Patents

Literature

110results about How to "High metal capacity" patented technology

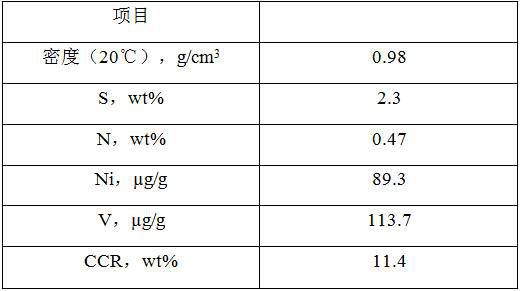

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal tar hydrodemetalization catalyst and preparation method thereof

ActiveCN102847541AUnobstructed pore structureIncrease profitCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsOrganic acidPtru catalyst

The invention discloses a coal tar hydrodemetalization catalyst and a preparation method thereof. The method comprises the steps of: (1) taking or preparing an alumina carrier; (2) treating the alumina carrier from the step (1) with an organic acid solution with pH value lower than 3; then impregnating the alumina carrier subjected to acid treatment with an aluminium nitrate solution; and drying and roasting to obtain a modified alumina carrier; and (3) loading and hydrogenating an active component by an impregnation method to obtain the coal tar hydrodemetalation catalyst. Compared with the prior art, the coal tar hydrodemetalation catalyst provided by the invention has better activity and activity stability, and longer operation cycle.

Owner:上海竣铭化工工程设计有限公司

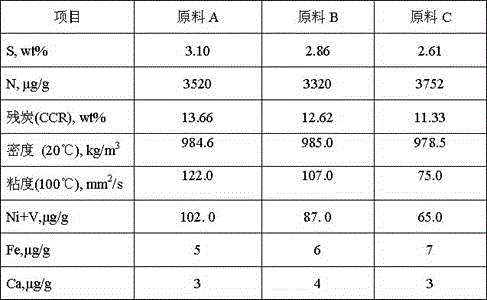

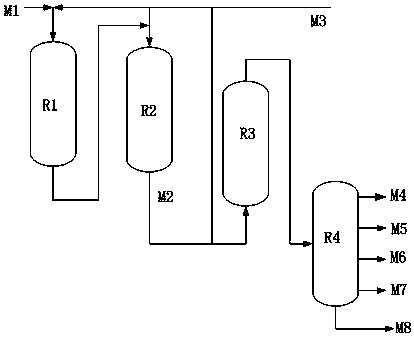

Process for treating inferior oil product

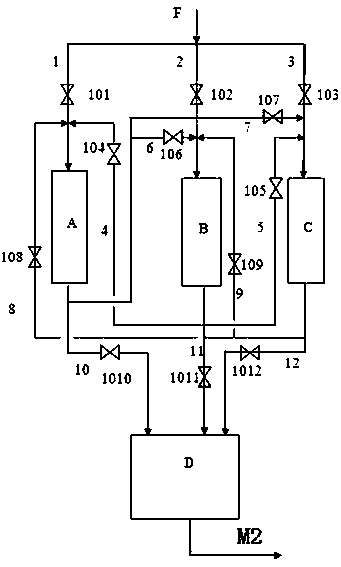

ActiveCN106701190AImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesChemistryPre treatment

The invention discloses a process for treating an inferior oil product. The process comprises a hydropretreating reaction zone, a hydrotreating reaction zone and a catalytic cracking reaction zone. The process comprises the following contents: mixing a residual oil raw material and hydrogen, then successively allowing the mixture to pass through the hydropretreating reaction zone and the hydrotreating reaction zone which are connected in series, subjecting a reaction effluent of the hydrotreating reaction zone to gas-liquid separation, allowing a gas phase to recycle back to the hydropretreating reaction zone and / or the hydrotreating reaction zone, allowing a liquid phase to directly enter the catalytic cracking reaction zone and carrying out a catalytic cracking reaction, and separating a catalytic cracking reaction effluent so as to obtain dry gas, liquefied gas, catalytically cracked gasoline fraction, catalytically cracked diesel fraction, catalytically cracked heavy recycle oil and catalytically cracked slurry oil, wherein the catalytically cracked diesel oil, the catalytically cracked heavy recycle oil and the slurry oil are partially or completely recycled back to the hydrotreating reaction zone for a hydrotreating reaction. The method provided by the invention can prolong the cycle of stable operation of equipment.

Owner:CHINA PETROLEUM & CHEM CORP +1

Loading method of hydroprocessing catalyst

ActiveCN1609172AIncreased average macroporosityIncrease the porosityRefining to eliminate hetero atomsNitrogenEngineering

The present invention is loading method of hydroprocessing catalyst. Unlike conventional grading loading scheme, The hydrogenating and denitrogenating reaction region is loaded with the catalyst in antitone grading mold, in which the activity of the hydrogenating and denitrogenating catalyst in the downstream bed side is slightly lower than that in the upstream bed side, and the pore size of the catalyst in the downstream bed side is slightly greater than that in the upstream bed side. The said loading method can control the temperature raise of hydrogenating and denitrogenating catalyst bed, reduce cold hydrogen amount to lower the hydrogen consumption of the apparatus, reduce the carbon deposit speed in the catalyst bed to reduce bed pressure drop of bed, and prolong the service life of catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

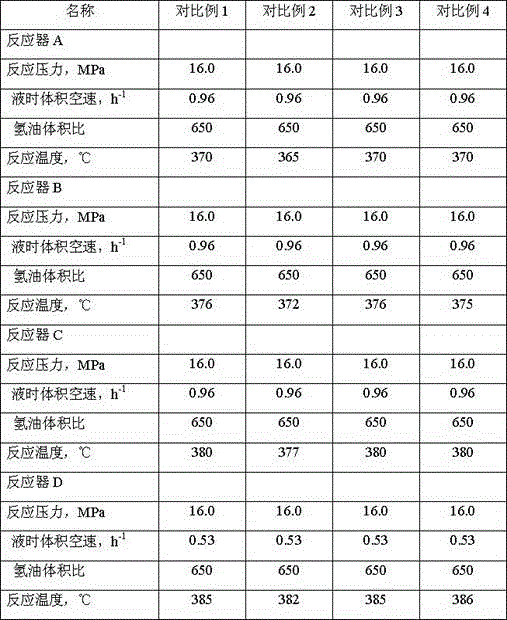

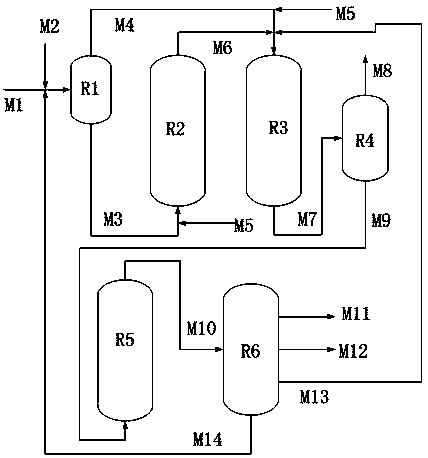

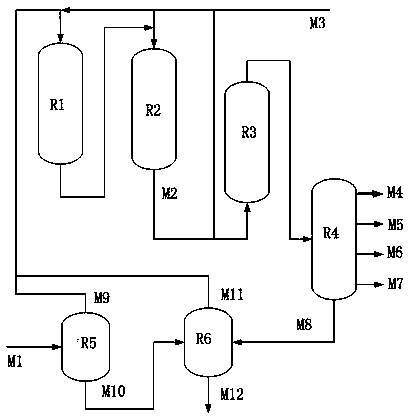

Residual oil hydrotreating-catalytic cracking combined process method

ActiveCN106701189AImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesGas phaseSlurry

The invention discloses a residual oil hydrotreating-catalytic cracking combined process method which includes a hydropretreating reaction zone, a hydrotreating reaction zone and a catalytic cracking reaction zone; the process method includes the following contents: a residual oil raw material, at least part of a catalytic cracking diesel oil fraction and hydrogen are mixed, and in turn pass through the hydropretreating reaction zone and the hydrotreating reaction zone which are in series connection, after gas-liquid separation of a hydrotreating reaction zone reaction effluent, a gas phase is recycled back to the hydropretreating reaction zone and / or the hydrotreating reaction zone, a liquid phase directly enters the catalytic cracking reaction zone for catalytic cracking reaction, a catalytic cracking reaction effluent is separated to obtain a dry gas, liquefied gas, a catalytic cracking gasoline fraction, a catalytic cracking diesel oil fraction, catalytic cracking heavy cycle oil and catalytic cracking oil slurry, and the catalytic cracking diesel oil is partially or totally recycled back to the hydrotreating reaction zone for hydrotreating reaction. The method can prolong the stable operation period of a device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst having hydrogenation catalysis function, and preparation method and application thereof, and method for hydrogenation treatment of hydrocarbon oil

ActiveCN103480390AHigh catalytic activityHigh metal capacityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsCelluloseRare-earth element

The invention provides a catalyst having a hydrogenation catalysis function, and a preparation method and an application thereof. The catalyst comprises a carrier, and at least one group VIII metal element and at least one group VIB metal element which are loaded on the carrier. The group VIII metal element and the group VIB metal element are separately in a non-uniform distribution along the radial cross section of the catalyst, wherein along the radial cross section of the catalyst, a ratio of Cexternal<VIII> to Cmiddle<VIII> is 0.1-0.9, and a ratio of Cexternal<VIB> to Cmiddle<VIB> is 0.1-0.85. The carrier is a hydrated alumina molded matter prepared from raw materials comprising at least one hydrated alumina, at least one rare earth element-containing compound and at least one cellulose ether. The invention also provides a method for hydrogenation treatment of a hydrocarbon oil. The catalyst provided by the invention shows higher catalytic activity, better catalytic stability and longer service life in a hydrogenation demetalization reaction of the hydrocarbon oil (especially a heavy hydrocarbon oil).

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for treating inferior oil

ActiveCN106701175AImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesCycle oilChemistry

The invention discloses a process for treating inferior oil, the process includes a hydropretreating reaction zone, a hydrotreating reaction zone and a catalytic cracking reaction zone; the process includes the following contents: a residual oil raw material and hydrogen are mixed, and in turn pass through the hydropretreating reaction zone and the hydrotreating reaction zone which are in series connection, after gas-liquid separation of a hydrotreating reaction zone reaction effluent, a gas phase is recycled back to the hydropretreating reaction zone and / or the hydrotreating reaction zone, a liquid phase directly enters the catalytic cracking reaction zone for catalytic cracking reaction, a catalytic cracking reaction effluent is separated to obtain a dry gas, liquefied gas, a catalytic cracking gasoline fraction, a catalytic cracking diesel oil fraction, catalytic cracking heavy cycle oil and catalytic cracking oil slurry, and the catalytic cracking diesel and the catalytic cracking heavy cycle oil are partially or totally recycled back to the hydrotreating reaction zone for hydrotreating reaction. The method can prolong the stable operation period of a device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process method for treating residual oil

ActiveCN106701192AImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesFractionationSlurry

The invention discloses a process method for treating residual oil. A hydrogenation pretreatment unit, a coking device, a hydrogenation treatment unit and a catalytic cracking device are provided; the hydrogenation pretreatment unit comprises a hydrogenation pretreatment reaction area and a hydrogenation treatment reaction area; the process method comprises the following steps: performing a reaction on a residual oil raw material by using the hydrogenation pretreatment unit, and performing oil fractionation so as to obtain light fraction and heavy fraction, feeding the heavy fraction into the coking device for treatment so as to obtain coked gasoline, coked diesel oil and coked wax oil, mixing the light fraction with the coked wax oil and hydrogen, passing through the hydrogenation pretreatment reaction area and the hydrogenation treatment reaction area which are connected in series, performing gas-liquid separation on a reaction effluent of the hydrogenation treatment reaction area, circulating vapor phase back to the hydrogenation pretreatment reaction area and / or the hydrogenation treatment reaction area, directly feeding liquid phase into the catalytic cracking reaction area for a catalytic cracking reaction, and separating a catalytic cracking reaction effluent, thereby obtaining a dry gas, a liquefied gas, catalytic cracking gasoline fraction, catalytic cracking area diesel oil fraction, catalytic cracking area recirculation oil and catalytic cracking area oil slurry. Due to adoption of the process method disclosed by the invention, the stable operation period of a device can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for treating residual oil with hydrogenation treatment and catalytic cracking processes

ActiveCN106701191AImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesGas phaseSlurry

The invention discloses a method for treating residual oil with hydrogenation treatment and catalytic cracking processes. A hydrogenation pretreatment reaction zone, a hydrogenation treatment reaction zone and a catalytic cracking reaction zone are contained; the method comprises steps as follows: a residual oil material and hydrogen are mixed and sequentially pass the hydrogenation pretreatment reaction zone and the hydrogenation treatment reaction zone which are connected in series; a reaction effluent in the hydrogenation treatment reaction zone is subjected to gas-liquid separation, a gas phase is recycled back to the hydrogenation pretreatment reaction zone and / or the hydrogenation treatment reaction zone, a liquid phase directly enters the catalytic cracking reaction zone for a catalytic cracking reaction, a catalytic cracking effluent is separated, and dry gas, liquefied gas, catalytic cracking gasoline fractions, catalytic cracking diesel fractions, catalytic cracking heavy cycle oil and catalytic cracking oil slurry are obtained, wherein parts of or all of catalytic cracking diesel and catalytic cracking oil slurry are recycled back to the hydrogenation treatment reaction zone for a hydrogenation treatment reaction. By means of the method, the stable operation cycle of a device can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment method of residual oil

ActiveCN106701185AImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesGas phaseSlurry

The invention discloses a treatment method of residual oil, which comprises a solvent deasphalting device, a hydrogenation pretreatment reaction area, a hydrogenation treatment reaction area and a catalytic cracking reaction area. The method comprises the following steps that the raw residual oil is fractionated to obtain a light fraction and a heavy fraction; the heavy fraction is treated in the solvent deasphalting device to obtain deasphalted oil and deoiled asphalt; the light fraction, the deasphalted oil and hydrogen are mixed and then sequentially pass through the hydrogenation pretreatment reaction area and the hydrogenation treatment reaction area which are connected in series; gas-liquid separation is performed on a reaction effluent of the hydrogenation treatment reaction area; a gas phase cycles back to the hydrogenation pretreatment reaction area and / or the hydrogenation treatment reaction area; a liquid phase directly enters the catalytic cracking reaction area to perform a catalytic cracking reaction; and a catalytic cracking reaction effluent is separated to obtain dry gas, liquefied gas, a catalytic cracking gasoline fraction, a catalytic cracking diesel fraction, catalytic cracking heavy cycle oil and catalytic cracking slurry oil. The method can prolong a stable operation period of a device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Combined process method for heavy oil conversion

ActiveCN108102714AImprove utilization efficiencyThe method flow is simpleTreatment with hydrotreatment processesFluidized bedGasoline

The invention discloses a combined process method for heavy oil conversion. The method comprises the following steps: heavy oil raw materials enter a solvent deasphalting device, deasphalted oil and deoiled asphalt are obtained; the obtained deoiled asphalt enters a fluidized bed hydrotreating device for fluidized bed hydrotreating; reaction effluent obtained from fluidized bed hydrotreating is mixed with deasphalted oil; meanwhile, at least part of recycle oil from the catalytic cracking device is added for mixing, and a mixture sequentially passes through a fixed bed hydropretreating reaction zone and a fixed bed hydrotreating reaction zone which are arranged in series; generated oil obtained from reaction effluent of the fixed bed hydrotreating reaction zone is used as a raw material of the catalytic cracking device; catalytic cracking gasoline, catalytic cracking diesel oil, reclaimed oil and oil slurry are obtained after a catalytic cracking reaction product is separated. With adoption of the method, the operation period of a treatment device can be greatly prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

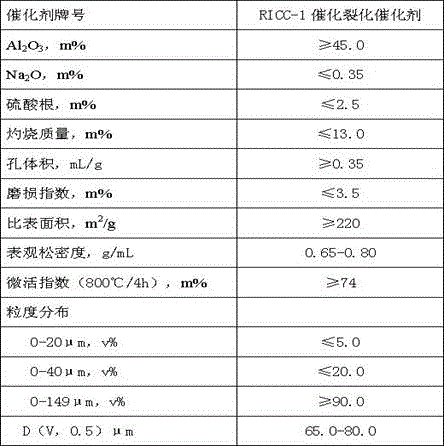

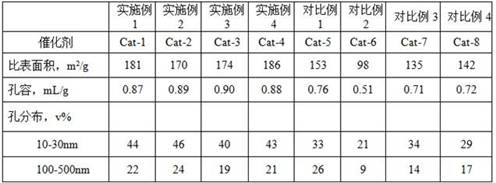

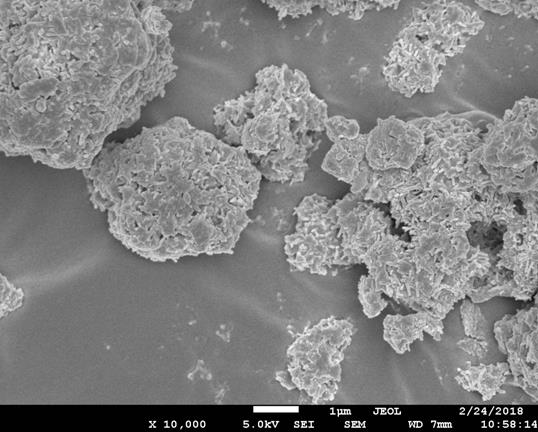

Residual oil hydrotreating catalyst and preparation method thereof

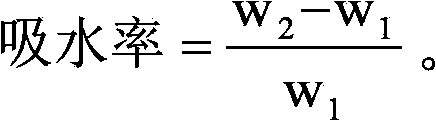

PendingCN111001411AGood diffusion performanceExcellent demetallization performanceHeterogenous catalyst chemical elementsCatalyst activation/preparationHeavy metal compoundAluminium oxides

The invention discloses a residual oil hydrotreating catalyst and a preparation method thereof. The pore diameters of mesopores of the catalyst are intensively and uniformly distributed; meanwhile, the catalyst is a bimodal pore catalyst with macropores, wherein 50% or more mesopores of 10-30 nm are distributed in a concentrated mode, 25% or more macropores are distributed in a concentrated mode,and the preparation method comprises the steps that an aluminum salt solution is prepared, sol is mixed through a pH swing method, an organic pore-enlarging agent is added, the mixture is guided and added into a gelatinizing tank to be gelatinized, and an aluminum oxide carrier is obtained through aging, drying, forming and roasting; the aluminum oxide carrier is impregnated in impregnation liquid; and by drying and roasting, the hydrodemetallization catalyst is obtained, the catalyst provided by the invention has good diffusivity and excellent demetalization performance, can meet the requirements of diffusion ducts of Ni and V-containing heavy metal compounds, significantly improves the nickel and vanadium removal performance of the catalyst, and improves the demetalization activity, metal capacity and activity stability of the catalyst, and the preparation process is simple and easy to operate.

Owner:浙江石油化工有限公司

Spherical hydrogenation catalyst and preparation method thereof

ActiveCN106669709AAdvantages of preparation methodAct as a dispersantCatalyst carriersHeterogenous catalyst chemical elementsIonic liquidAluminium salts

The invention discloses a spherical hydrogenation catalyst and a preparation method thereof. The catalyst comprises a modified alumina carrier and hydrogenation active metal, wherein the modified alumina carrier comprises an alumina carrier and an auxiliary agent. With the weight of the modified alumina carrier as the baseline, content of the alumina carrier is 95-98%, the auxiliary agent accounts for 2-5% when metered on the basis of elements, and concentration of the auxiliary agent is gradually reduced from the center of carrier particles to the external surface. The auxiliary agent is one of the following combinations I, II and III, wherein I is fluorine and phosphor; II is fluorine and boron; and III is fluorine, phosphor and boron. The preparation method comprises the following steps: respectively adding ionic liquids I, II and III during the gel forming process of sodium metaaluminate solution and aluminum sulfate solution so as to prepare the modified alumina carrier; dipping the active component, drying, and roasting to obtain the required hydrogenation catalyst. By the use of the catalyst, pore structure and acid distribution can be organically combined so as to enhance overall performance of the catalyst. The preparation method is suitable for preparation of a hydrogenation catalyst with high demetalization activity and strong metal melting capability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for treating residual oil

ActiveCN106701187AImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesFractionationSlurry

The invention discloses a method for treating residual oil. A coking device, a hydrogenation pretreatment reaction area, a hydrogenation treatment reaction area and a catalytic cracking reaction area are provided, the method comprises the following steps: performing fractionation on a residual oil raw material so as to obtain light fraction and heavy fraction, feeding the heavy fraction into the coking device for treatment so as to obtain coked gasoline, coked diesel oil and coked wax oil, mixing the light fraction with the coked wax oil and hydrogen, passing through the hydrogenation pretreatment reaction area and the hydrogenation treatment reaction area which are connected in series, performing gas-liquid separation on a reaction effluent of the hydrogenation treatment reaction area, circulating vapor phase back to the hydrogenation pretreatment reaction area and / or the hydrogenation treatment reaction area, directly feeding liquid phase into the catalytic cracking reaction area for a catalytic cracking reaction, and separating a catalytic cracking reaction effluent, thereby obtaining a dry gas, a liquefied gas, catalytic cracking gasoline fraction, catalytic cracking area diesel oil fraction, catalytic cracking area recirculation oil and catalytic cracking area oil slurry. By adopting the method disclosed by the invention, the stable operation period of a device can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

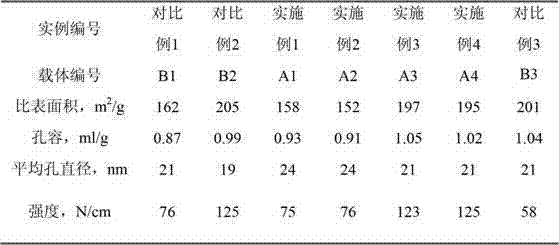

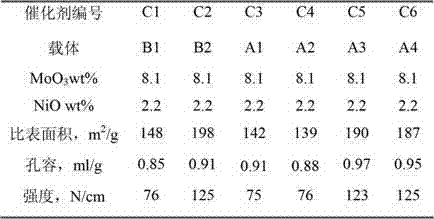

Catalyst having hydrogenation catalysis effect, preparation method and application thereof, and hydrotreatment method

ActiveCN103418398AHigh catalytic activityImprove catalytic stabilityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsCelluloseHydrated alumina

The invention provides a catalyst having a hydrogenation catalysis effect, and a preparation method and an application thereof. The catalyst contains a support, and at least one group VIII metal element and at least one group VIB metal element which are supported on the support, the at least one group VIII metal element and the at least one group VIB metal element are respectively non-uniformly distributed along the radial cross section of the catalyst, wherein the support is a molded siliceous hydrated alumina along the radial cross section of the catalyst, and is prepared through using raw materials containing at least one hydrated alumina, at least one siliceous compound and at least one cellulose ether. The invention also provides a hydrocarbon oil hydrotreatment method. The catalyst has a high catalysis activity, a good catalysis stability and a long service life in the hydrogenation and metal removal reaction of hydrocarbon oil (especially heavy hydrocarbon oil).

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst having hydrogenation catalysis function, and preparation method and application thereof, and method for hydrogenation treatment of hydrocarbon oil

ActiveCN103480409AHigh catalytic activityHigh metal capacityMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveCellulose

The invention provides a catalyst having a hydrogenation catalysis function, and a preparation method and an application thereof. The catalyst comprises a carrier, and at least one group VIII metal element and at least one group VIB metal element which are loaded on the carrier. The group VIII metal element and the group VIB metal element are separately in a non-uniform distribution along the radial cross section of the catalyst, wherein along the radial cross section of the catalyst, a ratio of Cexternal<VIII> to Cmiddle<VIII> is 0.1-0.9, and a ratio of Cexternal<VIB> to Cmiddle<VIB> is 0.1-0.85. The carrier is a hydrated alumina molded matter prepared from raw materials comprising at least one hydrated alumina, at least one Y molecular sieve and at least one cellulose ether. The invention also provides a method for hydrogenation treatment of a hydrocarbon oil. The catalyst according to the invention shows higher catalytic activity, better catalytic stability and longer service life in a hydrogenation demetalization reaction of the hydrocarbon oil (especially a heavy hydrocarbon oil).

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for removing metal from coal tar at low pressure

ActiveCN103725324ARaw materials are simpleHigh metal capacityTreatment with hydrotreatment processesPtru catalystHydrogenation reaction

The invention discloses a method for removing metal from coal tar at low pressure, which mainly solves the problem that the content of metal in all fraction of coal tar is generally higher than 200mu g / g, which highly restricts the operational cycle of a main hydrogenation unit. The method comprises steps of firstly mixing coal tar with hydrogen; then allowing the mixture to enter a fixed bed hydrogenation reactor from the top for hydrorefining reaction, wherein the fixed bed hydrogenation reactor is at least filled with a hydrogenation protective catalyst, which comprises a first protective catalyst, a second protective catalyst and a third protective catalyst which are sequentially filled from top to bottom, the reaction pressure for hydrorefining reaction is 2.8-8.5MPa; then carrying out gas-liquid separation on effluent of the fixed bed hydrogenation reactor so as to obtain the refined coal tar containing less than 2mu g / g of total metal. According to the method, the reaction is carried out at lower operation pressure, and the refined coal tar containing less than 2mu g / g of total metal is produced through hydrogenation at low pressure.

Owner:GUANGHAN TIANZHOU AERO ENGINE FUEL TECH CO LTD

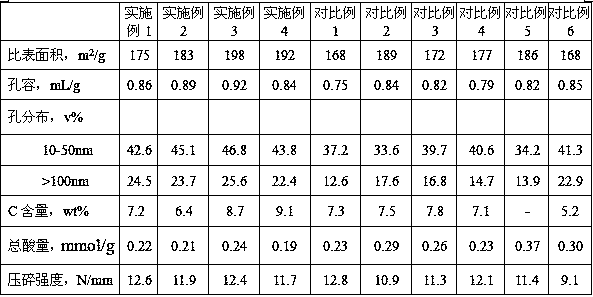

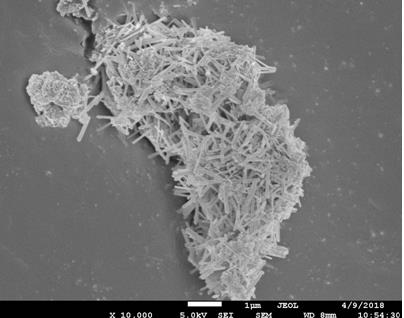

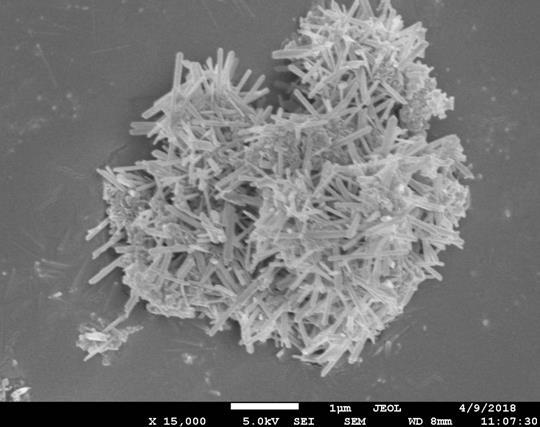

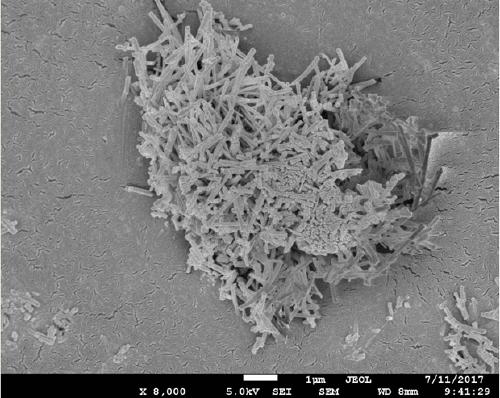

Preparation method of carbon-containing hydrodemetallization catalyst

ActiveCN110935464AEnhanced mass transferFacilitated DiffusionMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionPtru catalystMetal catalyst

The invention discloses a preparation method of a carbon-containing hydrodemetallization catalyst. The method comprises the following steps: (1) immersing alumina powder into an ammonium bicarbonate aqueous solution, carrying out sealed heat treatment, carrying out solid-liquid separation, drying the solid-phase material, immersing the dried material with a carbon-containing precursor solution I,carrying out solid-liquid separation on the immersed material, and drying the solid-phase material to obtain a modified rod-like alumina cluster body; (2) carrying out mixing kneading molding on the modified alumina cluster body obtained in the step (1) and pseudo-boehmite, drying the molded product, spraying and soaking the molded product with a carbon-containing precursor solution II, drying, and then sequentially carrying out carbonization treatment and microwave treatment in an inert atmosphere to obtain a carbon-containing alumina carrier; and (3) loading a hydrogenation active componenton the carbon-containing alumina carrier to obtain the hydrodemetallization catalyst. The hydrodemetallization catalyst has the advantages of large pore volume, large pore size, high mechanical strength and low acid content, and is suitable for the field of hydrodemetallization of heavy residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Heavy oil hydrotreating method

ActiveCN108102706AImprove utilization efficiencyThe method flow is simpleTreatment with hydrotreatment processesFixed bedFuel oil

The invention discloses a heavy oil hydrotreating method. The method comprises the following steps: (1) heavy oil raw materials are fractionated, and light fractions and heavy fractions are obtained;(2) the heavy fractions obtained in the step (1) enter a solvent deasphalting device, and deasphalted oil and deoiled asphalt are obtained after treatment; (3) the light fractions obtained in the step(1) and the deasphalted oil obtained in the step (2) are mixed with hydrogen, a mixture passes through a fixed bed hydropretreating reaction zone and a fixed bed hydrotreating reaction zone which arearranged in series sequentially, generated oil obtained in the fixed bed hydrotreating reaction zone enters a fluidized bed hydrocracking reaction zone, a reaction effluent from the fluidized bed hydrocracking reaction zone is separated, and gas, gasoline, diesel oil, wax oil and unconverted oil are obtained; (4) after the unconverted oil obtained in the step (3) is mixed with the heavy fractionsobtained in the step (1), the mixture enters a solvent deasphalting device for treatment. With adoption of the method, the operation period of a treatment device can be greatly prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of heavy oil hydrodemetallization catalyst

ActiveCN111821993AHigh activityImprove stabilityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystMetal catalyst

The invention discloses a preparation method of a heavy oil hydrodemetallization catalyst, and the method comprises the following steps: (1) pulverizing a waste hydrotreating catalyst, and roasting; (2) soaking the material obtained in the step (1) into an ammonium bicarbonate aqueous solution, carrying out sealed heat treatment, drying, soaking with a polyethylene glycol solution, and drying to obtain a pretreated material A; (3) performing high-temperature activation treatment on kaolin, then soaking into an ammonium bicarbonate aqueous solution, performing sealed heat treatment, and dryingthe material subjected to heat treatment to obtain a pretreated material B; and (4) kneading and molding pseudo-boehmite, the pretreated material A and the pretreated material B, drying and roasting the molded product to obtain a carrier, and loading a hydrogenation active component onto the carrier to obtain the catalyst. According to the method, the hydrodemetallization catalyst is prepared fromthe waste catalyst and kaolin, environmental pollution is reduced while the production cost is reduced, the content of macropores of the hydrodemetallization catalyst is appropriate, and the hydrodemetallization catalyst has high hydrodemetallization activity and hydrodesulfurization activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation catalyst composition and preparation method thereof

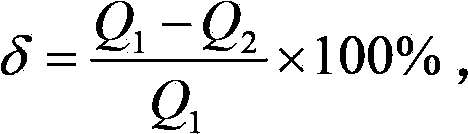

ActiveCN105817232AEasy to depositHigh metal capacityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsSiliconParticle-size distribution

The invention discloses a hydrogenation catalyst composition and its preparation method. The hydrogenation catalyst composition comprises an alumina carrier, active metal and an auxiliary agent, wherein the active metal is one or more metals selected from VIII group and / or VIB group metallic elements; and the auxiliary agent is one or two elements selected from silicon or zirconium. Concentration of silicon or zirconium in the catalyst is metered according to oxide and gradually decreases from the catalyst granule center to the external surface. Content of silicon and / or zirconium at R of granules is 1.0-3.0 wt%; content of silicon and / or zirconium at 1 / 3 of R is 0.5-1.0 wt%, and content of silicon and / or zirconium at 2 / 3 of R is 0.1-0.5 wt%, wherein R is radius of catalyst granules with the catalyst center as the starting point. The catalyst prepared by an impinging stream co-precipitation gelling mode has the following advantages: particle size distribution is centralized; the catalyst has an ideal pore structure; contents of the auxiliary agent and the active metal in the catalyst are reduced gradiently; inactivation rate of the catalyst can be effectively reduced; and metal-removal and metal-holding capabilities of the catalyst are enhanced.

Owner:CHINA PETROLEUM & CHEM CORP +1

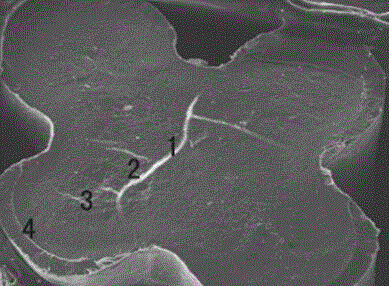

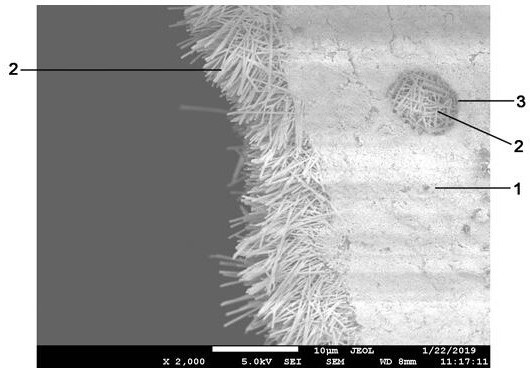

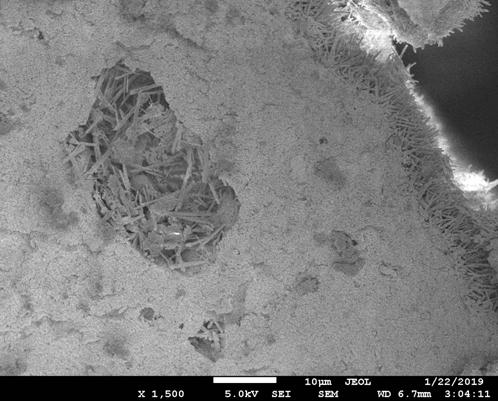

Residual oil hydrogenation protective agent carrier, catalyst and preparation method thereof

ActiveCN111821990ALarge specific surface areaHigh mechanical strengthCatalyst carriersCatalyst activation/preparationPtru catalystPhysical chemistry

The invention discloses a residual oil hydrogenation protective agent carrier, a catalyst and a preparation method thereof. The carrier is a modified alumina-based carrier, and the modified alumina-based carrier contains a modification element and a first hydrogenation active metal component; the modified alumina-based carrier comprises main body modified alumina and rod-like modified alumina, themain body modified alumina is alumina with micron-sized pore channels, and at least part of the rod-like modified alumina is distributed on the outer surface of the main body modified alumina and inthe micron-sized pore channels with the pore diameter D of 5-10 [mu] m; the modification element is vanadium, and the first hydrogenation active metal component is molybdenum. The catalyst prepared byadopting the hydrogenation protective agent carrier has the characteristics of good macromolecular diffusion performance, strong impurity capacity, high asphaltene conversion rate and the like, and is particularly suitable for a residual oil hydrotreatment process.

Owner:CHINA PETROLEUM & CHEM CORP +1

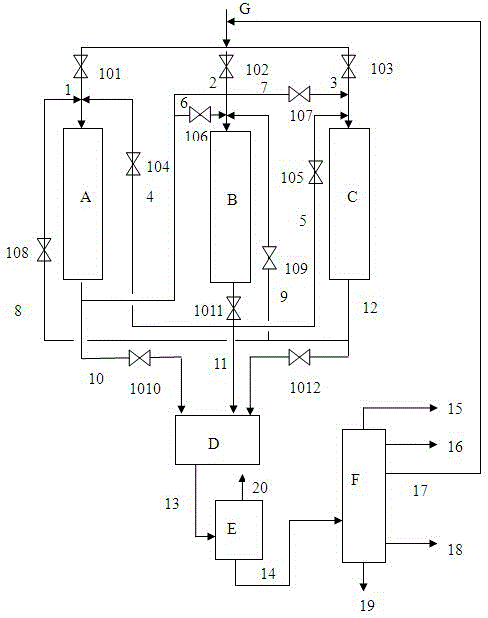

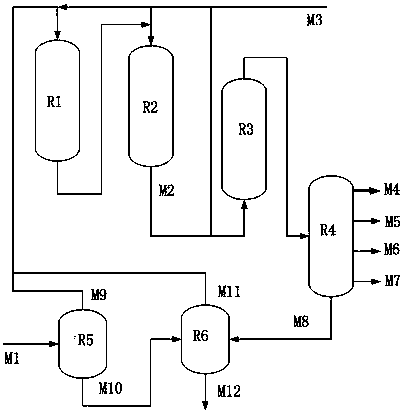

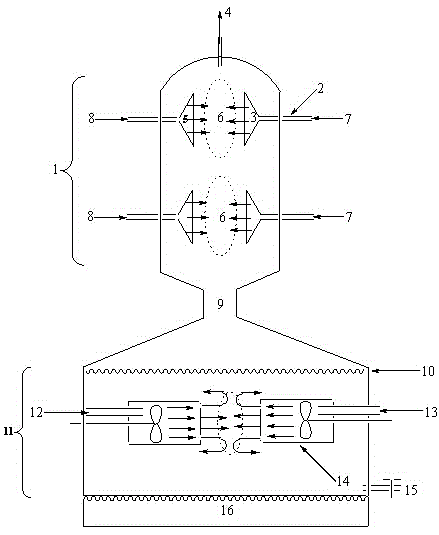

A kind of heavy oil hydrotreating process method and system

ActiveCN108102697BImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesHydrocarbon oils treatment productsWaxNaphtha

The invention relates to the field of heavy oil hydrotreatment, in particular to a heavy oil hydrotreating process method and system. The heavy oil hydrotreating process method comprises the followingsteps: heavy oil raw materials pass through a fixed bed hydropretreating reaction zone and a fixed bed hydrotreating reaction zone which are arranged in series sequentially; generated oil obtained from the fixed bed hydrotreating reaction zone enters a fluidized bed hydrocracking reaction zone; after reaction effluent of the fluidized bed hydrocracking reaction zone is separated, dry gas, liquefied gas, naphtha, diesel oil, wax oil and unconverted oil are obtained. With adoption of the heavy oil hydrotreating method, the operation period of a heavy oil hydrotreating device can be greatly prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

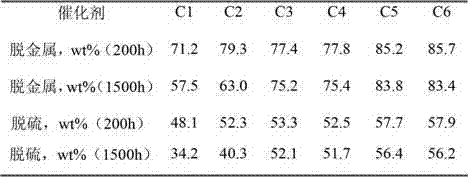

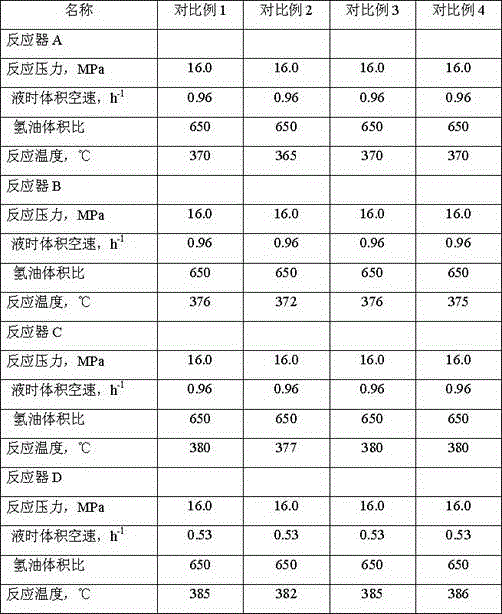

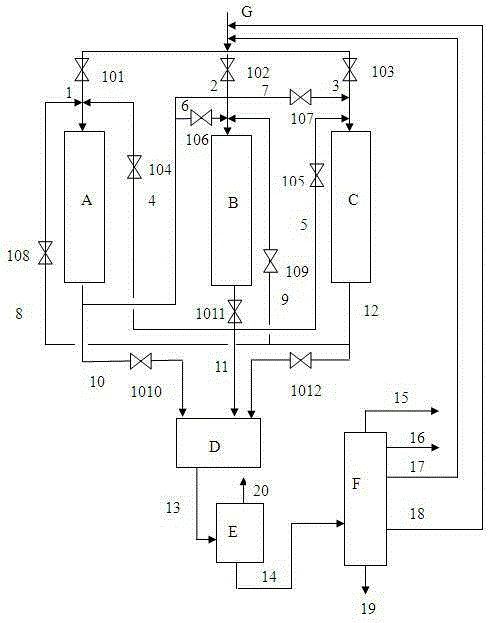

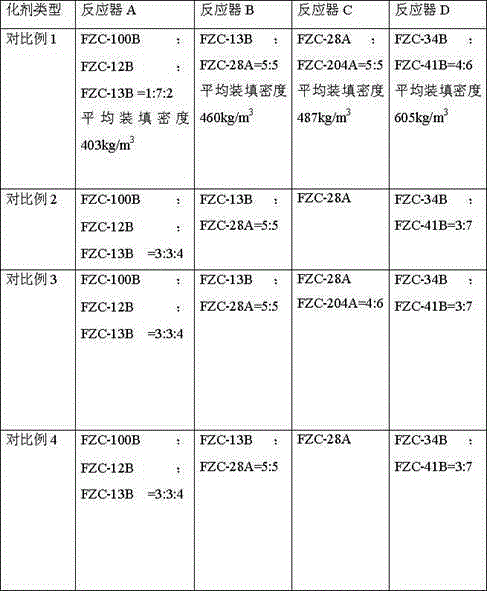

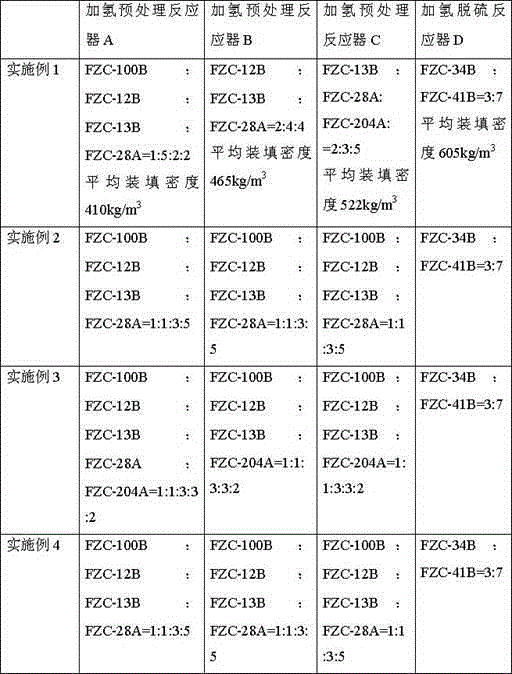

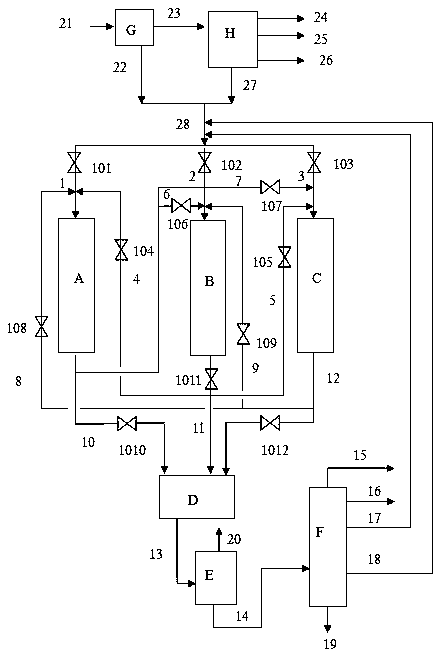

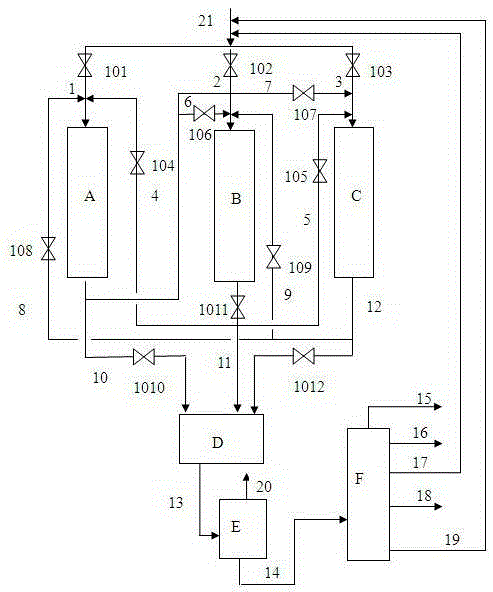

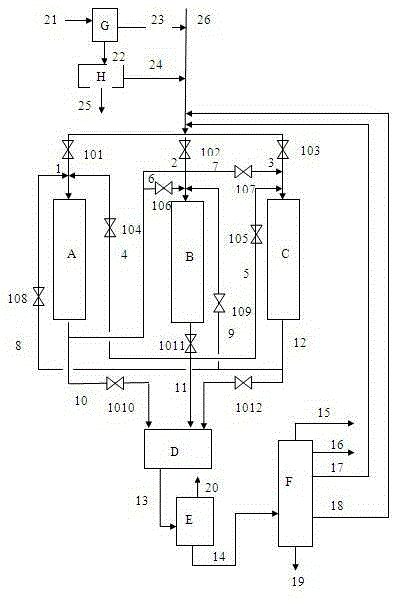

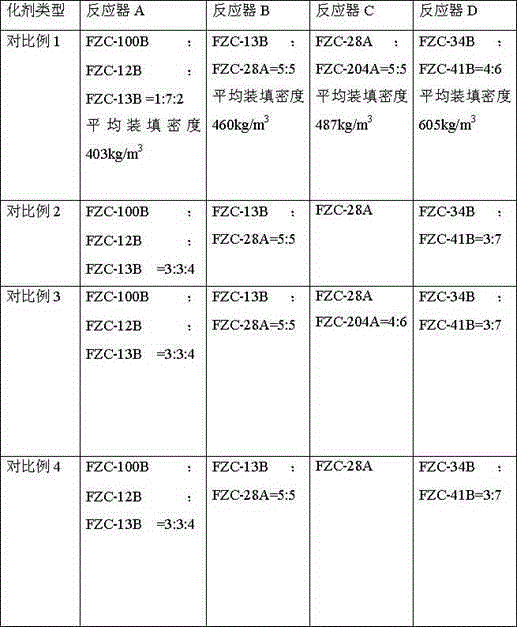

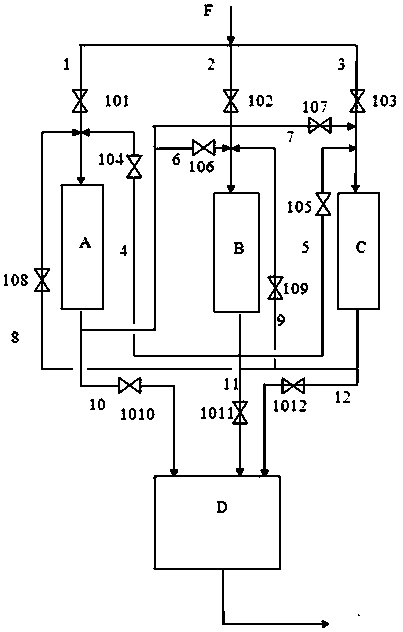

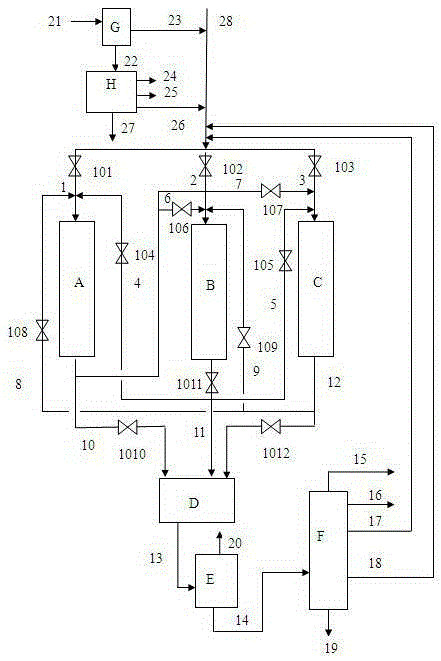

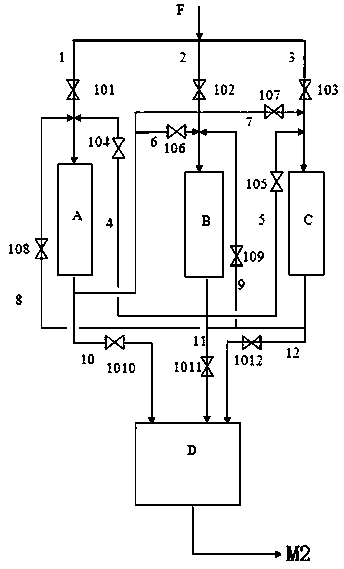

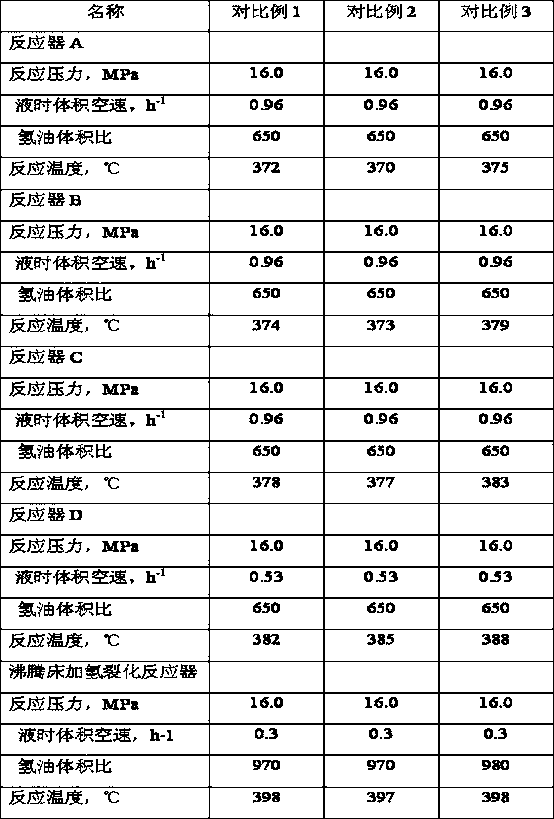

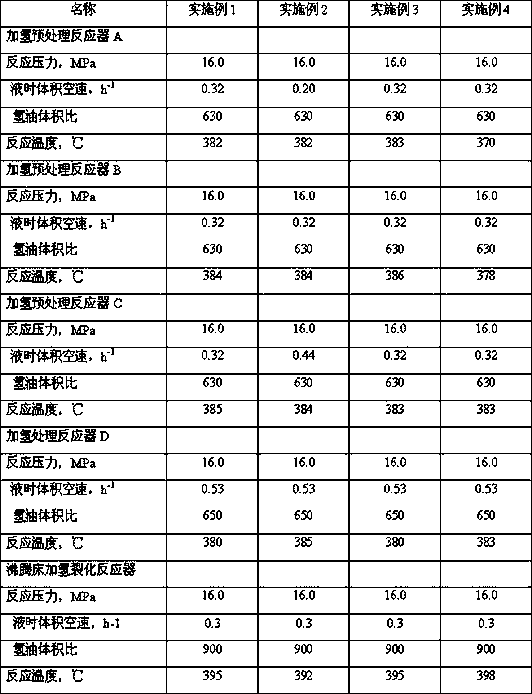

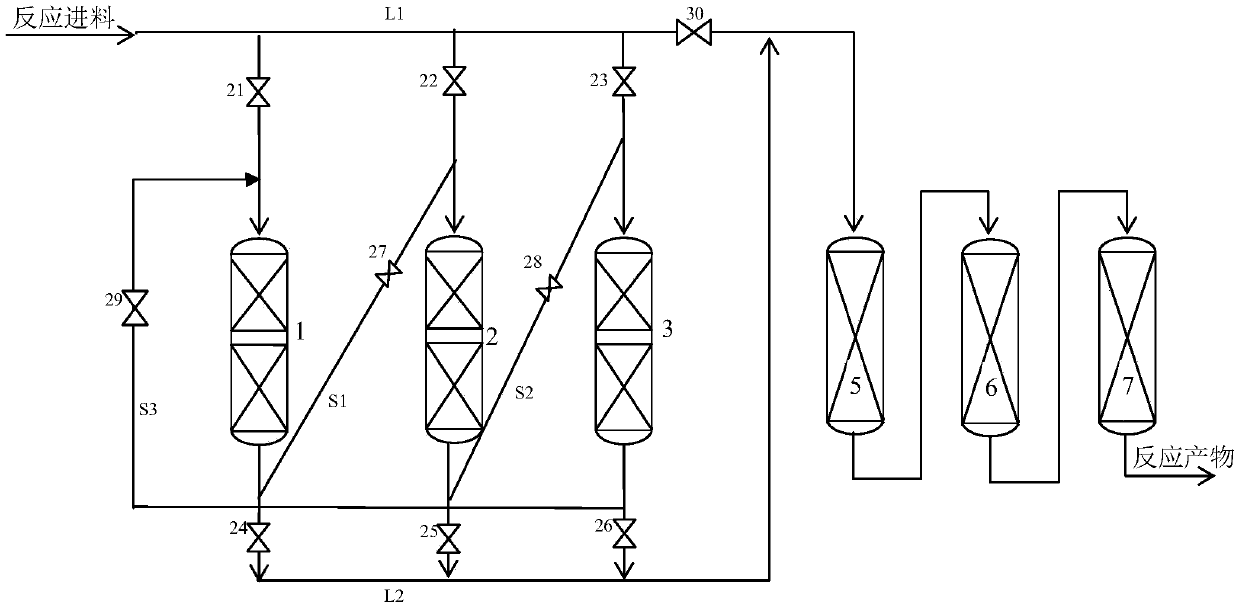

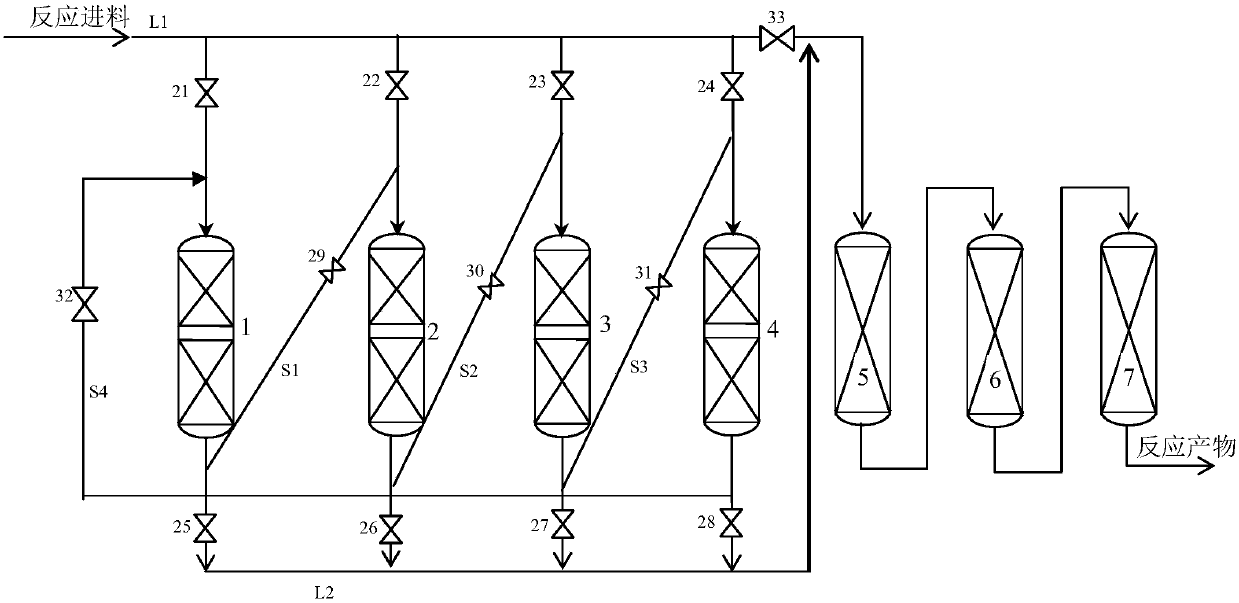

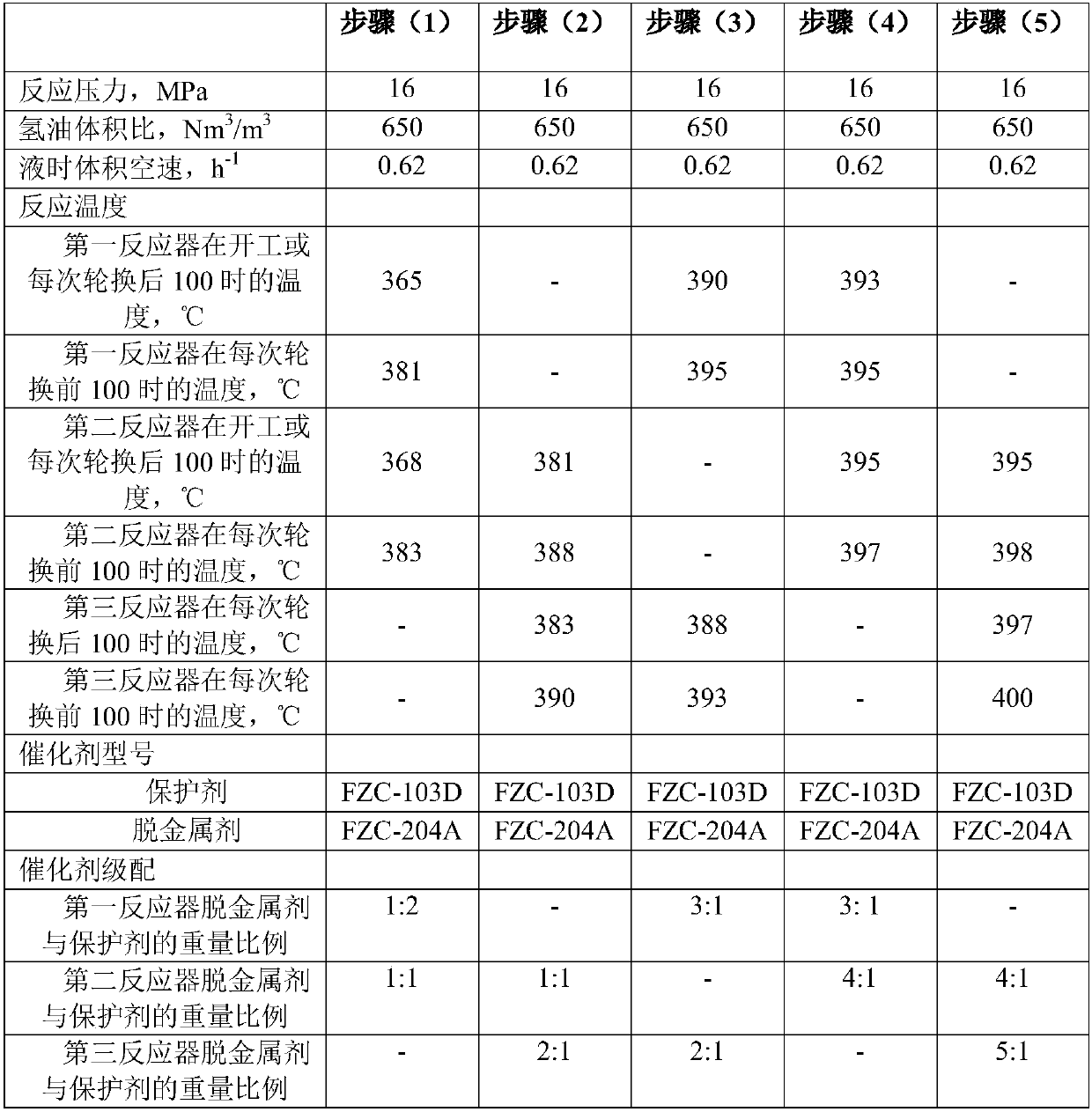

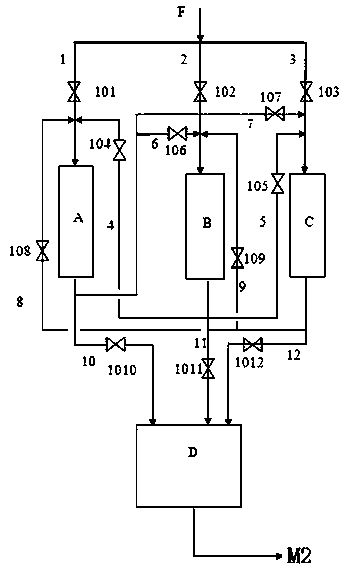

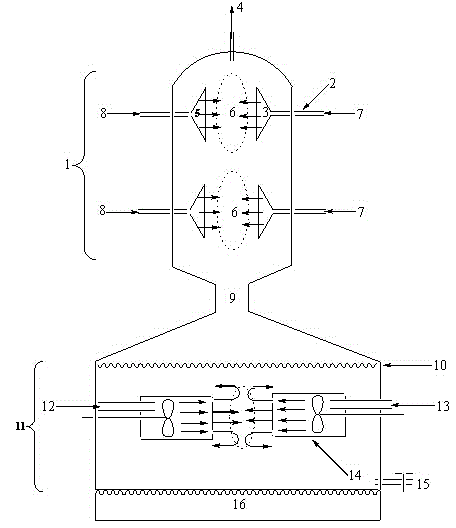

In-series alternated hydrotreating method and system for fixed-bed residue oil

ActiveCN110499188ARealize long-term operationExtended run timeTreatment with hydrotreatment processesFixed bedReaction zone

The invention discloses an in-series alternated hydrotreating method and system for fixed-bed residue oil. The method comprises the following steps: a hydropretreating reaction zone and a hydrotreating reaction zone are arranged in series for residue oil hydrotreating, and the hydropretreating reaction zone comprises N hydropretreating reactors, wherein the reactors from a first hydropretreating reactor to a (N-1)th hydropretreating reactor are sequentially connected in series to be used as an (N-1)-stage online hydropretreating reactor, and a Nth hydropretreating reactor is used as an off-line hydropretreating reactor; when pressure drop in the first hydropretreating reactor rises to a designed upper limit of pressure drop or the activity of a catalyst is lower than a required value, thefirst hydropretreating reactor is switched out, and the Nth hydropretreating reactor is used as the (N-1)-stage online hydropretreating reactor; and switching is performed according to the above manner, so that an uninterrupted (N-1)-stage hydropretreating reaction can be realized. The method provided by the invention can improve the utilization efficiency of a main catalyst and the operation stability of a device, and greatly extend the operating time of a hydrotreating reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

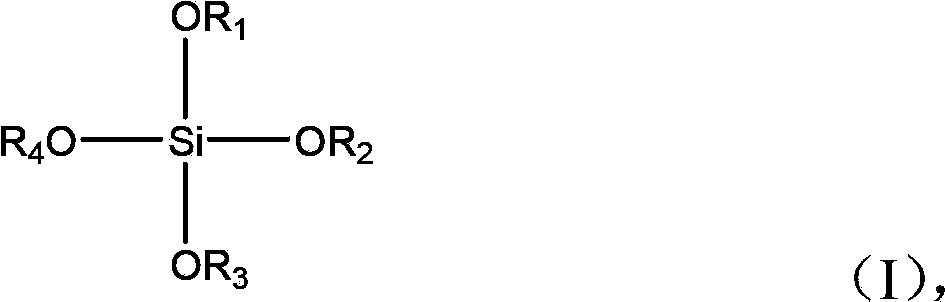

Catalyst with hydrogenation catalytic function, preparation, and applications thereof, and hydrogenation processing method of hydrocarbon oil

ActiveCN103480386AHigh catalytic activityHigh metal capacityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsCelluloseCatalytic function

The invention provides a catalyst with a hydrogenation catalytic function, a preparation method, and applications thereof. The catalyst comprises a carrier, at least one metal selected from the VIII group metals, and at least one metal selected from the VIB group metals, wherein the metals are loaded on the carrier; the VIII group metal element and the VIB group metal element are individually and unevenly distributed along the radial cross section of the catalyst, wherein along the radical cross section of the catalyst, a formula is represented in the description, and the carrier is a hydrate alumina forming product, which is prepared from following raw materials: at least a hydrate alumina, at least a compound containing magnesium, and at least a cellulose ether. The invention also provides a hydrogenation processing method of hydrocarbon oil. The catalyst provided by the invention has a higher catalytic activity, a better catalytic stability, and a longer service life in the hydrogenation and metal-removing reactions of hydrocarbon oil (especially heavy hydrocarbon oil).

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of heavy oil hydrogenation processing method

ActiveCN108102706BImproved ability to remove/accommodate metalsDoes not limit the operating cycleTreatment with hydrotreatment processesFixed bedFuel oil

The invention discloses a heavy oil hydrotreating method. The method comprises the following steps: (1) heavy oil raw materials are fractionated, and light fractions and heavy fractions are obtained;(2) the heavy fractions obtained in the step (1) enter a solvent deasphalting device, and deasphalted oil and deoiled asphalt are obtained after treatment; (3) the light fractions obtained in the step(1) and the deasphalted oil obtained in the step (2) are mixed with hydrogen, a mixture passes through a fixed bed hydropretreating reaction zone and a fixed bed hydrotreating reaction zone which arearranged in series sequentially, generated oil obtained in the fixed bed hydrotreating reaction zone enters a fluidized bed hydrocracking reaction zone, a reaction effluent from the fluidized bed hydrocracking reaction zone is separated, and gas, gasoline, diesel oil, wax oil and unconverted oil are obtained; (4) after the unconverted oil obtained in the step (3) is mixed with the heavy fractionsobtained in the step (1), the mixture enters a solvent deasphalting device for treatment. With adoption of the method, the operation period of a treatment device can be greatly prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of demetalization catalyst

ActiveCN111821994AHigh activityImprove stabilityCatalyst activation/preparationChemical recyclingPtru catalystMetal catalyst

The invention discloses a preparation method of a demetalization catalyst, and the method comprises the following steps: (1) pulverizing a waste hydrotreating catalyst, and roasting; (2) immersing thematerial obtained in the step (1) into an ammonium bicarbonate aqueous solution, carrying out sealed heat treatment, filtering, drying the material, soaking with a polyethylene glycol solution, filtering, and drying to obtain a pretreated material A; and (3) subjecting pseudo-boehmite and the pretreated material A to kneading molding, drying and roasting the molded product so as to obtain a carrier, and loading a hydrogenation active component onto the carrier so as to obtain the demetalization catalyst. According to the method, the hydrodemetallization catalyst is prepared from the waste catalyst, so that the production cost is reduced, the environmental pollution is reduced, the activity of the catalyst is guaranteed, the catalyst has good stability, and the operation period of a devicecan be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Loading method of hydroprocessing catalyst

InactiveCN1259395CHigh metal capacityReduce carbon depositionRefining to eliminate hetero atomsReverse orderReaction zone

Owner:CHINA PETROLEUM & CHEM CORP +1

Alumina carrier and preparation method thereof

ActiveCN105817215AHigh metal capacityHigh activityPhysical/chemical process catalystsCrystallinitySilicon

The invention discloses an alumina carrier and its preparation method. With the weight of the carrier as the basis, auxiliaries account for 2-5% when metered on the basis of oxide. The auxiliaries are one or two elements selected from silicon or zirconium; content of silicon or zirconium in alumina decreases progressively from the center of carrier particles to the external surface; content of silicon and / or zirconium at the particle center is 1.5-3.5 wt%; content of silicon and / or zirconium at 1 / 3 of R is 0.5-1.5 wt%; and content of silicon and / or zirconium at 2 / 3 of R is 0.1-0.5 wt%, wherein R is radius of the carrier particle with the alumina center as the starting point. The alumina carrier has high degree of crystallinity, complete crystalline grain and centralized particle size distribution. Distribution of the auxiliaries in alumina decreases gradiently. The alumina carrier is suitable for preparation of a hydrotreating catalyst with high demetalization and good metal-holding capabilities.

Owner:CHINA PETROLEUM & CHEM CORP +1

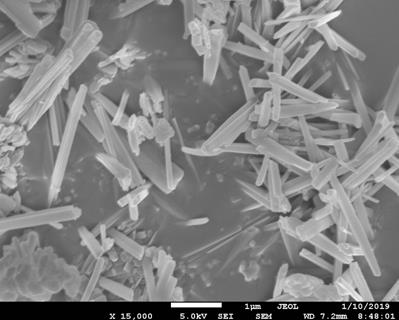

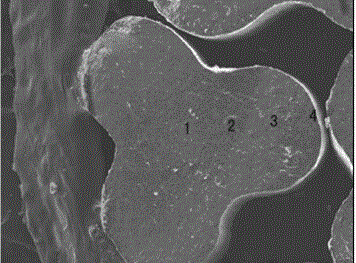

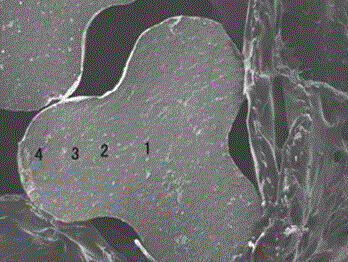

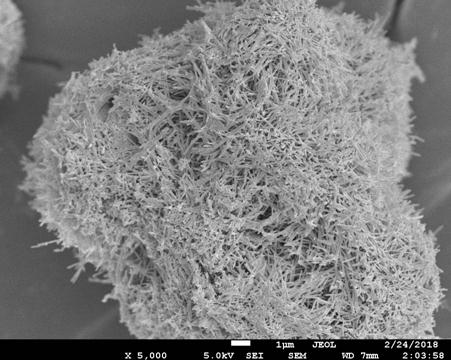

Double pore distribution alumina carrier and preparation method thereof, and hydrodemetallization catalyst

ActiveCN109718747AEnhanced mass transferFacilitated DiffusionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPore distributionPolyethylene glycol

The invention discloses a double pore distribution alumina carrier and a preparation method thereof, and a hydrodemetallization catalyst, wherein the double pore distribution alumina carrier containsa rod-like alumina cluster, and the rod-like alumina cluster is formed by disorderly staggered rod-like alumina. The preparation method of the double pore distribution alumina carrier comprises: calcining pseudo-boehmite A to obtain alumina; immersing the alumina in an ammonium bicarbonate aqueous solution, carrying out sealing heat treatment, drying, soaking with a polyethylene glycol solution, and drying the soaked material to obtain a rod-like alumina cluster; and carrying out mixing kneading molding on pseudo-boehmite B and the rod-like alumina cluster, drying the molded material, and calcining to obtain the double pore distribution alumina carrier. According to the present invention, the prepared double pore distribution alumina carrier has high pore volume and unique double pore distribution; and the hydrodemetallization catalyst prepared from the double pore distribution alumina carrier has advantages of ensured activity and good stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

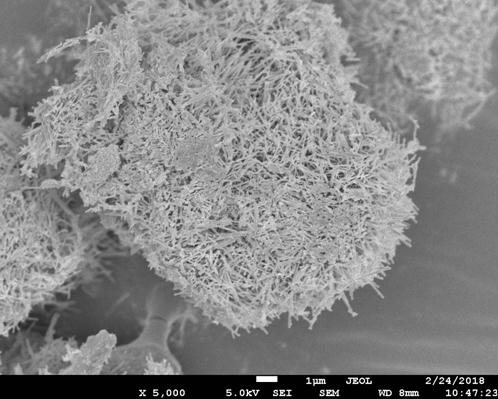

Preparation method of hydrodemetallization catalyst

ActiveCN111774065AHigh activityImprove stabilityMetal/metal-oxides/metal-hydroxide catalystsHydrocarbon oils treatmentPtru catalystMetal catalyst

The invention discloses a preparation method of a hydrodemetallization catalyst. The preparation method comprises the following steps of: (1) preparing a rod-like alumina cluster body; (2) impregnating the rod-like alumina cluster body obtained in the step (1) with an impregnation liquid containing a hydrogenation active component I, performing drying to obtain a modified rod-like alumina clusterbody, mixing and kneading the modified rod-like alumina cluster body and pseudo-boehmite, and performing molding, drying and roasting to obtain a carrier I; (3) mixing the carrier I obtained in the step (2) with ammonium bicarbonate and water, performing sealed heat treatment, and conducting drying and roasting to obtain a carrier II; and (4) impregnating the carrier II obtained in the step (3) with an impregnation liquid containing a hydrogenation active component II, and drying and roasting the carrier to obtain the hydrodemetallization catalyst. The hydrodemetallization catalyst prepared bythe method is through in pore channels and proper in pore distribution, the active components are non-uniformly distributed, and the catalyst is used for a heavy oil hydrogenation process and has relatively high hydrodemetallization activity and relatively high hydrodesulfurization activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com