Patents

Literature

543results about How to "Improve melting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkali ion conductive glass-ceramics and electric cells and gas sensors using the same

InactiveUS7211532B2Improve performanceImprove conductivityMaterial analysis by electric/magnetic meansSecondary cellsLithiumAlkali ions

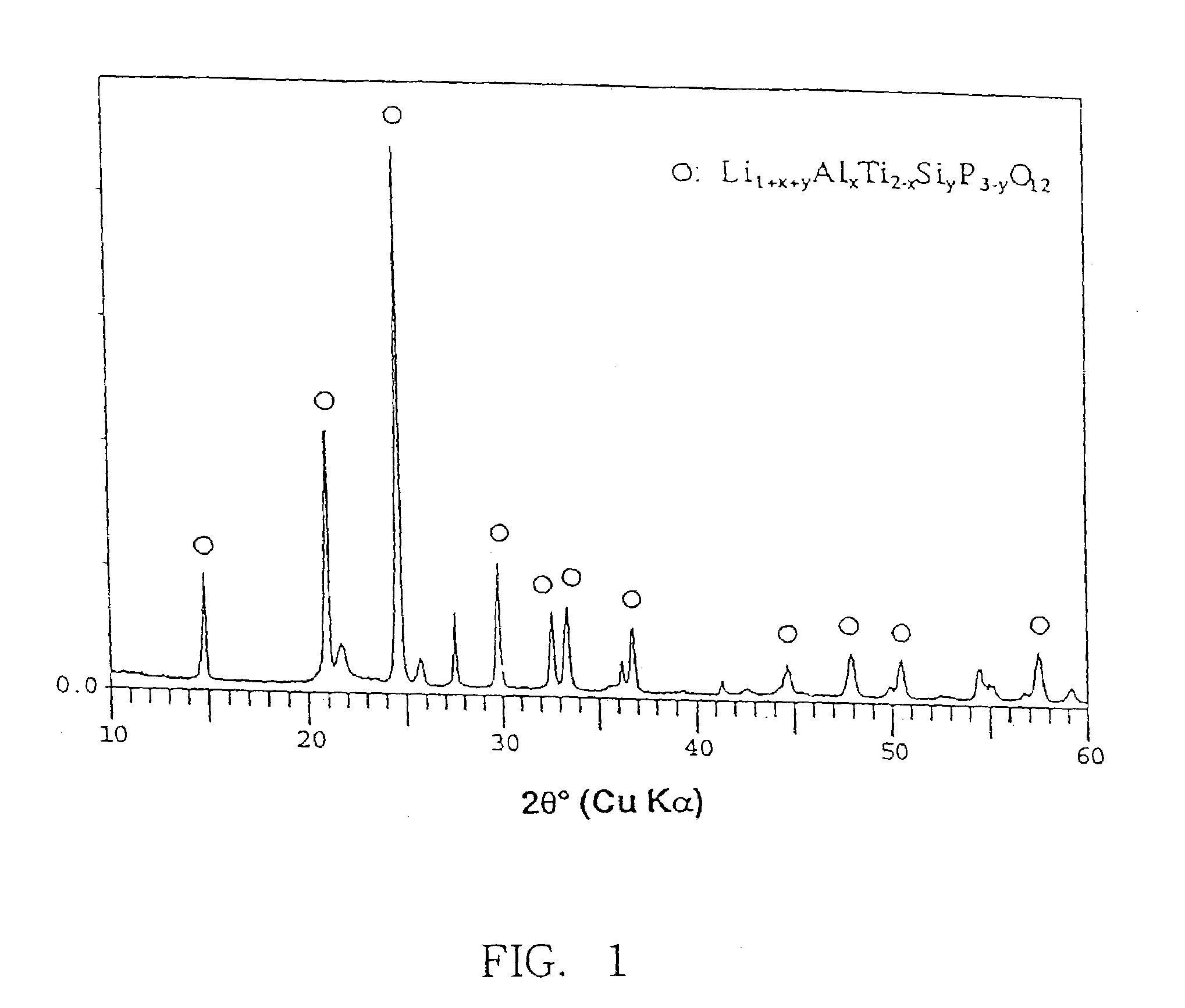

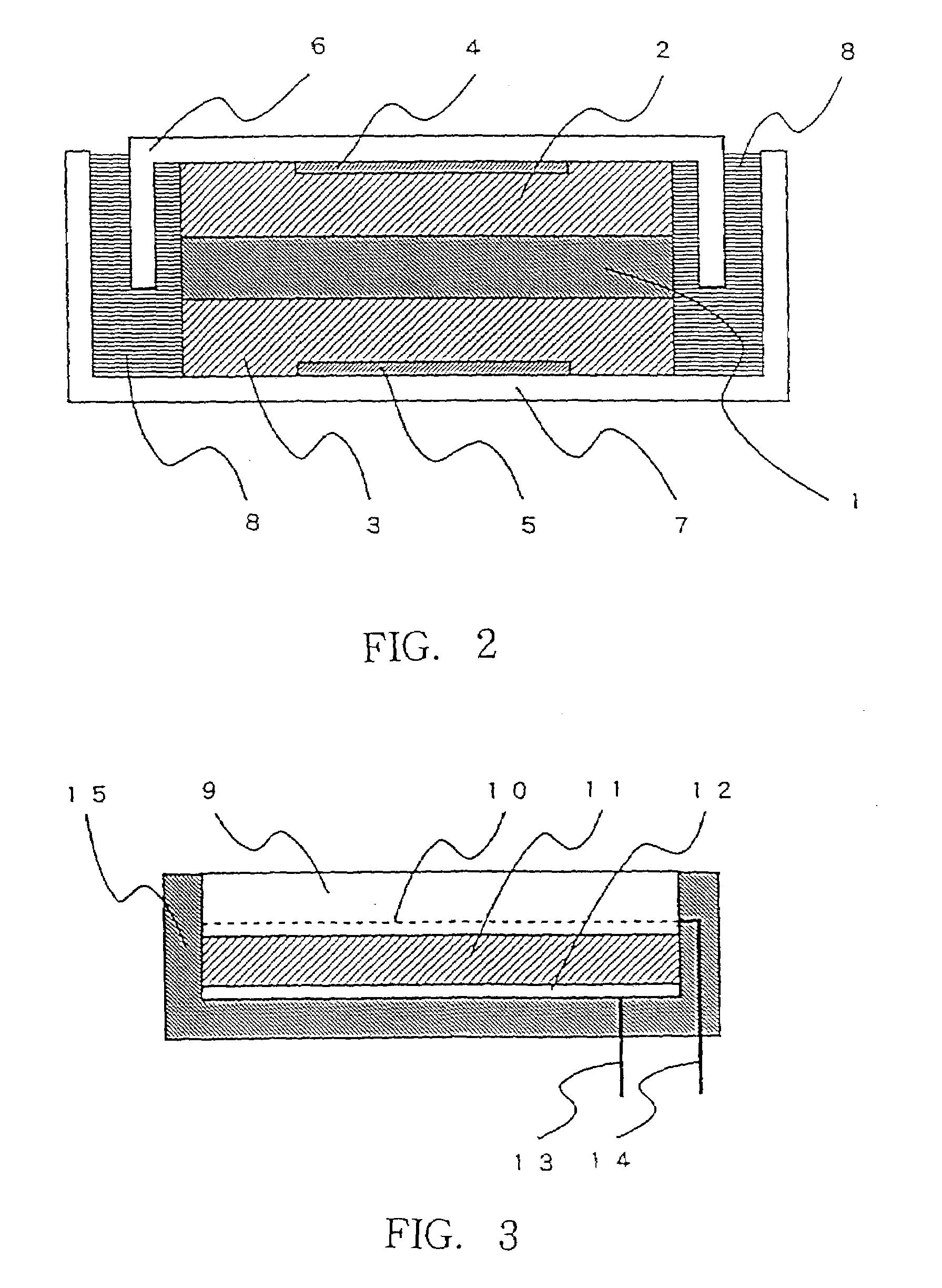

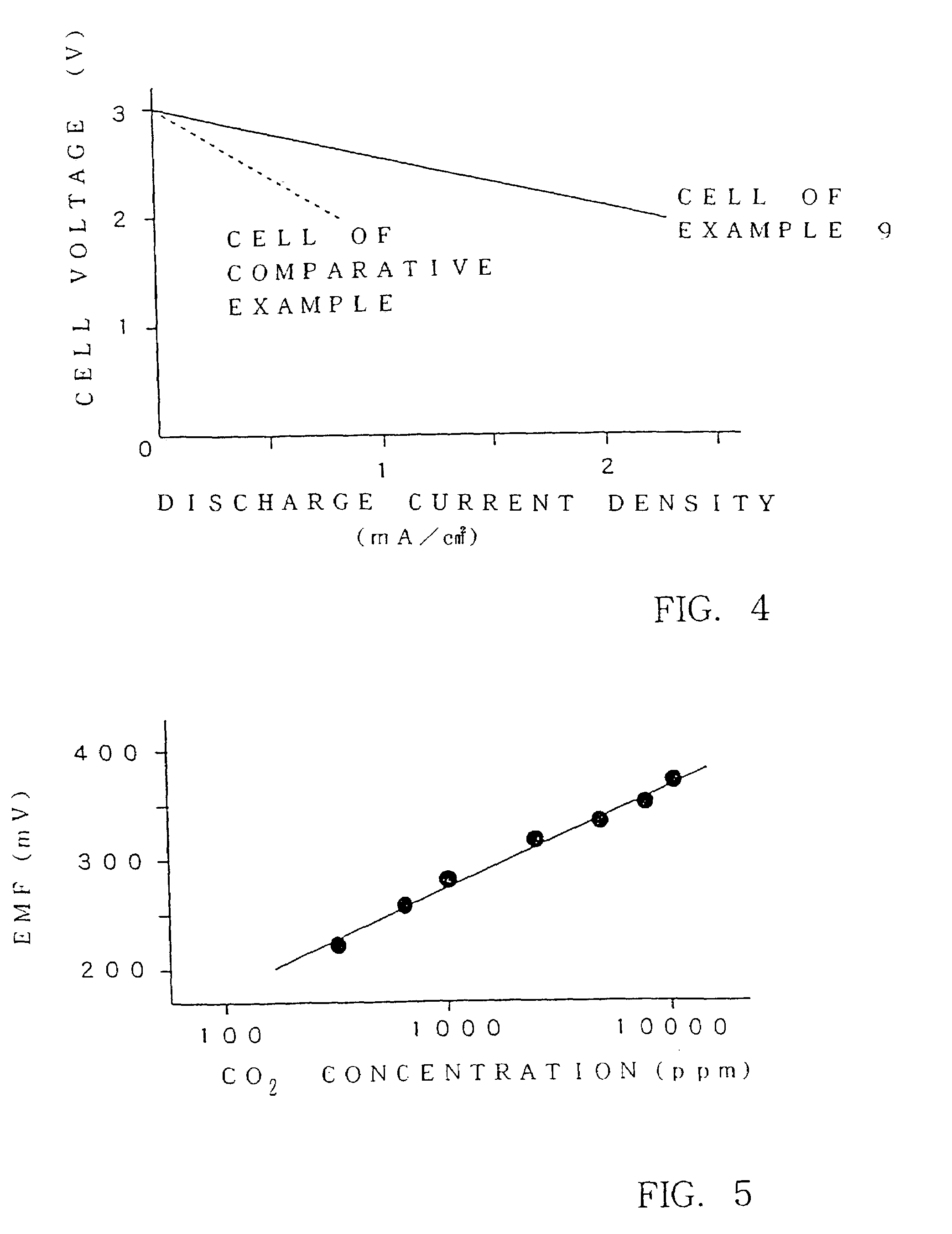

There are provided glass-ceramics having a high lithium ion conductivity which include in mol %:P2O538–40%TiO225–45%M2O3 (where M is Al or Ga) 5–15%Li2O10–20%and contain Li1+X(Al, Ga)XTi2−X(PO4)3 (where 0<X<0.8) as a main crystal phases. There are also provided glass-ceramics having a high lithium ion conductivity which include in mol %:P2O5 26–40%SiO20.5–12%TiO2 30–45%M2O3 (where M is Al or Ga) 5–10%Li2O 10–18%and contain Li1+X+YMXTi2−XSiYP3−YO12 (where 0<X≦0.4 and 0<Y≦0.6) as a main crystal phase. There are also provided solid electrolytes for an electric cell and a gas sensor using alkali ion conductive glass-ceramics, and a solid electric cell and a gas sensor using alkali ion conductive glass-ceramics as a solid electrolyte.

Owner:OHARA

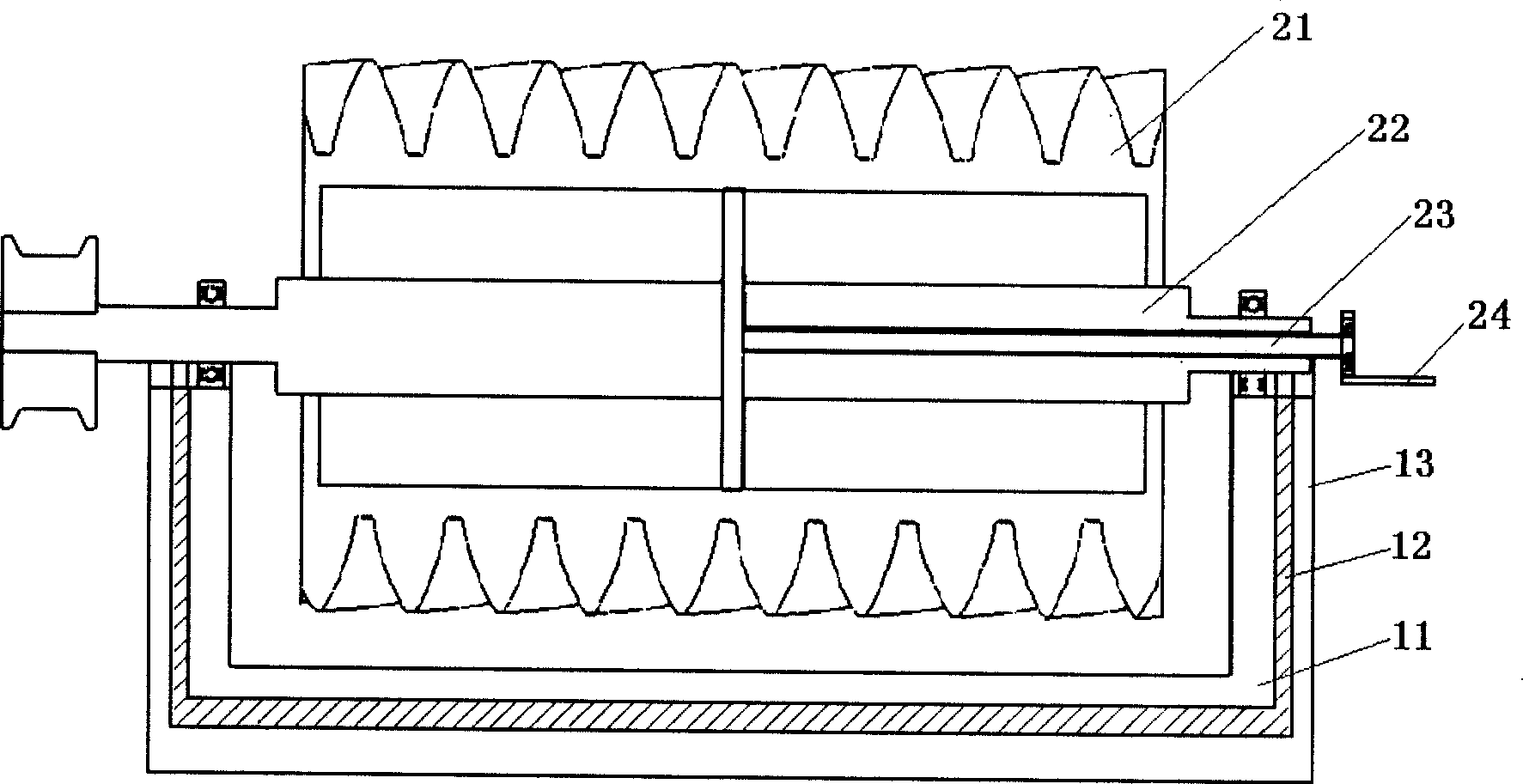

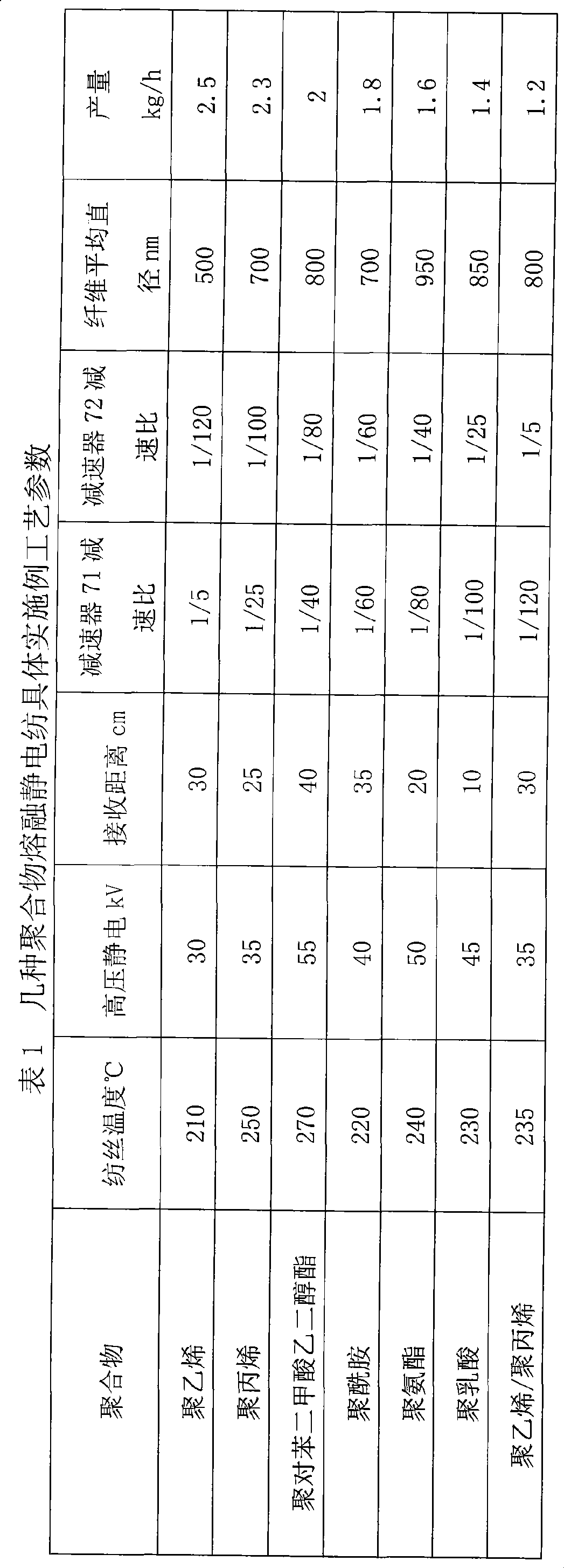

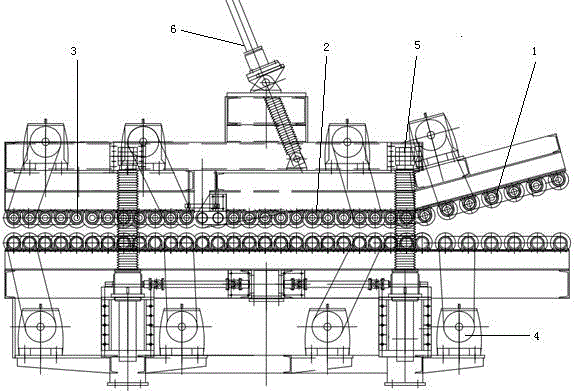

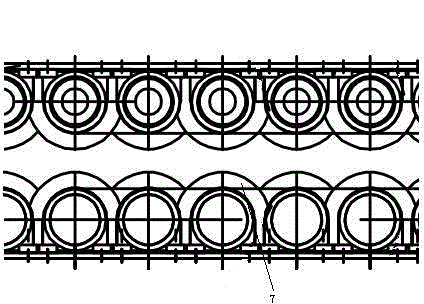

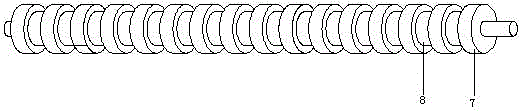

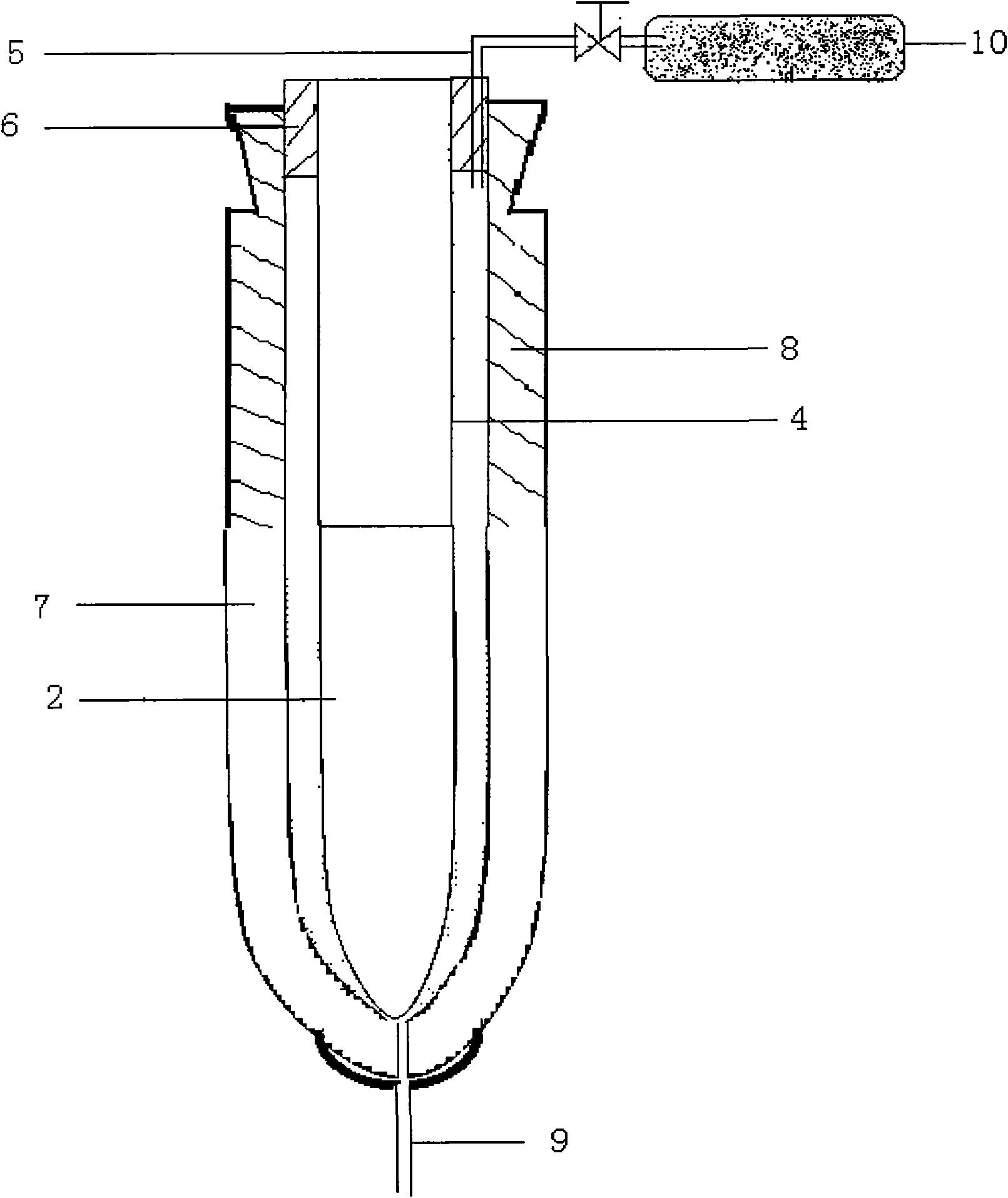

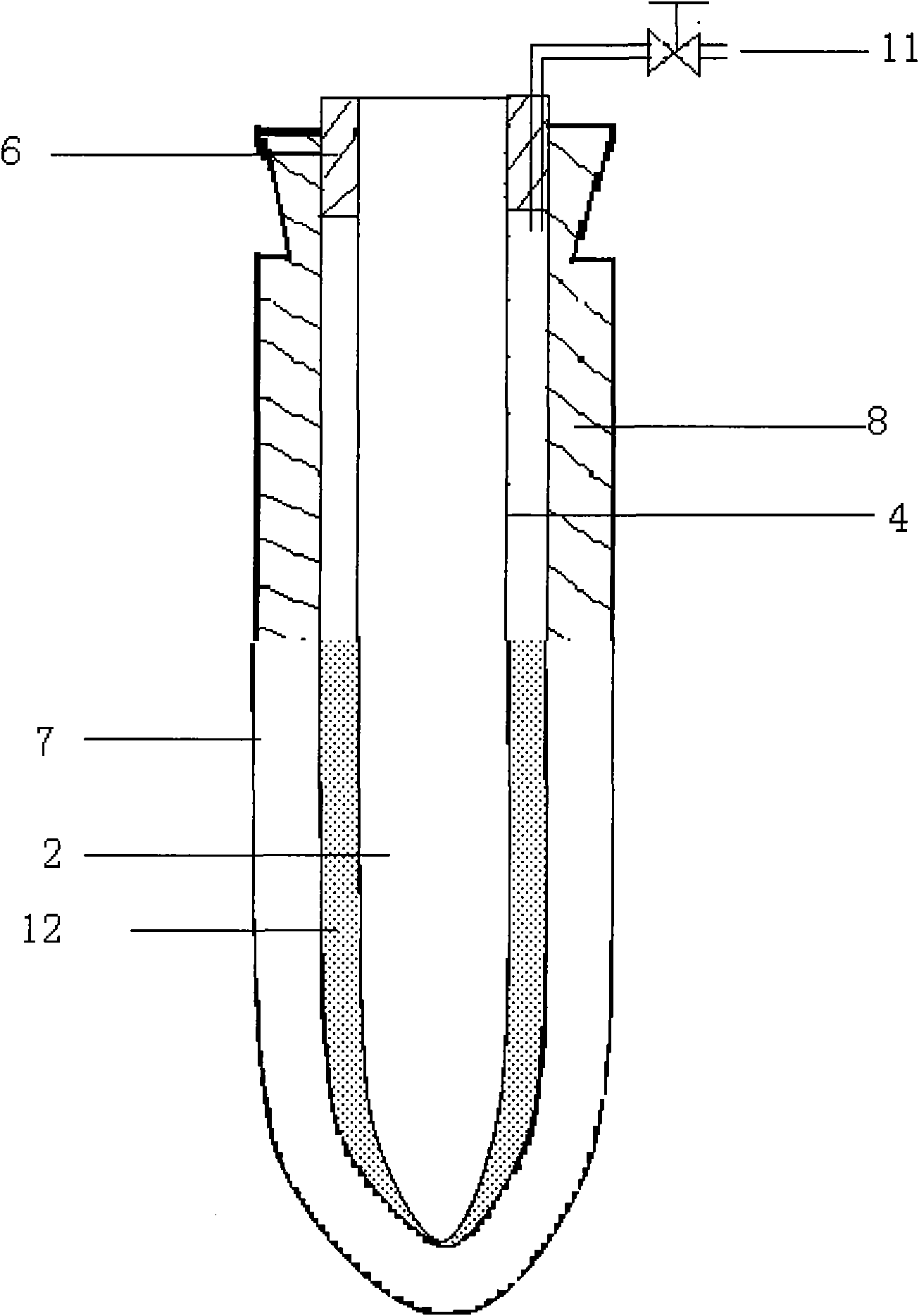

Electro-spinning nano fibre nonwoven production apparatus

ActiveCN101476167AImprove melting effectSolve insulation problemsFilament/thread formingNon-woven fabricsSynchronous motorNanofiber

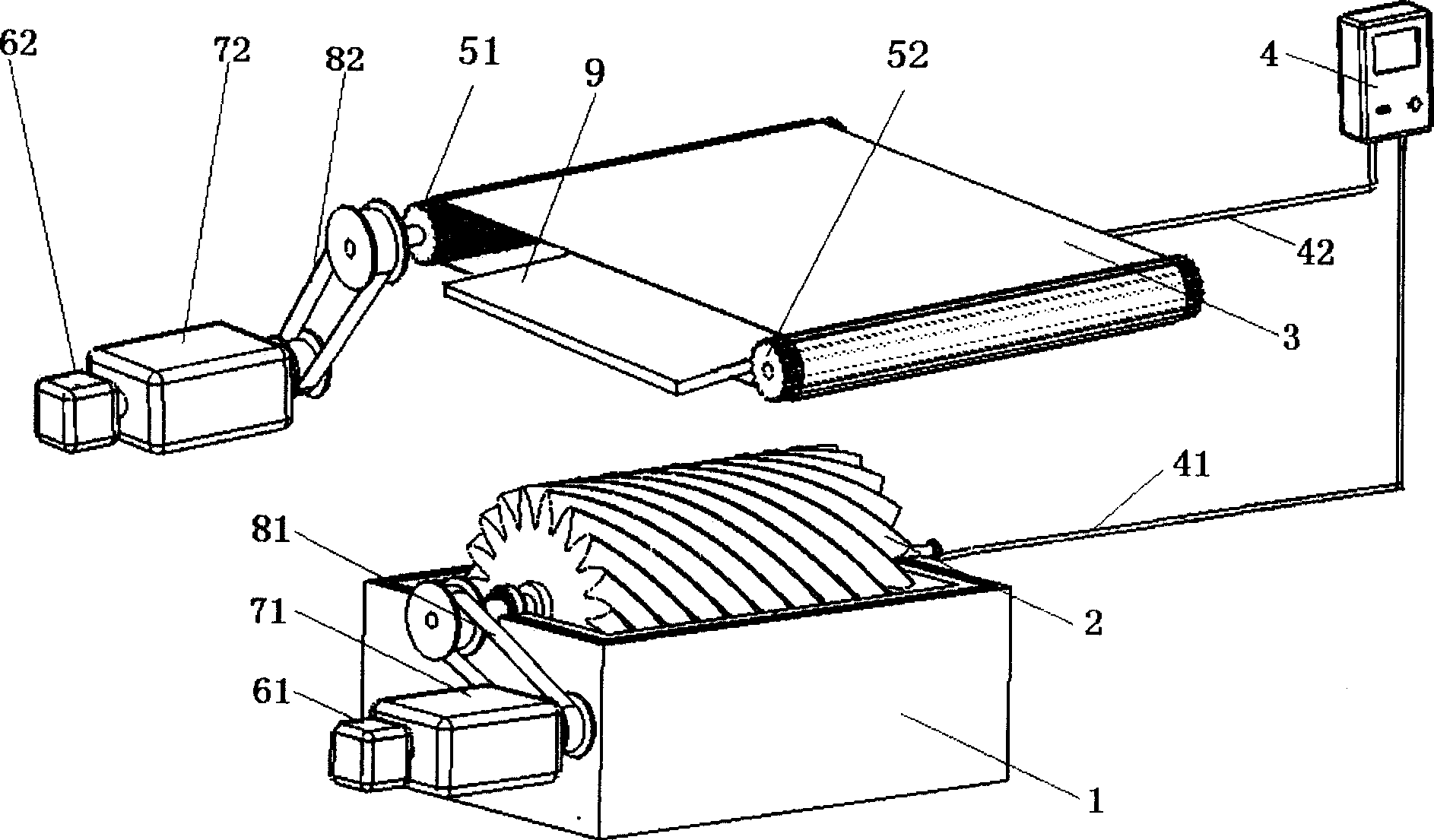

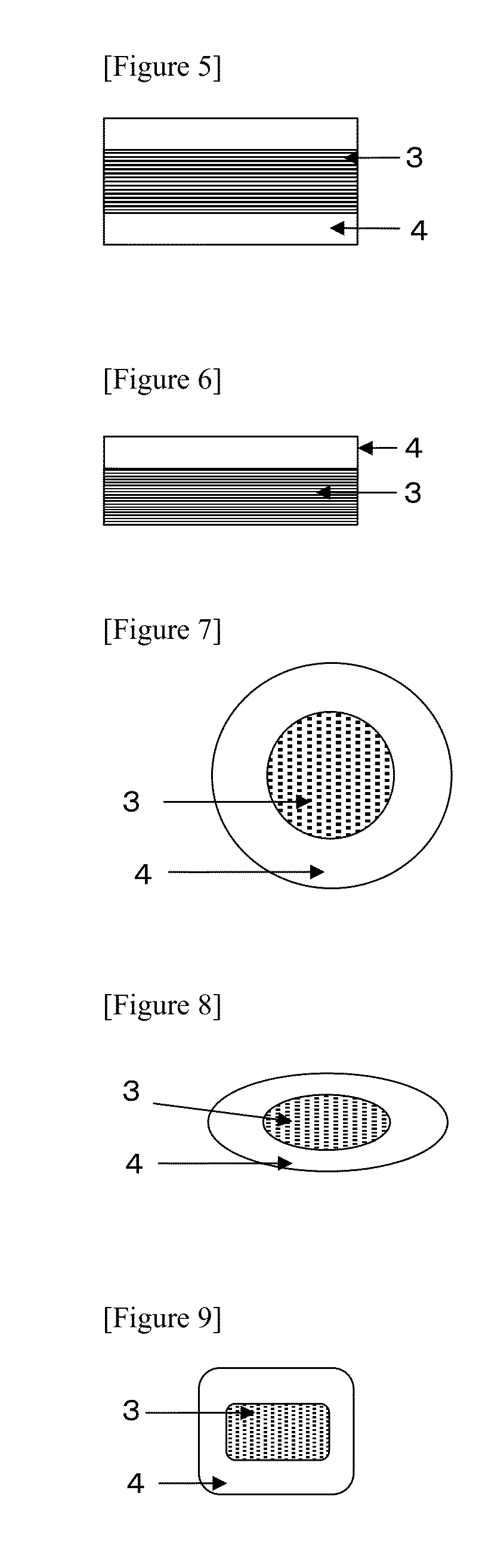

The invention provides a production unit for mass producing electro-spinning nano fibre non-weaving cloth which includes: a meltdown pool 1, a metal roller 2, a receiving lace curtaining 3, a high voltage static generator 4, an initiative guide roll 51 and a passivity guide roll 52, a roller synchronous motor 62, a roller reductor 71, a roller belt pulley 72, a lace curtaining reductor 81, a lace curtaining belt pulley 82, an earth metal plate 9. Four sides and bottom of the meltdown pool 1 is composed of a ceramic outside wall 13, a middle heating layer 12 and a ceramic inner wall 11, the sandwich design structure has better insulation effect and solves heating problem of polymer melt. Compared with prior electro-spinning mass production, the unit can satisfy melt electro-spinning need, and also can be used for solution electro-spinning for realizing multi-use of one machine.

Owner:TIANJIN WEICHER TECH

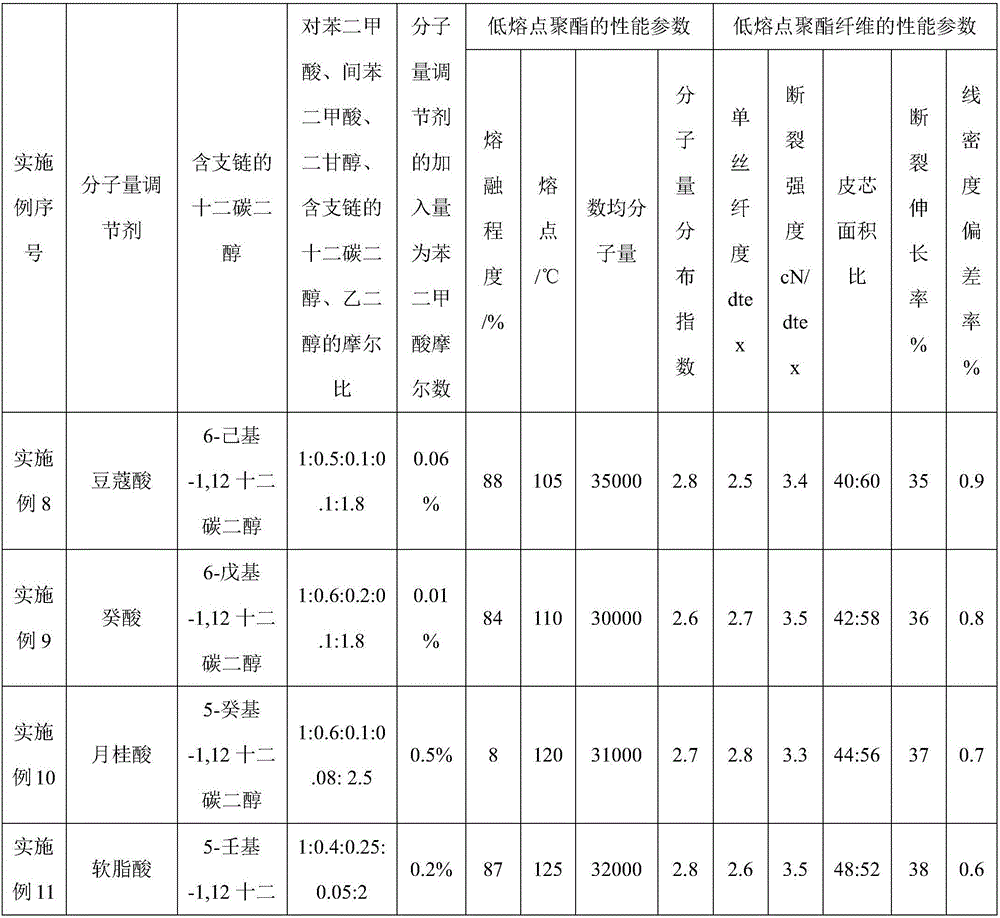

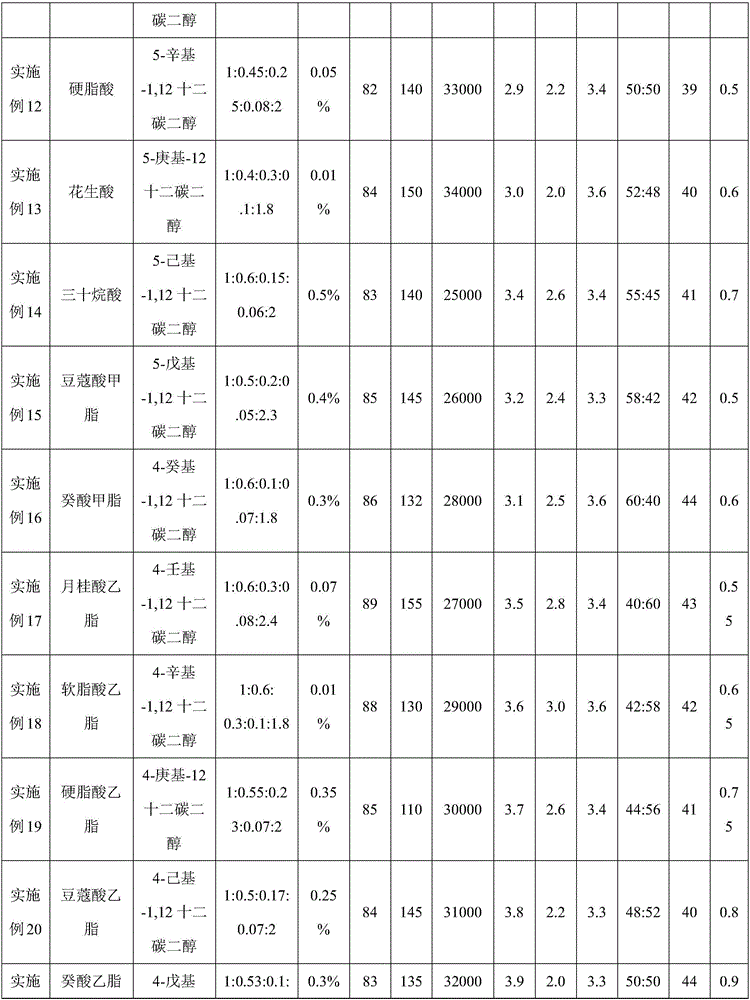

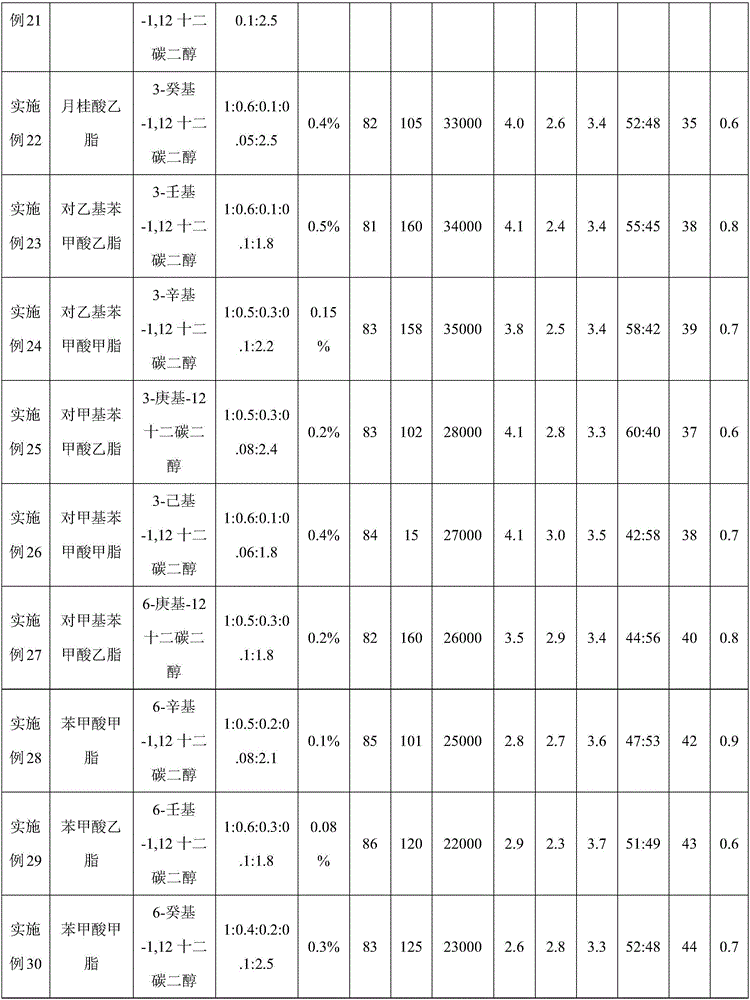

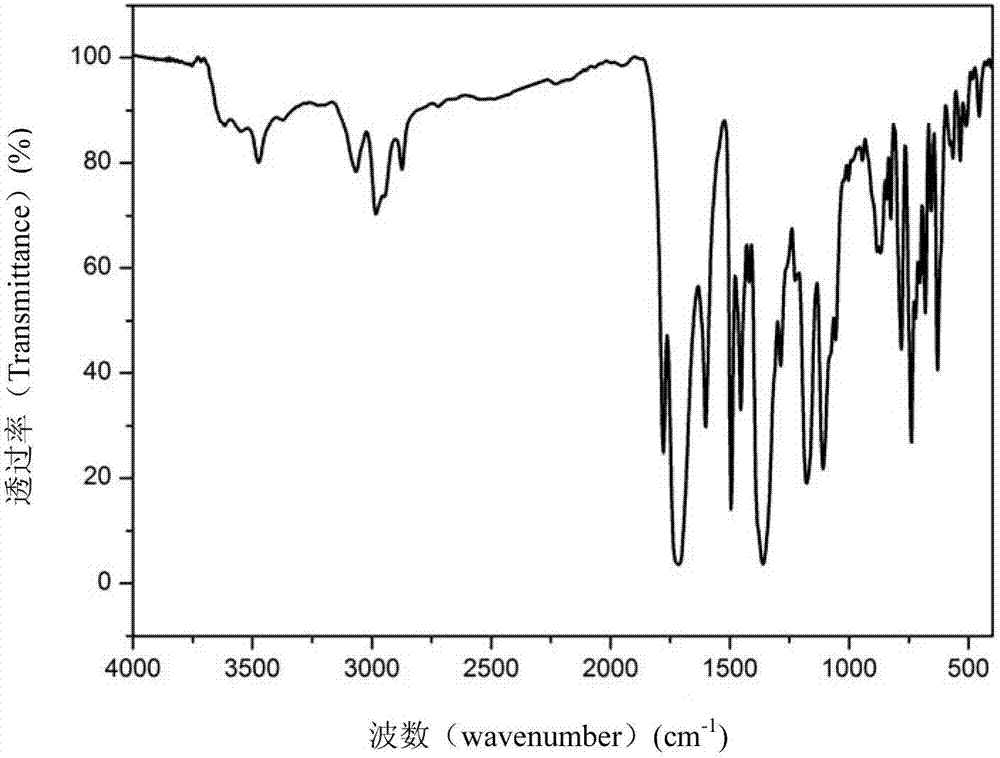

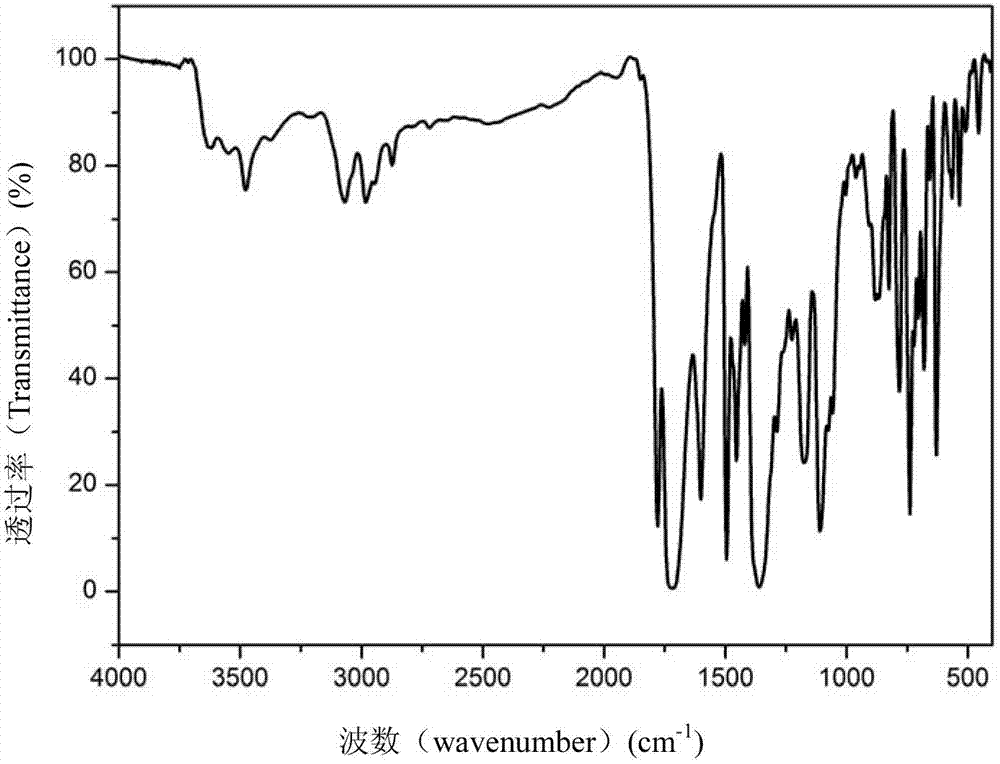

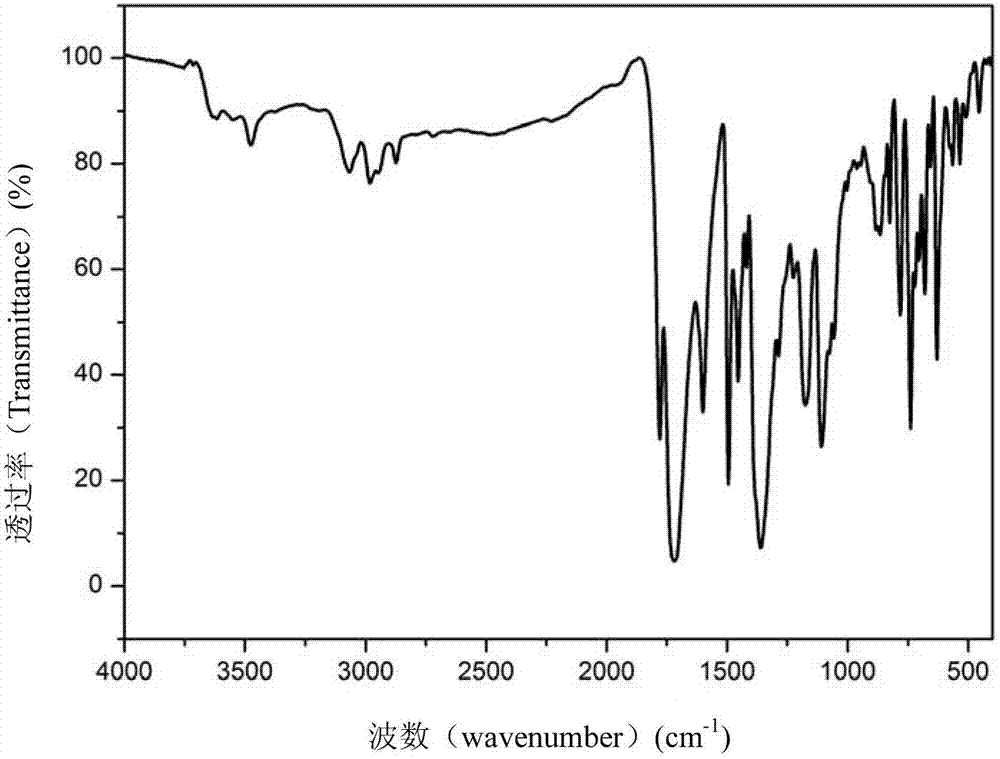

Filament low-melting-point polyester fiber and preparation method thereof

ActiveCN106757518AImprove fitImprove stabilityFilament/thread formingConjugated synthetic polymer artificial filamentsPolymer sciencePolyethylene terephthalate

The invention relates to a filament low-melting-point polyester fiber and a preparation method thereof. The filament low-melting-point polyester fiber is in a skin-core structure, a skin layer is made of low-melting-point polyester; a core layer is made of PET (polyethylene terephthalate); the low-melting-point polyester consists of a terephthalic acid chain segment, an isophthalic acid chain segment, an ethylene glycol chain segment, a diethylene glycol chain segment, a molecular weight modifier chain segment and a 1, 12-Dodecanediol chain segment containing branched chains; a molecular weight modifier corresponding to the molecular weight modifier chain segment is specifically a monoacid series or a diacid series; the preparation method of the filament low-melting-point polyester fiber comprises the following steps: polymerization of the low-melting-point polyester and skin-core composite spinning, so as to obtain the filament low-melting-point polyester fiber. The prepared filament low-melting-point polyester fiber has the advantages that the initial melting point is reduced, the melting speed is increased, the polyester fiber is immediately melted at the corresponding temperature, and the melting effect is good.

Owner:扬州富威尔复合材料有限公司

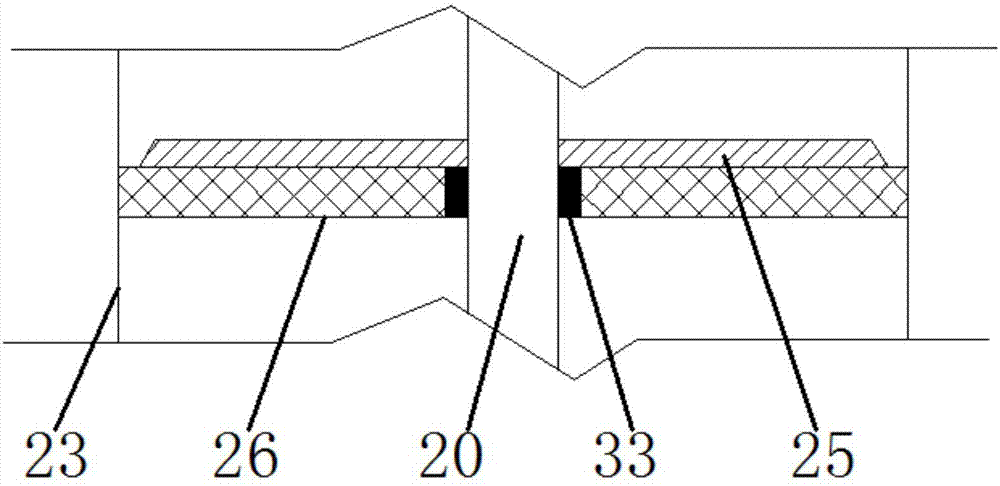

Method for preparing platy or lump processed cheese and cheese obtained

ActiveCN101564062AMaintain drawabilityLow heating temperatureCheese manufactureEngineeringBrowning reaction

The invention discloses a method for preparing a platy or lump processed cheese, comprising steps as follows: (1) shearing and mixing materials which contain natural cheese, butter oil, emulsifying salt and water; (2) heating under the shearing condition; (3) shearing emulsification; (4) forming the platy or lump cheese and then cooling. The method is characterized in that: both the shearing condition in step (2) and shearing emulsification in step (3) use a cutter with a blade thickness of 2-10mm, at a shearing rotating speed of 200-800rpm; in step (2), the materials are heated to 70-80 DEG C; and in step (3), the temperature for shearing emulsification ranges from 70 to 80 DEG C. The invention also discloses a platy or lump processed cheese prepared by the method. The invention improves the prior technique for preparing processed cheese by using low shearing condition to overcome the defect that the prior processed cheese has no stringiness, and provides a platy or lump processed cheese with stringiness, favorable mouth feel and texture and long guarantee period without browning reaction.

Owner:BRIGHT DAIRY & FOOD

High temperature-resistant anti-compression cross-linking polyimide foam material and preparation method and application thereof

The invention discloses a novel high temperature-resistant anti-compression cross-linking polyimide foam material, a precursor and a preparation method and an application thereof. The structural formula of the cross-linking polyimide foam material precursor is shown as a formula I. The preparation method comprises the following steps: mixing organic tetracarboxylic dianhydride or malonate ester of organic tetracid, norbornene mono acid monoester and aromatic diamine mixture in organic solvent to form a polyimide precursor resin solution, removing part solvent, drying and grinding to obtain precursor powder, and heating the precursor powder to 300-400 DEG C and foaming to obtain the cross-linking polyimide foam. The method has the characteristics of simple process and low forming temperature, and the obtained foam material is high in temperature resistance, strength and toughness and low in compression deformation at high temperature. The material can be applied to preparing high temperature-resistant sandwich materials, high temperature-resistant thermal insulation materials, high temperature-resistant damping materials and high temperature-resistant wave-transmitting materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Alkali - free glass and liquid crystal display panel

InactiveUS20070027019A1Excellent in reducing resistanceDeterioration of propertyNon-linear opticsAlkali freeLiquid-crystal display

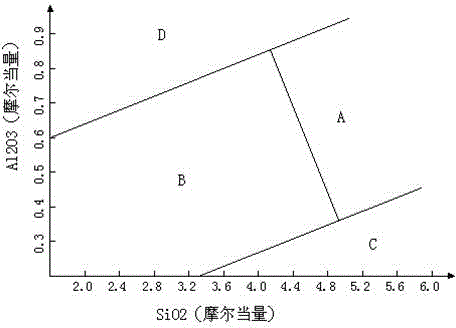

To provide an alkali-free glass excellent in the properties for glass substrates to be used for display, excellent in the resistance to reduction, and suitable for forming by a float process. An alkali-free glass consisting essentially of, as represented by mol %: SiO2at least 60% and less than 66%,Al2O30 to 12%,B2O35 to 10%,MgO0 to 18%,CaO0 to 18%,SrO0 to 18%,BaO0 to 6%, CaO + SrO10 to 25%, MgO + CaO + SrO + BaO15.5 to 30% and containing substantially no alkali metal oxide.

Owner:ASAHI GLASS CO LTD

Rapid Prototyping Method and Radiation-Curable Composition for Use Therein

InactiveUS20090224438A1Low melting pointEasily adjust and adaptAdditive manufacturing apparatusAdditive manufacturing with liquidsUltraviolet lightsSolvent

The invention relates to a method for producing three-dimensional objects, comprising producing a three-dimensional structure by sequential selective curing of layers of a composition curable with visible and / or ultraviolet light into a solid polymeric material by sequential exposure of the individual layers to UV and / or visible light, whereafter a three-dimensional object is produced by use of the three-dimensional structure thus formed, followed by removing the three-dimensional structure from or of the three-dimensional object, characterized in that removing the three-dimensional structure is accomplished by chemically cleaving the polymeric material as well as simultaneously or subsequently dissolving the material in a solvent or mixed solvent and / or melting the material.

Owner:VIENNA UNIVERSITY OF TECHNOLOGY

Manufacturing method of novel rock wool material

The invention discloses a manufacturing method of a novel rock wool material. The manufacturing method comprises the following steps: blending the following materials in parts by weight: 70-80 parts of basalt, 5-8 parts of limestone, 8-10 parts of slag, 20-30 parts of coke and 3-5 parts of auxiliary materials into a mixed raw material, placing into a cupola furnace, and fusing into magma at temperature lower than 900 DEG C; then forming a fiber, collecting wool, and paving the wool; then pressing on a three-dimensional wool presser, and solidifying and modifying to form the novel rock wool material. The rock wool material manufactured through the method disclosed by the invention has the advantages of uniformity in distribution, good hydrophobic effect and good mechanical property.

Owner:GUANGDE SKD ROCKWOOL MFG

Crystallizer protective slag for effectively controlling carbon steel cracks in compact strip production (CSP)

The invention discloses crystallizer protective slag for effectively controlling carbon steel cracks in a compact strip production (CSP). The crystallizer protective slag comprises the following chemical components in percentage by mass: 35 to 38 percent of CaO, 28 to 31 percent of SiO2, 1 to 3 percent of Al2O3, 1 to 2 percent of MgO, 0.5 to 1.5 percent of Fe2O3, 10 to 11.5 percent of F, 9 to 11.5 percent of Na2O, 1.5 to 3.5 percent of MnO, 5 to 8 percent of fixed carbon, and the balance of inevitable trace elements. Through the crystallizer protective slag for controlling the carbon steel cracks in the CSP, the alkalinity is improved by 0.04 to 0.09, the alkalinity is controlled to be 1.20 to 1.25, the constraint that the alkalinity cannot be more than 1.16 in the field is broken, the viscosity is controlled to be 0.08 to 0.09Pa.S, and the melting point is from 1,155 to 1,185 DEG C; capabilities of dissolving and absorbing inclusions are improved, and heat transfer is retarded by reducing a vitreous body, so that an aim of reducing longitudinal cracks is fulfilled; and by adjusting the proportioned carbon and controlling the thickness of a liquid slag layer, bonding steel leakage caused by high crystallization temperature and deteriorated lubricating performance due to over high alkalinity of the protective slag is relieved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

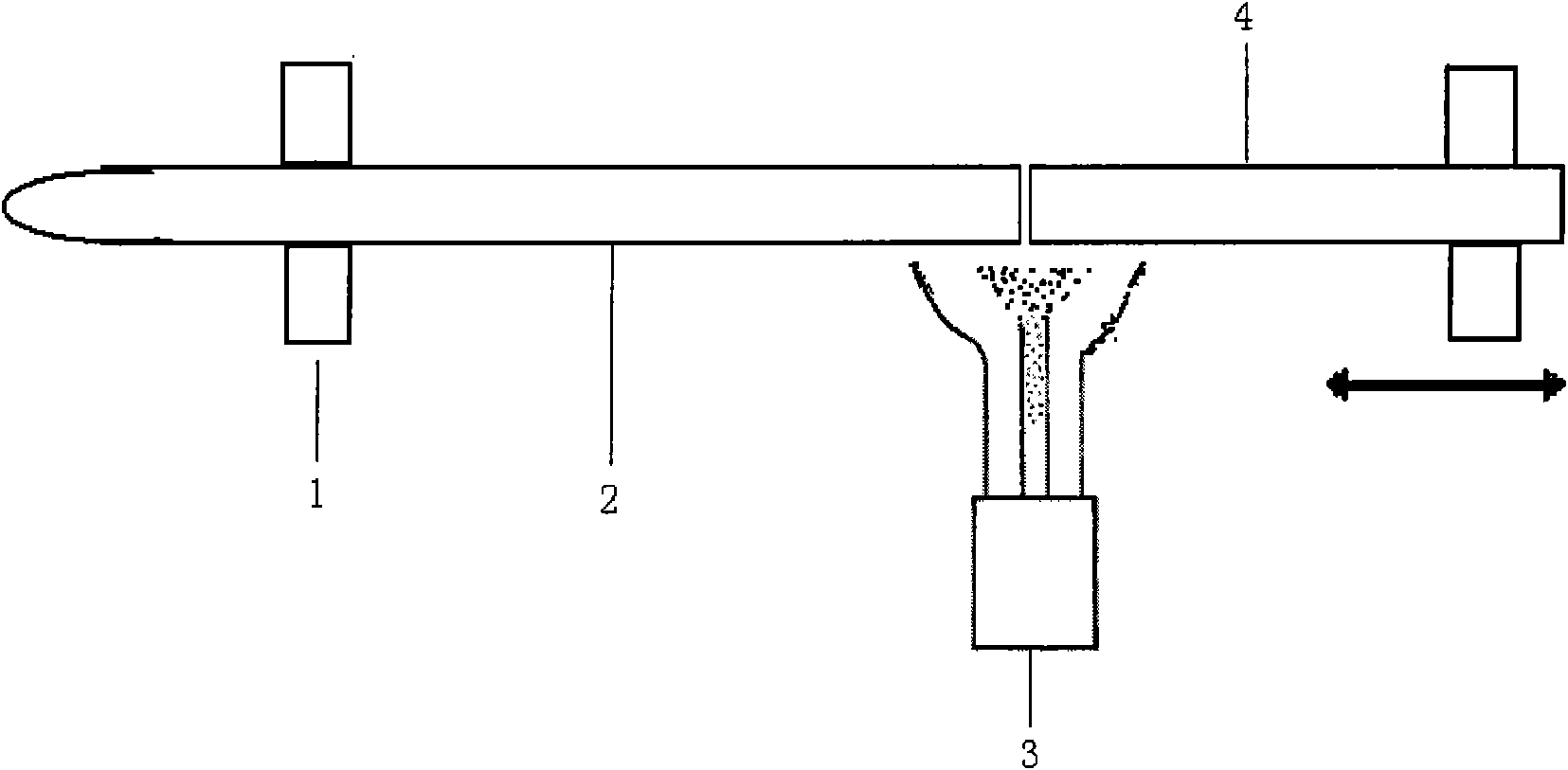

Method for preparing a microgap sleeve optical fiber prefabrication bar and method for drawing and preparing an optical fiber by microgap sleeve optical fiber prefabrication bar

ActiveCN101538113AThere will be no uneven shrinkageStable cladding geometryGlass fibre drawing apparatusGlass productionHydrofluoric acidMicro gap

The invention discloses a method for preparing a microgap sleeve optical fiber prefabrication bar and a method for drawing and preparing an optical fiber by the microgap sleeve optical fiber prefabrication bar and relates to the production of an optical fiber prefabrication bar and a method for drawing the wire by the optical fiber prefabrication bar. The method for preparing the microgap sleeve optical fiber prefabrication bar comprises the following steps: 1) a joint handle adopts a glass lathe and uses oxyhydrogen flame for separately abutting a core bar, a handle bar, a sleeve and a tail handle end face after high-temperature melting; 2) the joint handle is cleaned and dried, and 2-3 percent of hydrofluoric acid is used for cleaning the surfaces of the core bar and the sleeve for 2 hours so as to remove pollutants on the surfaces; and 3) in the assembly process, the cleaned and dried core bar is assembled into the sleeve, and then quartz sand is filled between the sleeve and the core bar so as to obtain the microgap prefabrication bar. The microgap sleeve optical fiber prefabrication bar is fixed on a collet of an optical fiber wire drawing tower and then molten so that an optical fiber can be drawn out from a lower opening of a wire-drawing stove and then is sequentially measured in diameter by a diameter measurer, cooled by a cooling pipe, coated, solidified by optical fiber coating and drawn by a main drawing device so as to reach a double-wire-collecting machine for optical fiber winding.

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD +2

Molding material, molding method using same, method for producing molding material, and method for producing fiber-reinforced composite material

InactiveUS20140155540A1Easy to produceImprove dynamic performancePlastic/resin/waxes insulatorsWood working apparatusProduction rateOligomer

Provided is a molding material comprising a composite of 1 to 50 wt % of a continuous reinforcing fiber bundle (A) and 0.1 to 20 wt % of a poly(phenylene ether ether ketone) oligomer (B); and 30 to 98.9 wt % of a thermoplastic resin (C) adhering to the composite, wherein the component (B) has a melting point of not higher than 270° C. Also provided are a method for molding the molding material, a method for producing the molding material, and a method for producing a fiber-reinforced composite material.A molded article having high heat resistance and dynamic properties can be easily produced without impairing the economic efficiency and productivity during the process for producing a molding material. In addition, a fiber-reinforced composite material can be produced with more ease and high productivity.

Owner:TORAY IND INC

De-icing solution

InactiveUS6905631B2More propertyIncreased ice melting propertyLiquid surface applicatorsOther chemical processesPhytic acidDepressant

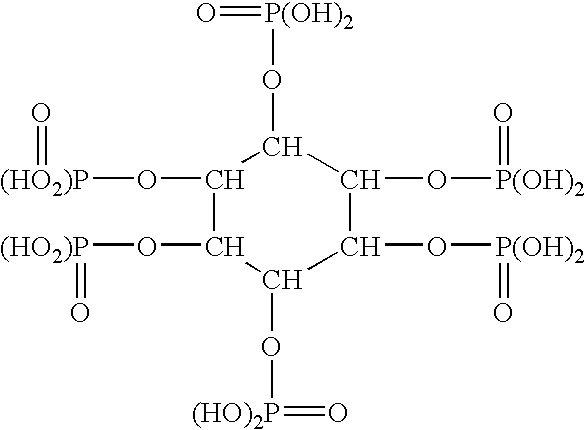

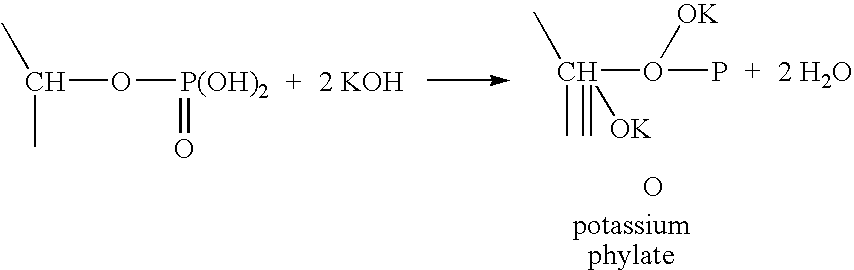

A de-icing and anti-icing composition in the form of an aqueous solution which includes a carbohydrate, a freezing point depressant and an anti-corrosion agent in the form of phytic acid and its salts.

Owner:SEARS ECOLOGICAL APPL CO

Leadless environmentally-friendly glass glaze, preparation method thereof, and glazed surface preparation method

The invention relates to a leadless environmentally-friendly glass glaze. The leadless environmentally-friendly glass glaze comprises base glaze, and the base glaze comprises 25-60wt% of SiO2, 5-30wt% of ZnO, 1-8wt% of CaO + MgO, 0-10wt% of BaO, 0-10wt% of SrO, 5-33wt% of B2O3, 0.5-11wt% of Al2O3, 0.5-10wt% of TiO2, 0-10wt% of ZrO2, 1-22wt% of K2O +Na2O and 1-10wt% of Li2O. The environmentally-friendly glass glaze contains no lead, can avoid damages to human bodies and the environment, can substitute traditional lead-containing glazes, has a lower price than leadless bismuth-containing glazes, is suitable for common flat glass, and can be toughened or sintered.

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE

Metallurgy type refining slag special for ladle and manufacture method thereof

ActiveCN101343680AImprove performance qualityImprove internal qualityProcess efficiency improvementSlagMolten steel

The invention relates metallurgical auxiliary materials used for molten steel refinement in the metallurgy field, in particular to metallurgy type steel ladle refining slag used for deeply desulfurizing and strongly absorbing various impurities in molten steel. The metallurgy type steel ladle refining slag is characterized in that the metallurgy type steel ladle refining slag is composed of the substances according to the weight percentages, namely, high activity lime accounting for 50 percent to 65 percent, fluorite powder accounting for 5 percent to 10 percent, AD30 accounting for 10 percent to 20 percent, magnesia powder accounting for 1 percent to 5 percent and pre-melting type refining slag accounting for 15 percent to 35 percent. The metallurgy type steel ladle refining slag adopts the preparation method that the high activity lime stone, good quality fluorite, AD30, pre-melting type refining slag and magnesia powder are selected as raw material, which are broken into particles of 6 mm to 12 mm according to the component range of the metallurgy type steel ladle refining slag to blend the ratio, and then the particles are packed into finished products according to the weight requirement. The metallurgy type steel ladle refining slag is mainly used for secondary refining for the molten steel without being treated through the refining furnace, the purposes of the effective absorbing of various impurities in the molten steel, the deep desulphurization, and the like in a short time and the refinement of the molten steel are achieved, and the cost of using the refining furnace is saved.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Function protecting material of continuous casting crystallizer for large square low-carbon steel

The invention discloses a function protecting material of a continuous casting crystallizer for large square low-carbon steel, comprising the following raw materials by weight percentage: 46% of melting stock , 5.0% of barium carbonate, 7.0% of sodium carbonate, 4.0% of fluorite, 18.0% of wollastonite, 10.0% of graphite carbon, 4.0% of fused magnesia, 4.0% of carbon black and 2.0% of bentonite. The melting stock comprises the following components by weight percentage: 28% of SiO2, 40% of CaO, 4.0% of Al2O3, 9.0% of R2O, 7% of F, 5.0% of MgO and the balance of ignition lost. The function protecting material has excellent spreadability, heat preservation and melting property in the crystallizer, the capacity of heat transmission in the crystallizer is stable and uniform, thereby satisfying the requirement of casting speed in the fluctuation range. The invention has the advantages of small slag block of test slag, improvement of unevenly inflow and good lubricity of the function protecting material, thereby avoiding cohesive bleed-out.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

Preparation method of low-viscosity casting powder for preparing steelmaking cast ingots

The invention discloses a preparation method of a low-viscosity casting powder for preparing steelmaking cast ingots, which comprises the following steps: using fly ash and blast-furnace granulated slag as basic slag materials, successively placing the ignited fly ash in 20-25% of hydrochloric acid and 15-20% of sodium hydroxide solution to be stirred for 20-24h, then washing the fly ash filtered from acid-alkali immersion liquid to be neutral with de-ionized water, testing with pH test paper for determination, and finally filtering and drying, wherein the addition amount of fly ash is 45-65 parts by weight. The preparation method provided by the invention has the advantages of reducing the unit weight of raw materials, improving the melting property, the spreading property and the thermal insulation property, and effectively reducing the usage amount of ingot carbon.

Owner:马鞍山科润冶金材料有限公司

Fusion-method-prepared functional graphene cellulose fiber and preparation method thereof

ActiveCN106149083AGood physical and mechanical propertiesFar infrared is goodSpinning head liquid feederMonocomponent cellulose artificial filamentCellulose fiberUltraviolet protection

The invention discloses fusion-method-prepared functional graphene cellulose fiber. The fiber mainly comprises 0.5-10.0% of graphene and 90.0-99.5% of cellulose. A preparation method of the graphene cellulose fiber comprises procedures of graphene dispersion liquid preparation, cellulose / ionic liquid mixture preparation, mixing, pre-fusing, spinning solution preparation and spinning. The far infrared normal emissivity of the prepared functional graphene cellulose fiber reaches 0.83-0.98, the ultraviolet protection coefficient reaches 62.78-560.21, the ultraviolet a transmittance is smaller than 4.92%, and compared with common viscose, the graphene cellulose fiber has the advantage that the thermal decomposition temperature is raised by 10-42 DEG C. By means of the method, the production process is short, less pollution is caused to the environment, the requirement of sustainable development is met, and the method has great significance for achieving a high-temperature melt spinning route of the functional cellulose.

Owner:潍坊欣龙生物材料有限公司

Special low-temperature curing powder coating for electrostatic spraying and preparation method thereof

InactiveCN106752759AGood storage stabilityImprove melting effectPowdery paintsEpoxy resin coatingsEpoxyModified carbon

The invention relates to a special low-temperature curing powder coating for electrostatic spraying and a preparation method thereof. The powder coating is prepared from the following raw materials in parts by weight: 55-75 parts of polyester resin, 15-25 parts of epoxy resin, 5-10 parts of organic silicon resin, 2-8 parts of modified carbon nano tubes, 1-3 parts of graphite powder, 2-6 parts of white carbon black, 5-15 parts of titanium dioxide, 5-40 parts of filler, 1-10 parts of a pigment, 2-5 parts of a curing agent, 0.05-0.5 part of a curing catalyst, 1-3 parts of a flatting agent, 1-3 parts of a dispersing agent, 0.1-0.5 part of a coupling agent and 1-5 parts of a styrene-acrylic emulsion. The powder coating has the advantages of being simple in formula, low in curing temperature, good in mechanical property, smooth in film, high in adhesive force and stable to store, electrostatic spraying can be achieved, the construction difficulty is reduced and the work efficiency is improved.

Owner:TIANCHANG JINLING ELECTRONICS

Carbon-free casting powder for casting steel making die

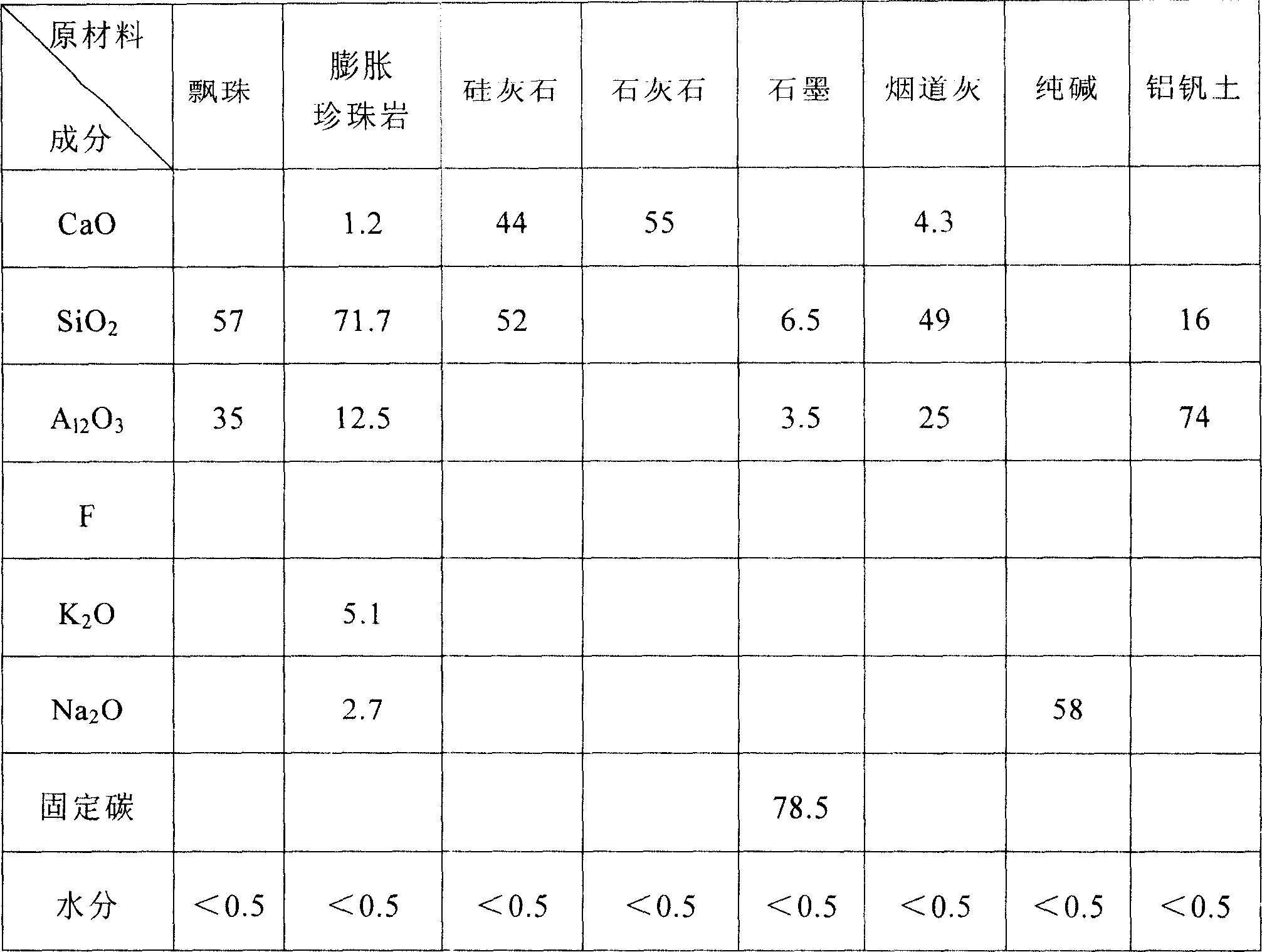

The invention provides a carbon-free protective slag for steel-making mould casting, the percentage by weight compositions of components in the invention are as follows: 50 to 70 percent of e basic slag charge containing CaO, SiO2 and little Al2O3, 5 to 20 percent of hollow microsphere containing SiO2 and Al2O3, 10 to 25 percent of expanded perlite containing SiO2 and Al2O3, 5 to 15 percent of calcined soda for industrial purpose. The protective slag of the invention has fewer kinds of raw materials, good melting performance, good spreadability, low volume weight, good heat-insulating property, and can effectively avoid adding carbon to ingot steel.

Owner:BAOSHAN IRON & STEEL CO LTD

Special double-layer carbon-free tundish covering agent for silicon steel and use method thereof

ActiveCN102000794AStrong adsorption and inclusion capacityComplete Coverage GuaranteedChemical compositionGranularity

The invention discloses a special double-layer carbon-free tundish covering agent for silicon steel and a use method thereof. The production process of the special double-layer carbon-free tundish covering agent for the silicon steel is simpler and more convenient, and a production process of an the upper layer of covering agent comprises the following steps of: crushing a mixture prepared from all component with qualified chemical components; grinding the mixture to fine granules with the granularity of 0-0.21 mm; uniformly stirring and drying until the water content is less than 0.5 percent; and packaging. A production process of a lower layer of covering agent comprises the following steps of: crushing a mixture prepared from all component with qualified chemical components; grinding the mixture to fine granules with the granularity of 0-0.15mm; uniformly stirring and drying until the water content is less than 0.5 percent; and packaging. The special double-layer carbon-free tundish covering agent for the silicon steel with good fusion performance and spreadability produced by the invention can ensure that the fluctuation of the components C, N, S, P and Al of the molten steel in the tundish is within 10PPm (the fluctuation of the casting in 5PPM is up to more than 80 percent) during the smelting process of the silicon steel, thereby ensuring the smooth operation of continuous casting process.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

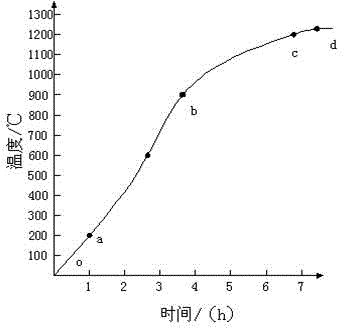

Medium-temperature color glaze formula and sintering process thereof

The invention discloses a medium-temperature color glaze formula and a sintering process thereof, wherein the parent glaze of the formula contains the following raw materials by weight percent: 35-45% of potassium-sodium integrated feldspar, 6-8% of kaolin, 13-18% of quartz, 10-15% of limestone, 0-8% of talcum, 0-6% of zinc oxide and 0-6% of barium carbonate. The formula is characterized in that the potassium-sodium integrated feldspar is selected in stead of potassium feldspar or solidum feldspar in combination with the local material reality, so that the production cost and sintering temperature are reduced, and simultaneously, the eutectic point of potassium and sodium is low, the melting range is wide, the solution viscosity is reduced slowly as the temperature rises, and the shrinkage of the glaze can be reduced; meanwhile, the mechanical properties, melting performance and thermal stability of the glaze layer are improved, and the dilatation coefficient of the glaze can be reduced to prevent crazing; and in addition, the elasticity of the glaze is improved, the glossiness of the glaze layer is improved, the surface tension of the glaze is reduced and the generation of the intermediate layer is promoted.

Owner:福建省德化县科力陶瓷厂

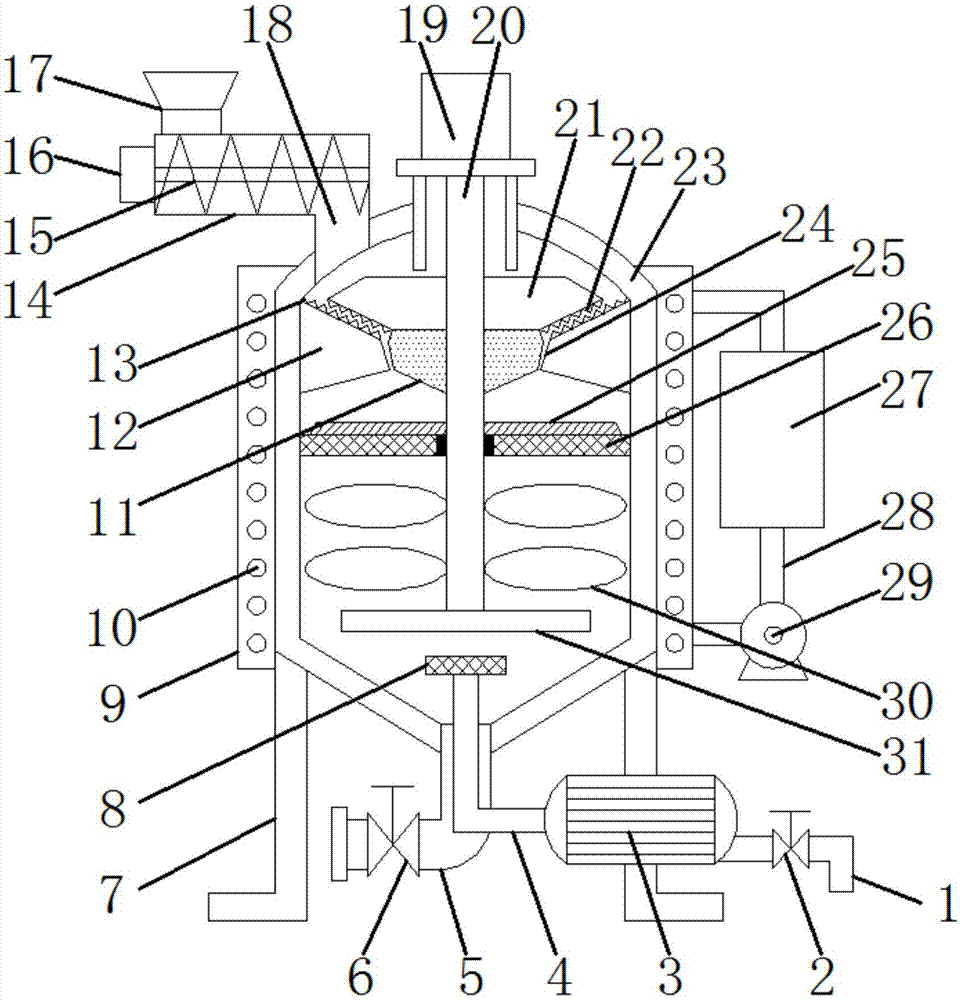

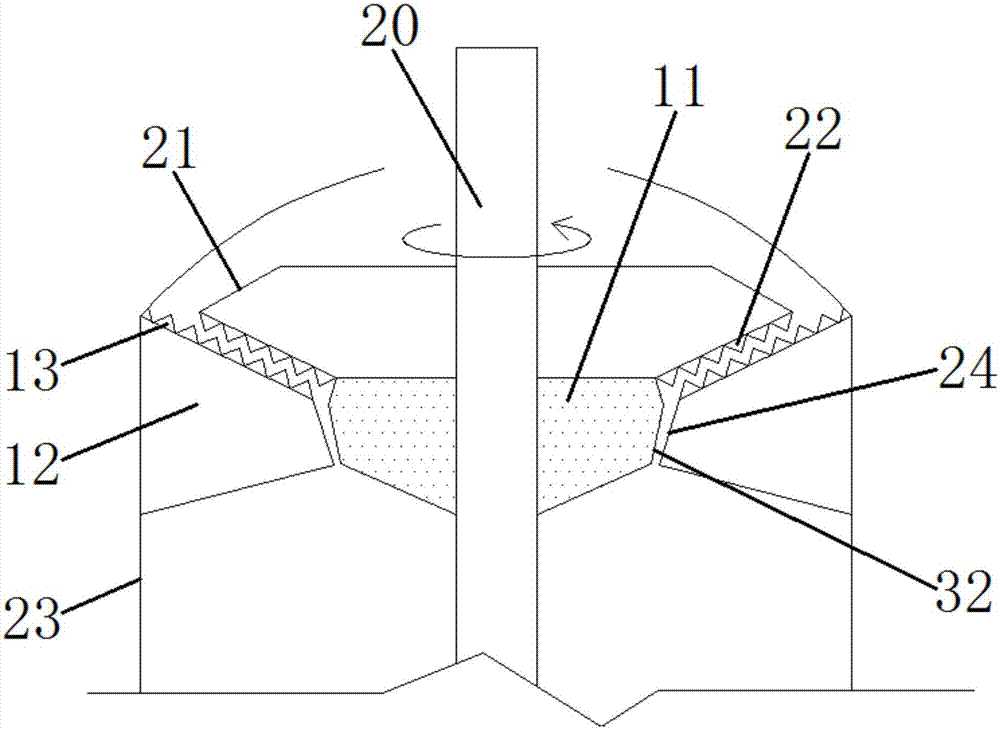

Asphalt crushing and melting equipment for municipal construction

InactiveCN107365596AEasy to crushCrushing and meltingWorking-up pitch/asphalt/bitumen by meltingWorking-up pitch/asphalt/bitumen by solidifying/disintegratingMelting tankCoupling

The invention discloses an asphalt crushing and melting equipment for municipal construction, which comprises a non-melting slag discharge pipe, a heating sleeve, a grinding roller, a fixed breaking hammer and an asphalt melting tank. A support frame is installed at the bottom of the asphalt melting tank. The upper end of the melting tank is connected to the asphalt input pipe; the top of the asphalt melting tank is equipped with a stirring motor, the rotating shaft of the stirring motor is connected to the rotating shaft through a coupling, and the rotating shaft is installed vertically inside the asphalt melting tank, and the top of the rotating shaft is welded Breaker, the bottom side of the rotary breaker is equipped with a number of rotating breaker teeth, and the bottom side of the rotary breaker is equipped with a fixed breaker; it realizes the convenient addition of asphalt blocks and avoids clogging; it realizes grinding treatment and further crushing, which is convenient for asphalt Block melting operation; realize the separate discharge of non-melting slag and asphalt melt, improve the effect and quality of asphalt melting; it is beneficial to the melting of asphalt, the heat transfer oil circulates, and the heating effect is good.

Owner:CHANGSHA KEYUE ENTERPRISE MANAGEMENT CONSULTING CO LTD

Alkali-free glass and liquid crystal display panel

InactiveUS7838451B2Excellent in reducing resistanceDeterioration of propertyNon-linear opticsAlkali freeLiquid-crystal display

Owner:ASAHI GLASS CO LTD

Preparation method of anti-carburizing electrothermal alloy

ActiveCN104630633AImprove melting effectQuality improvementHeating element materialsElectric heatingSolderability

The invention discloses a preparation method of an anti-carburizing electrothermal alloy, and relates to the iron chromium aluminum alloy processing and manufacturing field; the preparation method includes five technological processes of alloy smelting, steel wire rod preparation, heat treatment, alkali boiling and pickling, and drawing; in the preparation method, a medium-frequency vacuum induction furnace is selected as a melting device, moreover, through strict control of a tapping temperature, a furnace material undergoes a full reaction in the furnace, a smelting effect is good, and a prepared electrothermal alloy steel ingot has good quality; in a forging process, through control of a die forging temperature, the surface quality and the core part quality of a fogged steel wire rod are both relatively good, the steel wire rod after rolling is subjected to alkali boiling and pickling processes, an oxidation film on the surface of an electrothermal alloy wire is basically cleaned, impurity residues are few, and the anti-carburizing electrothermal alloy wire produced by the preparation method has strong anti-carburizing ability, can be widely used in heating elements in a carburizing furnace, and is long in service life, good in weldability, intact in welding surface and worthy of promotion.

Owner:江苏禾一电热材料有限公司

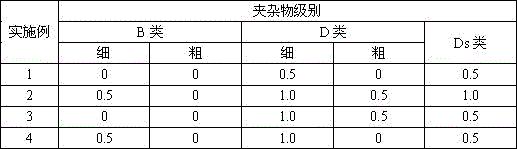

Refining method for controlling brittle inclusions in bearing steel

The invention discloses a refining method for controlling brittle inclusions in bearing steel, comprising an LF refining procedure and an RH refining procedure; the LF refining procedure comprises a process from steel tapping and alloying to pre-deoxidation slag formation on an LF treatment position and an LF treatment process; the process from steel tapping and alloying to pre-deoxidation slag formation on the LF treatment position comprises the steps of controlling the molten steel temperature at a converter smelting end point at 1600-1650 DEG C; adding 7-10kg / t of refining slag at the later stage of steel tapping, wherein the refining slag has high alkalinity and a low melting point; controlling the flow of argon blown to a steel ladle in the steel tapping process at 2.5-3.5NL / min.t<-1>; carrying out slag stopping operation at the last stage of steel tapping, and adding 20-40kg of aluminum particles; and controlling the flow of argon blown to the steel ladle at 0.15-0.35L / min.t<-1> in the process from steel tapping ending to LF refining; and the LF treatment process comprises the steps of controlling the flow of argon blown to the steel ladle at 2.5-5.0L / min.t<-1> in the LF treatment process; adding 30-50kg of aluminum particles at the earlier stage of LF smelting; and in the middle stage of LF smelting, adding 30-50kg of quartz and 200-400kg of lime, and adopting refining slag with medium-lower alkalinity. By using the method, the brittle inclusions in the steel can be effectively prevented and removed.

Owner:XINGTAI IRON & STEEL

Production process of high tower melt-granulated compound fertilizer

InactiveCN101993277ALower melting temperatureReduce the temperatureAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPotassiumSlurry

The invention relates to a production process of a high tower melt-granulated compound fertilizer. Potassium chloride is added in the process of melting urea, and the temperatures of urine and slurry are reduced according to a characteristic that the melting temperature is reduced after the urea is mixed with the potassium chloride serving as a cosolvent. The liquid solid ratio of the slurry can be regulated so as to reduce the melting temperature of the urea, the melting capacity of urea melting equipment is improved, and the foundation for improving the yield is laid.

Owner:河南财鑫实业化工有限责任公司

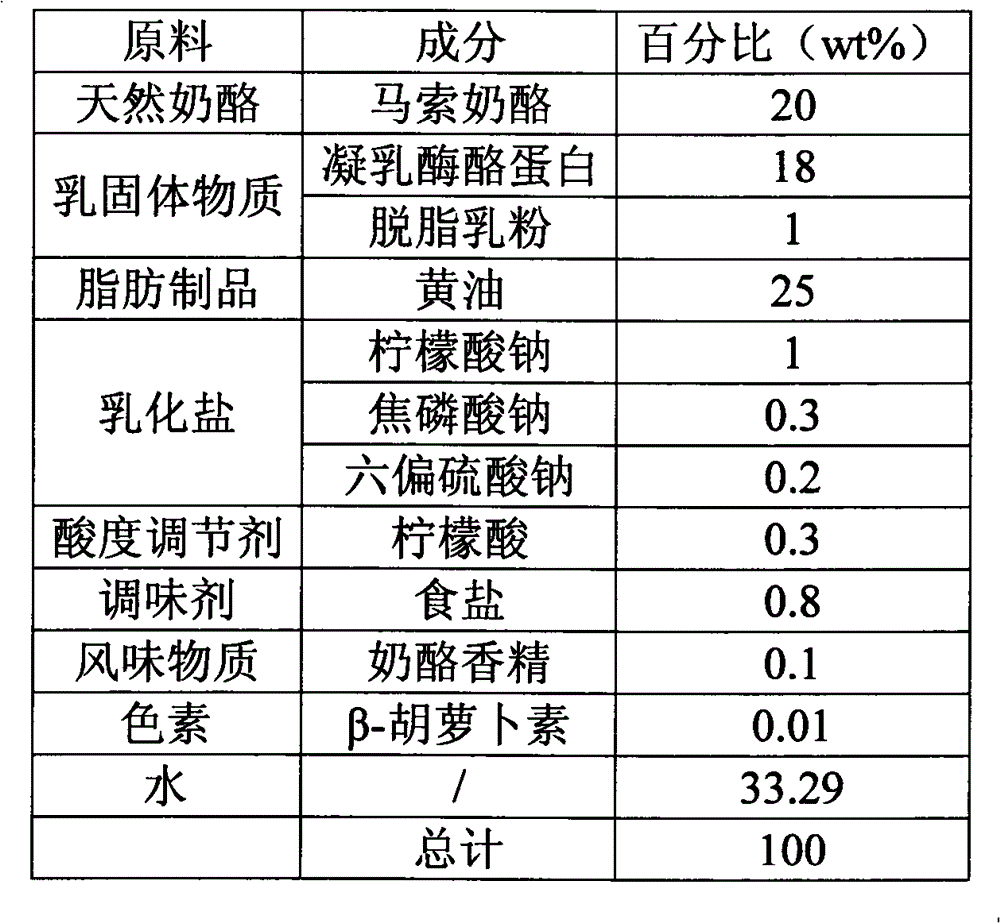

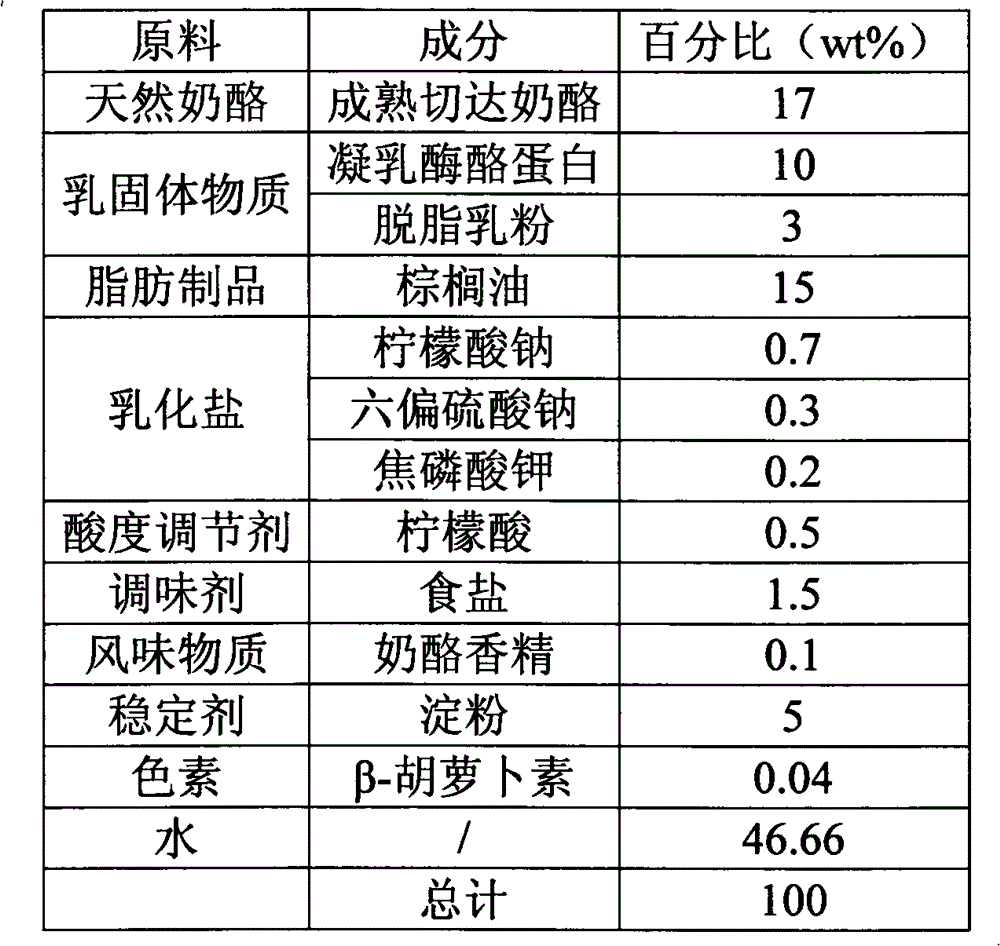

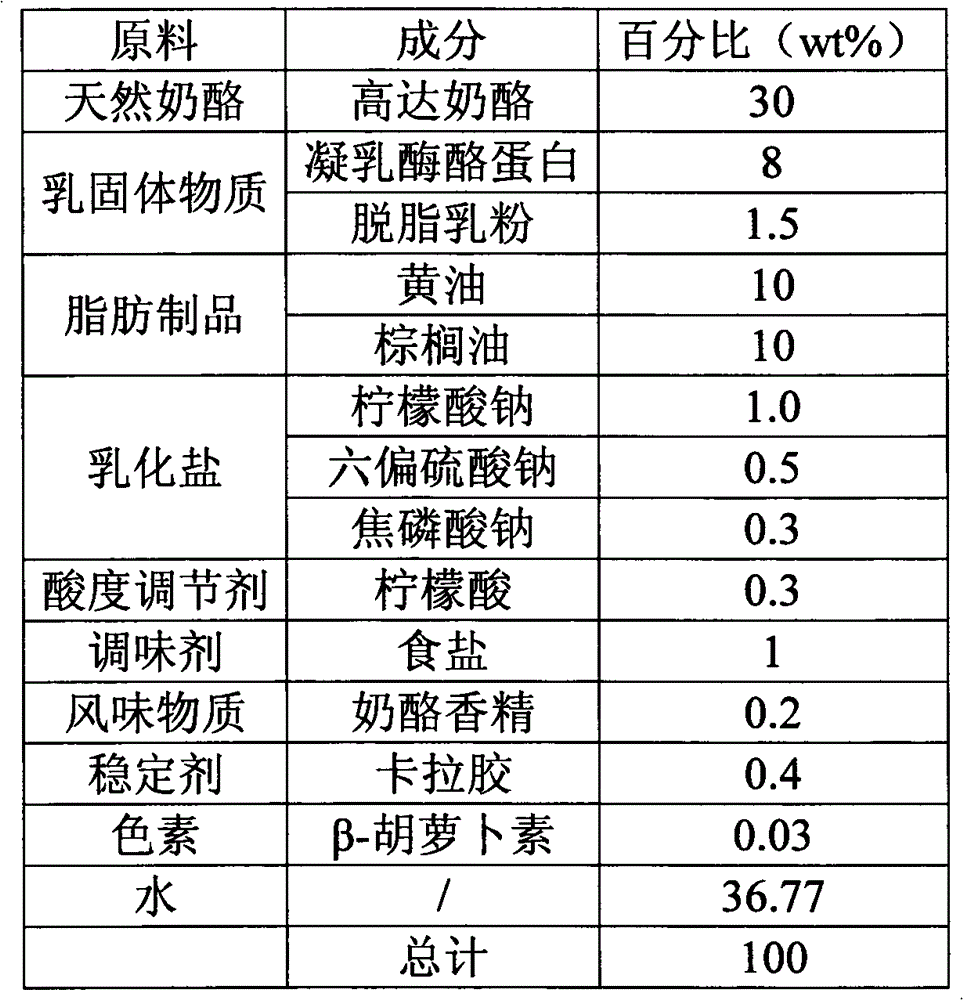

Reproduced cheese and preparation method thereof

The invention discloses reproduced cheese and a preparation method thereof. The reproduced cheese comprises raw materials of 5 to 30% of natural cheese, 15 to 40% of one or more fat products, 9.5 to 23% of one or more milk solids, 1.2 to 2.0% of one or more emulsification salts, 0 to 0.05% of one or more pigments, 0 to 1.8% of table salt, 0 to 0.2% of one or more flavor substances, 0 to 10% of one or more stabilizers, 0.3 to 0.6% of one or more acidity regulators, 0 to 0.1% of one or more antiseptics, and 29.05 to 46.7% of water. The preparation method comprises the following steps of 1, carrying out cutting premixing of the raw materials but the one or more fat products and the natural cheese by 2 to 5 cutting knives having blade thickness of 2.5mm at a mixing rate of 900 to 1800rpm to obtain slurry, 2, heating the slurry, the one or more fat products and the natural cheese to a temperature of 80 to 95 DEG C with stirring for emulsification, and 3, cooling and carrying out refrigeration. The reproduced cheese obtained by the preparation method has excellent meltability and drawing performances, has a shelf life of at least 6 months, overcomes the defect of poor meltability of the existing reproduced cheese in the Chinese market, can be used for Pizza manufacture, retains a unique flavor and functional characteristics of the classical cheese and has a low production cost. The preparation method is simple and fast and can be operated easily.

Owner:BRIGHT DAIRY & FOOD

Modification of polyethylene with ozone

InactiveUS20090088534A1Improve melting effectReduce weightOther chemical processesWater/sewage treatmentBlow moldingPolymer science

A method of modifying polyethylene is disclosed. The method comprises contacting the polyethylene powder with ozone. The modified polyethylene exhibits an increase in melt elasticity and the complex viscosity at low shear rates. The rheological benefits are achieved without a significant reduction in the weight average molecular weight of the polyethylene. The modified polyethylene can be used in applications that require higher melt strength such as film or blow molding.

Owner:EQUSR CHEM LP

Method for producing high-protein soybean snack food

InactiveUS20090291179A1Excellent meltabilityImprove melting effectMeat/fish preservation by freezing/coolingFood shapingChemistryCalcium carbonate

A high-protein soybean snack food which is excellent in moldability and melting in the mouth unlike a conventional expanding snack food mainly composed of starch is obtained. By using not undegraded separated soybean protein but hydrolyzed soybean protein as a main raw material and combining calcium carbonate therewith, adding water thereto, extruding and expanding the mixture by a high-temperature and high-pressure treatment with an extruder, a high-protein soybean snack food which is excellent in moldability and melting in the mouth can be produced.

Owner:FUJI OIL CO LTD

Hard butter composition and its production

InactiveUS6258398B1Improve melting effectEasy to produceFatty-oils/fats separationCocoaTriglycerideStearic acid

A hard butter composition is described that comprises 50 to 80% by weight of SUS type triglycerides, less than 2% by weight of SSS type triglycerides and at least 1% by weight of a polyglycerol fatty acid ester (wherein S's are saturated fatty acid residues which are substantially palmitic acid and / or stearic acid residues and U's are unsaturated fatty acid residues which are substantially C16 and / or C18 unsaturated fatty acids). The composition further comprises SSU type triglycerides in an amount of at least 15% by weight based on the total amount of SUS type triglycerides and SSU type triglycerides. The hard butter composition is a non-tempering type hard butter composition having good meltability in the mouth, which is free from trans acids and lauric acid. A process for producing the hard butter composition is also disclosed.

Owner:FUJI OIL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com