Hybrid magnetic circuit rotor of permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and hybrid magnetic circuit, which is applied in the direction of magnetic circuit rotating parts, magnetic circuit, magnetic circuit shape/style/structure, etc. The effects of small magnetic coefficient, reduced magnetic flux leakage coefficient, and wide operating range of constant power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

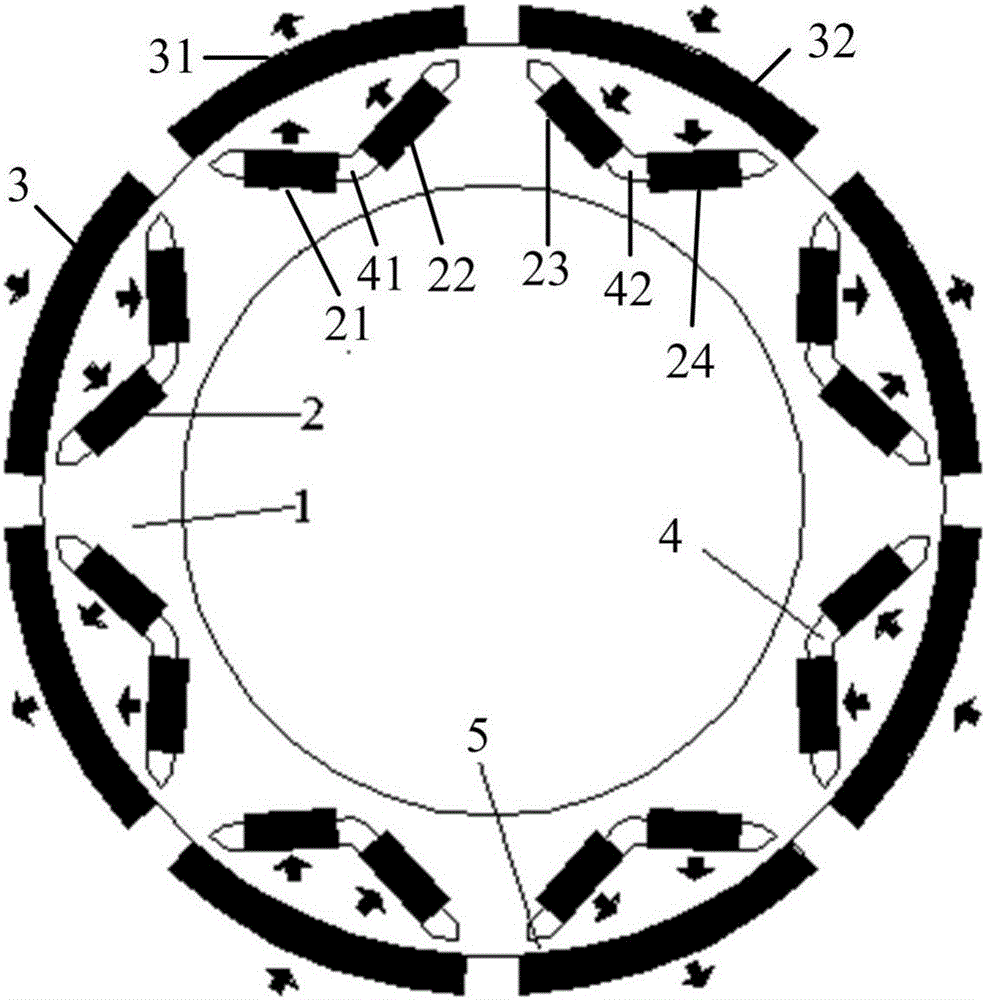

[0032] Embodiment 1: as figure 1 As shown, the hybrid magnetic circuit rotor of the present invention includes a rotor structural body 1 , a built-in permanent magnet 2 , a surface-mounted permanent magnet 3 and a magnetic isolation bridge 5 . A plurality of permanent magnet slots 4 are provided on the rotor structure body 1, and the magnetic isolation bridge 5 is arranged between the extension of the permanent magnet slot 4 and the outer edge of the rotor structural body 1, and the width of the magnetic isolation bridge 5 is 1-5 mm. , the thickness range is 0.5-3mm. The V-shaped permanent magnet slot 4 includes two inline embedded parts. The built-in permanent magnet 3 is embedded in the permanent magnet groove 4, and each inline embedded part is built with a built-in permanent magnet 2, and the built-in permanent magnet 2 is a rectangular permanent magnet, and the surface-mounted permanent magnet 3 is facing each permanent magnet. The magnet slots 4 are fixed on the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com