High temperature-resistant anti-compression cross-linking polyimide foam material and preparation method and application thereof

A polyimide and foam material technology, which is applied to the high temperature resistant and high compression resistant cross-linked polyimide foam material and its preparation and application fields, can solve the problem that it is difficult to obtain high closed cell ratio and high compressive strength polyamide The imine foam material does not disclose the closed cell ratio and mechanical properties of the foam, softening and deformation of the cells, etc., and achieves the effects of high compressive strength, good meltability and low foaming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

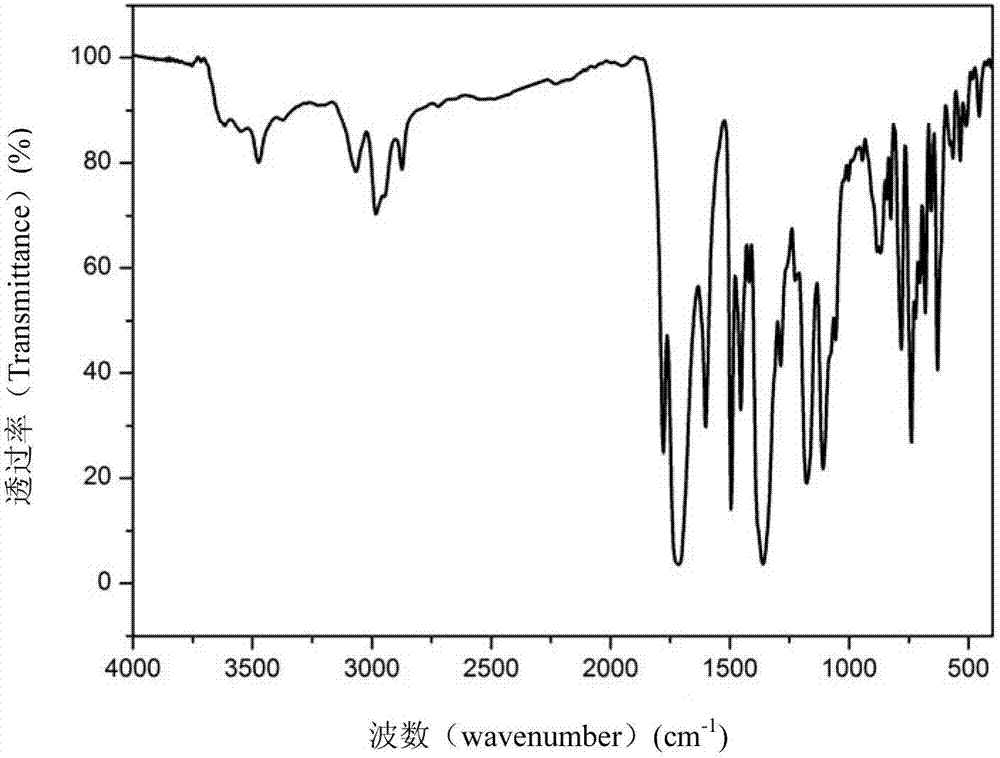

Embodiment 1

[0070] 1) Add 29 parts of α-BPDA, 37 parts of absolute ethanol, and 29 parts of anhydrous tetrahydrofuran into a three-neck flask equipped with a mechanical stirrer, a spherical reflux condenser and a thermometer, and heat and reflux for 3 hours under stirring to obtain a uniform phase solution.

[0071] 2) Add 33 parts of NA and 67 parts of absolute ethanol into a single-necked bottle equipped with an electromagnetic stirring device and a spherical reflux condenser, and heat for 3 hours under stirring to obtain a homogeneous solution. After cooling to room temperature, add this solution to the solution prepared in step 1) of cooling to room temperature, and add 22 parts of p-PDA, 0.13 parts of isoquinoline, and heat under reflux and stir for 15 minutes under nitrogen protection to obtain a homogeneous solution . After cooling to room temperature, add 0.25 parts of polyoxyethylene ether nonionic fluorocarbon surfactant FSO-100, stirred at room temperature for 20 minutes und...

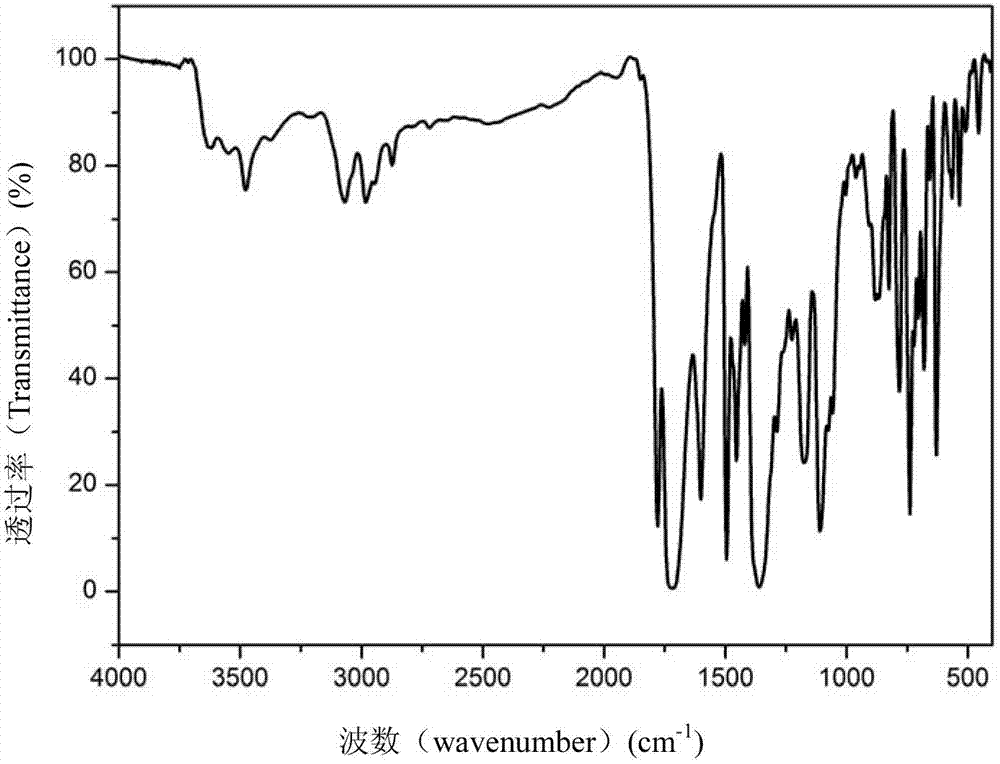

Embodiment 2

[0083] 1) Add 29 parts of α-BPDA, 37 parts of absolute ethanol, and 29 parts of anhydrous tetrahydrofuran into a three-neck flask equipped with a mechanical stirrer, a spherical reflux condenser and a thermometer, and heat and reflux for 3 hours under stirring to obtain a uniform phase solution.

[0084] 2) Add 36 parts of MNA and 67 parts of absolute ethanol into a single-necked bottle equipped with an electromagnetic stirring device and a spherical reflux condenser, and heat for 3 hours under stirring to obtain a homogeneous solution. After cooling to room temperature, this solution was added to the solution in step 1) cooled to room temperature, and 22 parts of p-PDA and 0.13 parts of isoquinoline were added, and heated under reflux and stirred for 15 minutes under nitrogen protection to obtain a homogeneous solution . After cooling to room temperature, add 0.25 parts FSO-100, stirred at room temperature for 20 minutes under the condition of nitrogen protection, to obtain...

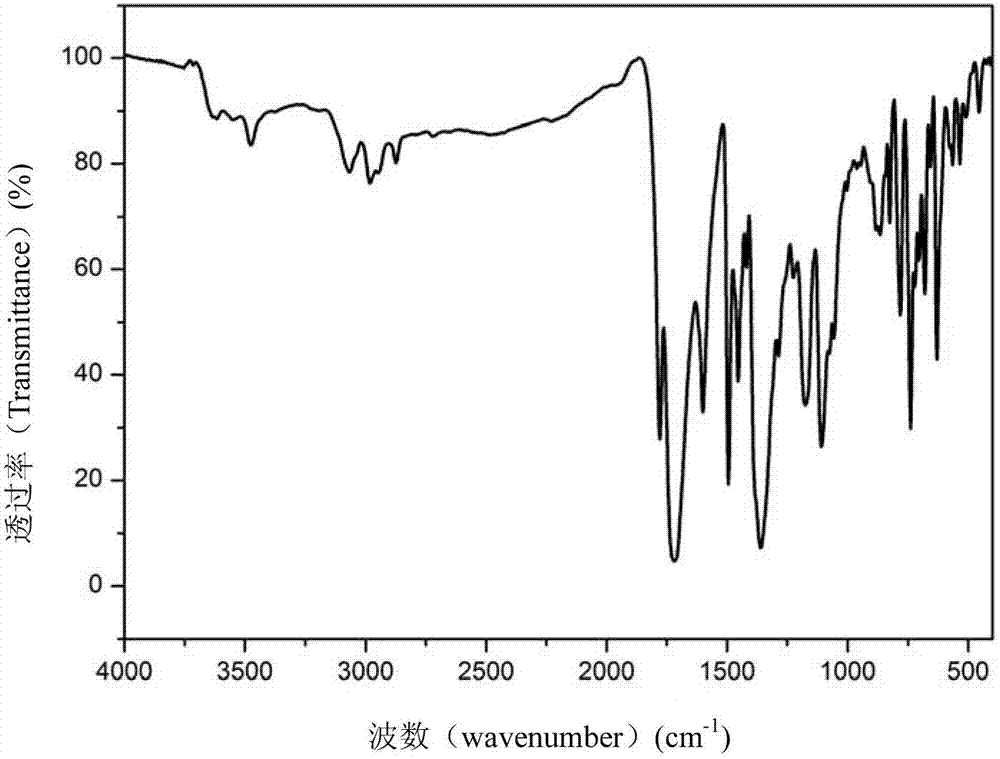

Embodiment 3

[0091] 1) Add 29 parts of α-BPDA, 37 parts of absolute ethanol, and 29 parts of anhydrous tetrahydrofuran into a three-neck flask equipped with a mechanical stirrer, a spherical reflux condenser and a thermometer, and heat and reflux for 3 hours under stirring to obtain a uniform phase solution.

[0092] 2) Add 11 parts of NA and 25 parts of absolute ethanol into a single-necked flask equipped with an electromagnetic stirring device and a spherical reflux condenser, and heat for 3 hours under stirring to obtain a homogeneous solution. After cooling to room temperature, this solution was added to the solution in step 1) cooled to room temperature, and 14 parts of p-PDA and 0.13 parts of isoquinoline were added, and heated under reflux and stirred for 15 minutes under nitrogen protection to obtain a homogeneous solution . After cooling to room temperature, add 0.22 parts FSO-100, stirred at room temperature for 20 minutes under the condition of nitrogen protection, to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com