Patents

Literature

241results about "Working-up pitch/asphalt/bitumen by melting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

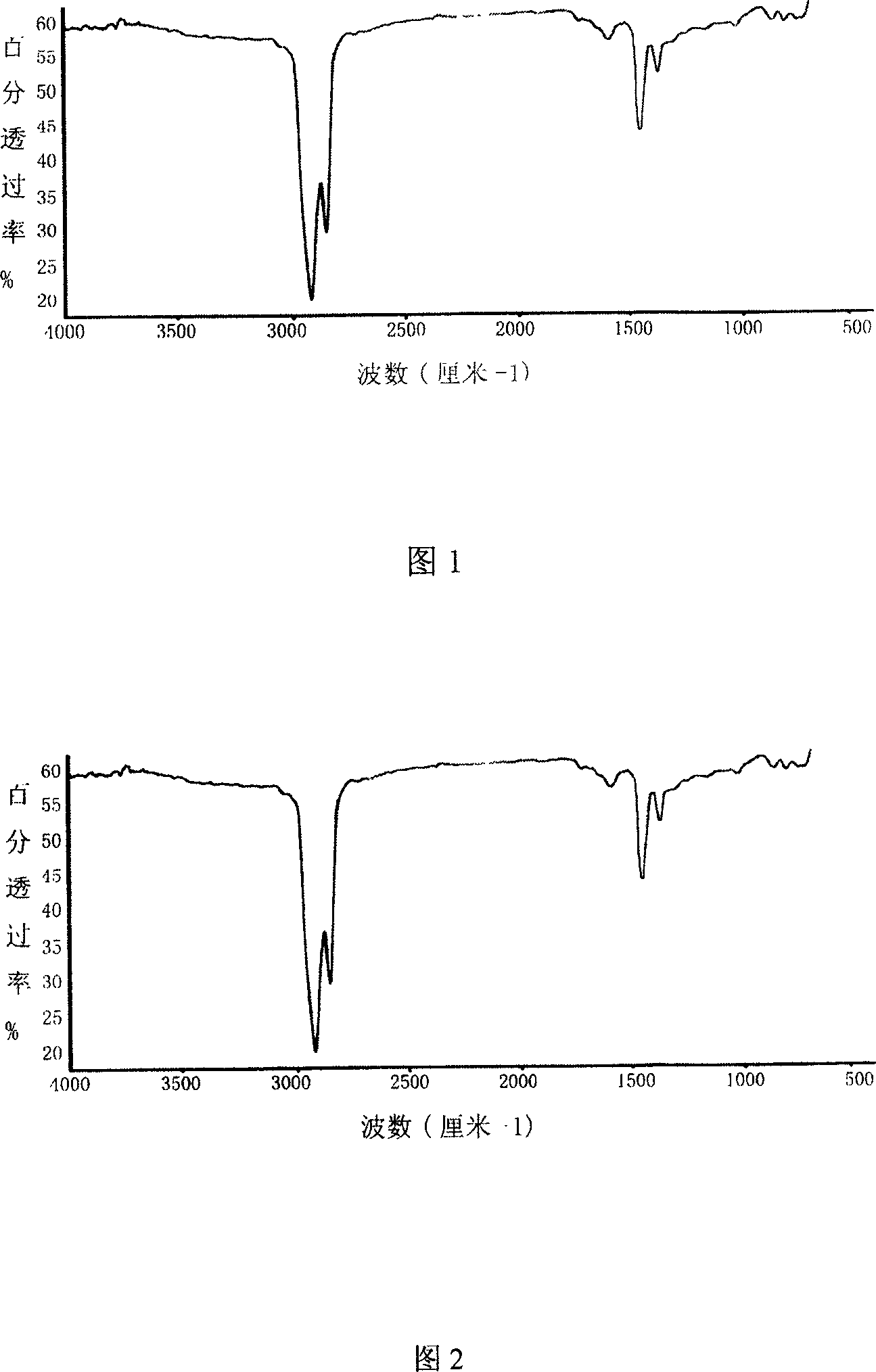

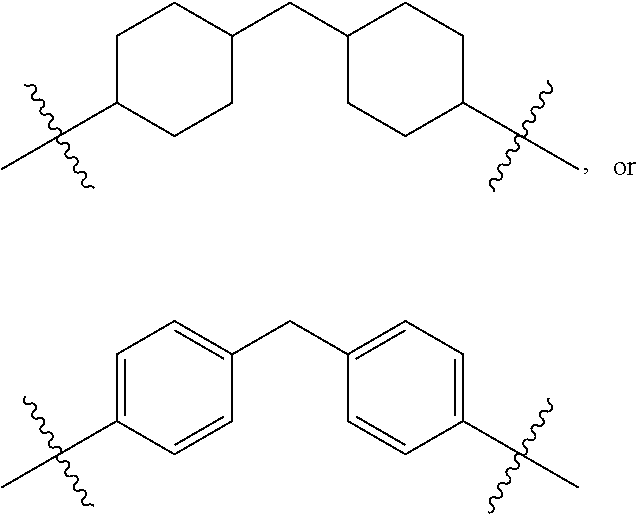

Thermosetting epoxy asphalt material, preparation method and its dedicated compatibilizer

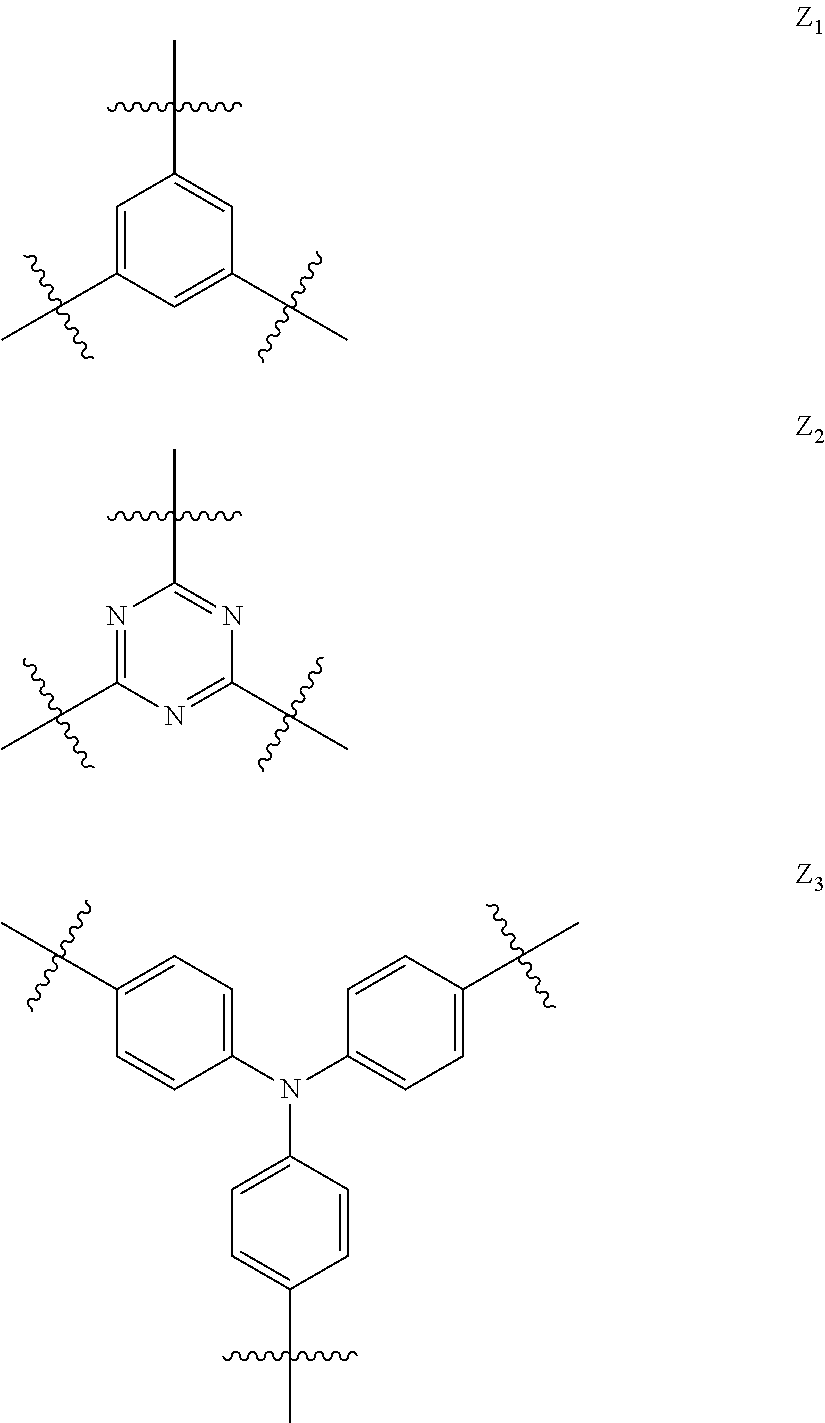

InactiveCN1952012AEasy to operateLow costWorking-up pitch/asphalt/bitumen by meltingBuilding insulationsTarCarbon chain

The invention discloses a heat-solidity epoxy tar material, preparing method and specific dissolving-reinforcing agent, which comprises the following steps: allocating the raw material with 100% tar, 20-40% epoxy resin, 20-40% hardener and 20-60% heat-solidity epoxy tar; blending evenly; heating to 80-90 deg.c; stirring evenly; solidifying under 100-120 deg.c for 0.5-7h; obtaining the product. The invention provides a specific dissolving-reinforcing agent of heat-solidity epoxy tar material, which contains weak-polarity high-grade fat carbon chain and strong-polarity Mannish alkaline or compound of epoxy resin and polyol.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

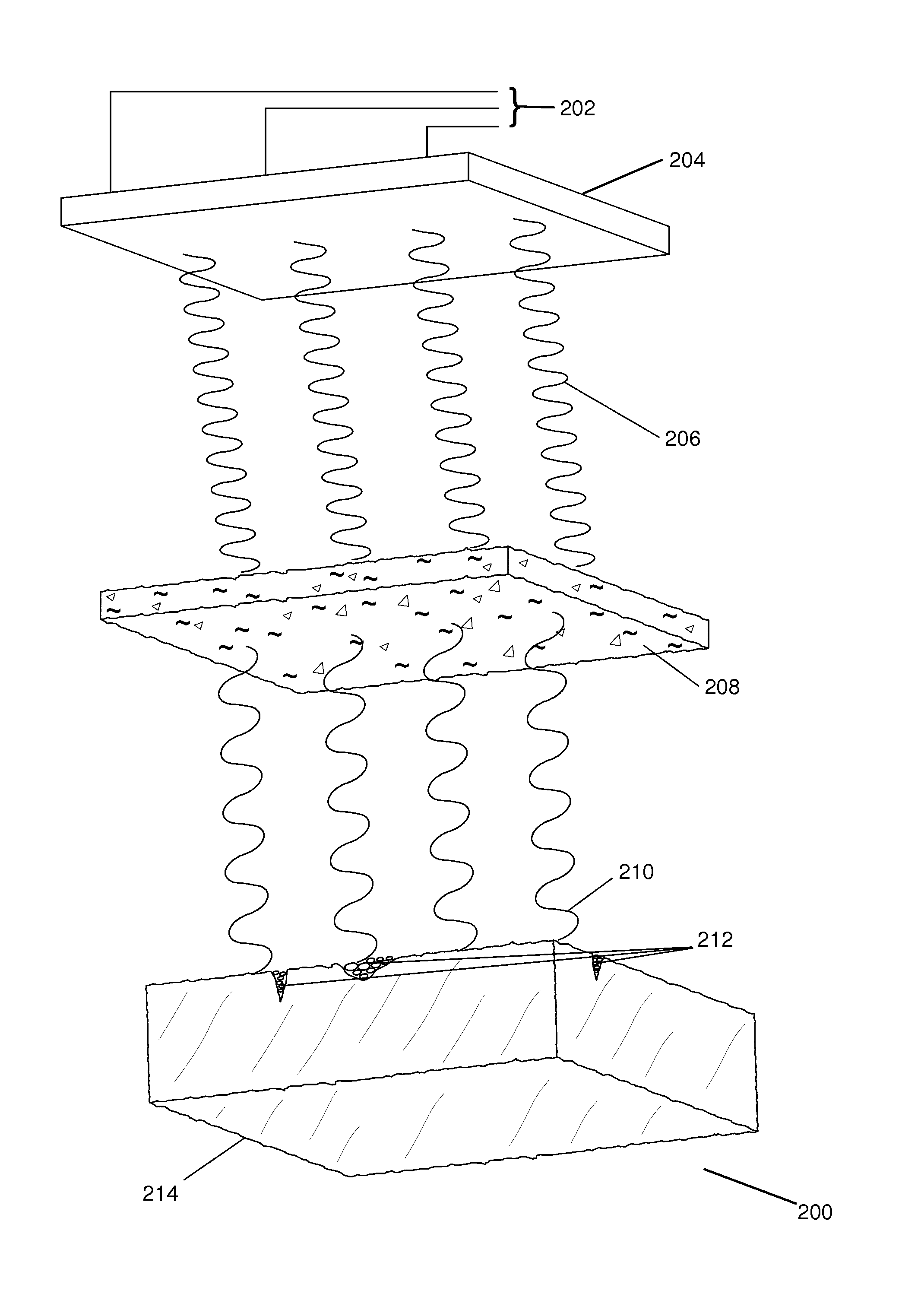

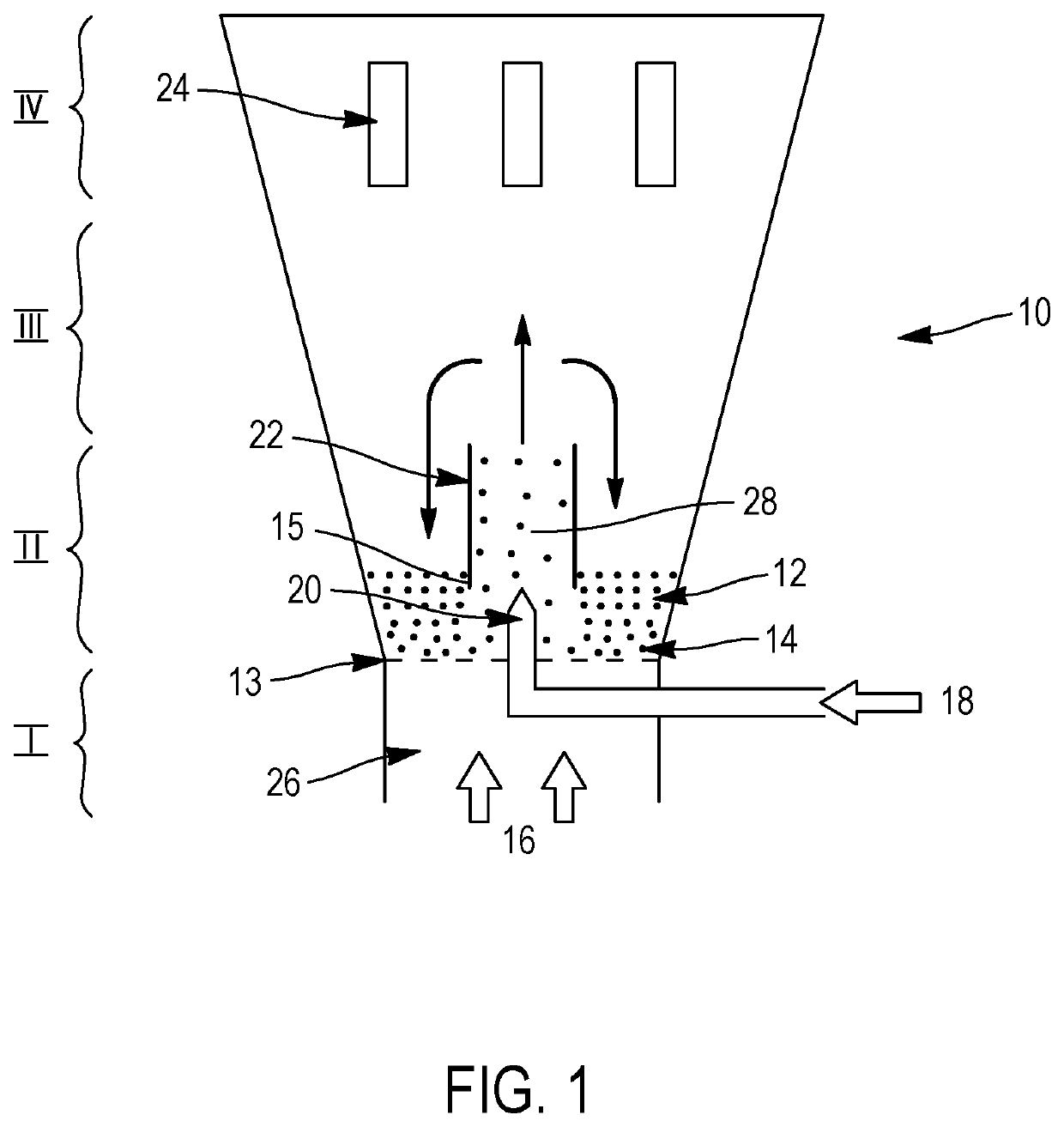

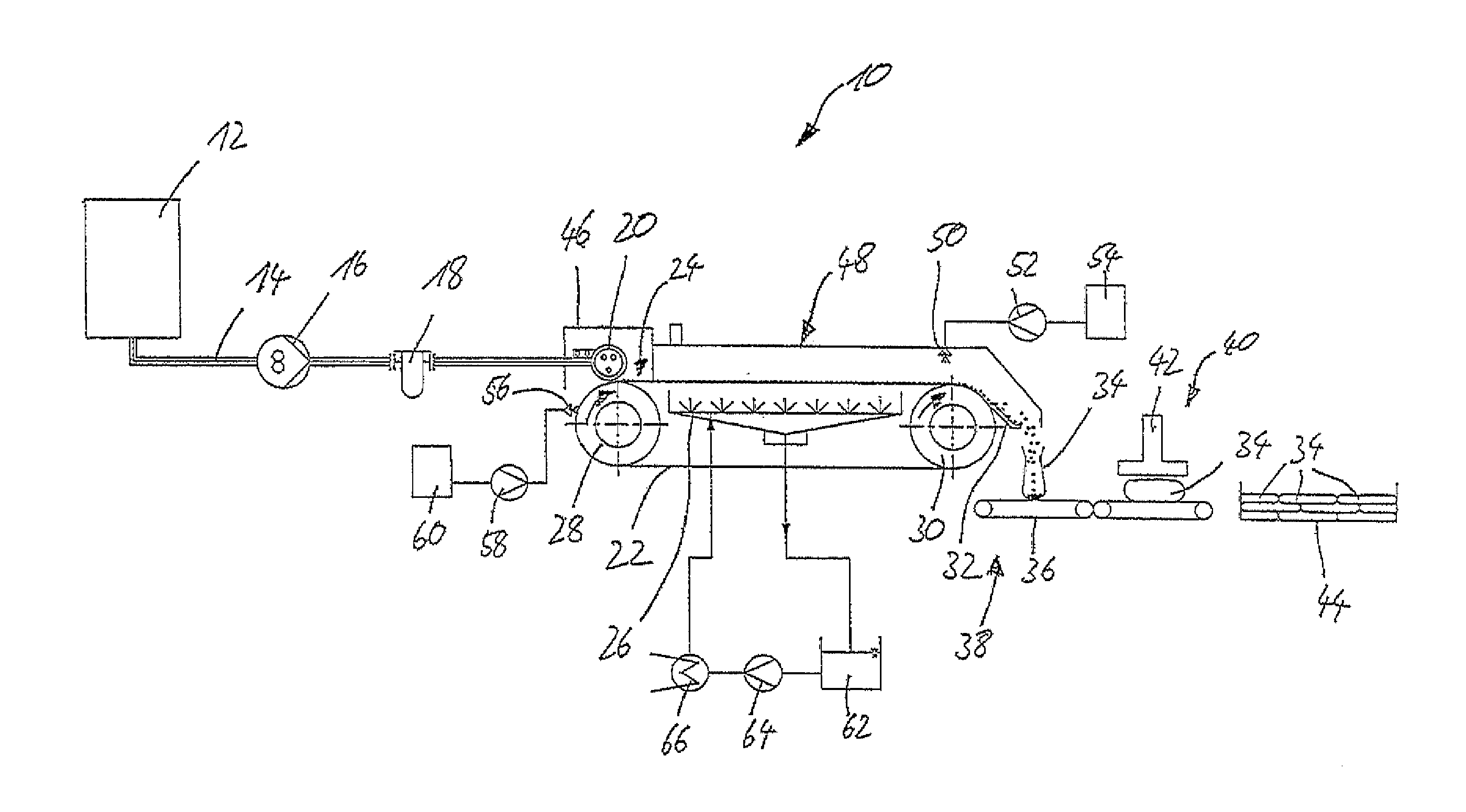

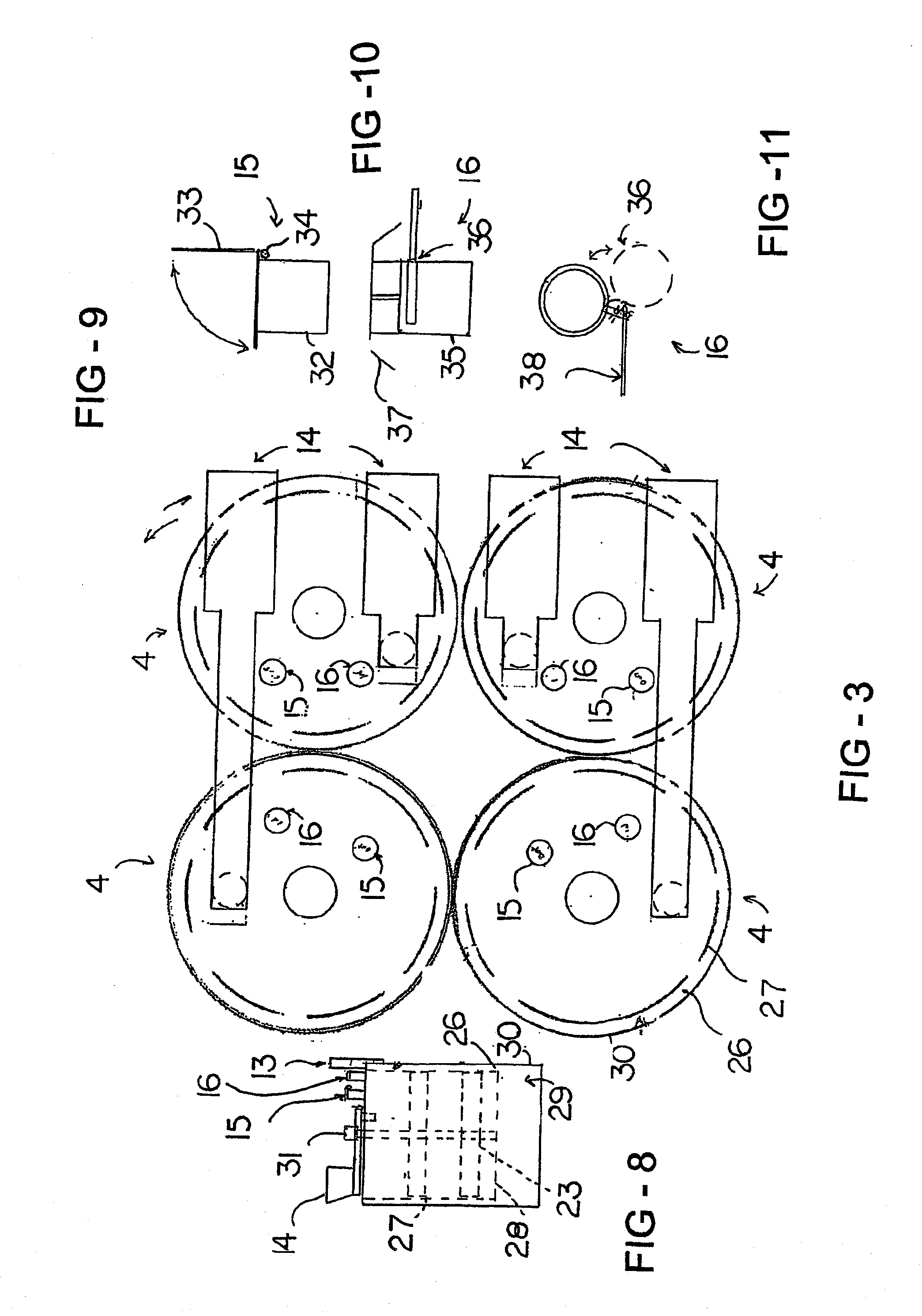

Pavement repair system utilizing solid phase autoregenerative cohesion

ActiveUS8992118B2Long and longer useful lifePaving propertyPaving reinforcementsIn situ pavingsOligomerEmulsion

A method for repairing an aged or damaged asphalt pavement is provided. The method involves preparing a surface of the aged or damaged asphalt pavement by filling in deviations from a uniform surface plane with dry aggregate and compacting the dry aggregate; applying a reactive asphalt emulsion to the prepared surface; and passing an emitter over the prepared pavement, wherein the emitter generates electromagnetic radiation having a wavelength of from 2-5 mm that penetrates into the pavement to a depth of at least 2 inches. The asphalt pavement is repaired by disturbing voids and interstices in the damaged pavement without dehydrogenation of the asphalt, such that oligomers present in the aged asphalt are linked together into longer polymer chains to improve ductility of the aged asphalt.

Owner:COE WILLIAM B

Asphalt shingle recycling system and method

InactiveUS20100064937A1Improve consistencySmall particle sizeSolid waste disposalPlastic recyclingAsphalt shingleEngineering

A method of recycling asphalt roofing material is provided. The asphalt roofing material is delivered into a treatment chamber of a processor. A heat source is provided to the treatment chamber. Heat energy is transferred from the heat source to the asphalt roofing material to produce a heated product, and the heated product is removed from the treatment chamber.

Owner:HARMON THOMAS B +1

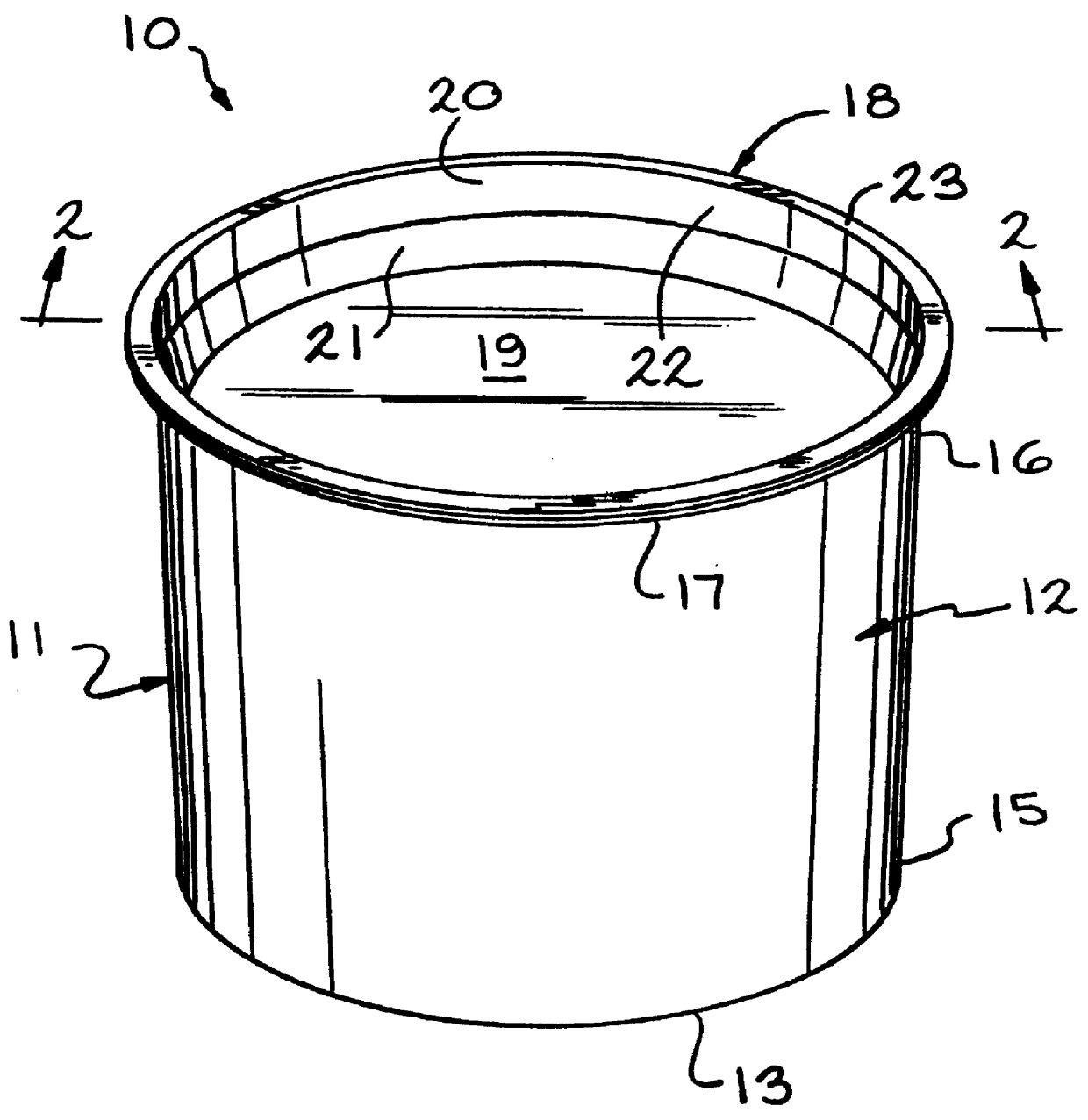

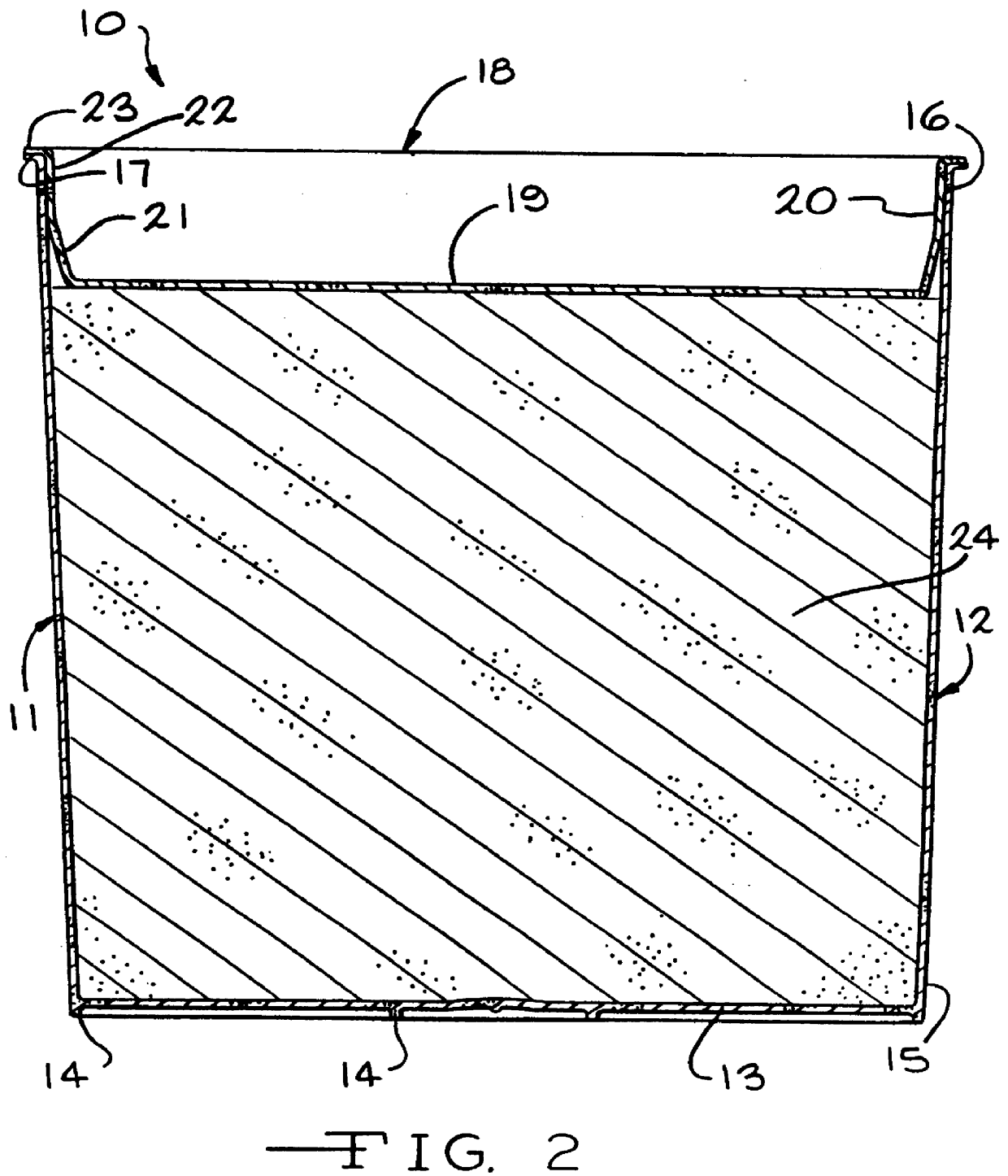

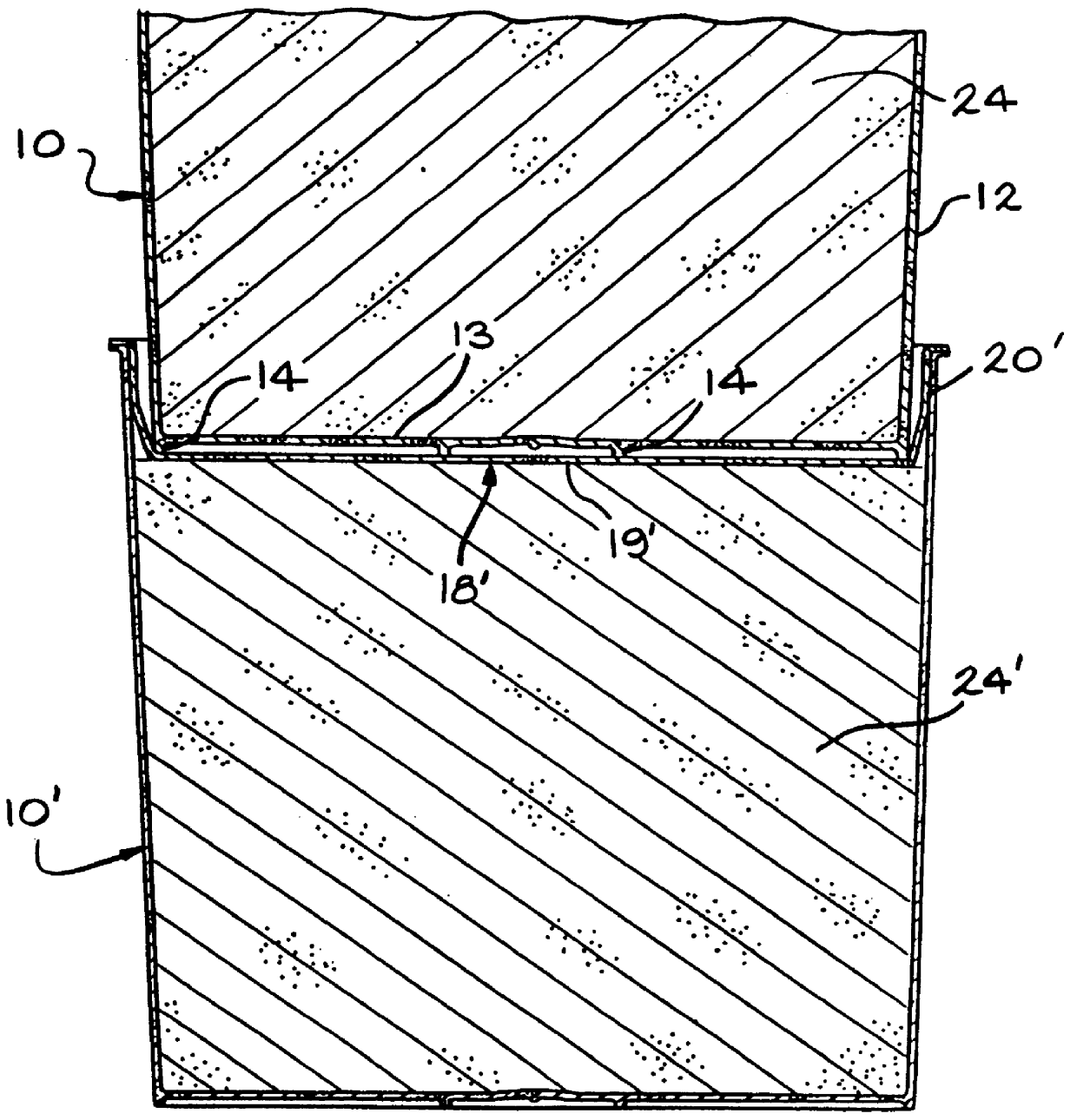

Consumable asphalt containers and method of reducing fumes from a kettle of molten asphalt

InactiveUS6107373AAvoid problemsReduce fumingFlexible coversIn situ pavingsParticulatesAdditive ingredient

A consumable container is molded from a composition comprising 40 to 90 weight % of an asphalt and 10 to 60 weight % of a polymer material, which advantageously can include a first polymer such as PP that imparts heat resistance and a second polymer such as EVA that imparts toughness and impact resistance. This molded asphalt / polymer material preferably has an unnotched Izod impact strength of at least 2 joules. The container is consumable-it can be melted along with roofing asphalt held in the container without adversely affecting the properties of the asphalt and without requiring undue mixing. The composition also can be used to reduce fumes normally emitted from a kettle of molten asphalt, e.g., as measured by a reduction of the visual opacity of the fumes by at least 25%, a reduction of the hydrocarbon emissions of the fumes by at least 20%, or a reduction of the total suspended particulates emissions of the fumes by at least 15%. The container may be used, e.g., to hold roofing or paving asphalt or a recyclable petroleum-derived material, such as used motor oil. In one embodiment, the container composition may include one or more ingredients to improve the quality of paving-grade asphalt

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

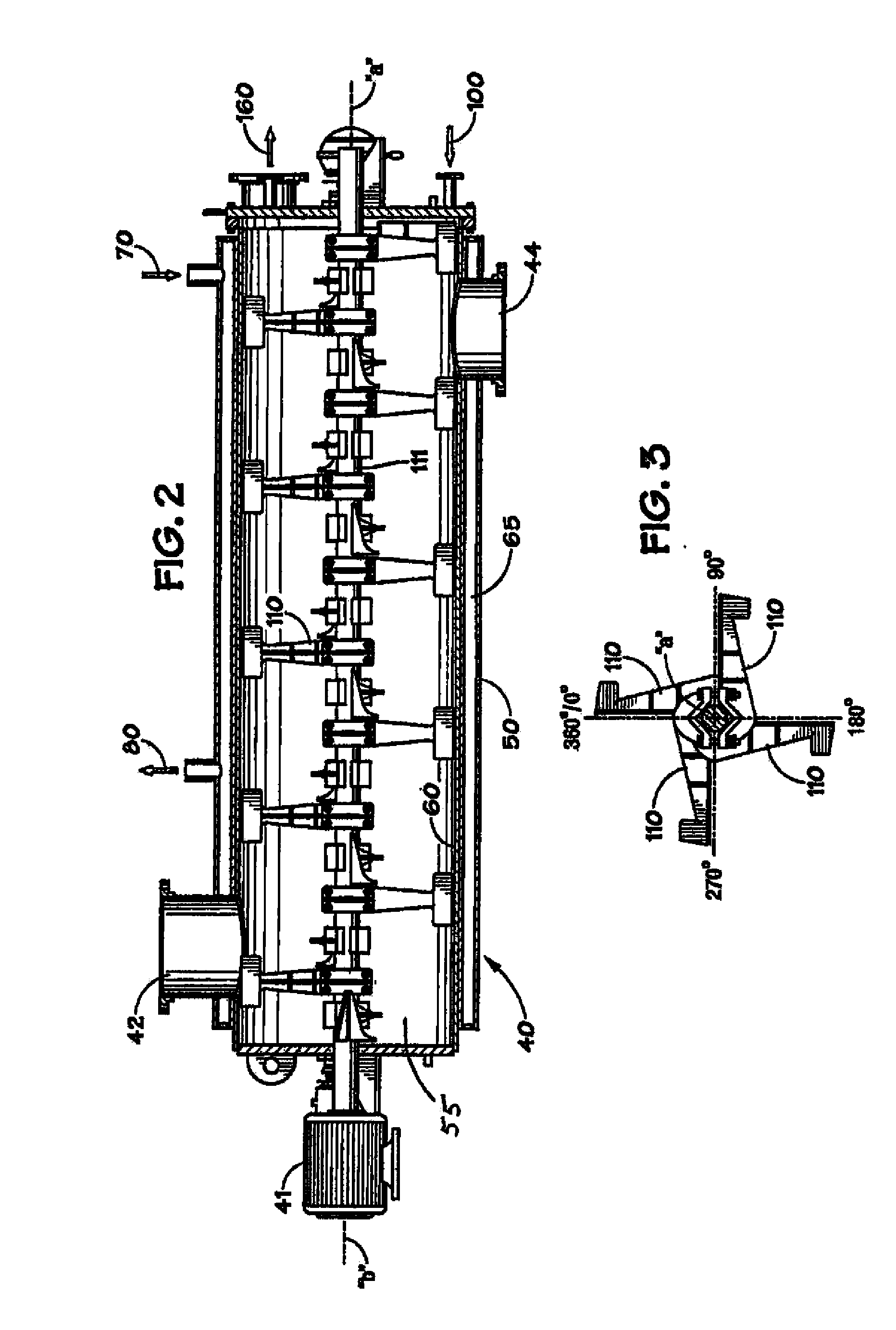

Devices and methods for heating pipes or tubing

InactiveUS20090092941A1Efficient meltingIncrease the areaCombustible gas coke oven heatingOther heat production devicesBiomedical engineering

Owner:PERRY WARREN KEITH +1

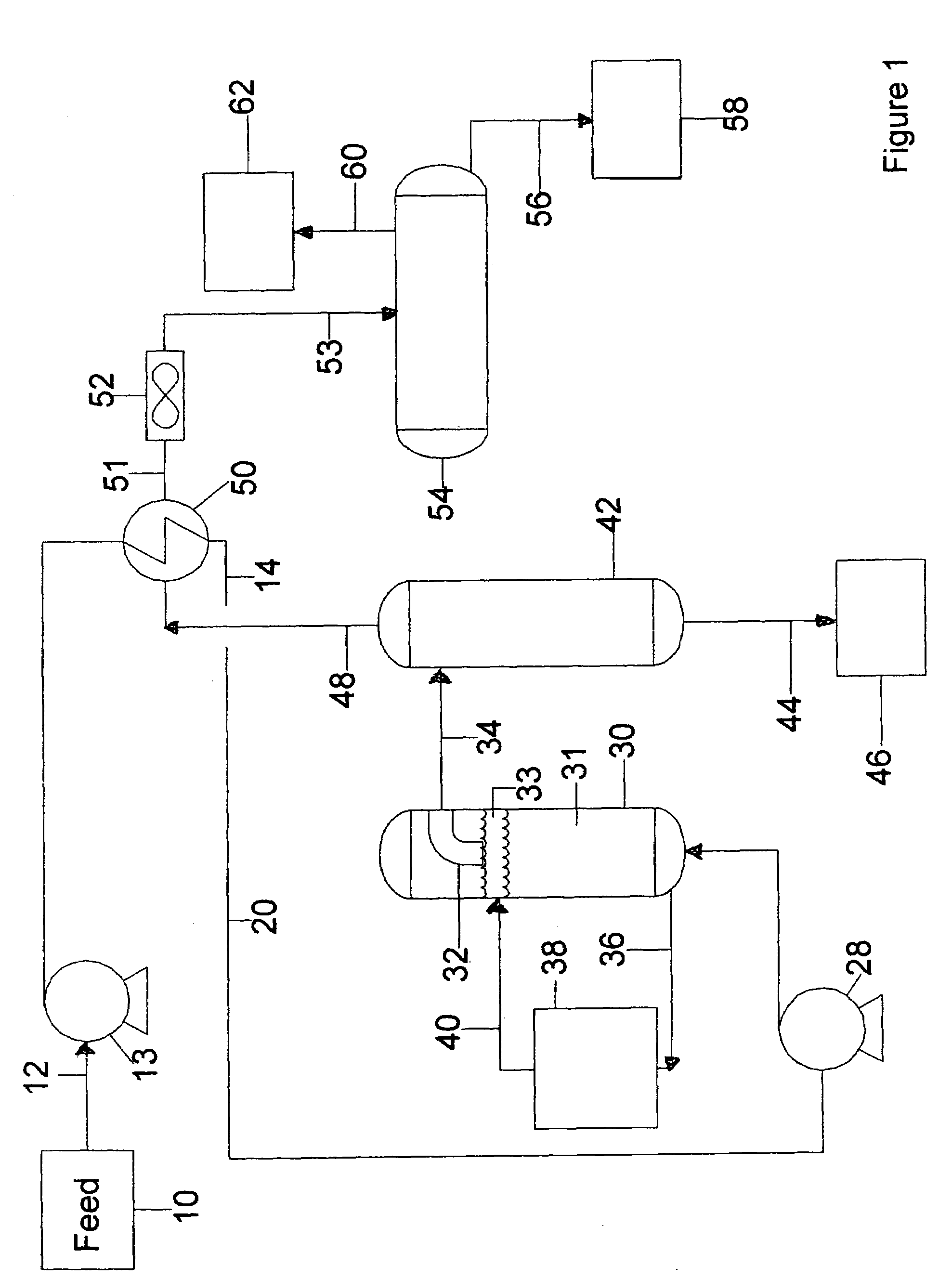

Preparation method and device of high-softening-point asphalt, high-softening-point asphalt, and binding agent prepared from high-softening-point asphalt

ActiveCN102876344AAvoid uncontrollableShort reaction timeWorking-up pitch/asphalt/bitumen by chemical meansBituminous material adhesivesNarrow rangeAsphalt

The invention provides a preparation method of high-softening-point asphalt, which comprises the following steps: introducing modified asphalt into a single container, and introducing inert gas into the single container, wherein the single container is sequentially provided with at least three independent heating zones from top to bottom, an independent heater is arranged in each heating zone, the heating temperatures gradually increase, and the reaction pressure is 0.03-0.05 MPa; and after heating the modified asphalt to the target temperature, keeping the temperature for 6-18 hours, thereby obtaining the high-softening-point asphalt. The invention also provides a preparation device, a prepared high-softening-point asphalt and a binding agent prepared from the high-softening-point asphalt. The invention can control the softening point of the modified asphalt within a narrow range, so that the modified asphalt has more stable quality, and the high-softening-point asphalt and binding agent with high softening point and high fixed carbon content can be prepared.

Owner:山东杰富意振兴化工有限公司

Preparation method of high modulus asphalt-based carbon fiber

ActiveCN106544758ARich sourcesLow costWorking-up pitch/asphalt/bitumen by chemical meansWorking-up pitch/asphalt/bitumen by meltingFiberCarbon fibers

The invention relates to a preparation method of a high modulus asphalt-based carbon fiber. The preparation method comprises (1) carrying out high-pressure hydrogenation pretreatment on catalytic slurry oil under hydrogen pressure of 12-18Mpa at a reaction temperature of 420-450 DEG C for 1-3h to obtain a hydrogenation product, (2) carrying out vacuum distillation to separate a fraction at a temperature of greater than or equal to 400 DEG C and carrying out a polycondensation reaction process in an inert gas or nitrogen atmosphere at a reaction temperature of 460-500 DEG C for 6-8h to obtain a primary polycondensation product, (3) feeding nitrogen into the primary polycondensation product at a nitrogen flowing rate of 5-8L / (s. kg) under normal pressure and carrying out a reaction process at a reaction temperature of 450-500 DEG C for 4-6h to obtain high quality mesophase pitch and (4) carrying out melt spinning on the mesophase pitch and carrying out pre-oxidation, carbonization and graphitization to obtain the high modulus carbon fibers.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Asphalt shingle recycling system and method

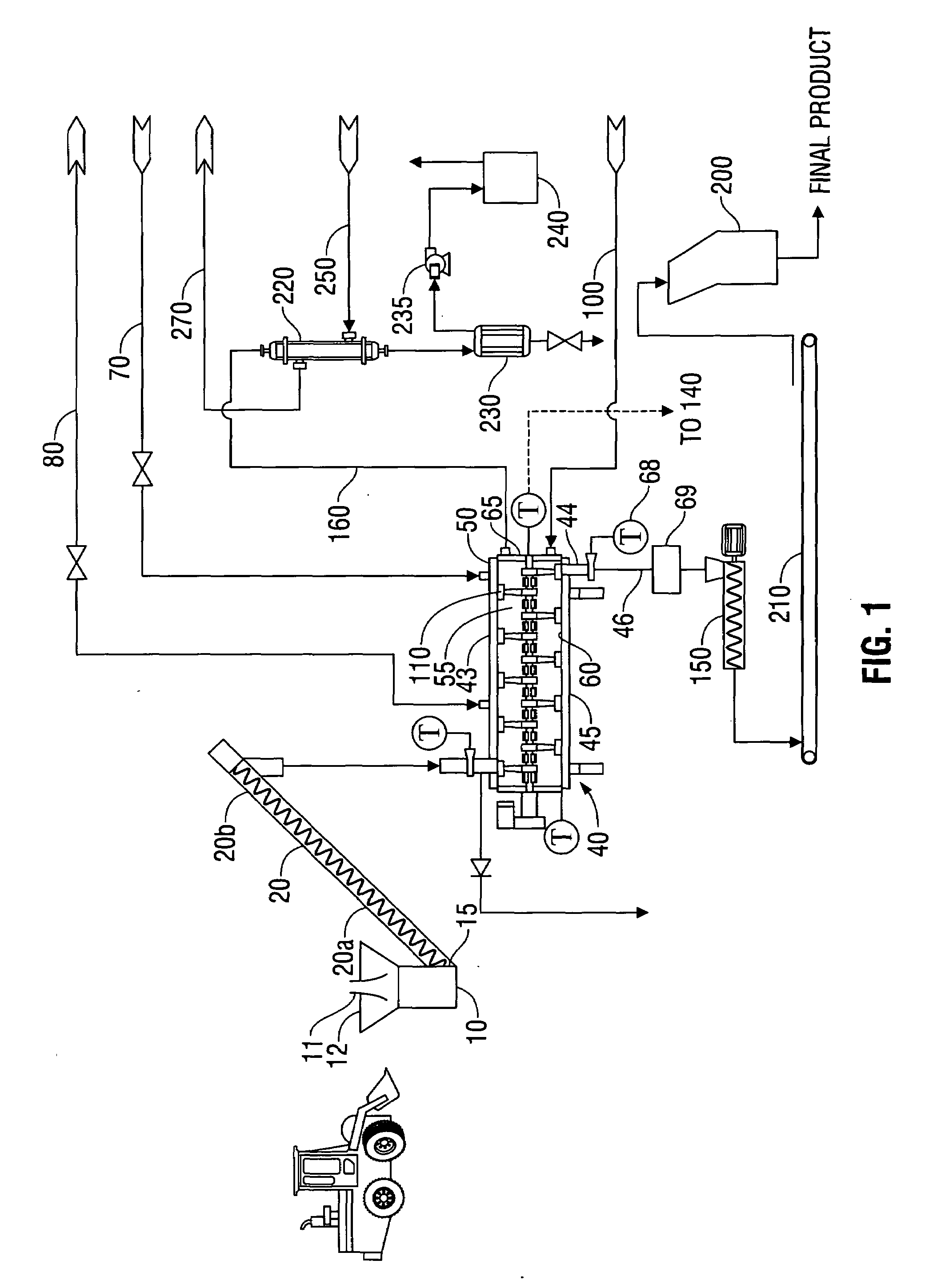

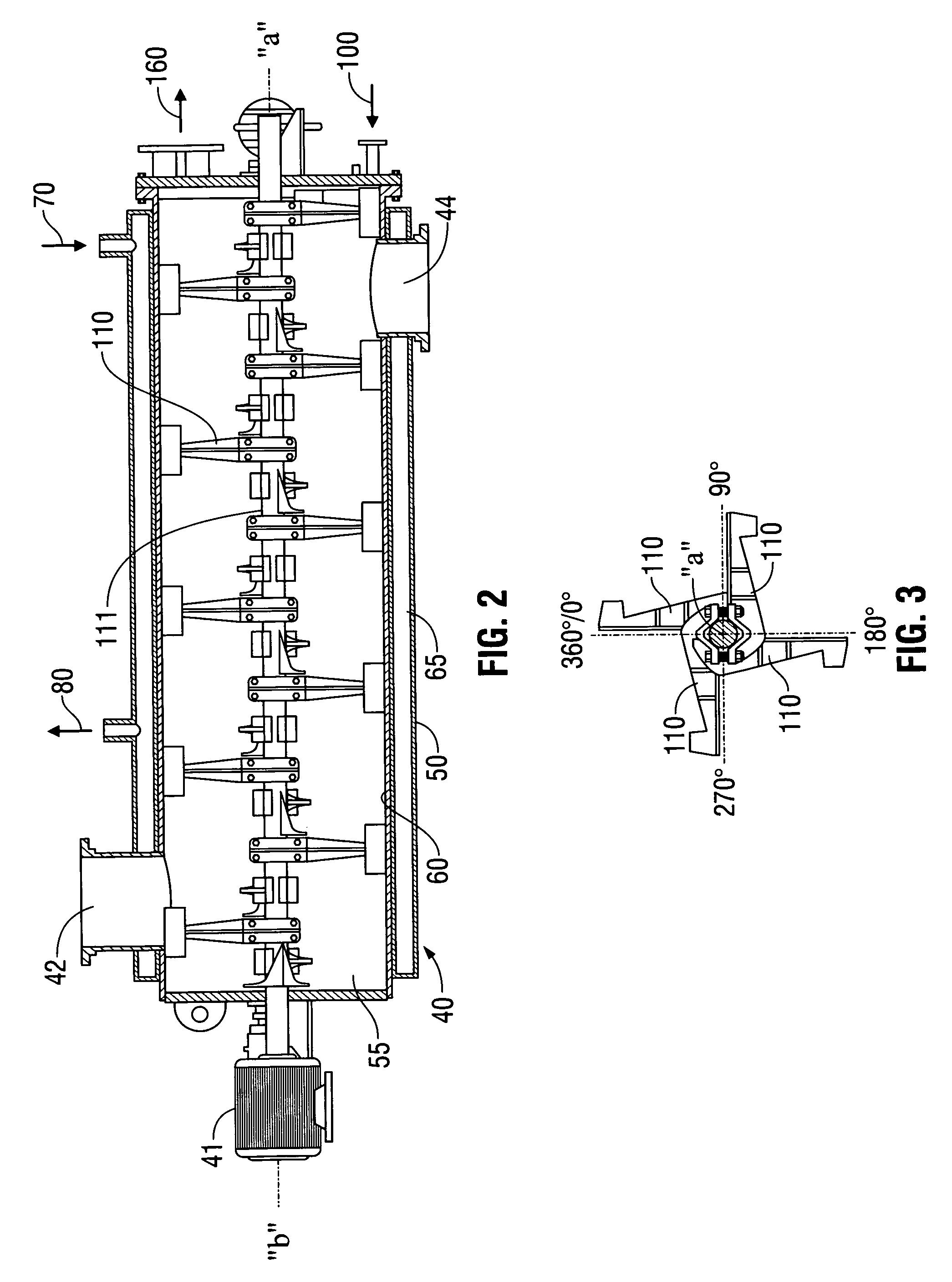

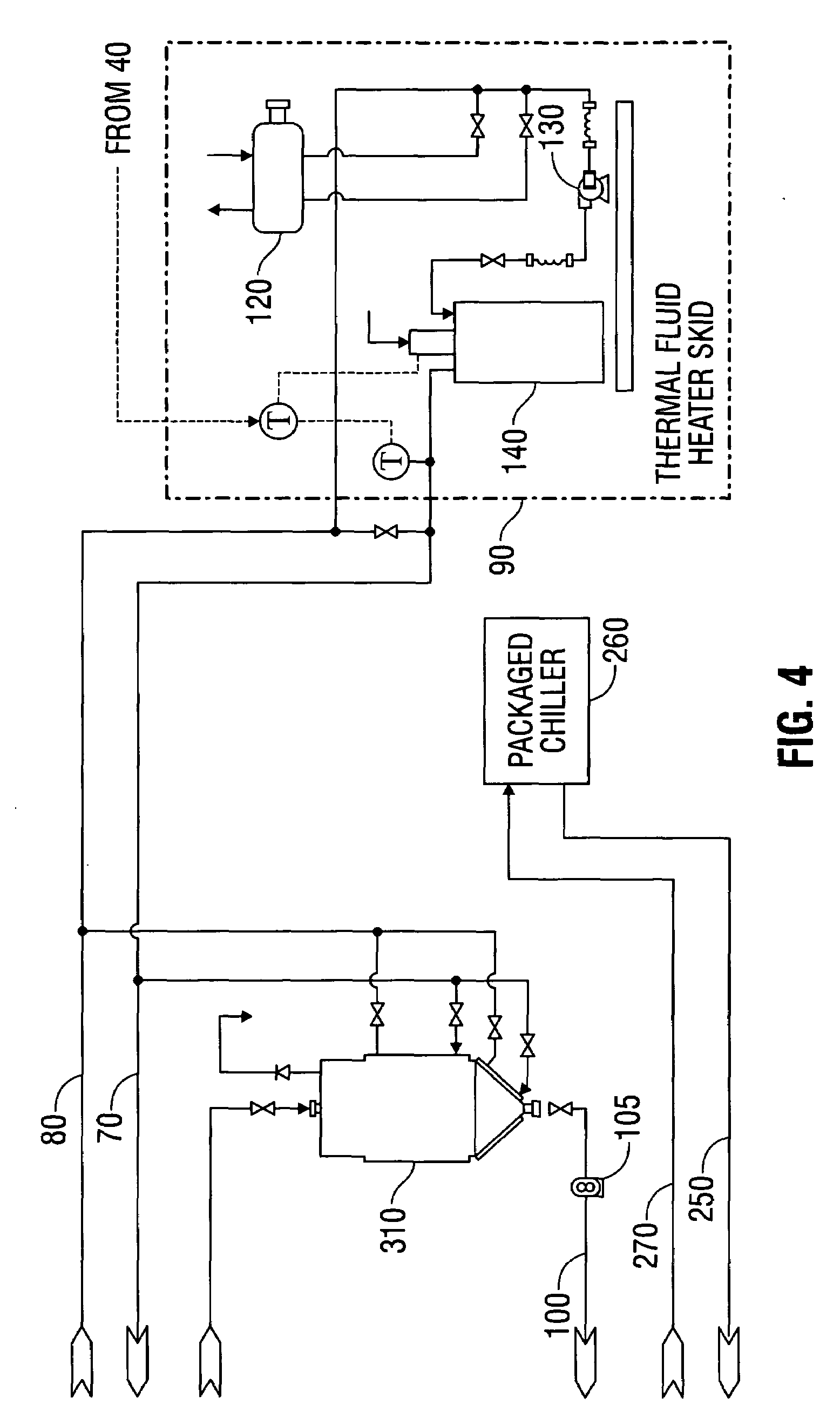

ActiveUS20090229491A1Small particle sizeImprove consistencySolid waste disposalPlastic recyclingAsphalt shingleSolid particle

The asphalt roofing material is delivered into a treatment chamber of a processor. Hot oil is passed through a jacket surrounding the treatment chamber. Heated asphalt forms a hot solid and / or a liquefied slurry. The hot solid and / or the liquefied slurry is then removed from the treatment chamber. The asphalt roofing material in the treatment chamber can be agitated to promote mixing. The asphalt is heated to a temperature in the range from 200 degrees Fahrenheit to 650 degrees Fahrenheit within the treatment chamber. The solid and / or liquefied slurry is milled after it has been removed from the treatment chamber. The solid and / or the liquefied slurry is cooled after it exits the treatment chamber, preferably to a temperature in the range of approximately 90 degrees Fahrenheit to 110 degrees Fahrenheit. The hot solid and / or the liquefied slurry is passed through a hammer mill after the hot solid and / or the liquefied slurry exits the treatment chamber to reduce the particle size of the solid particles.

Owner:DUPPS

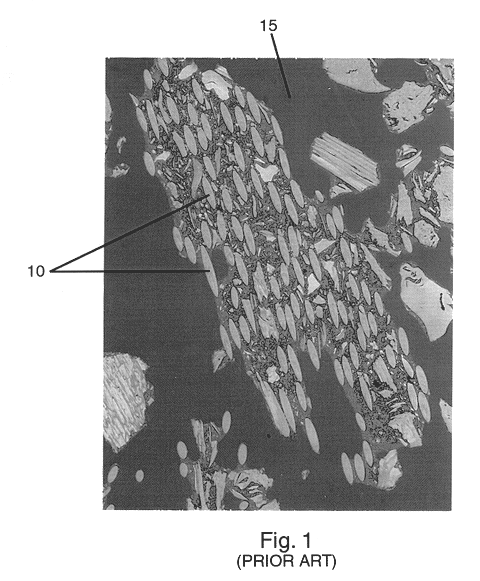

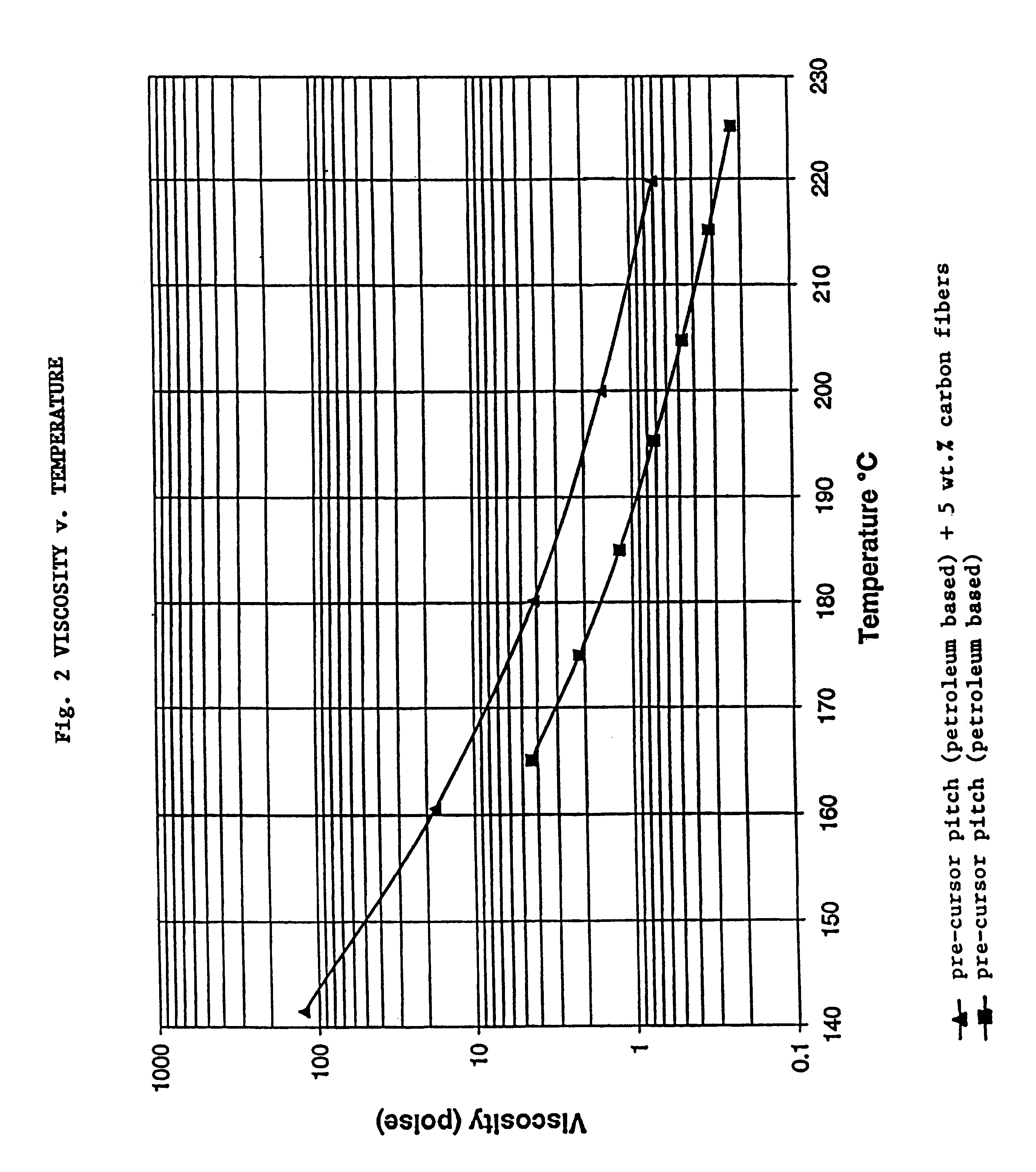

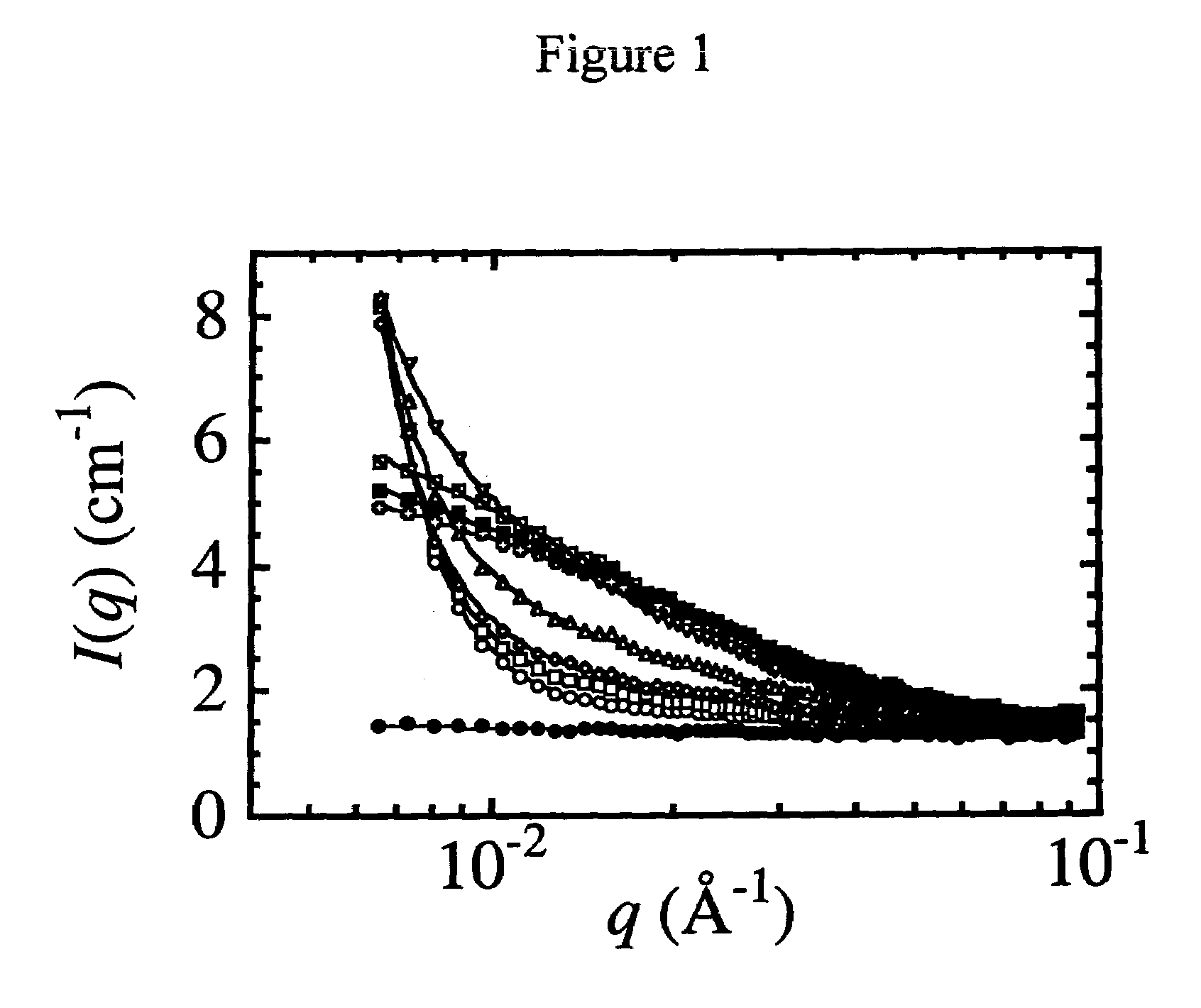

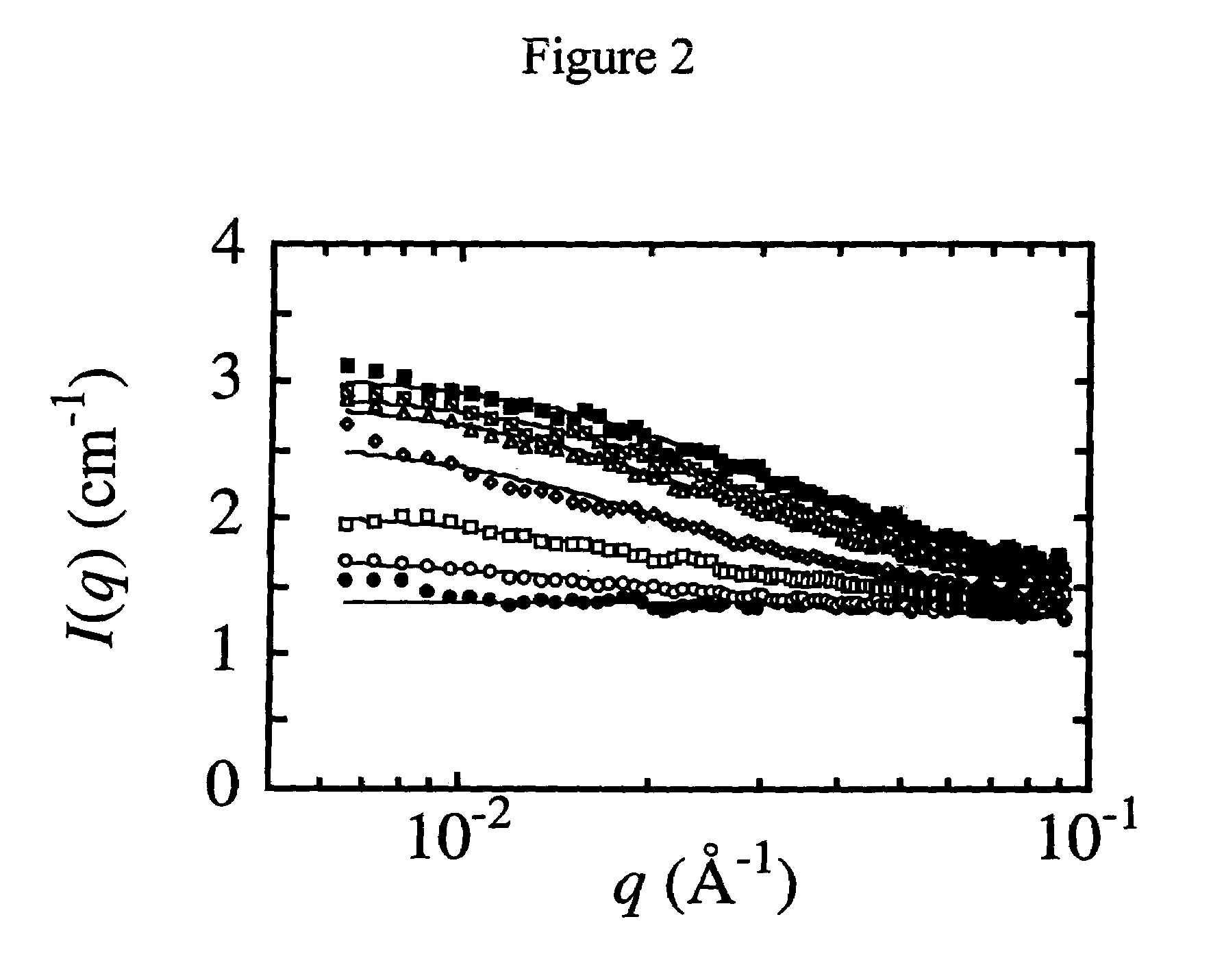

Carbon fiber binder pitch

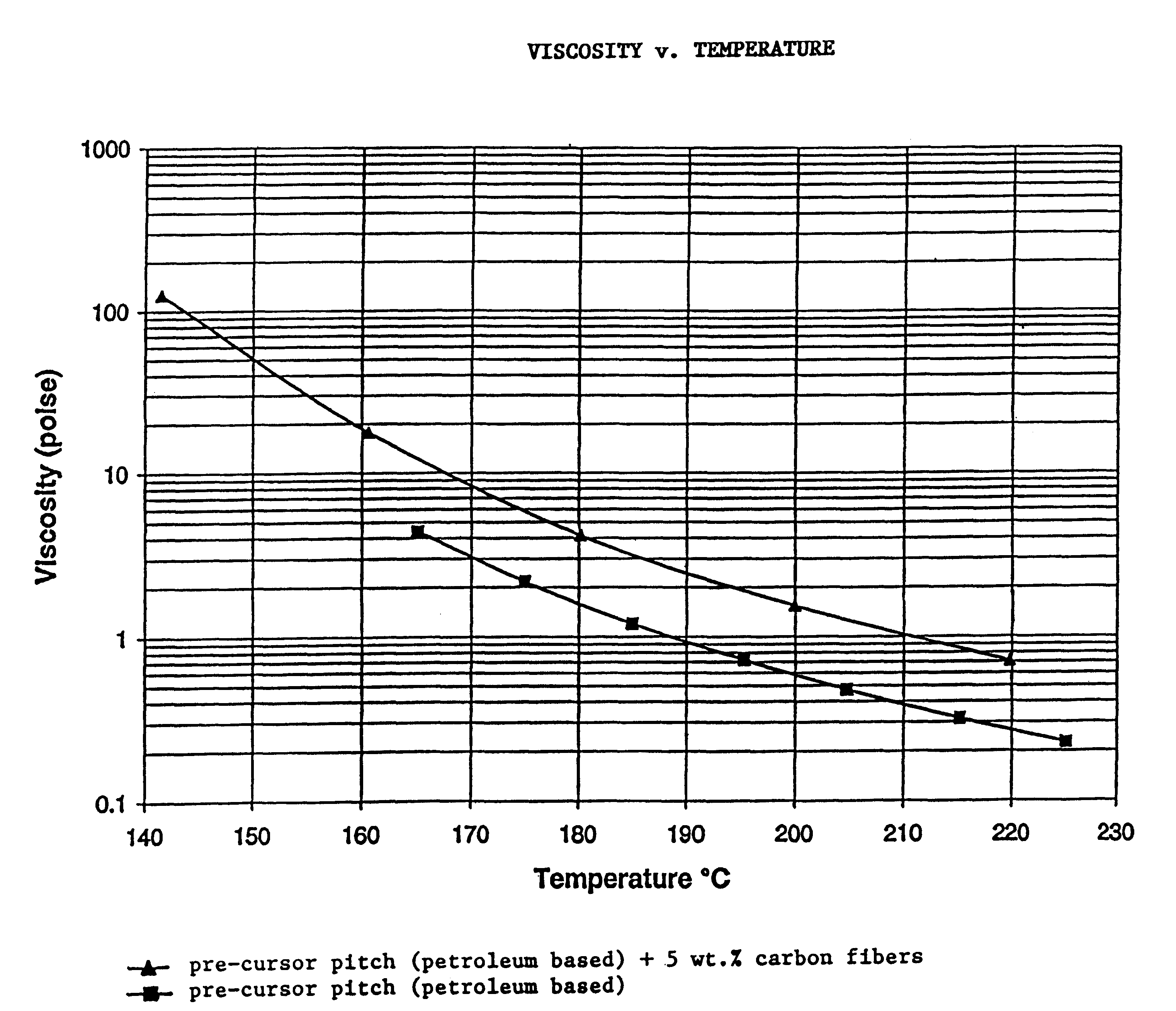

InactiveUS6395220B1Minimal amountCoke ovensWorking-up pitch/asphalt/bitumen by chemical meansGraphite electrodeFiber bundle

Carbon fiber bundles may be dispersed into substantially single mono-filaments in pitch by stirring a mixture of fibers and pitch at a temperature at which the pitch has a viscosity of about 0.1 to about 5 poise. The resulting fiber pitch binder contains about 0.5 to about 10.0 wt. % carbon fibers substantially dispersed as substantially single mono-filaments which are randomly oriented which may then be used directly as a binder for producing carbon bodies, for example, graphite electrodes, pinstock or specialty graphite articles. This unique binder using an economical amount of carbon fibers has the capacity to increase the strength and reduce the coefficients of thermal expansion of the resulting carbon products in more than one direction due to the random orientation of the carbon fibers.

Owner:JPMORGAN CHASE BANK NA

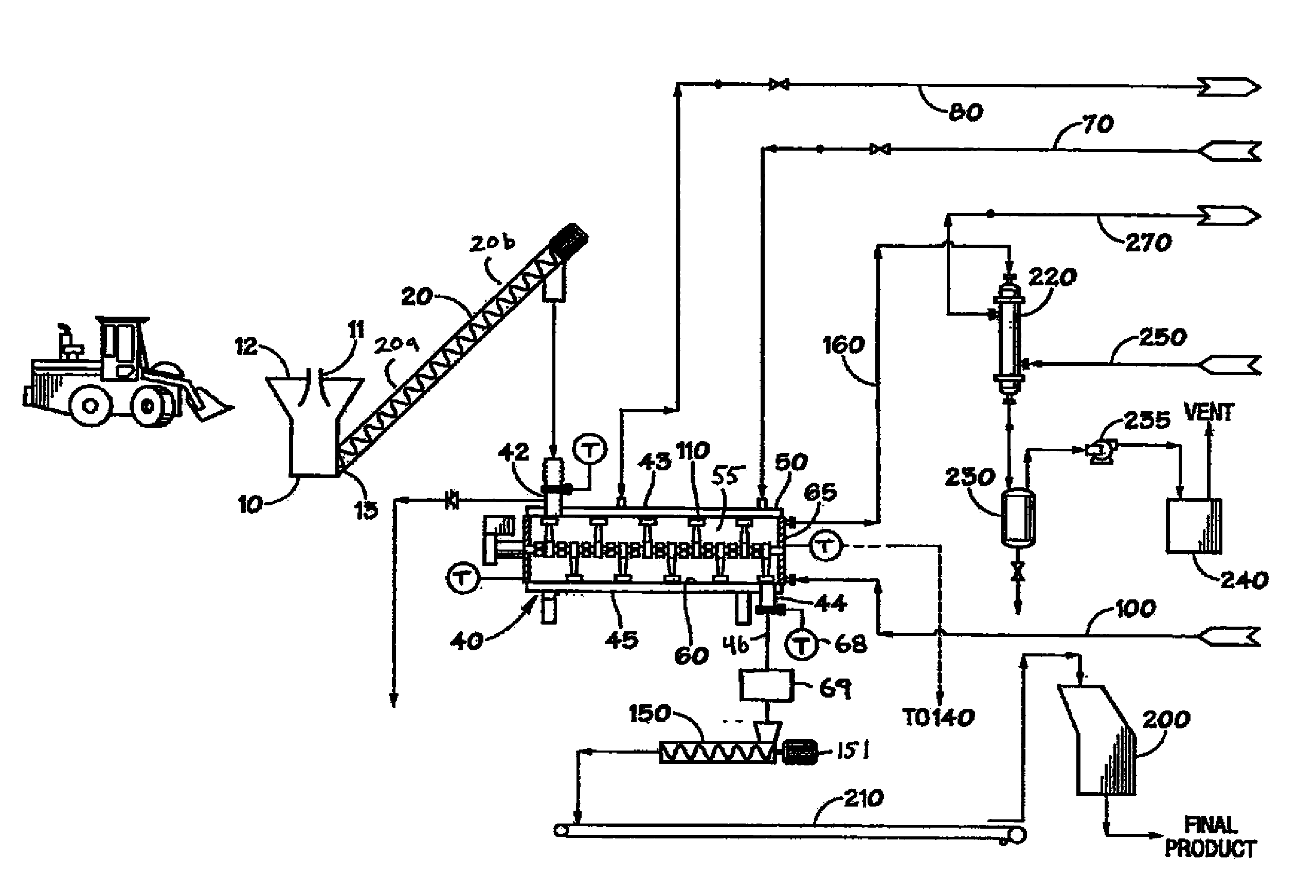

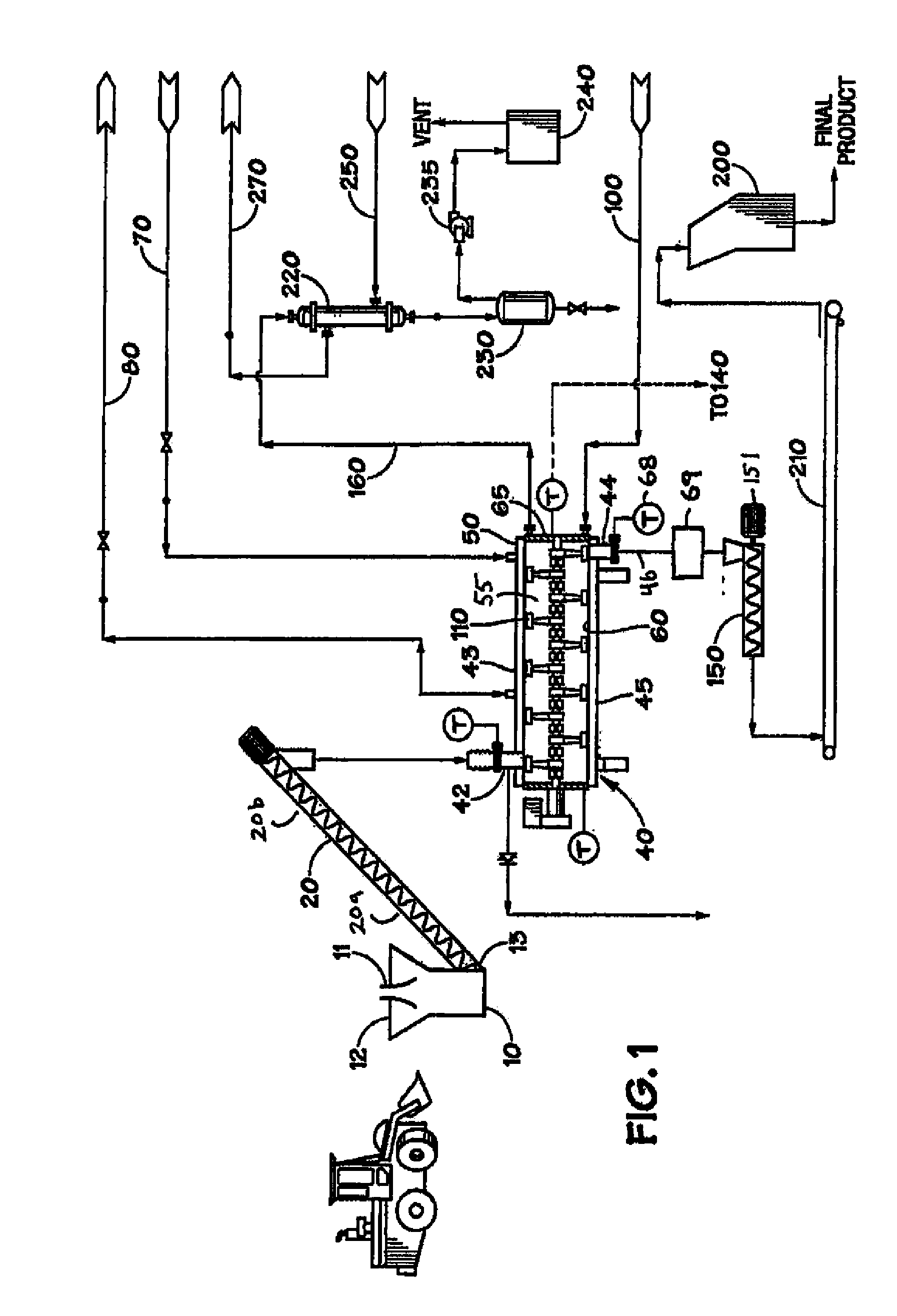

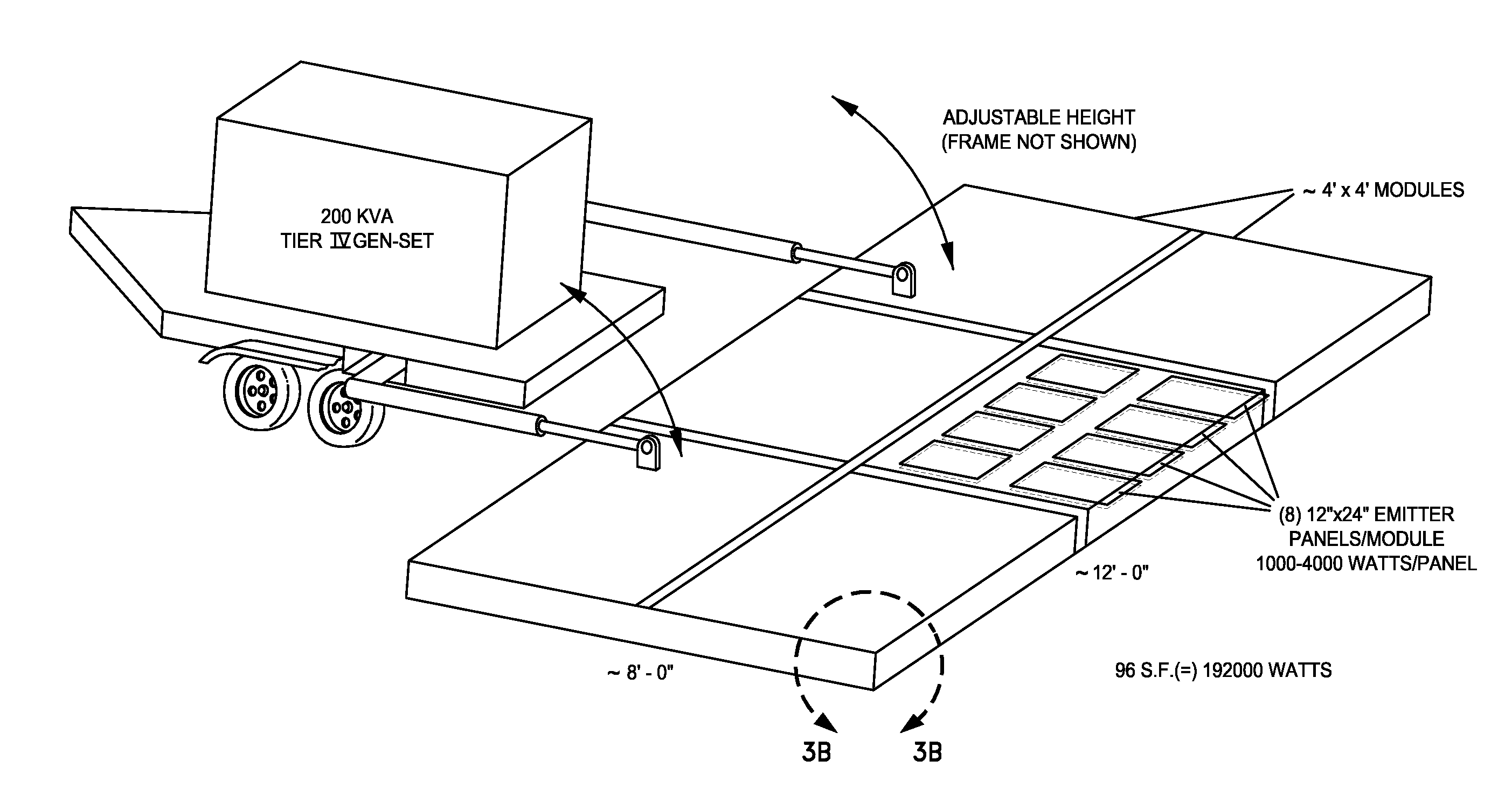

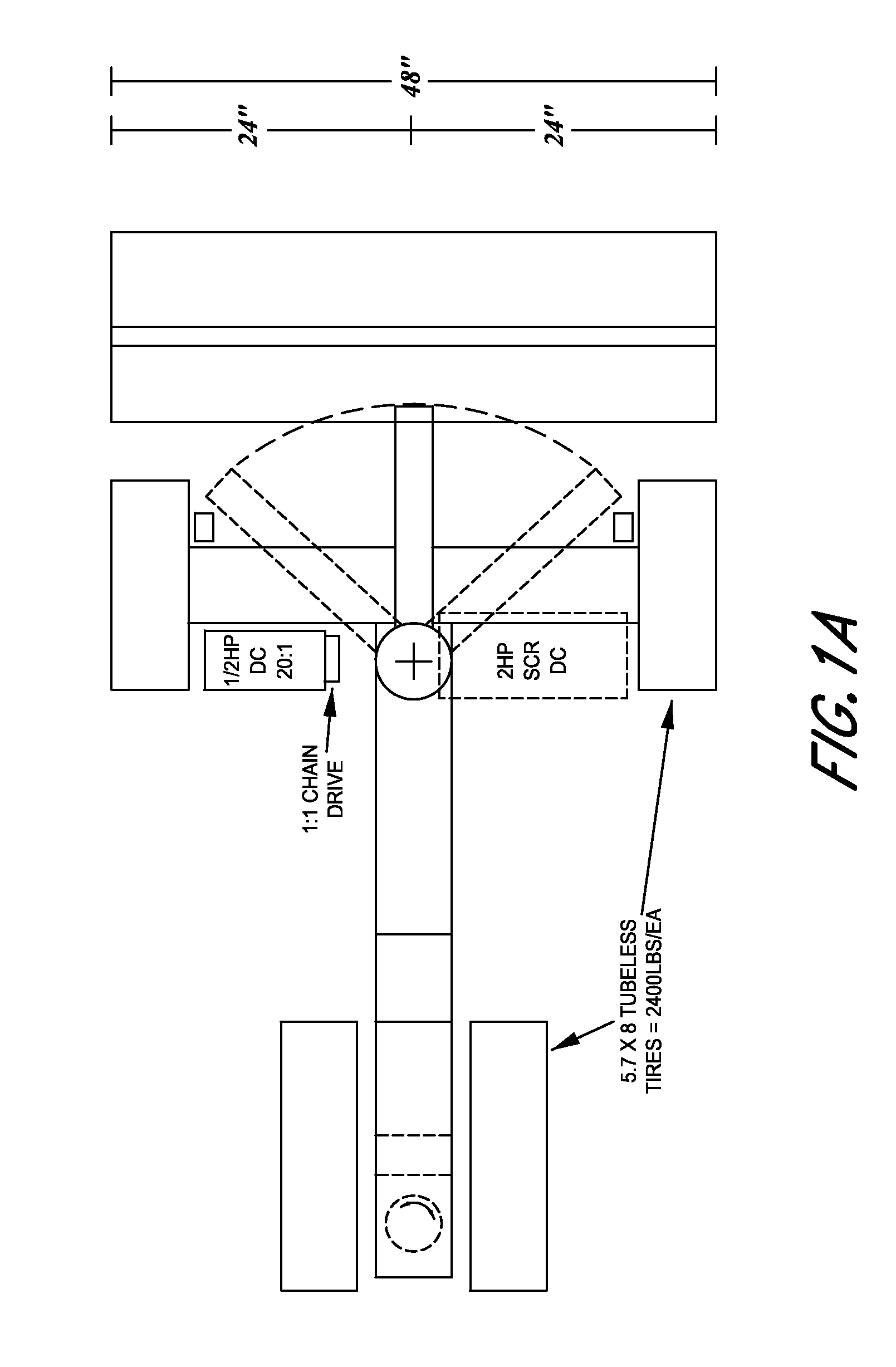

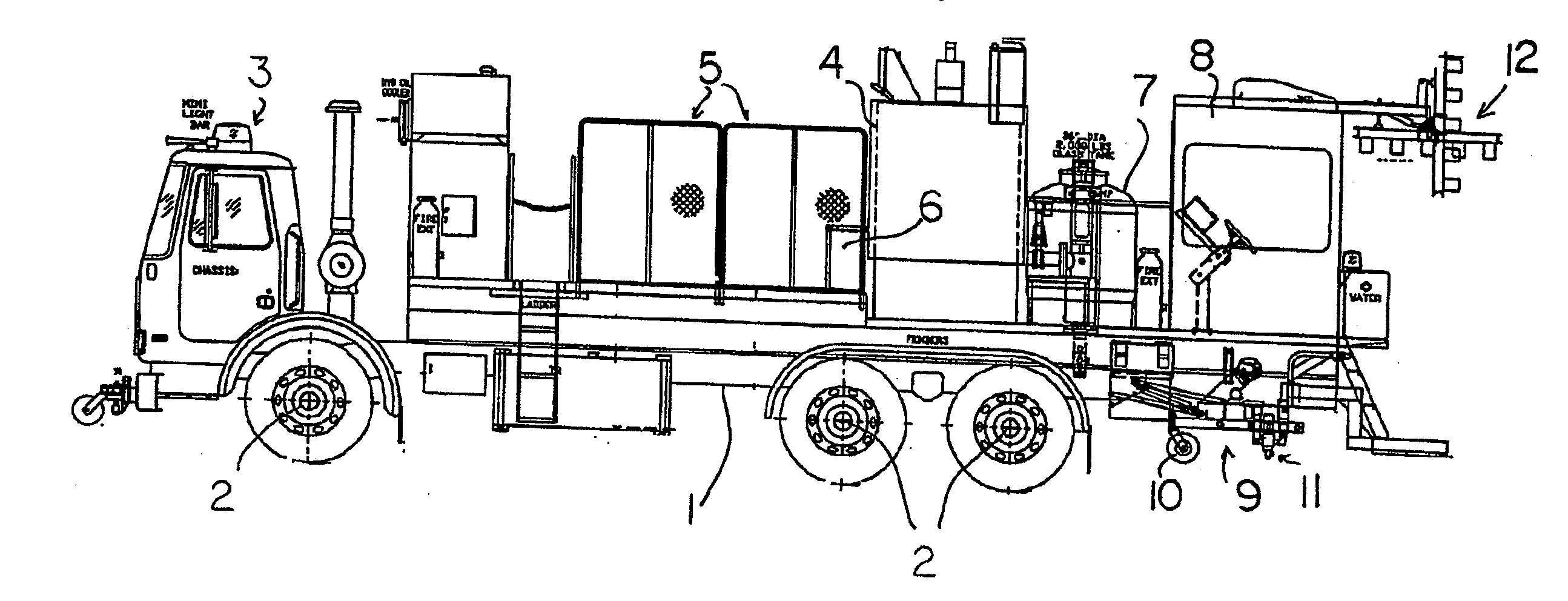

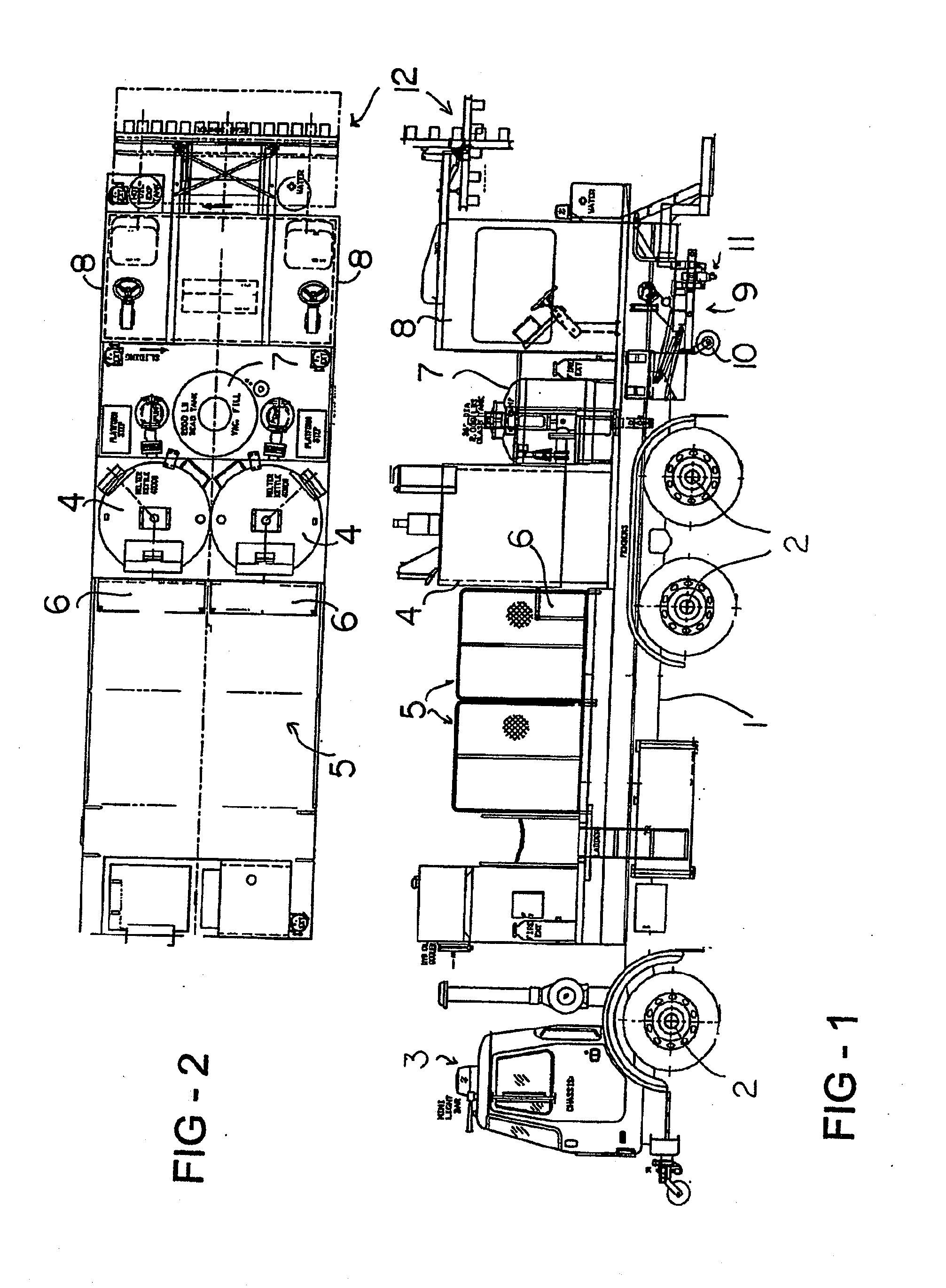

Pavement repair system utilizing solid phase autoregenerative cohesion

ActiveUS20140270955A1Long and longer useful lifePaving propertyPaving reinforcementsIn situ pavingsRoad surfaceLiquid phase

A pavement repair system is provided utilizing Solid Phase Auto Regenerative Cohesion (SPARC) Homogenization by Liquid Asphalt Oligopolymerization (HALO) technologies. The SPARC-HALO system is suitable for use in repairing asphalt pavement, including pavement exhibiting a high degree of deterioration (as manifested in the presence of potholes, cracks, ruts, or the like) as well as pavement that has been subject to previous repair and may comprise a substantial amount of dirt and other debris (e.g., chipped road paint or other damaged or disturbed surfacing materials). The HALO system is suitable for rejuvenating aged asphalt, thereby improving properties of the paving material.

Owner:COE WILLIAM B

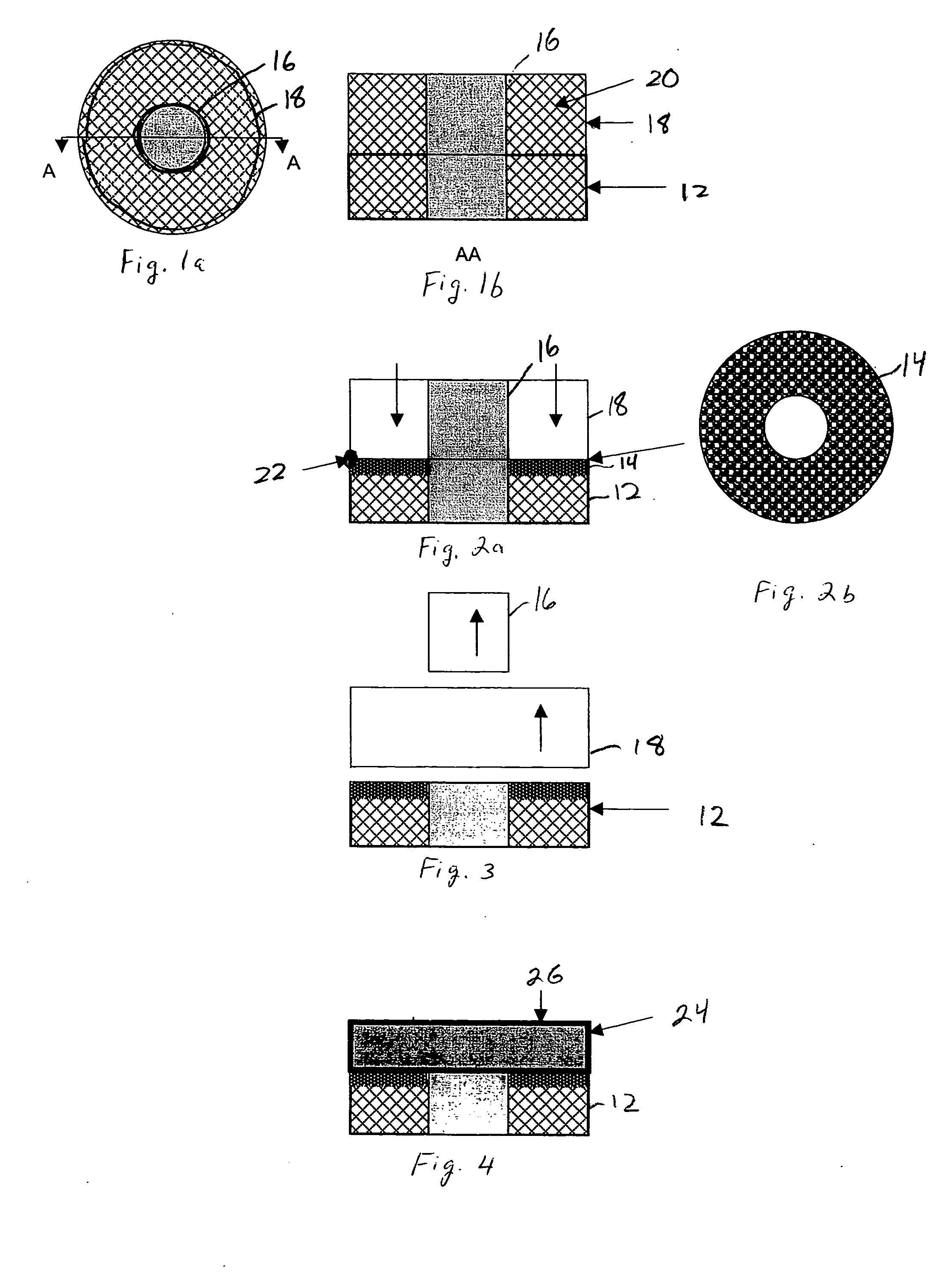

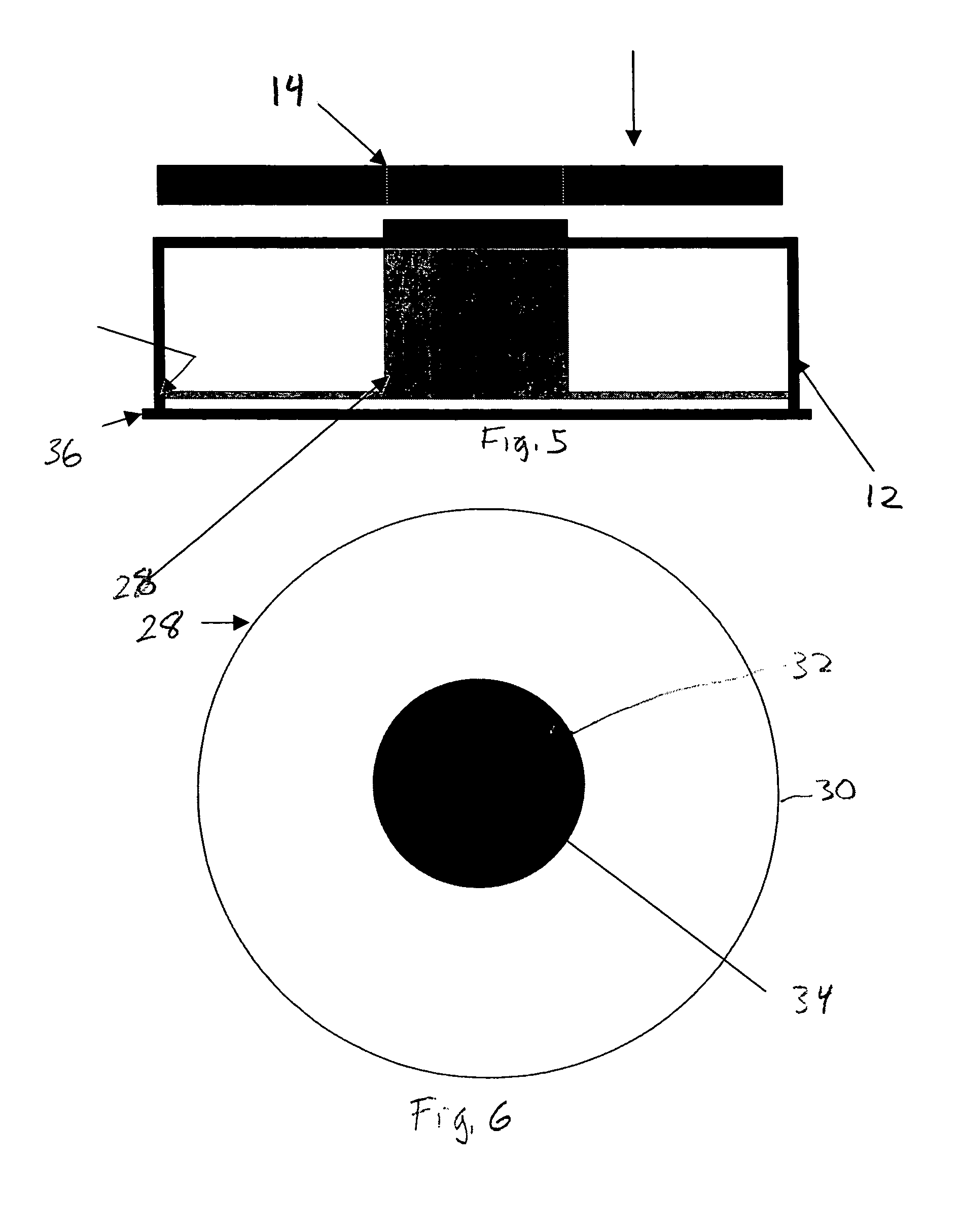

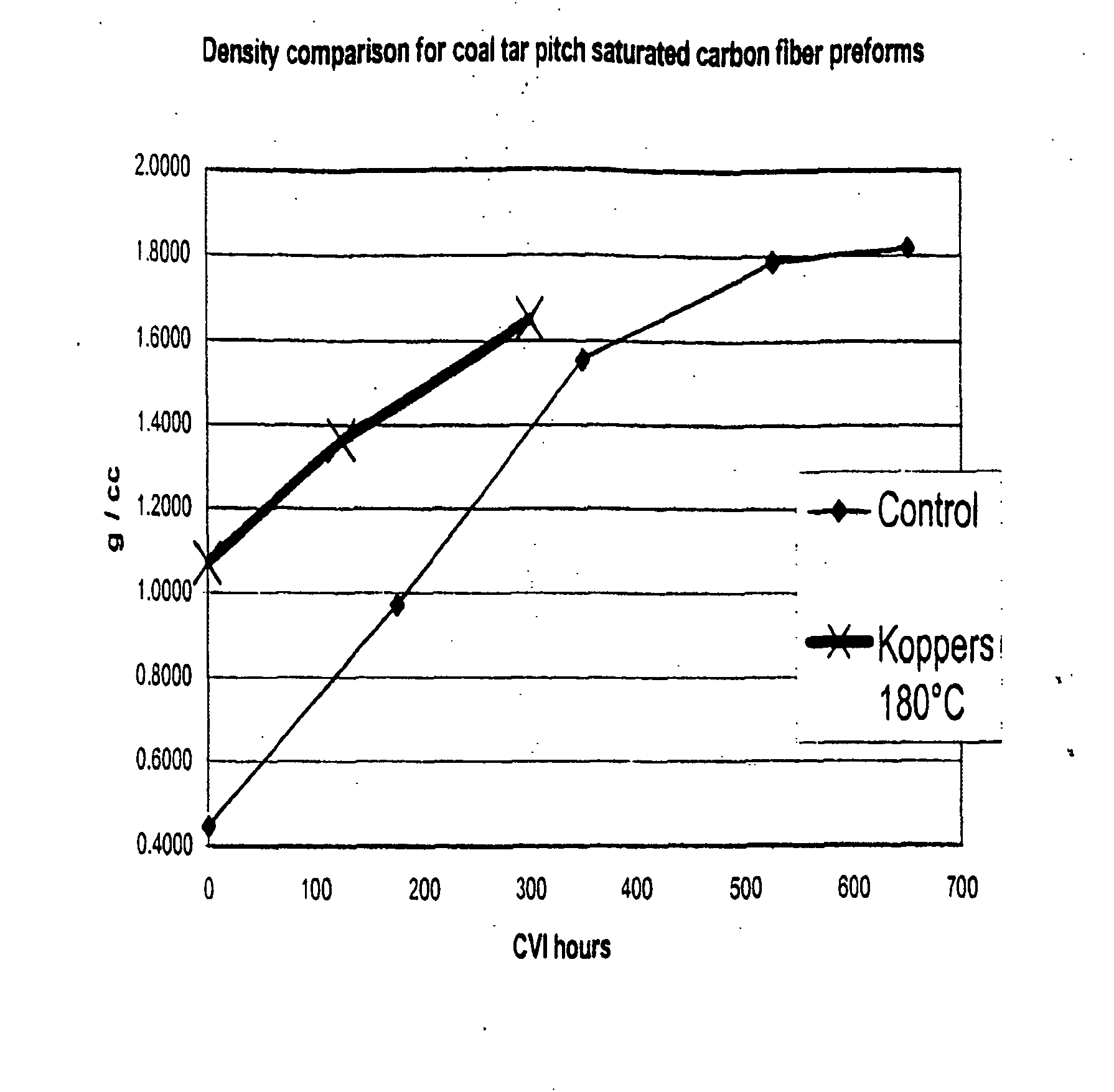

Chopped carbon fiber preform processing method using coal tar pitch binder

InactiveUS20050081752A1High densityExcellent propertyWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansFiberCarbon fibers

Owner:KOPPERS DELAWARE INC

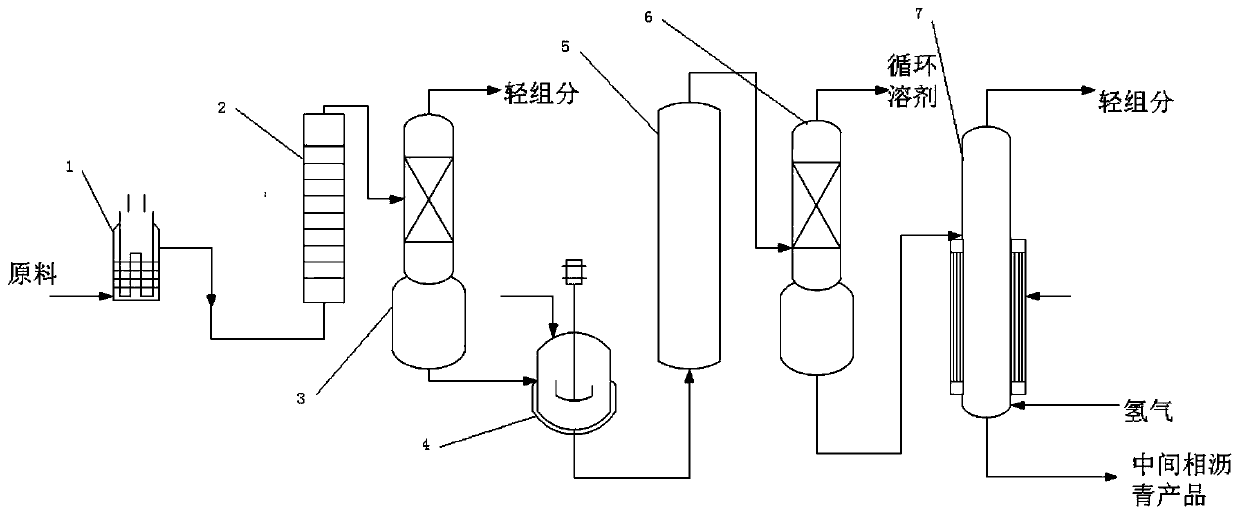

Method for FCC oil slurry hydrogenation modification-fractional thermal polycondensation preparation of mesophase pitch

InactiveCN107189802AImprove spin performanceReduce usageWorking-up pitch/asphalt/bitumen by chemical meansWorking-up pitch/asphalt/bitumen by meltingFiberCarbon fibers

The invention provides a preparation method of petroleum-based mesophase pitch having a uniform molecular structure and a low softening point. The method comprises carrying out reduced pressure distillation on catalytic cracking oil slurry of naphthenic crude oil, taking a fraction having a boiling point of 380 and 540 DEG C as a raw material, carrying out a reaction process at a temperature of 380 to 450 DEG C under pressure of 4 MPa for 1 to 14 hours to obtain petroleum asphalt having a softening point of 110 to 180 DEG C, adding 1 to 15wt% of a hydrogen donor into the raw material, carrying out a self-pressure reaction process at 380 to 420 DEG C under nitrogen initial pressure of 5MPa for 1 to 8h, reducing the pressure to the normal pressure, cooling the product to 350 DEG C, carrying out high purity nitrogen purging for 0.5h to obtain hydrogenated asphalt, and carrying out a reaction process on the hydrogenated asphalt at 400 to 480 DEG C under pressure of 4MPa for 2 to 16h to obtain high quality mesophase pitch. The preparation method has simple processes and realizes a low production cost. The petroleum-based mesophase pitch has anisotropic structure content greater than 98%, a lower softening point of 230 to 250 DEG C, has a large basin type optical structure and good spinnability and is an excellent precursor for production of high modulus carbon fibers.

Owner:QINGDAO UNIV OF SCI & TECH

Noah's pitch process

A process for producing pitch from pitch precursors, such as wood tar, coal tar or petroleum fractions is disclosed. Direct contact heat exchange of the pitch precursor with molten metal, preferably maintained as a metal continuous bath, heats the pitch precursor to a temperature sufficient to induce thermal polymerization reactions and produce a pitch product.

Owner:DTX TECH

Pitch fractionation and high softening point pitch

InactiveUS7318890B1Reduce contentThermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by distillationFractionationBituminous materials

A process for fractionating crude pitch by direct contact heating with molten metal is disclosed. The crude pitch, which may contain water, contaminants and / or distillables is heated by direct contact heat exchange with molten metal, preferably maintained as a metal continuous bath, operating at a temperature of 100 to 600° C. The molten metal heating zone is maintained at a temperature and pressure sufficient to vaporize a desired amount of contaminants or volatile material from crude pitch to produce pitch product having a desired softening point. New pitch materials, having a softening point above those achievable by conventional techniques, are also produced.

Owner:DTX TECH

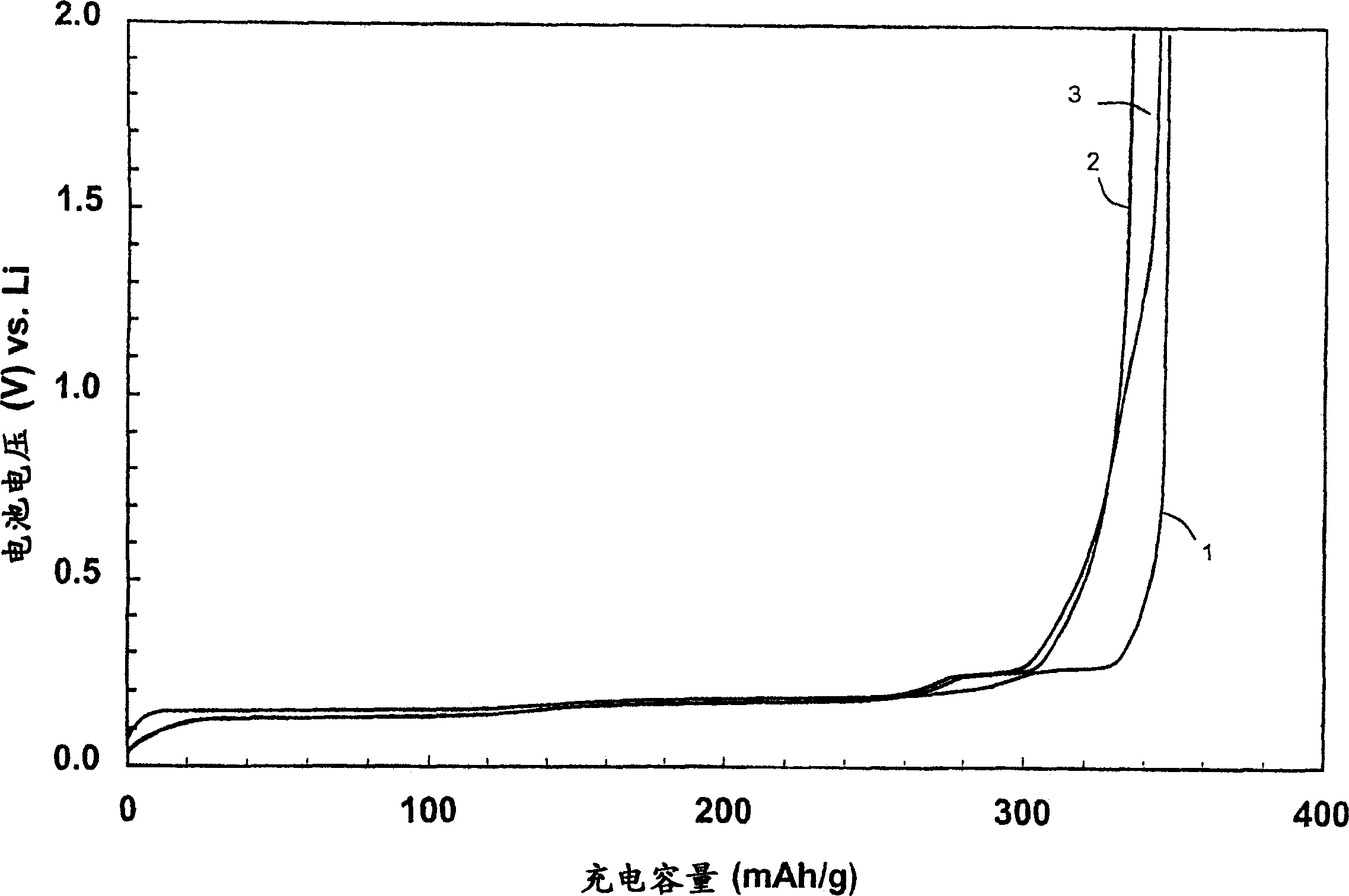

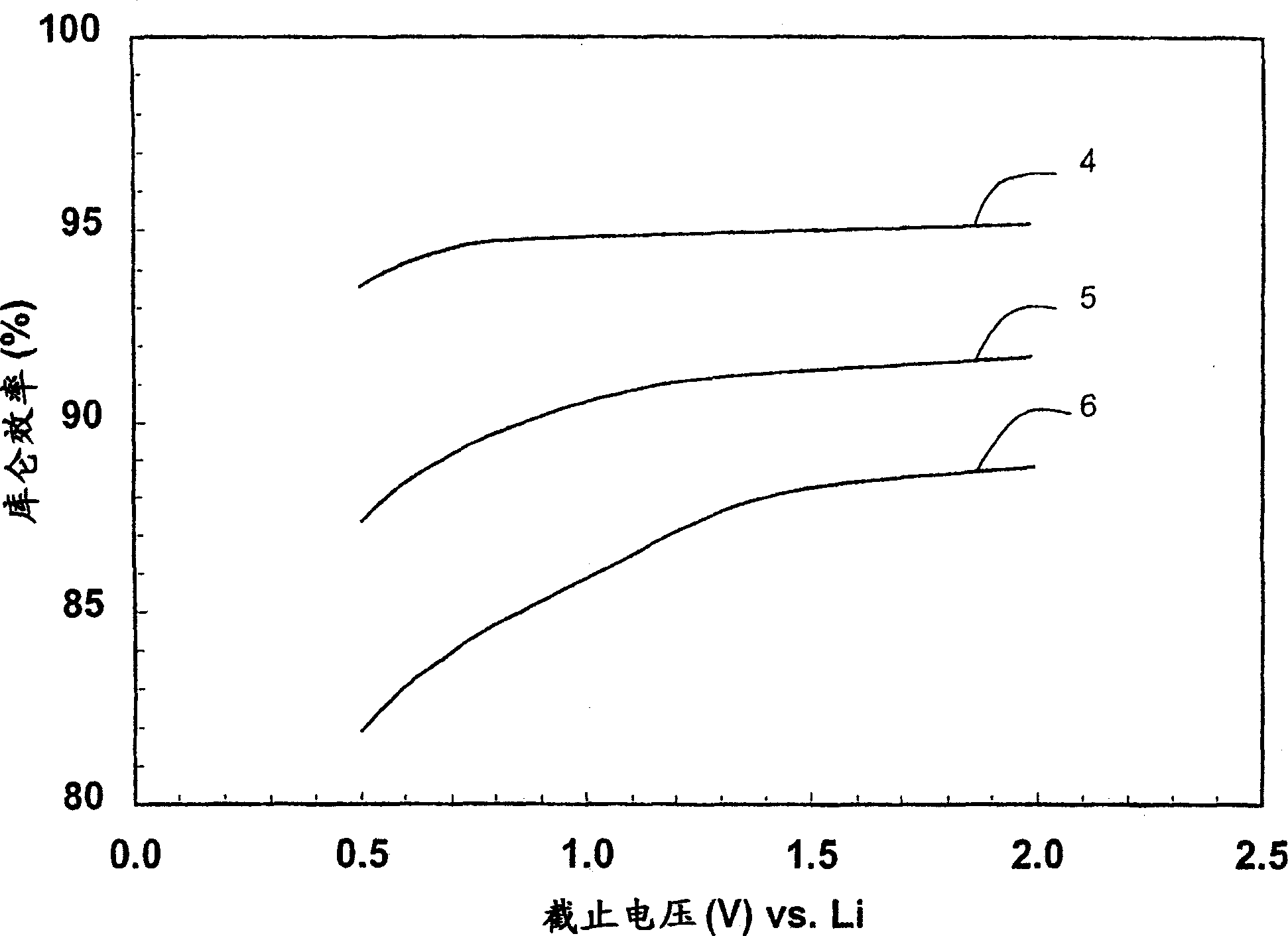

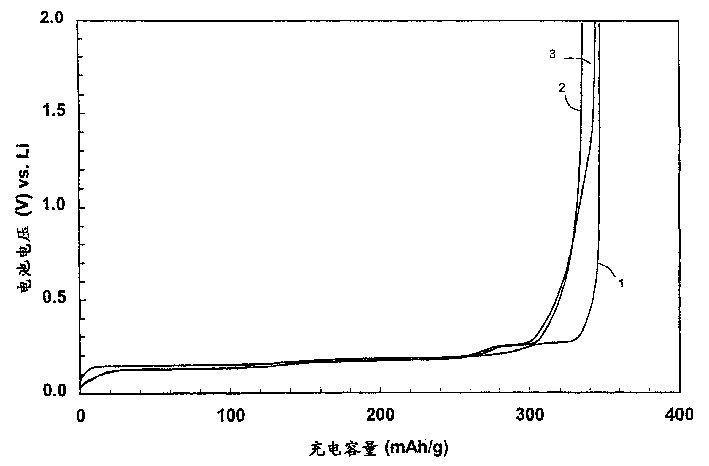

Coated carbonaceous particles particularly useful as electrode materials in electrical storage cells, and methods of making the same

InactiveCN1625593AGood fluidity of powderIncrease capacityFinal product manufactureConductive materialStorage cellMaterials science

A method of making coated carbonaceous particles comprising: providing a carbon residue forming material; providing particles of the carbonaceous material; mixing the carbon residue forming material with the particles of the carbonaceous material at an elevated temperature; depositing a coating of carbon residue forming material thereon; and stabilizing the coated particles by subjecting the coated particles to an oxidation reaction. These coated carbon-containing particles are particularly suitable for the production of electrodes in accumulators, especially rechargeable accumulators.

Owner:PYROTECK INC

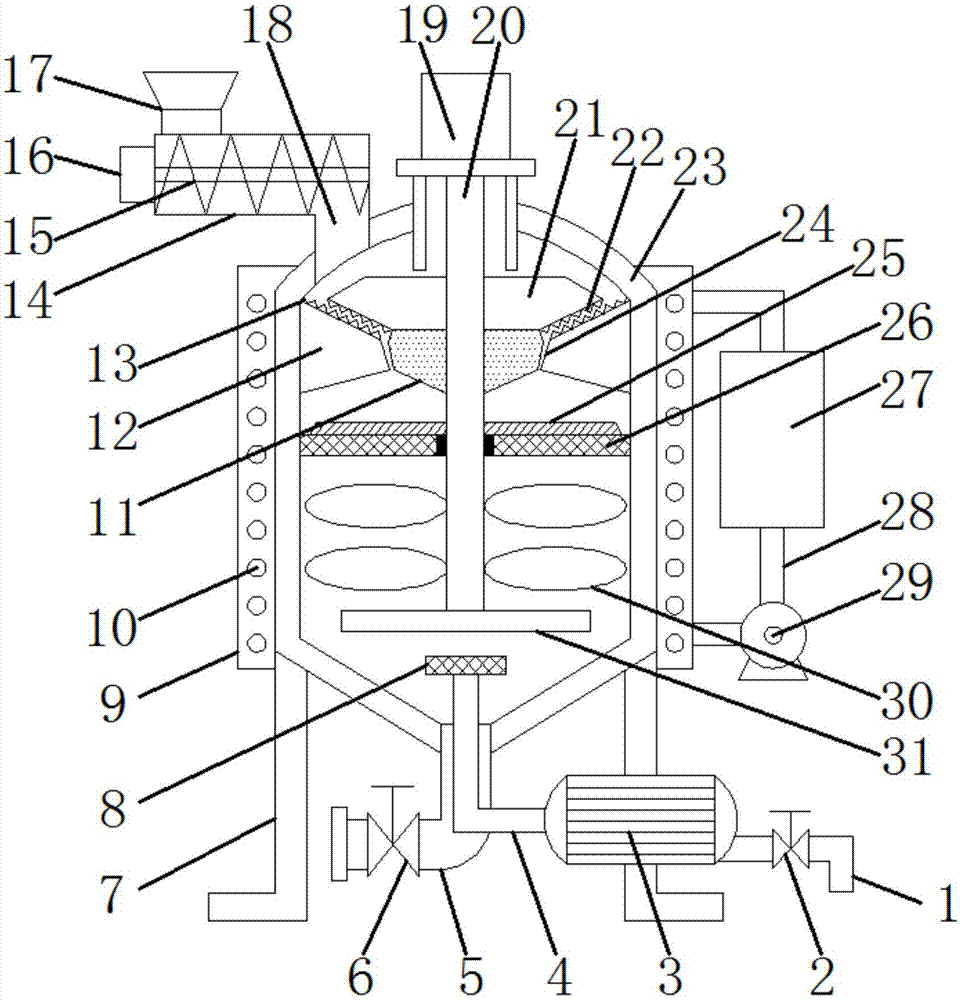

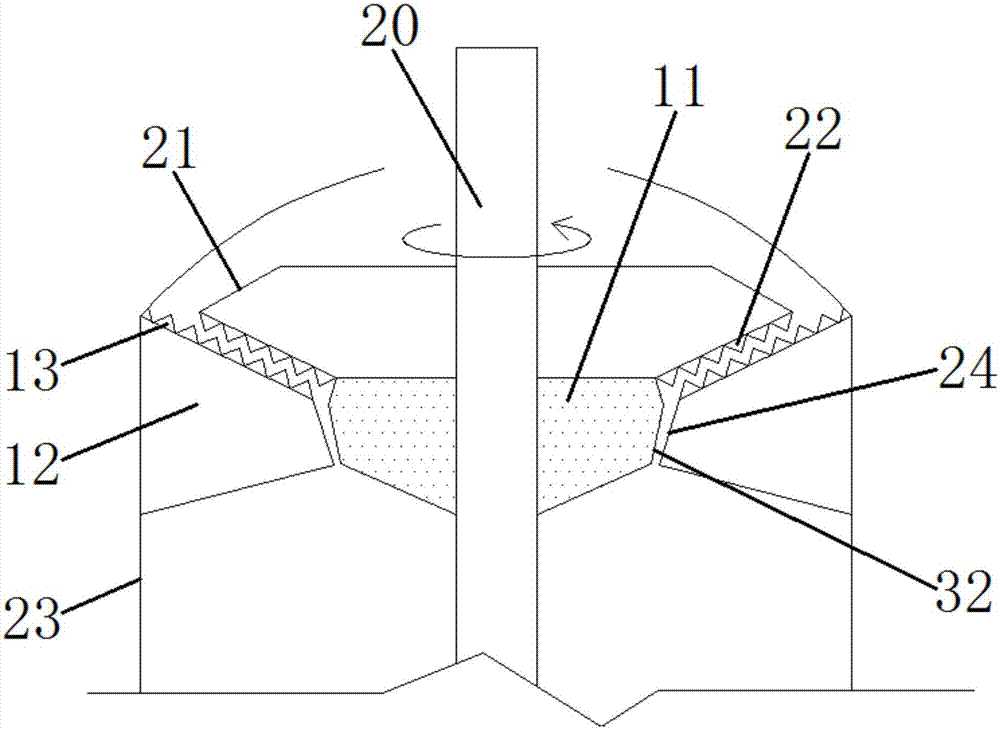

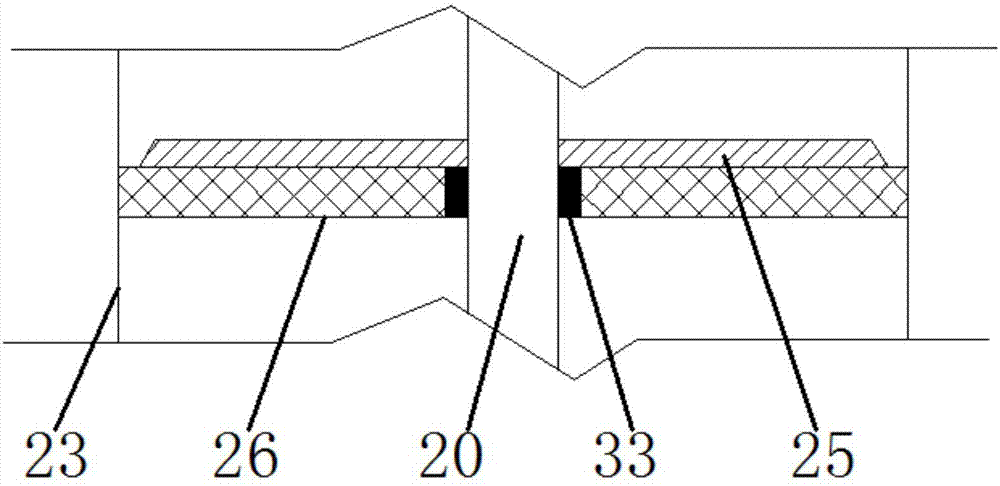

Asphalt crushing and melting equipment for municipal construction

InactiveCN107365596AEasy to crushCrushing and meltingWorking-up pitch/asphalt/bitumen by meltingWorking-up pitch/asphalt/bitumen by solidifying/disintegratingMelting tankCoupling

The invention discloses an asphalt crushing and melting equipment for municipal construction, which comprises a non-melting slag discharge pipe, a heating sleeve, a grinding roller, a fixed breaking hammer and an asphalt melting tank. A support frame is installed at the bottom of the asphalt melting tank. The upper end of the melting tank is connected to the asphalt input pipe; the top of the asphalt melting tank is equipped with a stirring motor, the rotating shaft of the stirring motor is connected to the rotating shaft through a coupling, and the rotating shaft is installed vertically inside the asphalt melting tank, and the top of the rotating shaft is welded Breaker, the bottom side of the rotary breaker is equipped with a number of rotating breaker teeth, and the bottom side of the rotary breaker is equipped with a fixed breaker; it realizes the convenient addition of asphalt blocks and avoids clogging; it realizes grinding treatment and further crushing, which is convenient for asphalt Block melting operation; realize the separate discharge of non-melting slag and asphalt melt, improve the effect and quality of asphalt melting; it is beneficial to the melting of asphalt, the heat transfer oil circulates, and the heating effect is good.

Owner:CHANGSHA KEYUE ENTERPRISE MANAGEMENT CONSULTING CO LTD

System, method, apparatus, means, and computer program product for recycling asphalt shingles

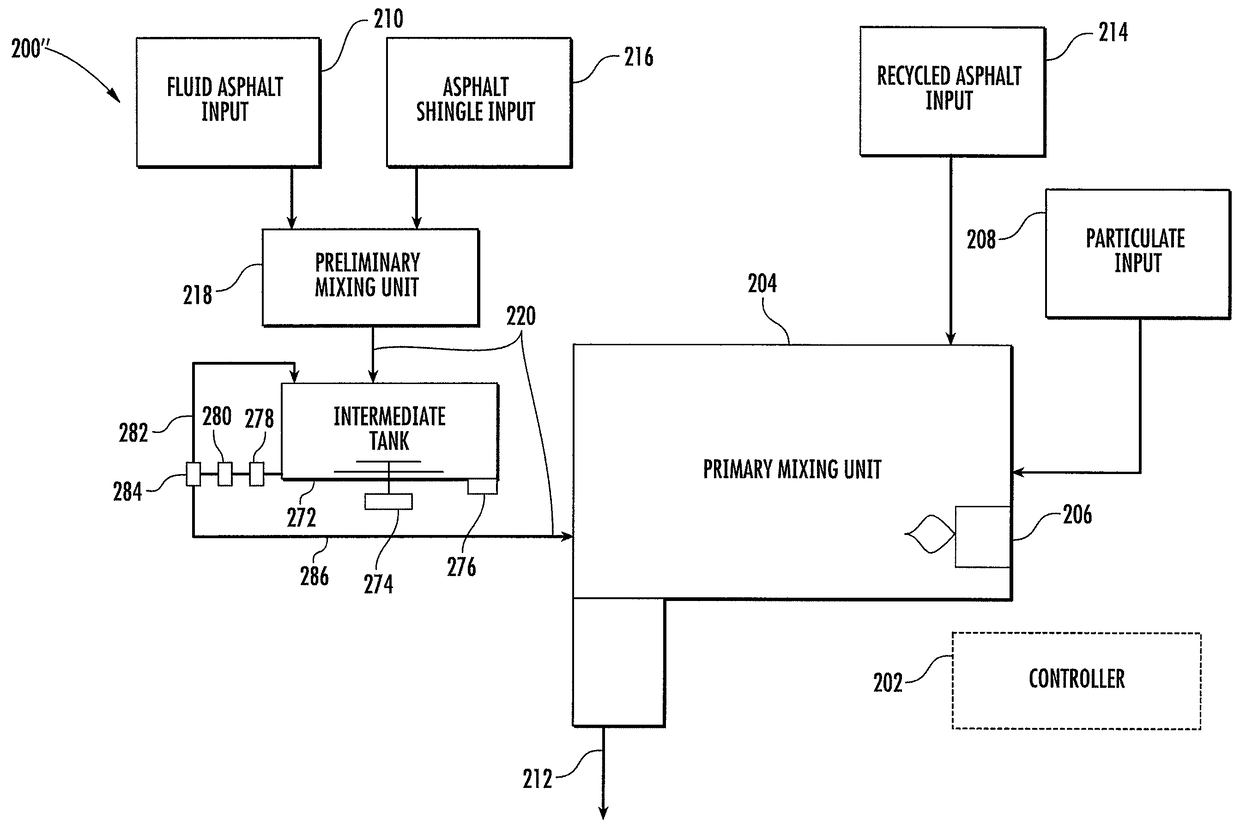

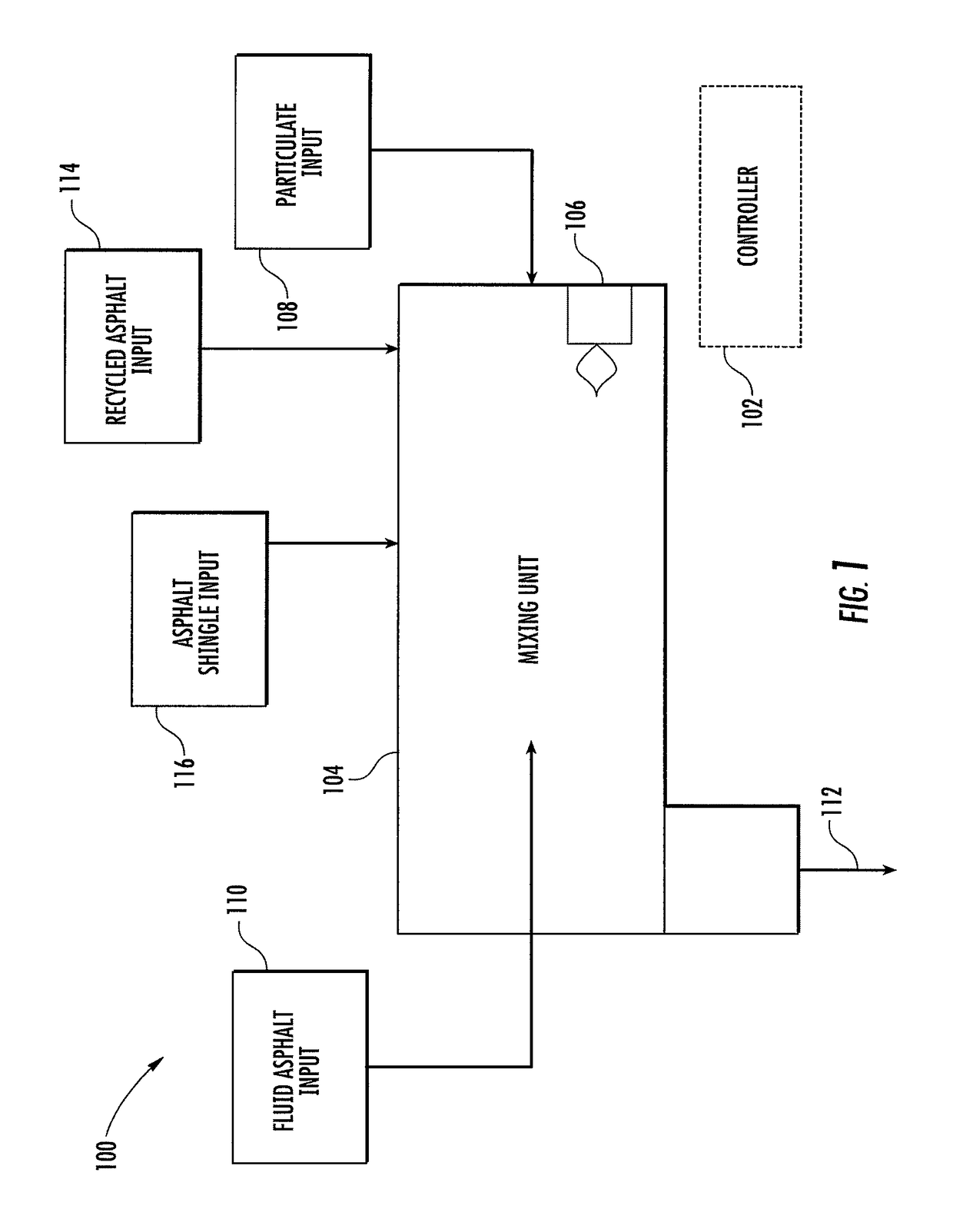

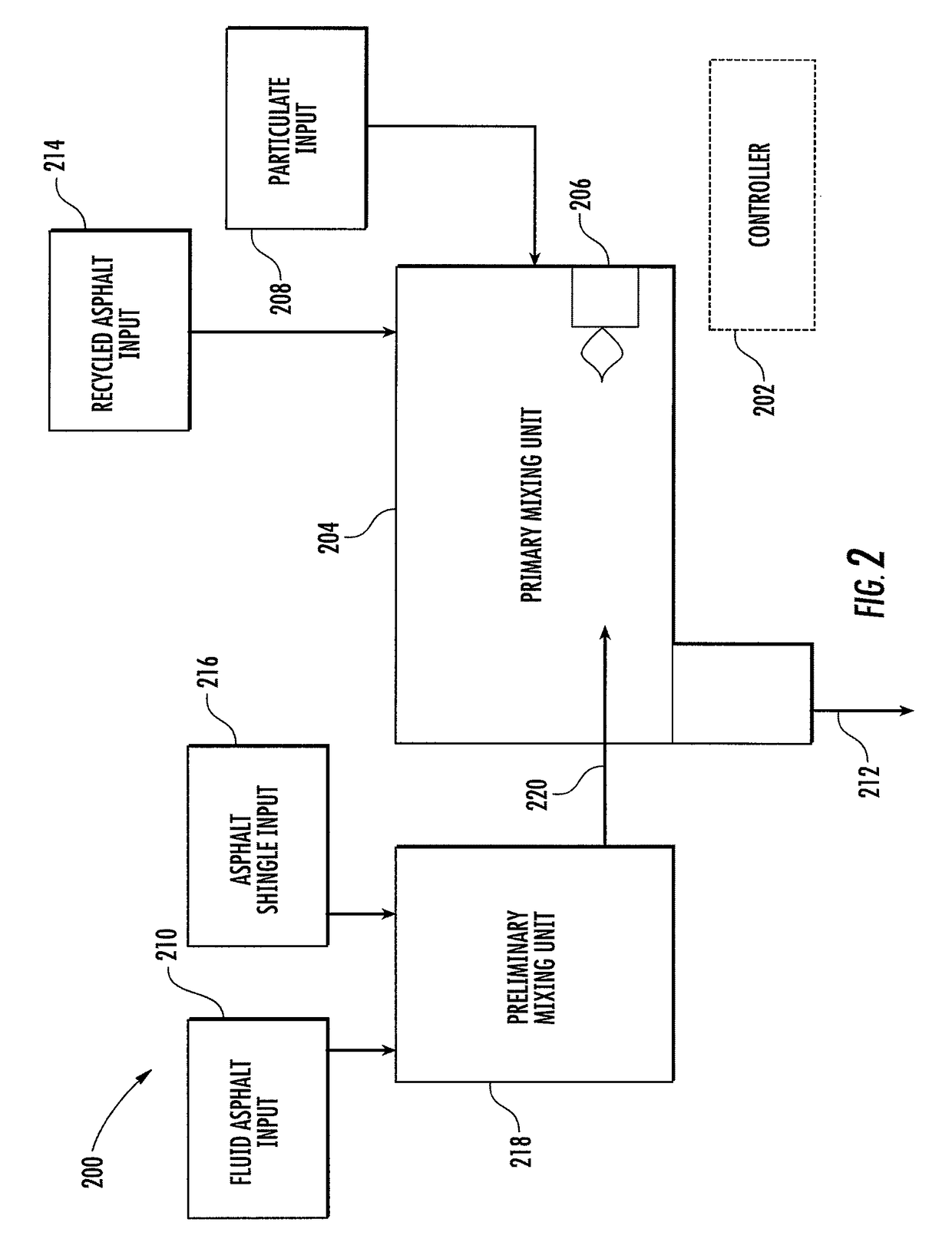

A system for producing an asphalt mix output suitable for use as an asphalt pavement is provided. The system may include a preliminary mixing unit configured to mix asphalt shingles with hot fluid asphalt to melt the asphalt shingles. The molten asphalt formed from the asphalt shingles and the hot fluid asphalt may be mixed with aggregate material and / or recycled asphalt material to form an asphalt mix output. An intermediate tank may store the molten asphalt prior to mixing with the aggregate material and / or the recycled asphalt material.

Owner:RUSSELL ATLAS JAMES

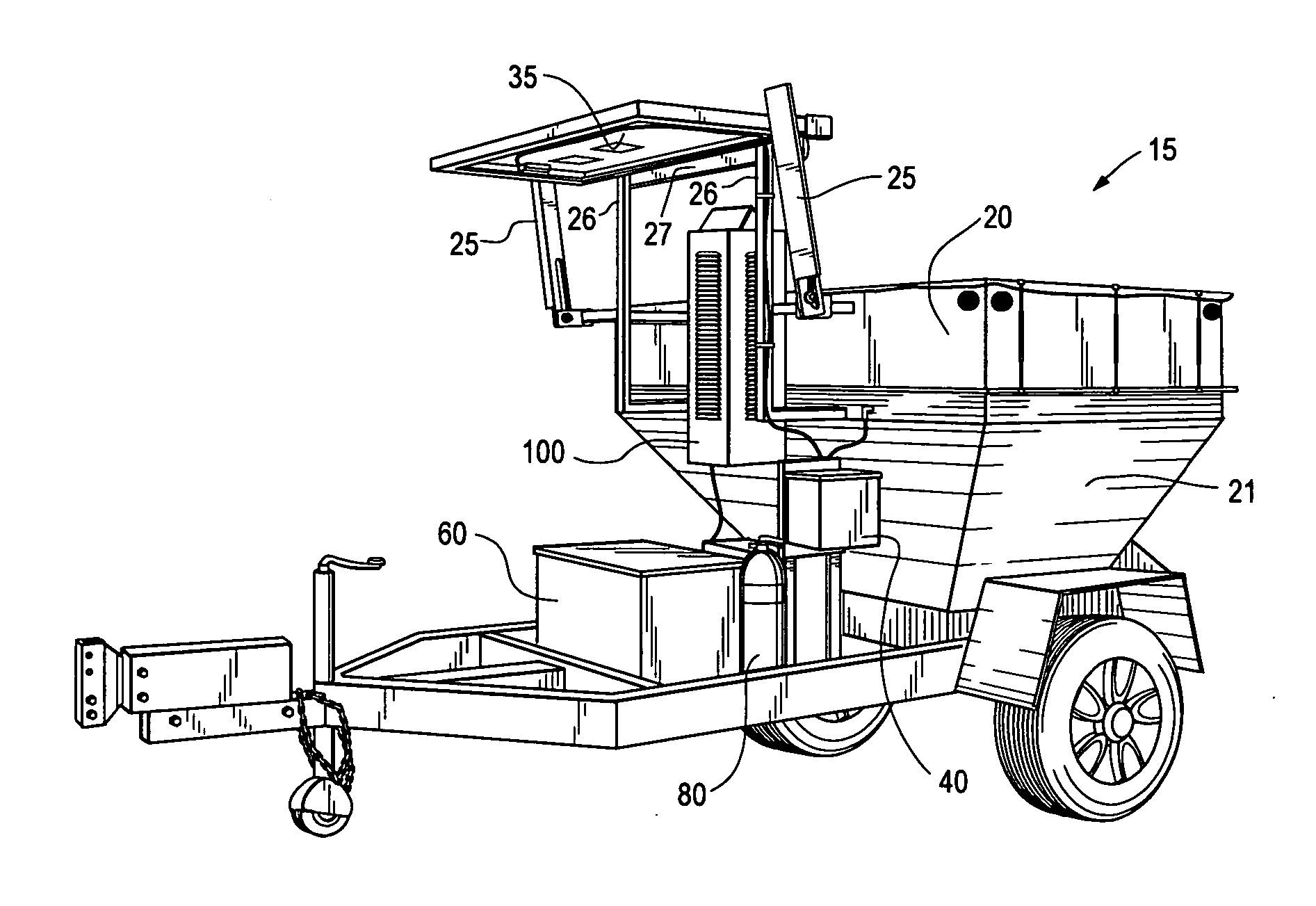

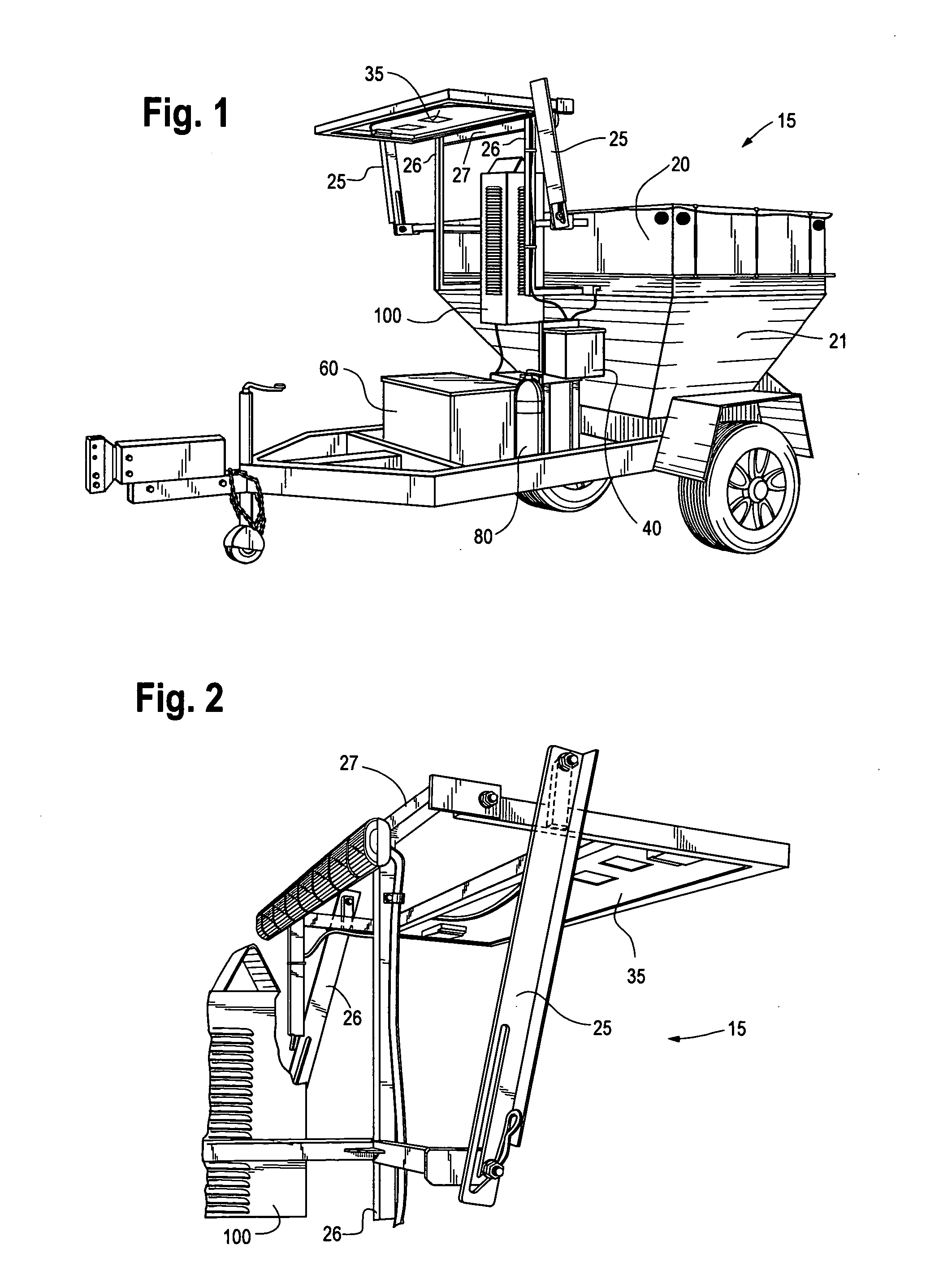

Solar-assisted patch cart

InactiveUS20060099031A1Easy maintenanceWorking-up pitch/asphalt/bitumen by meltingWater heatersElectricityCombustor

A solar energy-assisted patch cart with a support surface for carrying and heating bituminous materials, a heating source located adjacent to the support surface, and a battery powered at least in part by solar energy for igniting a burner associated with the heating source. Preferably, a charge controller is used to maintain the battery with a predetermined level of charge. The solar energy may be supplied by one or more retractable solar panels in electric communication with the battery.

Owner:RATHE RANDY

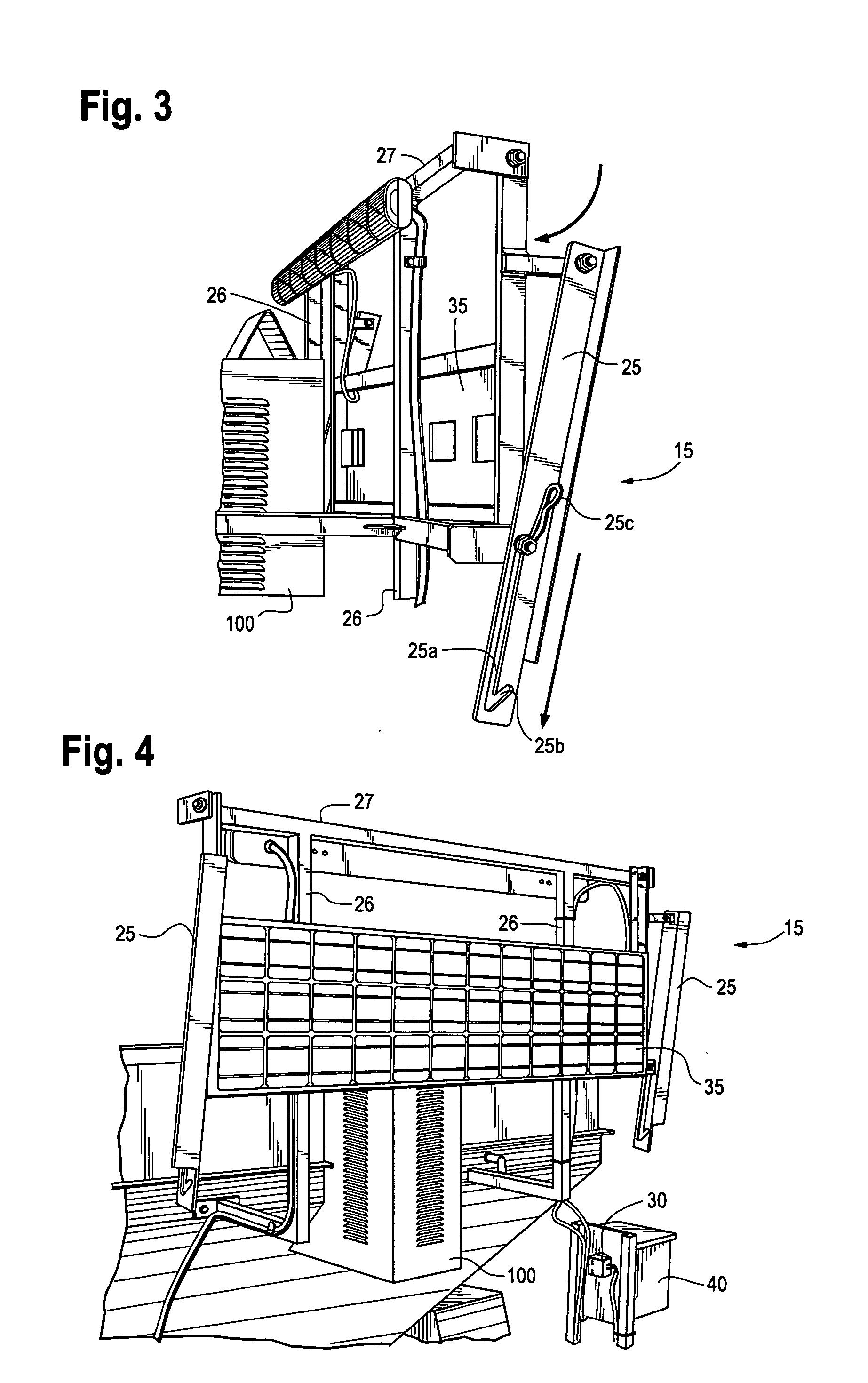

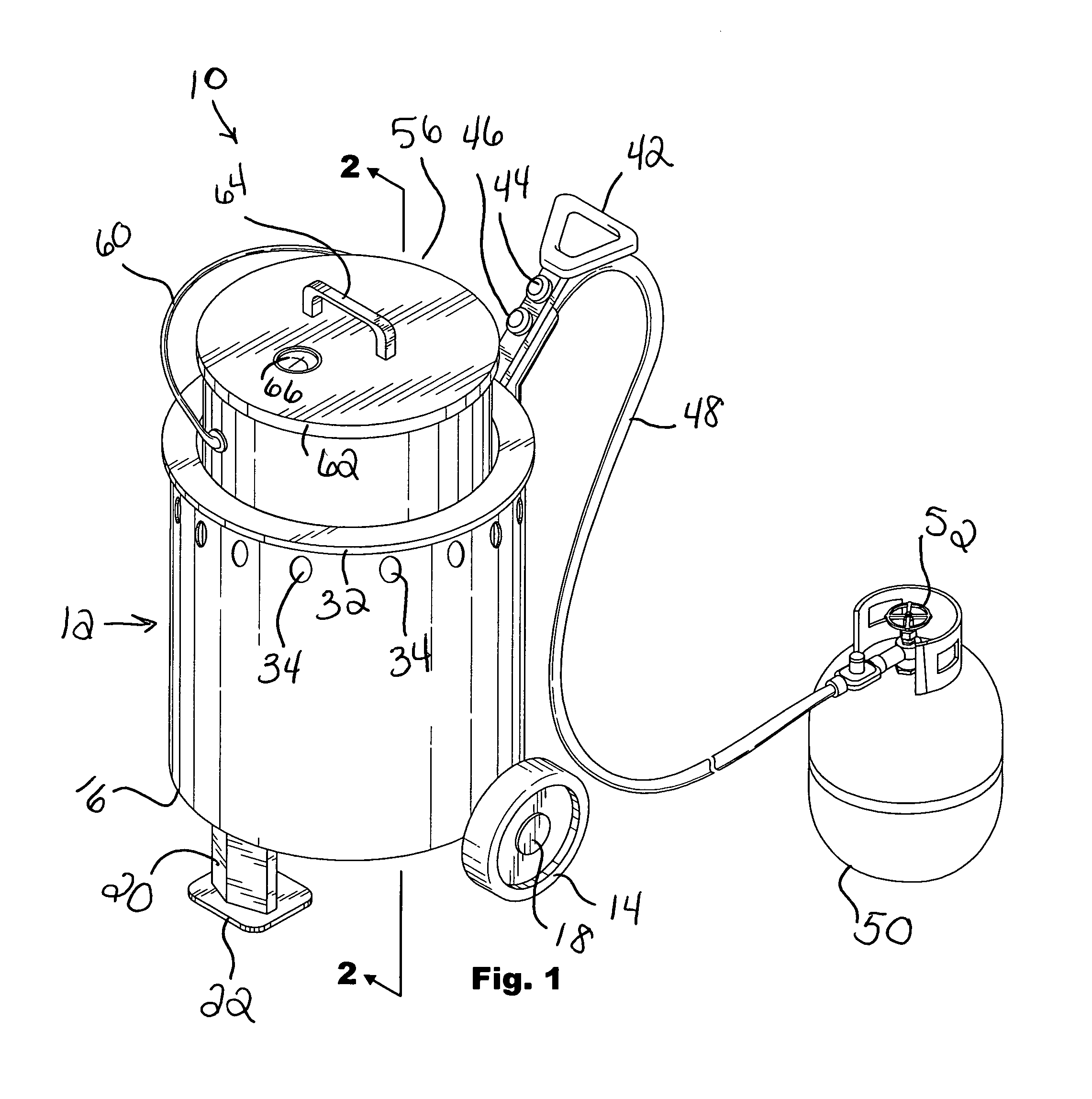

Portable tar heating and melting apparatus

InactiveUS6935331B2Fast recovery timeHigh cooking timeWater heating stoves/rangesCooking vesselsTarEngineering

A portable tar kettle includes a steel containment body mounted on wheels and having a handle projecting therefrom with the handle including an integral gas line that interconnects to an external propane tank and internally registers with a gas burner located within the containment body. Disposed within the containment body is a tar cooking vessel that holds the tar, and other material, to be heated and melted. The tar cooking vessel includes a lid with an integral temperature gauge. When the tar is appropriately heated and melted, the tar cooking vessel can be removed and carried to the roof of the structure, and this process can be repeated as many times as necessary to effect roof repair and maintenance.

Owner:FARMER RODNEY ANTHONY

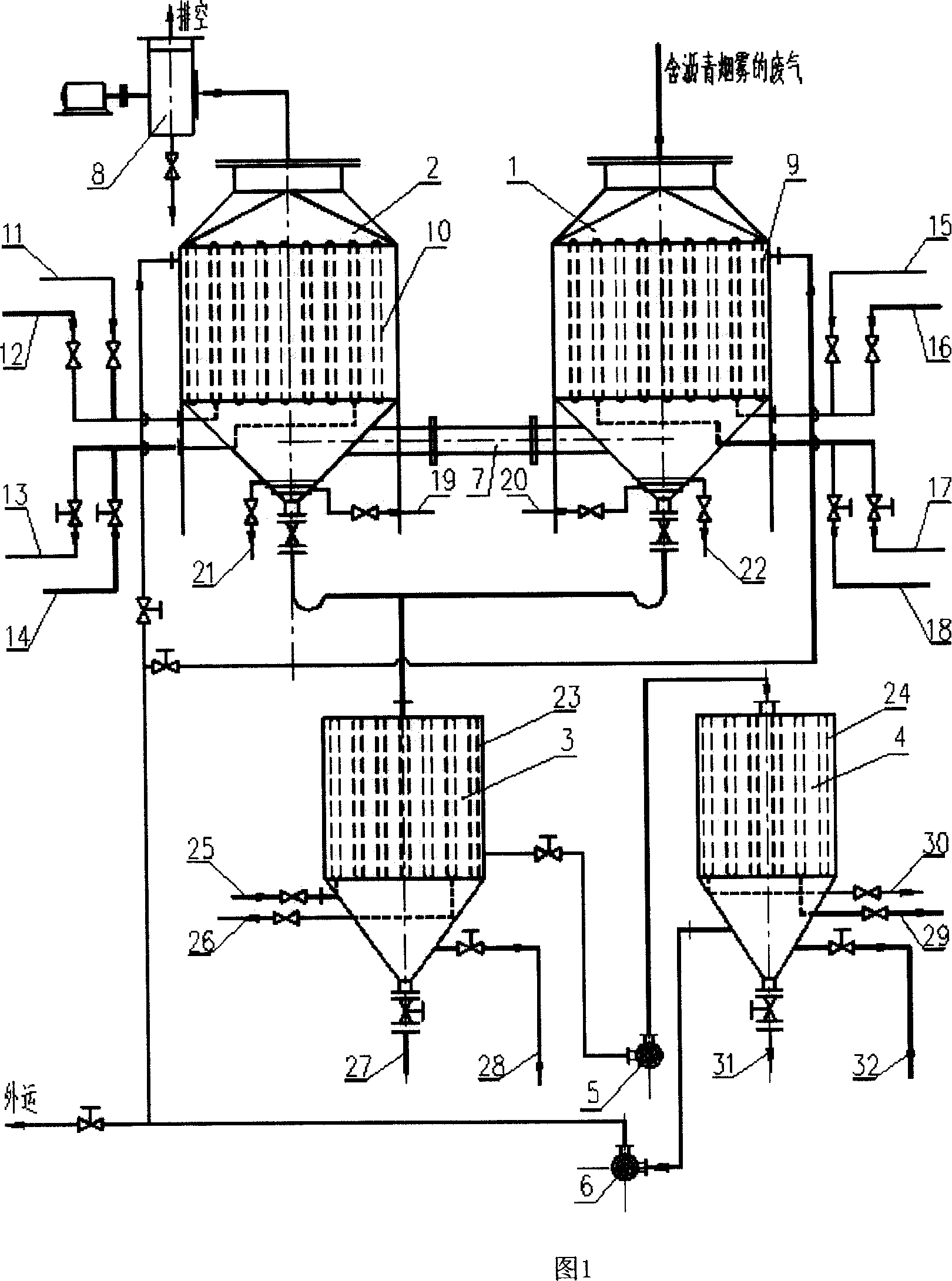

Bitumen flue gas purifying method and device

InactiveCN101134148AGuaranteed uptimeReliable maintenanceVapor condensationWorking-up pitch/asphalt/bitumen by meltingAtmospheric airExhaust gas emissions

The present invention discloses asphalt fume cleaning process and apparatus. The asphalt fume cleaning process includes sucking asphalt fume with one induced draft fan, condensing for the first time in the first condensator and condensing for the second time in the second condensator to convert asphalt component into tar, separating in a tar-water separator, pumping the tar to one tar storage tank and exhausting waste gas to atmosphere. The asphalt fume cleaning apparatus includes one induced draft fan, one first condensator, one second condensator, one tar-water separator, one tar pump and one tar storage tank connected together. The present invention has reliable technological principle, simple structure low running cost and low fault rate.

Owner:GUIYANG AL-MG DESIGN & RES INST

Bitumen solid at ambient temperature

ActiveUS20200165458A1Conserving formIn situ pavingsWorking-up pitch/asphalt/bitumen by meltingCelluloseAnticaking agent

Granules of material usable as a road binder or as a sealing binder including a core and a coating layer, wherein: the core consists of a first composition including at least one material selected from: a bitumen base, a pitch, a clear binder, and the coating layer consists of a second composition which includes: at least one viscosifying compound selected from cellulose ethers, and at least one anticaking agent. Also, a method for producing granules of material that can be used as a road binder or as a sealing binder, and the use thereof as a road binder, in particular for the production of coated materials. Also, a method for producing coatings from granules of material that can be used as a road binder or as a sealing binder and to a method for transporting and / or storing and / or handling granules.

Owner:TOTAL MARKETING SERVICES SA

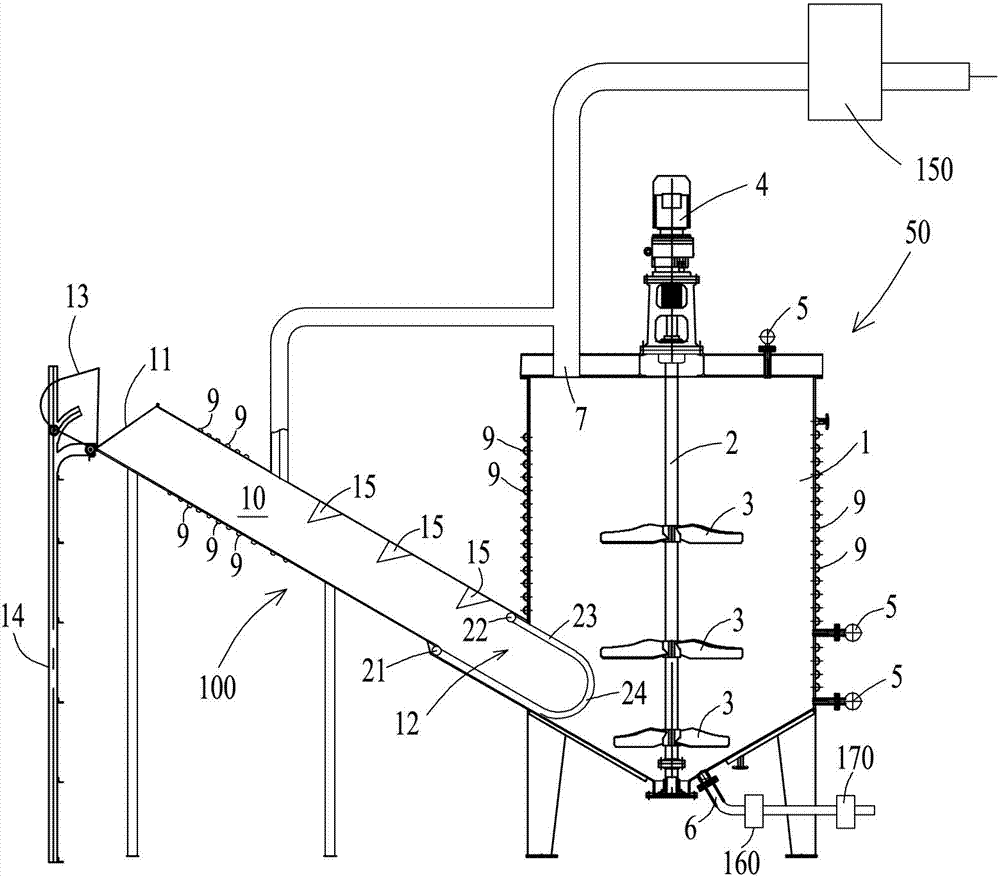

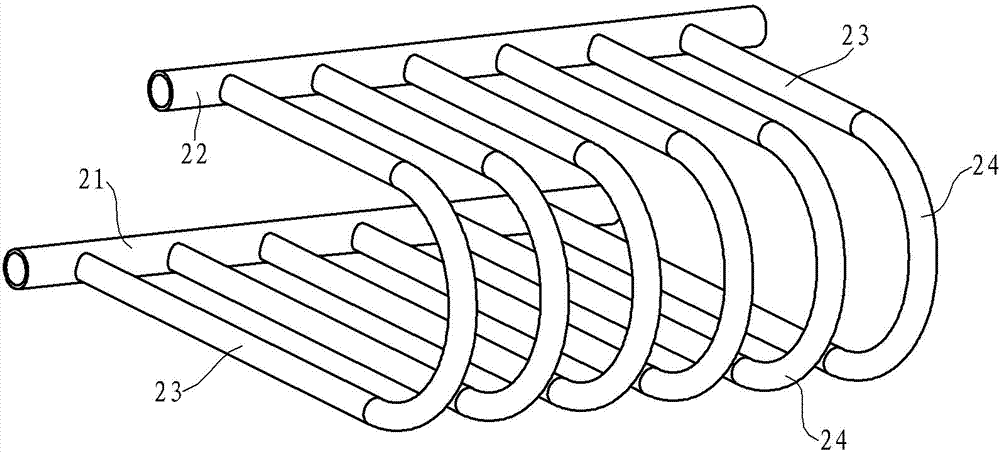

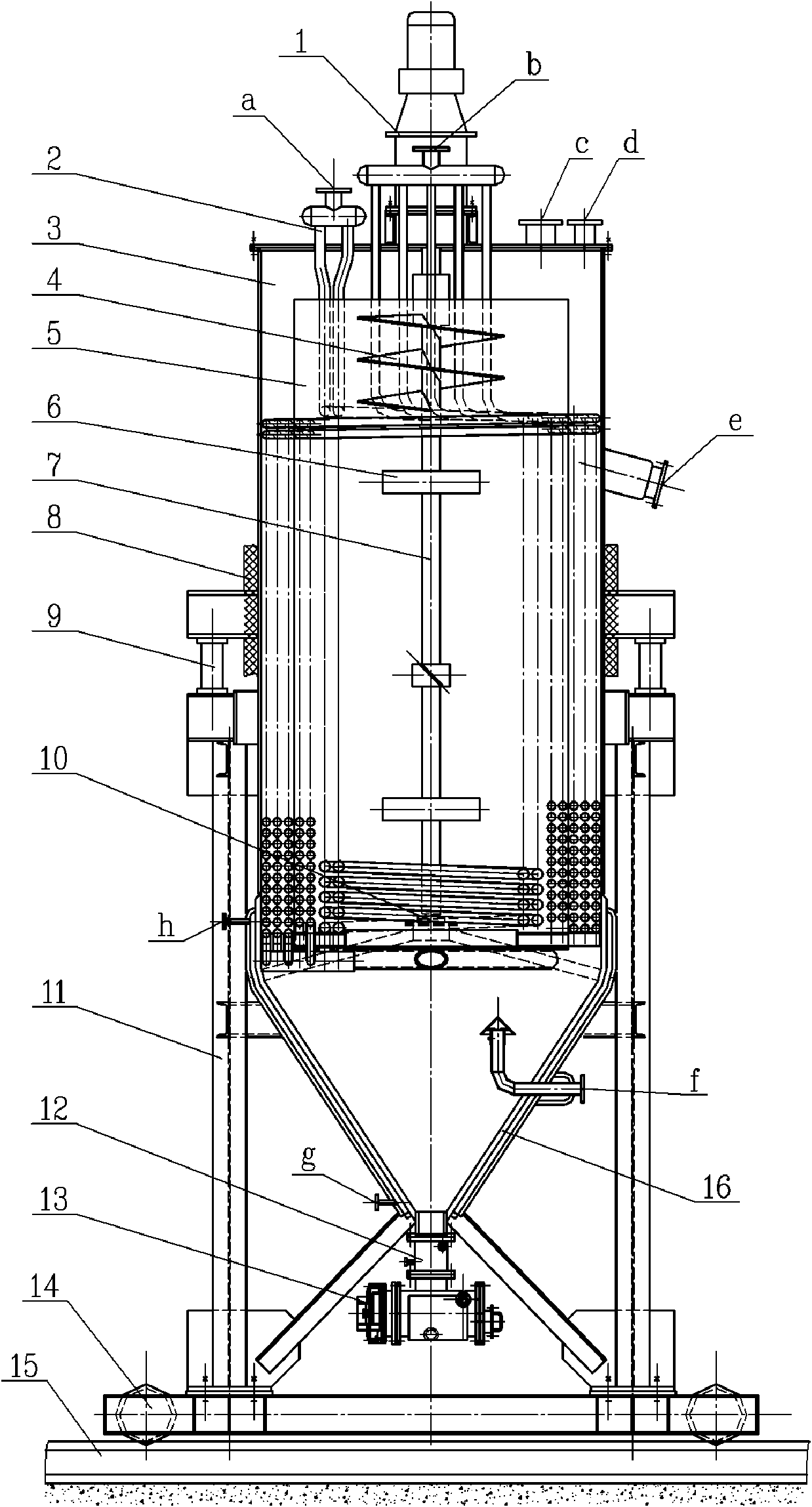

Lake asphalt melting and stirring system

ActiveCN102732281AAvoid high temperature heatingReduce the temperatureWorking-up pitch/asphalt/bitumen by meltingAsphaltPolymer chemistry

The invention relates to a melting and stirring system in the building material industry, in particular to a lake asphalt melting and stirring system for treating naturally mined lake asphalt solidified into solid state. The lake asphalt melting and stirring system comprises a heat insulating stirring pot, and also comprises a melting device communicated with the pot body of the heat insulating stirring pot; the melting device comprises a melting bin with a first heating unit and a second heating unit installed on the outer wall; the second heating unit is provided with a gap part for the lake asphalt molten into liquid to flow into the heat insulating stirring pot; and the lake asphalt enters the heat insulating stirring pot after the completion of melting. Both the heat insulating stirring pot and the melting device can be used for continuous production, and intermittent shutdown is avoided, so that the yield is improved, and as only the melting device is subject to high-temperature heating, the temperature of the heat insulating stirring pot keeps low, not all the asphalt is subject to high-temperature heating, and energy consumption is reduced.

Owner:JIZHOU XINCHENG CHEM EQUIP TECH +1

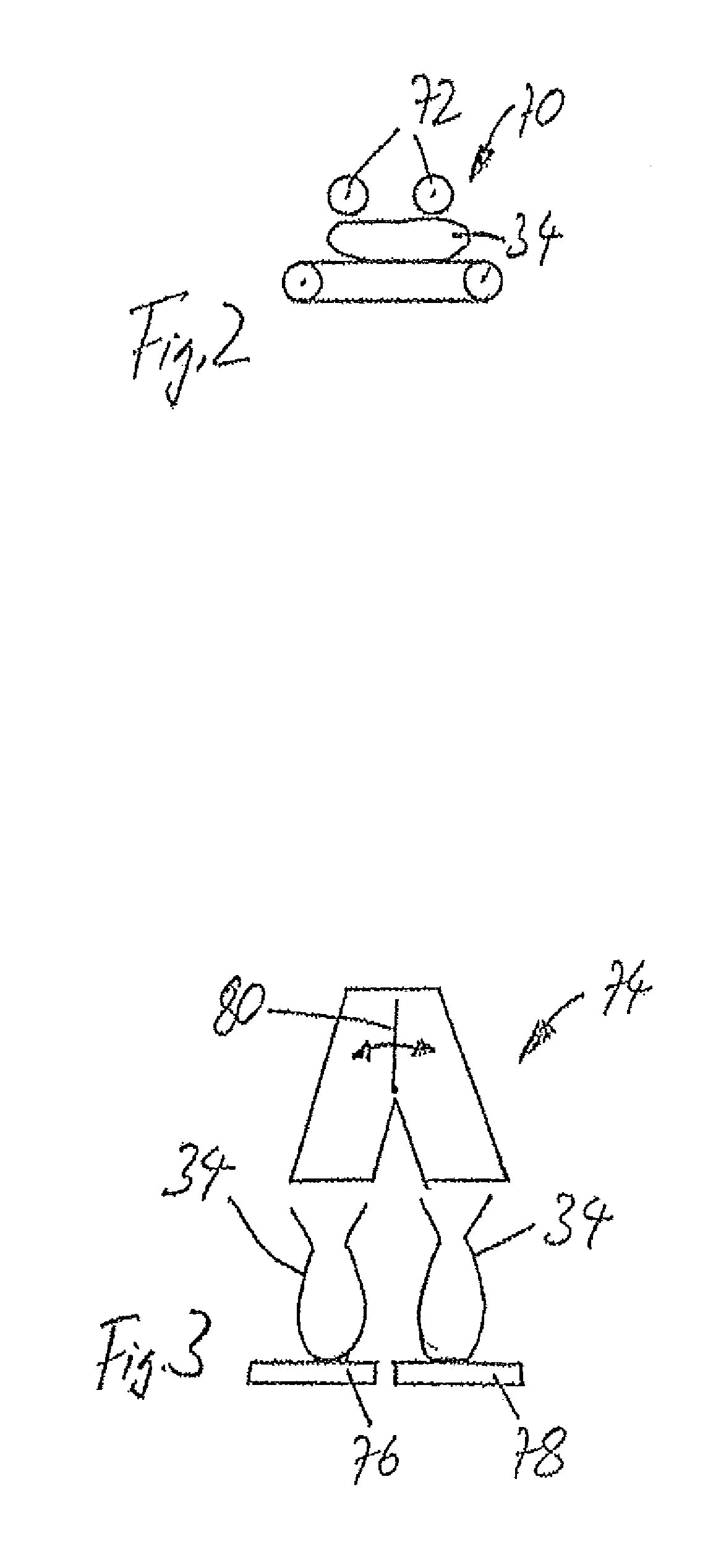

Method and apparatus for the production of bitumen blocks

InactiveUS20150166897A1Highly accurate adherenceEnough timeLaminationWorking-up pitch/asphalt/bitumen by meltingEngineeringMechanical engineering

A method and an apparatus for the production of bitumen blocks, with a drop former for generating bitumen drops from molten bitumen, with a belt cooler having a rotating belt for cooling and solidifying the bitumen drops deposited on the rotating belt into tablets, and with a decanting device for decanting the tablets into bags, the tablets being at least partially combined, inside the bags filled with tablets, into a compact bitumen mass.

Owner:IPCO GERMANY GMBH

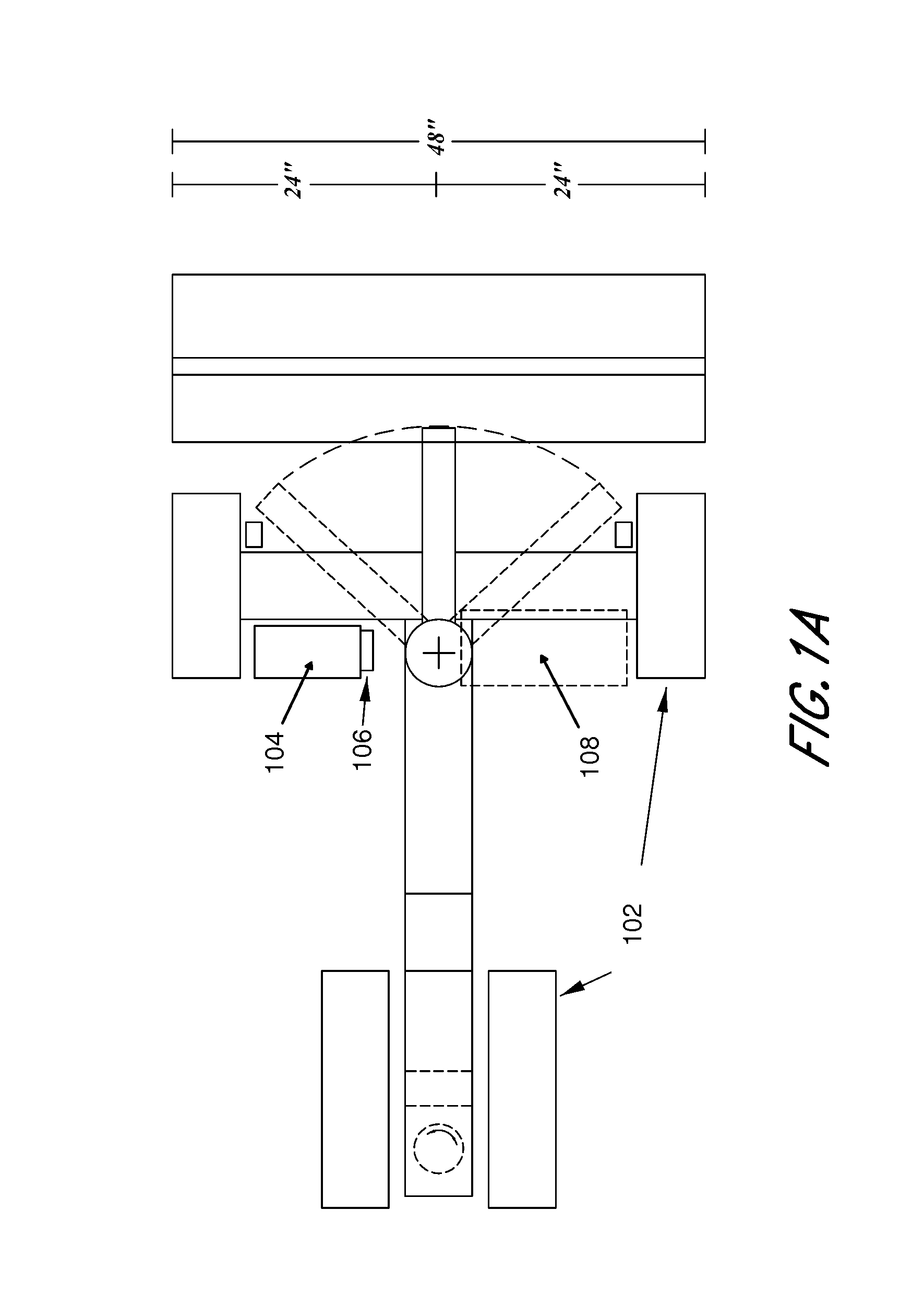

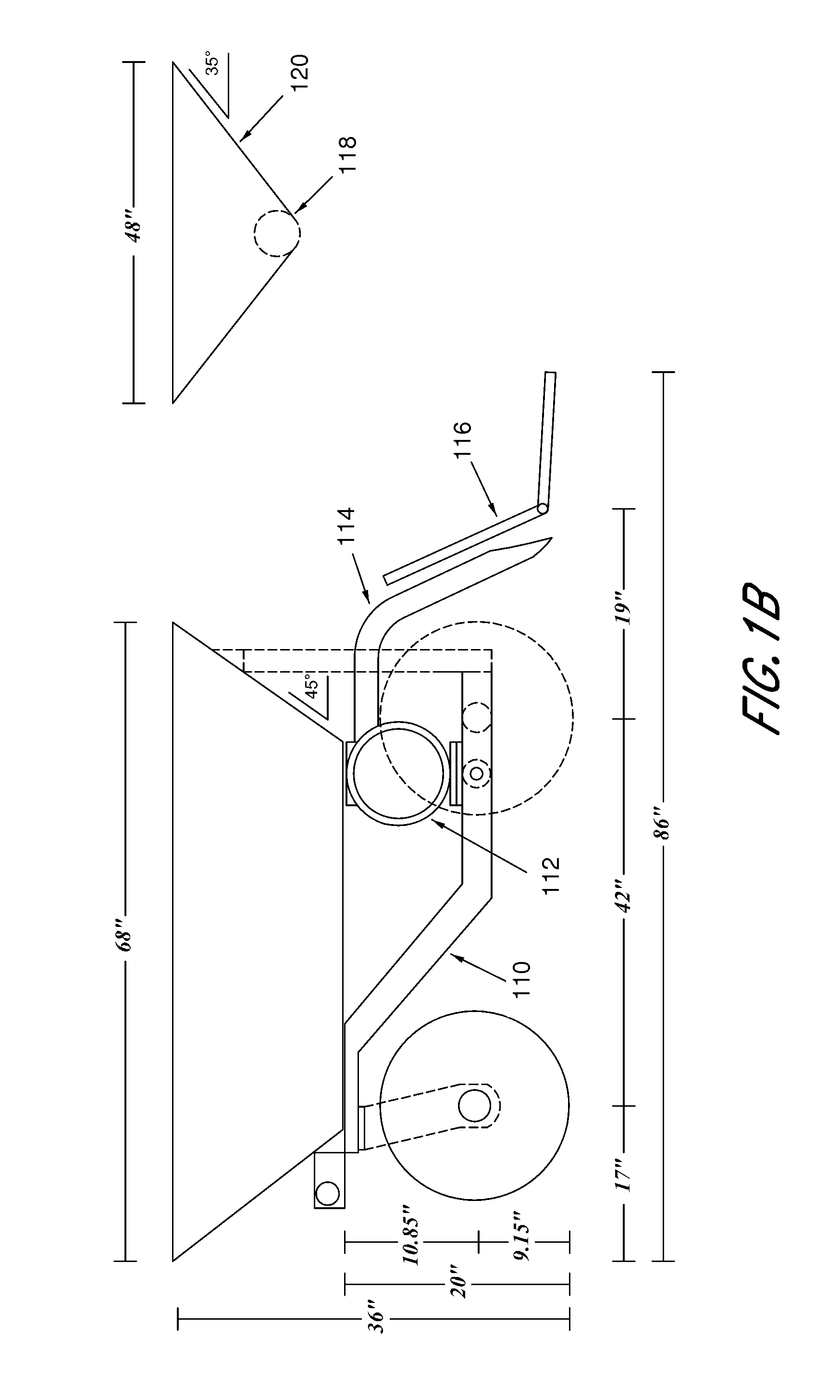

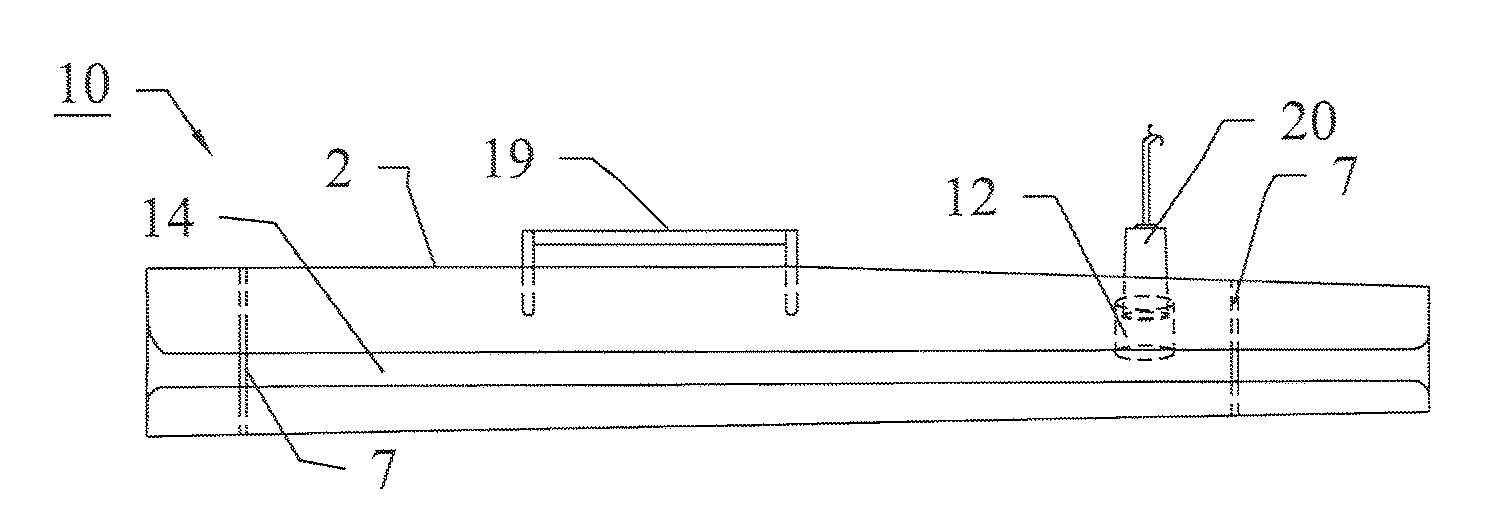

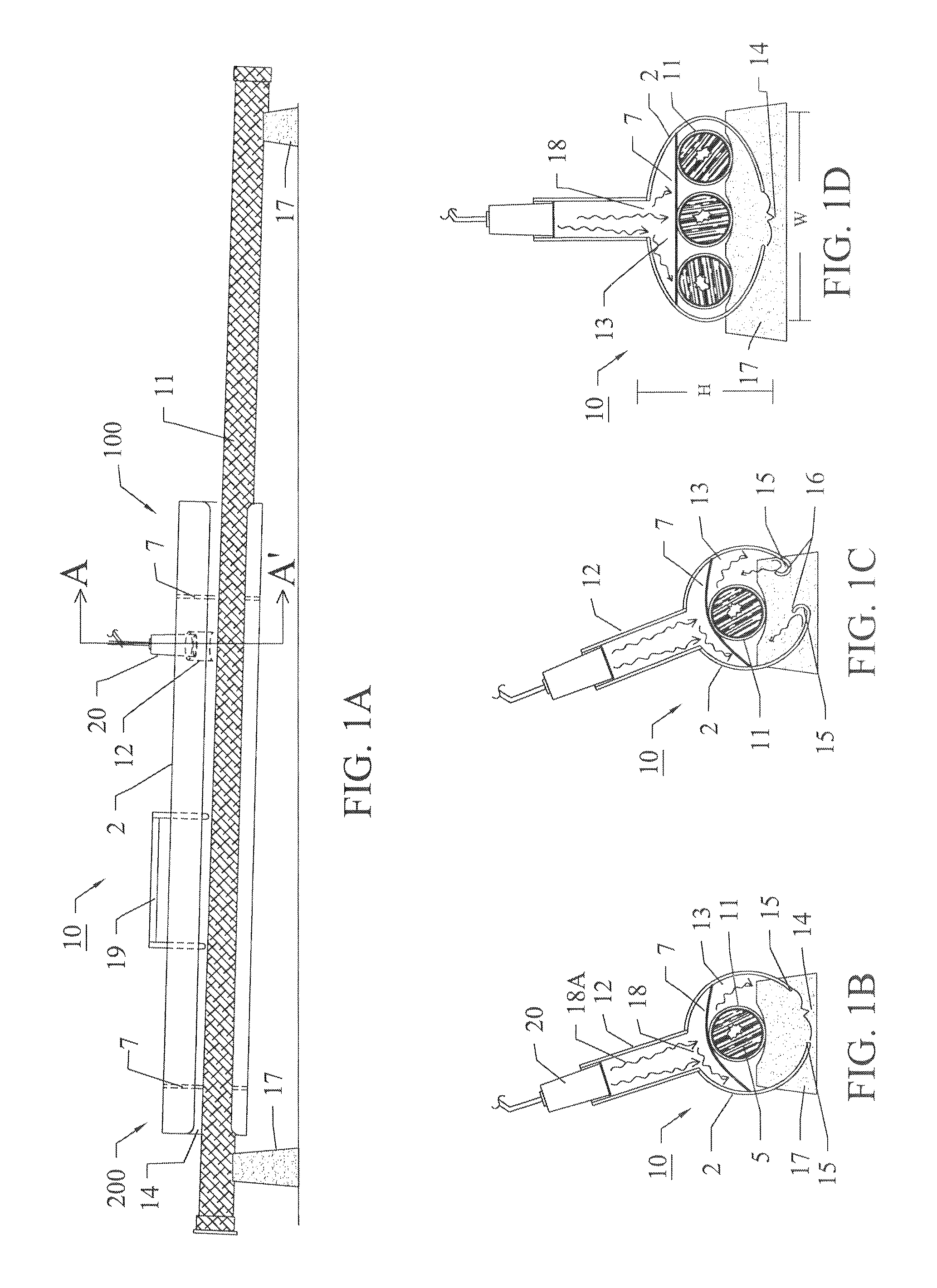

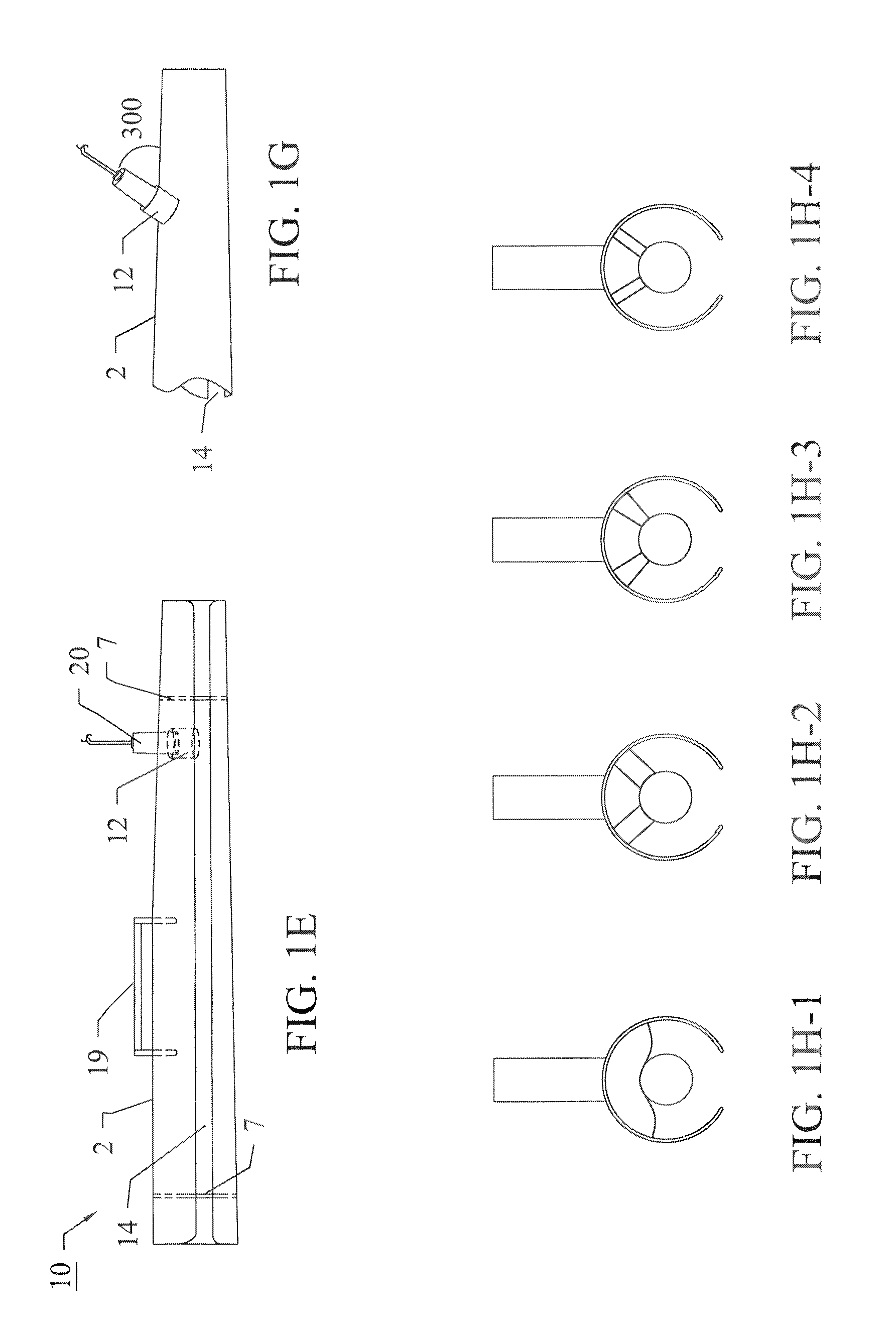

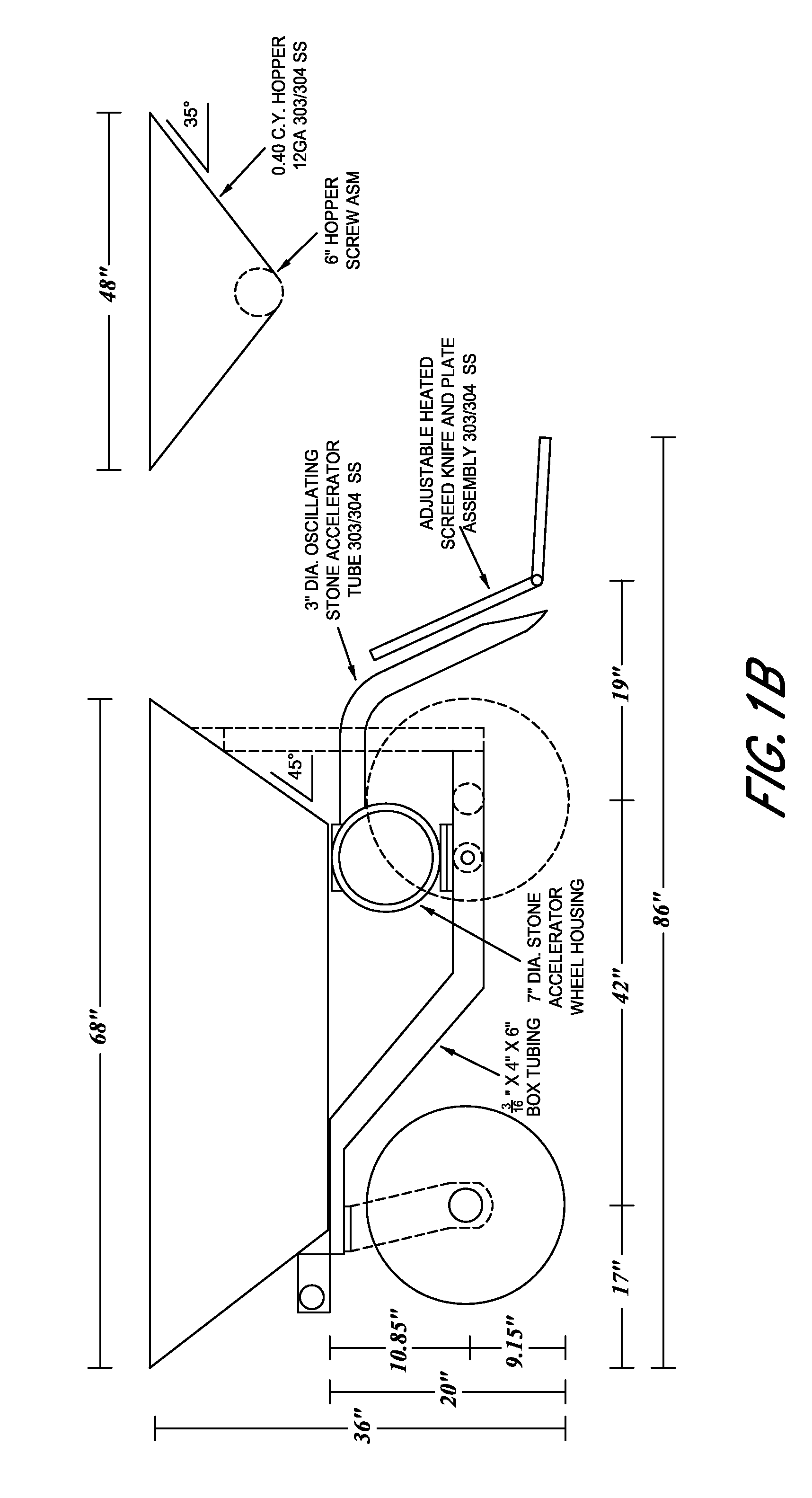

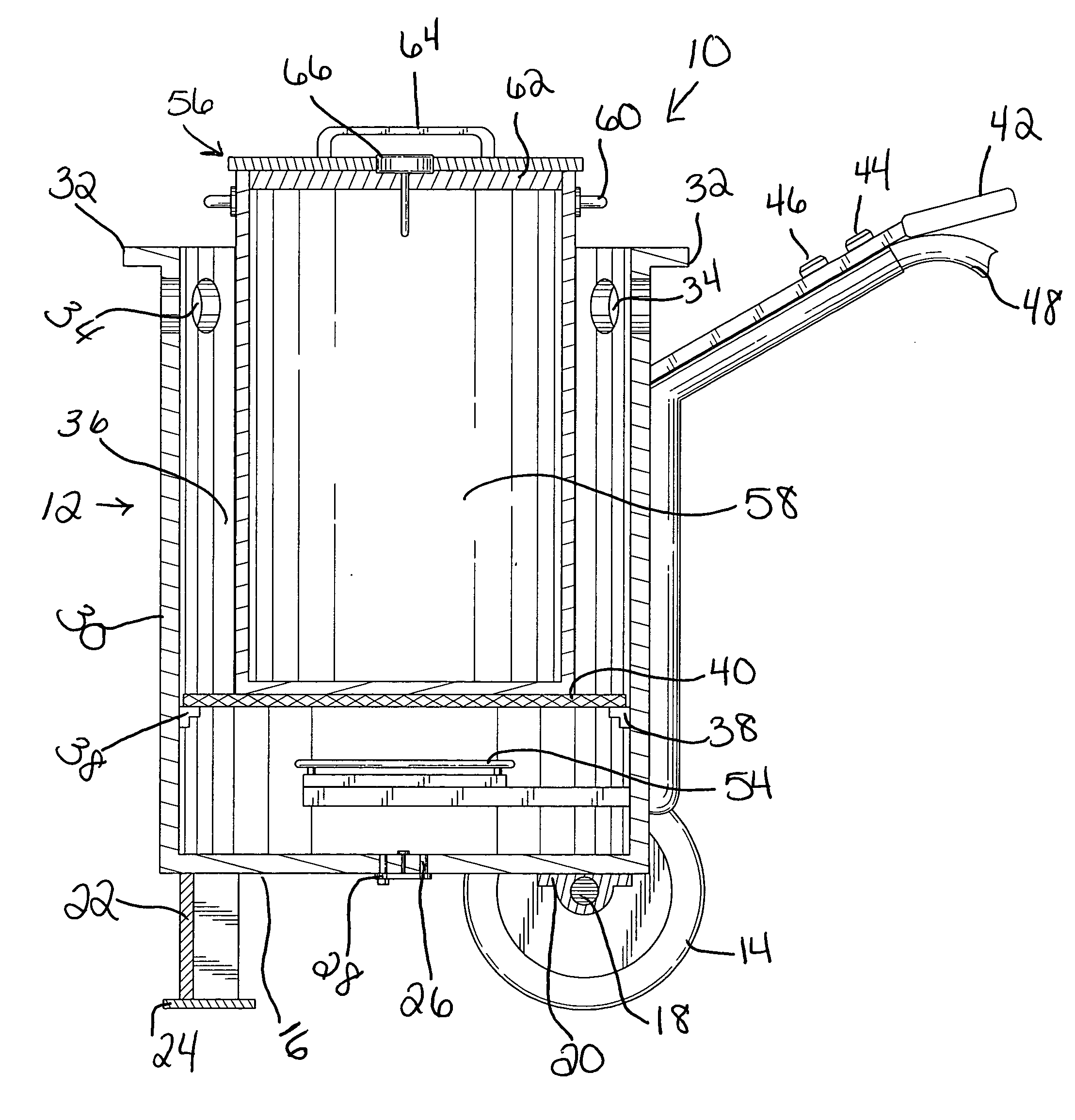

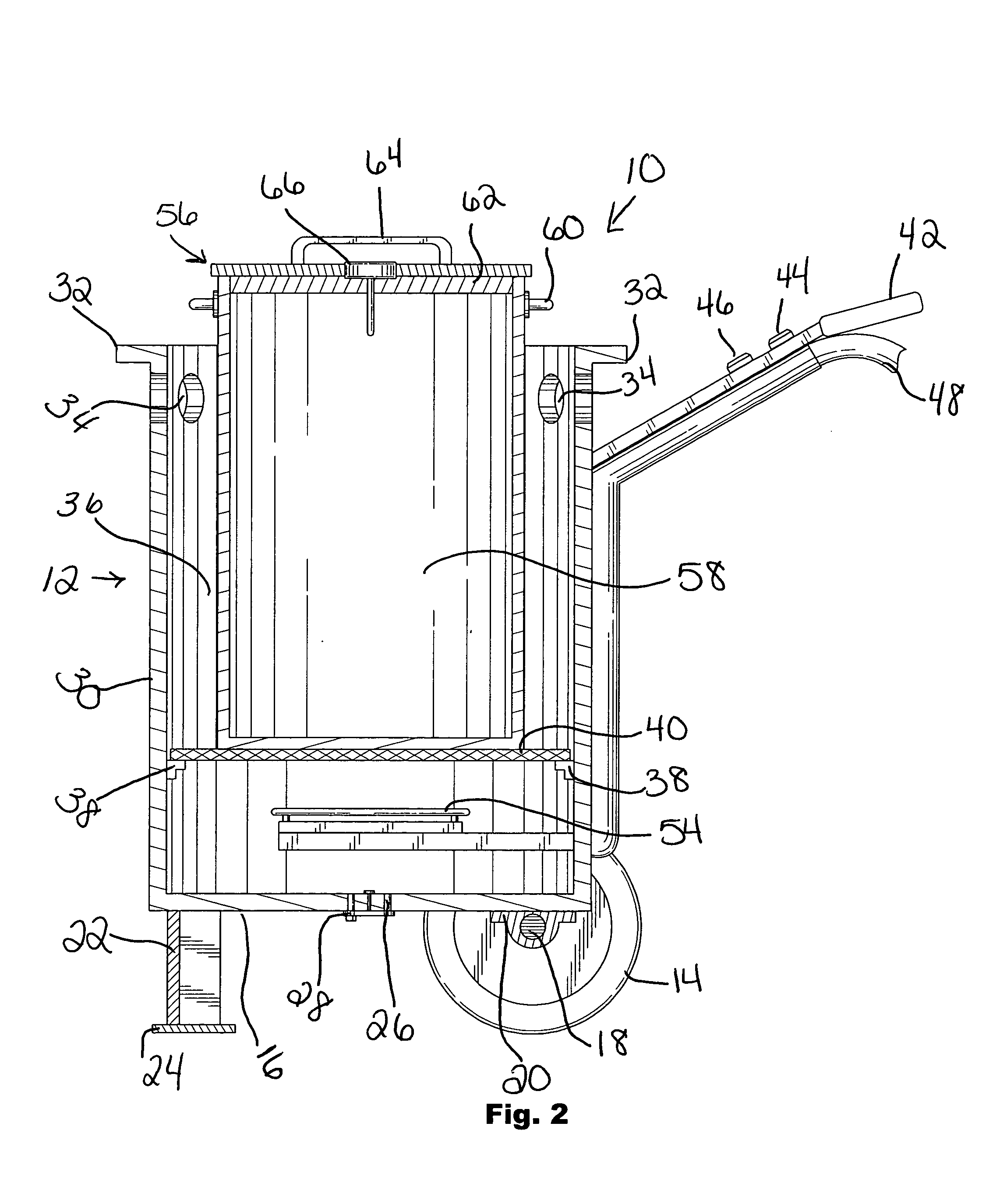

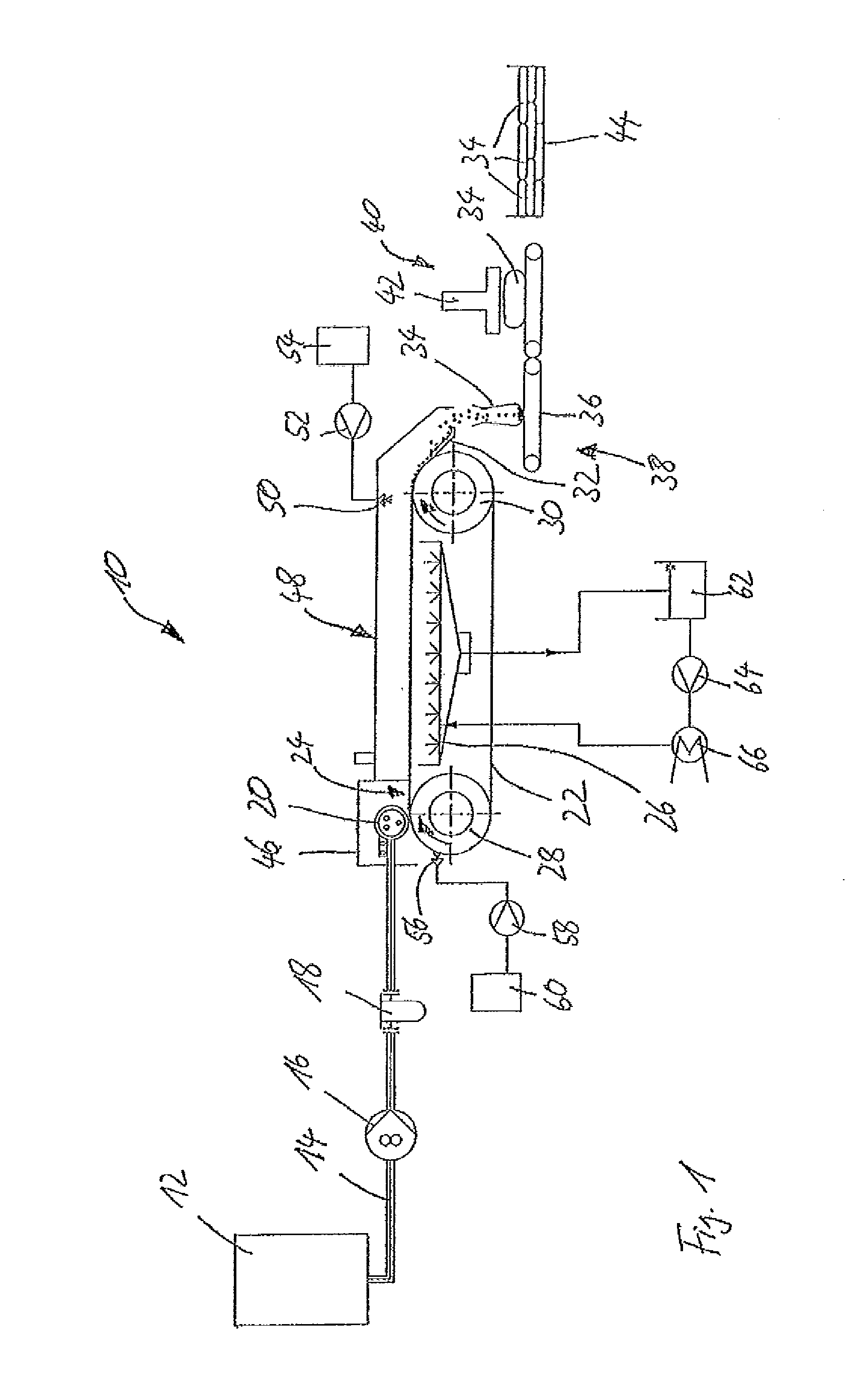

Material feed system for melter kettles

InactiveUS20110253124A1Drying solid materials with heatWorking-up pitch/asphalt/bitumen by meltingElectrical conductorEngineering

A material feed system for melter kettles which provides an area for a tender to load material to be charged into a melter kettle at a location which is safely remote from a flame conductor assembly that allows any flames or gasses that build up in melter kettle to be released. The material feed system also includes an air intake duct through which free air is allowed to enter into the melter kettle so as to equalize pressure with the atmosphere and / or burn off any superheated material.

Owner:PK CONTRACTING INC

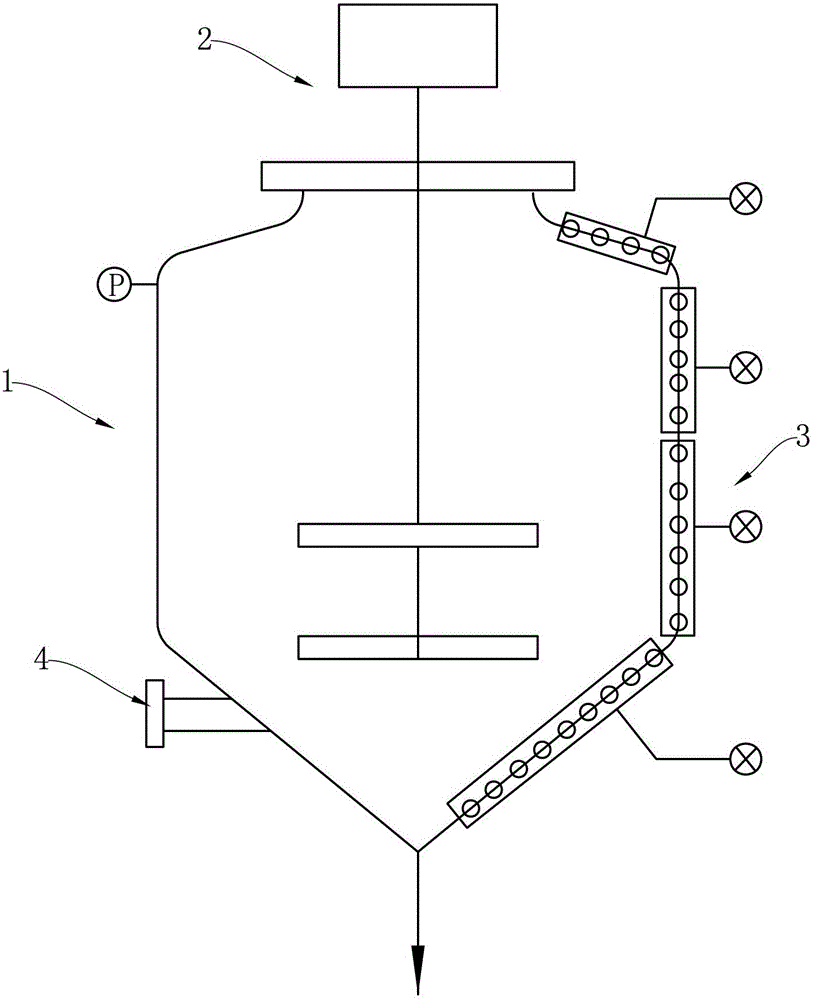

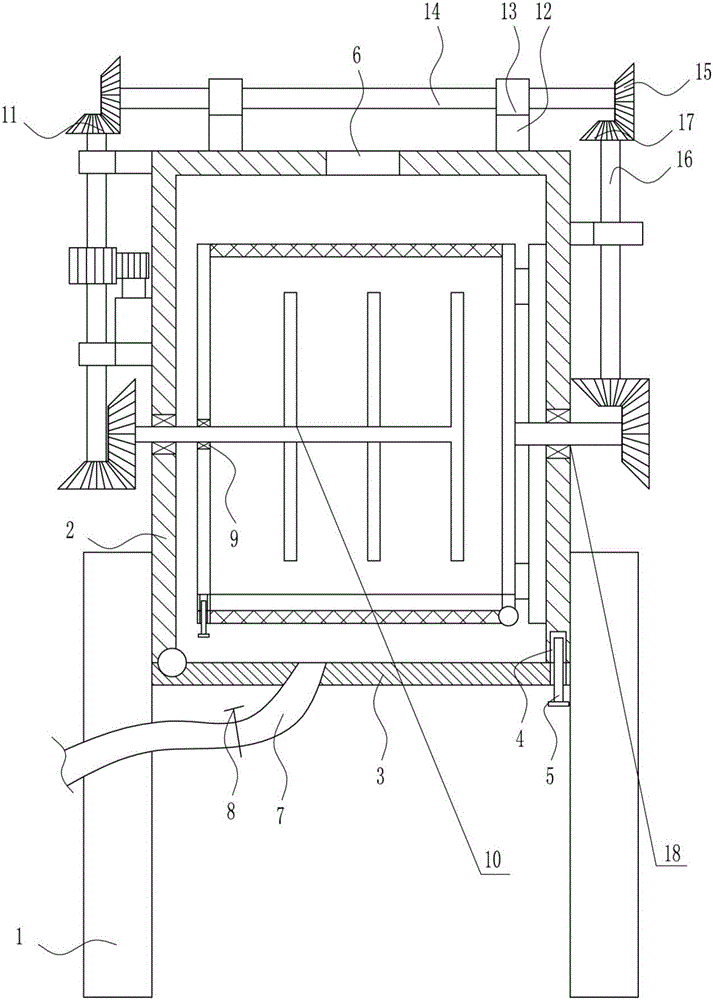

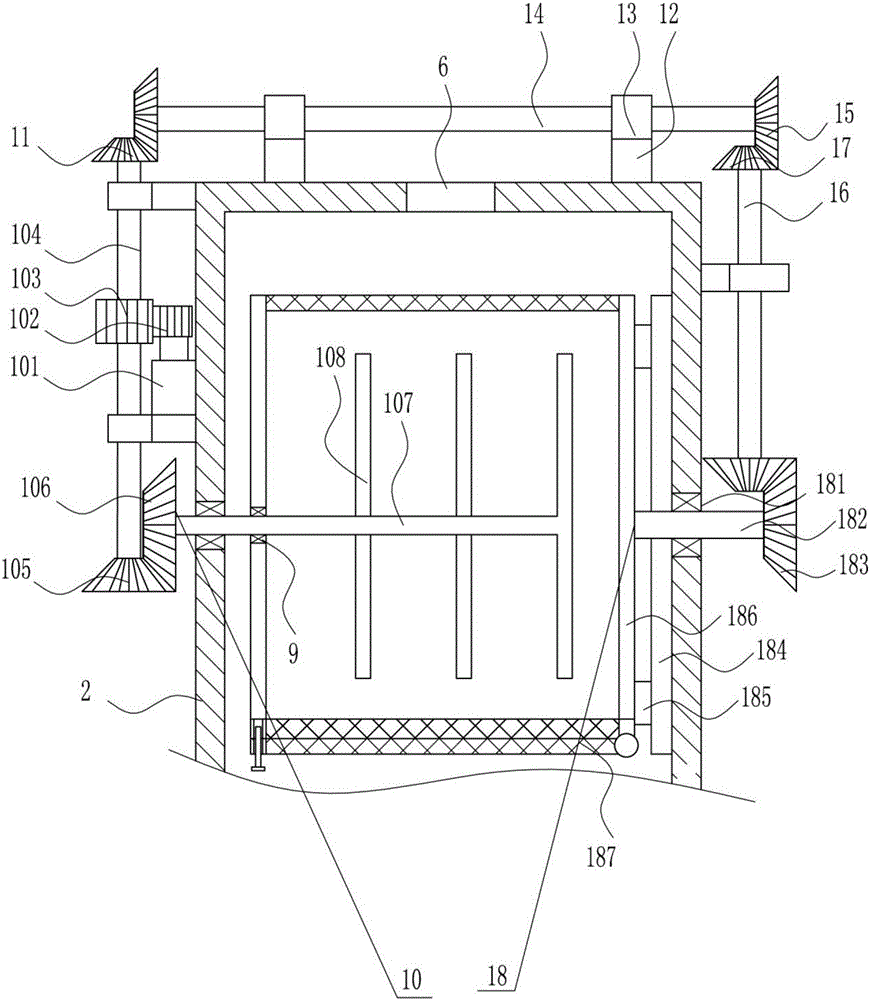

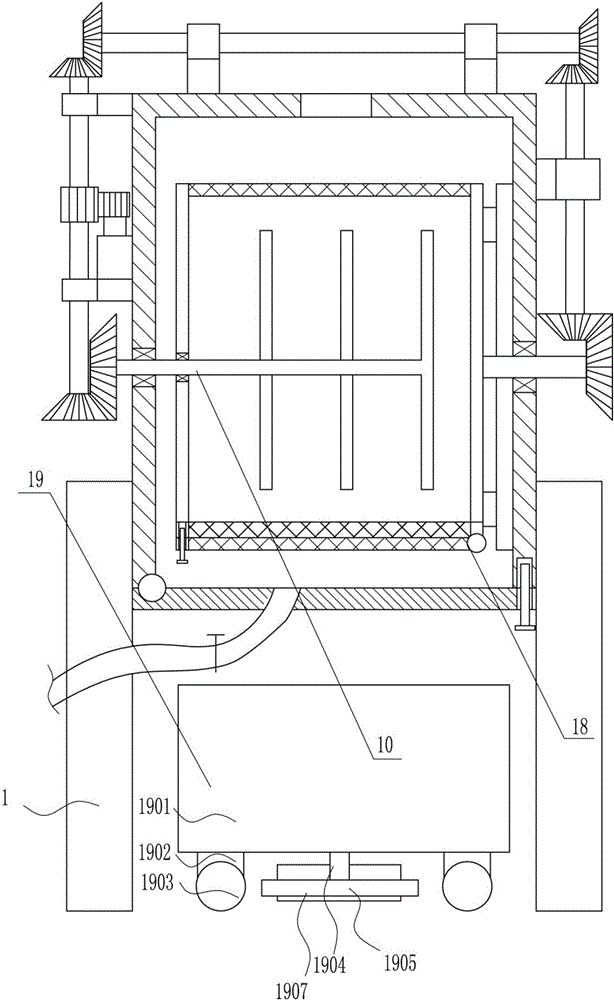

Asphalt melting device

InactiveCN101586035AMelting fastEasy dischargeWorking-up pitch/asphalt/bitumen by meltingAsphaltHeating system

The invention provides an asphalt melting device, which comprises a tank body (3) and a bracket (11). The tank body (3) is arranged on the bracket (11); a transmission stirring device (1), a hot oil heating system (2) and an inner guide cylinder body (5) are arranged in the tank body (3); the lower end of the inside of a straight cylindrical section of the tank body (3) is welded with a support frame (10); and a stirring shaft (7) of the transmission stirring device (1), the hot oil heating system (2) and the inner guide cylinder body (5) are arranged on the support frame (10) inside the tank body (3). The asphalt melting device can ensure that the high-temperature asphalt can be quickly melted in short time, the liquid asphalt at a discharge hole of the device reaches the temperature of process requirement, asphalt clinker is easy to discharge, the power consumption of equipment is lowered, and the environment-friendly requirement is met.

Owner:GUIYANG AL-MG DESIGN & RES INST

Disaggregation of asphaltenes in incompatible petroleum oil mixtures

InactiveUS7029570B2Thermal non-catalytic crackingWorking-up pitch/asphalt/bitumen by meltingPetroleumAsphaltene

The thermal decomposition of Athabasca asphaltene at relatively low (<350° C.) temperatures is believed to proceed by elimination of groups situated on peripheral sites of the asphaltene. More severe degradation of the asphaltene structure does not occur until elevated (>350° C.) temperatures are attained.

Owner:EXXON RES & ENG CO

Asphalt treatment device used after petroleum refining

InactiveCN107523320AStir wellAvoid influenceTransportation and packagingRotary stirring mixersToxic gasAsphalt

The invention relates to a treatment device, in particular to an asphalt treatment device used after petroleum refining and aims to provide an asphalt treatment device which is used after petroleum refining, can save time and labor, has a good stirring effect and can purify toxic gases during stirring without affecting the surroundings. In order to solve the technical problems, the asphalt treatment device used after petroleum refining comprises support legs, a box body, a first box cover and the like, wherein the support legs are symmetrically mounted at lower parts of left and right side surfaces outside the box body, a feeding port is formed in the middle of the top of the box body, and the first box cover is arranged at the bottom of the box body. The stirred asphalt can be molten by a melting device, manual asphalt melting is not required, a purification device can purify toxic gases without affecting the surroundings, time and labor are saved, the stirring effect is good, toxic gases can be purified during stirring while the surroundings are not affected.

Owner:聂新杰

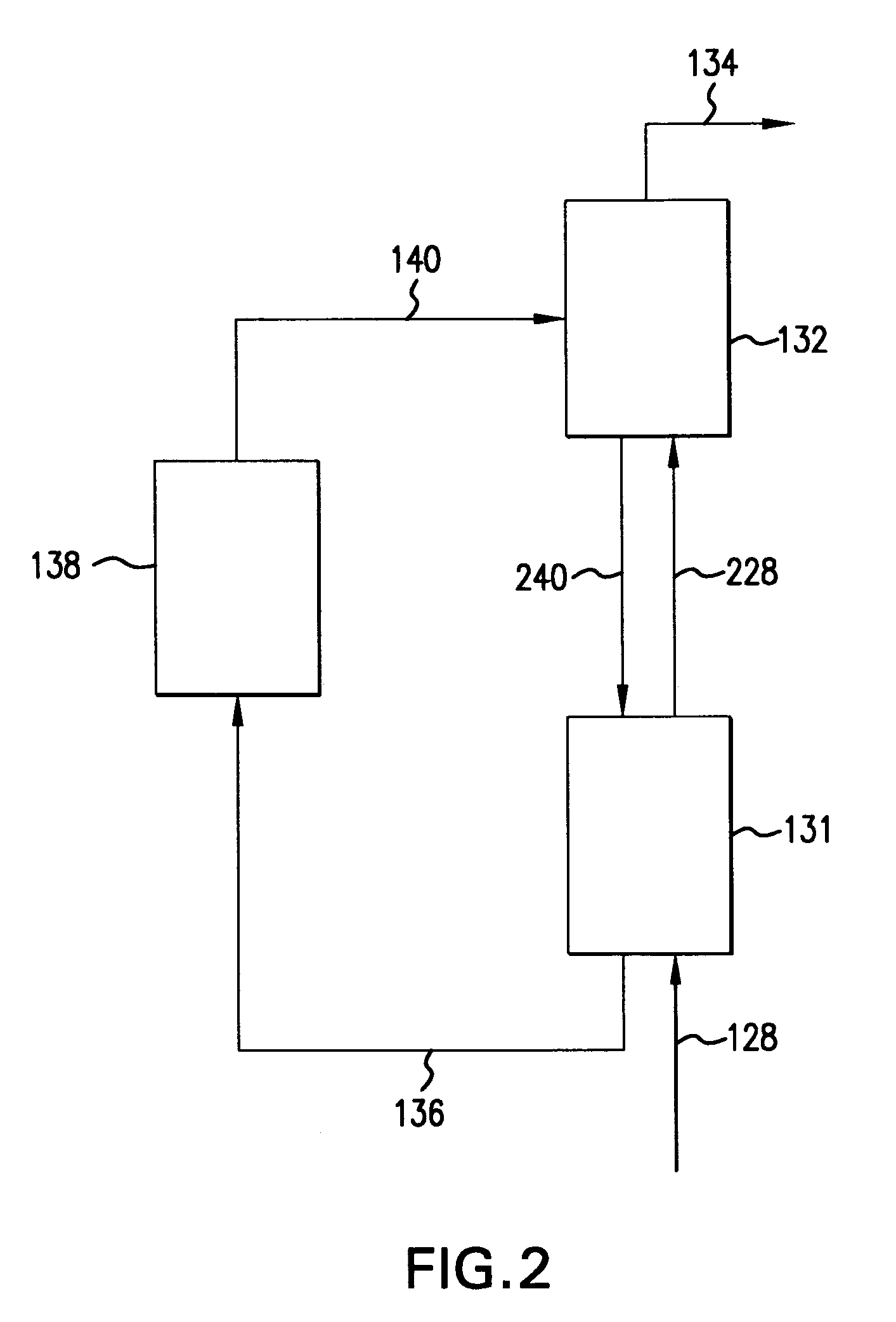

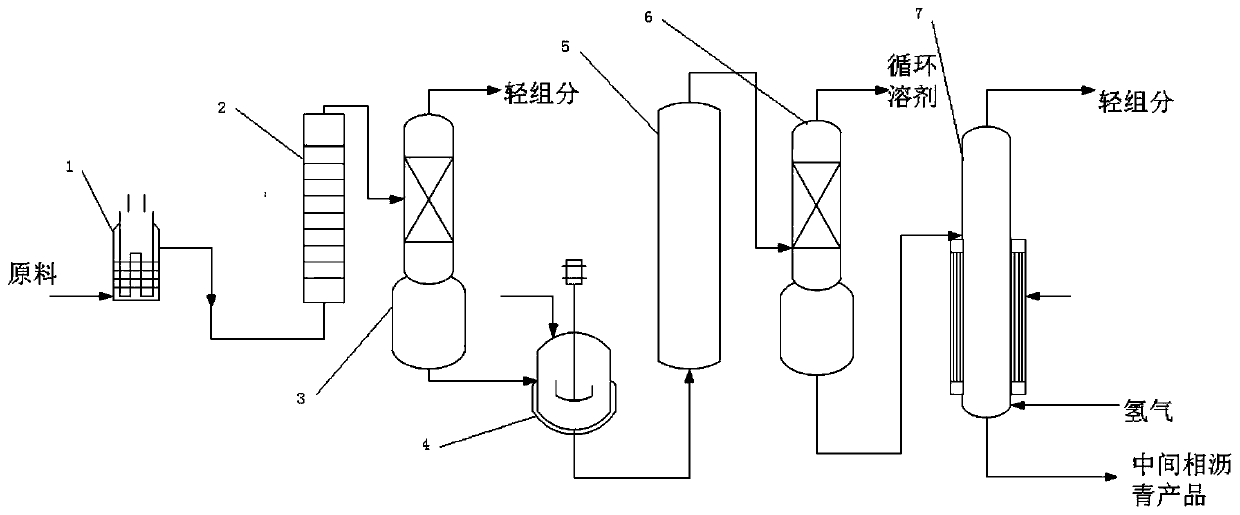

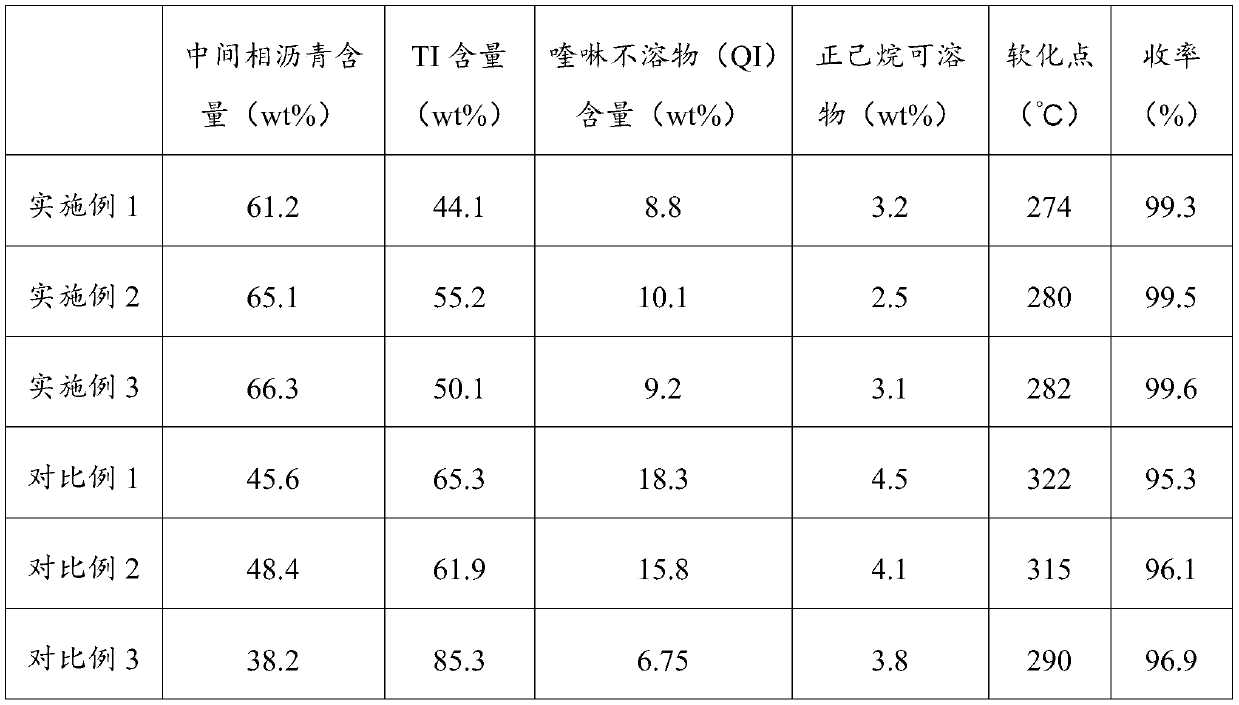

Mesophase pitch and preparation method thereof

ActiveCN110041952AEasy to changePromote aromatizationWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by chemical meansHeat sensitizationDistillation

The invention provides an application of a heavy product with a boiling point at 350-410 DEG C prepared through a lignite thermal melting catalysis technology as a raw material in preparing a mesophase pitch and a preparation method of the mesophase pitch. The preparation method comprises the following steps: taking the heavy product with the boiling point at 350-410 DEG C prepared through the lignite thermal melting catalysis technology as the raw material, and then performing thermal polycondensation, reduced pressure distillation, hydrogenation reaction, flashing and heat sensitization, thereby acquiring the mesophase pitch. The content of raw quinoline insolubles in the mesophase pitch product can be extremely reduced; the conversion of hydrogenated pitch into the mesophase pitch can be boosted; the loss of high-value components in the reaction process can be obviously reduced; the yield and quality stability of high-quality mesophase pitch product can be promoted; light componentsare removed by flashing, so that all hydrogen-donor solvent can be recycled; continuous production can be realized; lastly, the high-quality mesophase pitch product with mesophase pitch content not less than 61.2%, softening point at 274-282 DEG C and yield not less than 99.3% can be prepared.

Owner:广东煤基碳材料研究有限公司

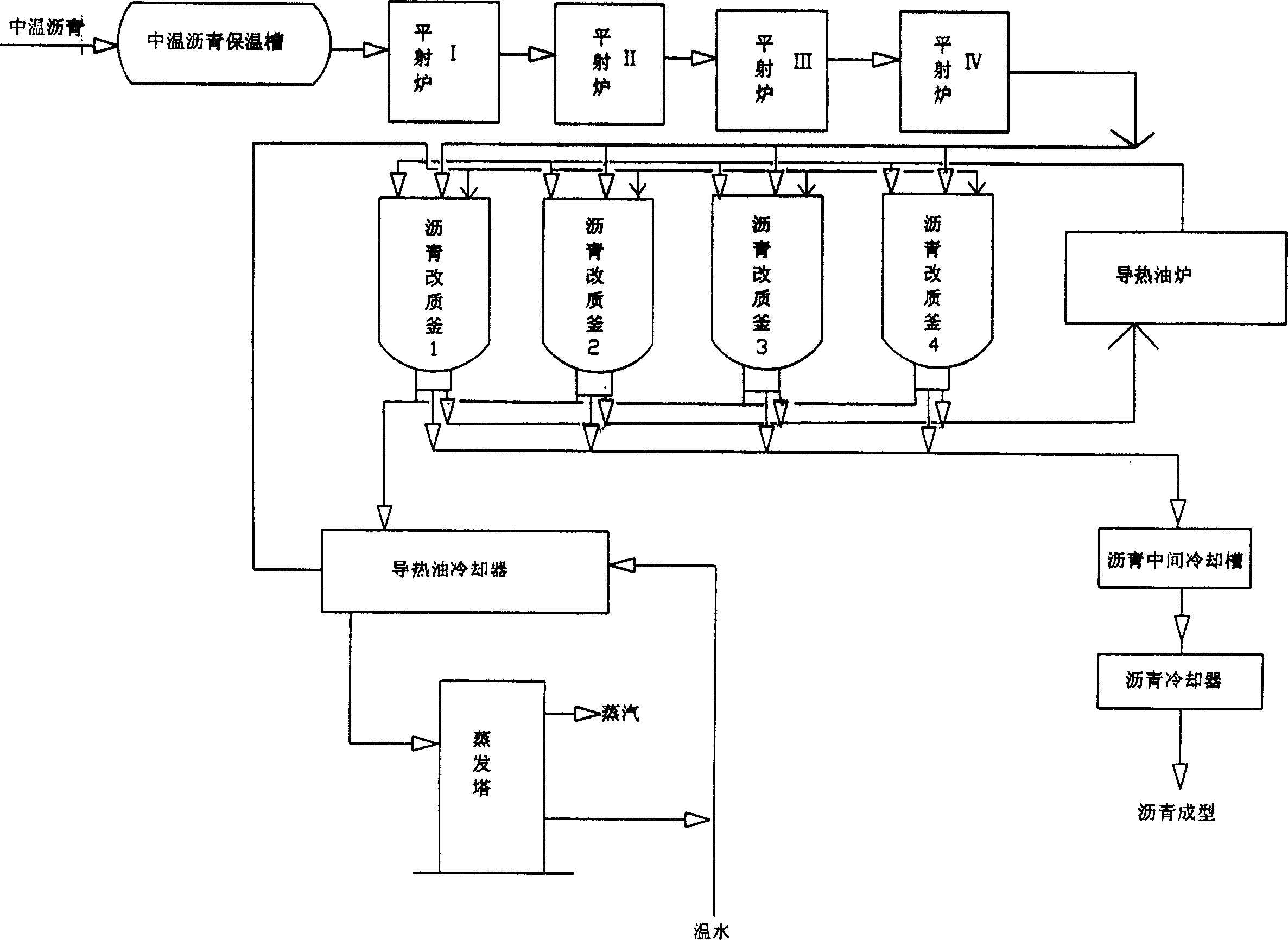

Process for preparing modified asphalt

InactiveCN1970689AAvoid cokingControl QI contentWorking-up pitch/asphalt/bitumen by meltingTarDirect heating

Owner:杨东平

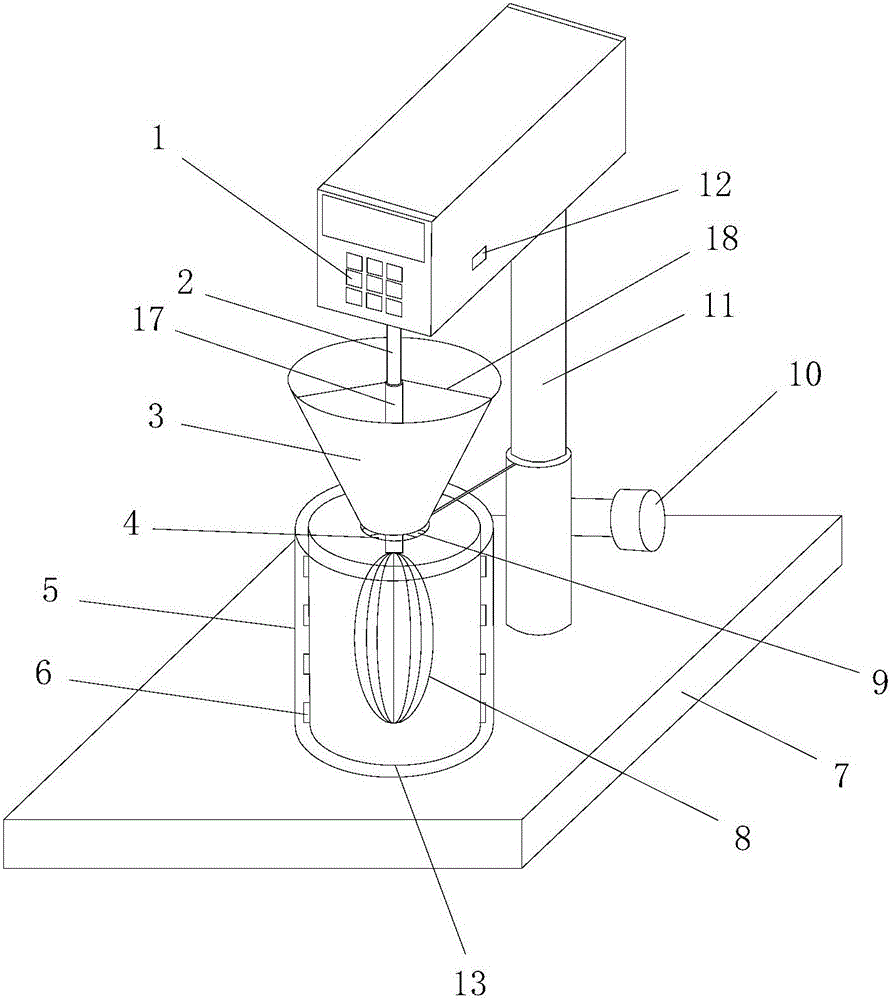

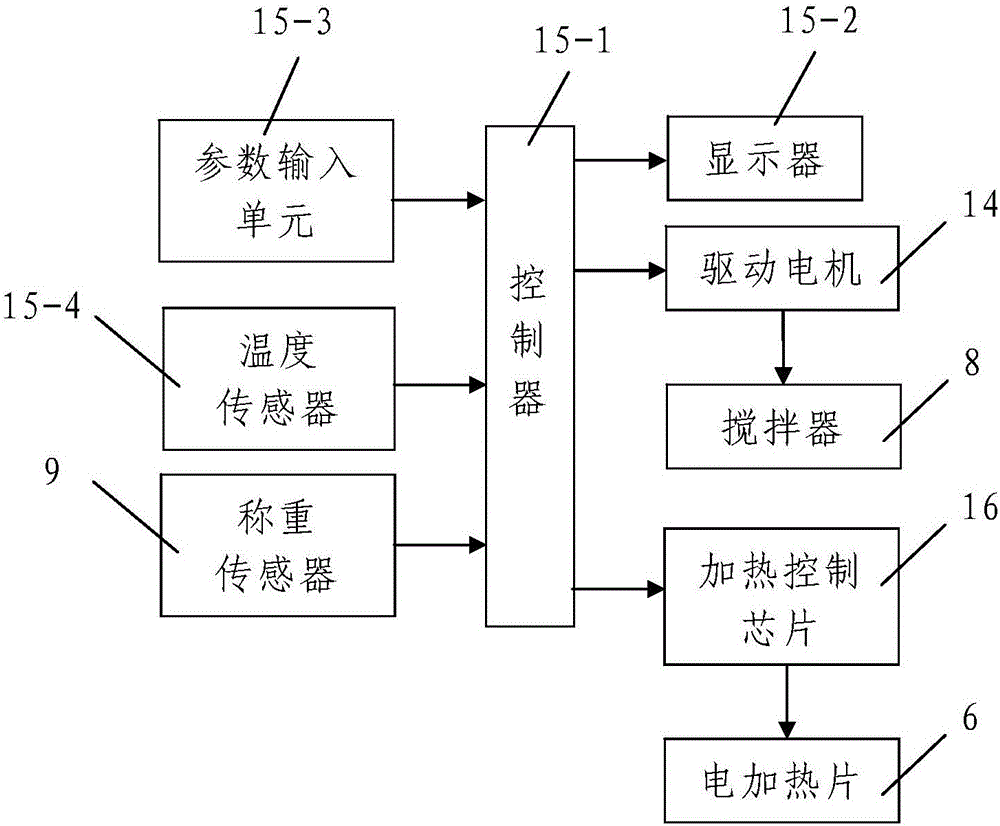

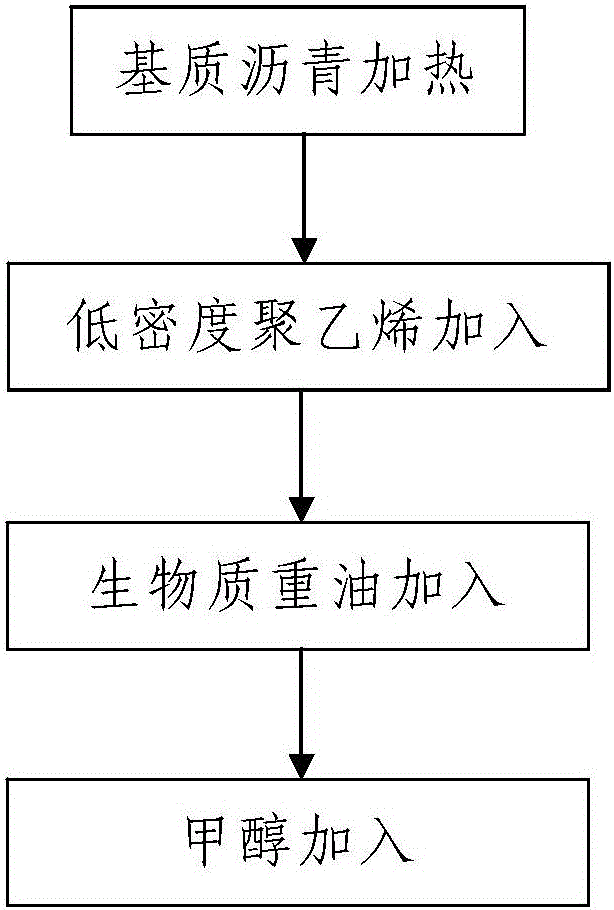

Biological asphalt for road as well as preparation device and preparation method of biological asphalt

ActiveCN105038832ALow costEasy to manufactureWorking-up pitch/asphalt/bitumen by meltingLow-density polyethyleneEngineering

The invention discloses biological asphalt for road. The biological asphalt is prepared from the following raw materials in percentage by weight: 10-30% of biomass heavy oil, 60-84% of matrix asphalt, 5% of methanol and 1-5% of low density polyethylene. The biological asphalt provided by the invention is low in cost, convenient to prepare, good in performance and high-temperature property, and low in temperature sensitivity; in addition, the invention further discloses a preparation device of the biological asphalt for road; the device includes a horizontal base, a liftable support pillar, a heating cup, a stirring cup, a feeding device and a control box; the device is simple in structure, reasonable in design, convenient to operate and good in use effect, and can simply and quickly complete the preparation of the biological asphalt; meanwhile, the invention also discloses a preparation method of the biological asphalt for road; the method includes the following steps: I, heating the matrix asphalt; II, adding low-density polyethylene; III, adding biomass heavy oil; IV, adding methanol; the method is simple in steps, reasonable in design and simple to operate; the prepared biological asphalt is excellent in performance.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com