A method for treating residual oil by hydrotreating-catalytic cracking process

A technology of catalytic cracking diesel oil and catalytic cracking oil slurry, which is applied in the field of heavy oil treatment by hydrogenation-catalysis combined process, and can solve the problems that cannot fundamentally change the pressure drop growth trend of the pre-reactor and unfavorable stable operation of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

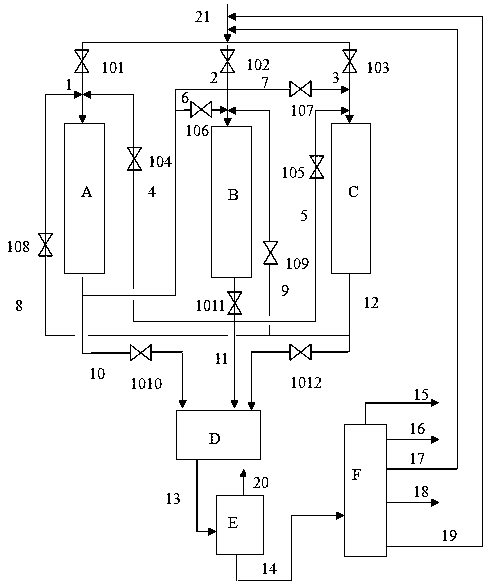

Image

Examples

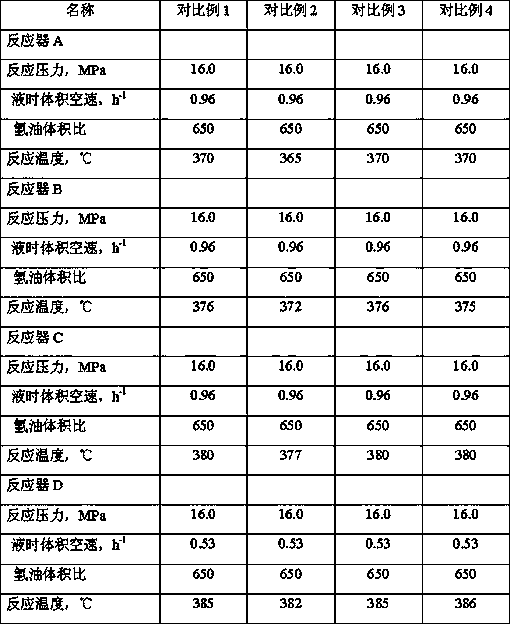

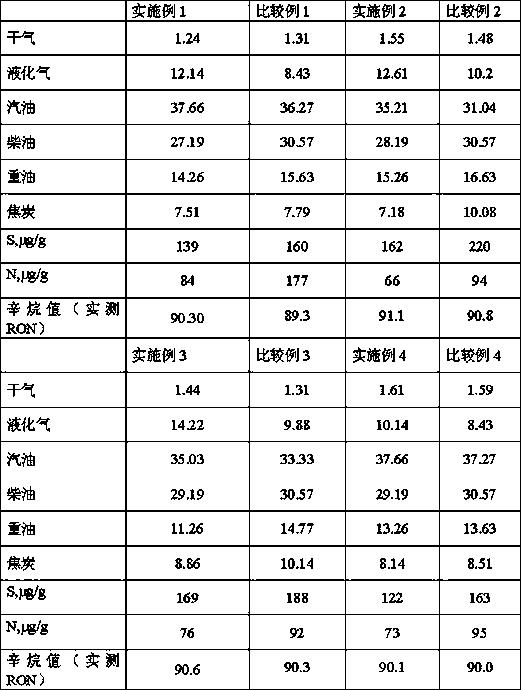

Embodiment 1

[0072]Hydrogenation pretreatment reactor A described in embodiment 1, hydrogenation pretreatment reactor B, hydrogenation pretreatment reactor C residual oil feed all adopt raw material A property to see table 1, the catalysis of 50% of catalytic cracking unit The cracked diesel oil and all the catalytic cracking oil slurry are recycled to the hydrogenation pretreatment reaction zone, and the properties are shown in Table 2. Among them, the catalytic cracking oil slurry is all distributed to the hydrogenation pretreatment reactor A, the proportion of the catalytic cracking diesel oil distributed to the hydrogenation pretreatment reactor B is 15%, and the proportion of the catalytic cracking diesel oil distributed to the hydrogenation pretreatment reactor C is 35%. %. The total catalyst loading, feed properties and feed amount of the hydropretreatment reactor A, hydrogenation pretreatment reactor B, and hydrogenation pretreatment reactor C are exactly the same, and the hydrogen...

Embodiment 2

[0074] In embodiment 2, in described hydrogenation pretreatment reactor A, hydrogenation pretreatment reactor B, hydrogenation pretreatment reactor C, all adopt residual oil raw material B, the catalytic cracking diesel oil of 30% with catalytic cracking unit and All the catalytic cracking oil slurry is circulated to the hydrogenation pretreatment reaction zone, in which the catalytic cracking oil slurry is all distributed to the hydrogenation pretreatment reactor A, and the proportion of catalytic cracking diesel oil distributed to the hydrogenation pretreatment reactor B is 15%. The proportion of FCC diesel to hydropretreatment reactor C is 15%. The space velocity of each reverse feed is different, and the volume space velocity of liquid A in the hydrogenation pretreatment reactor is 0.20h -1 , the hourly volumetric space velocity of liquid B in the hydrogenation pretreatment reactor is 0.32h -1 , the volumetric space velocity of liquid C in the hydrogenation pretreatment r...

Embodiment 3

[0076] In Example 3, the raw material A is used in the hydrogenation pretreatment reactor A, the raw material B is used in the hydrogenation pretreatment reactor B, and the raw material C is used in the hydrogenation pretreatment reactor C. The properties of the residual oil raw materials used are shown in the table 1. Circulate 50% of the catalytic cracking diesel oil and all the catalytic cracking oil slurry in the catalytic cracking unit to the hydrogenation pretreatment reaction zone, in which the catalytic cracking oil slurry is all distributed to the hydrogenation pretreatment reactor A and to the hydrogenation pretreatment reactor The proportion of FCC diesel in treatment reactor B is 25%, and the proportion of FCC diesel allocated to hydropretreatment reactor C is 25%. The feed amount of described hydrogenation pretreatment reactor A, hydrogenation pretreatment reactor B, hydrogenation pretreatment reactor C is the same, and described hydrogenation pretreatment reactor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com