Novel permanent magnetism auxiliary exciter rotor structure

A permanent magnet auxiliary exciter and rotor structure technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc., can solve the problems of poor workmanship, poor economy, large magnetic flux leakage coefficient, etc., and achieve the utilization of magnetic steel The effect of high efficiency, convenient processing, and small magnetic flux leakage coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

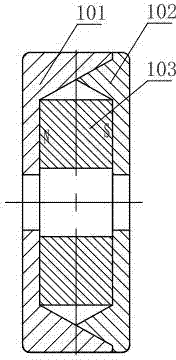

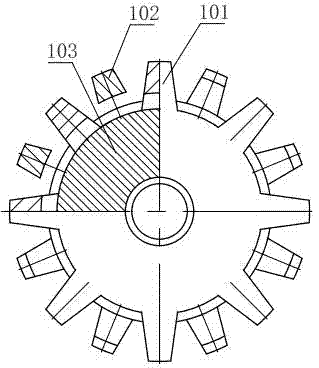

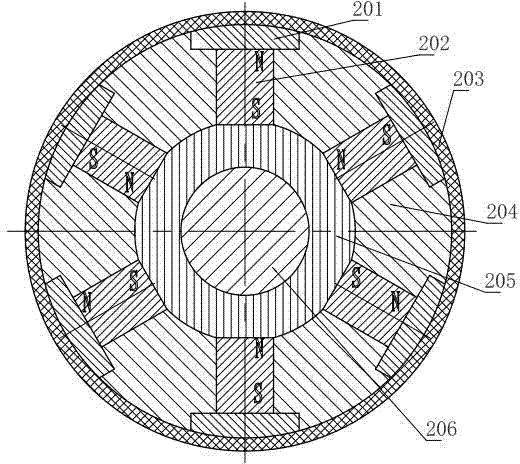

[0021] Such as Figure 4 As shown, the novel permanent magnet sub-exciter rotor structure of the present invention is provided with a rotating shaft 5 inside the annular yoke 4, and the permanent magnet 2 and the pole piece 1 are locked on the outer periphery of the annular yoke 4 by stainless steel screws 3 on the yoke. 4, the number of stainless steel screws 3 is determined according to the calculation of mechanical strength.

[0022] The invention adopts stainless steel screws to directly rake the pole shoe and the permanent magnet on the yoke. The parts are easy to process, easy to assemble and operate, and the air gap is small, the magnetic flux leakage coefficient is small, the utilization rate of the magnetic steel is high, the performance is good, stable and reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com