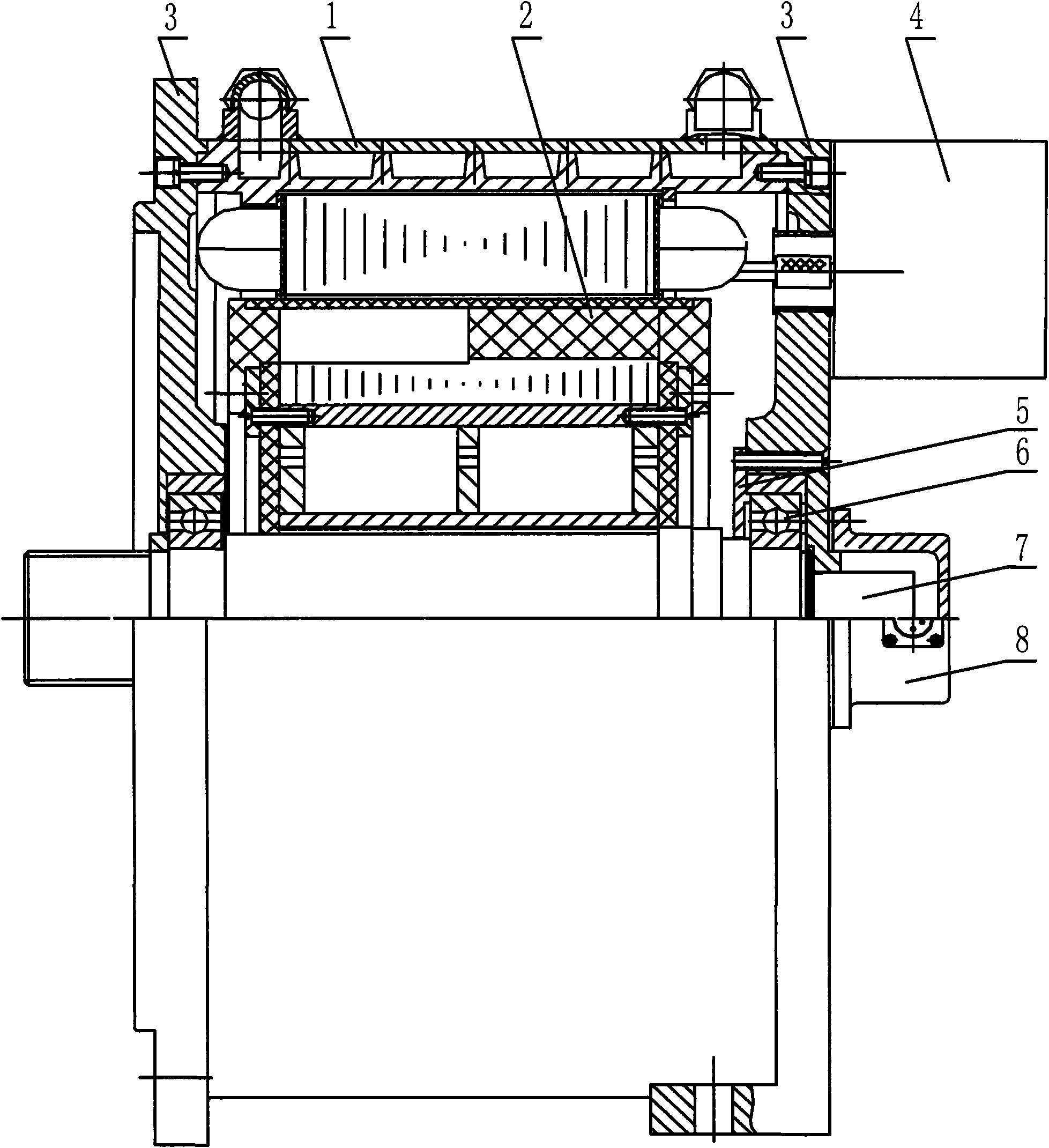

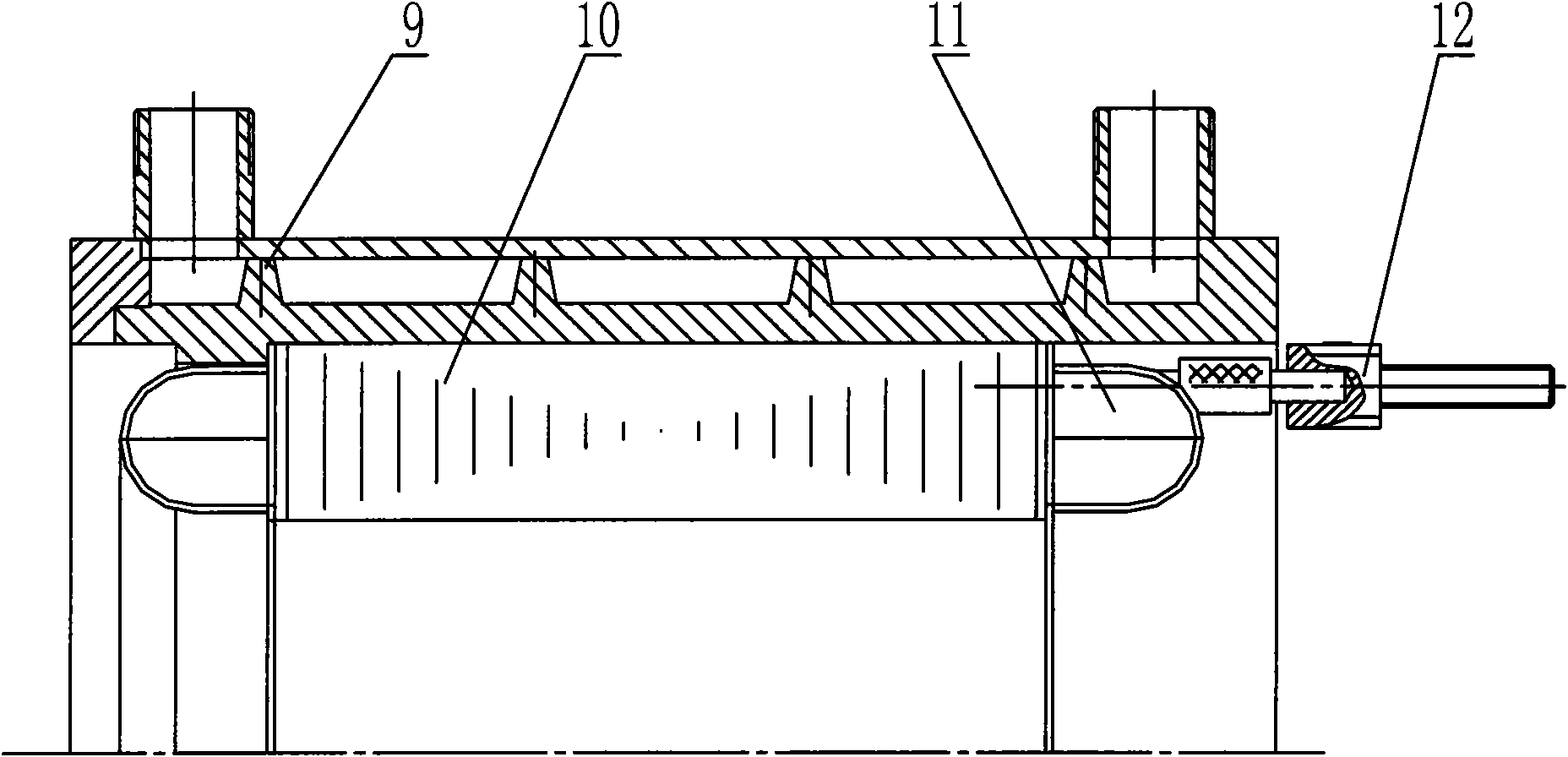

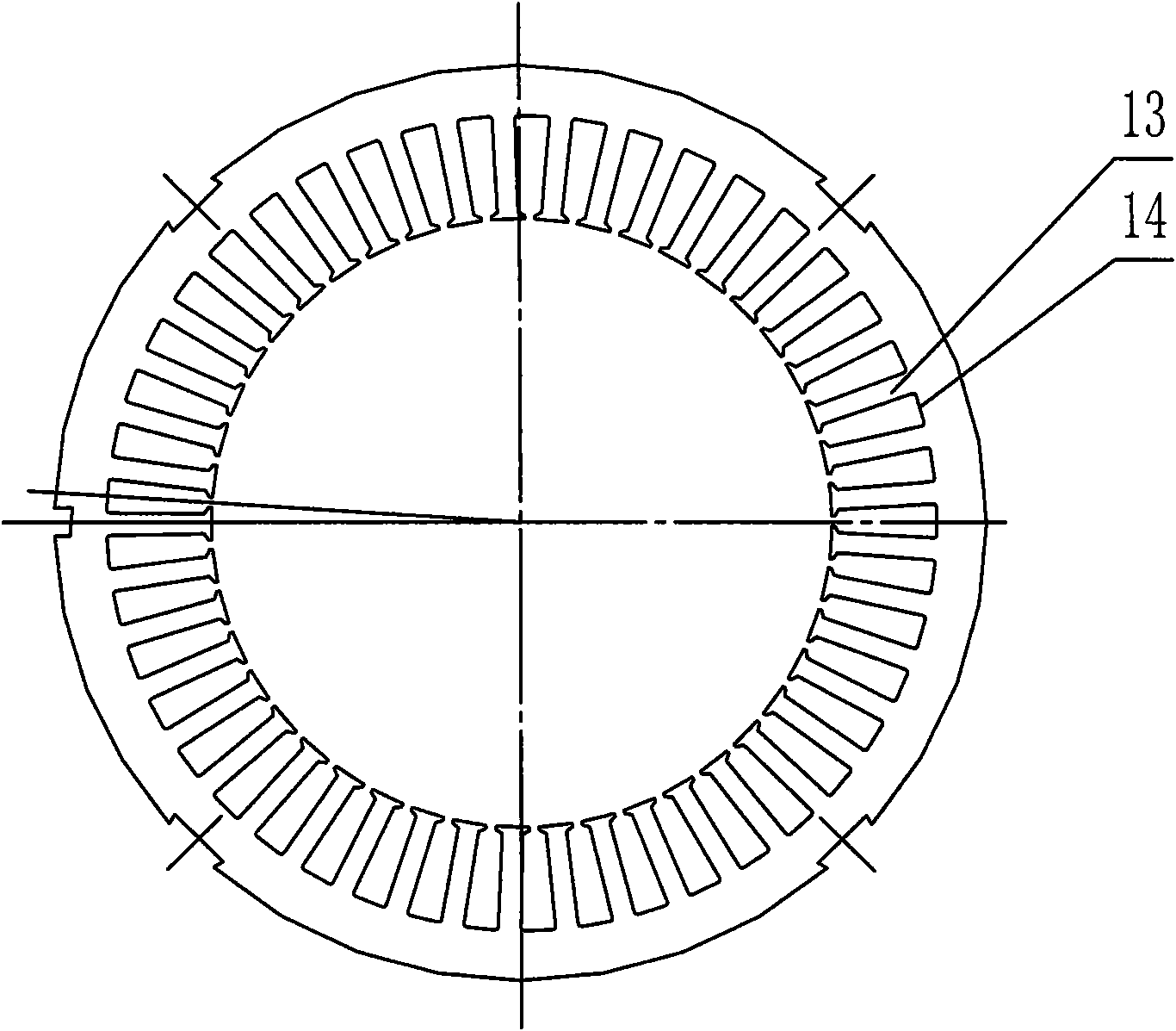

Three-phase water-cooling permanent magnet synchronous motor

A permanent magnet synchronous motor and water cooler technology, which is applied to the static parts of the magnetic circuit, the rotating parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc. Large winding ends, etc., to achieve good heat dissipation effect, reduce magnetic flux leakage coefficient, and increase the effect of air gap energy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] According to market demand, we have successively designed 60Kw and 130Kw three-phase water-cooled permanent magnet synchronous motors for electric sanitation vehicles and electric buses. The specific technical indicators are as follows:

[0027] 60Kw three-phase water-cooled permanent magnet synchronous motor main technical indicators

[0028] a>Rated power: P=60Kw

[0029] b>Rated speed: n=3500r / min

[0030] c> rated voltage: V = 248v (AC)

[0031] d>Rated current: I=147A

[0032] e>Motor efficiency: η=95%

[0033] f>Rated torque: Nm=164N·m

[0034] g>Maximum torque: M max=330N·m (time 5 minutes)

[0035] h>Maximum speed: n max=7000r / min (time 5 minutes)

[0036] i>Insulation level: stator class H rotor rotor class F

[0037] j> Duty system: continuous

[0038] k>Protection grade: IP55

[0039] l>Cooling water inlet temperature: 70°C flow rate 16L / min

[0040] m>Weight: 80kg.

[0041] Main technical indicators of 130Kw three-phase water-cooled permanent magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com