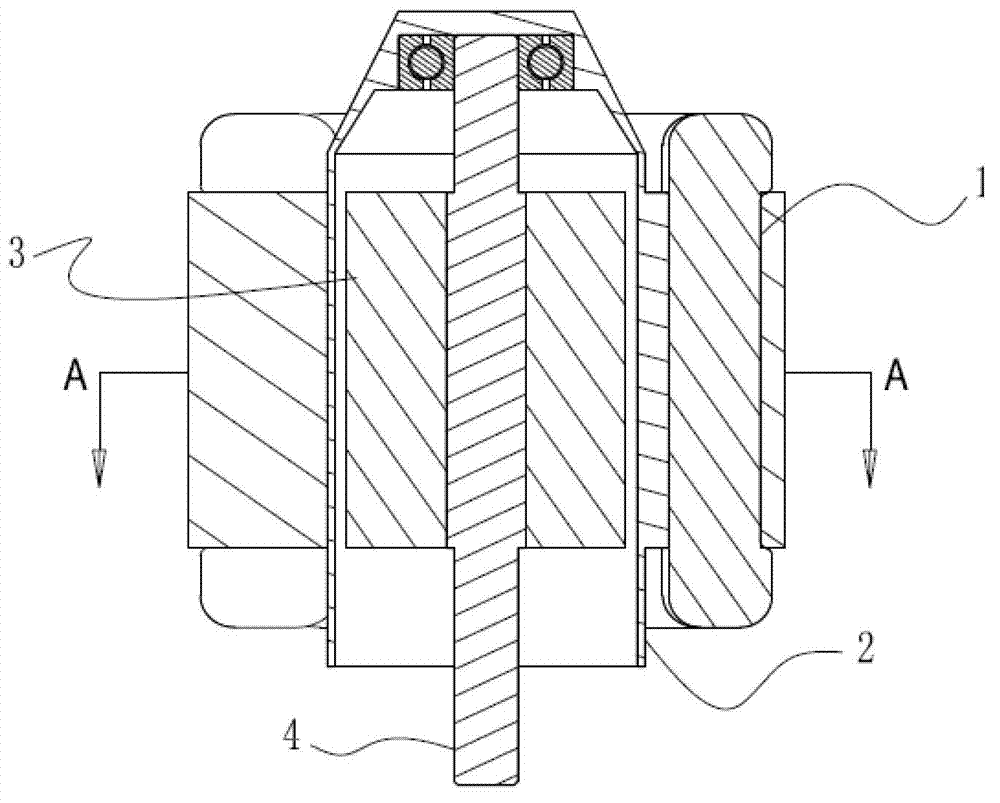

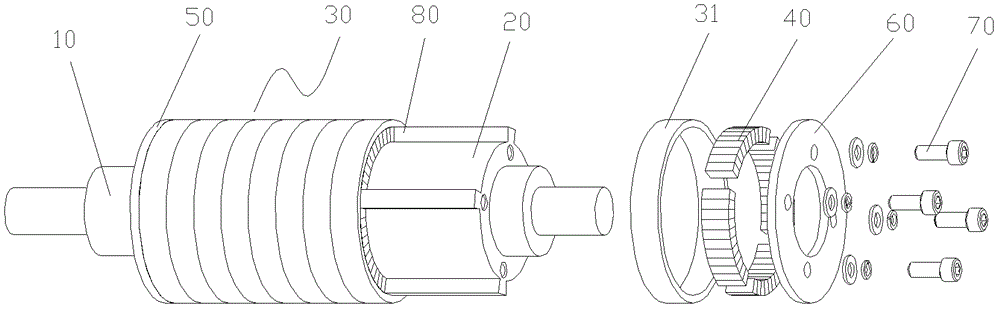

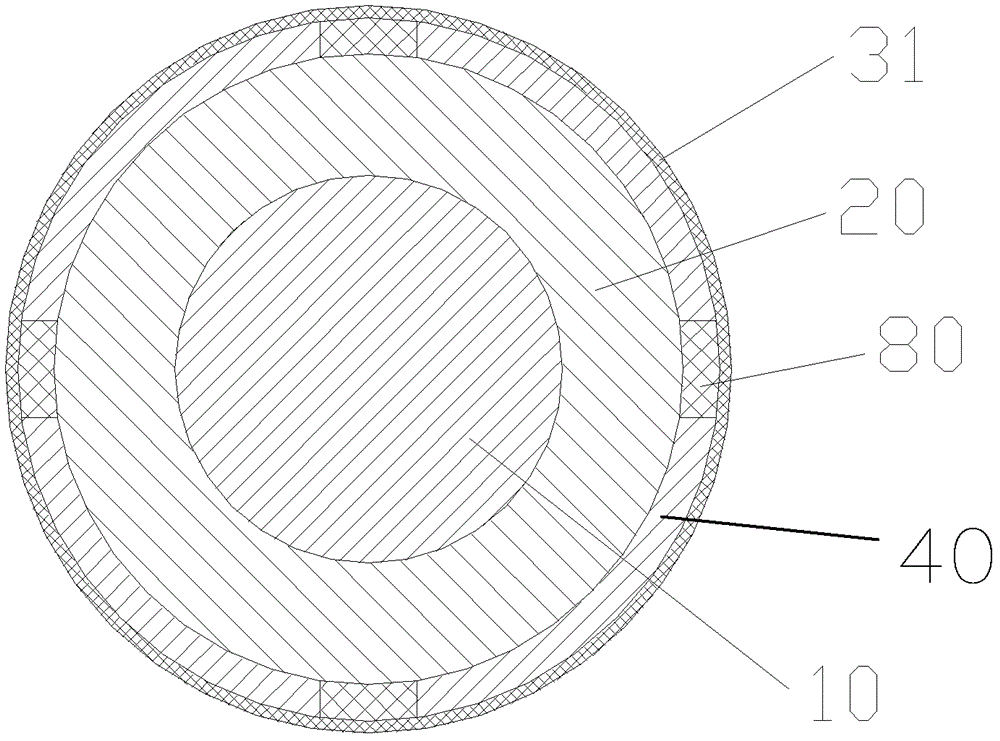

Electric motor used for wet-type operation pump and assembly method

InactiveCN103199640AHigh strengthEmbedding convenienceMagnetic circuit stationary partsManufacturing dynamo-electric machinesManufacturing technologyElectric machine

The invention relates to an electric motor used for a pump, in particular to an electric motor used for a wet-type operation pump. The electric motor used for the wet-type operation pump comprises a stator 1, a casing pipe 2 and a rotor 3 which is combined with a rotating shaft 4 into a whole, wherein one end of the rotating shaft 4 is used as an energy output end of the electric motor, and the casing pipe 2 is located between the stator 1 and the rotor 3. The rotor 3 is located in the casing pipe 2, and the casing pipe 2 enables the space of the rotor 3 to be sealed relative to the space of the stator 1. The stator 1 and the casing pipe 2 are in an integrated seamless-connection structure. According to the assembly method of the electric motor used for the wet-type operation pump, the casing pipe 2 is directly molded on the stator 1 in an injection mode with injection molding technology adopted, and then the rotor 3 is arranged in the casing pipe 2. According to the electric motor used for the wet-type operation pump and the assembly method, on the premise of ensuring the strength of the casing pipe, an air gap between the stator and the rotor is effectively reduced, and the operation efficiency of the electric motor used for the wet-type operation pump is improved. Besides, the manufacturing technology is simple, and the cost is low.

Owner:CHANGZHOU XINYA ELECTROMOTOR

Disc type permanent magnet synchronous exhaust fan motor

PendingCN108539944AImprove reliabilityFew partsMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsPermanent magnet rotorEngineering

The invention discloses a disc type permanent magnet synchronous exhaust fan motor. The motor comprises a rotary transformer cover plate, a rotary transformer, a fan permanent magnet rotor and a stator. With the adoption of an axial magnetic circuit, the axial length of the motor is reduced, and the motor is suitable for being used in a place with small axial space and large radial space.

Owner:包头天工电机有限公司

A magnetic circuit structure of a double-V permanent magnet hub motor

InactiveCN109831080BImprove running characteristicsFlux leakage coefficient is smallMagnetic circuit rotating partsMagnetic circuit stationary partsLow noiseElectric machine

The invention discloses a double V-type permanent magnet hub motor magnetic circuit structure and relates to the technical field of motor structure. The double V-type permanent magnet hub motor magnetic circuit structure comprises a stator, a rotor, a rotor shaft, a permanent magnet, a magnetic isolation bridge, a winding slot and a ventilation hole. The permanent magnet hub motor has good runningcharacteristics. The rotor is an embedded radial rotor and has a low magnetic flux leakage coefficient. No magnetic isolation measures are required on a rotating shaft. A pole-arc coefficient is easyto control. Rotor punching pieces have high mechanical strength. The ventilation hole reduces the magnetic flux at the alignment position. The magnetic circuit structure has low noise performance, reduces the core loss of the rotor, and enhances a heat dissipation effect.

Owner:HARBIN UNIV OF SCI & TECH

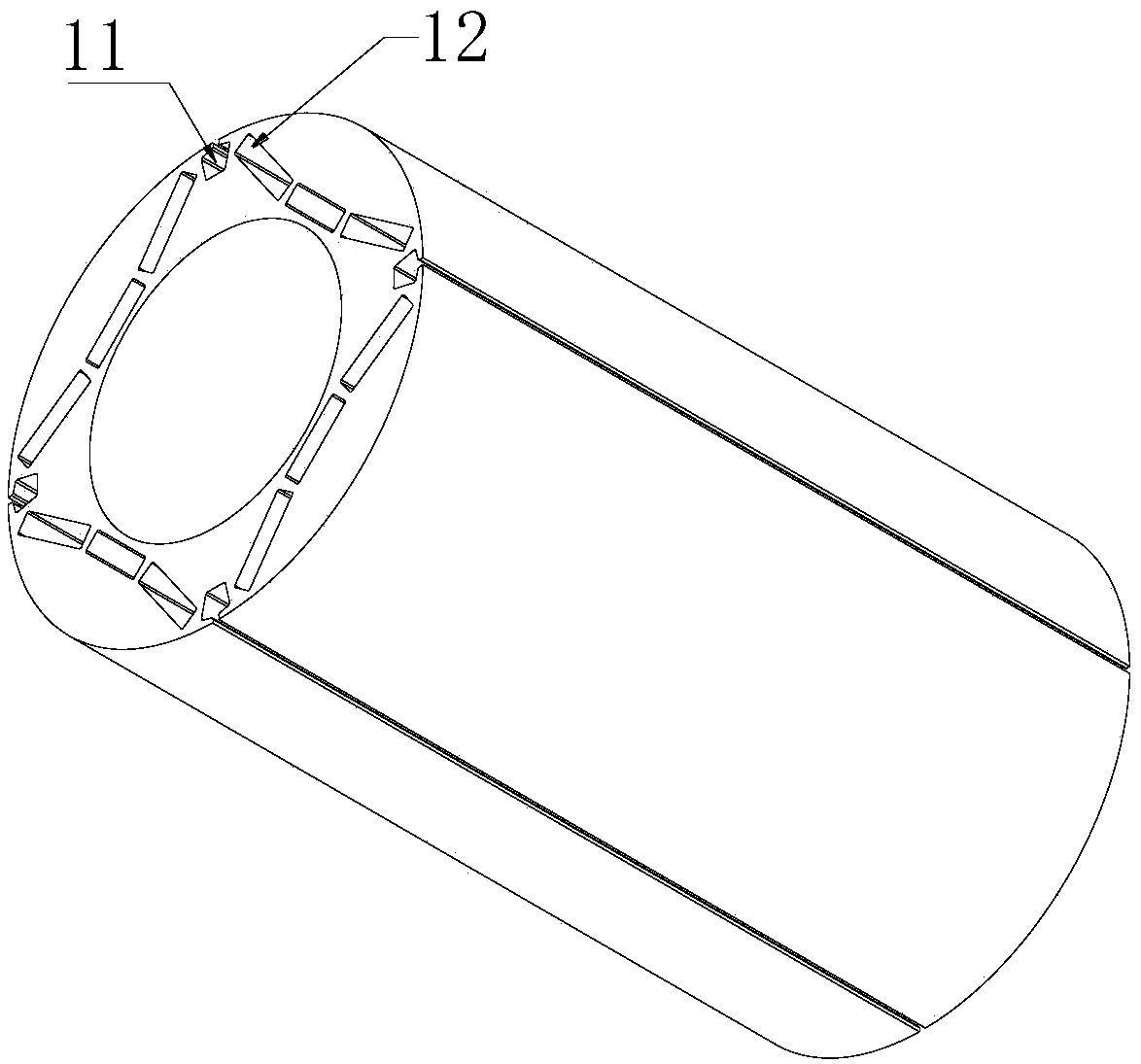

Motor permanent magnet fixing structure, fixing method and motor including the same

ActiveCN103312069BReduce thicknessGuaranteed accuracyMagnetic circuit rotating partsManufacturing stator/rotor bodiesAdhesivePermanent magnet motor

The invention provides a fixed structure and a fixing method of motor permanent magnets and a motor comprising the fixed structure. The fixed structure of the motor permanent magnets comprises a rotor iron core, a composite material sleeve and the permanent magnets, wherein the composite material sleeve is sleeved on the outer surface of the rotor iron core and comprises a plurality of composite material sleeve rings which are arranged along the axial direction and independent from one another; each permanent magnet is arranged between a gap between the rotor iron core and each composite material sleeve ring. The fixing method comprises the following steps: coating anaerobic adhesive on the outer surface of the rotor iron core and the inner surfaces of the composite material sleeve rings, and sleeving the composite material sleeve rings on the rotor iron core; embedding the permanent magnets in the gaps between the rotor iron core and the composite material sleeve rings; and repeating the steps until the permanent magnets are all distributed on the outer surface of the rotor iron core, wherein the composite material sleeve rings form the composite material sleeve along the axial direction. According to the fixed structure and the fixing method of the motor permanent magnets and the motor comprising the fixed structure, the assembling efficiency and assembling precision of the permanent magnets can be improved, and the gaps between the permanent magnets and a stator winding are reduced so that the leakage coefficient is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

Built-in permanent magnet motor and rotor thereof

InactiveCN105958684AFlux leakage coefficient is smallIncrease profitMagnetic circuit rotating partsPunchingPermanent magnet motor

The invention discloses a rotor of a built-in permanent magnet motor. The rotor comprises a rotating shaft, a rotor punching plate, permanent magnets and slot wedges, wherein the rotor punching plate is sleeved on the rotating shaft, and permanent magnet slots and slot wedge slots are formed in the outer side of the rotor punching plate; the slot wedge slots are positioned between the permanent magnet slots and the rotating shaft; the permanent magnets are arranged in the permanent magnet slots; the slot wedges are arranged in the slot wedge slots; first magnetic isolation bridges are arranged between the permanent magnet slots and the outer side of the rotor punching plate; and second magnetic isolation bridges are arranged between the adjacent slot wedge slots. According to the rotor, the first magnetic isolation bridges are arranged between the permanent magnet slots and the outer side of the rotor punching plate, the permanent magnet slots are through holes formed in the rotor punching plate, and the second magnetic isolation bridges are arranged between the adjacent slot wedge slots; through the arrangement, the width of each magnetic bridge can be adjusted, so that the magnetic density of air gaps is high, and the utilization rate of the permanent magnets is high, namely the magnetic leakage factor of the built-in permanent magnet motor is reduced. The invention also discloses the built-in permanent magnet motor with the rotor.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

Permanent magnetic brushless DC four-quadrant electric machine

InactiveCN1933286BFlux leakage coefficient is smallPlay the role of magnetic protectionMagnetic circuit rotating partsMagnetic circuit stationary partsFour quadrantsElectric machine

Owner:林祥钟

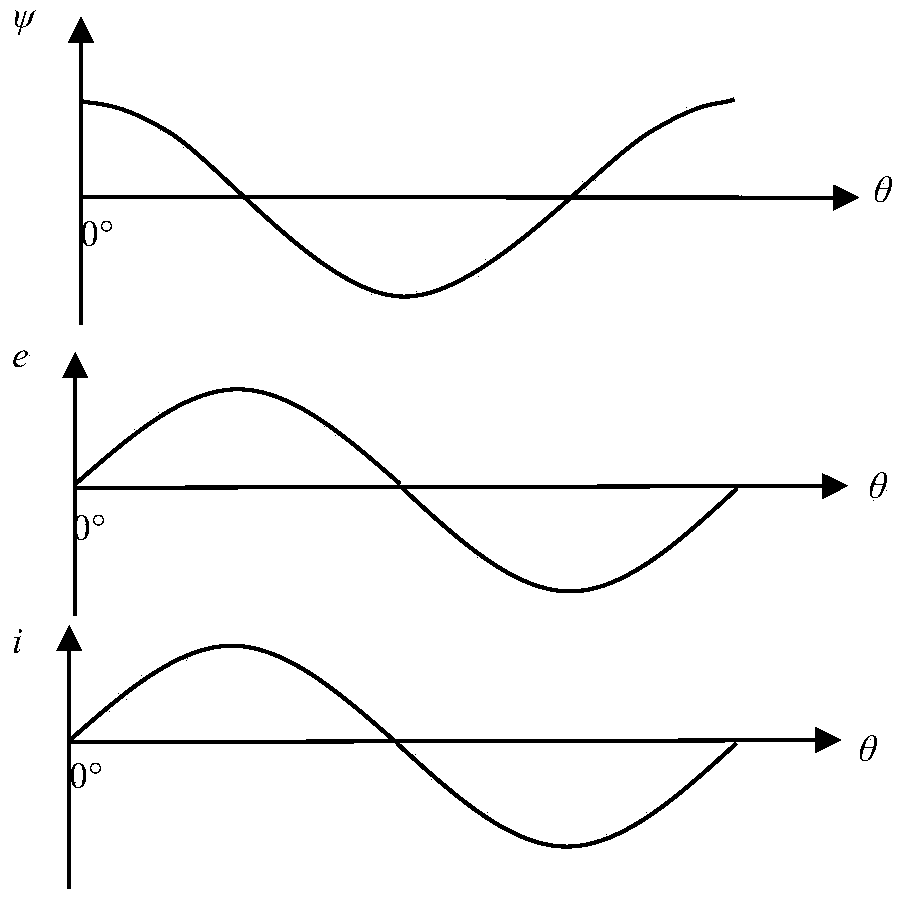

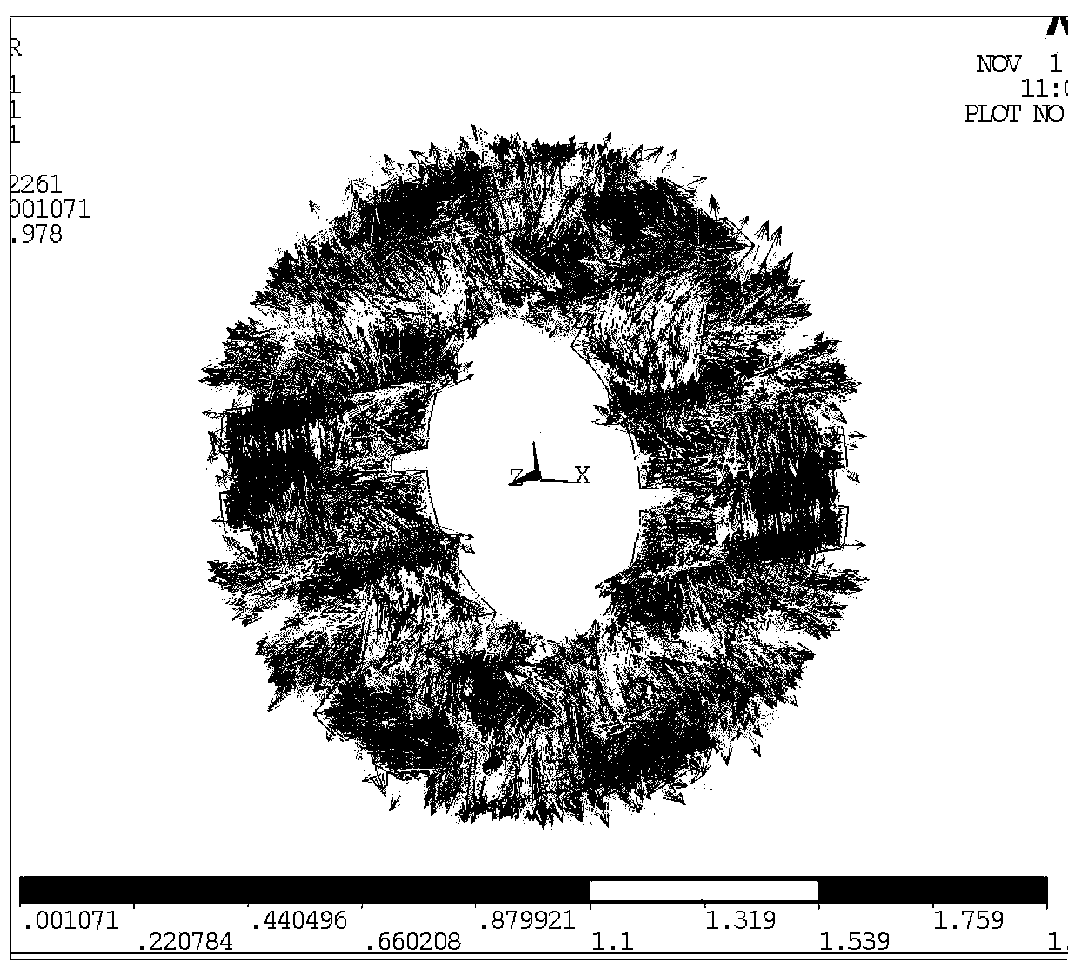

Novel high-temperature resistant solid rotor asynchronous magnetic coupling design method

InactiveCN107786064AIncrease axial lengthIncrease the nominal diameterPermanent-magnet clutches/brakesMagnetic tension forceRare earth

The invention discloses a design method of a novel high-temperature-resistant solid rotor asynchronous magnetic coupling. The method is a new type of non-contact electromagnetic induction power transmission device developed in recent years. Rare earth permanent magnets are arranged on the inner side of the outer rotor of the coupling. . The internal rotation adopts a solid rotor and does not require permanent magnet materials. The high-temperature-resistant asynchronous solid-rotor magnetic coupling designed by sample selection effectively solves the problem that the previous magnetic-drive pumps cannot transport high-temperature media, and has high economic value and good application prospects. The design and analysis of the magnetic circuit of the magnetic coupling is an important basis for solving the electromagnetic torque of the magnetic coupling. It is necessary to optimize the design of the magnetic circuit, so the present invention selects the magnets to be closely arranged for magnetic concentration, and derives the magnetic permeability and magnetic flux leakage system, which has good practicability and has very important reference value for the research of green machinery.

Owner:申茂军

Stator punching sheet, stator and motor

ActiveCN107872107AImprove slot area utilizationFast temperature riseMagnetic circuit stationary partsPunchingEngineering

The invention provides a stator punching sheet, a stator and a motor. The stator punching sheet comprises a punching sheet body; a central hole is formed in the punching sheet body; small grooves andbig grooves are formed in the punching sheet body in the circumferential direction of the central hole; and the punching sheet body is in symmetrical arrangement by taking the central line of the groove openings of the small grooves as the axis. By virtue of the stator punching sheet, the problem of increasing of the motor cost caused by the stator punching sheet in the prior art is solved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com