Super-weather-resistance powder coating for electrostatic spraying and preparation method thereof

A technology of electrostatic spraying and powder coatings, applied in powder coatings, conductive coatings, polyester coatings, etc., can solve the problems of poor substrate bonding, restrictions on the development of powder coatings for electrostatic spraying, complex dispersion processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

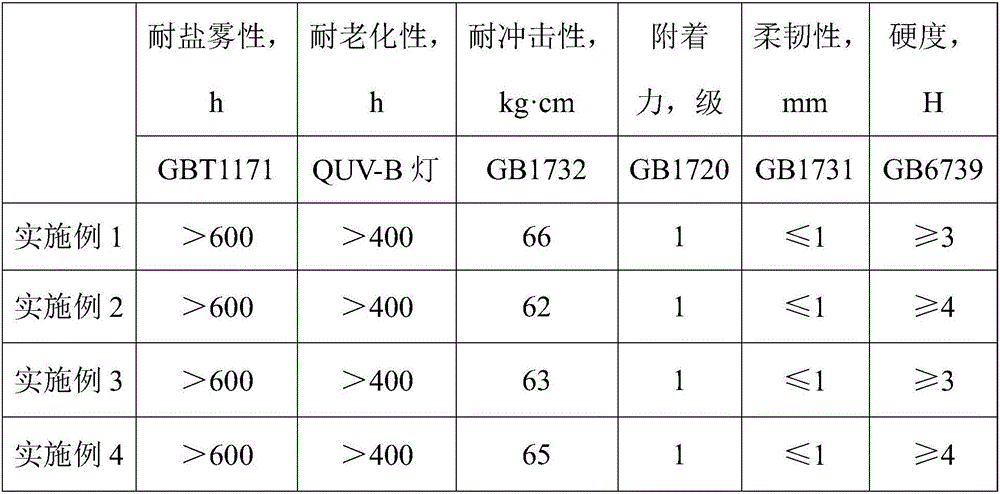

Examples

Embodiment 1

[0020] A powder coating for super weather-resistant electrostatic spraying, comprising the following raw materials in parts by weight: 50 parts of polyester resin, 35 parts of alkyd resin, 3 parts of polyester-coated carbon nanotubes, 6 parts of nano-titanium dioxide, and 1 part of nano-zinc oxide , 3 parts of aluminum nitride, 0.5 parts of phosphotungstic acid, 2 parts of quartz, 5 parts of bauxite, 6 parts of vinyltriethoxysilane, 5 parts of titanium dioxide, 2 parts of benzoin, polyether modified organosiloxane 0.5 parts of solution, 1 part of polyacrylate polymer, 1 part of propylene glycol methyl ether acetate, 10 parts of β-hydroxyalkylamide;

[0021] Wherein, the polyol monomer adopted in the synthetic method of the polyester resin is neopentyl glycol, and the polyacid monomer adopted is terephthalic acid; the vegetable oleic acid monomer adopted in the synthetic method of the alkyd resin It is soybean oil fatty acid, the polyol monomer used is pentaerythritol, and the ...

Embodiment 2

[0024] A powder coating for super weather-resistant electrostatic spraying, comprising the following raw materials in parts by weight: 80 parts of polyester resin, 15 parts of alkyd resin, 15 parts of polyester-coated carbon nanotubes, 2 parts of nano-titanium dioxide, and 5 parts of nano-zinc oxide , 1 part of aluminum nitride, 2 parts of phosphotungstic acid, 0.5 part of quartz, 15 parts of bauxite, 2 parts of vinyltriethoxysilane, 10 parts of titanium dioxide, 1 part of benzoin, alkyl modified organosiloxane 2 parts of solution, 0.1 part of polymer silicone, 5 parts of propylene glycol methyl ether acetate, 4 parts of β-hydroxyalkylamide;

[0025] Wherein, the polyol monomer adopted in the synthetic method of the polyester resin is ethylene glycol and trimethylolpropane, and the polybasic acid monomer adopted is isophthalic acid; The vegetable oleic acid monomer is linolenic acid, the polyol monomers used are pentylene glycol and trimethanol propane, and the polyacid monome...

Embodiment 3

[0028] A powder coating for super weather-resistant electrostatic spraying, comprising the following raw materials in parts by weight: 60 parts of polyester resin, 30 parts of alkyd resin, 5 parts of polyester-coated carbon nanotubes, 5 parts of nano-titanium dioxide, and 3 parts of nano-zinc oxide , 2 parts of aluminum nitride, 0.8 parts of phosphotungstic acid, 1.6 parts of quartz, 8 parts of bauxite, 5 parts of vinyltriethoxysilane, 7 parts of titanium dioxide, 1.8 parts of benzoin, 0.8 parts of acrylate copolymer solution, 0.7 parts of fluorine-modified acrylate polymer, 3 parts of propylene glycol methyl ether acetate, and 8 parts of β-hydroxyalkylamide;

[0029] Wherein, the polyhydric alcohol monomer adopted in the synthetic method of polyester resin is trimethylolethane and glycerin, the polybasic acid monomer adopted is adipic acid; In the synthetic method of described alkyd resin, adopt The vegetable oleic acid monomer is dehydrated ricinoleic acid, the polyol monome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com