Patents

Literature

32results about How to "Synchro deactivation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for treating inferior oil product

ActiveCN106701190AImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesChemistryPre treatment

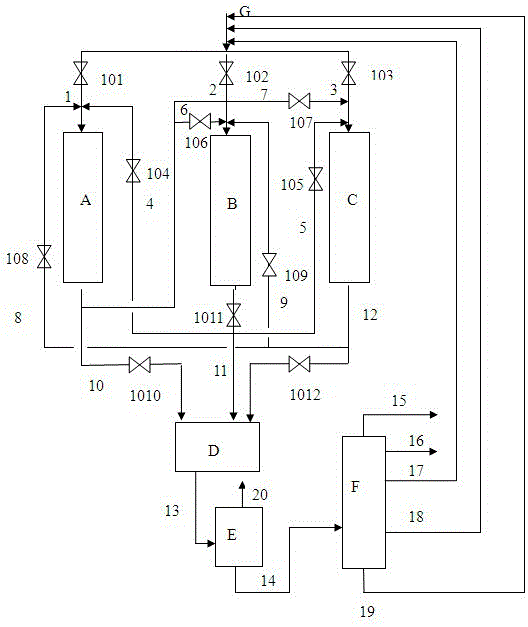

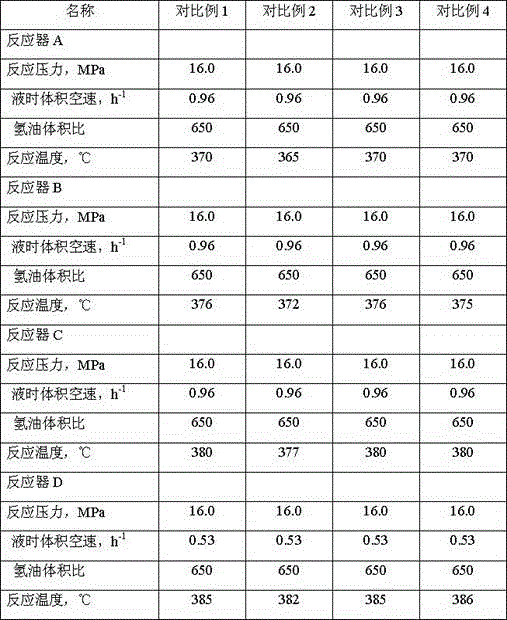

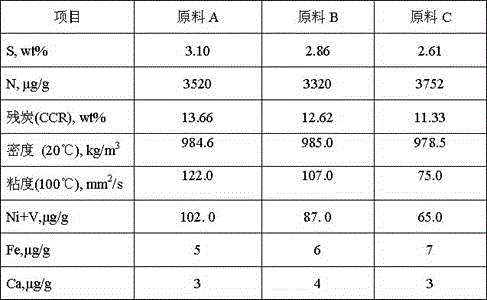

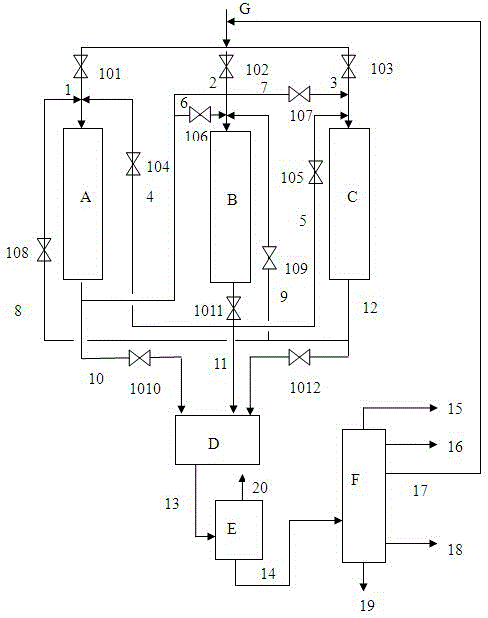

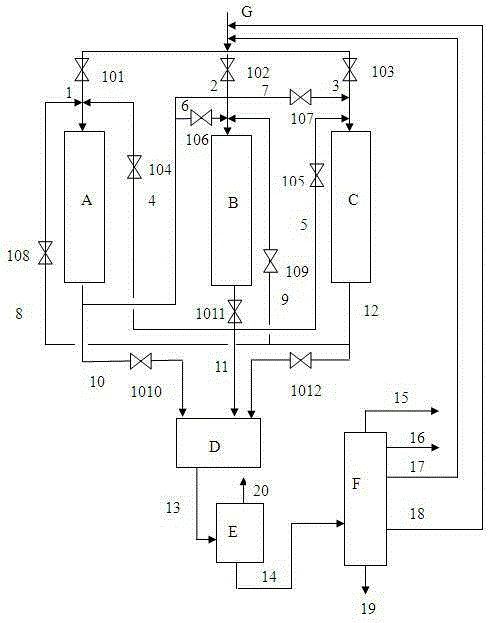

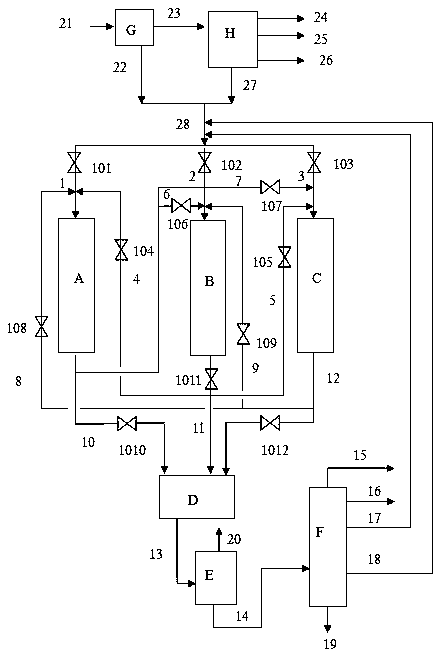

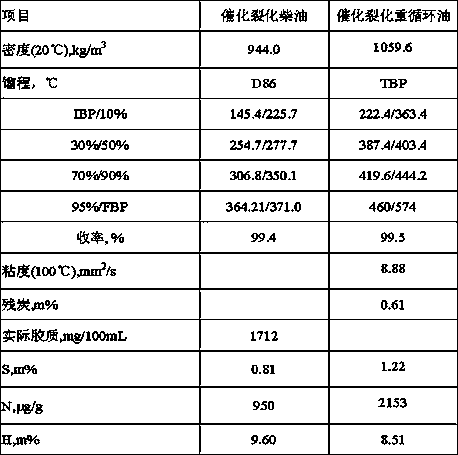

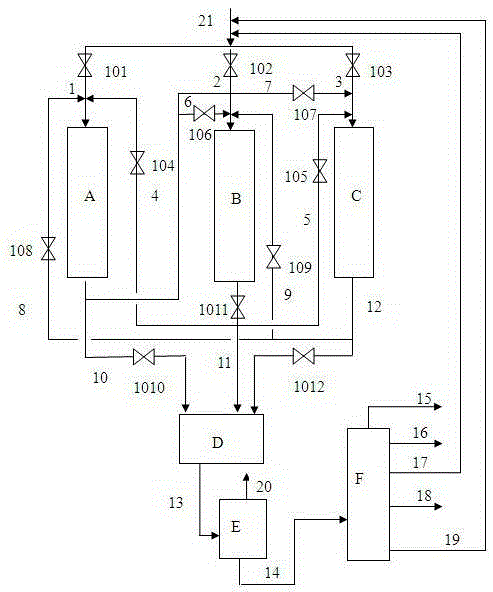

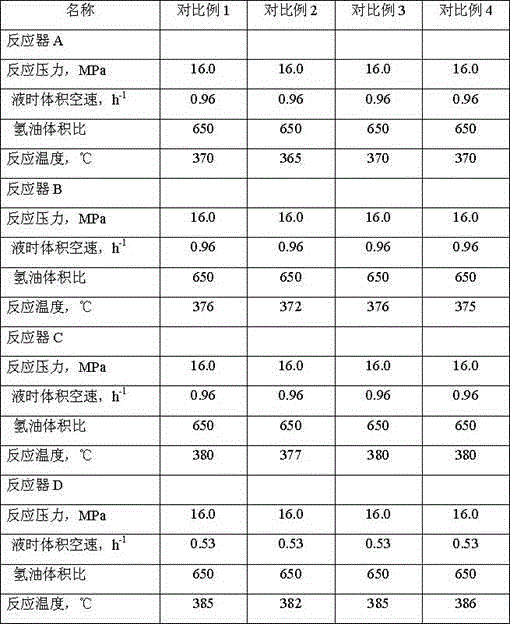

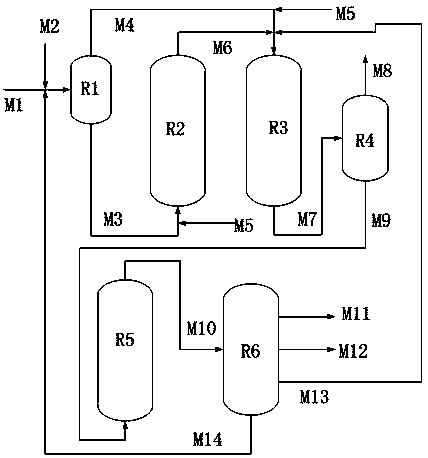

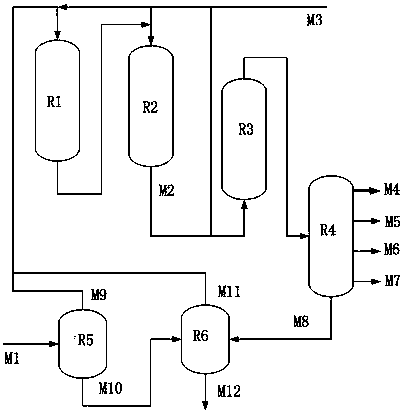

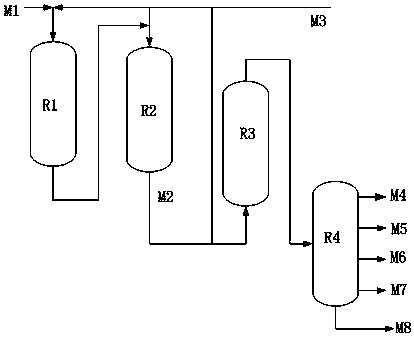

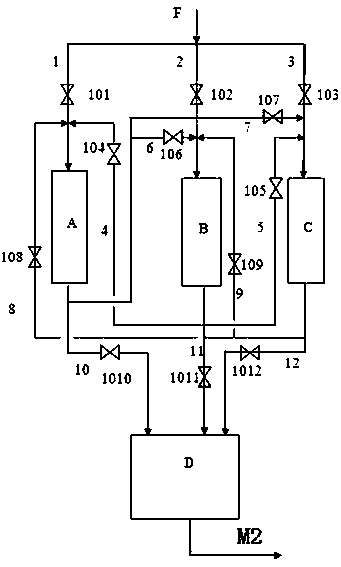

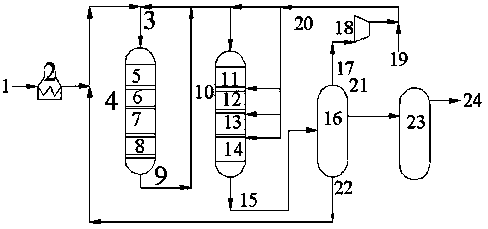

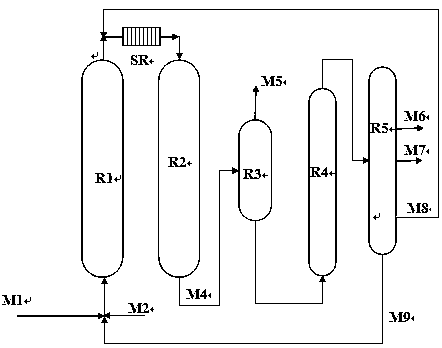

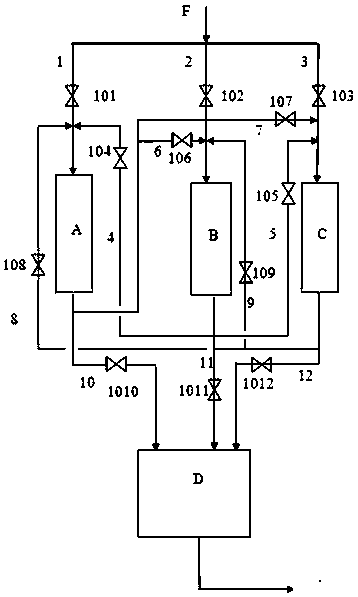

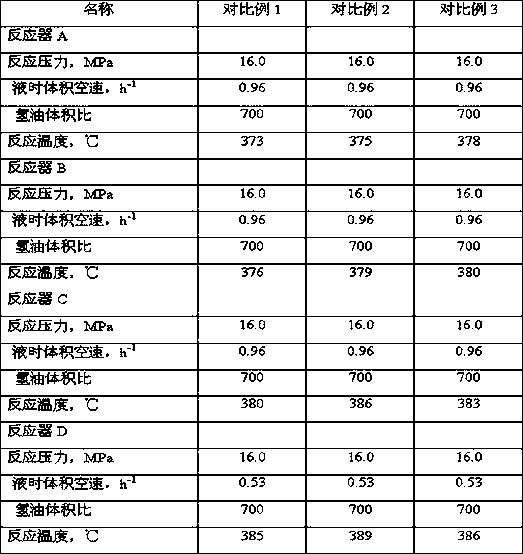

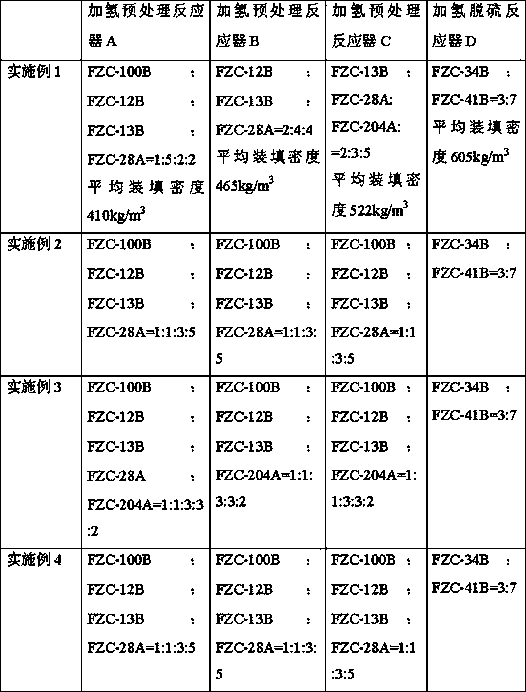

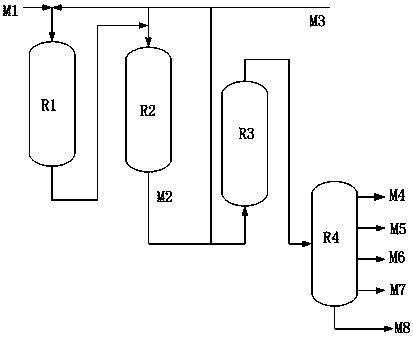

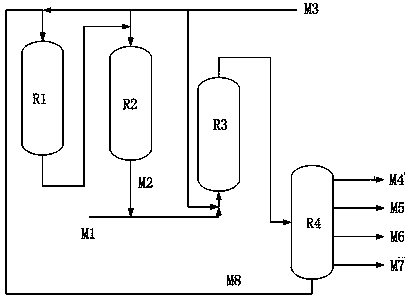

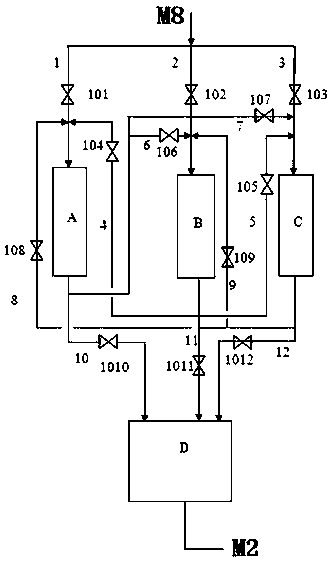

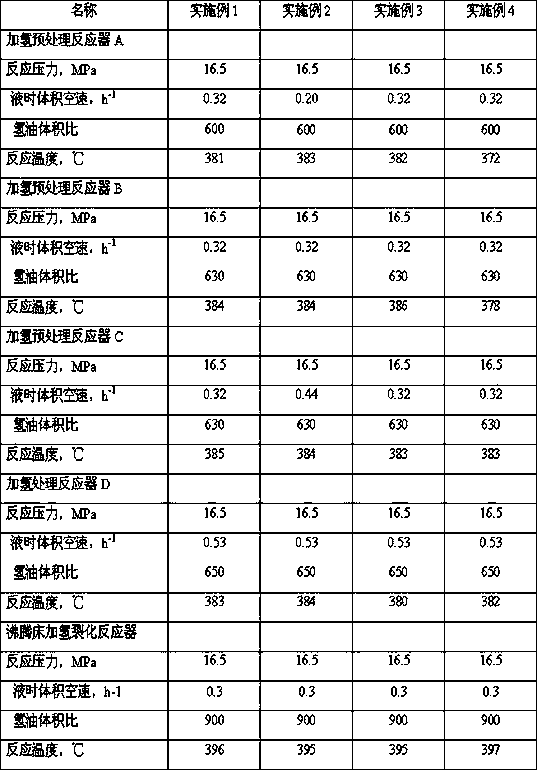

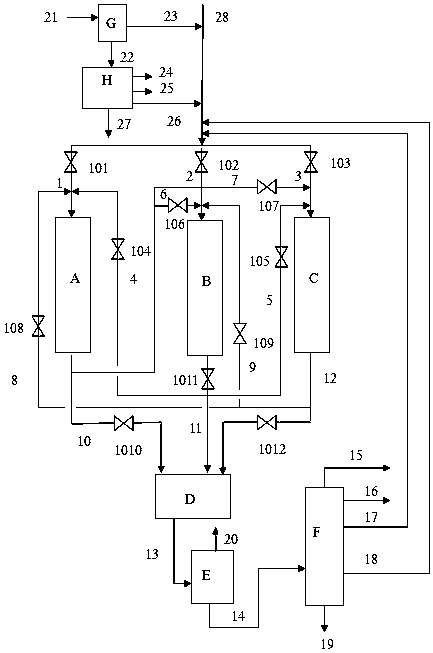

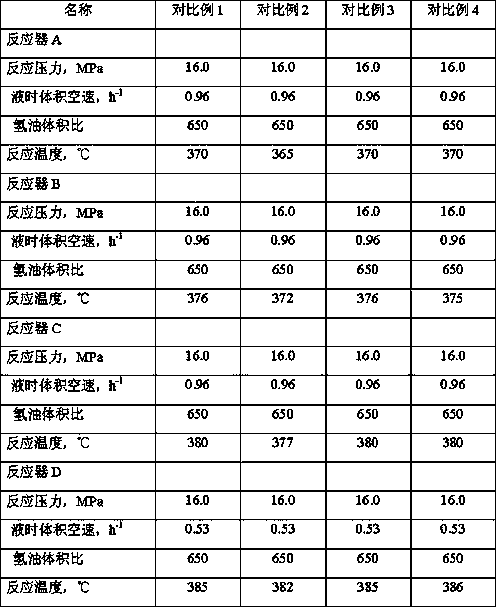

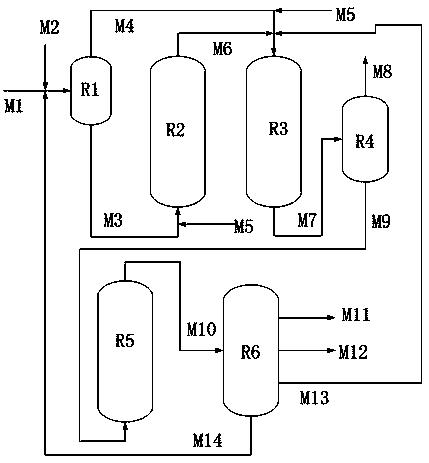

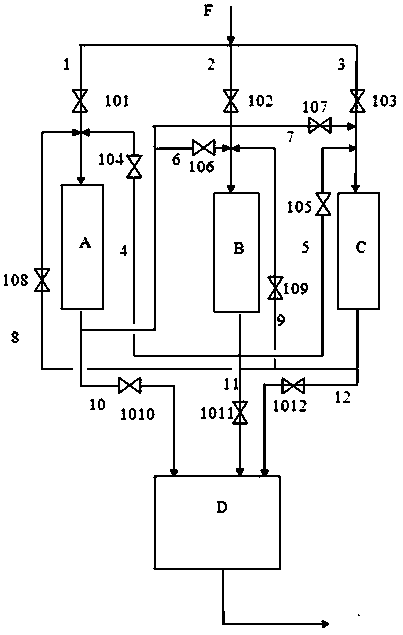

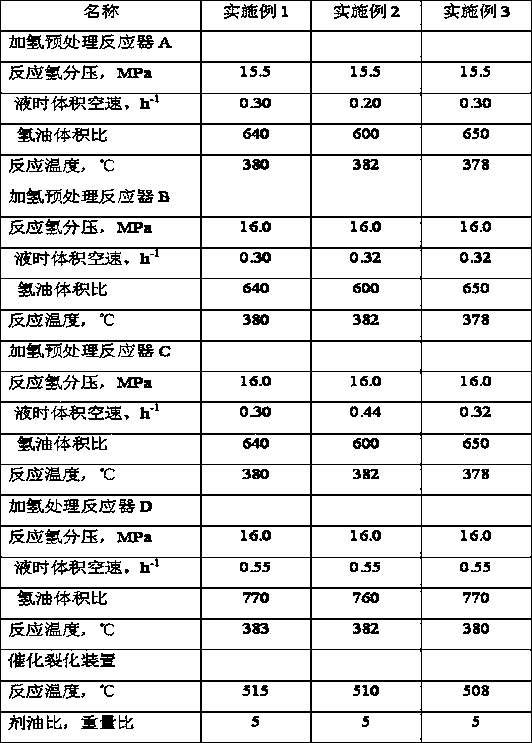

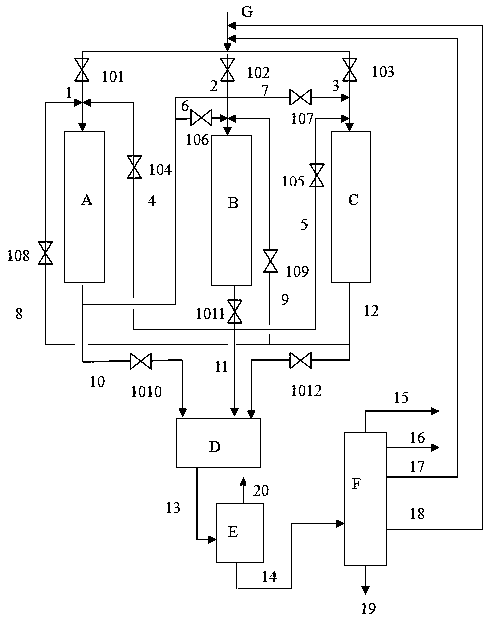

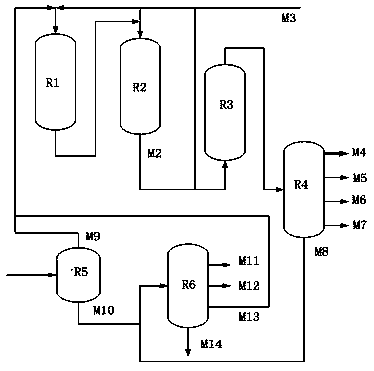

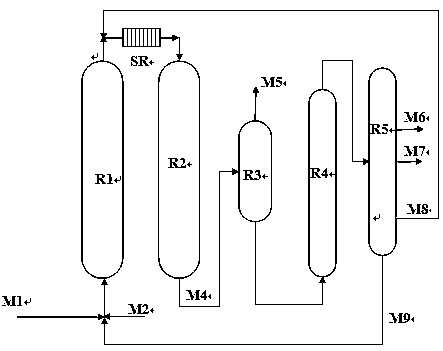

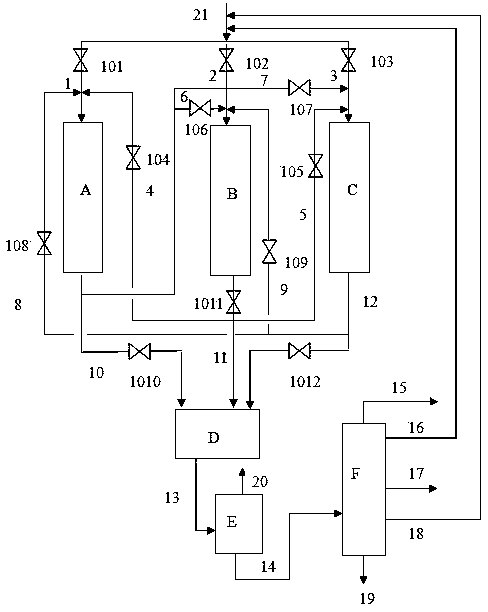

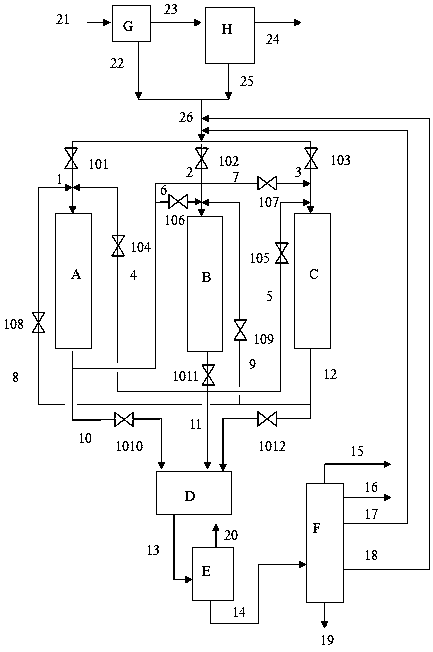

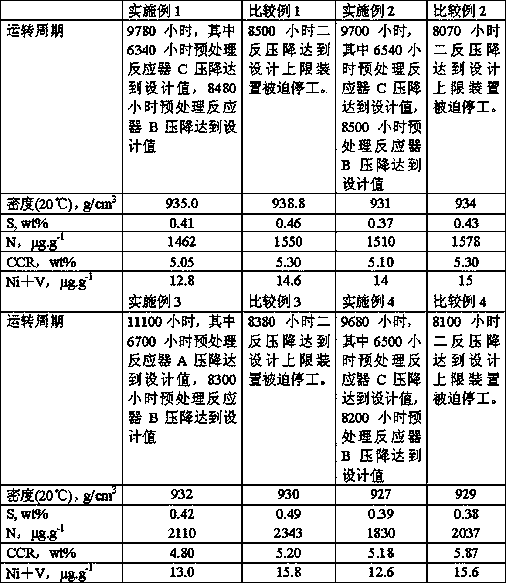

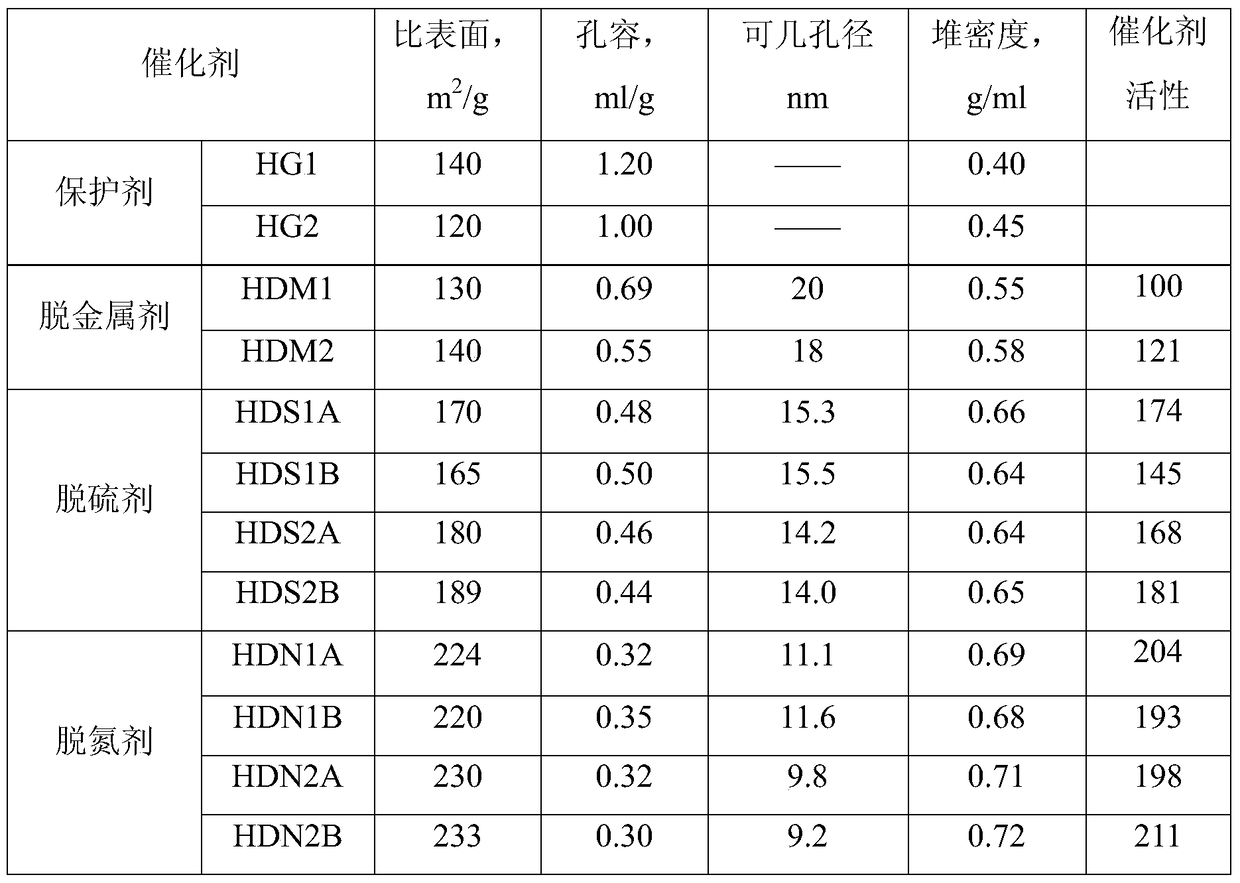

The invention discloses a process for treating an inferior oil product. The process comprises a hydropretreating reaction zone, a hydrotreating reaction zone and a catalytic cracking reaction zone. The process comprises the following contents: mixing a residual oil raw material and hydrogen, then successively allowing the mixture to pass through the hydropretreating reaction zone and the hydrotreating reaction zone which are connected in series, subjecting a reaction effluent of the hydrotreating reaction zone to gas-liquid separation, allowing a gas phase to recycle back to the hydropretreating reaction zone and / or the hydrotreating reaction zone, allowing a liquid phase to directly enter the catalytic cracking reaction zone and carrying out a catalytic cracking reaction, and separating a catalytic cracking reaction effluent so as to obtain dry gas, liquefied gas, catalytically cracked gasoline fraction, catalytically cracked diesel fraction, catalytically cracked heavy recycle oil and catalytically cracked slurry oil, wherein the catalytically cracked diesel oil, the catalytically cracked heavy recycle oil and the slurry oil are partially or completely recycled back to the hydrotreating reaction zone for a hydrotreating reaction. The method provided by the invention can prolong the cycle of stable operation of equipment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Residual oil hydrotreating-catalytic cracking combined process method

ActiveCN106701189AImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesGas phaseSlurry

The invention discloses a residual oil hydrotreating-catalytic cracking combined process method which includes a hydropretreating reaction zone, a hydrotreating reaction zone and a catalytic cracking reaction zone; the process method includes the following contents: a residual oil raw material, at least part of a catalytic cracking diesel oil fraction and hydrogen are mixed, and in turn pass through the hydropretreating reaction zone and the hydrotreating reaction zone which are in series connection, after gas-liquid separation of a hydrotreating reaction zone reaction effluent, a gas phase is recycled back to the hydropretreating reaction zone and / or the hydrotreating reaction zone, a liquid phase directly enters the catalytic cracking reaction zone for catalytic cracking reaction, a catalytic cracking reaction effluent is separated to obtain a dry gas, liquefied gas, a catalytic cracking gasoline fraction, a catalytic cracking diesel oil fraction, catalytic cracking heavy cycle oil and catalytic cracking oil slurry, and the catalytic cracking diesel oil is partially or totally recycled back to the hydrotreating reaction zone for hydrotreating reaction. The method can prolong the stable operation period of a device.

Owner:CHINA PETROLEUM & CHEM CORP +1

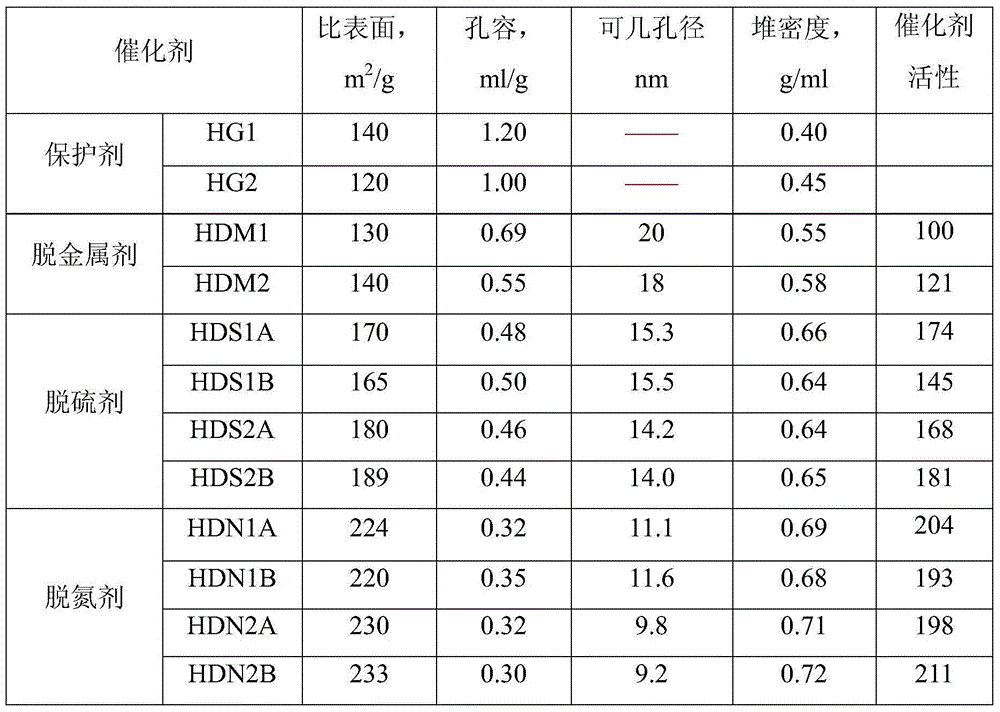

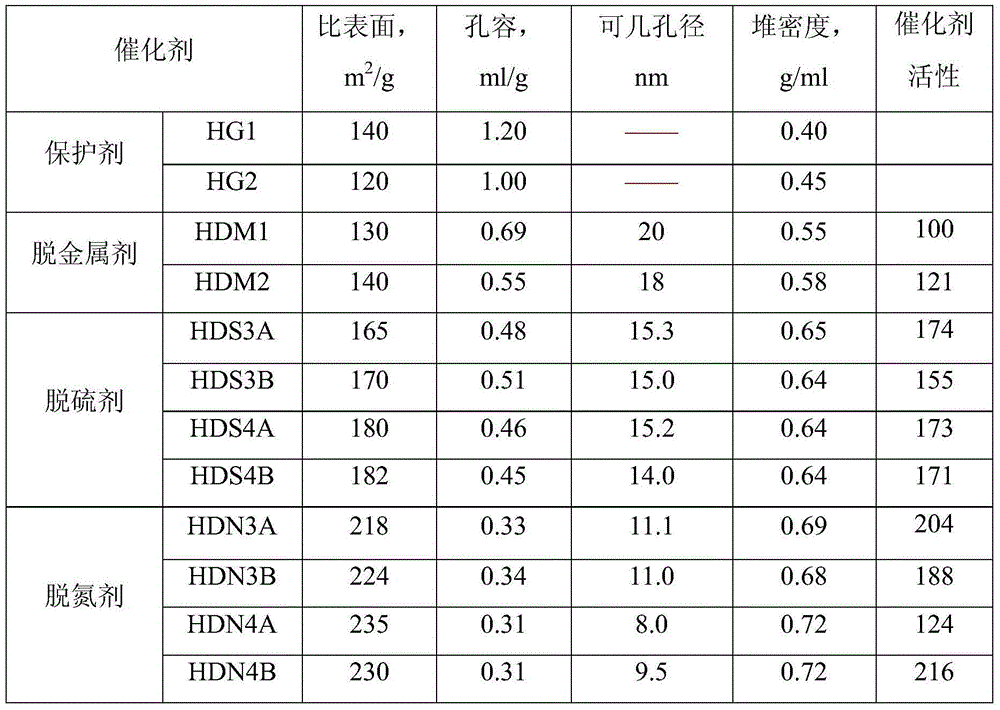

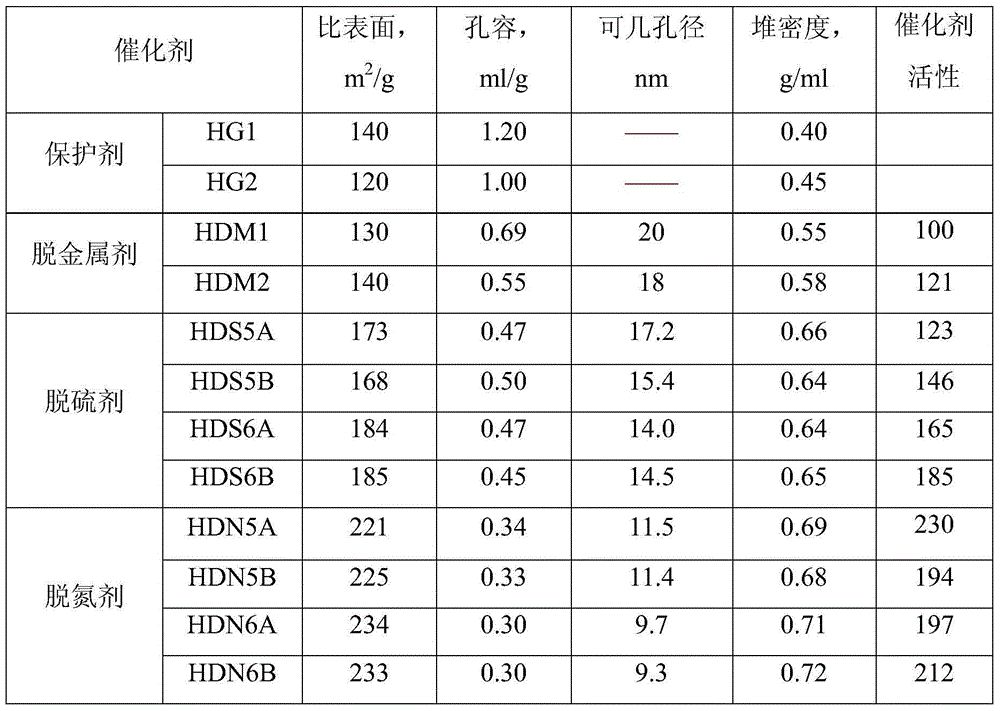

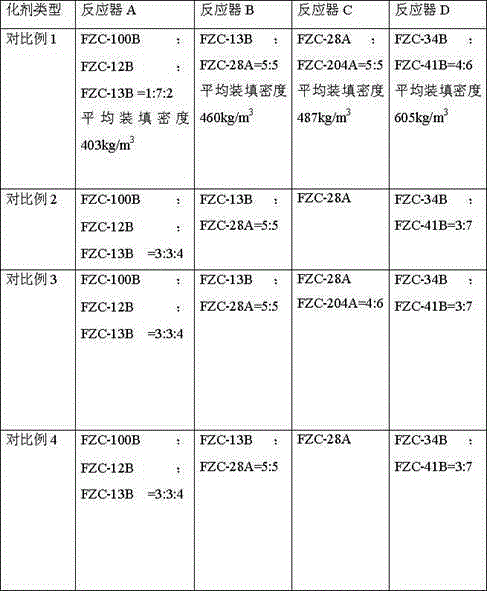

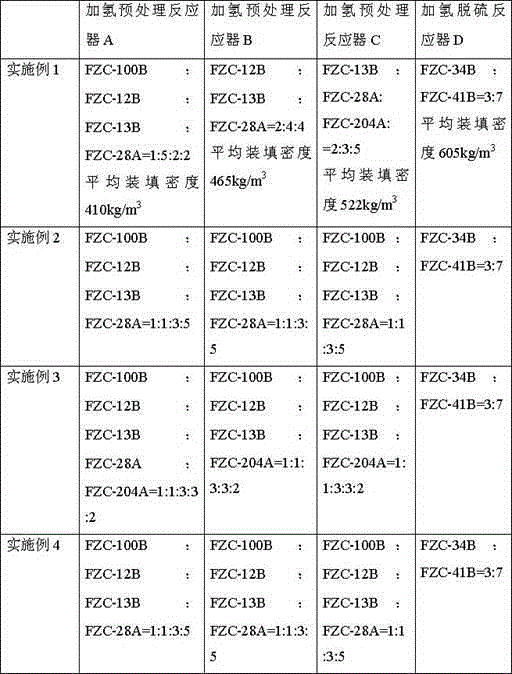

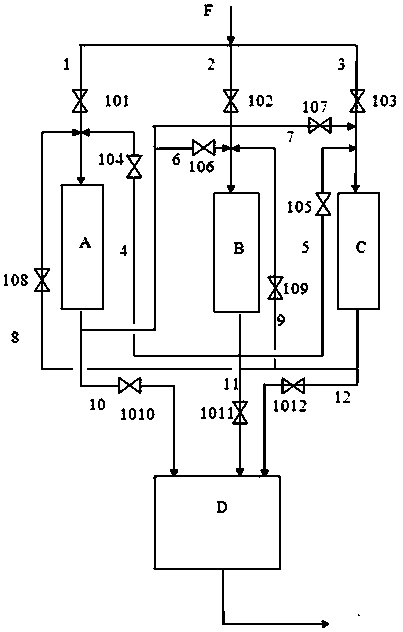

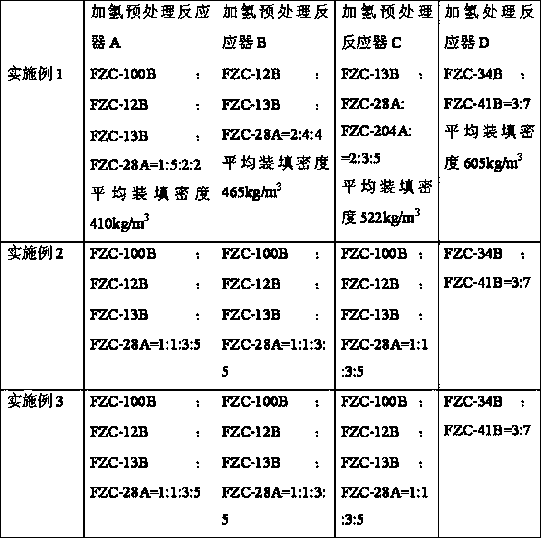

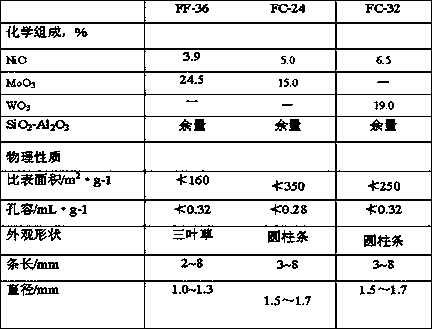

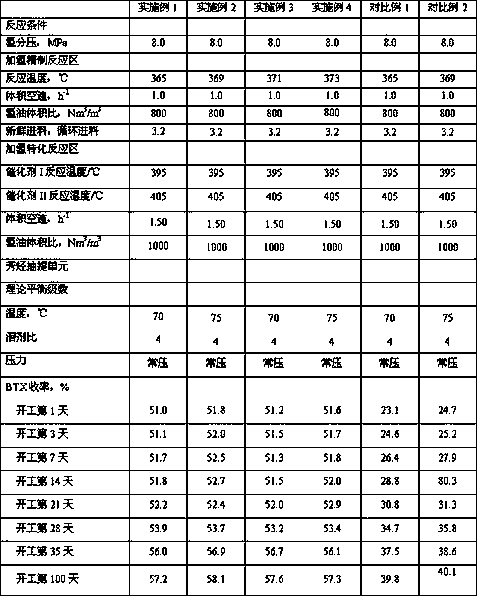

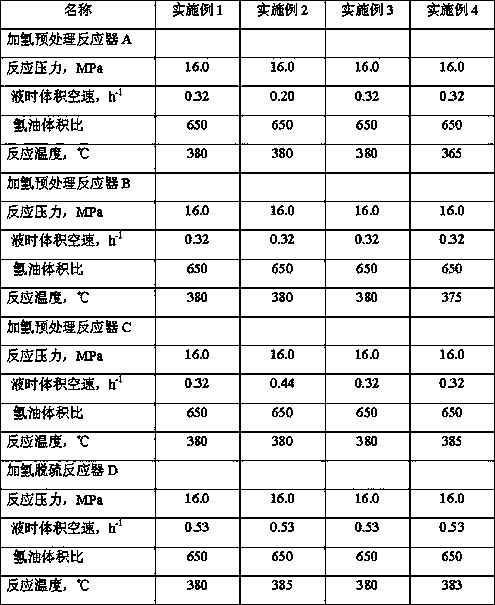

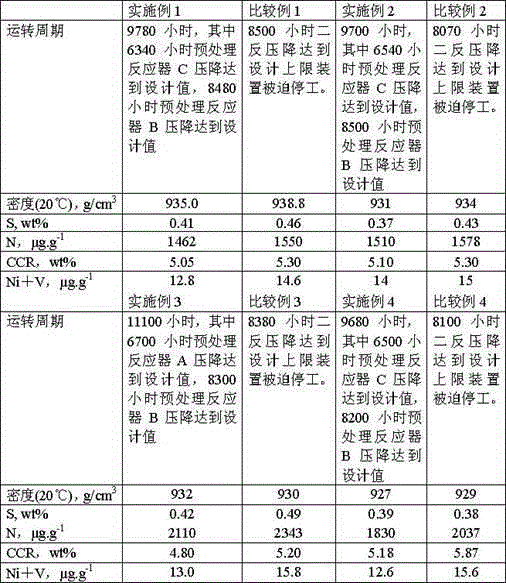

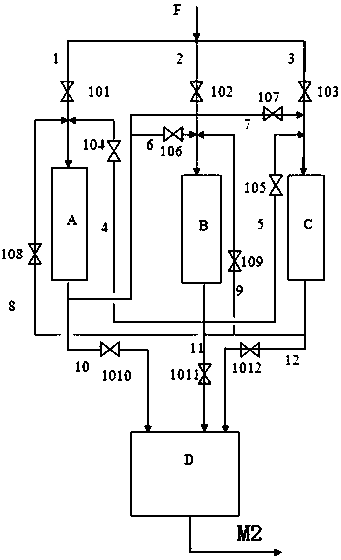

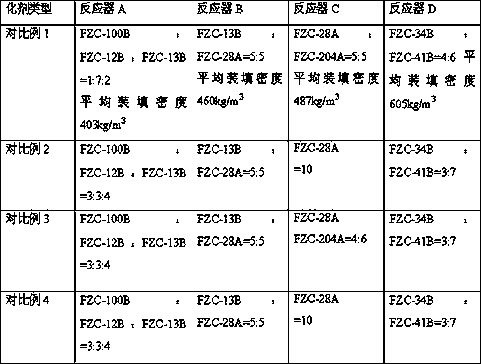

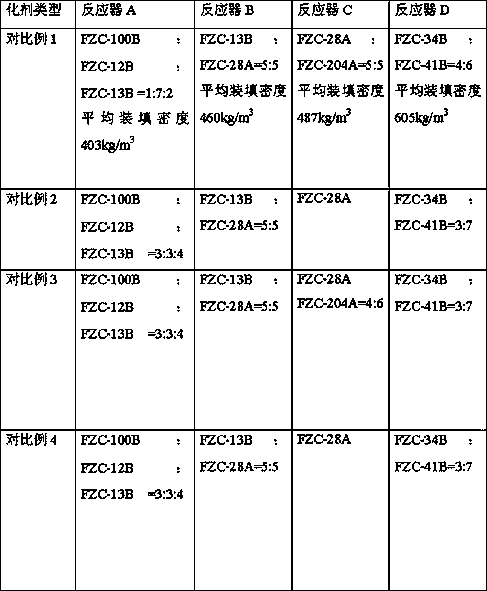

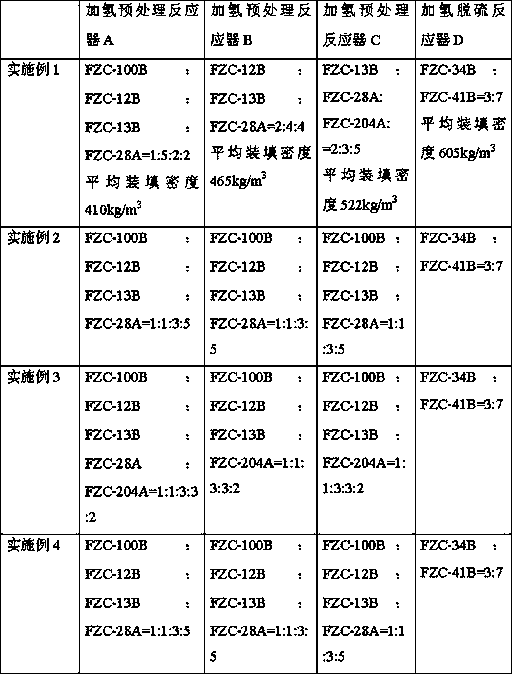

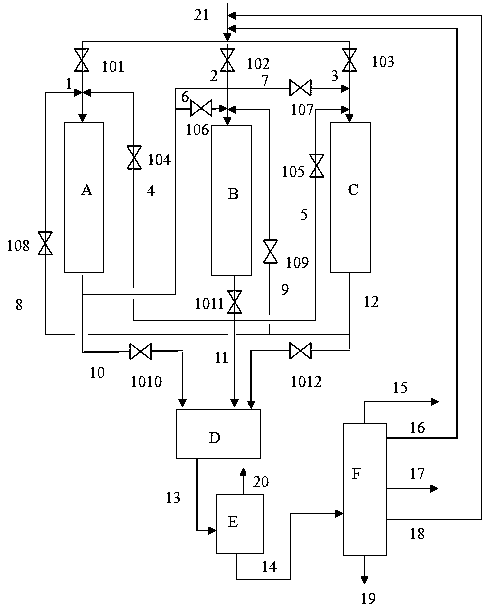

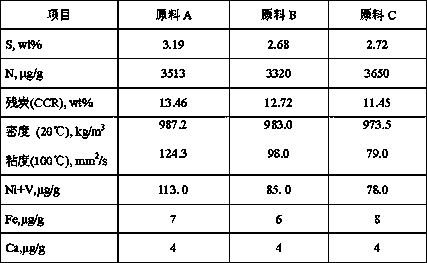

Gradation filling method of heavy oil hydrogenation treatment catalyst

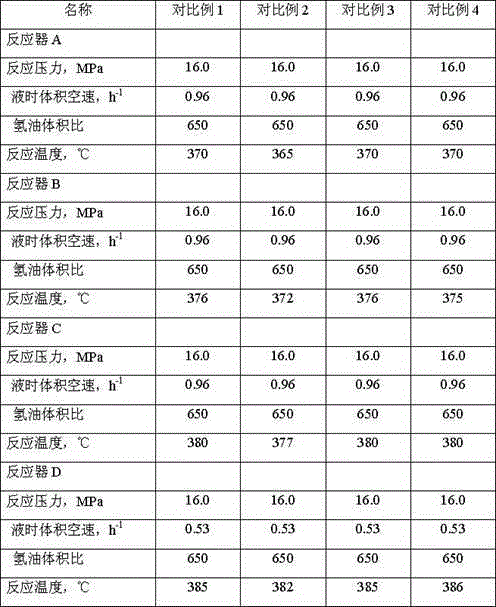

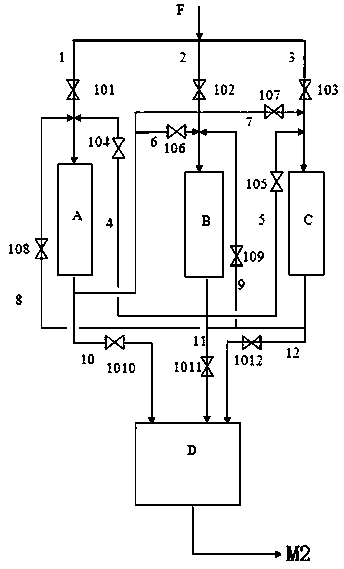

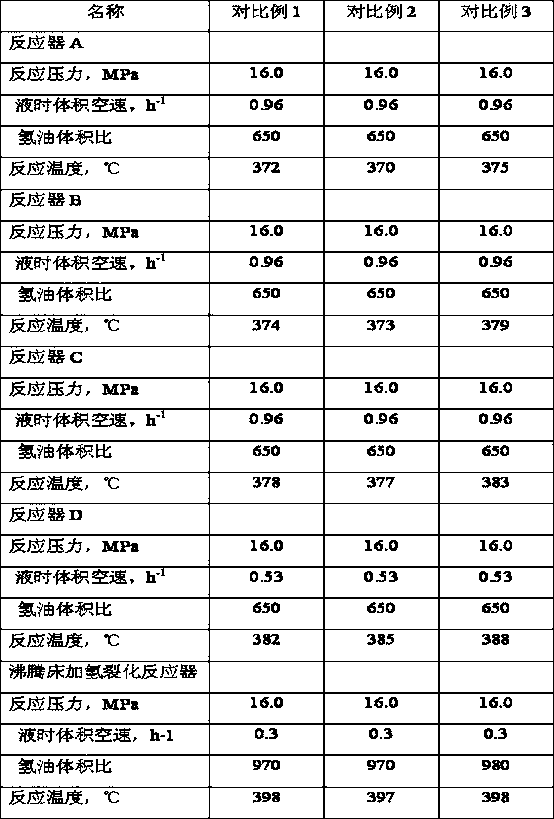

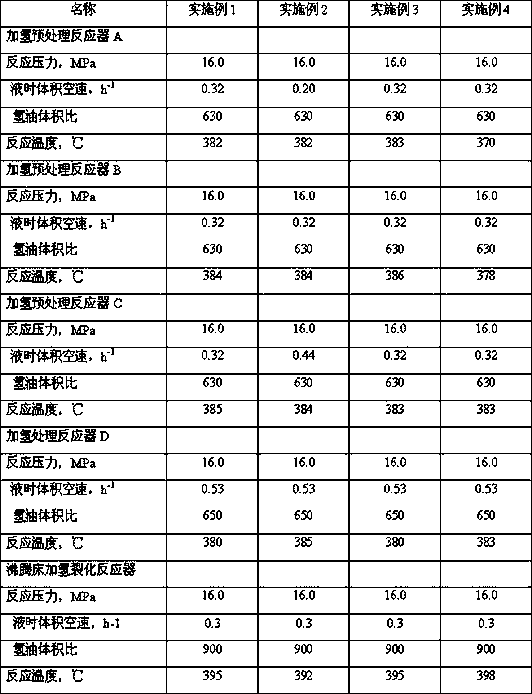

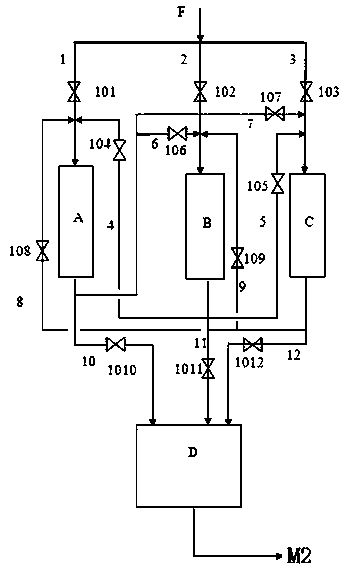

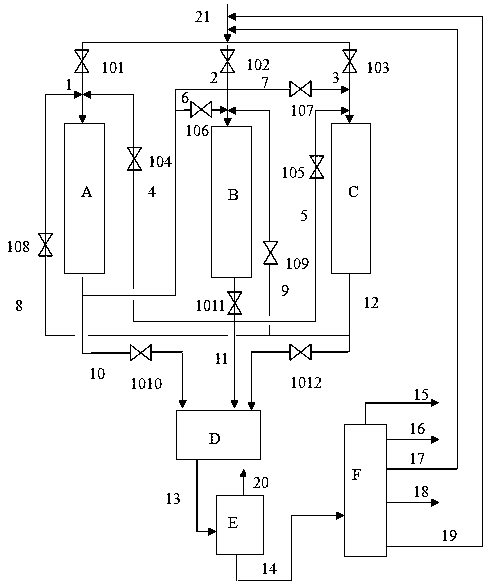

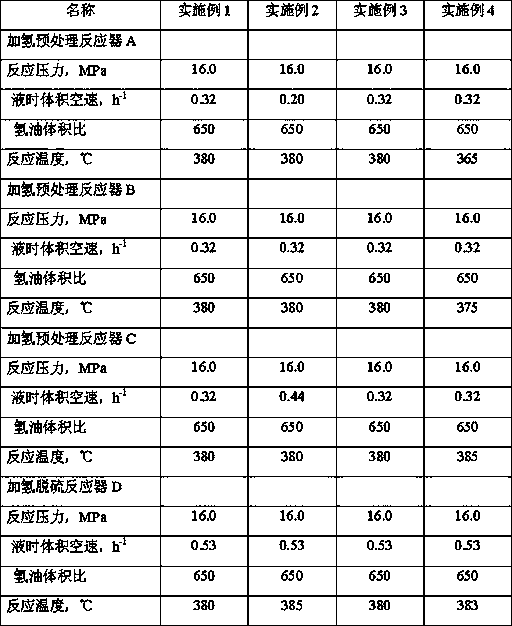

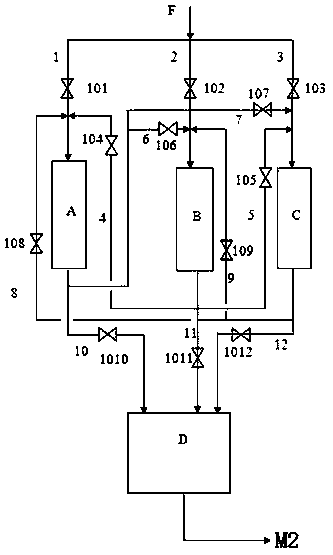

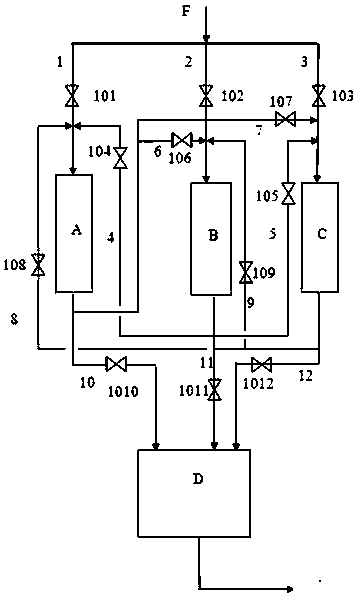

ActiveCN105985805AControl temperature riseRealize an organic relayTreatment with hydrotreatment processesHydrogenation reactionReaction system

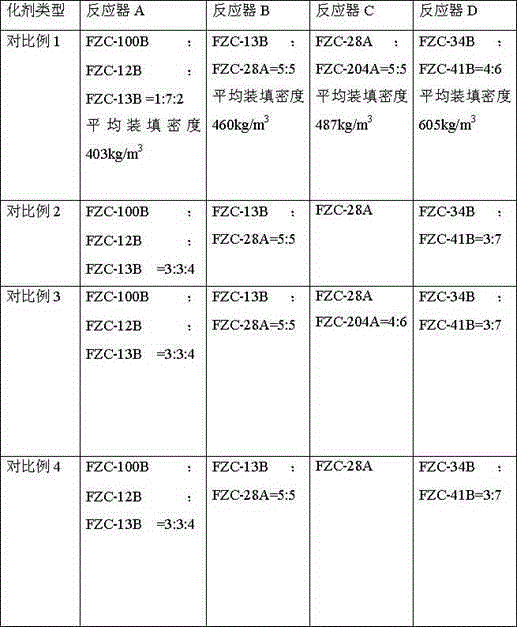

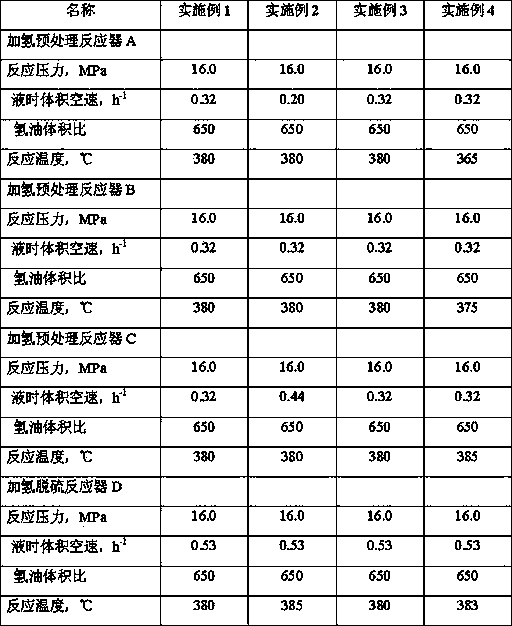

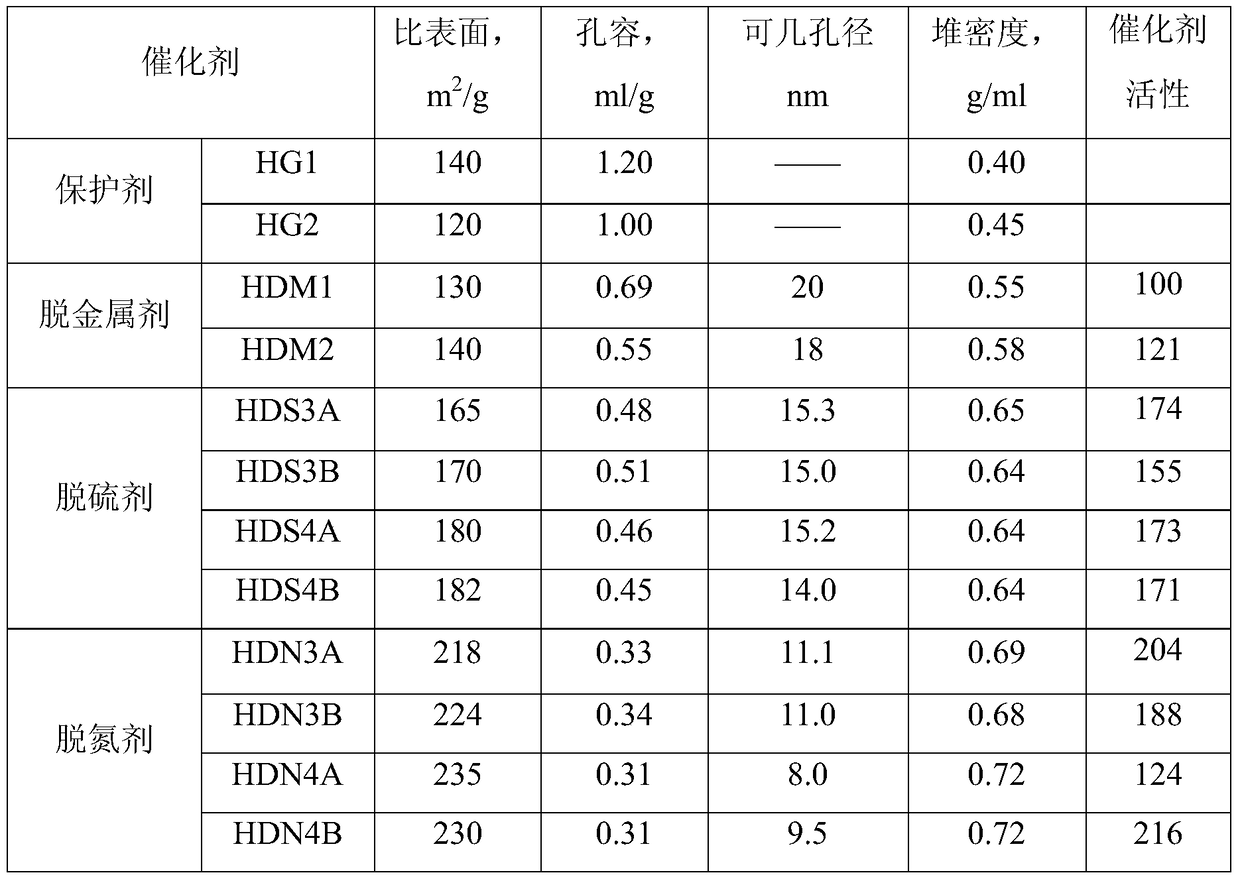

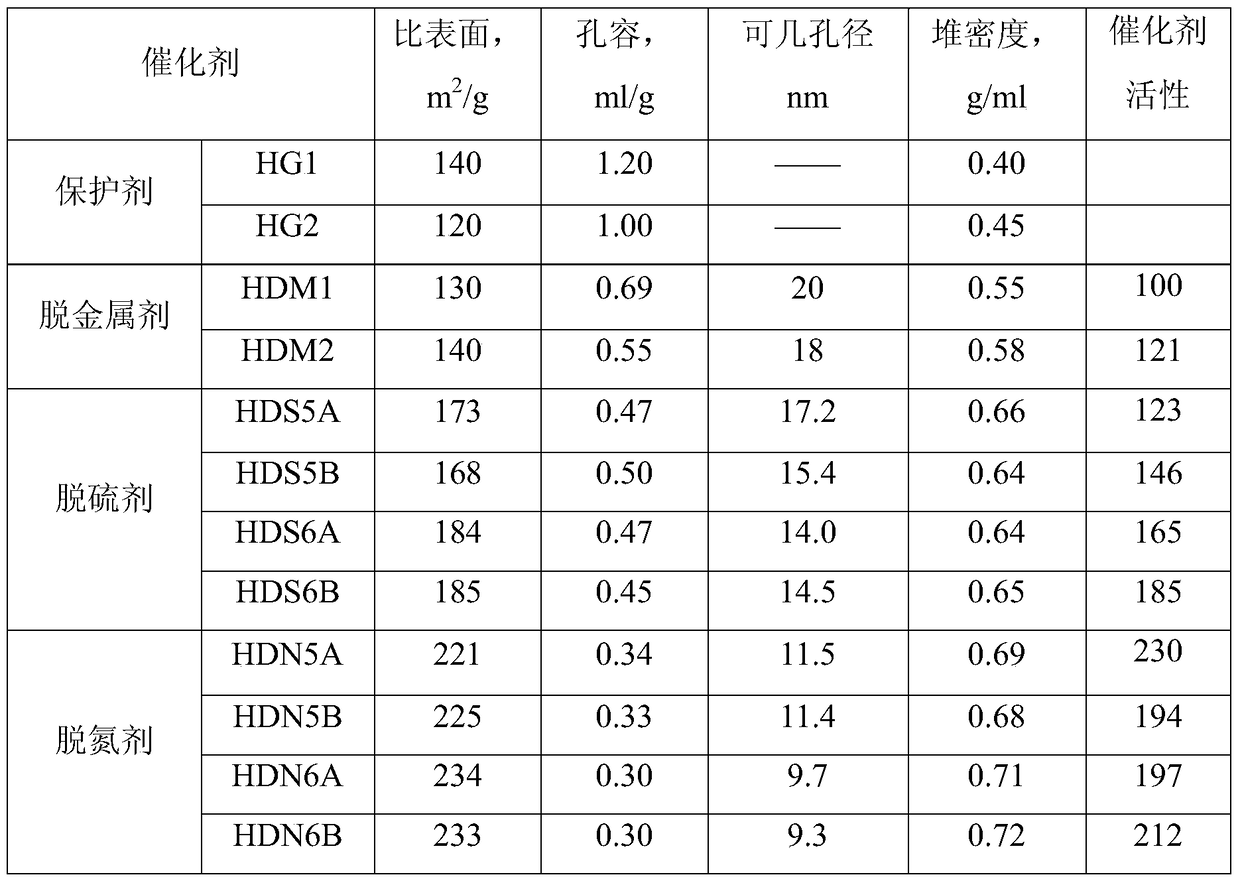

A gradation filling method of a heavy oil hydrogenation treatment catalyst. A reaction system includes two or more hydrogenation reactors connected in series. From the second reactor, the activity and probable pore size of the catalyst are both gradually decreased according to the sequence of contact with a reaction material flow in the same reactor. Between two adjacent reactors, according to the sequence of contact with the reaction material flow, the activity of the catalyst at the bottom of one reactor is lower than that at the top of the next one reactor, and the probable pore size of the catalyst at the bottom of one reactor is not more than that at the top of the next one reactor. Meanwhile, the activity of the catalyst at the bottom of one reactor is lower than that at the bottom of the next one reactor, and the probable pore size of the catalyst at the bottom of one reactor is large than that at the top of the next one reactor.

Owner:PETROCHINA CO LTD

Process for treating inferior oil

ActiveCN106701175AImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesCycle oilChemistry

The invention discloses a process for treating inferior oil, the process includes a hydropretreating reaction zone, a hydrotreating reaction zone and a catalytic cracking reaction zone; the process includes the following contents: a residual oil raw material and hydrogen are mixed, and in turn pass through the hydropretreating reaction zone and the hydrotreating reaction zone which are in series connection, after gas-liquid separation of a hydrotreating reaction zone reaction effluent, a gas phase is recycled back to the hydropretreating reaction zone and / or the hydrotreating reaction zone, a liquid phase directly enters the catalytic cracking reaction zone for catalytic cracking reaction, a catalytic cracking reaction effluent is separated to obtain a dry gas, liquefied gas, a catalytic cracking gasoline fraction, a catalytic cracking diesel oil fraction, catalytic cracking heavy cycle oil and catalytic cracking oil slurry, and the catalytic cracking diesel and the catalytic cracking heavy cycle oil are partially or totally recycled back to the hydrotreating reaction zone for hydrotreating reaction. The method can prolong the stable operation period of a device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process method for treating residual oil

ActiveCN106701192AImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesFractionationSlurry

The invention discloses a process method for treating residual oil. A hydrogenation pretreatment unit, a coking device, a hydrogenation treatment unit and a catalytic cracking device are provided; the hydrogenation pretreatment unit comprises a hydrogenation pretreatment reaction area and a hydrogenation treatment reaction area; the process method comprises the following steps: performing a reaction on a residual oil raw material by using the hydrogenation pretreatment unit, and performing oil fractionation so as to obtain light fraction and heavy fraction, feeding the heavy fraction into the coking device for treatment so as to obtain coked gasoline, coked diesel oil and coked wax oil, mixing the light fraction with the coked wax oil and hydrogen, passing through the hydrogenation pretreatment reaction area and the hydrogenation treatment reaction area which are connected in series, performing gas-liquid separation on a reaction effluent of the hydrogenation treatment reaction area, circulating vapor phase back to the hydrogenation pretreatment reaction area and / or the hydrogenation treatment reaction area, directly feeding liquid phase into the catalytic cracking reaction area for a catalytic cracking reaction, and separating a catalytic cracking reaction effluent, thereby obtaining a dry gas, a liquefied gas, catalytic cracking gasoline fraction, catalytic cracking area diesel oil fraction, catalytic cracking area recirculation oil and catalytic cracking area oil slurry. Due to adoption of the process method disclosed by the invention, the stable operation period of a device can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for treating residual oil with hydrogenation treatment and catalytic cracking processes

ActiveCN106701191AImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesGas phaseSlurry

The invention discloses a method for treating residual oil with hydrogenation treatment and catalytic cracking processes. A hydrogenation pretreatment reaction zone, a hydrogenation treatment reaction zone and a catalytic cracking reaction zone are contained; the method comprises steps as follows: a residual oil material and hydrogen are mixed and sequentially pass the hydrogenation pretreatment reaction zone and the hydrogenation treatment reaction zone which are connected in series; a reaction effluent in the hydrogenation treatment reaction zone is subjected to gas-liquid separation, a gas phase is recycled back to the hydrogenation pretreatment reaction zone and / or the hydrogenation treatment reaction zone, a liquid phase directly enters the catalytic cracking reaction zone for a catalytic cracking reaction, a catalytic cracking effluent is separated, and dry gas, liquefied gas, catalytic cracking gasoline fractions, catalytic cracking diesel fractions, catalytic cracking heavy cycle oil and catalytic cracking oil slurry are obtained, wherein parts of or all of catalytic cracking diesel and catalytic cracking oil slurry are recycled back to the hydrogenation treatment reaction zone for a hydrogenation treatment reaction. By means of the method, the stable operation cycle of a device can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment method of residual oil

ActiveCN106701185AImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesGas phaseSlurry

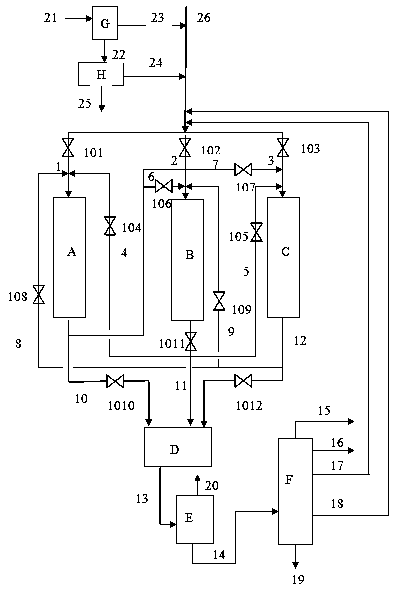

The invention discloses a treatment method of residual oil, which comprises a solvent deasphalting device, a hydrogenation pretreatment reaction area, a hydrogenation treatment reaction area and a catalytic cracking reaction area. The method comprises the following steps that the raw residual oil is fractionated to obtain a light fraction and a heavy fraction; the heavy fraction is treated in the solvent deasphalting device to obtain deasphalted oil and deoiled asphalt; the light fraction, the deasphalted oil and hydrogen are mixed and then sequentially pass through the hydrogenation pretreatment reaction area and the hydrogenation treatment reaction area which are connected in series; gas-liquid separation is performed on a reaction effluent of the hydrogenation treatment reaction area; a gas phase cycles back to the hydrogenation pretreatment reaction area and / or the hydrogenation treatment reaction area; a liquid phase directly enters the catalytic cracking reaction area to perform a catalytic cracking reaction; and a catalytic cracking reaction effluent is separated to obtain dry gas, liquefied gas, a catalytic cracking gasoline fraction, a catalytic cracking diesel fraction, catalytic cracking heavy cycle oil and catalytic cracking slurry oil. The method can prolong a stable operation period of a device.

Owner:CHINA PETROLEUM & CHEM CORP +1

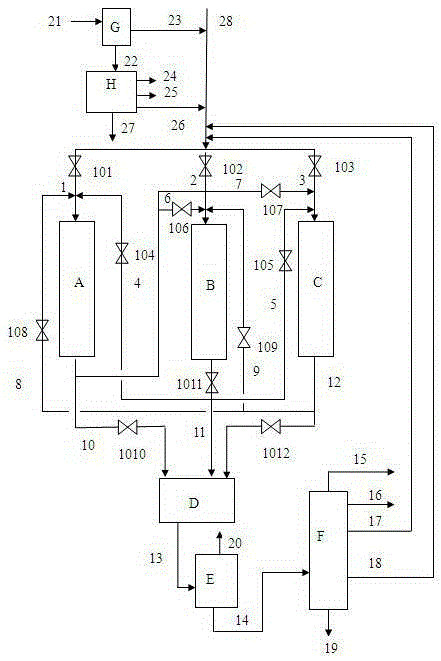

Combined process method for heavy oil conversion

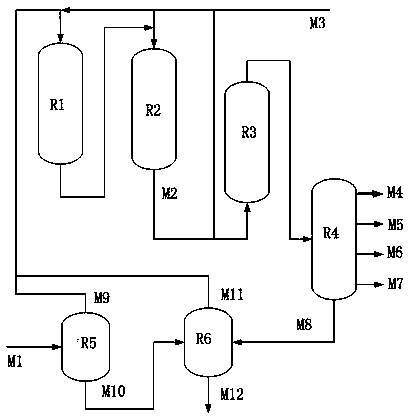

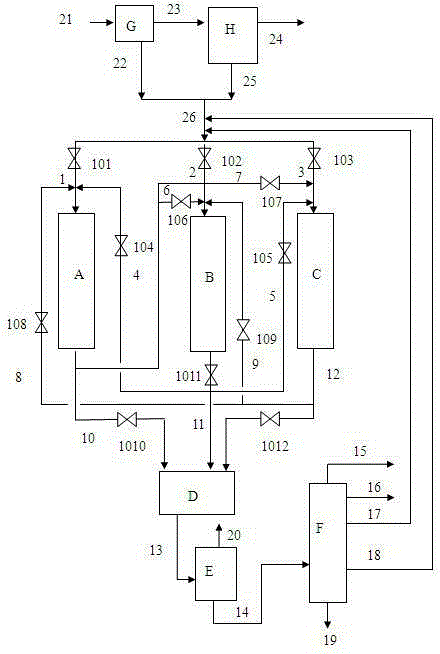

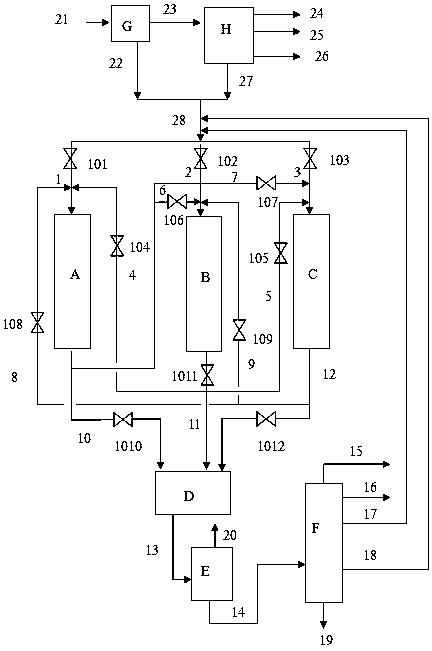

ActiveCN108102714AImprove utilization efficiencyThe method flow is simpleTreatment with hydrotreatment processesFluidized bedGasoline

The invention discloses a combined process method for heavy oil conversion. The method comprises the following steps: heavy oil raw materials enter a solvent deasphalting device, deasphalted oil and deoiled asphalt are obtained; the obtained deoiled asphalt enters a fluidized bed hydrotreating device for fluidized bed hydrotreating; reaction effluent obtained from fluidized bed hydrotreating is mixed with deasphalted oil; meanwhile, at least part of recycle oil from the catalytic cracking device is added for mixing, and a mixture sequentially passes through a fixed bed hydropretreating reaction zone and a fixed bed hydrotreating reaction zone which are arranged in series; generated oil obtained from reaction effluent of the fixed bed hydrotreating reaction zone is used as a raw material of the catalytic cracking device; catalytic cracking gasoline, catalytic cracking diesel oil, reclaimed oil and oil slurry are obtained after a catalytic cracking reaction product is separated. With adoption of the method, the operation period of a treatment device can be greatly prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for treating residual oil

ActiveCN106701187AImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesFractionationSlurry

The invention discloses a method for treating residual oil. A coking device, a hydrogenation pretreatment reaction area, a hydrogenation treatment reaction area and a catalytic cracking reaction area are provided, the method comprises the following steps: performing fractionation on a residual oil raw material so as to obtain light fraction and heavy fraction, feeding the heavy fraction into the coking device for treatment so as to obtain coked gasoline, coked diesel oil and coked wax oil, mixing the light fraction with the coked wax oil and hydrogen, passing through the hydrogenation pretreatment reaction area and the hydrogenation treatment reaction area which are connected in series, performing gas-liquid separation on a reaction effluent of the hydrogenation treatment reaction area, circulating vapor phase back to the hydrogenation pretreatment reaction area and / or the hydrogenation treatment reaction area, directly feeding liquid phase into the catalytic cracking reaction area for a catalytic cracking reaction, and separating a catalytic cracking reaction effluent, thereby obtaining a dry gas, a liquefied gas, catalytic cracking gasoline fraction, catalytic cracking area diesel oil fraction, catalytic cracking area recirculation oil and catalytic cracking area oil slurry. By adopting the method disclosed by the invention, the stable operation period of a device can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heavy oil hydrotreating method

ActiveCN108102706AImprove utilization efficiencyThe method flow is simpleTreatment with hydrotreatment processesFixed bedFuel oil

The invention discloses a heavy oil hydrotreating method. The method comprises the following steps: (1) heavy oil raw materials are fractionated, and light fractions and heavy fractions are obtained;(2) the heavy fractions obtained in the step (1) enter a solvent deasphalting device, and deasphalted oil and deoiled asphalt are obtained after treatment; (3) the light fractions obtained in the step(1) and the deasphalted oil obtained in the step (2) are mixed with hydrogen, a mixture passes through a fixed bed hydropretreating reaction zone and a fixed bed hydrotreating reaction zone which arearranged in series sequentially, generated oil obtained in the fixed bed hydrotreating reaction zone enters a fluidized bed hydrocracking reaction zone, a reaction effluent from the fluidized bed hydrocracking reaction zone is separated, and gas, gasoline, diesel oil, wax oil and unconverted oil are obtained; (4) after the unconverted oil obtained in the step (3) is mixed with the heavy fractionsobtained in the step (1), the mixture enters a solvent deasphalting device for treatment. With adoption of the method, the operation period of a treatment device can be greatly prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of heavy oil hydrotreating process method and system

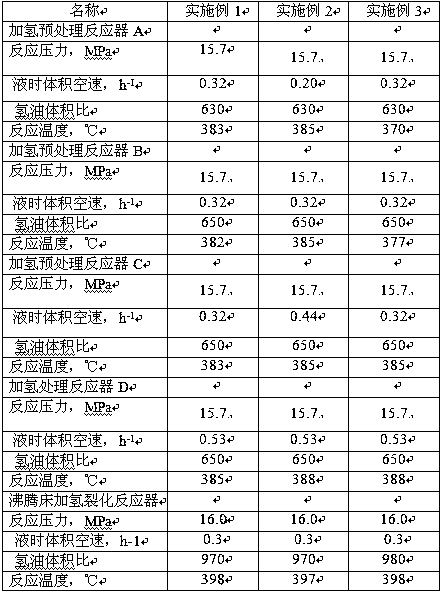

ActiveCN108102697BImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesHydrocarbon oils treatment productsWaxNaphtha

The invention relates to the field of heavy oil hydrotreatment, in particular to a heavy oil hydrotreating process method and system. The heavy oil hydrotreating process method comprises the followingsteps: heavy oil raw materials pass through a fixed bed hydropretreating reaction zone and a fixed bed hydrotreating reaction zone which are arranged in series sequentially; generated oil obtained from the fixed bed hydrotreating reaction zone enters a fluidized bed hydrocracking reaction zone; after reaction effluent of the fluidized bed hydrocracking reaction zone is separated, dry gas, liquefied gas, naphtha, diesel oil, wax oil and unconverted oil are obtained. With adoption of the heavy oil hydrotreating method, the operation period of a heavy oil hydrotreating device can be greatly prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of heavy oil hydrogenation processing method

ActiveCN108102706BImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesFixed bedFuel oil

The invention discloses a heavy oil hydrotreating method. The method comprises the following steps: (1) heavy oil raw materials are fractionated, and light fractions and heavy fractions are obtained;(2) the heavy fractions obtained in the step (1) enter a solvent deasphalting device, and deasphalted oil and deoiled asphalt are obtained after treatment; (3) the light fractions obtained in the step(1) and the deasphalted oil obtained in the step (2) are mixed with hydrogen, a mixture passes through a fixed bed hydropretreating reaction zone and a fixed bed hydrotreating reaction zone which arearranged in series sequentially, generated oil obtained in the fixed bed hydrotreating reaction zone enters a fluidized bed hydrocracking reaction zone, a reaction effluent from the fluidized bed hydrocracking reaction zone is separated, and gas, gasoline, diesel oil, wax oil and unconverted oil are obtained; (4) after the unconverted oil obtained in the step (3) is mixed with the heavy fractionsobtained in the step (1), the mixture enters a solvent deasphalting device for treatment. With adoption of the method, the operation period of a treatment device can be greatly prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for maximizing production of aromatic hydrocarbon by catalyzing diesel oil hydro-conversion

PendingCN111100705ABalance activitySolve the problem of low yield and non-compliance for a long timeTreatment with hydrotreatment processesPetroleum naphthaPtru catalyst

The invention discloses a method for maximizing production of aromatic hydrocarbon by catalyzing diesel oil hydro-conversion, comprising the following steps: (1) high aromatic hydrocarbon catalytic diesel oil and recycle hydrogen are mixed and enter a hydrofining reaction zone for reaction, the hydrofining reaction zone is provided with at least two catalyst beds, and the vulcanization degree of the catalyst in the material flow direction is in a decreasing trend; (2) the generated oil obtained in the step (1) enters a hydrocracking reaction zone to be in contact with at least two sulfurized hydrocracking catalysts to carry out ring-opening conversion reaction of polycyclic aromatic hydrocarbon; (3) the generated oil obtained in the step (2) passes through a separation system to obtain gas, gasoline and diesel oil fractions, and the diesel oil fractions are completely recycled back to the hydrofining reaction zone; and (4) naphtha obtained in the step (3) enters an aromatic hydrocarbonextraction device, and a BTX product is obtained through solvent extraction. Hydrogenation catalysts with different vulcanization degrees are used through grading, the initial activity of the catalyst is balanced, and the problems that the initial adjustment period is long in the technical application process and the octane number of a main target product gasoline fraction is low for a long timeare solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for processing heavy raw materials

ActiveCN108102715AExtended operating cycleImprove utilization efficiencyTreatment with hydrotreatment processesHydrocarbon oils treatment productsFluidized bedGasoline

The invention discloses a method for processing heavy raw materials. The method comprises the following steps: heavy raw materials are mixed with at least part of oil slurry of a catalytic cracking device, and a mixture enters a fluidized bed reactor for hydrotreatment; obtained f reaction effluent of luidized bed hydrotreatment, at least part of recycle oil from the catalytic cracking device andhydrogen are mixed and then sequentially pass through a fixed bed hydropretreating reaction zone and a fixed bed hydrotreating reaction zone which are arranged in series for a reaction; generated oiltaken as a raw material of the catalytic cracking device enters the catalytic cracking device, catalytic cracking reaction products obtained by a fractionating tower of the catalytic cracking device comprise gasoline fraction, diesel fraction, the recycle oil and the oil slurry. With adoption of the method, the operation period of a processing device can be greatly prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of residual oil processing method

ActiveCN106701185BImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesGas phaseSlurry

The invention discloses a treatment method of residual oil, which comprises a solvent deasphalting device, a hydrogenation pretreatment reaction area, a hydrogenation treatment reaction area and a catalytic cracking reaction area. The method comprises the following steps that the raw residual oil is fractionated to obtain a light fraction and a heavy fraction; the heavy fraction is treated in the solvent deasphalting device to obtain deasphalted oil and deoiled asphalt; the light fraction, the deasphalted oil and hydrogen are mixed and then sequentially pass through the hydrogenation pretreatment reaction area and the hydrogenation treatment reaction area which are connected in series; gas-liquid separation is performed on a reaction effluent of the hydrogenation treatment reaction area; a gas phase cycles back to the hydrogenation pretreatment reaction area and / or the hydrogenation treatment reaction area; a liquid phase directly enters the catalytic cracking reaction area to perform a catalytic cracking reaction; and a catalytic cracking reaction effluent is separated to obtain dry gas, liquefied gas, a catalytic cracking gasoline fraction, a catalytic cracking diesel fraction, catalytic cracking heavy cycle oil and catalytic cracking slurry oil. The method can prolong a stable operation period of a device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heavy oil product treatment processing method

ActiveCN106701188AImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesHydrocarbon oils treatment productsGas phaseSlurry

The invention discloses a heavy oil product treatment processing method. The method comprises a hydrogenation pretreatment device, a solvent deasphalting device, a hydrogenation treatment device and a catalytic cracking device, wherein the hydrogenation treatment device comprises a hydrogenation pretreatment reaction area and a hydrogenation treatment reaction area; the processing method comprises the following steps: residual oil raw material generated oil is subjected to fractional distillation after being reacted through a hydrogenation pretreatment unit to obtain light fraction and heavy fraction, wherein the heavy fraction is treated after entering the solvent deasphalting device so as to obtain deasphalted oil and deoiled asphalt, and the light fraction orderly passes through the hydrogenation pretreatment reaction area and the hydrogenation treatment reaction area which are in series connection after mixing with the deasphalted oil and hydrogen; gas-liquid separation is performed on reaction effluent of the hydrogenation treatment reaction area, and a gas phase is recycled back to the hydrogenation pretreatment reaction area and / or the hydrogenation treatment reaction area; a liquid phase directly enters a catalytic cracking reaction area to perform catalytic cracking reaction, and effluent of the catalytic cracking reaction is separated to obtain dry gas, liquefied gas, catalytic-cracked gasoline fraction, catalytic-cracked diesel fraction, catalytic-cracked heavy cycle oil and catalytic-cracked oil slurry. The stable operation period of the device can be prolonged by use of the method disclosed by the invention.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heavy oil hydrotreating process method and system

ActiveCN108102697AImprove utilization efficiencyExtended operating cycleTreatment with hydrotreatment processesHydrocarbon oils treatment productsWaxNaphtha

The invention relates to the field of heavy oil hydrotreatment, in particular to a heavy oil hydrotreating process method and system. The heavy oil hydrotreating process method comprises the followingsteps: heavy oil raw materials pass through a fixed bed hydropretreating reaction zone and a fixed bed hydrotreating reaction zone which are arranged in series sequentially; generated oil obtained from the fixed bed hydrotreating reaction zone enters a fluidized bed hydrocracking reaction zone; after reaction effluent of the fluidized bed hydrocracking reaction zone is separated, dry gas, liquefied gas, naphtha, diesel oil, wax oil and unconverted oil are obtained. With adoption of the heavy oil hydrotreating method, the operation period of a heavy oil hydrotreating device can be greatly prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for treating residual oil by hydrotreating-catalytic cracking process

ActiveCN106701191BImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesGas phaseSlurry

The invention discloses a method for treating residual oil with hydrogenation treatment and catalytic cracking processes. A hydrogenation pretreatment reaction zone, a hydrogenation treatment reaction zone and a catalytic cracking reaction zone are contained; the method comprises steps as follows: a residual oil material and hydrogen are mixed and sequentially pass the hydrogenation pretreatment reaction zone and the hydrogenation treatment reaction zone which are connected in series; a reaction effluent in the hydrogenation treatment reaction zone is subjected to gas-liquid separation, a gas phase is recycled back to the hydrogenation pretreatment reaction zone and / or the hydrogenation treatment reaction zone, a liquid phase directly enters the catalytic cracking reaction zone for a catalytic cracking reaction, a catalytic cracking effluent is separated, and dry gas, liquefied gas, catalytic cracking gasoline fractions, catalytic cracking diesel fractions, catalytic cracking heavy cycle oil and catalytic cracking oil slurry are obtained, wherein parts of or all of catalytic cracking diesel and catalytic cracking oil slurry are recycled back to the hydrogenation treatment reaction zone for a hydrogenation treatment reaction. By means of the method, the stable operation cycle of a device can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Combined technique and system for treating inferior oils

ActiveCN108102700AImprove utilization efficiencyProcess method is simpleHydrocarbon oil crackingTreatment with hydrotreatment processesHydrogenFixed bed

The invention discloses a combined technique and system for treating inferior oils and relates to the field of treatment of inferior oils. The combined technique for treating inferior oils comprises the steps as follows: a heavy oil material produces oil and hydrogen in a fixed bed hydrogenation treatment reaction zone, the oil and the hydrogen are mixed to enter a bubbling bed hydrocracking reaction zone to react, a reaction effluent is separated, and dry gas, liquefied gas, gasoline, diesel and a heavy faction are obtained; the obtained heavy faction sequentially passes through a fixed bed hydrogenation pretreatment reaction zone and the fixed bed hydrogenation treatment reaction zone which are connected in series, and produced oil obtained in the fixed bed hydrogenation treatment reaction zone enters the bubbling bed hydrocracking reaction zone. The operation cycle of a treatment device can be substantially prolonged with the method.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for treating residual oil

ActiveCN106701187BImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesFractionationSlurry

The invention discloses a method for treating residual oil. A coking device, a hydrogenation pretreatment reaction area, a hydrogenation treatment reaction area and a catalytic cracking reaction area are provided, the method comprises the following steps: performing fractionation on a residual oil raw material so as to obtain light fraction and heavy fraction, feeding the heavy fraction into the coking device for treatment so as to obtain coked gasoline, coked diesel oil and coked wax oil, mixing the light fraction with the coked wax oil and hydrogen, passing through the hydrogenation pretreatment reaction area and the hydrogenation treatment reaction area which are connected in series, performing gas-liquid separation on a reaction effluent of the hydrogenation treatment reaction area, circulating vapor phase back to the hydrogenation pretreatment reaction area and / or the hydrogenation treatment reaction area, directly feeding liquid phase into the catalytic cracking reaction area for a catalytic cracking reaction, and separating a catalytic cracking reaction effluent, thereby obtaining a dry gas, a liquefied gas, catalytic cracking gasoline fraction, catalytic cracking area diesel oil fraction, catalytic cracking area recirculation oil and catalytic cracking area oil slurry. By adopting the method disclosed by the invention, the stable operation period of a device can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

A combined process method and system for processing inferior oil products

ActiveCN108102700BImproved ability to remove/accommodate metalsDoes not limit the operating cycleHydrocarbon oil crackingTreatment with hydrotreatment processesHydrogenFixed bed

The invention discloses a combined technique and system for treating inferior oils and relates to the field of treatment of inferior oils. The combined technique for treating inferior oils comprises the steps as follows: a heavy oil material produces oil and hydrogen in a fixed bed hydrogenation treatment reaction zone, the oil and the hydrogen are mixed to enter a bubbling bed hydrocracking reaction zone to react, a reaction effluent is separated, and dry gas, liquefied gas, gasoline, diesel and a heavy faction are obtained; the obtained heavy faction sequentially passes through a fixed bed hydrogenation pretreatment reaction zone and the fixed bed hydrogenation treatment reaction zone which are connected in series, and produced oil obtained in the fixed bed hydrogenation treatment reaction zone enters the bubbling bed hydrocracking reaction zone. The operation cycle of a treatment device can be substantially prolonged with the method.

Owner:CHINA PETROLEUM & CHEM CORP +1

A combined process method for heavy oil conversion

ActiveCN108102714BImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesFluidized bedGasoline

The invention discloses a combined process method for heavy oil conversion. The method comprises the following steps: heavy oil raw materials enter a solvent deasphalting device, deasphalted oil and deoiled asphalt are obtained; the obtained deoiled asphalt enters a fluidized bed hydrotreating device for fluidized bed hydrotreating; reaction effluent obtained from fluidized bed hydrotreating is mixed with deasphalted oil; meanwhile, at least part of recycle oil from the catalytic cracking device is added for mixing, and a mixture sequentially passes through a fixed bed hydropretreating reaction zone and a fixed bed hydrotreating reaction zone which are arranged in series; generated oil obtained from reaction effluent of the fixed bed hydrotreating reaction zone is used as a raw material of the catalytic cracking device; catalytic cracking gasoline, catalytic cracking diesel oil, reclaimed oil and oil slurry are obtained after a catalytic cracking reaction product is separated. With adoption of the method, the operation period of a treatment device can be greatly prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of low-quality oil treatment process method

ActiveCN106701175BImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesOil processingGas phase

The invention discloses a process for treating inferior oil, the process includes a hydropretreating reaction zone, a hydrotreating reaction zone and a catalytic cracking reaction zone; the process includes the following contents: a residual oil raw material and hydrogen are mixed, and in turn pass through the hydropretreating reaction zone and the hydrotreating reaction zone which are in series connection, after gas-liquid separation of a hydrotreating reaction zone reaction effluent, a gas phase is recycled back to the hydropretreating reaction zone and / or the hydrotreating reaction zone, a liquid phase directly enters the catalytic cracking reaction zone for catalytic cracking reaction, a catalytic cracking reaction effluent is separated to obtain a dry gas, liquefied gas, a catalytic cracking gasoline fraction, a catalytic cracking diesel oil fraction, catalytic cracking heavy cycle oil and catalytic cracking oil slurry, and the catalytic cracking diesel and the catalytic cracking heavy cycle oil are partially or totally recycled back to the hydrotreating reaction zone for hydrotreating reaction. The method can prolong the stable operation period of a device.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of method of combined process processing residual oil

ActiveCN106701184BImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesGas phaseSlurry

The invention discloses a method for treating residual oil by a combined process; and a hydrogenation pretreatment reaction zone, a hydrotreating reaction zone and a catalytic cracking reaction zone are included. The method comprises the following steps: mixing a residual oil raw material and hydrogen, successively passing the mixture through the hydrogenation pretreatment reaction zone and the hydrotreating reaction zone which are connected in series; conducting gas-liquid separation on the reaction effluent from the hydrotreating reaction zone; recycling the gas phase to the hydrogenation pretreatment reaction zone and / or the hydrotreating reaction zone; sending the liquid phase directly into the catalytic cracking reaction zone and conducting a catalytic cracking reaction; and separating the effluent obtained by the catalytic cracking reaction to obtain dry gas, liquefied gas, a catalytic cracking gasoline fraction, a catalytic cracking diesel oil fraction, catalytic cracking heavy cycle oil and catalytic cracking slurry oil, wherein the catalytic cracking gasoline and the catalytic cracking heavy cycle oil are partially or completely recycled into the hydrotreating reaction zone for a hydrotreating reaction. The method provided by the invention can extend the stable operation period of the device.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for lightening heavy oil

ActiveCN108102705BImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesWaxAfter treatment

The invention discloses a light treatment method for heavy oil. The method comprises the following steps: a heavy oil raw material is fractionated, light fractions and heavy fractions are obtained, the obtained heavy fractions enter a coking device, and coked gasoline, coked diesel oil, coked wax oil and coke are obtained after treatment; the light fractions, the coked wax oil and hydrogen are mixed and sequentially pass through a fixed bed hydropretreating reaction zone and a fixed bed hydrotreating reaction zone which are arranged in series, generated oil obtained from the fixed bed hydrotreating reaction zone enters a fluidized bed hydrocracking reaction zone, and after reaction effluent of the fluidized bed hydrocracking reaction zone is separated, gas, gasoline, diesel oil, wax oil and unconverted oil are obtained; the obtained unconverted oil is mixed with the heavy fractions, and a mixture enters a coking unit for treatment. With adoption of the method, the operation period of aheavy oil hydrotreating device can be greatly prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of processing method of heavy oil raw material

ActiveCN108102715BLess investmentImproved ability to remove/accommodate metalsTreatment with hydrotreatment processesHydrocarbon oils treatment productsFluidized bedGasoline

The invention discloses a method for processing heavy raw materials. The method comprises the following steps: heavy raw materials are mixed with at least part of oil slurry of a catalytic cracking device, and a mixture enters a fluidized bed reactor for hydrotreatment; obtained f reaction effluent of luidized bed hydrotreatment, at least part of recycle oil from the catalytic cracking device andhydrogen are mixed and then sequentially pass through a fixed bed hydropretreating reaction zone and a fixed bed hydrotreating reaction zone which are arranged in series for a reaction; generated oiltaken as a raw material of the catalytic cracking device enters the catalytic cracking device, catalytic cracking reaction products obtained by a fractionating tower of the catalytic cracking device comprise gasoline fraction, diesel fraction, the recycle oil and the oil slurry. With adoption of the method, the operation period of a processing device can be greatly prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of processing method of residual oil

ActiveCN106701192BImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesFractionationSlurry

The invention discloses a process method for treating residual oil. A hydrogenation pretreatment unit, a coking device, a hydrogenation treatment unit and a catalytic cracking device are provided; the hydrogenation pretreatment unit comprises a hydrogenation pretreatment reaction area and a hydrogenation treatment reaction area; the process method comprises the following steps: performing a reaction on a residual oil raw material by using the hydrogenation pretreatment unit, and performing oil fractionation so as to obtain light fraction and heavy fraction, feeding the heavy fraction into the coking device for treatment so as to obtain coked gasoline, coked diesel oil and coked wax oil, mixing the light fraction with the coked wax oil and hydrogen, passing through the hydrogenation pretreatment reaction area and the hydrogenation treatment reaction area which are connected in series, performing gas-liquid separation on a reaction effluent of the hydrogenation treatment reaction area, circulating vapor phase back to the hydrogenation pretreatment reaction area and / or the hydrogenation treatment reaction area, directly feeding liquid phase into the catalytic cracking reaction area for a catalytic cracking reaction, and separating a catalytic cracking reaction effluent, thereby obtaining a dry gas, a liquefied gas, catalytic cracking gasoline fraction, catalytic cracking area diesel oil fraction, catalytic cracking area recirculation oil and catalytic cracking area oil slurry. Due to adoption of the process method disclosed by the invention, the stable operation period of a device can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for treating residual oil by combined process

ActiveCN106701184AImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesGas phaseSlurry

The invention discloses a method for treating residual oil by a combined process; and a hydrogenation pretreatment reaction zone, a hydrotreating reaction zone and a catalytic cracking reaction zone are included. The method comprises the following steps: mixing a residual oil raw material and hydrogen, successively passing the mixture through the hydrogenation pretreatment reaction zone and the hydrotreating reaction zone which are connected in series; conducting gas-liquid separation on the reaction effluent from the hydrotreating reaction zone; recycling the gas phase to the hydrogenation pretreatment reaction zone and / or the hydrotreating reaction zone; sending the liquid phase directly into the catalytic cracking reaction zone and conducting a catalytic cracking reaction; and separating the effluent obtained by the catalytic cracking reaction to obtain dry gas, liquefied gas, a catalytic cracking gasoline fraction, a catalytic cracking diesel oil fraction, catalytic cracking heavy cycle oil and catalytic cracking slurry oil, wherein the catalytic cracking gasoline and the catalytic cracking heavy cycle oil are partially or completely recycled into the hydrotreating reaction zone for a hydrotreating reaction. The method provided by the invention can extend the stable operation period of the device.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of heavy oil treatment process method

ActiveCN106701188BImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesHydrocarbon oils treatment productsOil processingGas phase

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of graded packing method of heavy oil hydrotreating catalyst

ActiveCN105985805BControl temperature riseAchieve matchingTreatment with hydrotreatment processesPore diameterReaction system

A gradation loading method for heavy oil hydrotreating catalysts, the reaction system includes two or more hydrogenation reactors in series, starting from the second reactor, in the same reactor, according to the order of contact with the reactant stream , both the catalyst activity and the possible pore size show a decreasing trend; in two adjacent reactors, according to the order of contact with the reactant stream, the activity of the catalyst at the bottom of the former reactor is lower than that of the catalyst at the top of the latter reactor, and the catalyst at the bottom of the former reactor The pore diameter of the catalyst at the top of the latter reactor is not greater than the pore diameter of the catalyst at the top of the latter reactor; at the same time, the activity of the catalyst at the bottom of the former reactor is lower than that of the catalyst at the bottom of the latter reactor, and the pore diameter of the catalyst at the bottom of the former reactor is larger than that of the catalyst at the top of the latter reactor Can be several apertures.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com