Disc type permanent magnet synchronous exhaust fan motor

A permanent magnet synchronous, electromechanical technology, applied to synchronous motors, electromechanical devices, magnetic circuits, etc. The effect of reducing copper loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following description illustrates specific embodiments of the invention sufficiently to enable those skilled in the art to practice and reproduce it.

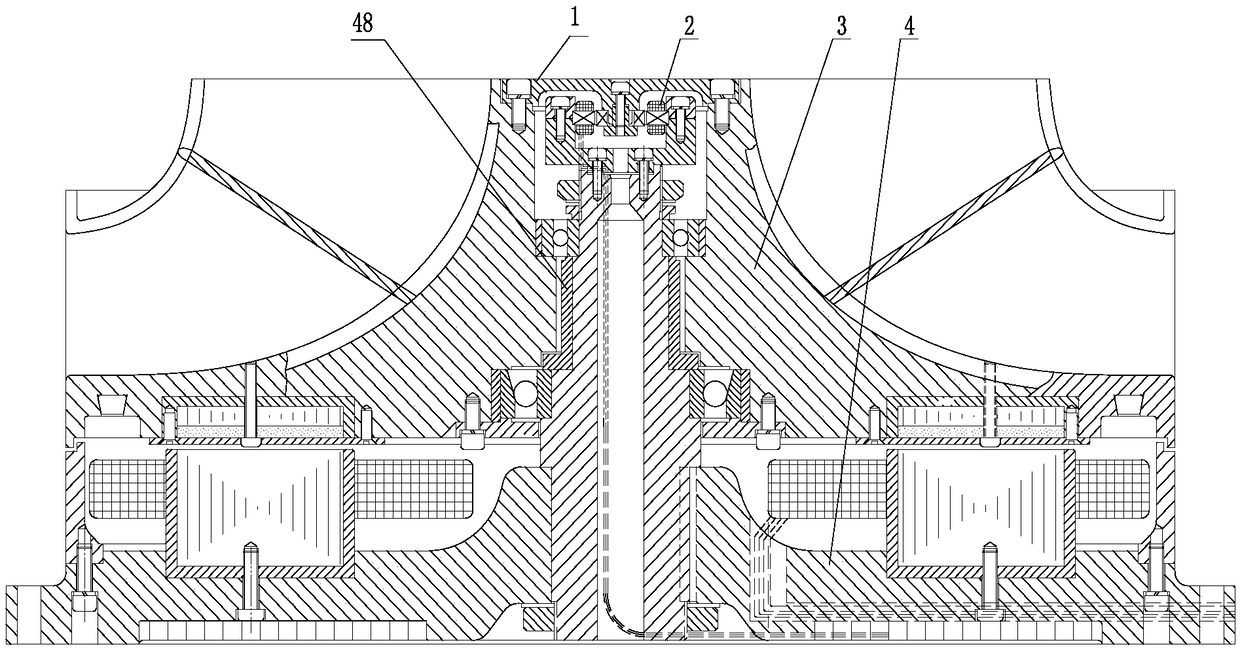

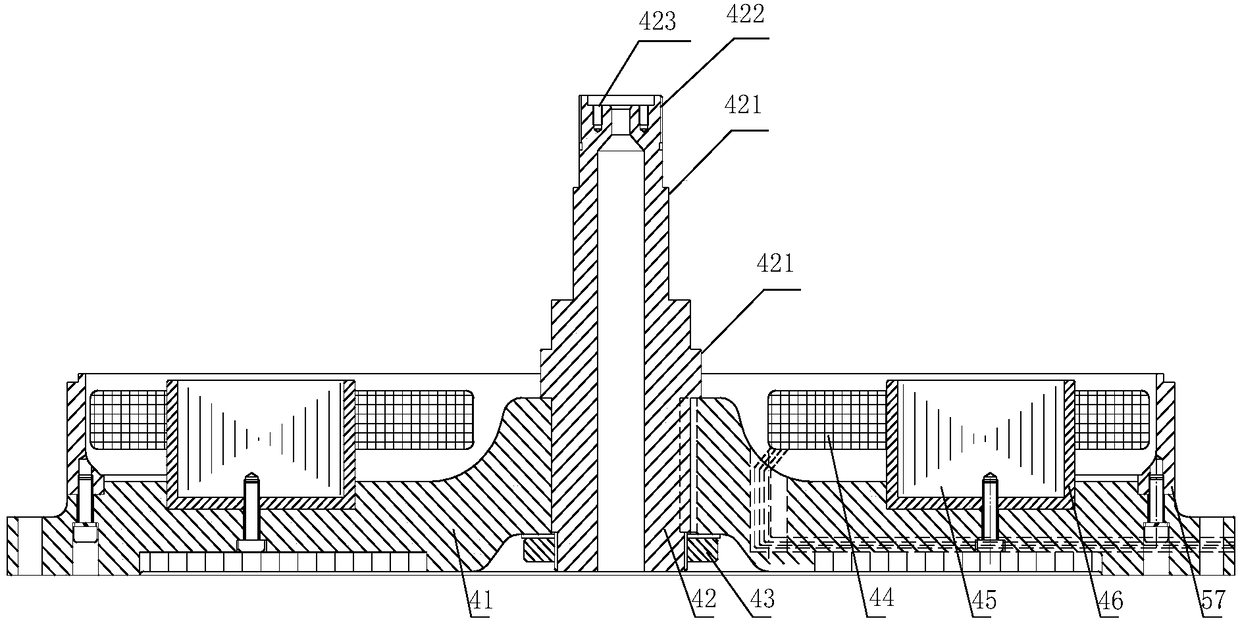

[0029] Such as figure 1 Shown is a schematic structural view of the disc-type permanent magnet synchronous exhaust fan motor of the present invention. Such as figure 2 Shown is a schematic structural view of the stator 4 in the present invention.

[0030] The structure of the disc type permanent magnet synchronous exhaust fan motor includes: a resolver cover plate 1, a rotary transformer 2, a fan permanent magnet rotor 3, and a stator 4. The stator 4 does not move, and after the stator coil 44 is energized, the fan permanent magnet rotor 3 rotates, and the fan 32 works to output wind energy.

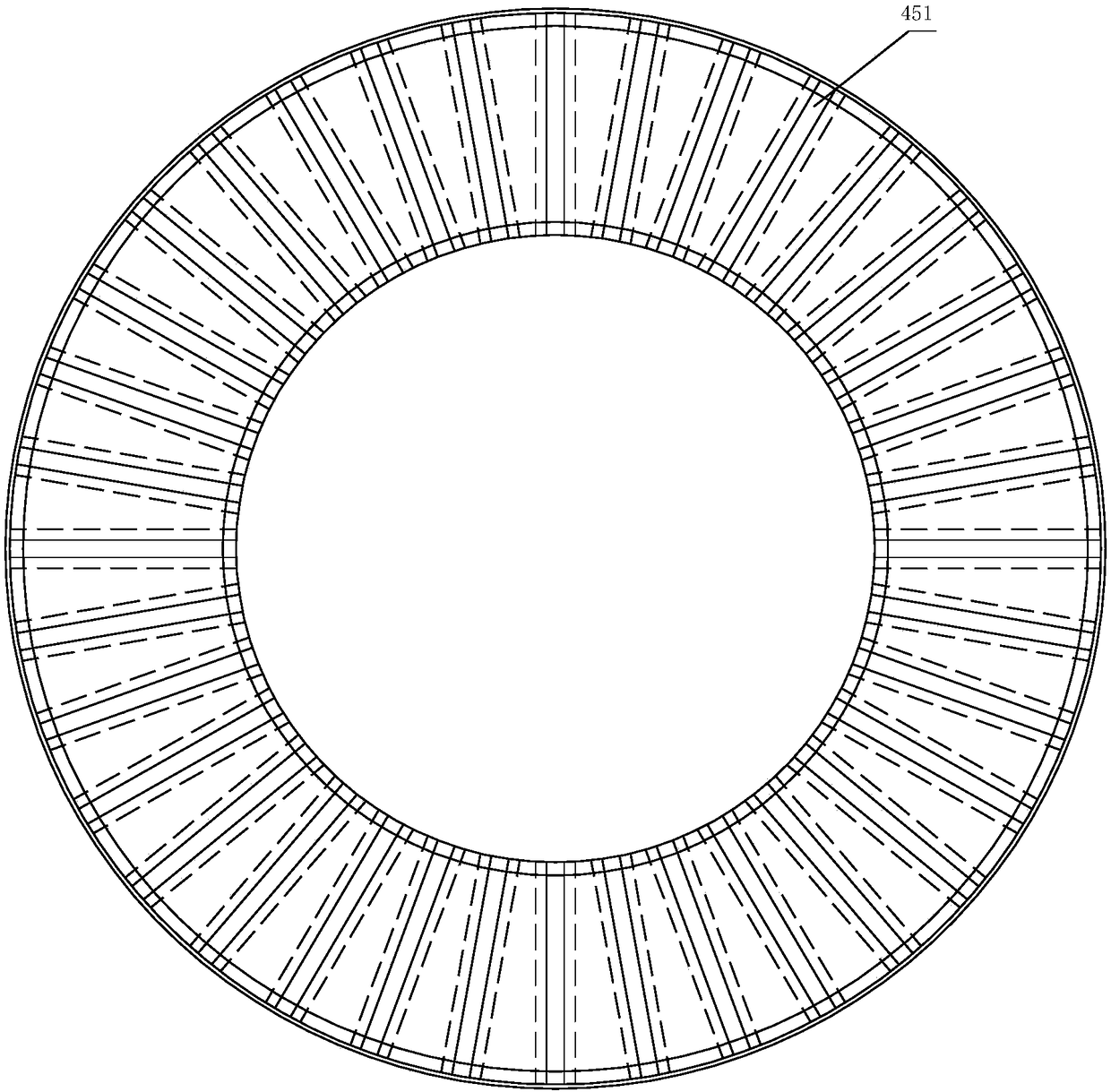

[0031] The stator 4 includes: a base 41, a rotating shaft 42, a first lock nut 43, a stator coil 44, a stator punch 45, a stator core pressure ring 46, and a seat ring 57; There is a coil fixing groove; the rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com