Guided tissue regeneration membrane and its preparation method

A technology for guiding tissue regeneration and guiding regeneration, which is applied in the field of guiding tissue regeneration membrane and its preparation, can solve the problems of low strength, inconvenient operation, and fast degradation speed of guiding tissue regeneration membrane, and achieves low antigenicity, good growth state, Strong effect of guiding tissue regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0052] The specific preparation method of the guide film prepared by the present invention is as follows:

[0053] 1) Use 0.5% acetic acid solution within the range of PH=2-3 to prepare a collagen solution with a concentration of 0.6%;

[0054] 2) After the collagen is dissolved, centrifuge at a speed of 4400rp / min;

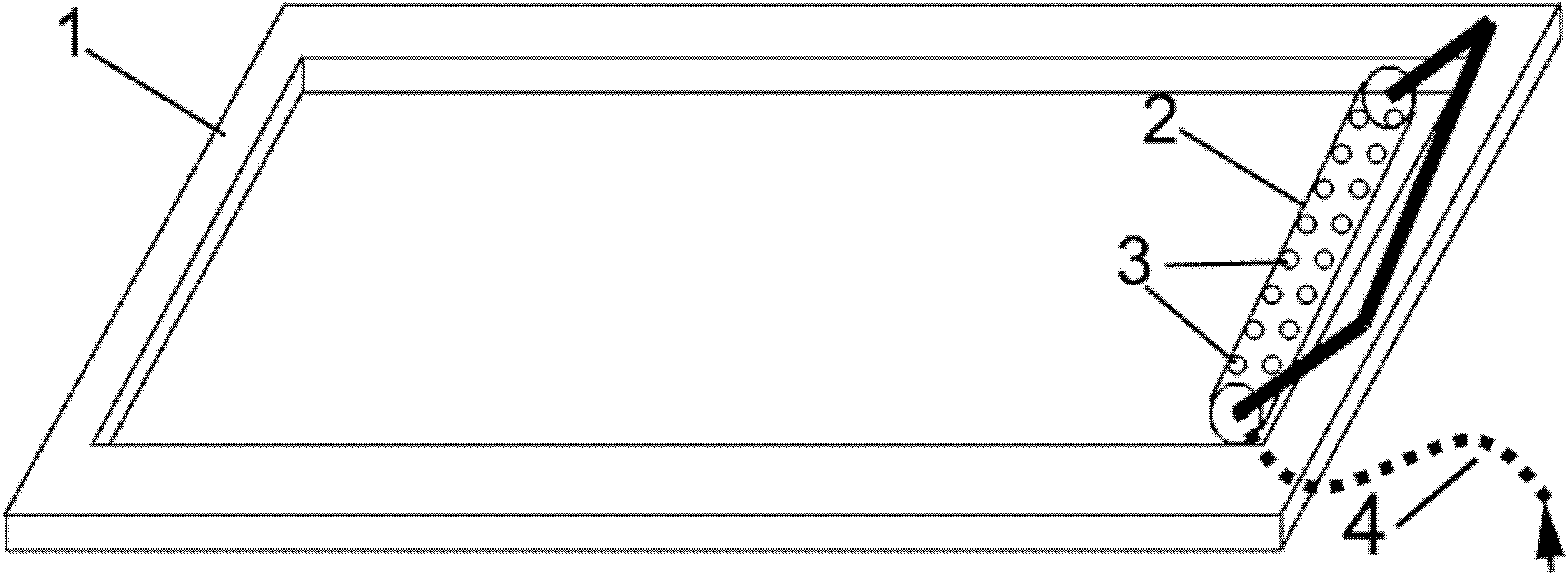

[0055] 3) A certain amount of centrifuged collagen is injected into the mold 1 through the expander 2, the mold is heated to 45°C, and dried in the air for two days to prepare a dense layer;

[0056] 4) After the dense layer is prepared, inject a certain amount of centrifuged collagen solution on it through the spreader 2 and spread it evenly, and place it for 1 hour;

[0057] 5) After placement, put the mold in an ultra-low temperature refrigerator at -86°C for two hours, and then put it in a freeze dryer to dry for 24 hours to prepare a guide film with a double-layer structure;

[0058] 6) Put the prepared guide film into a vacuum dryer, and cross-link at 90°...

example 2

[0064] The specific preparation method of the guide film prepared by the present invention is as follows:

[0065] 1) Use 0.5% acetic acid solution within the pH range of 2-3, and prepare I collagen solution with a concentration of 1%;

[0066] 2) After the collagen is dissolved, centrifuge at 4400rp / min;

[0067] 3) A certain amount of centrifuged collagen is injected into the mold 1 through the expander 2, the mold is heated to 45°C, and dried in the air for two days to prepare a dense layer;

[0068] 4) In the centrifuged collagen solution, add β-tricalcium phosphate and stir evenly, the mass fraction of β-tricalcium phosphate is 0.5%; 0.5% β-tricalcium phosphate collagen solution, spread evenly, and place for 1 hour;

[0069] 5) After placement, put the mold in an ultra-low temperature refrigerator at -86°C for two hours, and then put it in a freeze dryer to dry for 24 hours to prepare a guide film with a double-layer structure;

[0070] 6) Put the prepared guide film i...

example 3

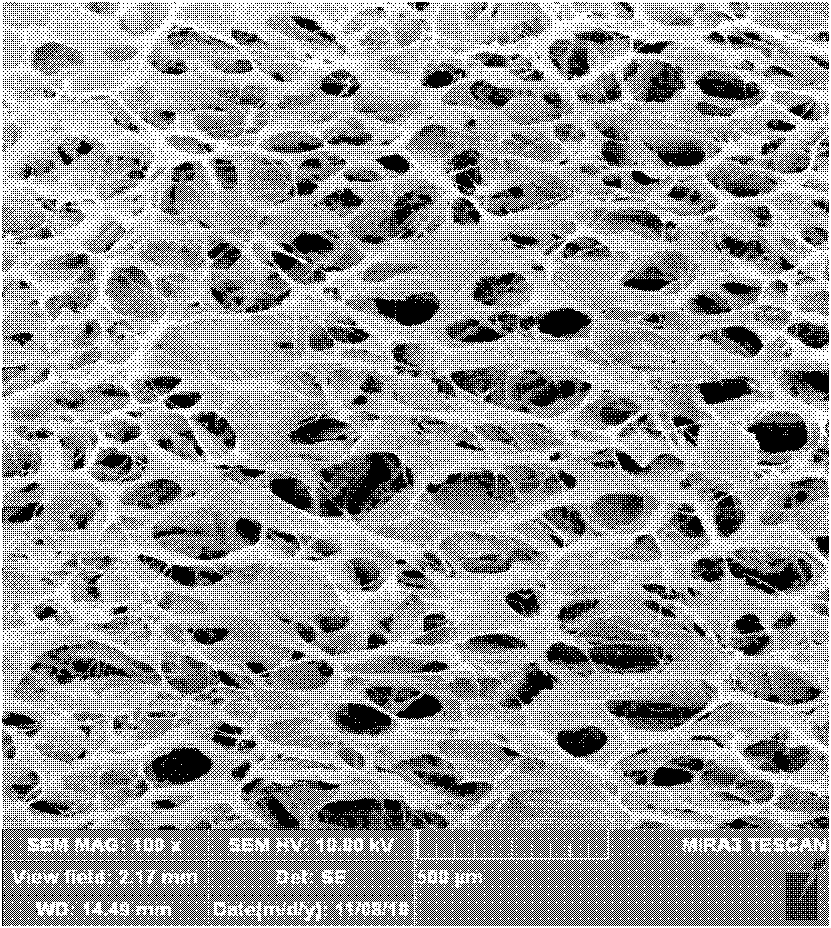

[0076] The guide membrane prepared by Example 1 and Example 2 of the present invention was carried out in animal experiments, and used for the repair of the bone defect model around the dog's dental implant. Soft tissue contact, to prevent soft tissue from growing into the bone defect site; guide the loose layer of the membrane downward, in contact with the tissue surface of the bone defect, guide the bone-forming cells from the periosteum and bone marrow to attach to the surface, and then proliferate and differentiate into osteoblasts cells to promote the repair of bone defects. In this application example, the period of degradation of the guide membrane in vivo is 6 months.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com