Method and apparatus for the production of bitumen blocks

a technology of bitumen blocks and methods, applied in the direction of baking, sports equipment, containers, etc., can solve the problems of not being able to adhere exactly to a specified filling quantity or a specified filling weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

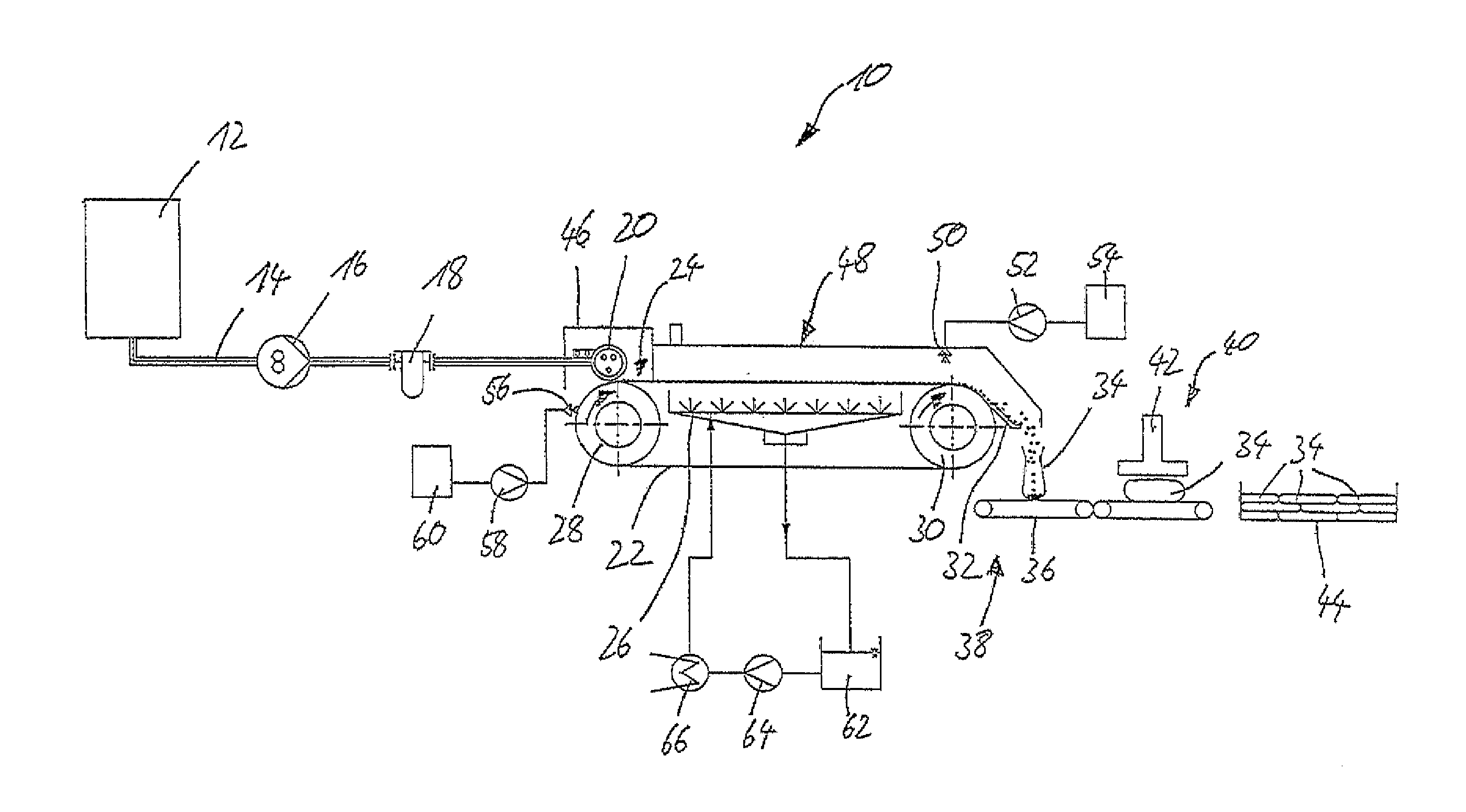

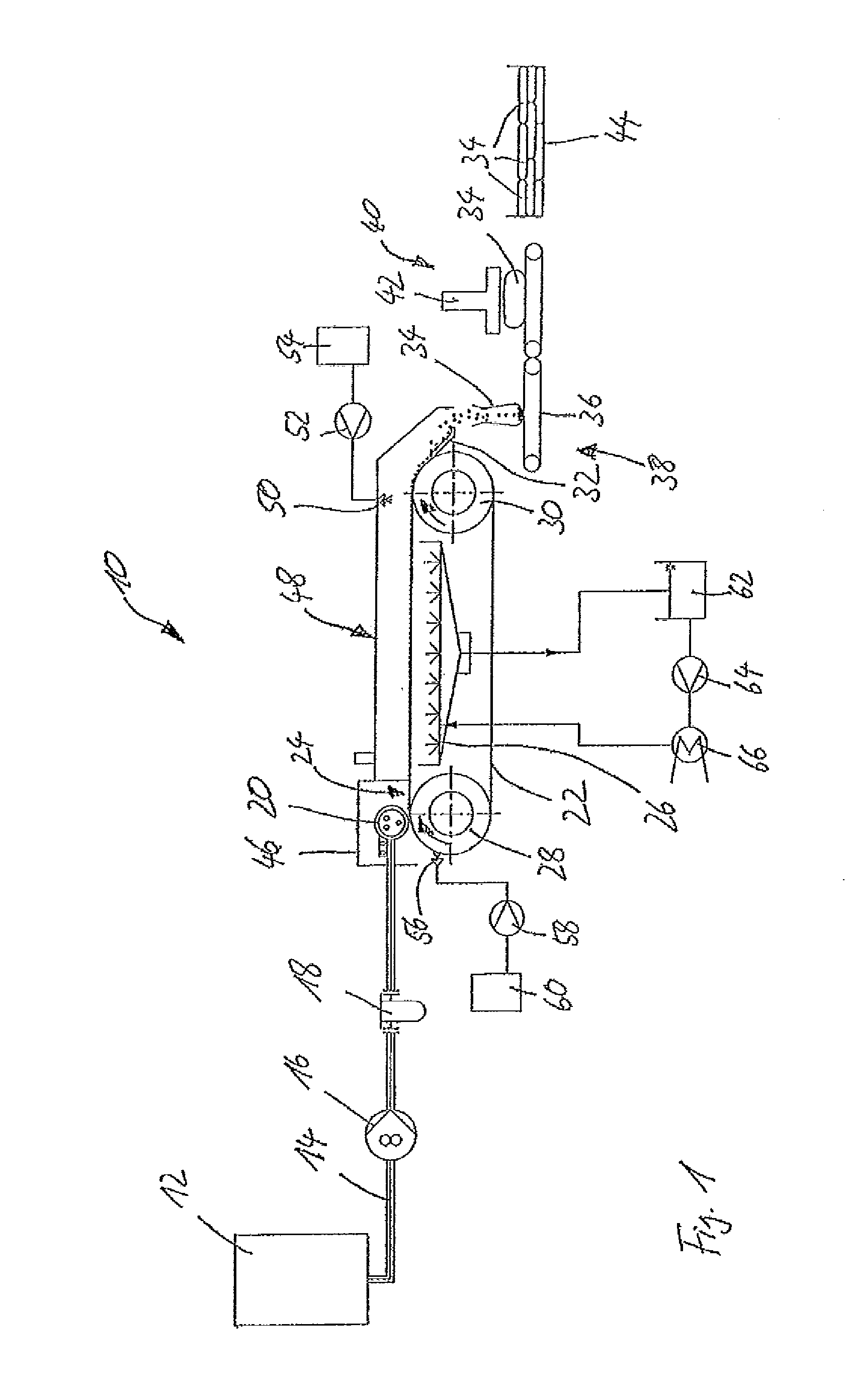

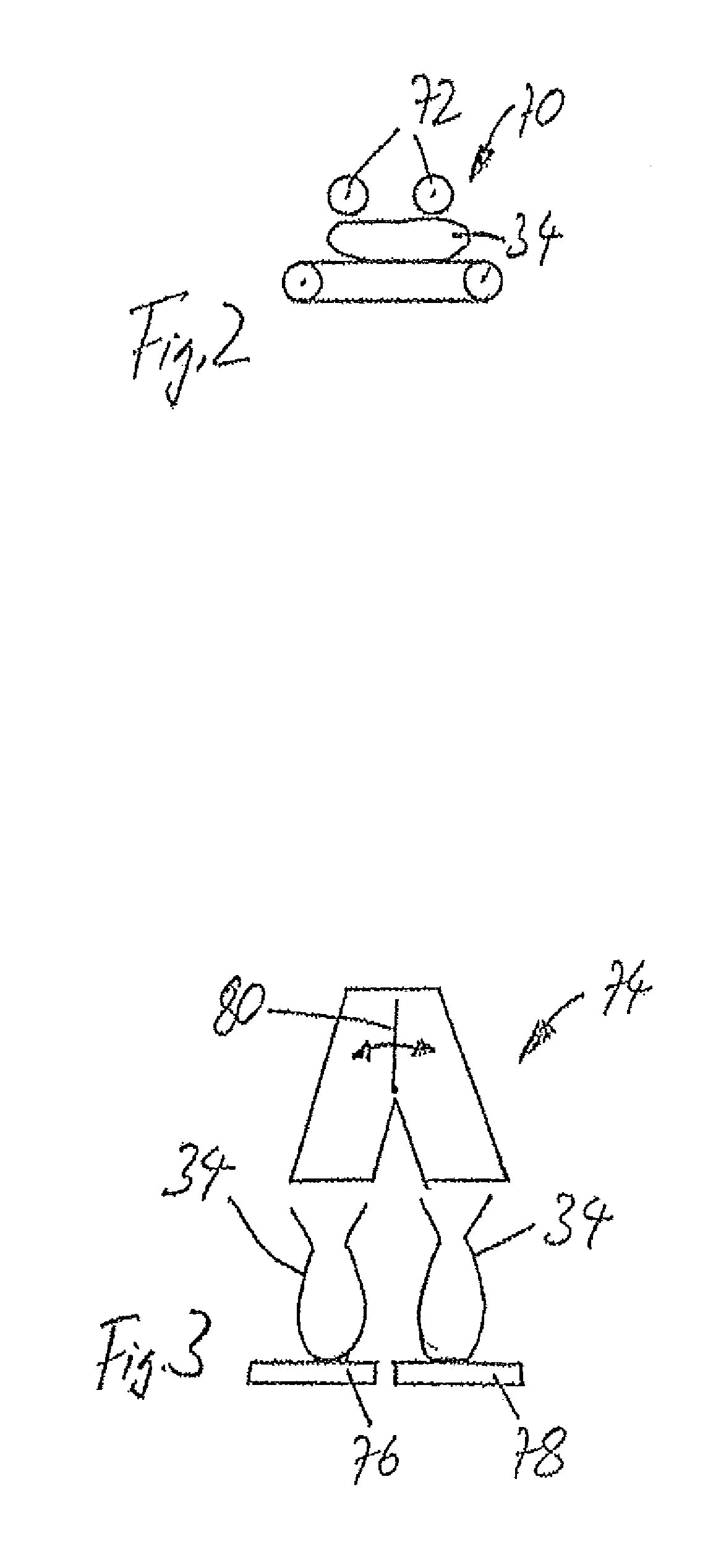

[0031]FIG. 1 illustrates an apparatus 10 for the tabletting and packaging of bitumen, in particular soft bitumen, by means of which the method according to the invention can be carried out. What is designated in this case as soft bitumen is bitumen which, under what is known as “needle penetration” according to DIN EN 1426 “Bitumen and bitumen-containing binders—determination of needle penetration”, has penetration values of 10 dmm (decimillimeters) or more. Hard bitumen, as it is known, usually has penetration values in the range of 2-3 dmm. What is known as soft bitumen, for example for the sealing of roofs, has penetration values of about 20 dmm to 40 dmm. Very soft bitumen qualities for road building lie in the range of 60 dmm to 100 dmm or even higher. What is designated as bitumen in the context of the invention is in this case also bitumen with fillers, in particular with up to 30% fillers, and coldtar pitch, as well as pure bitumen.

[0032]The apparatus 10 has a storage tank 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| shape | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com