Aluminum oxide specially used for hydrogen peroxide fluidized bed and production technology for aluminum oxide

A water-fluidized bed, production process technology, applied in physical/chemical process catalysts, inorganic chemistry, aluminum compounds, etc., to achieve the effects of increasing pore volume, increasing specific surface area, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

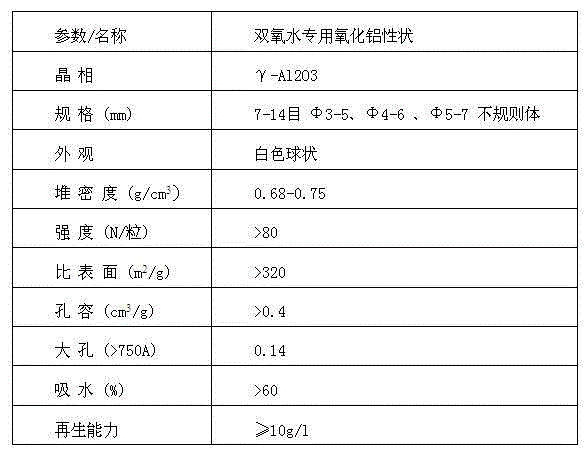

Image

Examples

Embodiment 1

[0043] The production process of activated alumina by rapid dehydration method is as follows: the raw material aluminum hydroxide containing 6-14% free water is dried at 120°C by airflow dryer, and then crushed into α-gibbsite with a fineness of 325 mesh in the crushing process. Contact with hot gas at 600-900 ℃ in the high-temperature rapid dehydration device, stay in the highly turbulent hot air for 0.1-1s, a set of systems forms χ-Al 2 o 3 , ρ-Al 2 o 3 The transitional alumina mainly enters the cyclone separator for solid-gas separation, and the hot gas is further captured by a cloth bag and then emptied; a system forms a transitional state alumina mainly composed of pseudo-boehmite, which is also separated by a first-stage cyclone and utilized The waste heat gas preheats the pulverized material, collects the material through the secondary cyclone separator and cloth bag, and enters (returns) the rapid dehydration system. While creating an atmosphere that meets the requir...

Embodiment 2

[0057] The production process of special alumina for hydrogen peroxide fluidized bed, the process comprises the following steps:

[0058] (1) Drying: The raw material aluminum hydroxide containing 10% free water is dried at 120°C by an airflow dryer, and 25% boehmite is added in this step;

[0059] (2) Pulverization: pulverize the dried material in step (1) to 325 mesh;

[0060] (3) Quick dehydration: In the high-temperature rapid dehydration device, the pulverized material in step (2) is contacted with 800 ℃ hot gas;

[0061] Stay in the highly turbulent hot gas flow for 0.5s to form χ-Al 2 o 3 , ρ-Al 2 o 3 The main transitional alumina enters the cyclone separator for solid-gas separation. After the separation, it will be de-powdered quickly, and the fast-powdered powder will be reduced to 8.3%. The hot gas will be further captured by the cloth bag and then emptied;

[0062] (4) Balling: add deionized water to the separated fine powder and make balls of required size in...

Embodiment 3

[0068] The production process of special alumina for hydrogen peroxide fluidized bed, the process comprises the following steps:

[0069] (1) Drying: The raw material aluminum hydroxide containing 6% free water is dried at 120°C by an airflow dryer, and 20% boehmite is added in this step;

[0070] (2) Pulverization: pulverize the dried material in step (1) to 325 mesh;

[0071] (3) Quick dehydration: In the high-temperature rapid dehydration device, the crushed material in step (2) is contacted with hot gas at 600-900 °C;

[0072] Stay in the highly turbulent hot air for 0.1~1s to form χ-Al 2 o 3 , ρ-Al 2 o3 The main transitional alumina enters the cyclone separator for solid-gas separation. After the separation, it will be de-powdered quickly, and the fast-powdered powder will be reduced to 8.3%. The hot gas will be further captured by the cloth bag and then emptied;

[0073] (4) Balling: add deionized water to the separated fine powder and make balls of required size in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com