Kitchen ware dedicated electrostatic spraying powder coating and preparation method thereof

An electrostatic spraying, powder coating technology, applied in powder coatings, conductive coatings, anti-corrosion coatings, etc., can solve problems such as affecting health, yellowing, and hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

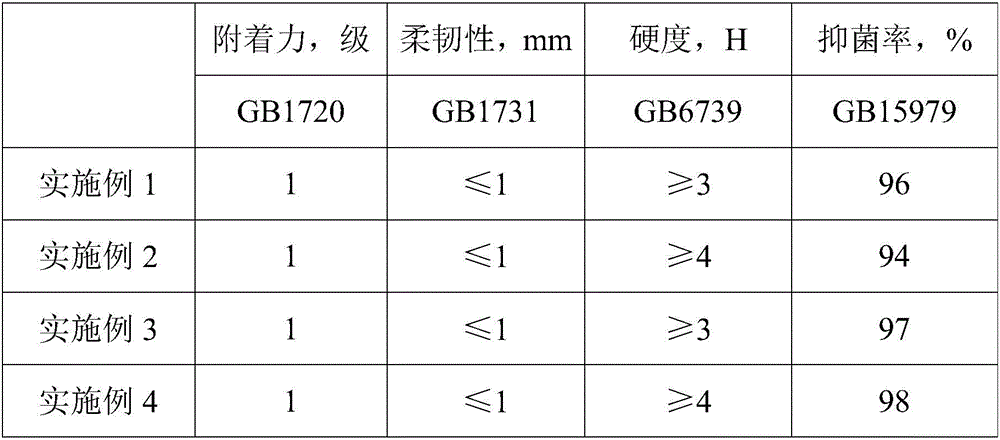

Examples

Embodiment 1

[0019] A special electrostatic spraying powder coating for kitchen utensils, comprising the following raw materials in parts by weight: 60 parts of bisphenol A solid epoxy resin E-12, 35 parts of fluororesin, 3 parts of phenolic hydroxyl resin, 25 parts of antibacterial adsorbent, nanometer dioxide 2 parts of silicon, 5 parts of nano-titanium dioxide, 1 part of nano-calcium carbonate, 15 parts of bauxite, 5 parts of precipitated barium sulfate, 20 parts of titanium dioxide, 2 parts of zinc stearate, 3 parts of benzoin, hydroxyethyl methylcellulose 2 parts, 1 part of polyamide wax, 0.5 parts of fluorocarbon modified polyacrylate leveling agent, 6 parts of polyamine curing agent;

[0020] Wherein, the preparation method of the fluororesin comprises: adding 45 parts of chlorotrifluoroethylene monomer, 35 parts of vinyl acetate, 5 parts of hydroxyethyl vinyl ether, 1 part of acrylic acid and 0.05 parts of initiator into the reaction kettle in parts by weight In the process, water ...

Embodiment 2

[0023] A special electrostatic spraying powder coating for kitchen utensils, comprising the following raw materials in parts by weight: 90 parts of bisphenol A solid epoxy resin E-12, 15 parts of fluororesin, 8 parts of phenolic hydroxyl resin, 5 parts of antibacterial adsorbent, nanometer dioxide 6 parts of silicon, 1 part of nano-titanium dioxide, 5 parts of nano-calcium carbonate, 5 parts of bauxite, 10 parts of precipitated barium sulfate, 10 parts of titanium dioxide, 5 parts of zinc stearate, 1 part of benzoin, hydroxyethyl methylcellulose 6 parts, 0.2 parts of polyamide wax, 2 parts of polyether modified silicone oil leveling agent, 2 parts of modified polyamine curing agent;

[0024] Wherein, the preparation method of the fluororesin comprises: 60 parts by weight of chlorotrifluoroethylene monomer, 15 parts of vinyl butyrate, 10 parts of hydroxybutyl vinyl ether, 0.5 parts of crotonic acid and 0.15 parts of initiator Put it into a reaction kettle, use water and ethanol...

Embodiment 3

[0027] A special electrostatic spraying powder coating for kitchen utensils, comprising the following raw materials in parts by weight: 70 parts of bisphenol A solid epoxy resin E-12, 30 parts of fluororesin, 5 parts of phenolic hydroxyl resin, 20 parts of antibacterial adsorbent, nanometer dioxide 3 parts of silicon, 4 parts of nano titanium dioxide, 2 parts of nano calcium carbonate, 12 parts of bauxite, 7 parts of precipitated barium sulfate, 18 parts of titanium dioxide, 3 parts of zinc stearate, 2 parts of benzoin, hydroxyethyl methylcellulose 3 parts, 0.8 parts of polyamide wax, 1 part of acrylate copolymer leveling agent, 5 parts of dicyandiamide;

[0028] Wherein, the preparation method of the fluororesin comprises: 50 parts by weight of chlorotrifluoroethylene monomer, 25 parts of n-butyl vinyl ether, 7 parts of hydroxyethyl acrylate, 0.8 parts of undecylenic acid and 0.1 parts of initiator Add the mixture into the reactor, use water and ethanol as solvents, and under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com