Stator division type axial flux switching type mixed excitation synchronous motor

A hybrid excitation synchronous, axial magnetic flux technology, applied in electrical components, electromechanical devices, etc., can solve the problems of irreversible demagnetization of permanent magnets, reduced motor operating efficiency, and low utilization rate of permanent magnets, so as to reduce the risk of demagnetization, reduce the risk of motor The effect of improving efficiency and increasing the relative overlapping area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention is described in further detail:

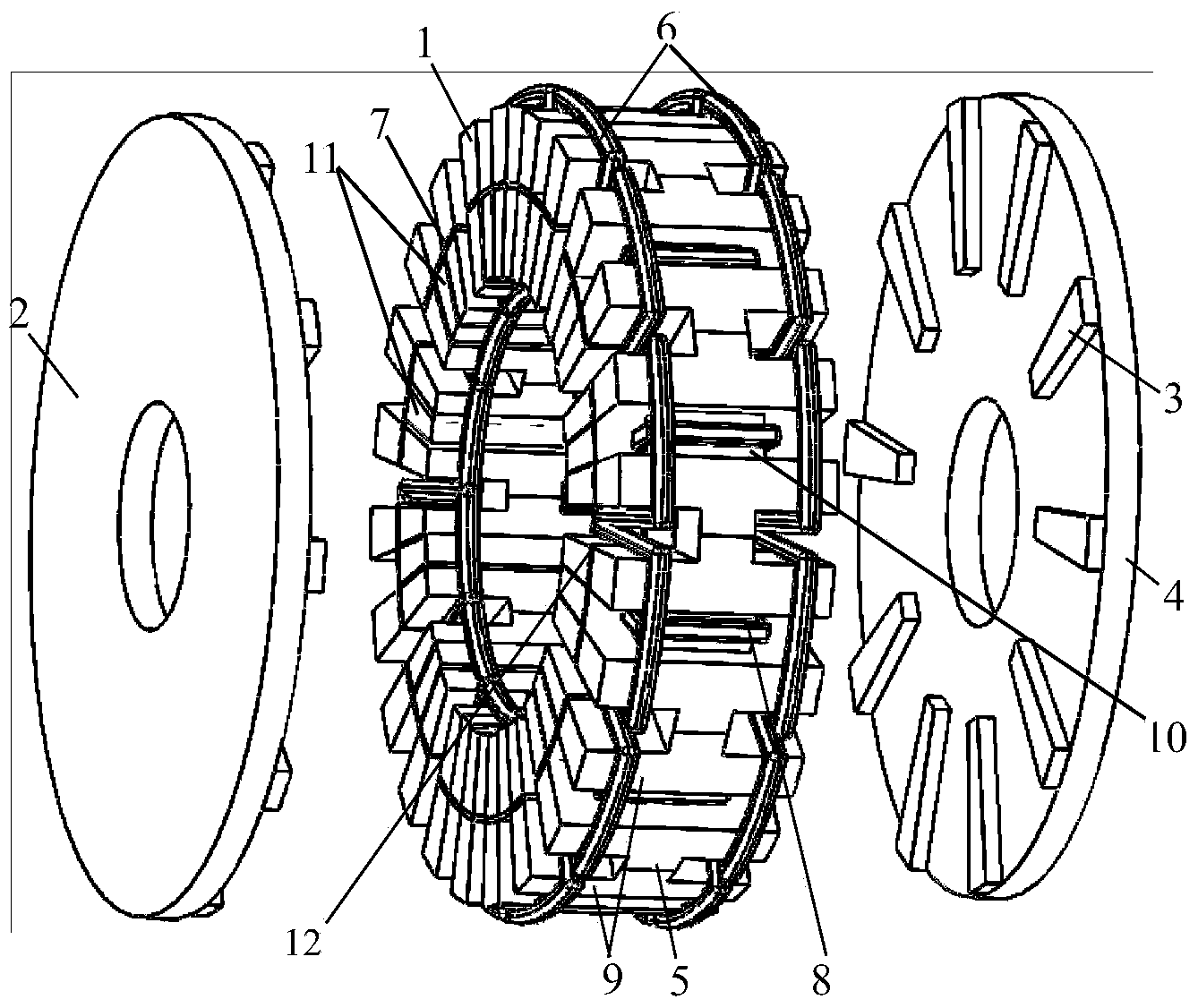

[0029] Such as figure 1 as shown,

[0030]A stator-divided axial flux switching hybrid excitation synchronous motor, which is composed of a stator 1 and a rotor 2, is characterized in that the stator is spliced into two winding concentric circles by splicing the inner and outer layers of "H"-shaped unit stator cores 5 The two concentric rings are separated by a magnetic isolation ring 7, and the armature winding 6 adopts a concentrated winding, and the armature winding 6 is wound on the stator teeth 9 of two adjacent "H" type unit stator cores 5, and the permanent magnet 11 is formed The N and S poles are distributed in the middle of the stator core 5 of the adjacent "H" type unit, and the permanent magnet 11 is tangentially magnetized; the permanent magnet 11 and the stator slot 12 both adopt a rectangular structure; the excitation bracket 10 is located directly a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com