Patents

Literature

92results about How to "Kong Ronggao" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

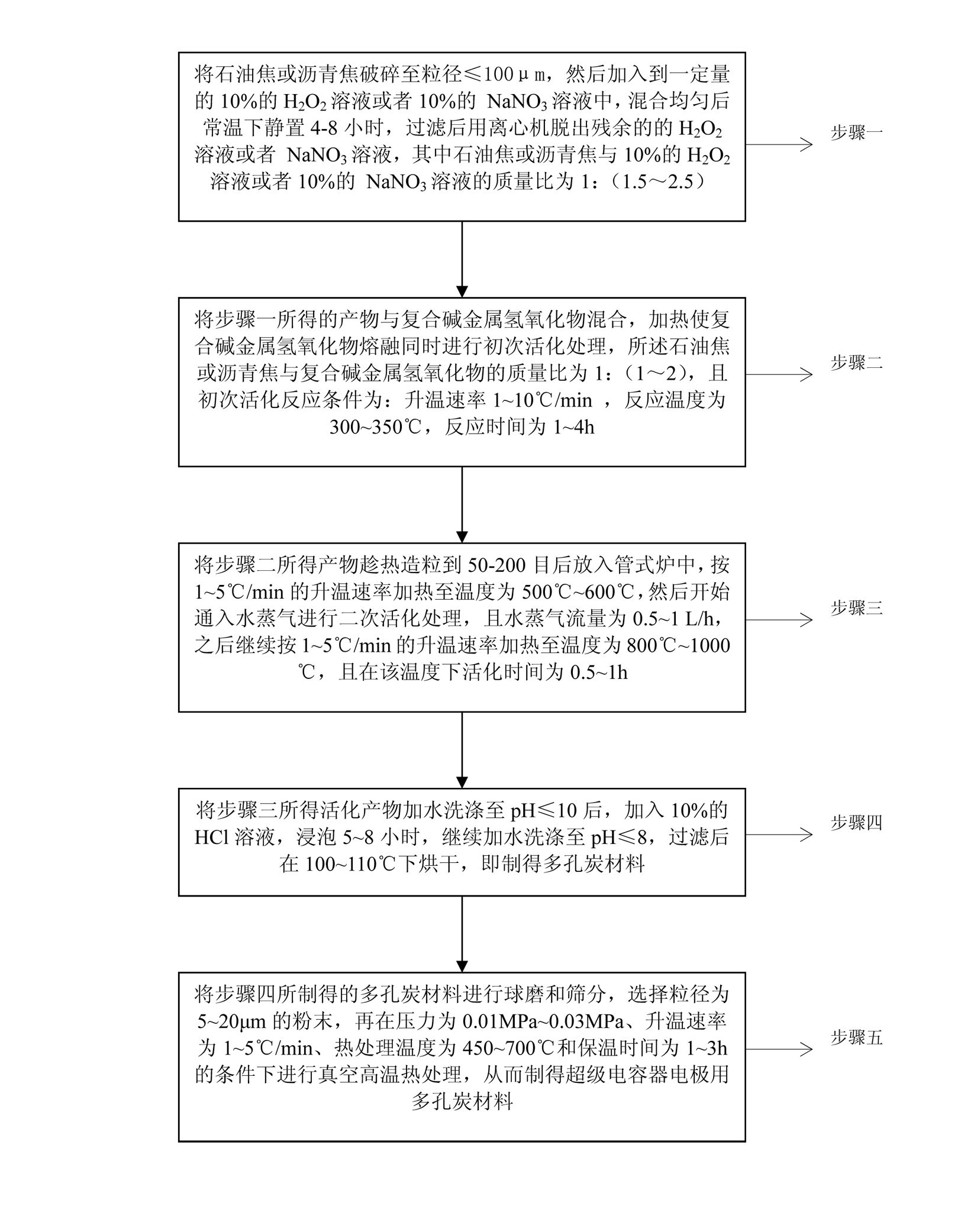

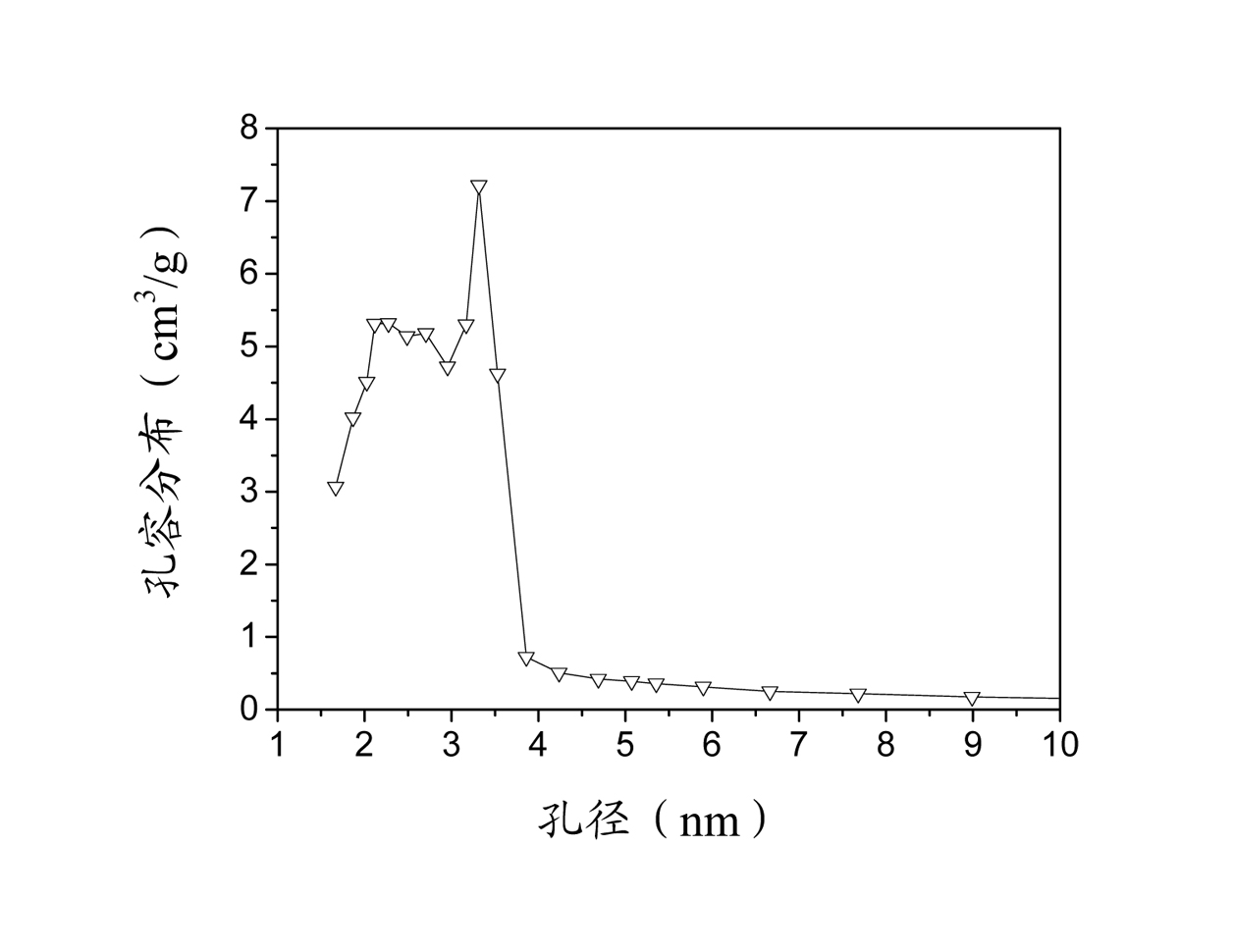

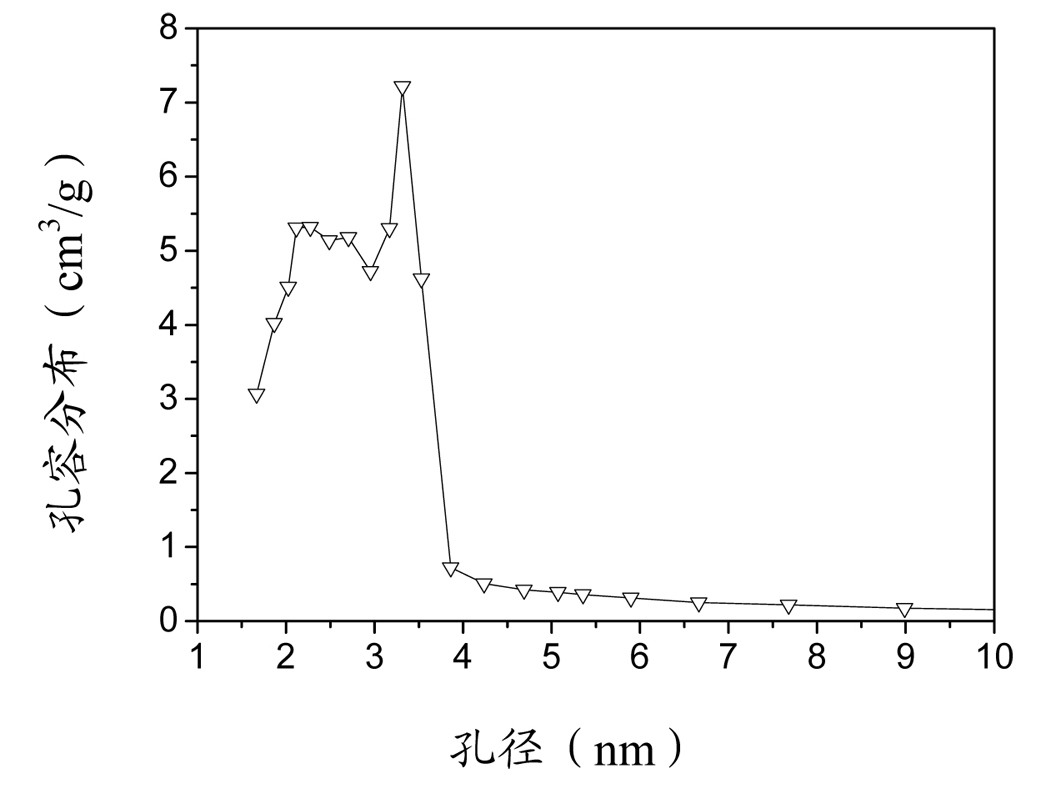

Preparation method of porous carbon material for supercapacitor

ActiveCN101973542AReduce dosageLarge specific surface areaElectrolytic capacitorsPorous carbonBiological activation

The invention provides a preparation method of porous carbon materials for a supercapacitor, in the preparation method, with refinery coke or pitch coke as raw materials and composite alkali metal hydroxide as an activating agent, the porous carbon material is prepared by using a two-stage activation process. The obtained porous carbon material has a specific surface area of 1500-1800m2 / g, has good adsorptive property and narrow aperture distribution, and the aperture distribution can be regulated according to requirements. A supercapacitor electrode made of the porous carbon materials has the characteristics of high capacity, high power, long cycle life, and the like. The preparation method has the characteristics of low hydroxid usage, simple production technology, and the like and is convenient to practicability.

Owner:TIG TECH CO LTD

Method of preparing silicon dioxide delustrant by large pore volume gel

ActiveCN101407324AHigh mattingHigh transparencySilicaPigment treatment with macromolecular organic compoundsFiltrationSilicon dioxide

The invention relates to a preparation method of a silicon dioxide flatting agent used for coating flatting with a large pore volume gelatin method, which comprises the following steps of: adding a sodium silicate water solution in a reaction kettle; at the temperature of 26 DEG C and under stirring, adding 30% sulphuric acid until forming gelatin in the kettle; then stirring for 15min, raising the temperature to 50 DEG C and continually adding the sulphuric acid until pH value being up to 3; when no gelatin block by stirring, slowly adding 30% sodium hydroxide into the reaction kettle, regulating the pH value to be 5-6, and then regulating the pH value to be 9-10 by using ammonia water; and raising the temperature to 98 DEG C, ageing for 1 hour, adding water for cooling to the temperature of 75 DEG C, filtration washing, slurrying, sponging drying and crashing classifying to obtain the finished product. The product has the characteristics of large pore volume, large specific surface area, high purity, moderate DBP absorption value, good dispersion performance, high transparency and the like as well as the advantages of reasonable technology and high production efficiency. The product can be added with wax for carrying out surface treatment, thus leading the surface paint film of the coating to be smooth, and improving scratch resistance and precipitate resistance.

Owner:通化双龙化工股份有限公司

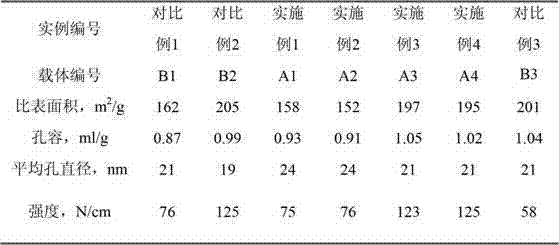

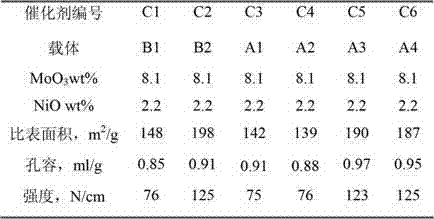

Coal tar hydrodemetalization catalyst and preparation method thereof

ActiveCN102847541AUnobstructed pore structureIncrease profitCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsOrganic acidPtru catalyst

The invention discloses a coal tar hydrodemetalization catalyst and a preparation method thereof. The method comprises the steps of: (1) taking or preparing an alumina carrier; (2) treating the alumina carrier from the step (1) with an organic acid solution with pH value lower than 3; then impregnating the alumina carrier subjected to acid treatment with an aluminium nitrate solution; and drying and roasting to obtain a modified alumina carrier; and (3) loading and hydrogenating an active component by an impregnation method to obtain the coal tar hydrodemetalation catalyst. Compared with the prior art, the coal tar hydrodemetalation catalyst provided by the invention has better activity and activity stability, and longer operation cycle.

Owner:上海竣铭化工工程设计有限公司

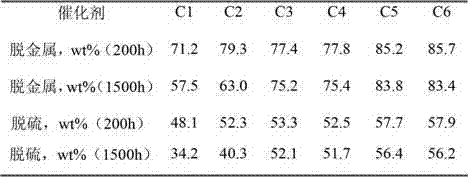

Preparation method of silica gel for polyolefin catalyst carrier

ActiveCN106477587AImprove pore volumeSimple process controlCatalyst carriersSilicon compoundsColloidal particlePolyolefin

The invention provides a preparation method of a silica gel carrier for a polyolefin catalyst. The silica gel is prepared through a gel reaction by using alkaline silica gel, silicate and an inorganic acid as raw materials. The preparation process comprises the steps of: taking the alkaline silica sol as a reaction base solution; adding the silicate and the inorganic acid through a concurrent flow mode; and finishing the preparation process of the silica gel carrier by controlling a pH value of a reaction system and combining a high temperature hydrothermal reaction. The preparation method of the silica gel carrier for the polyolefin catalyst has the advantages that in the reaction, new colloidal particles generated in the gel reaction and the sol reaction directly react with hydroxyl on the silicon sol surface, and the cross-linking between sol particles is finished by constant aggregation; and the high temperature hydrothermal reaction at the later period quickens the reaction between gel particles, thereby greatly improving the pore volume and the aperture of the silica gel. Because the performance of the added silica sol is similar to that of the silica gel, the process control is easy. The silica gel pore volume and the aperture are improved, and the technology repeatability is good. The preparation method of the silica gel carrier for the polyolefin catalyst brings benefits for the industrial production.

Owner:PETROCHINA CO LTD

Cerium-zirconium-based solid solution rare earth oxygen-storage material and preparation method thereof

ActiveCN103127925ASmall particlesLarge specific surface areaMetal/metal-oxides/metal-hydroxide catalystsReaction rateHeat stability

The invention discloses a cerium-zirconium-based solid solution rare earth oxygen-storage material and a preparation method thereof. The cerium-zirconium-based solid solution rare earth oxygen-storage material has a specific surface area equal to or greater than 90m<2>.g<-1>, has a specific surface area equal to or greater than 30m<2>.g<-1> after being calcined at a temperature of 1000 DEG C for 4 hours, and has a specific surface area equal to or greater than 20m<2>.g<-1> after being calcined at a temperature of 1050 DEG C for 12 hours. Compared with the prior art, the preparation method has the advantages that before precipitation, a mixed metal salt solution is added with a certain amount of an organic acid so that acidity of the mixed metal salt solution is improved or the mixed metal salt solution forms sol; a reaction rate is inhibited and a precipitation rate is controlled so that a stable precursor having the uniform grain size is obtained; and the precipitate precursor surface treatment is carried out by a surfactant so that the aperture size and the aperture volume of a calcination product are improved and the cerium-zirconium-based solid solution rare earth oxygen-storage material having good heat stability is prepared. The cerium-zirconium-based solid solution rare earth oxygen-storage material has the advantages of small granule size, large specific surface area, high temperature aging resistance and high activity.

Owner:上海华明高纳稀土新材料有限公司

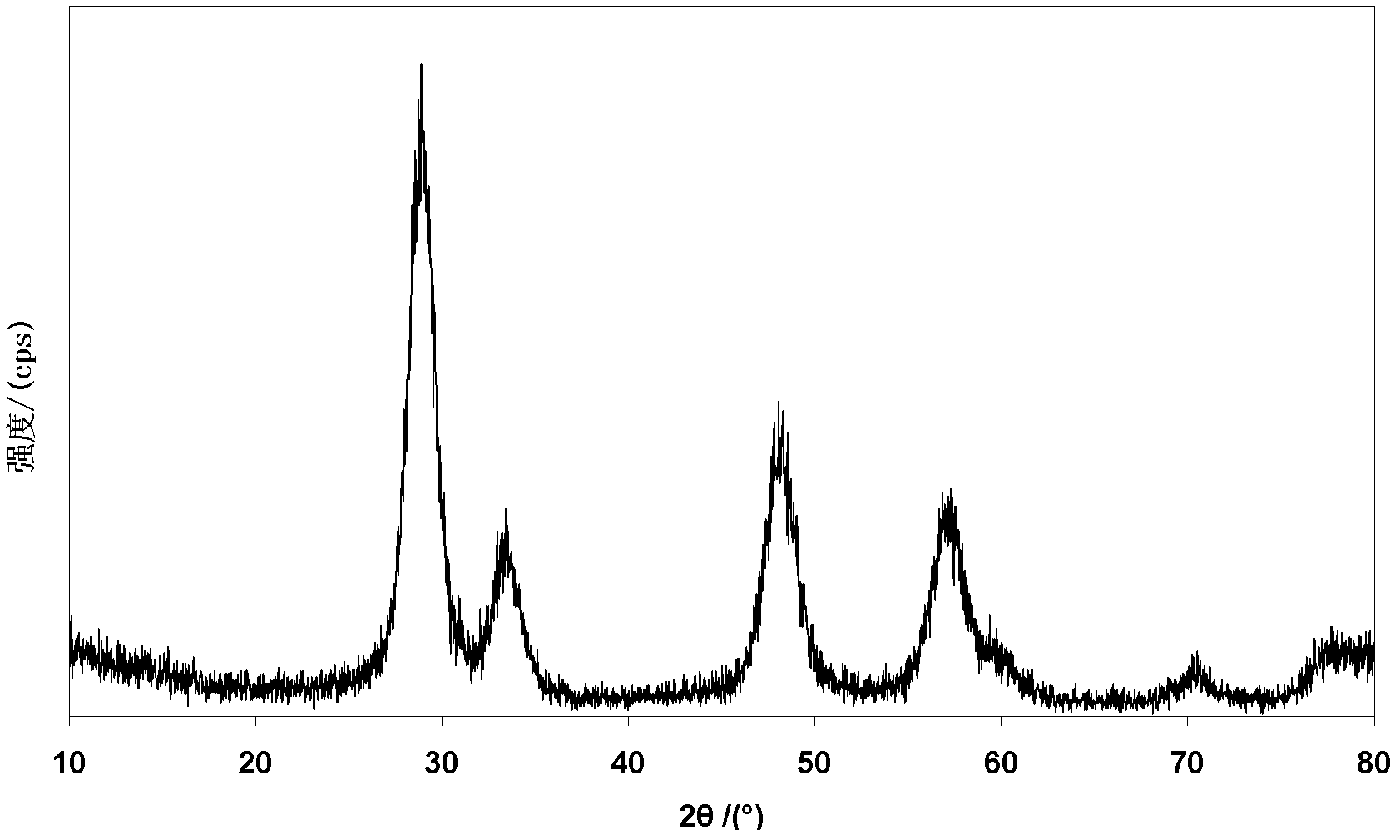

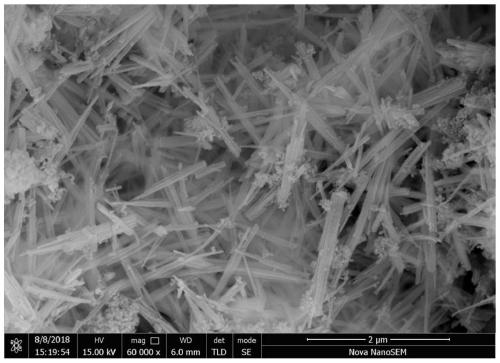

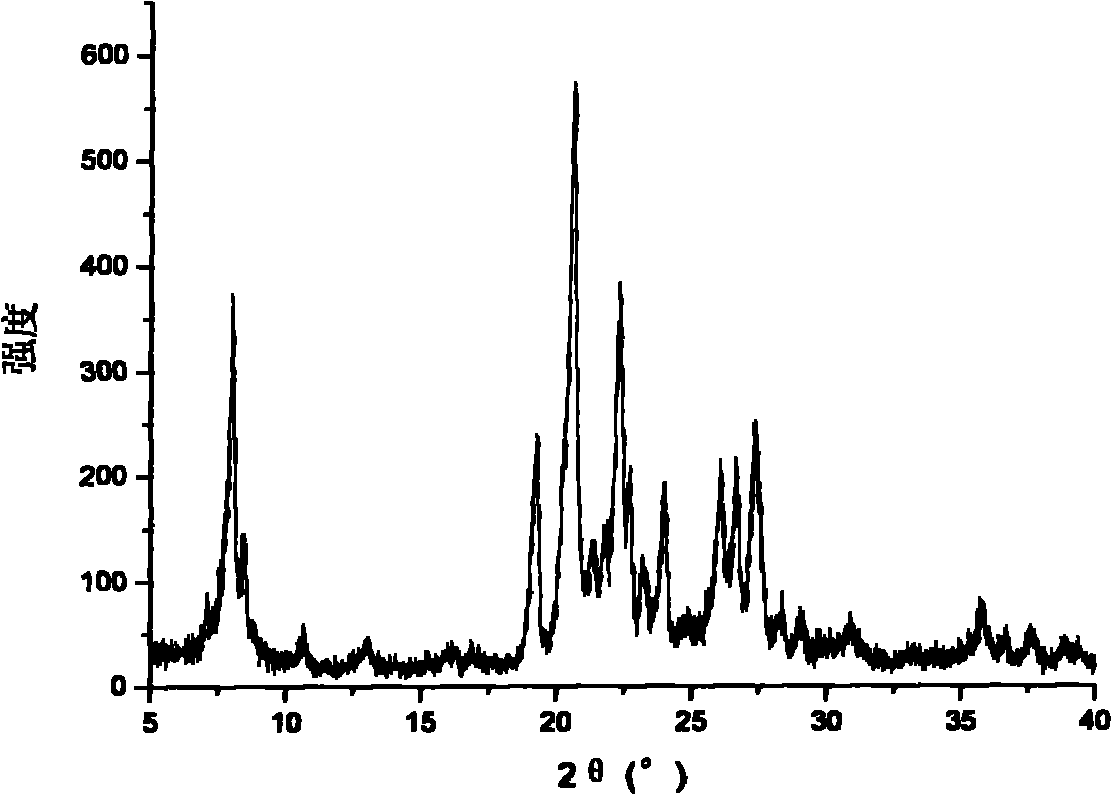

Preparation method of ZSM-48 molecular sieve with low silica-alumina ratio

ActiveCN110342536ALow costShorten crystallization timeMolecular sieve catalystsMolecular-sieve and base-exchange compoundsChemistryMolecular sieve

The invention provides a preparation method of a ZSM-48 molecular sieve with low silica-alumina ratio. The method utilizes a dual template agent to synthesize the ZSM-48 molecular sieve with low silica-alumina ratio at low cost, compared with the existing preparation method of ZSM-48 molecular sieve with low silica-alumina ratio, by adopting the dual template agent, the method shortens the crystallization time while lowering the template agent cost, efficiently synthesizes the pure phase ZSM-48 molecular sieve with high crystallinity and low silica-alumina ratio, at the same time achieves easier and effective removal of the template, increases the specific surface area, pore volume, pore diameter and acid content of the molecular sieve, can realize more effective hydroisomerization reaction, and improves the isomerization selectivity. The molecular sieve has high application value and prospect in the hydroisomerization dewaxing field.

Owner:PETROCHINA CO LTD

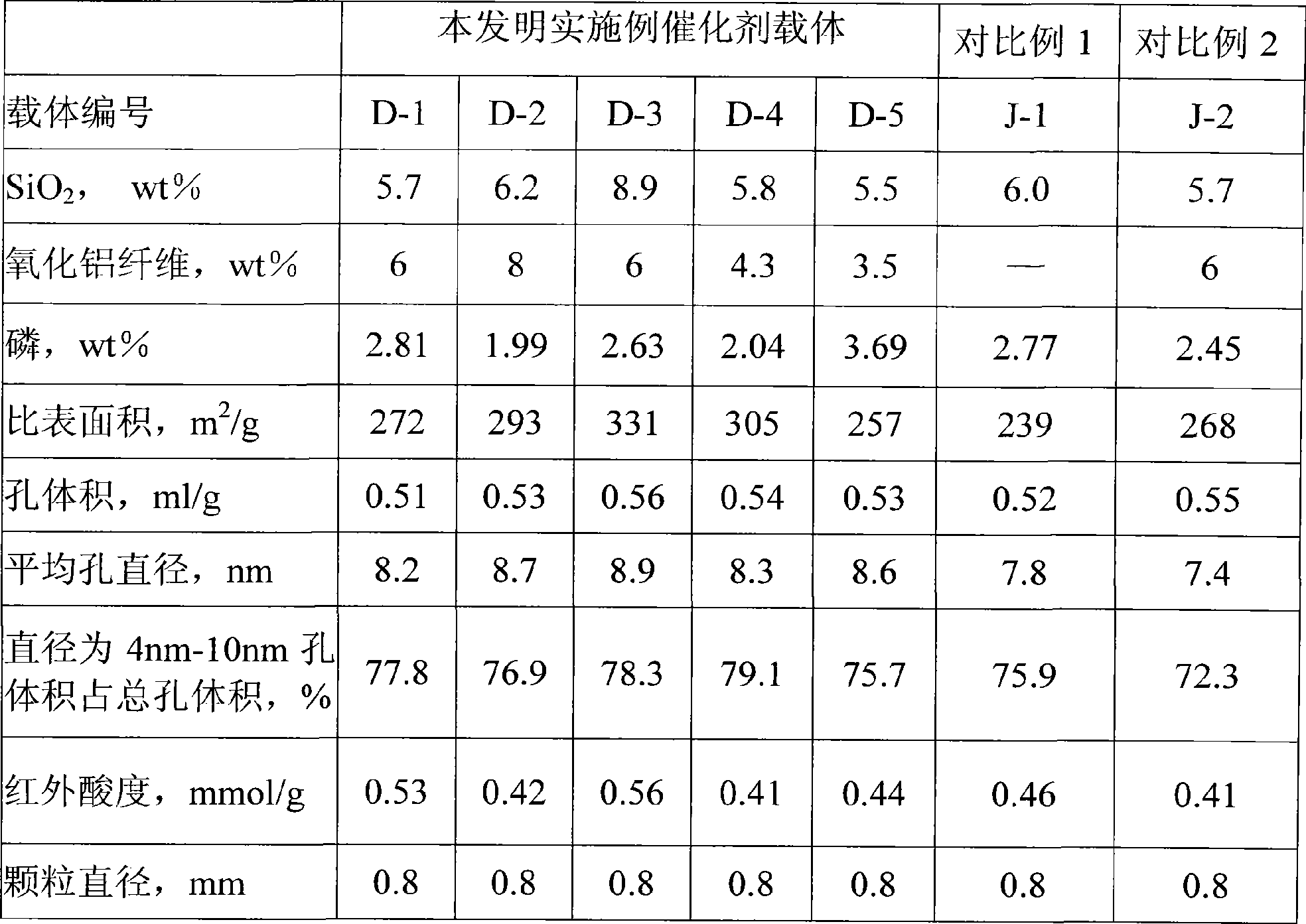

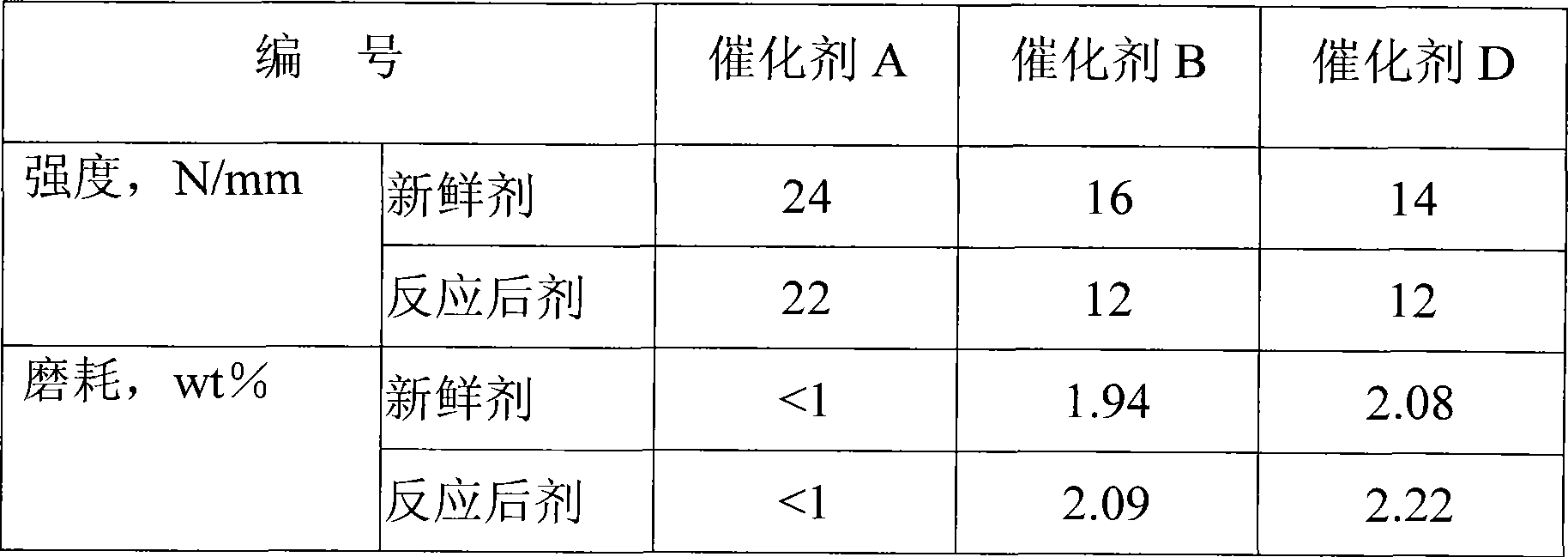

Coal liquefied oil boiling bed hydrogenation catalyst carrier and preparation method thereof

ActiveCN101085935AHigh mechanical strengthImprove wear resistanceRefining to eliminate hetero atomsFiberWear resistance

The invention discloses a catalyst carrier for coal liquification oil hydrogenation on boiling bed and the preparation method. Besides normal hydrogenation catalyst carrier component, the catalyst aslo contains aluminium oxide fiber, the content of which in carrier is 3- 10wt%. The mechanical strength and wearing resistance of catalyst are strong, which increases carrier stability and life length and reduces production cost. The active aluminium oxide utilization can increase the hydrogeneration activity and stability.

Owner:神华煤制油研究中心有限公司

Coal liquefied oil boiling bed hydrogenation technique

ActiveCN101085933AHigh mechanical strengthImprove wear resistanceRefining to eliminate hetero atomsFiberSulfur

The invention discloses a process of hydrogenation for coal liquification oil on boiling bed. The process employs hydrogenation catalyst which contains fiber adjuvant, the fiber adjuvant content in catalyst is 3- 10 wt%. The mechanical strength and wearing resistance are strong, so it can remove nitrogen and sulfur from coal liquification oil maximumly, reduces olefin and aromatic hydrocarbons content, increases product stability and provides high performance coal liquification solvent oil.

Owner:神华煤制油研究中心有限公司

Coal liquefied oil boiling bed hydrogenation treatment catalyst and preparation method thereof

ActiveCN101085934AHigh mechanical strengthImprove wear resistanceRefining to eliminate hetero atomsFiberSulfur

The invention discloses a catalyst for coal liquification oil hydrogenation on boiling bed and the preparation method. Besides normal hydrogenation catalyst, the catalyst aslo contains silicon oxide fiber, the content of which in catalyst is 3- 10wt%. The mechanical strength and wearing resistance of catalyst are strong, which increases catalyst stability and life length. It can remove nitrogen and sulfur from coal liquification oil maximumly, reduces olefin and aromatic hydrocarbons content, increases product stability and provides high performance coal liquification solvent oil.

Owner:神华煤制油研究中心有限公司

Hydrotreating catalyst carrier and preparation thereof

ActiveCN101376830AHigh mechanical strengthImprove wear resistanceCatalyst carriersRefining to eliminate hetero atomsFiberAdditive ingredient

The invention discloses a hydrotreatment catalyst carrier and a preparation method thereof. The carrier contains alumina fibers and an accessory ingredient of phosphorus; wherein, the accessory ingredient of phosphorus is partially or completely led in the form of aluminum dihydrogen phosphate. During the preparation process, the alumina fibers and the aluminum dihydrogen phosphate are added in the catalyst, thus being capable of improving the mechanical intensity and the wear resistance of the carrier, improving the stability of the catalyst, prolonging the service life of the catalyst and reducing the product cost. When the catalyst is used as the carrier of a boiling bed hydrotreatment catalyst for treating heavy fractions, the impure atoms like nitrogen, sulfur in the oil products can be removed to the largest extent; the contents of olefin and aromatic hydrocarbon can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

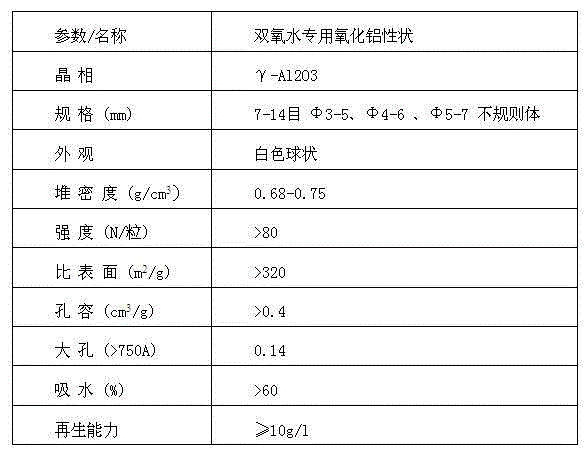

Aluminum oxide specially used for hydrogen peroxide fluidized bed and production technology for aluminum oxide

ActiveCN103818939AImprove regenerative abilityHigher than the tableAluminium compoundsPhysical/chemical process catalystsFluidized bedAluminium oxides

The invention belongs to the field of chemical engineering and in particular relates to aluminum oxide specially used for a hydrogen peroxide fluidized bed and a production technology for the aluminum oxide specially used for the hydrogen peroxide fluidized bed. The aluminum oxide specially used for the hydrogen peroxide fluidized bed is characterized in that the bulk density of the aluminum oxide is 0.68-0.75 g / cm<3>, and the intensity is higher than 80; the specific surface area is larger than 320 m<2> / g; the pore volume is bigger than 0.4 cm<3> / g, and the water absorption rate is higher than 60 percent. The method comprises the following steps of (1) drying; (2) smashing; (3) quick removal; (4) balling; (5) nourishing; (6) activation; (7) crushing and cooling; (8) screening and packaging. The aluminum oxide and the production technology have the benefits of improvement on the regeneration of working liquid in a hydrogen peroxide production process and prolonged service cycle.

Owner:石家庄恒诺科技有限公司

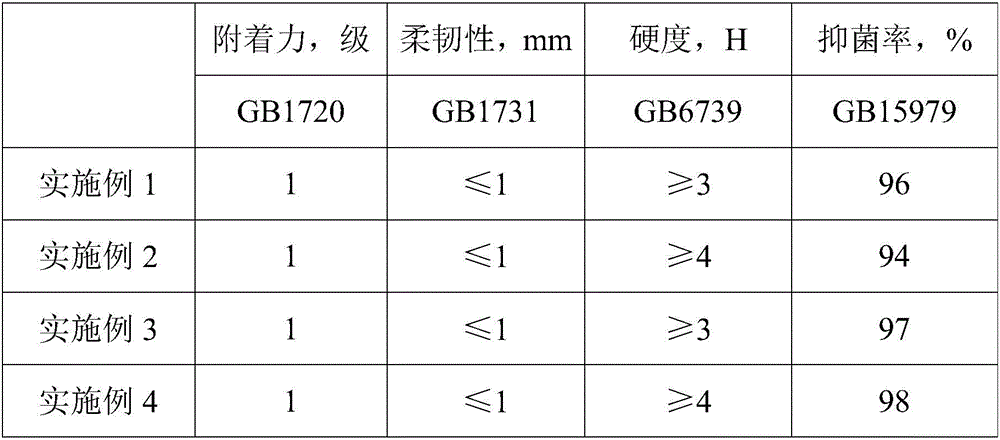

Kitchen ware dedicated electrostatic spraying powder coating and preparation method thereof

InactiveCN106609096AStorage Stability BalanceMelting balanceAntifouling/underwater paintsPaints with biocidesEpoxySorbent

The invention relates to a kitchen ware dedicated electrostatic spraying powder coating and a preparation method thereof, wherein the coating comprises the following raw materials in parts by weight: 60-90 parts of epoxy resin, 15-35 parts of fluororesin, 3-8 parts of phenolic hydroxyl resin, 5-25 parts of an antibacterial adsorbent, 2-6 parts of nano silicon dioxide, 1-5 parts of nano titanium dioxide, 1-5 parts of nano calcium carbonate, 5-15 parts of bauxite, 5-10 parts of precipitated barium sulfate, 10-20 parts of titanium dioxide, 2-5 parts of zinc stearate, 1-3 parts of benzoin, 2-6 parts of hydroxyethylmethylcellulose, 0.2-1 part of polyamide wax, 0.5-2 parts of a leveling agent, and 2-6 parts of an amine curing agent. According to the kitchen ware dedicated electrostatic spraying powder coating and the preparation method thereof disclosed by the invention, the construction requirements of electrostatic spraying can be met, moreover, the bacteriostatic and bactericidal effects can be played, and the coating also has the ability to adsorb odorous substances in kitchens.

Owner:TIANCHANG JINLING ELECTRONICS

Bubbling bed hydrotreating catalyst and preparation thereof

ActiveCN101376829AImprove mechanical strength and wear resistanceExtended service lifeRefining to eliminate hetero atomsPhosphateNitrogen

The invention discloses a boiling bed hydrotreatment catalyst and a preparation method thereof. The catalyst adopts an alumina carrier which contains alumina fibers and an accessory ingredient of phosphorus; wherein, the accessory ingredient of phosphorus is partially or completely led in the form of aluminum dihydrogen phosphate. During the preparation process, the alumina fibers and the aluminum dihydrogen phosphate are added in the catalyst, thus being capable of improving the mechanical intensity and the wear resistance of the catalyst, improving the stability of the catalyst, prolonging the service life of the catalyst and reducing the product cost. When the catalyst is used for the heavy oil products of boiling bed hydrotreatment, the impure atoms like nitrogen, sulfur in the oil products can be removed to the largest extent, the contents of olefin and aromatic hydrocarbon can be reduced and the product stability can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

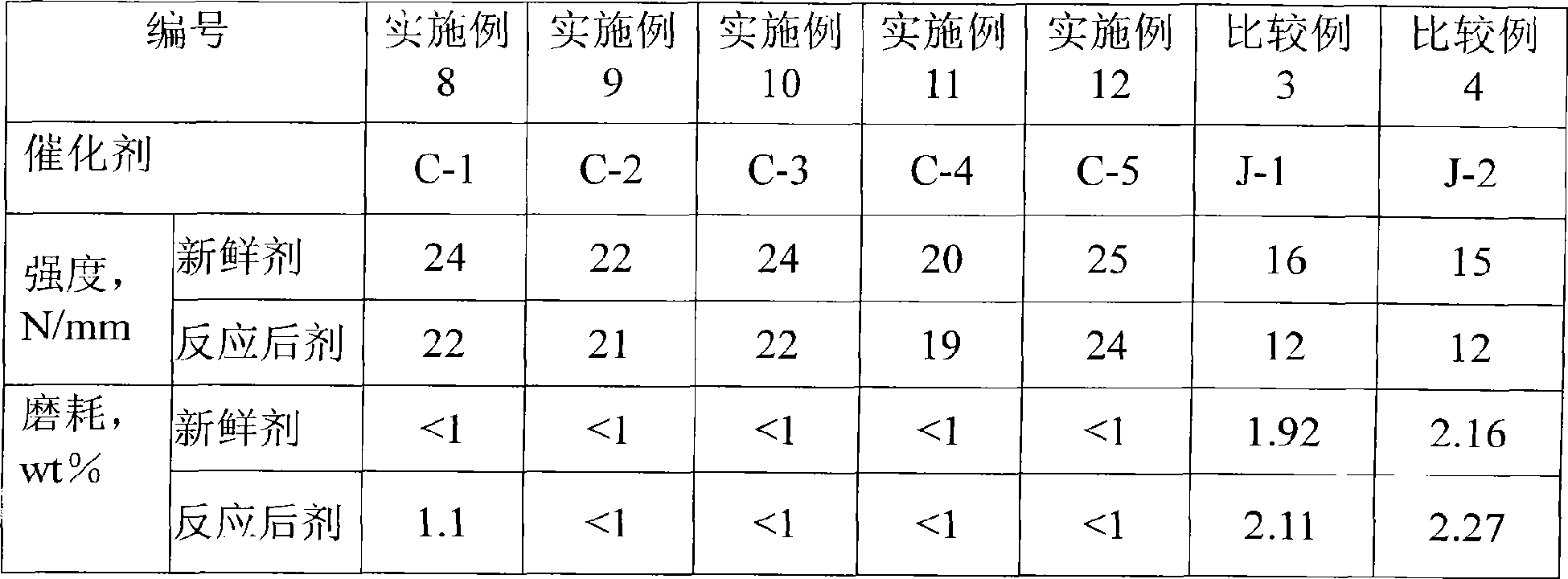

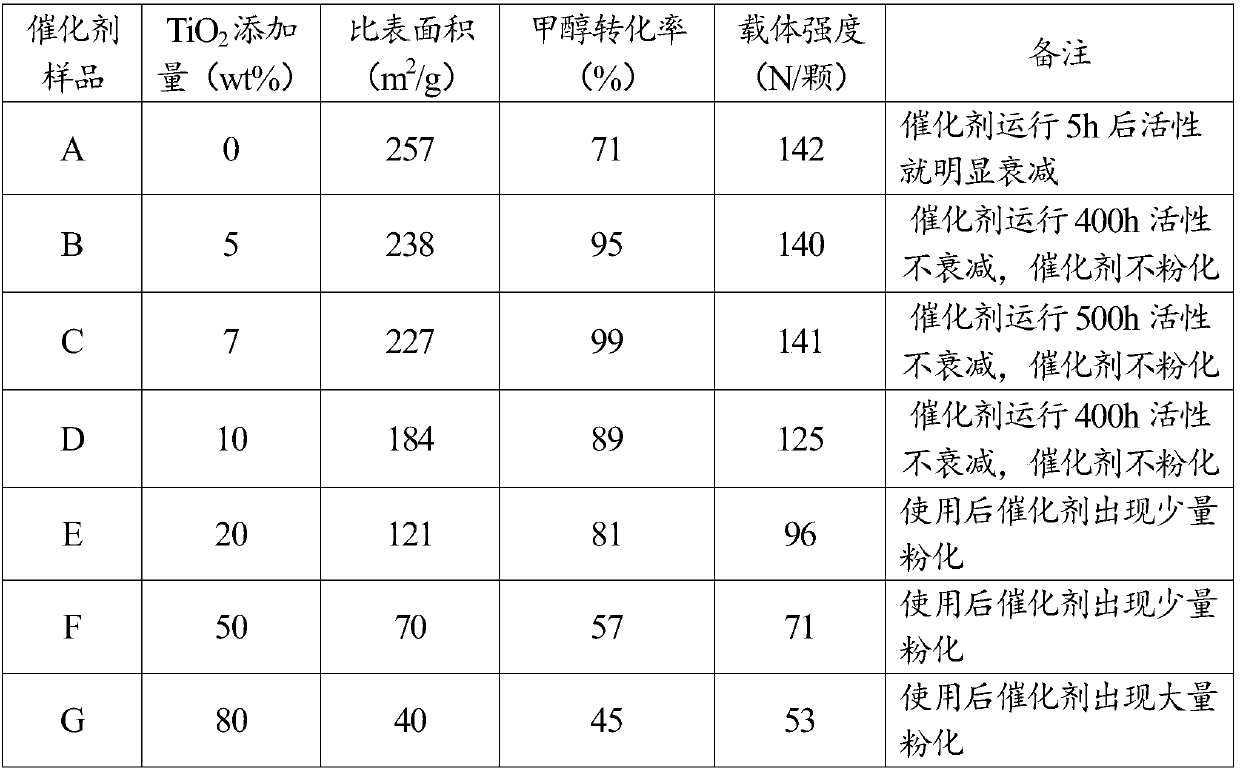

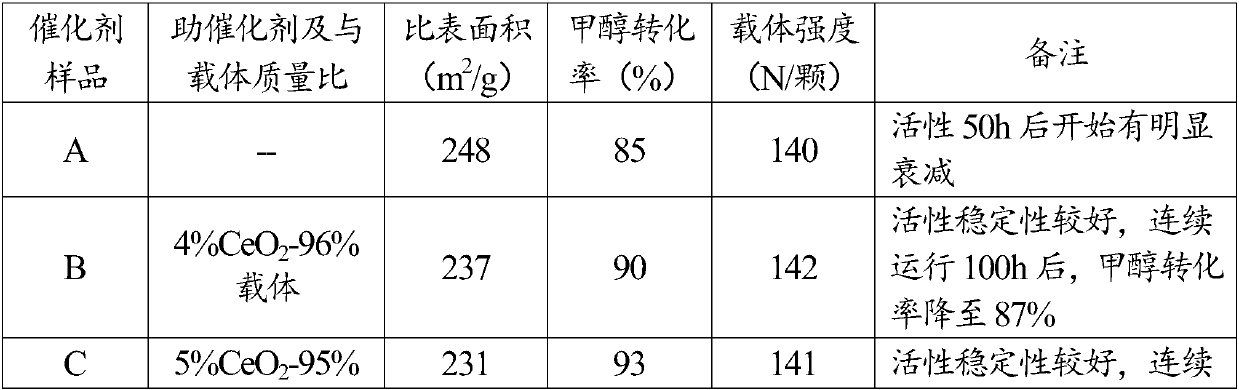

Catalyst for hydrogen production by steam high-temperature reforming of methanol and preparation method and application of catalyst

ActiveCN107649137AHigh activityThe active center acts as a catalyst for increased activityHydrogenHeterogenous catalyst chemical elementsWater vaporActive component

The invention discloses a catalyst for hydrogen production by steam high-temperature reforming of methanol and a preparation method and application of the catalyst. The catalyst takes TiO2 / Al2O3 as acarrier, CeO2 and / or ZrO2 loaded on the carrier as a promoter and a ZnO-NiO bi-active center dispersed on the carrier as a catalyst active component, wherein the mass of the catalyst active componentaccounts for 15-30% of the total mass of the catalyst; and in the ZnO-NiO bi-active center, the mass ratio of ZnO to NiO is (70-90):(10-30), and the mass ratio of the promoter to the carrier is (5-15):(85-95). A noble metal is not taken as the raw material, shortcomings of a traditional Zn-Cr catalyst can be overcome, the catalyst can be applied to the high-temperature range of 350-550 DEG C and has high activity and selectivity and stable catalytic performance.

Owner:四川蜀泰化工科技有限公司

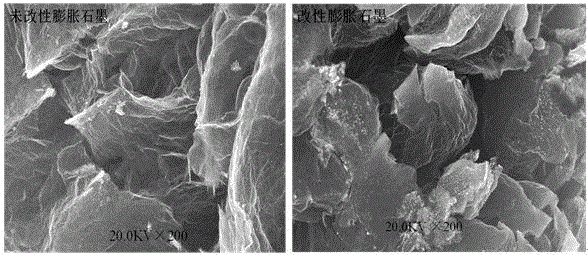

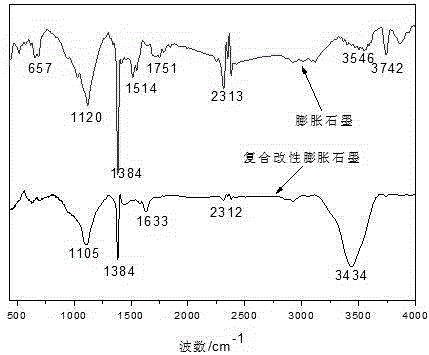

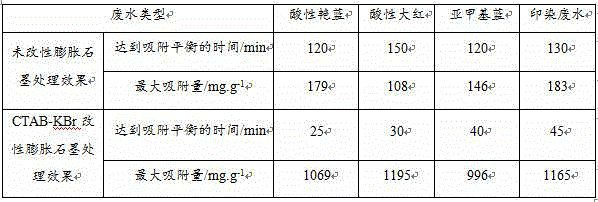

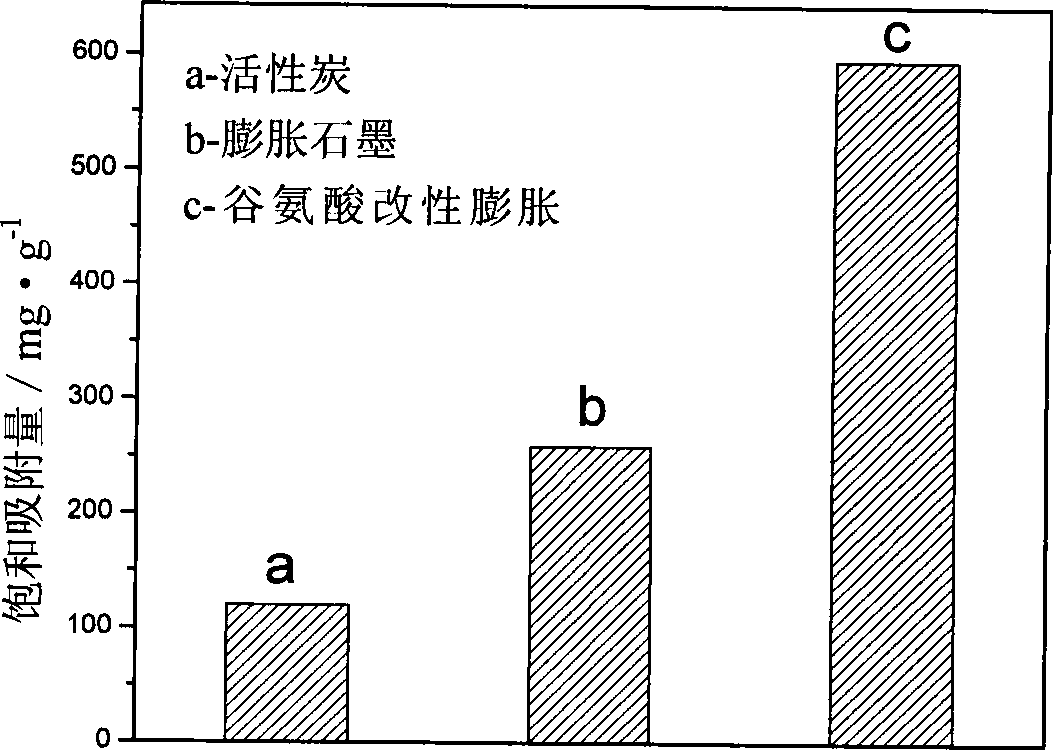

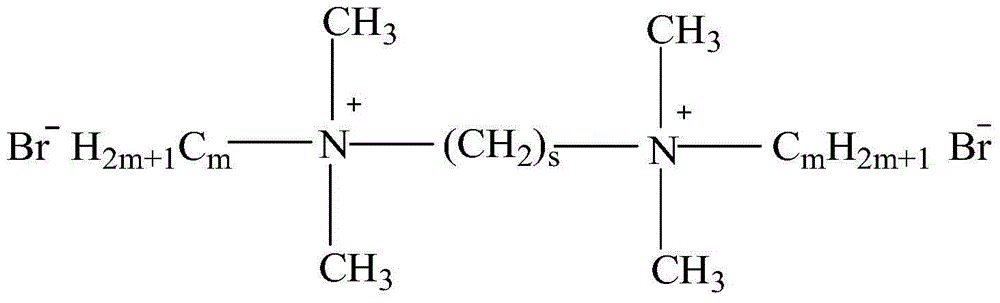

Preparation of expanded graphite through compound modification and application of expanded graphite to printing and dyeing wastewater treatment

InactiveCN104888707AKong RonggaoImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionPhysical chemistryDyeing wastewater

The invention relates to the field of preparation and application of modified expanded graphite, in particular to a method for preparing expanded graphite through CTAB-KBr compound modification and low-temperature electric furnace puffing. The method is characterized by including the following steps: soaking a certain amount of expandable graphite, which is prepared using natural flake graphite as a raw material, in a CTAB-KBr mixed solution with different concentrations of CTAB and KBr at a certain temperature; washing and drying, and then puffing using a low-temperature electric furnace to obtain modified expanded graphite. As the common low-temperature electric furnace is used to replace a muffle furnace as the puffing device, the expansion temperature is low, and energy conservation is remarkable; the expanded graphite after compound modification is increased in surface active sites, and rich surface functional groups are loaded on the surface, so that various types of dyes can be effectively adsorbed, and purification of printing and dyeing wastewater is realized.

Owner:BEIJING UNIV OF CHEM TECH

Refining recovery process for crude glycerin

InactiveCN106518617AImprove adsorption capacitySmall steric hindranceHydroxy compound separation/purificationActivated carbonSorbent

The invention discloses a refining recovery process for crude glycerin. The refining recovery process comprises the following steps: adding dilute acid into the crude glycerin and then adjusting pH to 5-6; heating to 70-80 DEG C and then stirring for 40-60min; standing by and layering, and then removing the fatty acid on the upper layer; adding water for diluting till the water content is 30-35wt%; preheating to 30-60 DEG C and adopting a D201 macro-pore strong basic anion exchange resin column for performing ion exchange treatment; preheating to 30-40 DEG C and then adding an efficient adsorbing material, stirring, standing by and filtering; reducing pressure and dewatering, and then adding activated carbon, stirring and filtering, thereby acquiring an end product of refined glycerin. According to the refining recovery process for crude glycerin provided by the invention, the end product of glycerin with purity reaching 99.5% or above can be effectively produced, the production cost can be effectively lowered and the energy and resource can be saved.

Owner:天长市康宁甘油科技有限公司

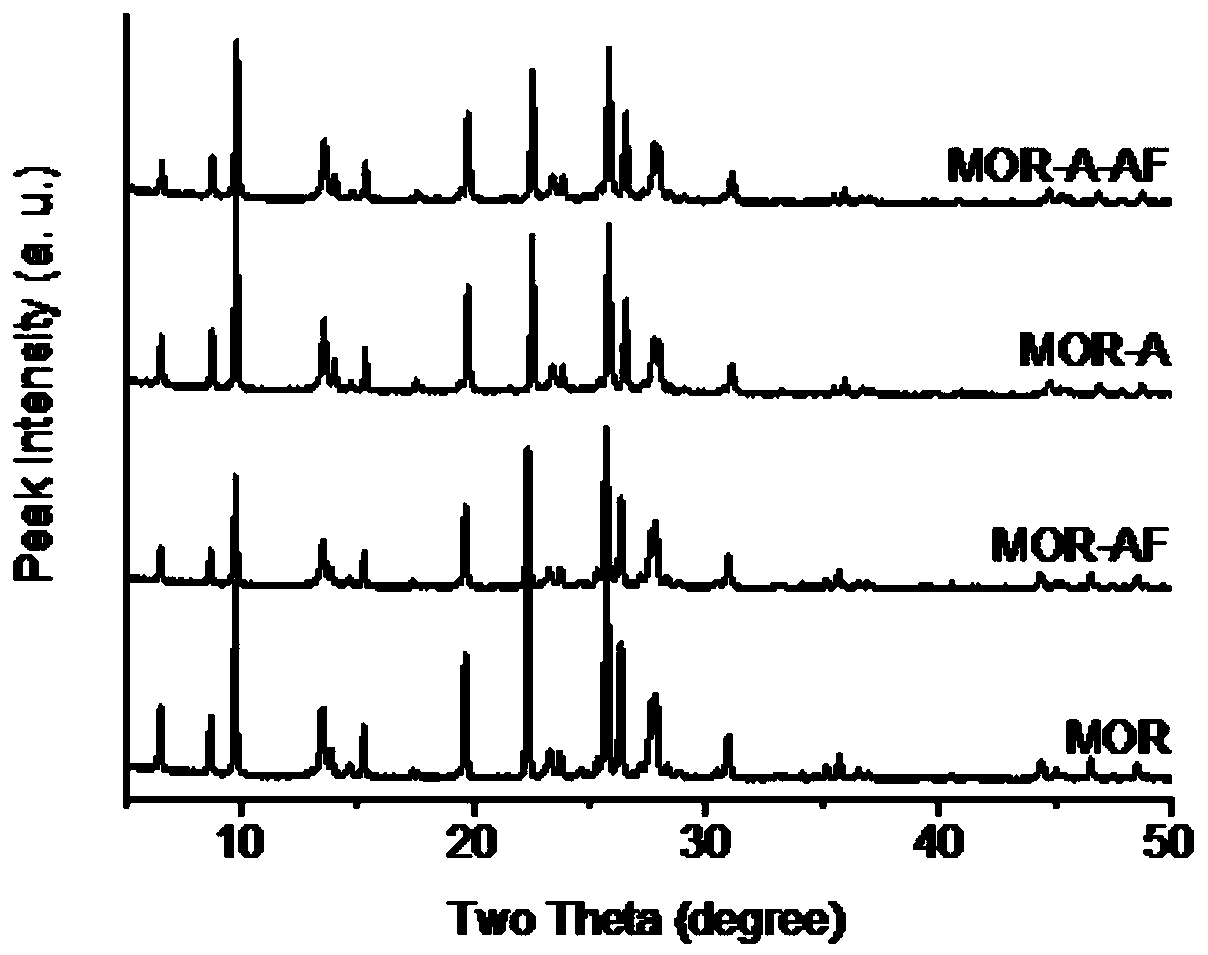

Molecular sieve pore-expanding method

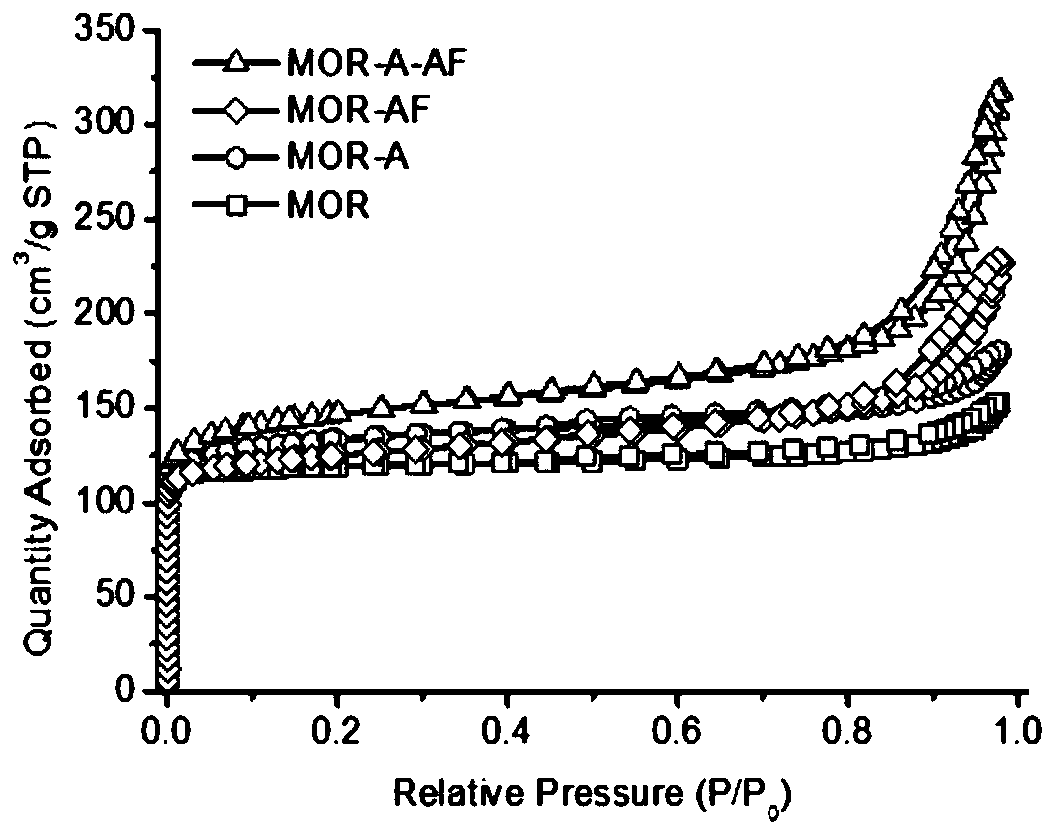

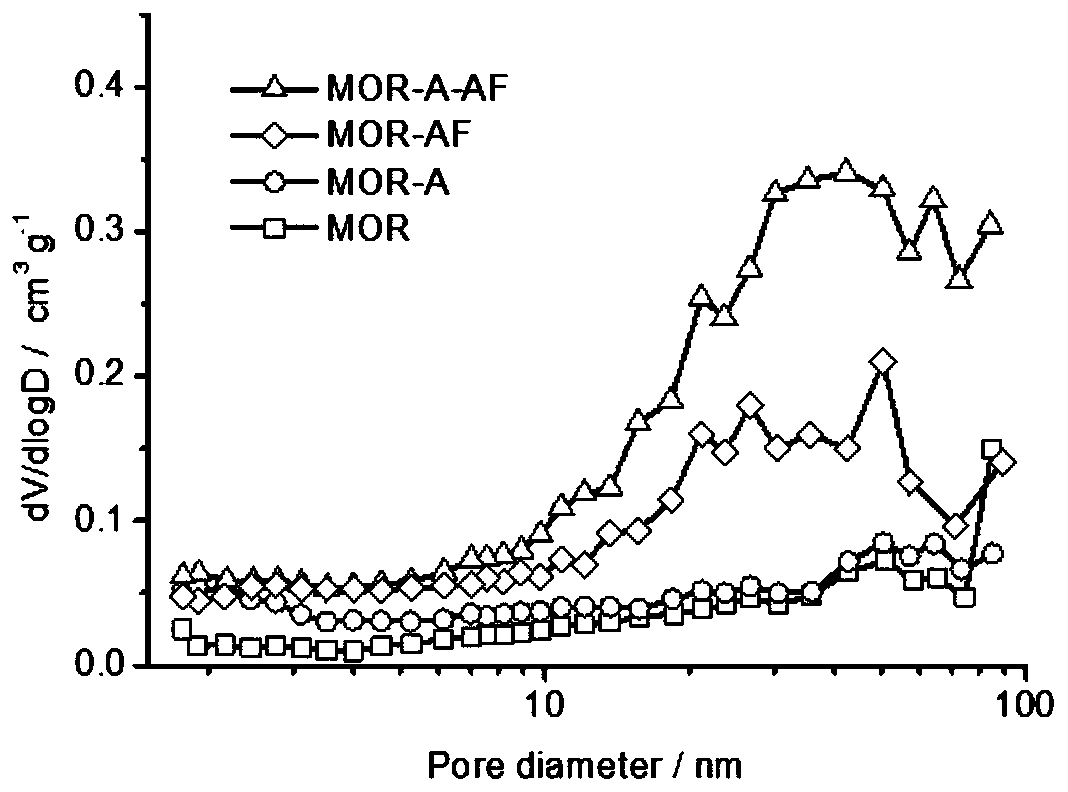

ActiveCN111320185ASmall sizeKong RonggaoFaujasite aluminosilicate zeoliteMordenite aluminosilicate zeoliteMolecular sievePhysical chemistry

A molecular sieve pore-expanding method comprises the following steps: (1) introducing defects into a molecular sieve: preprocessing the molecular sieve by using an acid solution, an alkali solution or water vapor, cleaning, and drying the preprocessed molecular sieve to obtain a defect-containing molecular sieve; and (2) removing skeleton atoms in the defect-containing molecular sieve obtained inthe step (1) by adopting an ammonium fluoride solution to realize regulation and control of a pore structure. The method will not obviously destroy the crystal structure of the molecular sieve, the micro-pore size of the obtained molecular sieve is properly increased, the micro-pore volume is increased, and the molecular sieve has a micro-pore mesopore stepped pore structure after being treated.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Activation regeneration treatment process for semi-coke used for industrial flue gas dry desulfurization

InactiveCN110227428ALarge poresImprove adsorption capacityGas treatmentOther chemical processesWater vaporFlue gas

The invention provides an activation regeneration treatment process for semi-coke used for industrial flue gas dry desulfurization. The activation regeneration treatment process comprises the semi-coke. The semi-coke is successively subjected to water vapor activation, nitric acid activation and potassium hydroxide activation, so a semi-coke activation product with good sulfur dioxide adsorption performance is obtained; and the semi-coke activation product reaches the standards of flue gas adsorption, has low price, is applicable to large-range flue gas treatment, and has high environmental friendliness and economic benefits.

Owner:PINGXIANG HUAXING ENVIRONMENTAL PROTECTION ENG TECH CO LTD

Silicon-phosphorus contained aluminum hydrate and its preparation

InactiveCN1552526AExcellent deep hydrofining activityReduce competitionCatalyst carriersCatalyst activation/preparationAluminium hydroxideAluminum hydrate

An aluminium hydroxide particle containing Si and P dispersed on its surface is disclosed, which can be used for hydrorefining the fractional oil or preparing the hydrocatalyst. It is prepared by introducing the cheap Si-contained compound and P-contained compound in the process for preparing the alpha-AlO(OH) type aluminium hydroxide by Co2 method step by step. Its advantages are excellent physical and chemical properties, large pore volume and specific surface area, proper, surface acidity and better peptization.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for heavy oil hydrogenation catalyst carrier

ActiveCN104549537AEfficient use ofKong RonggaoCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsSalt solutionAluminium oxide

The invention discloses a preparation method for a heavy oil hydrogenation catalyst carrier. The preparation method comprises the following steps: (1) preparing an acidic aluminum salt solution and an alkaline aluminum salt solution; (2) performing pulverizing grinding on production wastes of a hydrogenation catalyst taking aluminum oxide as a carrier to form a powder body, and adding the powder body into the acidic aluminum salt solution in the step (1) for uniform stirring; (3) performing parallel flow co-sol reaction on the alkaline aluminum salt solution prepared in the step (1) and the acidic aluminum salt solution added with the powder body in the step (2), and then performing aging, filtering, washing, drying and molding to obtain the final hydrogenation catalyst carrier. The heavy oil hydrogenation catalyst carrier prepared by the method has the advantages of larger pore volume, larger aperture and higher mechanical strength.

Owner:CHINA PETROLEUM & CHEM CORP +1

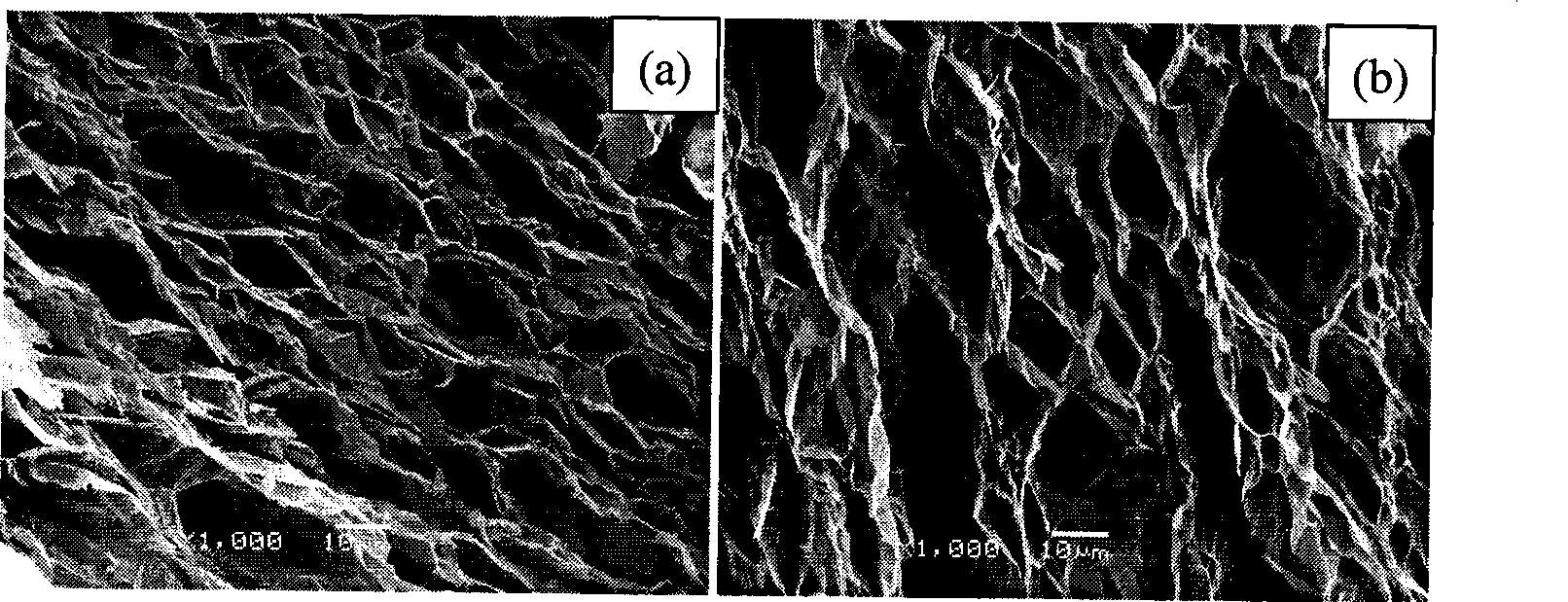

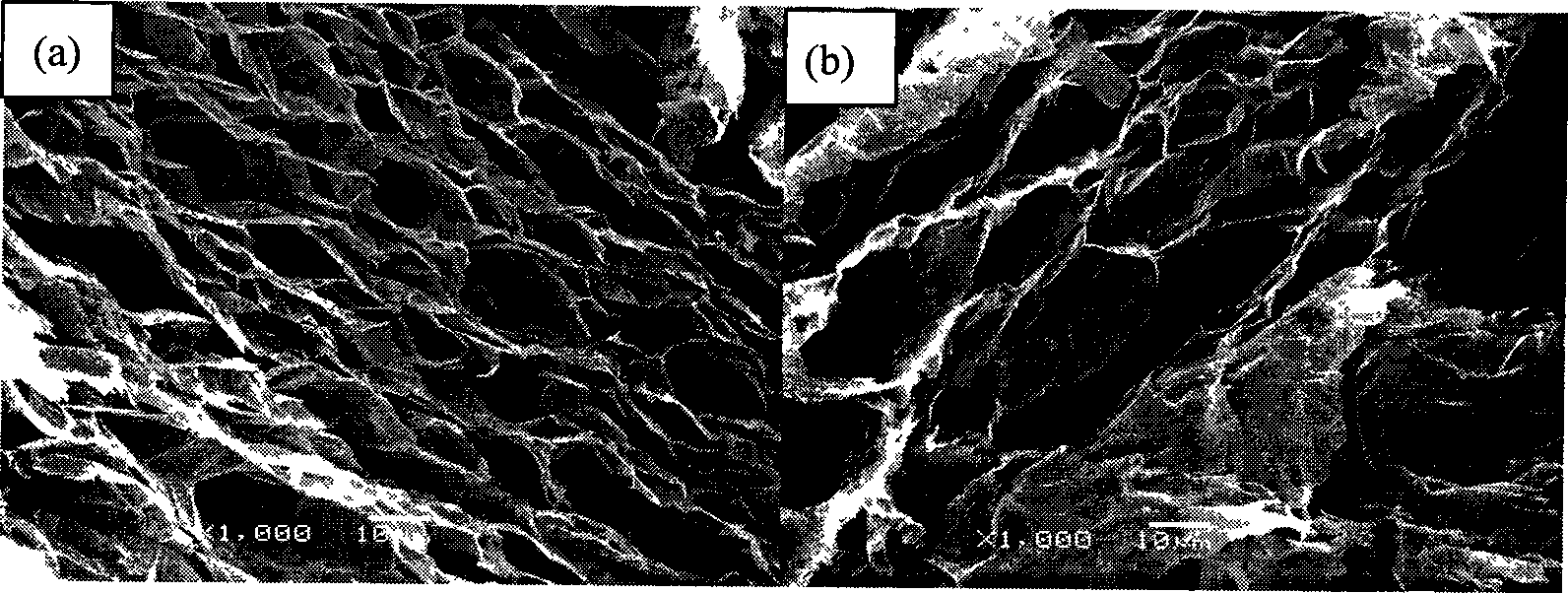

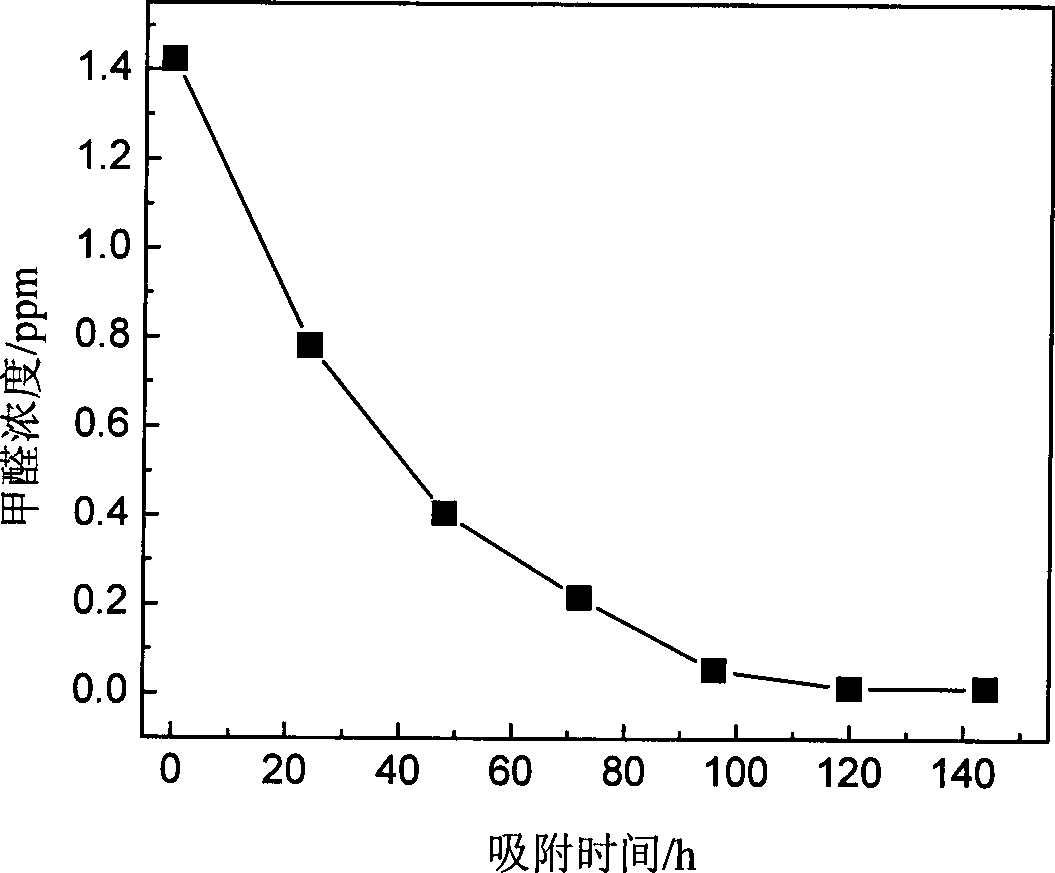

Method for preparing aminoglutaric acid modified expanded graphite and use in methyl aldehyde gas adsorption

InactiveCN101439281AHigh pore volumeImprove surface activityOther chemical processesDispersed particle separationAbsorption capacityFlake graphite

The invention relates to the fields of preparing modified expansion graphite and applications thereof, in particular to a preparation method for glutamic acid modified expansion graphite. The invention is characterized in that: a fixed amount of expandable graphite prepared by taking natural crystalline flake graphite as a material is dipped into glutamic acid solution with a certain concentration, the expandable graphite is bathed, dried and puffed to prepare the modified expansion graphite; wherein, the weight ratio of the expandable graphite to the glutamic acid is 1: 0.1 to 1 : 0.4; the dipping temperature is 40 DEG C and the dipping time is 1.5h; the modified expansion graphite is applied to absorb indoor formaldehyde gas. After the expandable graphite is modified by the glutamic acid, the surface active site of the expandable graphite is increased; abundant functional groups are loaded; meanwhile the millipore wall of the expansion expandable graphite is eroded and collapsed; the increase of the large and middle holes of a submicron structure and the etching effect of modifier solution to the surface of the millipore enhance the absorption capacity of the expandable graphite to formaldehyde; the expandable graphite can be used for purifying indoor air.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

Refining process of biodiesel product crude glycerol

InactiveCN106831345AImprove adsorption capacityEfficient removalOther chemical processesHydroxy compound separation/purificationHydrogenBiodiesel

The invention discloses a refining process of a biodiesel by-product, namely crude glycerol. The refining process comprises the following steps: adding an acid solution into the crude glycerol and acidifying until the pH (Potential of Hydrogen) is 3 to 4; after heating to 30 DEG C to 50 DEG C, stirring for 10min to 30min; after standing and layering, removing upper-layer fatty acid; adding water and diluting until the water content is 25 weight percent to 35 weight percent; adding an efficient alkalization adsorbent and stirring for 30min to 60min; then standing and filtering; pre-heating to 60 DEG C to 80 DEG C; adding an alkaline solution and alkalifying until the pH is 6.5 to 7.5 and filtering; finally, conveying the solution into a distillation kettle and decompressing and distilling, wherein the vacuum degree is 0.075MPa to 0.095MPa; after collecting a fraction at 160 DEG C to 180 DEG C, cooling and condensing to obtain a refined glycerol finished by-product. The refining process of the biodiesel by-product, namely the crude glycerol, provided by the invention, can be used for efficiently preparing the glycerol finished by-product with the purity which is 99.5 percent or more; the production cost can be effectively reduced, and energy sources and resources are saved.

Owner:天长市康宁甘油科技有限公司

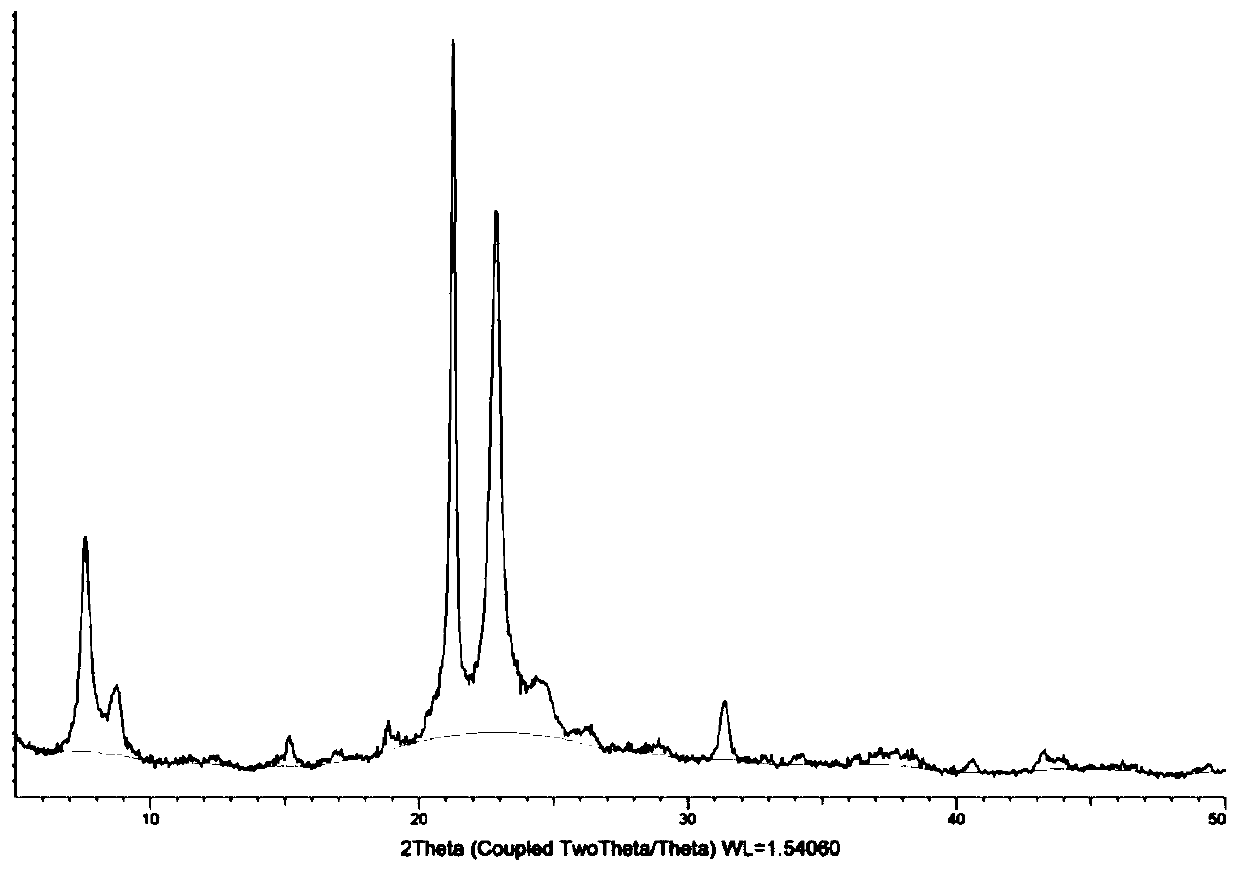

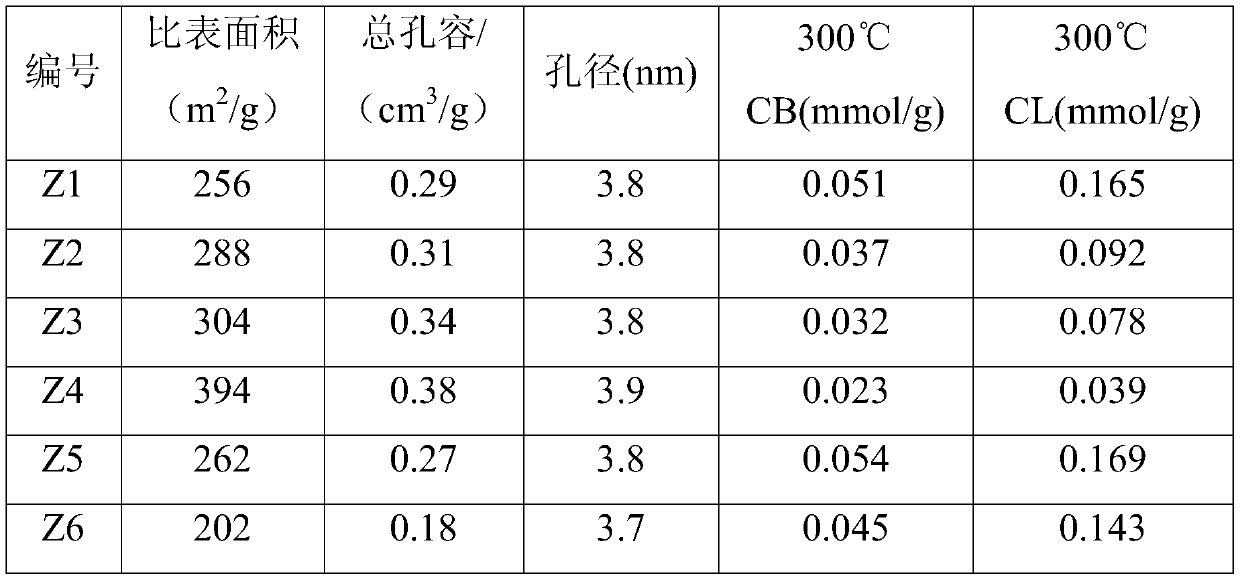

Hydrogen pillared saponite and preparation method and application thereof

The invention provides hydrogen pillared saponite. Total specific surface area of the hydrogen pillared saponite is above 390 m<2> / g, and total pore volume is above 0.4 cm<3> / g. The invention provides a method for preparing the hydrogen pillared saponite. The method comprises the following steps: in the presence of an aqueous solvent, a sodium saponite raw material is contacted with a cation surfactant to carry out first exchange; after the first exchange, the reaction product is contacted with a pillaring agent to carry out second exchange; after the second exchange, drying and roasting are carried out. The invention provides an application of the hydrogen pillared saponite in the field of acid catalysis. The hydrogen pillared saponite has large total specific surface area and large total pore volume. According to the preparation method, the hydrogen pillared saponite can be directly prepared without ammonia exchange. The prepared hydrogen pillared saponite can be directly used as a catalyst or a catalyst acid component.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Closestool cover coating capable of purifying air

The invention discloses a closestool cover coating capable of purifying the air. The closestool cover coating comprises raw materials in parts by weight: 35-45 parts of aqueous acrylic resin, 20-30 parts of aqueous polyurethane resin, 20-30 parts of aqueous alkyd resin, 10-15 parts of modified medical stone powder, 5-9 parts of diatomite, 6-9 parts of calcinated kaolin, 2-4 parts of tourmaline powder, 1-3 parts of hexacyclic stone powder, 3-4 parts of gas-phase silicon oxide, 1-2 parts of tween-60, 2-3 parts of zinc stearate, 2-4 parts of polyethyleneglycol , 1-3 parts of methyl hydroxypropyl cellulose, 1-3 parts of a leveling agent, 0.5-2 parts of a de-foaming agent, 2-4 parts of a preservative and 2-4 parts of a drier. The closestool cover coating capable of purifying the air, disclosed by the invention, has excellent ability to absorb stink substances in a washing room, can release negative ions to realize the effect of air purification, and has excellent weather resistance stability and flexibility.

Owner:阳信华胜清真肉类有限公司

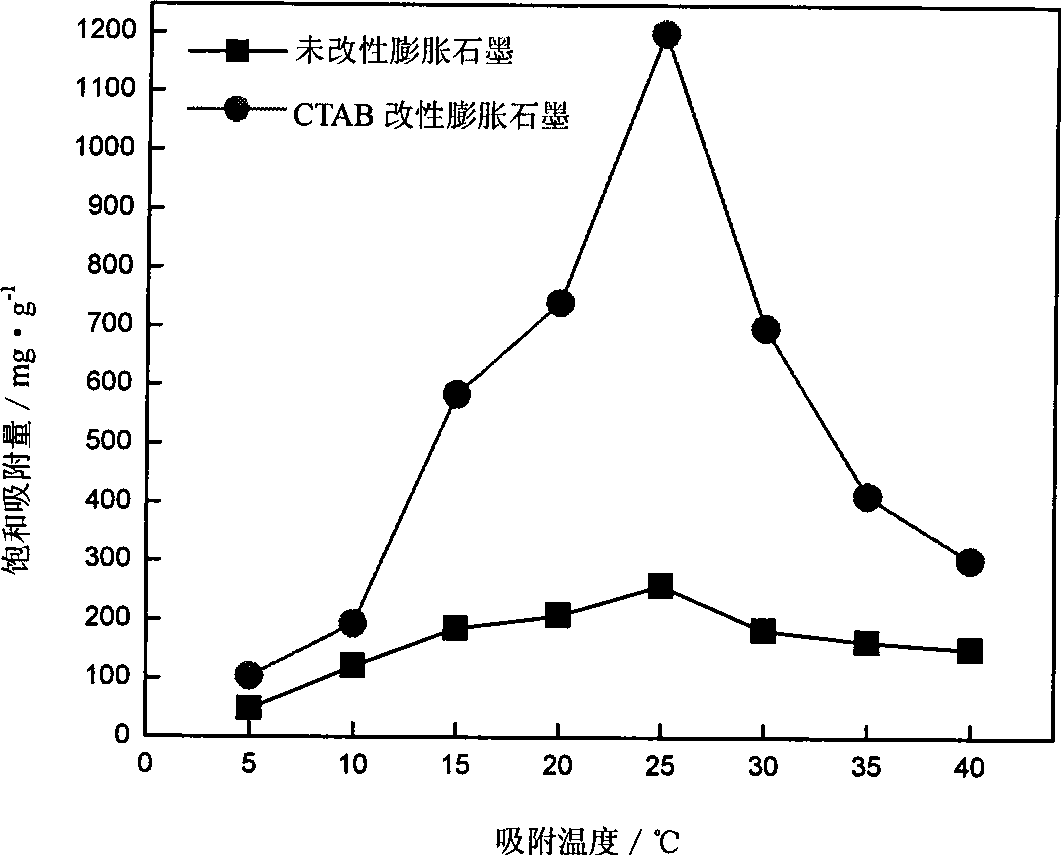

Method for preparing CTAB modified expanded graphite and use in absorbing formaldehyde gas

InactiveCN101433823ALarge specific surface areaHigh activityOther chemical processesActive siteApplication areas

The invention relates to preparation of modified expansion graphite and application field thereof, in particular to a method for preparing CTAB modified expansion graphite. The method is characterized in that certain amount of expandable graphite prepared by taking natural flake graphite as a raw material is soaked in a CTAB solution with a concentration of between 0.01 and 0.5mol / L at certain temperature, and the modified expansion graphite is obtained through washing, drying and swelling, wherein the proportion of the expandable graphite to CTAB is 1: 0.1-1: 1, the soaking temperature is between 40 and 100 DEG C, the soaking time is 1 to 8 hours, and the CTAB modified expansion graphite is applied to the absorption to formaldehyde gas indoors. The expansion graphite modified by the CTAB increases surface active sites, and the surface is loaded with rich functional groups, so the modified expansion graphite can perform static and dynamic absorption on formaldehyde to purify the indoor air when the modified expansion graphite is used for the treatment of the formaldehyde gas.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

Adsorption purification process of crude glycerol

InactiveCN106831344AIncrease the areaIncrease volumeOther chemical processesHydroxy compound separation/purificationSorbentGlycerol

The invention discloses an adsorption purification process of crude glycerol. The adsorption purification process comprises the following steps: adding water into the crude glycerol for diluting; adding an efficient adsorbent for carrying out adsorption treatment; after filtering, carrying out ion exchange treatment through an alkaline ion exchange resin column and an acidic ion exchange resin column in sequence; decompressing, distilling and dehydrating; de-coloring with active carbon to obtain a purified glycerol finished product. A method for preparing the purified glycerol finished product comprises the following steps: after roasting bentonite and medical stones; adding water for uniformly dispersing; adding silica sol, organic amine and sodium metaaluminate, and uniformly dispersing with ultrasounds; putting a mixture into a closed container and raising the temperature to 160 DEG C to 190 DEG C to carry out hydrothermal reaction; after cooling, filtering to remove a mother solution; adding a sodium tartrate solution and uniformly mixing to obtain a product. The adsorption purification process of the crude glycerol, provided by the invention, can be used for effectively removing salt in the crude glycerol and impurities of oligomers; a glycerol finished product with the purity of 99.5 percent or more is obtained; the production cost can be reduced and energy sources and resources are saved.

Owner:天长市康宁甘油科技有限公司

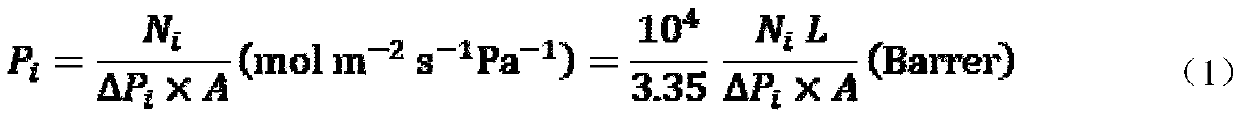

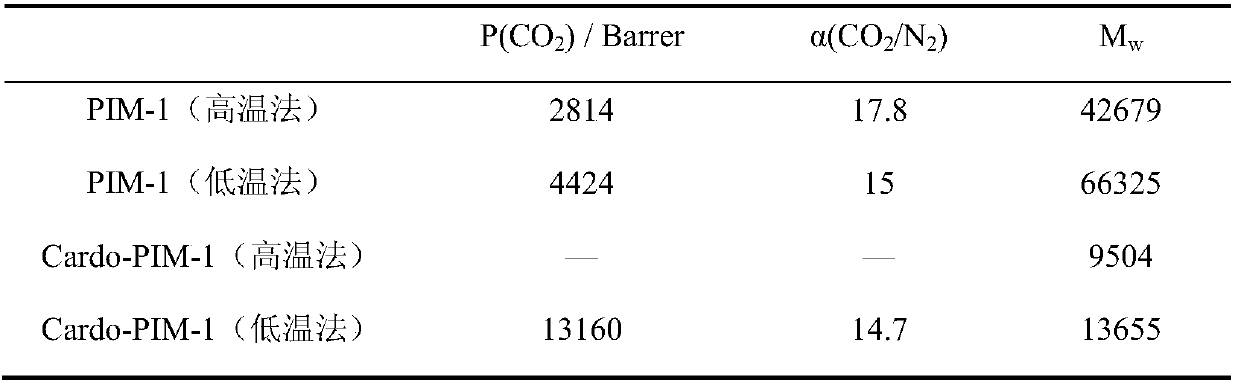

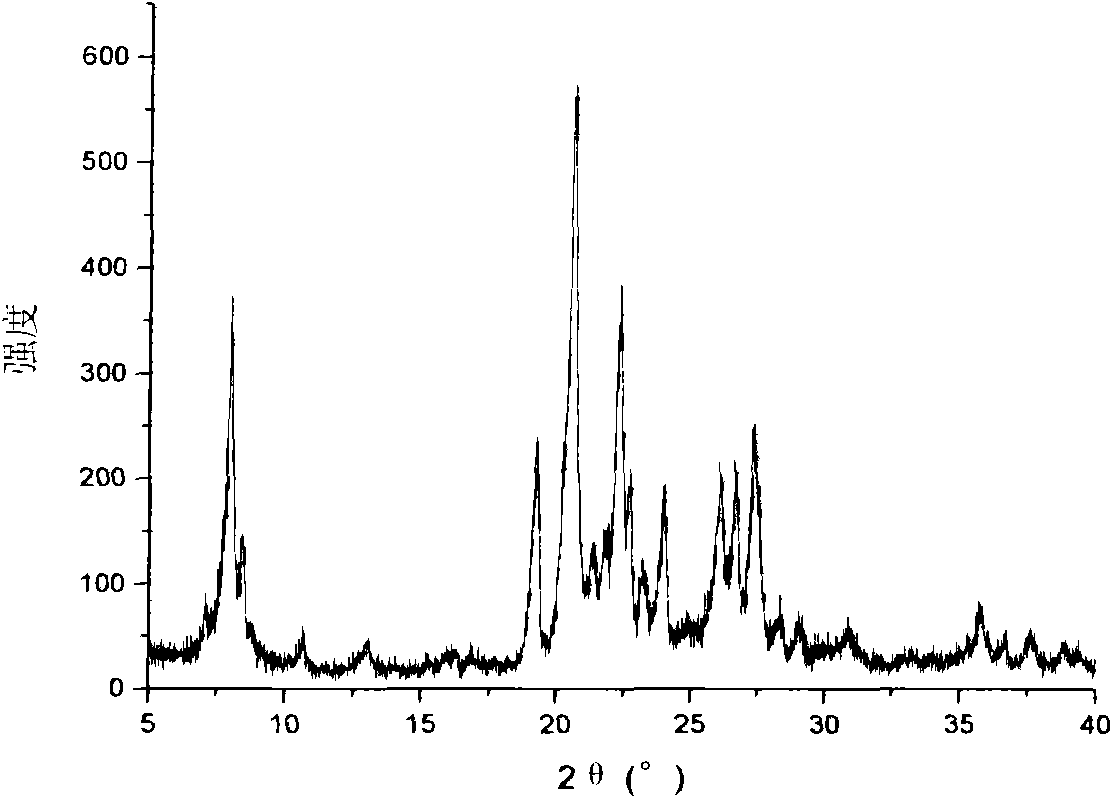

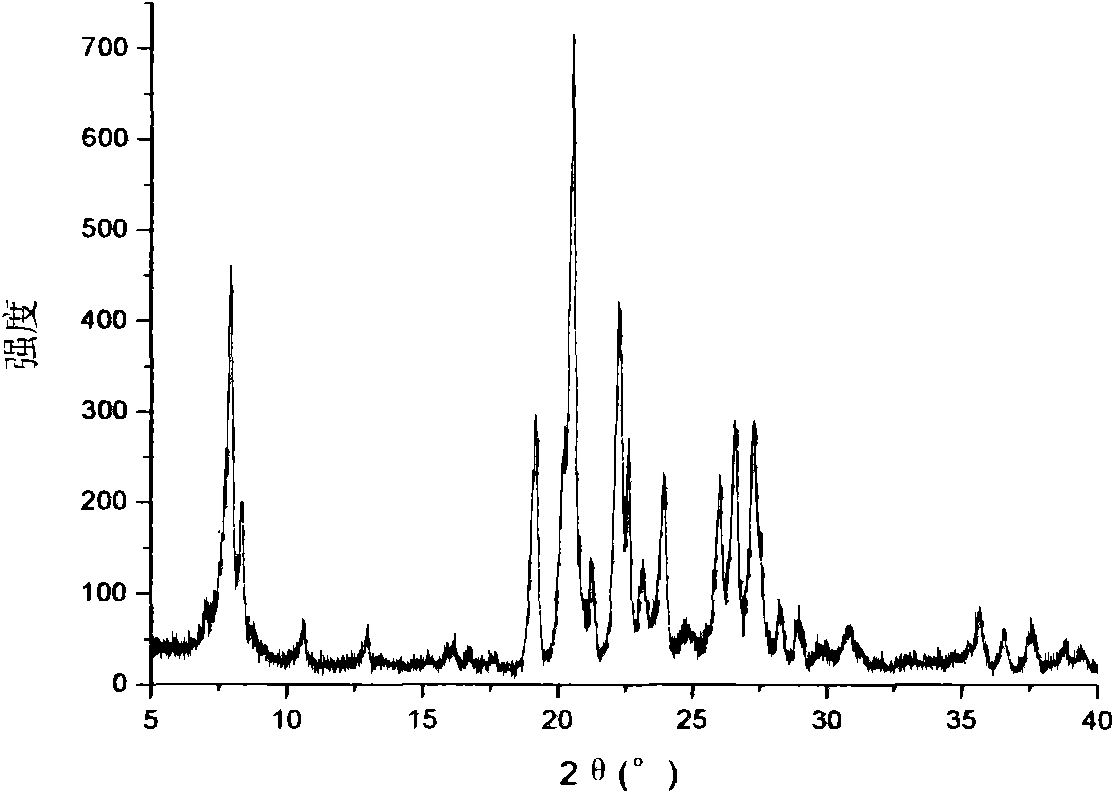

Preparation of PIMs film having a cardo structure and applications of the film in the field of gas separation

ActiveCN107774140AKong RonggaoIncrease the apertureMembranesSemi-permeable membranesFilm materialFluorene

A PIMs (polymers of intrinsic microporosity) polymer which is Cardo-PIM-1 and which has a novel cardo structure is prepared by utilizing a bimolecular nucleophilic reaction among tetrafluoroterephthalonitrile (TFTPN), 5,5',6,6'-tetrahydroxy-3,3',3,3'-tetramethyl-1,1'-spirobisindane (TTSBI) and 9,9-bis(3,4-hydroxyphenyl)fluorene (BDPF) in the invention, and the polymer is prepared into a gas separation film used for CO2 / N2 separation. Compared with traditional PIM-1 gas separation films, gas permeability of the film material is greatly improved by introduction of the cardo structure, thus developing a novel thought and a novel method for researching gas separation films.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Special environment-friendly electrostatic spraying primer for bathrooms and construction method thereof

InactiveCN106634483AImprove adhesionStrong adhesionAnti-corrosive paintsBuilding material handlingAcrylic resinPolyamide

The invention relates to a special environment-friendly electrostatic spraying primer for bathrooms and a construction method thereof. The primer comprises the following raw materials in parts by weight: 60-90 parts of unsaturated polyester resin, 15-35 parts of organic-silicon-modified acrylic resin, 5-15 parts of environment-friendly adsorbent, 2-6 parts of nano silicon dioxide, 1-5 parts of nano titanium dioxide, 1-5 parts of nano calcium carbonate, 5-15 parts of diatomite, 2-8 parts of talcum powder, 10-20 parts of titanium white, 2-10 parts of antirust pigment, 2-5 parts of zinc stearate, 2-6 parts of hydroxyethyl methyl cellulose, 1-2 parts of fumed silica, 0.1-0.5 part of polyamide wax, 0.2-0.8 part of defoaming agent, 0.5-2 parts of leveling agent and 2-10 parts of styrene. The special environment-friendly electrostatic spraying primer for bathrooms can satisfy the construction requirements of electrostatic spraying, has the capacity of adsorbing stinky matters in the bathroom, and has the advantages of excellent moisture resistance, excellent weather resistance and excellent stability.

Owner:TIANCHANG JINLING ELECTRONICS

Deodorization closestool cover coating with high adhesive force

The invention discloses a deodorization closestool cover coating with high adhesive force, which comprises the following raw materials in parts by weight: 25-30 parts of aqueous epoxy resin, 40-50 parts of aqueous acrylic acid resin, 15-20 parts of aqueous amino resin, 10-15 parts of modified medical stone powder, 8-12 parts of nano zeolite powder, 15-20 parts of nano talcum powder, 8-12 parts of heavy calcium carbonate,1-2 parts of organic bentonite, 0.5-1.5 parts of polyether-polyester modified organic siloxane, 0.2-0.8 part of a fluorine-modified acrylic leveling agent, 0.2-0.5 part of stearin, 2-4 parts of polyethyleneglycol, 1-3 parts of hydroxymethyl cellulose, 0.5-2 parts of a de-foaming agent, 2-4 parts of a preservative, 1-1.5 parts of rosin zirconium salt and 0.5-1.2 parts of linoleic acid zirconium salt. The deodorization closestool cover coating with high adhesive force has the excellent ability to absorb stink substances, avoids secondary pollution to the air, lowers the spread probability of disease, and is good in the adhesive force.

Owner:YANGXIN XINRUI DYEING & WEAVING

NU-87 molecular sieve and preparation method thereof

ActiveCN102211780AImprove catalytic performanceAdjust the ratioCrystalline aluminosilicate zeolitesInorganic saltsMolecular sieve

The invention discloses an NU-87 molecular sieve and a preparation method thereof. The method comprises a preparation process of a crystallization material, a crystallization process and a recovery and treatment process of a crystallization product, wherein in the preparation process of the crystallization material, an aluminum source, a silicon source, alkali, a template agent, inorganic salt, an EU-1 molecular sieve and water are mixed; and the mass ratio of the EU-1 molecular sieve fed into the crystallization material to SiO2 contained in other components is 0.1-0.4. The NU-87 molecular sieve prepared by the method has the advantages of low silicon-aluminum ratio, high pore volume, low cost, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com