Magnetism gathering type direct-driven permanent magnet motor

A permanent magnet motor and magnetism-concentrating technology, which is applied in the field of magnetism-concentrating direct-drive permanent magnet motors, can solve the problems of short motor life, high additional cost for installation and transportation, and high cost, and achieve high-strength load performance and magnetism-concentrating effect Visible, easy to install and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with a specific implementation example of the present invention.

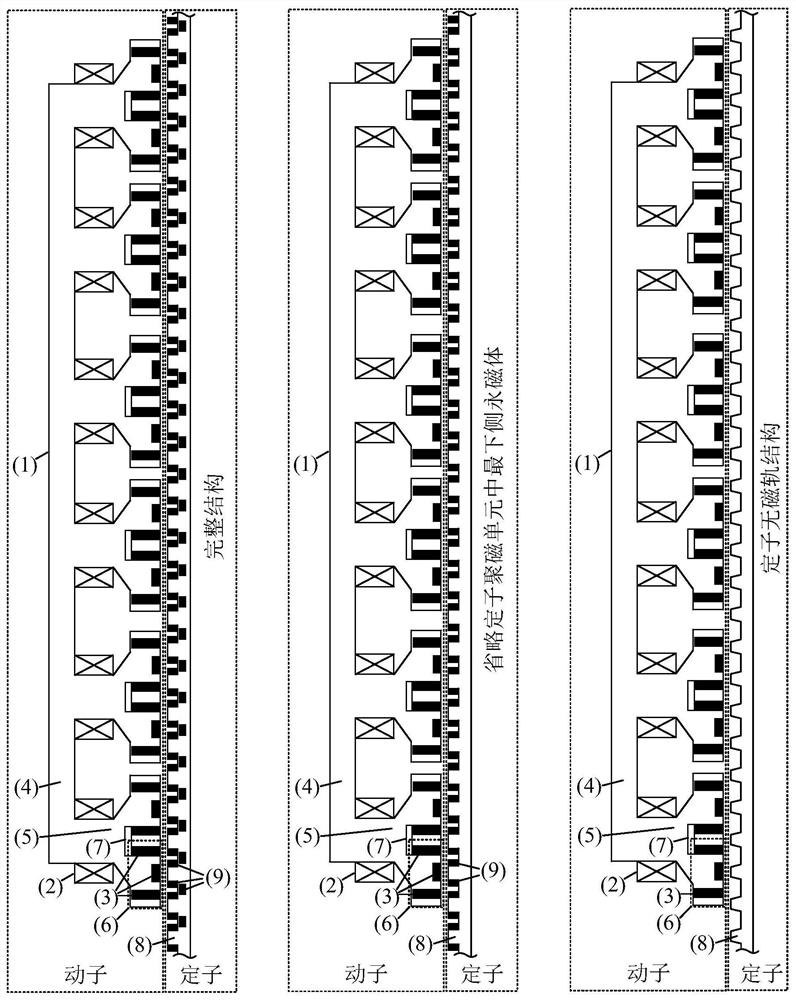

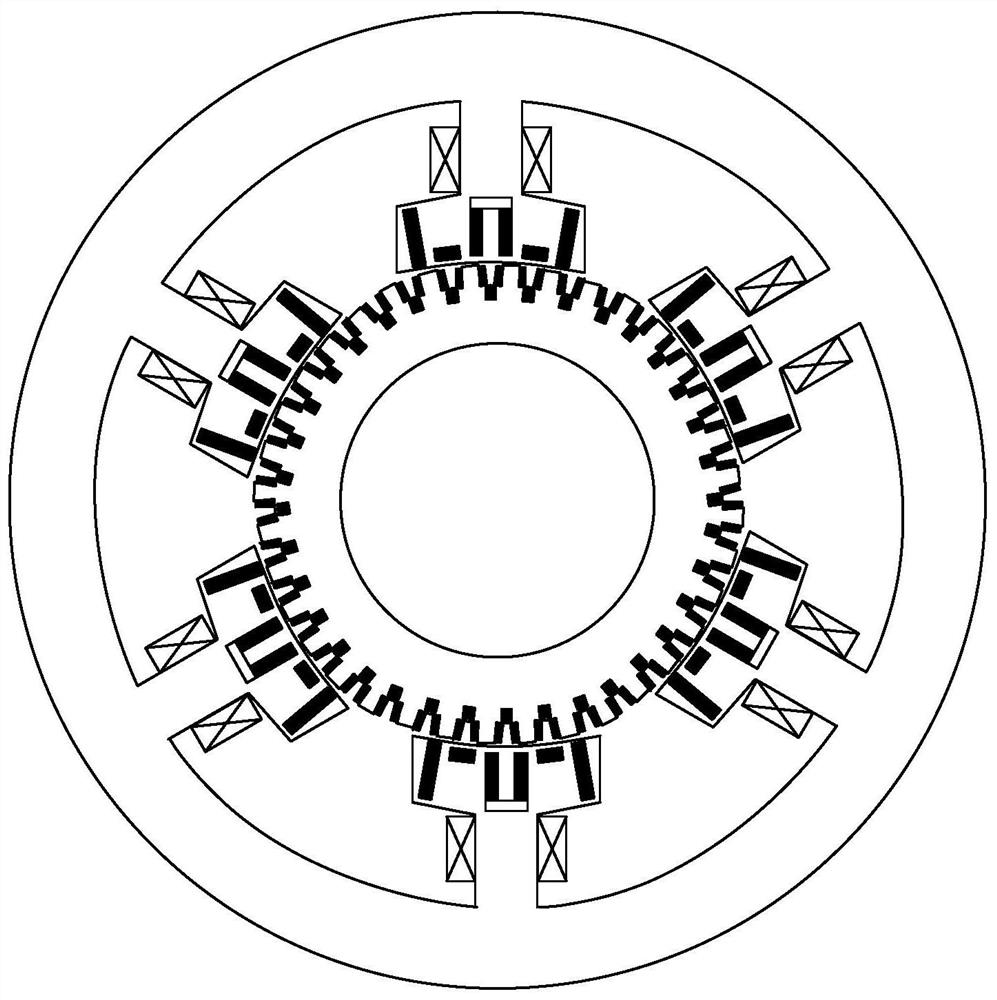

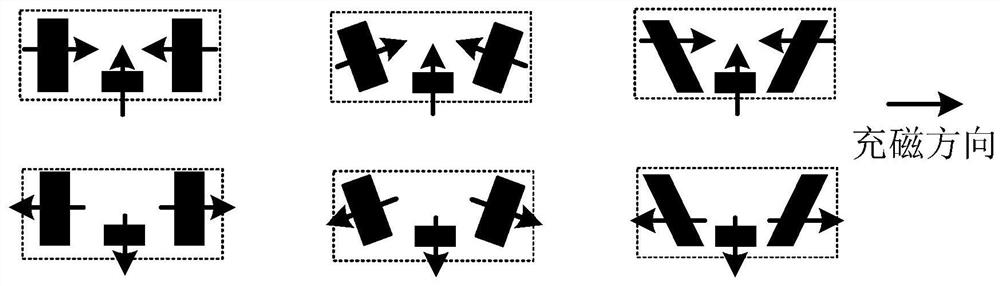

[0025] A magnetism-concentrating direct-drive permanent magnet motor, comprising two major components of a mover and a stator, characterized in that the mover includes a mover iron core (1), a winding (2), and a mover permanent magnet (3), wherein The iron core of the mover is made of soft magnetic material, which is composed of several mover teeth (4) connected through the mover yoke (5). Two sets of mover magnetic gathering units (6) are installed on the mover teeth. The magnetism gathering unit is located at the pole shoe of the mover teeth, each mover magnet collection unit contains three mover permanent magnets and soft magnetic material for fixing its installation position, the magnetization direction of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com